To create a digital trail to physical equipment, asset labels are the smartest available solution. Asset label links the physical device to its digital counterpart.

To create a digital trail to physical equipment, asset labels are the smartest available solution. Asset label links the physical device to its digital counterpart.

01 The benefits of labeling assets

02 Technologies for tracking assets

a. Passive and active asset tracking

b. RFID, NFC, barcode and QR code

c. Examples of different labels

d. Scanning asset labels

03 Process for asset labeling

a. What is the best process for us?

04 Most common challenges with labels

Asset labels are a brilliant enabler for digitalising something that isn’t digital by nature. Today, we need data about everything to streamline operations and ensure cost efficiency also in those non-digital areas of business.

When information is gathered through asset labels, it can be used for smarter decisions and more efficient planning. The information is also available for checking at any time.

There are multiple benefits to asset labeling. There are also multiple technologies and materials to choose from when it comes to the actual labels. This whitepaper gives a good overview of the world of asset tagging.

When a non-digital asset is tagged, it becomes part of the digital world bringing tons of possibilities to utilise the digital trail. It’s important that the information about a non-digital device is in a digital format so that it can be updated and checked throughout the asset's lifetime.

When there is an asset label in place, the asset operations become fast and fluent. The asset can easily be logged as

The physical label might offer also the possibility to attach a company logo to the asset. This is an excellent way to mark asset ownership visually. Now everyone knows for example where the asset should be returned to, in case it is misplaced.

There are multiple technologies with small differences available for tracking assets. We introduce the ones that are supported in connection to Trail Asset Management system.

But before going into the technologies, let’s look at the differences between passive and active tracking.

Whitepaper by

Trail Systems Ltd

When talking about asset labels, it usually doesn’t take long for someone to bring up GPS tracking. It’s important to go through the differences between passive and active tracking.

GPS tracking is a good example of active tracking. It means that the tags are equipped with a power source. Often they require some type of data-transferring service and wellfunctioning internal processes. Processes are needed to make

the label. Ultra-high frequency (UHF) RFID tags can be scanned from a distance of up to 10 meters. A high-frequency (HF) RFID requires a distance smaller than 1 meter for scanning.

RFID (Radio Frequency Identification) is a remote identifying technology that is based on the utilization of radio frequencies. Its usage in identifying and tagging assets, animals, and even people has significantly expanded since the 1980s.

NFC stands for Near Field Communication. It is an application of RFID technology and allows scanning over very short distances.

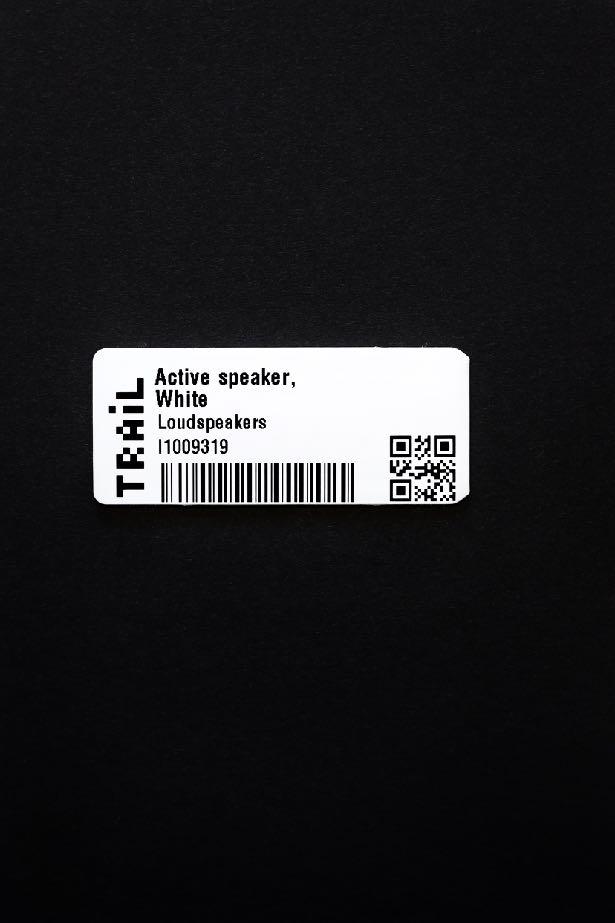

Linear 1D barcodes are familiar barcodes with parallel vertical lines. Similarly to other tags, they often contain only a short string of characters. Matrix codes, i.e., two-dimensional 2D codes (such as QR codes) can include even more information than a linear barcode.

by Trail Systems Ltd

by Trail Systems Ltd

Trail offers designing customer’s logo on the label as part of the service

There are labels for outdoors as well, and some that endure exposure to chemicals. Labels can be also found in different shapes, sizes, colours and materials.

The most common method for mounting for tags in indoor use is sticker-like adhesive mounting. There are, however, multiple mounting options available, including screws and cable ties.

Good quality labels endure normal usage well. Sometimes protective laminates are used to improve tag durability.

Trail also allows using previously attached labels for tracking - even if those are from other service providers.

Linear 1D and 2D barcodes can be scanned easily with a mobile device. In Trail Asset Management system, scanning the item’s barcode takes you to the item page with all information about the device.

The near-readable RFID labels can also be scanned with a mobile device. However, the labels that are based on UHF RFID, require a separate scanning device to function.

The biggest advantage of UHF RFID is the remote reading capability. It brings significant efficiency to inventories. Typically the saved time is definitely worth the label and scanner investment.

Whitepaper by Trail Systems Ltd

Here we describe the possibilities of labeling with Trail Asset Management system. The process might look and feel very different from other solutions.

There are two process possibilities for labeling with Trail. The first process option starts by creating asset information and then producing labels for the created assets. The other possibility is to have preprepared labels and only link them to assets whenever available in the system.

labels can be added in masses to the equipment without worrying about which goes where. This enables for example labeling already at the factory for new equipment.

Use the chart on the next slide to determine the right choice for your organisation.

Whitepaper by Trail Systems Ltd

Are item details (such as model or ID) needed on the labels?

Have you done an inventory of all assets?

Would you rather first attach labels and only then link assets to the labels?

Sounds like any labeling solution works for you!

With asset labels, we are talking about physical attachable elements. From time to time we learn about the challenges customers run into when using labels. Here are a few most common ones with instructions on how to avoid the most common mistakes.

One might think it would be convenient to use the basic office printer for producing barcodes and QR codes for equipment. There lies however multiple challenges in the seemingly simple approach.

The quality of the labeling material should be carefully considered. The choice of material is not so critical for those labels which are attached to some even surface and are never touched. The criticality increases with the labels which are in constant use, scanned, touched, and scratched all the time.

The choice of material should be made based on the use case that requires more durability. The reason is that for the most used equipment, the process falls short if the label is easily ripped off. Then the equipment management system cannot be systematically used. The outcome can be that the users become unhappy with the chosen solution. There can also arise a need to spend time and money in replacing the poor labels, and more importantly, the process cannot be trusted.

Whitepaper by Trail Systems LtdAt Trail, we only offer labels of good quality and know that they last in use. Therefore we can also provide support in designing and using them. This is our way of ensuring customer happiness with our solution. For us, it is a high priority to make sure that the labels on our customer’s most used equipment are there tightly in place when the user comes to scan those.

There is increasing interest in many industries towards utilising remote scannable RFID labels. From time to time we run into poor experiences with trying to scan RFIDs on a metal surface.

With RFID it is important to ensure that the labels used are meant for the correct surface material. Otherwise, there is a risk of running into problems when scanning. When it comes to RFID labels, there are specific label materials for metal surfaces and other materials for other surfaces. It’s key to ensure that correct materials are used together.

Even when the choice of materials is the correct one, sometimes remote scannable RFID labels struggle if the metal is too close to the label when scanned. To avoid problems, we recommend taking the time to evaluate the positioning of the label on the equipment. The best solution is that there are as few other materials near the label as possible.

Microphones are an excellent example of equipment that needs to endure touching. Also, the labels attached to microphones should be too. The problem is that human skin is efficient in causing wear and tear to any paper material and QR codes are no different from that. For this problem, the smart solution is to improve the durability of the label by attaching a protective laminate on top of it. That helps to protect the label itself from