Irrigation Water and Produce Safety Dr. Zepei Tang1, Dr. Niroj Aryal1, Dr. Jimo Ibrahim2, Dr. Laurent Ahiablame1, and Dr. Yewande Fasina3 1Department

of Natural Resources and Environmental Design, 2Cooperative Extension, 3Department of Animal Sciences College of Agriculture and Environmental Sciences, North Carolina A&T State University

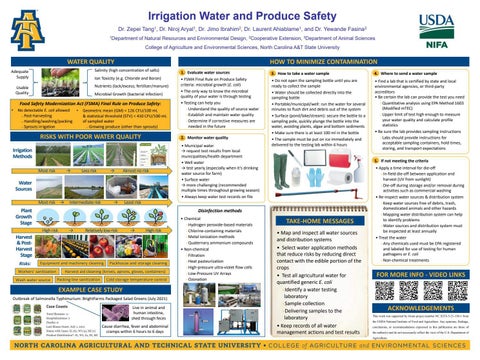

WATER QUALITY

HOW TO MINIMIZE CONTAMINATION

Salinity (high concentration of salts)

Adequate Supply

Ion Toxicity (e.g. Chloride and Boron) Nutrients (lack/excess; fertilizer/manure)

Usable Quality

Microbial Growth (bacterial infection)

Food Safety Modernization Act (FSMA) Final Rule on Produce Safety: •

No detectable E. coli allowed • o Post-harvesting o Handling/washing/packing o Sprouts irrigation

Geometric mean (GM) < 126 CFU/100 mL & statistical threshold (STV) < 410 CFU/100 mL of sampled water o Growing produce (other than sprouts)

RISKS WITH POOR WATER QUALITY

→

Less risk

→

Almost no risk

Water Sources Most risk →

Intermediate risk

→

Least risk

Plant Growth Stage Harvest & PostHarvest Stage Risks:

• FSMA Final Rule on Produce Safety criteria: microbial growth (E. coli) • The only way to know the microbial quality of your water is through testing • Testing can help you >Understand the quality of source water >Establish and maintain water quality >Determine if corrective measures are needed in the future 2. Monitor water quality

Irrigation Methods Most risk

1. Evaluate water sources

• Municipal water → request test results from local municipalities/health department • Well water → test yearly (especially when it’s drinking water source for farm) • Surface water → more challenging (recommended multiple times throughout growing season) • Always keep water test records on file

3. How to take a water sample

4. Where to send a water sample

• Do not open the sampling bottle until you are ready to collect the sample • Water should be collected directly into the sampling bottle • Portable/municipal/well: run the water for several minutes to flush dirt and debris out of the system • Surface (pond/lake/stream): secure the bottle to a sampling pole, quickly plunge the bottle into the water, avoiding plants, algae and bottom sediments • Make sure there is at least 100 ml in the bottle • The sample must be put on ice immediately and delivered to the testing lab within 6 hours

• Find a lab that is certified by state and local environmental agencies, or third-party accreditors • Be certain the lab can provide the test you need >Quantitative analysis using EPA Method 1603 (Modified mTEC) >Upper limit of test high enough to measure your water quality and calculate profile statistics • Be sure the lab provides sampling instructions >Labs should provide instructions for acceptable sampling containers, hold times, storing, and transport expectations 5. If not meeting the criteria

Disinfection methods

High risk

→

Relatively low risk

Equipment and machinery cleaning

Workers’ sanitization Wash water source

→

High risk

Packhouse and storage cleaning

Harvest aid cleaning (knives, aprons, gloves, containers) Packing line sanitization

Cold storage temperature control

EXAMPLE CASE STUDY Outbreak of Salmonella Typhimurium: BrightFarms Packaged Salad Greens (July 2021) Live in animal and human intestine, shed through feces Cause diarrhea, fever and abdominal cramps within 6 hours to 6 days

• Chemical >Hydrogen peroxide-based materials >Chlorine-containing materials >Metal ionization methods >Quaternary ammonium compounds • Non-chemical >Filtration >Heat pasteurization >High-pressure ultra-violet flow cells >Low-Pressure UV Arrays >Ozonation

TAKE-HOME MESSAGES • Map and inspect all water sources and distribution systems • Select water application methods that reduce risks by reducing direct contact with the edible portion of the crops • Test all agricultural water for quantified generic E. coli >Identify a water testing laboratory >Sample collection >Delivering samples to the laboratory • Keep records of all water management actions and test results

• Apply a time interval for die-off >In-field die-off between application and harvest (UV from sunlight) >Die-off during storage and/or removal during activities such as commercial washing • Re-inspect water sources & distribution system >Keep water sources free of debris, trash, domesticated animals and other hazards >Mapping water distribution system can help to identify problems >Water sources and distribution system must be inspected at least annually • Treat the water >Any chemicals used must be EPA registered and labeled for use of testing for human pathogens or E. coli >Non-chemical treatments

FOR MORE INFO - VIDEO LINKS

ACKNOWLEDGEMENTS This work was supported by Grant project number NC.X333-5-21-130-1 from the USDA National Institute of Food and Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.