ANTHONY GUZMAN PORTFOLIO

Instructor: David Moon

Partner:Theodore Milbourne, Dana Zou

Adaptive

Reuse: Floyd Bennett Field, NY OLDER

Floyd Bennett Field, located in South Brooklyn’s Gateway National Recreation Area, has a rich history. Originally a series of islands, it became New York City’s first commercial airport in 1931 and later served as a Naval Air Station during World War II. Today, its abandoned buildings echo its past, while the site remains underutilized despite its national park status.

Our project addresses these challenges by proposing a trade school for Brooklyn and New York residents, offering an alternative educational pathway in response to lower graduation rates and income levels in surrounding neighborhoods. The school will teach trade fundamentals with a focus on circular construction practices.

Floyd Bennett Field is also a growing birdwatching destination, home to species rarely seen in other city parks. To embrace this, our project restores an abandoned airplane hangar as both a park welcome center and the trade school’s hub. Salvaged materials from derelict buildings will be reused to construct Bird Towers—structures supporting bird habitats while enhancing the visitor experience. These towers will be built, adapted, and deconstructed by students, responding to bird migration, breeding cycles, and visitor needs, fostering a sustainable relationship between architecture, nature, and community.

Distribution: Site

Inspection

Distribution: Greater NY

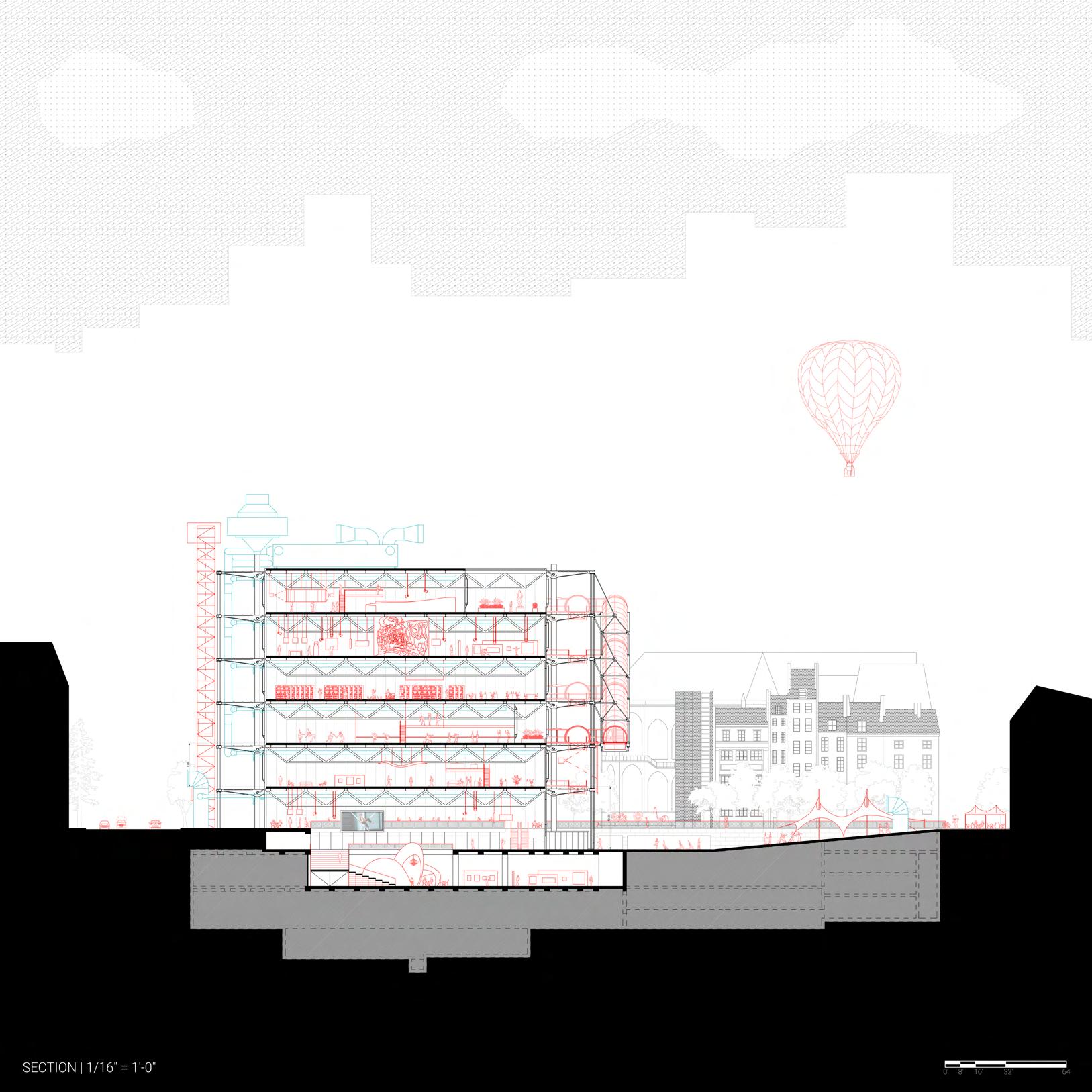

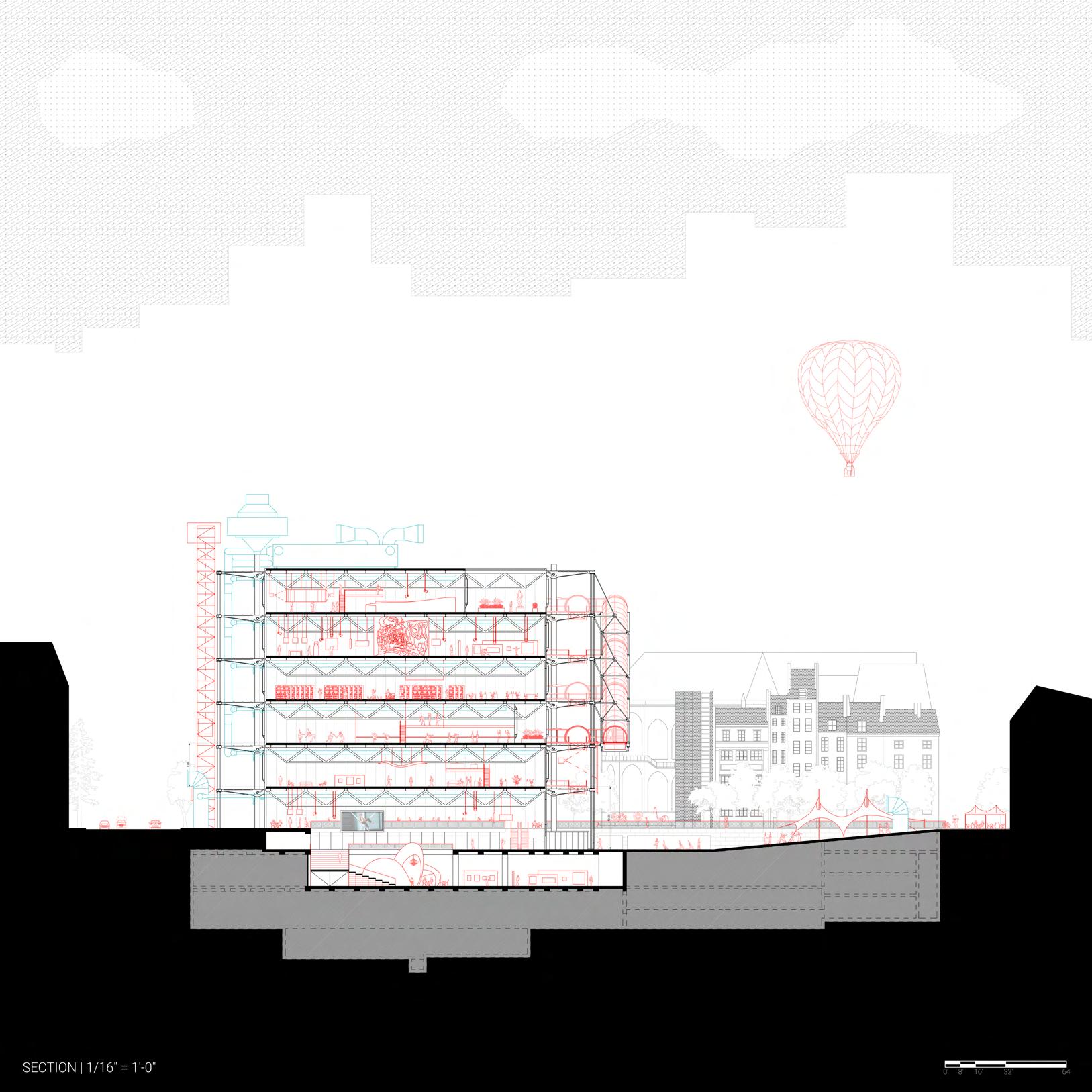

Instructor: Emma Silverblatt, Adam Frampton

Partner:Jessica Kim

Housing: Bushwick, NY

Made in Bushwick is a mixed-use development designed in response to the anticipated residential growth in Bushwick. As the neighborhood continues to experience demographic shifts and the pressures of gentrification, this project takes a dynamic approach to counter the cycle of wealthier residents displacing long-term community members. Rather than catering solely to new, affluent populations, the development transforms into a vibrant sports center, public pool house, and water park, addressing the community’s pressing need for accessible recreational spaces. By providing amenities that foster social interaction, physical activity, and leisure, the project ensures that existing residents have a space to gather, connect, and thrive. Made in Bushwick not only acknowledges the neighborhood’s evolving landscape but also prioritizes inclusivity and community well-being, offering a sustainable model for urban development that balances growth with the preservation of cultural and social fabric.

48"X12" 1/16" = 1'

24"X66" 1/8" = 1'

48"X12" 1/16" = 1'

FUTURE SLIDES

FUTURE POOLS HANGING FROM BOX TRUSS

Instructor: Sydney Maubert

Housing model: Liberty City, FL HOLDER

I was tasked with designing a housing prototype that integrates seamlessly into the Liberty City Projects, a public housing development in Miami serving a predominantly Black, bohemian population facing cultural erasure due to gentrification. Drawing inspiration from the neighborhood’s daily life and rich cultural history, particularly its ties to the Bahamas, the proposal reflects these influences through thoughtful design. Recognizing the significance of porch culture in the Black experience, each unit includes a communal porch space that fosters social interaction and unity. This design approach not only preserves the neighborhood’s unique identity but also strengthens its cultural resilience against external pressures. The proposed housing prototype complements the existing site’s architectural style while also serving as an artist residency. Each townhouse unit offers both living quarters and a workshop space for resident artists. Collectively, the units open onto the ground floor, creating a vibrant marketplace for local ambulant vendors to set up and sell their goods, further enriching and welcoming all members of the community.

A: Porch

B: Workshop/Studio

C: Residence

D: Open Market

4" RIGID INSULATION

2"X4" WOOD JOIST WINDOW TRIM

TRIPPLE PANE GLASS

1" SOUNDPROOF DRYWALL

VAPOR BARRIER

1"X3" FURRING STRIP

2" ROOF SHEATHING

12"X 3" RAFTERS

STRONG TIE BC46

BUILT UP BEAM

3" ORNAMETAL METAL

ORNAMENTAL WOOD POST

CMU-GROUT INFILL

TRIPLE PANE GLASS WINDOW TRIM

1" SOUND-PROOF DRYWALL

3" DOOR

3/4" STEEL DECK

ANCHOR BOLT

1" CORRUGATED METAL

2"X5" WOOD BLOCK HOLLOW METAL DOOR FRAME HINGE

1"X3" FURRING STRIP

STUCCO

1/10" WIRE LATHE VAPOR BARRIER STUCCO

8"X12"X8" CMU BLOCK MORTAR

2" RIGID INSULATION

1" MOLD-RESISTANT DRYWALL

2"X4" WOOD JOIST

3/4" REBAR

CONRETE SLAB FLOORING

3/4" PLYWOOD SUBFLOOR

1-1/2" HARDWOOD FLOORING

1'X1' WIDE-FLANGE GALVANIZED STEEL COULUM

3/4" STEEL DECK PUMP HINGE

CONRETE SLAB FLOORING

FOUNDATION DRAIN

GRAVEL

CONRETE FOOTING

Instructor: Emma Silverblatt

Library: Seneca Falls, NY HOLDER

My design thoughtfully separates active, high-traffic areas from quieter, more introspective spaces by establishing two distinct zones. At the base, a sculpted topography merges with the natural landscape, forming a hill that houses vibrant community spaces such as meeting rooms, social hubs, and multi-purpose areas. This lower zone encourages interaction and engagement, becoming the heart of the building’s public life. Above, a lightweight truss box with wood infill floats gracefully over the terrain, offering a tranquil environment for reading, studying, and focused work. The open truss structure provides expansive views of the surrounding landscape, particularly the nearby lake, enhancing the occupants’ sense of serenity and weightlessness. Supported by three strategically placed cores, the floating volume is stabilized while maximizing views and offering natural shade to the lower level during summer months, contributing to sustainability and comfort. This design choice grounds more public, communal programs at the base while elevating private, independent activities within the floating box, creating a dynamic yet harmonious architectural experience.

Slab

Wood Infill

-Clt Slabs

-Clt Columns

Concrete “Backbone” Core

Concrete Cores

5" ANCHOR BOLT

SUSPENSION ROD BRACKET

SUSPENSION ROD

CROSS TEES

50" x 50" WOOD PANEL

HANGING LAMP FIXTURE

STEEL TRUSS SYSTEM

5PLY CROSS LAMINATED TIMBER

1' x 1' CROSS LAMINATED TIMBER

TRIPPLE PANE GLASS

2" HARDWOOD FLOORING

3/4" PLYWOOD SUBFLOOR

1' x 3" WOOD JOIST

THERMAL BLOCK

INSULATION

LAYER OF VEGETATION SUBSTRATE IN QUILTED POCKET ARTIFICALLY WATERED AND FERTILIZED

CAST IN PLACE CONCRETE

3/4" MIRRORED STAINLESS STEEL CLADDING

1" REBAR DIAMETER

Instructors: Sasa Zivkovic & Felix Heisel

Bus Stop: Ithaca, NY

The project began with an in-depth exploration of loam as a versatile building material, inspiring the creation of modular loam units for a bus stop near the Ithaca Falls trail entrance. These units allow for a uniform arrangement of loam bricks, forming a textured wall that seamlessly interacts with the site’s existing stone walls. This connection effectively “closes the room,” creating a welcoming courtyard space that invites pedestrians to enter from the street. The design not only provides a functional bus stop but also enhances the user experience by offering a natural shelter. Additionally, the bus stop doubles as a small library, encouraging community interaction and engagement. When integrated with the surrounding site, the project extends beyond its primary function, transforming into a dynamic public space where people can gather, rest, and connect. This blend of thoughtful material use and spatial design enriches the area’s character, offering a unique intersection between urban utility and natural landscape.

MODULE ENSEMBLE

Renzo Piano and Richard Rogers designed the Centre Pompidou as a flexible structure, conceptualized as a “living organism” redefining architectural conventions. My partner and I focused on analyzing the building’s structural components, joinery details, and the dynamic atmosphere it creates. The exposed steel framework, featuring 48-meter Warren trusses and 10-ton die-cast steel gerberettes, reflects constructivist principles and allows for vast, open interior spaces. Our drawings highlight these critical structural elements. Illustrating how the precise detailing of trusses and gerberettes enables the museum’s flexible interior. Additionally, we represented the color-coded, exposed mechanical, electrical, and plumbing (MEP) systems, which reinforce the concept of the building turned inside out. Through our work, we aimed to capture both the technical precision and the transformative atmosphere of the Pompidou, emphasizing how its design fosters an ever-evolving cultural space.

GROUND PINNED CONNECTION

Joinery Details

Instructor: Sasa Zivkovic

Partner:John Conrad Material Research

HOLDER

This project investigates robotic fabrication and scripting methods to optimize timber joinery for constructing doubly curved surfaces from linear wood elements. Utilizing 6-axis robotic arms, the research develops bespoke joints that enable complex geometries without the need for foreign bonding agents. The focus is on creating structurally sound, easily disassemblable connections that preserve material integrity, tested through vaulted catenary forms and analog joinery models. This approach emphasizes sustainable timber use, parametric design integration, and the potential for automation in advanced timber construction.

My partner and I began by studying traditional Japanese joinery methods, known for their precision and interlocking mechanisms. We then generated an index cataloging slight variations of these joints, exploring how they could help us achieve our desired shapes. Building on this foundation, our next iteration moved beyond the constraints of traditional Japanese joinery, developing a more flexible system that could generate complex, doubly curved surfaces without being limited to the set axes of the initial joinery techniques. This evolution allowed for greater design freedom while maintaining structural efficiency and sustainability.

SHELL FORM

SCALED NEGATIVE GEOMETRY

GEOMETRY SECURED TO BASE

STOCK DIVIDED FOR FOUR PART SCRIPTING

MILLED VECTOR GEOMETRIES

WOOD SEGMENTS

ASSEMBLED KIT