B REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 redpathmining.com / PTFI EDITIONWINTER 2022/2023 THE REDPATH GROUP’S GLOBAL NEWSLETTER CELEBRATING 40 YEARS AT PT FREEPORT INDONESIA redpathmining.com Africa | Asia | Australia | Europe | North America | South America

COMMITMENT TO A FIRST-CLASS SAFETY CULTURE

JIM BUCKLE General Superintendent PTRI Safety & Training

Redpath Indonesia is extremely proud of all safety and training accomplishments in the past 40 years. We continue to be committed to delivering a safe, high-quality product to our valued client.

Along with accomplishments, there have naturally also been challenges. One of the current challenges is the increasing number of new supervisors. Strong and effective supervision is essential for incident prevention, and Redpath’s Supervisory Coaching & Mentoring

Program addresses this need. The Supervisory Coaching & Mentoring Program is created in accordance with the 5-point safety system. The program is intended to improve the quality of supervisor interaction so that an effective twoway interactivity can be created with workers.

Implementing a three-stage mentoring supervision program for all supervisors aims to achieve safe and effective production while developing exceptional leadership.

Another challenge revolves around hazards and risks associated with rigging knowledge and practices. Previous on-site rigging training focused on large overhead cranes used in shop facilities. This setup did not meet the requirements for

40 YEARS OF A COMMON GOAL: TO SAFELY BRING WORLD-CLASS MINES INTO PRODUCTION

bringing into production their worldclass block cave mines.

mobile equipment rigging and material handling.

Now, Redpath’s safety training team utilizes the boom truck for practical training in a more realistic underground environment. This new practical session provides operators with clear and precise instructions on how to handle materials safely in an underground mine.

Throughout Redpath’s years in Indonesia, the company has continued its commitment to developing a world-class safety culture. As we continue to excel in this area, we acknowledge that this would not be possible without the support from our client. We look forward to many more years of collaboration with PTFI as we continue to grow our safety culture to the highest standards.

Safety – First, Last and Always.

BRUCE MENNIE Vice President, International Projects

I’m pleased to welcome you to the PTRI 40th anniversary edition of the Advance. This special edition would not be possible without the unwavering support of our client PT Freeport Indonesia (PTFI).

PTRI works closely with PTFI, their partners and contractors, with the common goal of safely building and

My first time at the PTFI project was in 1989. To say that this location was remote was no stretch of one’s imagination. Employee contracts were six months in and six weeks out. Communication relied on telex machines, costly phone calls and mail taking six weeks to reach home. To work at the PTFI project required more than your average level of endurance.

Fast track to 2022 – technology has brought high speed internet,

on demand communication, state of the art equipment and remote production mucking to this mountain project. PTRI management has encouraged and mentored young motivated national talent. Our ongoing commitment to safety, along with 40 years of successes and achievements, has cemented PTRI’s place as PTFI’s partner for current and future mine projects.

Thank you for reading this edition dedicated to the PTFI project. It’s a tribute to everyone who has contributed directly or indirectly to the success of this project.

19 Local Papuan Promoted CONTENTS 02 Safety Message 03 CEO’s Message 04 Grasberg Mining District 06 Redpath at the PTFI Project 1982-2022 08 PTRI Groups 12 Project Masterminds 16 Life in Tembagapura 18 PTRI: A Family Affair

2 REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 / redpathmining.com

FANTASTIC TEAM EFFORT IN INDONESIA

GEORGE FLUMERFELTChief Executive Officer, The Redpath Group

ADAPTATION – CRITICAL TO REDPATH’S LONG-TERM SUCCESS

This issue of the Advance is largely dedicated to Redpath’s longest-term project at PTFI in Indonesia, where we have worked continuously for the past forty years. Really!

In 1982, Redpath was awarded a raiseboring contract which later expanded to include alimak raising, mine development as well as miscellaneous construction activities.

The ability of our team at the PTFI project to adapt and respond to the changing needs of our client has been key to providing a high level of service. Our team has had to adapt to all manners of different ground conditions, equipment and methods over the years. With each generation of block cave mine that PTFI has built, from the I0Z to D0Z to DMLZ and the GBC, new technology has been deployed, and the next mine

long-term clients, such as Glencore, whom we’ve worked with for over 50 years, South32 – Cannington (35 years), Hudbay (38 years), Northam (30+ years), and BGE (25+ years). This client longevity is only possible because of our ability to deliver safe, on time, on budget service to our clients consistently over time.

to be built, Kucing Liar, will no doubt push the technology envelope even further. The Redpath team will adapt as the drive to provide safe and more productive mining methods continues.

This capacity to adapt to and embrace change exists throughout the Redpath Group. This ability has allowed us to have a stable of

Our mission is to provide a level of service to the mining industry that exceeds normally accepted standards. It is what we will continue to do as we adapt to future innovations in the industry.

THE BEGINNING OF A 40-YEAR CLIENT RELATIONSHIP

MIKE KELLY President, Redpath Raiseboring Limited

My first trip to the PTFI project in 1982 was an eye opener! They chose us to bore ventilation raises. The program went so well that PTFI decided to keep us. From that first machine, the fleet of drills has grown to fifteen. We now have a world-class group of mining professionals who deliver the largest mass excavations and thousands of metres monthly of lateral development. Finance and HR ensure Ops can focus on the work!

Having visited the site regularly for 40 years, I’ve had the pleasure of working with so many talented PTFI and Redpath people. Everywhere I travel in the world, I share efficiencies learned at the PTFI project. We hope you enjoy reading about the teams’ impressive accomplishments in this publication!

THE LOGO

The 40th anniversary logo was conceived by the PTRI team in collaboration with Redpath’s Marketing department.

SPECIAL THANK YOU

Denny Dyatmoko is PTRI’s Project Service & Control Foreman and Redpath’s marketing coordinator on site. Denny has been at the project for over 12 years. His talent, efforts and artistic skills are showcased in photos and text in this special edition of the Advance.

CEO MESSAGE - George Flumerfelt

This capacity to adapt to and embrace change exists throughout the Redpath Group.

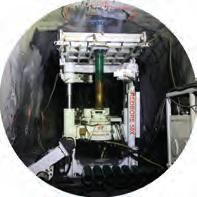

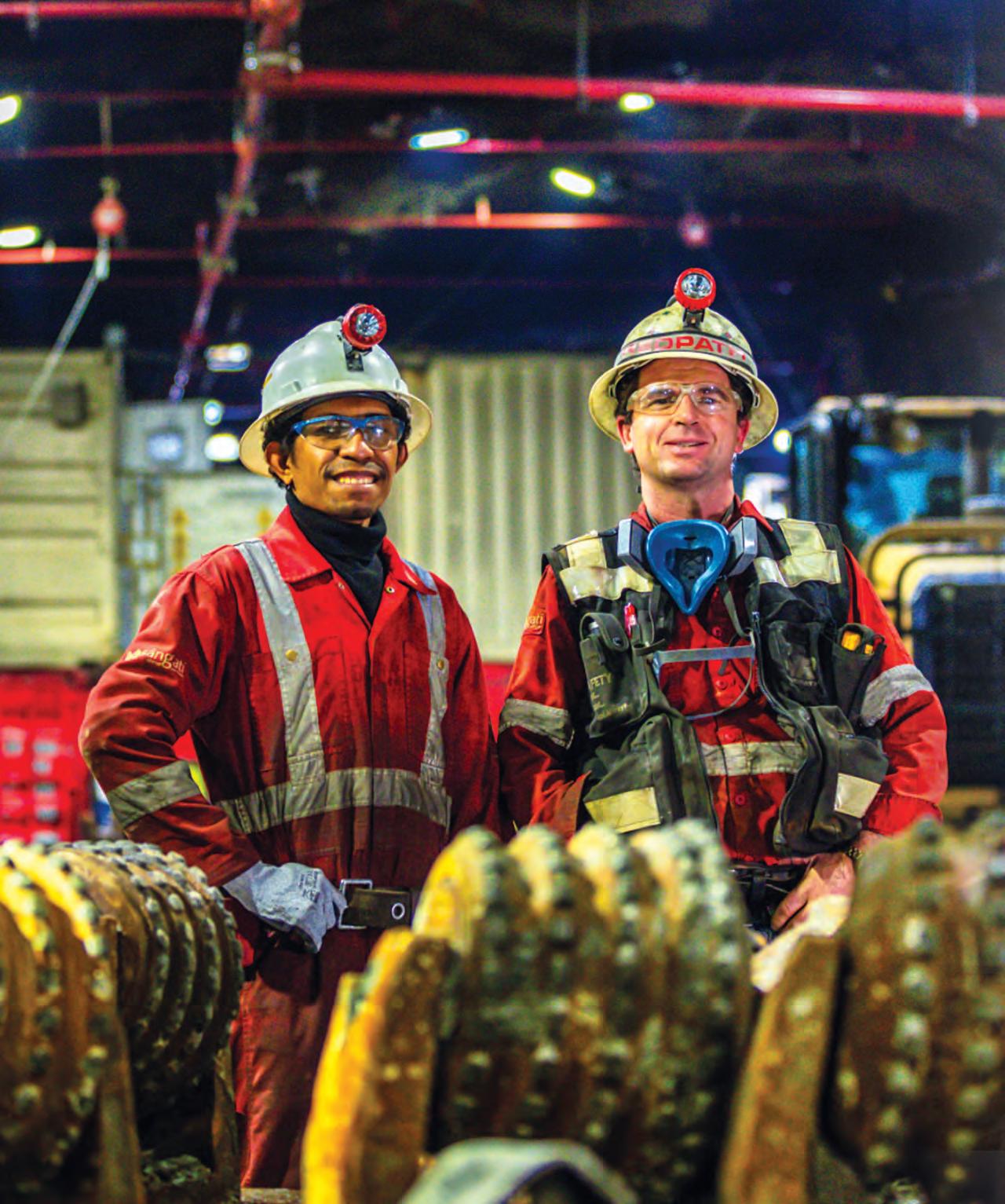

PTRI worker operating a Sandvik DD422i at the PTFI project.

redpathmining.com / REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023

3

In 1982, Redpath arrived on site in Indonesia with a crew of ten and a single raisebore drill, the 82R-1242. That first contract marked the start of what would become Redpath’s largest and longest running project to date.

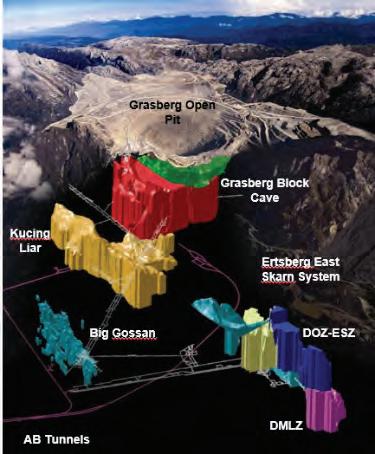

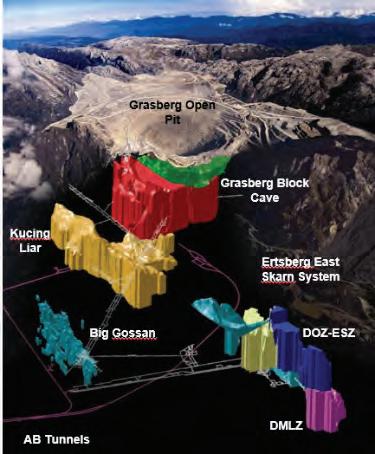

The Grasberg Mining District houses one of the world’s largest copper and gold deposits. The ore bodies were discovered in 1988, and are owned by FreeportMcMoRan Inc. (FCX) and Mining Industry Indonesia (MIND ID), which is owned by the Indonesian government. Freeport-McMoRan Inc. (FCX) operates the mining district.

The district is located within and around two main igneous intrusions; the Grasberg monzodiorite and the Ertsberg diorite. These open-pit and underground mines include Grasberg Open Pit, Grasberg Block Cave (GBC), Deep Ore Zone, Deep Mill Level Zone (DMLZ), and the Big Gossan Mine. The Deep Ore Zone (DOZ) ceased production in 2021 and Grasberg Open Pit in 2019. Mine development activities for the Kucing Liar deposit commenced in 2021.

GRASBERG BLOCK CAVE (GBC)

The Grasberg Block Cave ore body is the same ore body which was mined from the surface in the Grasberg open pit.

The emphasis of Redpath’s involvement in GBC has shifted from development and construction of the mine, to managing those activities and the caving operations, while ramping up the mine to full production. From lateral development, footprint construction, mine rehabilitation, mine service installation, massive excavation, to large-scale block cave production, the Redpath GBC team provides almost full turnkey mine contracting services to PTFI. The GBC Mine will be the largest block caving operation in the world when full production is reached.

GRASBERG MINING DISTRICT

Redpath’s involvement in the Grasberg Mining District is focused on the Grasberg Block Cave and the Deep Mill Level Zone.

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN IND ONESIA - WINTER 2022/2023 / redpathmining.com 4

DEEP MILL LEVEL ZONE (DMLZ)

The DMLZ ore body lies below the DOZ Underground Mine at the 2,590-metre elevation and represents the downward continuation of mineralization in the Ertsberg East Skarn system and neighboring Ertsberg porphyry.

Redpath’s involvement in DMLZ started off as PTRI AB Tunnel project, where PTRI developed the main AB1 and AB2 access ways, all the way to the GBC Terminal. The scope of the project then expanded to include the extraction of the ore body underneath the DOZ Mine. Currently, PTRI is responsible for the development of three main projects: Upper DMLZ (apex, undercut, and extraction levels), Lower DMLZ (intake, exhaust, truck haulage and drainage levels), and Production Block #4 - a new project expanding from the DMLZ footprint. Production at the DMLZ Underground Mine is expected to continue through 2041.

The Grasberg Mining District is in a remote location in the highlands of the Sudirman Mountain Range in the province of Papua, the western half of the island of New Guinea.

REDPATH’S SCOPE OF WORK

Lateral Development

Vertical Development by Mechanized Raise Climber (MRC)

Vertical Development by Raisebore

General Construction

Project Support and Supervision

Caving and Production

Extraction

Construction

Maintenance and Repair Services

Special Projects

GRASBERG MINING DISTRICT

Elevation 1,000 m 1,500 m 2,000 m 2,500 m 3,000 m 3,500 m 4,000 m 4,500 m 0 m 500 m Distance 4,585 m 100 km 80 km 60 km 40 km 20 km 0 km ZONES: A=Nival, B=Alpine, C=Sub-Alpine, D=Montane, E=Lowland, F=Sea Level Grasberg Mill Complex Tembagapura Timika Amamapare Port The Grasberg Mining District is located 4,200 m above sea level.

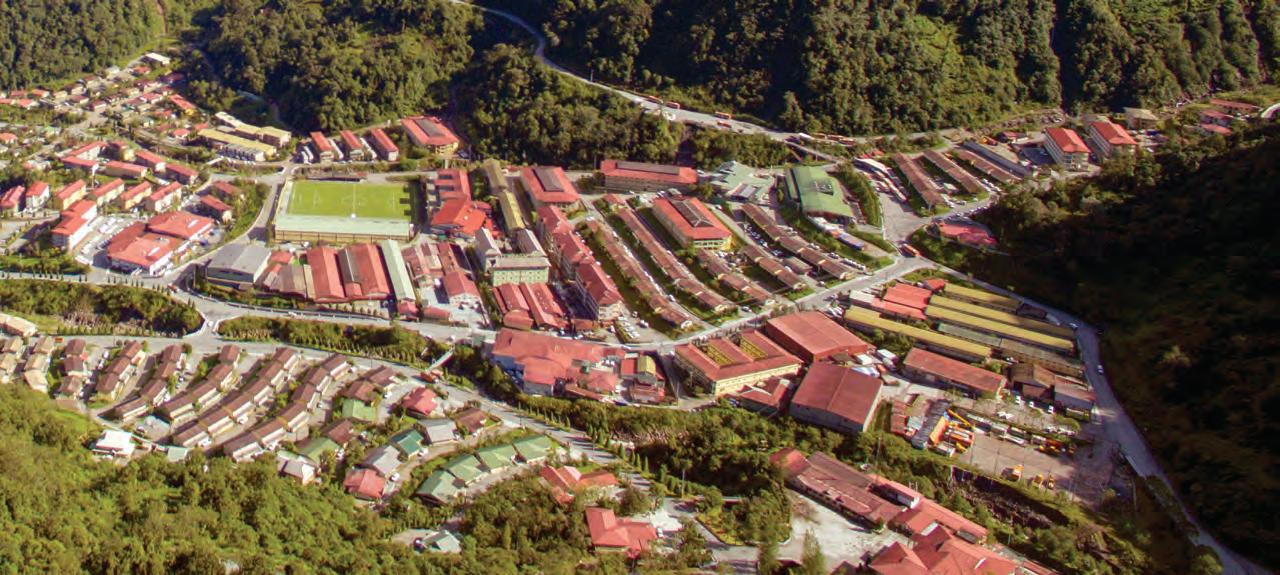

TEMBAGAPURA

MINE JAKARTA

Source: Freeport-McMoRan

GRASBERG

Source: Freeport-McMoRan www.fcx.com

redpathmining.com / REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 5 A C B D E F

Service Agreement between Redpath and PTFI. Starts with one 82R raisebore.

1981

Service Agreement for additional scope of vertical works including MRC raise development in the MLA, GBT and DOM* Mines.

1988

2000

1982

82R raisebore drill arrives on site. Scope of work includes ventilation raises, hydro electric boreholes and ore passes for GBT, DOM and Grasberg Open Pit Mines.

PT

2004

Indonesia Workforce Growth

2005

Starts to work on the Big Gossan Mine development

Work on the Ali Budiardjo (AB) Tunnel begins, connecting PTFI’s future UG mines - GBC, Big Gossan, DMLZ, and Kucing Liar.

2007

Nationals*

*Indonesian workforce

993 TOTAL

1,278

TOTAL

1,603 TOTAL 2,500% INCREASE in total employees (1997-2022)

731 TOTAL

200 TOTAL

Expatriates 64 TOTAL

Second 82R raisebore drill arrives on site. Scope of work includes Big Gossan pre-production vertical mine development – ore passes, ventilation raises and paste holes.

Starts to work on CI3 and Grasberg Ventilation Decline (GVD) for the GBC Mine.

Work on the Big Gossan Production Shaft begins.

REDPATH AT PT FREEPORT INDONESIA - 1982-2022 REDPATH

PT Redpath Indonesia (PTRI) is incorporated.

1999 72R raisebore drill arrives on site.

Mechanized lateral development Wanagon Lake project drifting begins. Start of MRC drawbell excavation in DOZ Mine.

2006

Redpath office is established in Indonesia’s capital Jakarta.

0 500 1000 1500

1997 2002 2007 2012 2017 2022

Redpath

2000

REDPATH’S ADVANCE - 40 YEARS A T THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 / redpathmining.com

6

* Mill Level Adit, Gunung Bijih Timur and Deep Ore Mine

1995

Work on the lower DMLZ Mine development begins.

High Scaling crew starts to work on the Heavy Equipment Access Trail (HEAT) road ground stability project.

2009

Commissioning of the Big Gossan Production Shaft.

Master Service Agreement between PTRI and PTFI.

Is awarded a 5-year raise development contract with two additional Redbore 70HX raisedrills.

Work begins on the GBC Construction project involving draw point, drain hole, grizzly construction and rock breaker installation.

PTRI, in collaboration with PTFI, successfully blast 21 drawbells in a month in the GBC

Is awarded the Large Diameter Raise Program involving Redbore 90EX for Kucing Liar and DMLZ Mines.

2018

Redbore 40S arrives on site, to be used in dewatering project in the GBC Mine.

Record of annual lateral development figures - 42,500 equivalent metres in a year

Is granted a construction works contract at the extraction level of the GBC Mine.

Is awarded boxhole drilling for drawbell in the DMLZ and GBC Mines. Purchases and mobilizes six Redbore 50X and three Redtrax to site.

Recipient of the Indonesian Government’s Mining Construction Contractor Award.

The GBC Production project begins with production drilling at both undercut and extraction levels.

2021 Starts to work on the development of the access to the Kucing Liar Mine.

REDPATH AT PT FREEPORT INDONESIA - 1982-2022

2013

2015 Starts partnering with PGD (now Sangati) regarding workforce supply.

2016

Mine.

2020

drill 5 REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 redpathmining.com /

2022

2008

Work starts on the Kasuang Drainage Tunnel.

2014

2017

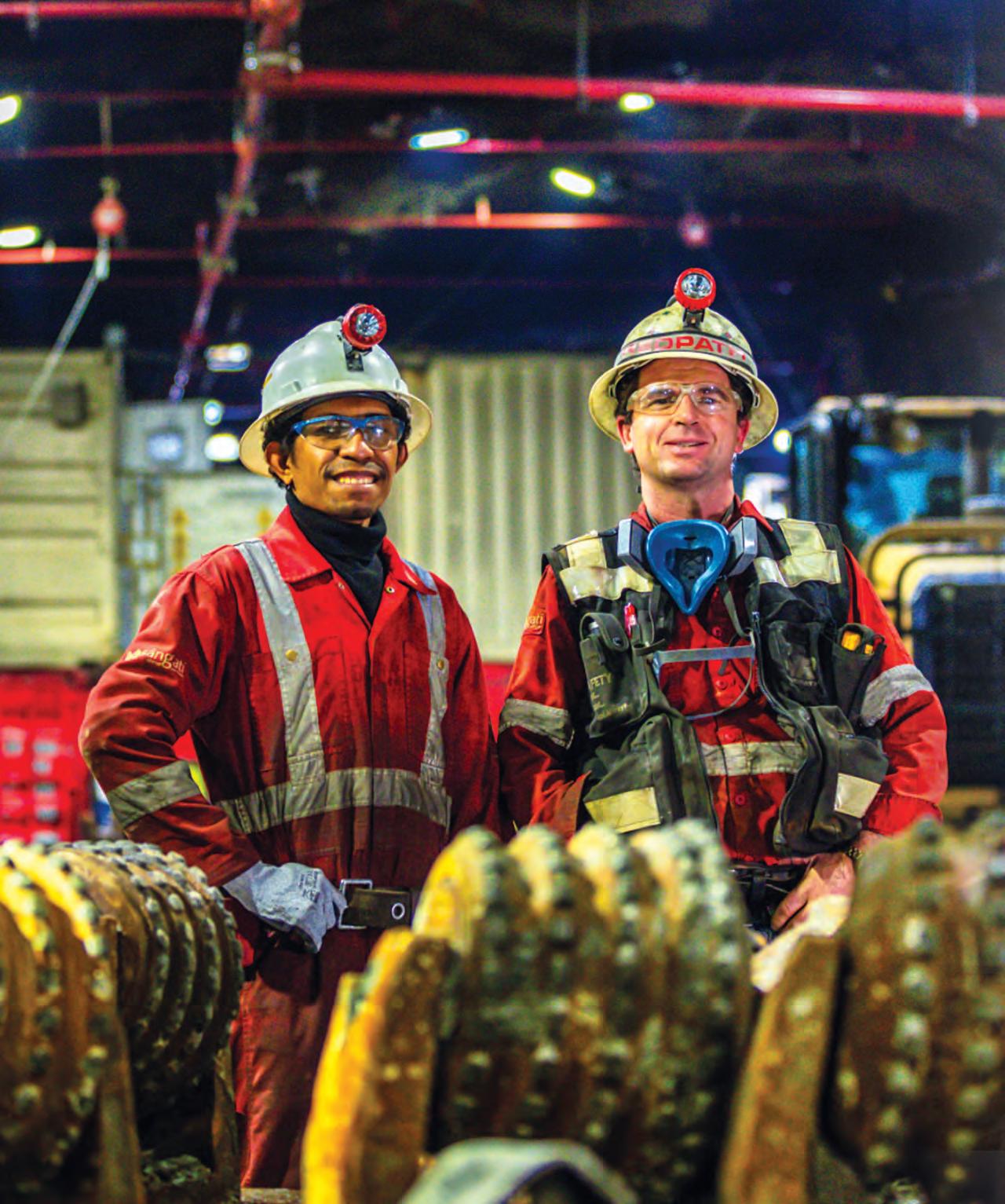

PTRI GROUPS

Meet Redpath’s versatile teams who participate in the construction of some of the world’s largest mining operations.

300

TEAM MEMBERS

DMLZ DEVELOPMENT

Main responsibilities: The DMLZ team is responsible for Deep Mill Level Zone (DMLZ) Mine lateral development of the upper and lower mine and the new Production Block #4 project. An average of 850 to 950 equivalent metres of development are achieved every month, while 3,000 m3 of shotcrete and 30,000 linear metres of resin bolts are applied every month.

250

TEAM MEMBERS

240

Major achievements: DMLZ crusher 504 development was completed seven months ahead of target. A major rehabilitation project was also completed ahead of schedule. The team successfully kickstarted the recent Production Block #4 project.

TEAM MEMBERS

MECHANIZED RAISE, REHABILITATION & CONSTRUCTION

Main responsibilities: The MRC team services the entire mining area, as required. It excavates vertical development by Mechanized Raise Climber (MRC), and rehabilitates ore passes and ore-pass liners, conveyor and ventilation drifts. The team also does raise inspections and ground consolidation work on an ongoing basis.

Major achievements: The team collaborated with Redpath’s GBC and DMLZ development teams to complete mass excavation, constructions, services and other permanent infrastructure works.

8

PTRI GROUPS

GBC DEVELOPMENT

Main responsibilities: The team is responsible for Grasberg Block Cave (GBC) Mine lateral development, with a monthly average close to 2,000 D-equivalent standard metres. From the initial 250,000 metres, an additional 100,000 m will be developed through the rampup period to full production.

Major achievements: The team completed three gyratory crusher mass excavations, five 5,000 Kw fan chamber excavations, and eight portal breakthroughs. In 2016, the team averaged 3,000 equivalent metres of development per month.

RAISEBORING

Main responsibilities: The raiseboring team provides ventilation raises, drain holes, ore/waste and chute passes, muck transfer raises and slot raises, enhancing lateral development efficiency and performance. It operates and maintains the raisebore fleet of Redbore 40S, 6 x Redbore 50X, 2 x Redbore 70HX, Raisebore 72R, 82R and Redbore 90EX on site, along with 3 x Redtrax carriers.

Major achievements: The team optimized drawbell boxhole drilling performance, from 8 days to 5 days. It completes 11 box holes/month, with a record of 19 box holes in January of 2021 (GBC and DMLZ Mines).

110

TEAM MEMBERS

230

TEAM MEMBERS

GBC PRODUCTION

Main responsibilities: The main focus of the GBC team is to muck ore from the cave of draw point to the ore pass as efficiently as possible. The team also supports the client with remote mucking in areas where wet muck is present. In addition to mucking, production drilling services in drawbell and undercut areas are also provided.

Major achievements: The team has blasted over 350 drawbells and set a record in September 2020 by blasting 21 drawbells in one month.

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 redpathmining.com / 9 PTRI GROUPS

100

TEAM MEMBERS

MECHANICAL CONSTRUCTION MATERIAL

Main responsibilities: The MCM team ensures that all project materials for GBC are constantly accessible. The team also supplies mining services for production and development, sump and pump maintenance, along with fan motor, ventilation door, bulkhead, and dumper installations.

Major achievements: The Mill Stockpile Project, started in 2016, is being completed ahead of schedule. Another major achievement of the team is the Amole Macken Dam repair for flood prevention in 2018 at Mile Point 74.

120

TEAM MEMBERS

GBC CONSTRUCTION

Main responsibilities: The GBC Construction team undertakes nearly all required construction in the GBC Mine at extraction level, including lintel set, grizzly construction and rock breaker installation.

Major achievements: The team has completed 28 rock-breaker installations, 44 grizzlies and 922 half-draw point lintels.

30

TEAM MEMBERS

ADMINISTRATION AND PROJECT CONTROL

Main responsibilities: This Admin and Project Control team ensures compliance with the client’s and local and central governments’ employment requirements. It also manages the workforce in accordance with company

regulations, and manages the company’s legislative requirements. Earned Value Management (EVM) is implemented to monitor monthly project performance.

PTRI GROUPS

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 / redpathmining.com 10

130

TEAM MEMBERS

ELECTRICAL

Main responsibilities: The Electrical team provides electrical support to underground mines, with a focus on tunnel development, raisebore power supply and electrical maintenance, geotechnical installations and seismic monitoring.

Major achievements: The team successfully implemented a seismic warning system and hydrofracture program, along with electrical construction for rock breakers, grizzlies, and the explosives magazine in the GBC Mine.

FINANCE

Main responsibilities: The Finance team manages payroll, income and expenses, as well as compliance with government taxation and regulations. The team strives to ensure effective business operations with minimal disruptions.

Major achievements: Significant improvements on free cash flow have been achieved through optimized collection method.

12

TEAM MEMBERS

20

TEAM MEMBERS

SAFETY & TRAINING

Main responsibilities: The Safety and Training team applies Redpath’s and PTFI’s safety programs, while meeting regulations and expectations of government departments. The team regularly audits for compliance and improvement opportunities.

Major achievements: The team improved the quality of supervision in accordance with the 5-Point Safety System through the Supervisor Coaching and Mentoring Program and the Integrated Safety Management System.

PTRI GROUPS

redpathmining.com / REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023

11

THE ACCOMPLISHMENTS OF THE PTRI TEAM WOULD NOT BE POSSIBLE WITHOUT THESE PROJECT MASTERMINDS.

NICKY HE RAULT

PTRI Operational Director

How and when did you get involved in the project?

I was interested in the PTFI project while I was working in the Matagami Isle Dieu shaft sinking project in the 1989-90 era. I contacted the Ram Raising office* in Timmins indicating my interest. I received information that I was accepted while I was working in Timmins at the Kidd Creek shaft sink. I landed in Timika on July 14, 1991. Back then, we flew through Cairns, Australia, on a privately chartered aircraft which, it was rumoured, had once belonged to Elvis Presley.

I was originally hired at the PTFI project as an Alimak miner with skills in shaft sinking and construction.

My experience and knowledge were quickly put to the test with an abundance of work and projects to work on.

What has this project meant for you personally?

The project for me is a source of challenges and a sense of acceptance of accomplishments. It offers the opportunity to influence people in a positive and constructive manner.

What are you most proud of when it comes to your involvement in this project?

The project has been an opportunity to express my values, knowledge and beliefs. Not too often does a project give you enough flexibility and freedom to influence its direction. I have been fortunate enough to be part of this project’s pioneering era and to manage its core values throughout the years. It’s very much a reflection of who I am as a person and a Redpath employee.

I’m also proud of the fact that I started at the bottom and climbed to the top, while

PROJECT MASTERMINDS - PTRI

“I started at the bottom and climbed to the top.”

REDPATH REDPATH REDPATH

REDPATH’S ADVANCE - 40 YEARS A T THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 / redpathmining.com 12

* A joint venture between Redpath and Angus Martin providing Alimak services.

developing and maintaining a worldclass team able to meet today’s difficult challenges with such a large operation.

What are the top three things that are key for the project’s success and why are they important?

1. To lead by example. All team leaders need to demonstrate by example. This is how we positively influence our employees.

2. To communicate openly. We need to be able to have clear, honest discussions with the workforce. It’s important to share the expectations and the desired outcomes.

3. To listen and acknowledge your employees. This does not necessarily mean that you fix all their problems, but it does mean that you understand their challenges and values.

Our industry continues to develop and meet the needs of a changing world. We need to ensure that our employees are also capable of meeting these changes. Future leaders will need to be more flexible and responsive in order to be successful.

I MADE PASEK

PTRI General Superintendent, GBC Mine

How and when did you get involved in the project?

I joined Redpath as a member of the engineering team in 2007. Once I got involved in the underground environment, I quickly realized that this is such a fantastic industry to be a part of. During my tenure, Redpath has provided me with the opportunity to be a part of several facets of mining; not only working in the office but also gaining direct mine operations experience in the field.

PROJECT MASTERMINDS - PTRI

“Challenge is always an opportunity.”

REDPATH REDPATH REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 redpathmining.com / 13

What has this project meant for you personally?

I have been involved in many challenging projects within Redpath Indonesia; one of them is the Grasberg Block Cave (GBC) project. The GBC project marked, no doubt, my life here. In my mind, simply nothing compares to it. It is the cornerstone of our company - a project meant to become one of the largest block cave mines in the world - something all of us should be proud of. My time with Redpath is one of the most exciting, challenging and definitely mind-blowing experiences I could ever have dreamt of. This mix of nationalities, experiences, skills, languages and even beliefs, all working together as a team, makes this place unique. To witness the company collaborate with the Indigenous Peoples, the Papuans, growing together, is something to be proud of as well. I remember once reading the slogan “Unity in diversity”; what a living example we

all give to this nation and to the world here at site.

What are you most proud of when it comes to your involvement in this project?

I’ve had the opportunity to orchestrate and integrate extraordinary teams within Redpath GBC, providing unparalleled solutions for project execution, from feasibility studies to reality. As an integral part of the GBC Mine, Redpath successfully tackles all of the project's scope, ranging from development and construction, to the production phase - on schedule, SAFELY. Redpath in Indonesia has demonstrated the ability to undertake one of the company’s most ambitious projects.

IVAN AGUSTIAN

How and when did you get involved in the project?

I started working on the project in August 2005 as a fresh graduate with some experience from a small underground coal mine. Unlike the typical hiring process at the time, I only had phone and online interviews with Redpath. Coming into one of the largest mines in the world and joining a reputable international contractor really pumped my adrenaline. I started working as a junior engineer at Redpath’s core operations projects at the Deep Ore Zone (DOZ) Mine.

PROJECT MASTERMINDS - PTRI

REDPATH REDPATH REDPATH REDPATH

Representing PT Redpath Indonesia at (left to right) are: Salipin Sudirman (NB Nicky Herault, Irwan Saputra & I-Made

“Joining a reputable international contractor really pumped my adrenaline.”

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 / redpathmining.com 14

Redpath’s reputation and extensive experience on-site has made it a go-to contractor that can respond to any challenge, anywhere, anytime!

What are the top three things that are key for the project’s success and why are they important?

1. Willing to tackle any challenge, SAFELY. Challenge is always an opportunity A challenging project encourages us to go beyond the obvious, use our resources efficiently, think outside the box, and narrow in on the project’s purpose. All these behaviours are necessary to continue to challenge ourselves to find a better, safer way, and we shouldn’t be afraid to be the first.

2. Stay relevant. Being relevant is essential in the extremely competitive mining industry. No contractor exists in isolation; we only exist in the context of the environment that surrounds us. When that environment rapidly changes, staying relevant helps us adapt to the

What has this project meant for you personally?

This project is part of my life, even after I left the mine site. I am closely attached to the project. This is where I have learned both technical and non-technical aspects of work and life. It has been a great journey to continuously learn from talented and passionate people within the project.

What are you most proud of when it comes to your involvement in this project?

There are multiple stages in my life and career to be proud of, and most of them are associated with the ability to overcome major challenges. My most proud moments are when I see team members, whom I have worked with, grow and then successfully step up to higher levels of responsibility.

new circumstances, enabling us to be the leader in the industry.

3. Plan for the best, prepare for the worst and communicate it! The best planning takes time as we need to consider every possibility in advance. The more prepared we are, the better we’ll be able to respond and keep the project safe, sustainable and secure. By communicating the plan and project status consistently, we ensure that team members and the client are aligned on project goals and that everyone understands exactly what’s expected of them. Consistent communication contributes to the development of trust, resulting in enhanced collaboration, from project inception to completion.

What are the top three things that are key for the project’s success and why are they important?

The first one is planning. This is a key mantra that leads to effectiveness. The second one is collaboration within your team, across departments and, more importantly, with the client. It is almost impossible to expect a successful project without collaboration and effective communication with stakeholders. The third one is continuous improvement. This is essential for survival in the industry. Our presence at the PTFI project for 40 years shows that we have done our best to continuously improve and create a desire in the industry for our continuing services.

PROJECT MASTERMINDS - PTRI REDPATH REDPATH

the Redpath Americas Safety Day based), Ivan Agustian (NB based), Pasek.

Ivan Agustian and Bruce Mennie have worked together on the PTFI project since 2005.

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 redpathmining.com / 15

HENDRIK YEMBISE

General Foreman

MRC Department

3:00 AM START DAY

Breakfast at the site’s mess hall.

3:50 AM ARRIVE TO GBC OFFICE

Meet cross-shift supervisor and discuss shift concerns and action plan.

4:10 AM LINE UP MEETING

Day shift task coordination, distribute documentation, progress reports, and plan for the shift.

4:50 AM SAFETY HUDDLE Update and share safety concerns, stretch, and remind crew to take their time and work safely.

5:30 AM COORDINATION MEETING

Follow-up on outstanding safety concerns and engineering requirements.

6:30 AM PREPARATION

Prepare and inspect PPE, get the list of headings and requirements. Coordinate with planner for outstanding materials or potential disruptions in the headings.

7:00 AM – 2:00 PM HEADING INSPECTION

Inspect headings, ensure the crew complies with line-up and safety, review and discuss Fatal Risk Management and 5 Point Safety System forms and inspect PPE. As the MRC headings are stretched across the mines, the supervisor strategizes underground traffic and travel time to ensure efficiency and effectiveness.

2:00 PM UG MRC OFFICE

Consolidate heading reports from frontline supervisor and hand-over end-ofshift report to the night-shift supervisor.

4:50 PM RETURN TO CAMP

What’s in a name?

Tembaga in Indonesian means “copper”, while pura in Sanskrit means “temple” or “town”.

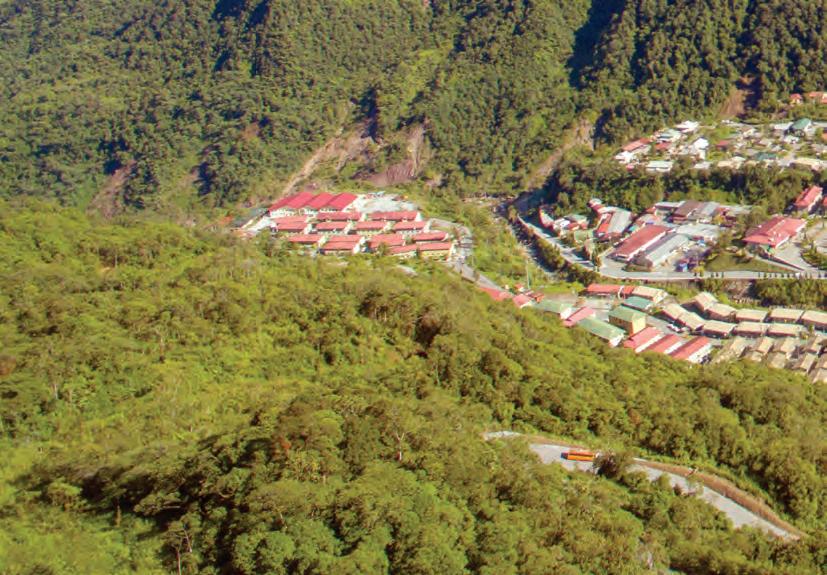

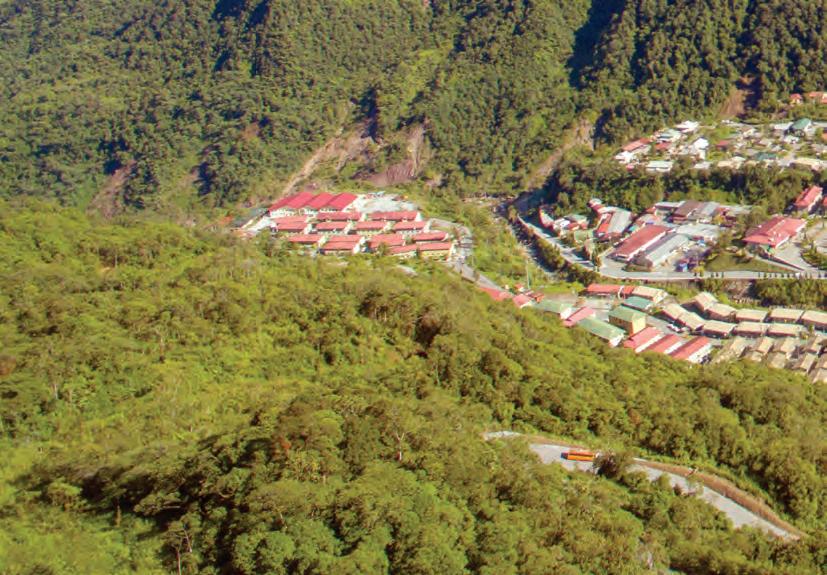

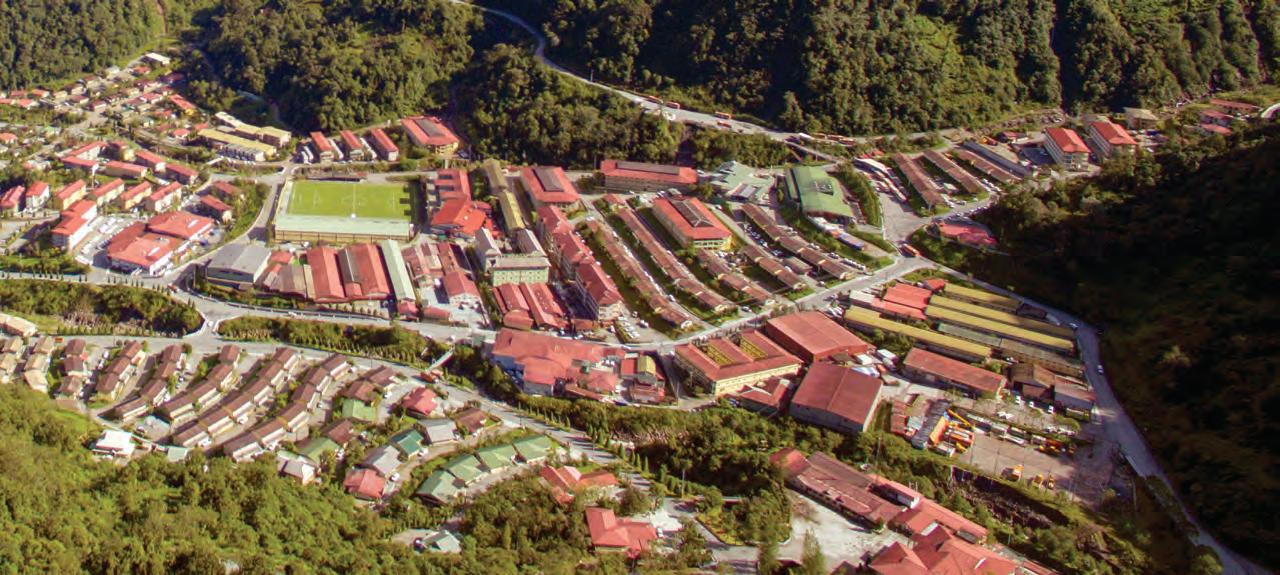

LIFE IN TEMBAGAPURA

Tembagapura (“Coppertown”) is the PTFI project’s primary townsite in the highland area, which provides employees with services including retail stores, restaurants, residences, schools, medical facilities, libraries, banks, postal services, sports, places of worship, training and recreational facilities. There is also a camp located closer to the mine called Ridge Camp. Tembagapura and Ridge Camp, combined, have a total population of 23,000.

Source: Wikipedia

LIFE IN TEMBAGAPURA A DAY IN THE LIFE

1,900 m ELEVATION >3 m RAINFALL per year 17°C AVERAGE DAILY TEMPERATURE 23,000 POPULATION (2020)

Badminton is a popular sport. A tournament is part of Redpath’s National Safety Month.

Redpath employees shopping at one of four grocery stores in town.

Many Redpath employees enjoy the outdoors, including this expedition to the Nggapulu peak.

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 / redpathmining.com 16

There are several opportunities for sporting activities in and around Tembagapura.

COMMEMORATION OF THE 77TH INDONESIAN INDEPENDENCE DAY

This year’s theme for Indonesia’s Independence Day on August 17 was “Recover Faster, Rise Stronger”.

All of PTFI’s contractors, departments and divisions were represented, along with Indonesian government officials, school and community representatives.

In addition to the traditional flag ceremony, which was held at

an altitude of 2,000 m above sea level, there was also a cultural carnival and an archipelago culinary festival event the same day Together with the PTFI community, PT Redpath Indonesia team members enthusiastically participated in the festival. They showcased the diversity of Indonesia by wearing costumes and performing dances from different regions, including North Sulawesi in the northern part of the country, and Bali.

LIFE IN TEMBAGAPURA / INDONESIAN INDEPENDENCE DAY

The Tembagapura Hospital on the left, and a restaurant on the right.

The mosque in town offers panoramic views.

Congregation in front of one of two churches in Tembagapura.

Overhead view of the shopping centre, which houses a variety of public facilities.

Typical apartment accommodations.

A Redpath employee taking his children to school in Tembagapura.

Redpath Indonesia Raising Flag Team

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 redpathmining.com / 17

COMMUNITY INVOLVEMENT IN PAPUA

AND

OTHER PARTS OF INDONESIA

Redpath strongly believes that community involvement is an important part of our business and operations.

committed to cover 2,500 Indigenous Papuans who don’t have fixed income.

In cooperation with Indonesia’s National Social Security Agency (BPJS), Redpath promotes Indigenous Papuans’ participation in the National Social Security Program. These Papuans live in the Kwamki Namara District, near the mine operation. Redpath covers their monthly premium contributions to make the Indigenous Papuans eligible for work accident insurance and death insurance. Redpath has

Redpath proudly supports local promotions, sport leagues, charitable activities and the arts.

Another example of Redpath’s support to the Papuan population and culture is the company’s partnership with the Canadian Embassy in Jakarta to promote Kamoro wood carvings from Papua. Redpath has also occasionally brought visitors to the Kamoro village to support their culture and handicraft.

With Indonesia located on the “Ring of Fire”, a band around the Pacific Ocean with seismic activity, earthquakes and volcanic activity are common. Redpath and company employees have taken immediate action after major unfortunate earthquakes and tsunami events in Indonesia, providing support to the impacted areas.

Redpath also regularly participates in events held in Tembagapura, including sporting events, the Monthly National

PTRI – A FAMILY AFFAIR

F or most Indonesians involved in the mining industry, working for PTFI is a great privilege. “Time really flies”, said Hasudungan Hutauruk, thinking back on his 35 years of mining experience, 20 of those years with Redpath. Hasudungan is the father of three sons and one daughter and still remembers when he was accepted to work with Redpath in early 2003. Although excited, Hasudungan also felt worried about

leaving his family, especially his young sons. The PTFI project is located in eastern Indonesia while Hasudungan lives in the western part of the country. It takes over 17 hours of road and air travel from his home to the mine site. He believed this job was God’s way of improving his family’s future.

Hasudungan started his career in the Mechanized Raise, Rehab and Construction (MRC) department as a raise miner. He developed his skills

and experience and, eight years later, was promoted to a supervisory position. During his 20 years with Redpath, Hasudungan maintains his commitment to work safely with two major things in mind – the family who is waiting for him at home, and the insight that his family members’ future relies on his ability to continue to work safely.

Franky Hutauruk, Hasudungan’s second oldest son, was, ever since he was a boy, keen to hear mining stories from his father. This may unconsciously

SOCIAL ENVIRONMENT / MULTI-GENERATIONAL FAMILY

Ceremony recognizing PTRI’s contributions to Indigenous Papuans’ insurances.

Redpath donated school uniforms for 180 local Papuan students of the Tsinga Village near the PTFI project.

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 / redpathmining.com 18

Safety Event, the

LOCAL PAPUAN PROMOTED TO KEY ROLE IN DMLZ MINE

Redpath continually strives to train and advance the local Papuan workforce, and to provide opportunity for career development within Redpath. One recent example is Benny Diwitau, who was promoted to Superintendent for the Deep Mill Level Zone Mine (DMLZ) lateral development project.

Benny joined Redpath in 2007 as an Alimak miner. He later became a shaft miner, then tunnel miner and supervisor before his recent promotion.

PT Redpath Indonesia achieved another milestone in November of 2022, when the first ever Redbore 90 EX large diameter raisebore was successfully commissioned. The commissioning followed the large diameter contract awarded to PTRI earlier in the year. The historic achievement was the culmination of a very demanding and concerted effort by Redpath’s teams in Canada, Australia, Indonesia and South Africa.

The Redbore 90 EX provides the ability to establish 5.0 m and 6.0 m diameter raises over distances more than 300 m in length, meeting the client’s expansion requirements in both ventilation and ore movement.

PTRI currently maintains and operates 12 raisebore machines at PTFI, drilling out a variety of holes for different applications ranging from drain holes of various diameters, intake ventilation raises, slot raises, exhaust raises, and ore passes. The addition of the Redbore 90 EX makes PTFI the mine with the single largest Redpath raisebore fleet at one site.

have driven him to pursue an engineering degree. It was a dream come true when he was accepted to work for Redpath at the MRC department after graduating from university. “It is always exciting and challenging to learn many new things and to meet new people", said Franky who joined Redpath in 2017 at the age of 24.

Hasudungan is very proud of knowing that, after he retires and reconvenes with his family, his son will continue his

work at the mine. “At first it was hard for me to let him work in the raise as I know how difficult it is. But then I realized he will need to find his own path to become the next good miner and leader”.

Hasudungan and Franky are just one example of many Redpath father-son miners who continue to strengthen and extend their family bond in the workplace, building a path for a better life for their families.

SUPERVISORY PROGRAM / PROJECT WIN / MULTI-GENERATIONAL FAMILY

Redpath employees supported the island of Lombok in West Nusa Tenggara, Indonesia, after the 2019 earthquake.

Redpath Stampede, religious events, Movember, and Tembagapura school events.

As part of the company’s community support, Redpath together with Sangati promote vision health by supporting a campaign that provides free eye examination and glasses to residents and administrators at the orphanage in Timika, Papua.

Benny Diwitau is responsible for lateral development at DMLZ.

Franky and Hasudungan Hutauruk.

PROJECT WIN!

REDPATH’S ADVANCE - 40 YEARS AT THE PTFI PROJECT IN INDONESIA - WINTER 2022/2023 redpathmining.com / 19

I am pleased that Redpath provides opportunities to improve and develop myself.

redpathmining.com