B REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 THE REDPATH GROUP’S GLOBAL NEWSLETTER 60TH ANNIVERSARY EDITION - SUMMER 2022 REDPATH: CELEBRATING 60 YEARS Africa | Asia | Australia | Europe | North America | South America redpathmining.com

DEREK BUDGE Director of Health, Safety and Environment, The Redpath Group

Workplace injuries and fatalities in mining were once thought of as being inevitable and part of doing business. Fortunately, things have changed significantly for the better. Improvements in technology, methodology and training have resulted in significant reductions in the number of workplace injuries and fatalities in the mining industry in general, as well as within Redpath.

Risk assessments are one of the best tools to help drive down the likelihood and consequence of unwanted events resulting in injury, damage to equipment and loss to process. The

formal Risk Assessment process has proven to be most effective when the right people are involved.

In some circles, operational risk assessments are seen as something to be done in isolation by the safety person involved in the project, but this is wrong. The proper way to go about it is to use the right team of individuals who can collectively determine the risks associated with the task. Depending on the circumstances, you may need to draw in subjectmatter experts, including engineers, mechanics, electricians and workers who are familiar with the task or will be involved in performing the work.

The Hierarchy of Controls is a key consideration in any Risk Assessment process. A key role of the safety department is to help facilitate this process and ensure the controls to be implemented are adequate and

that all relevant procedures, tools and equipment and training required to perform the work are available, understood and communicated.

In the workplace, we also use various types of Field Level Risk Assessments such as Take 5, SLAM - Stop Look Analyze and Manage - and the Neil George 5-point safety system. These tools typically prompt workers and supervisors to: check the entrance and travelways to their workplace, ensure the workplace and equipment are in good order, have a discussion about safety, correct any unsafe conditions, and question workers and supervisors about their attitude and ability to work safely.

As we move past the 60th year of operations at Redpath, we must continue to develop and implement safety innovations, utilize state-ofthe-art equipment and tools, and provide the best training available, both theoretical training and skills development. If we do these things well, we will continue on the right path to our goal of zero harm.

WHAT IS SAFETY?

“The condition of being safe from undergoing or causing hurt, injury, or loss”.

-Webster’s Dictionary

“A state of mind whereby we are constantly made aware of the possibility of injury at all times”.

-Neil George

CONTENTS 02 Safety Message 03

04

60-Year

06 The

09

17 60

17

18

19 Did You

CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS

CEO’s Message

A

History

Man Behind the Company

Global Review

Years of Shafts

Redpath’s Women in Mining

Redpath’s Long-Serving Employees

Know?

SAFETY IN THE MINING INDUSTRY HAS CERTAINLY COME A LONG WAY IN THE LAST 60 YEARS.

EFFECTIVENESS MORE LESS ELIMINATION REMOVE the hazard REPLACE the hazard ISOLATE people from the hazard CHANGE the way people work PROTECT the worker with personal protective equipment The hierarchy of controls is key in the risk-assessment process.

2 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 / redpathmining.com SUBSTITUTION ENGINEERING CONTROLS ADMIN. CONTROLS PPE

REDPATH – A LOT TO BE PROUD OF!

GEORGE FLUMERFELTChief Executive Officer, The Redpath Group

GEORGE FLUMERFELTChief Executive Officer, The Redpath Group

This issue of the Advance celebrates Redpath’s 60th anniversary. I would like to take some time and reflect on what we have accomplished as a company and take a look to the future and what lies ahead for Redpath.

Jim Redpath founded the company in 1962 to service the Canadian mining industry and it quickly developed a reputation for excellence in shaft sinking and mine development.

Redpath’s commitment to providing innovative solutions and superior service to our clients will continue to be the bedrock of the Redpath value proposition.

Opportunities for growth led Redpath to take on projects in Greenland and the United States in the early years. By the twenty-year mark, the company had branched out into the raiseboring business and took on work further from its home base, in

South America and with Freeport in Indonesia, where we are still active 40 years later!

Throughout these early formative years, Redpath developed a reputation for offering innovative solutions for our clients consistent with Redpath’s philosophy of ‘providing a level of service to the mining industry that exceeds normally accepted standards’.

1962 2022

establishment of Redpath Africa in 2006, Redpath Australia in 2008, and Redpath Deilmann in Europe in 2012.

As we have grown our business, our various business units have learned from one another. Today, we are able to provide even better service to our clients via internal Redpath joint ventures, which all business units are currently involved in.

The way that I think about our philosophy is that we are not interested in providing average service which will not differentiate us in the marketplace, so we must strive to always deliver superior service to our clients. This philosophy has allowed our company to grow to become the largest full-service provider of underground mining services in the world.

Over the last fifteen years, Redpath has expanded its services to cover most of the mining world with the

Looking to the future, I see tremendous opportunity for Redpath. Metal prices have risen significantly recently, and our clients are investing in the construction of new mines, which is leading to many important project opportunities for us.

Redpath’s commitment to providing innovative solutions and superior service to our clients will continue to be the bedrock of the Redpath value proposition as we go forward.

We can look ahead to further enhancing our reputation as we continue to improve our industryleading safety performance. I am confident that we will be able to report even greater success on the occasion of our 75th anniversary!

B REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022

CEO MESSAGE - George Flumerfelt

CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS We would like to thank this edition's contributors: • George Flumerfelt • Derek Budge • Bennie Burger • Paul Healy • Gavin Ramage • Jochen Greinacher • Kevin Melong • Scott Hayne • Mark Immonen • Andy McParland • Bruce Mennie REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 3

redpathmining.com /

‘Redpath The First Half-Century 1962-2012’, by Moira Jackson, has served as a great source of inspiration and material for this edition.

A 60-YEAR HISTORY

1962: J.S. Redpath Limited is founded, its first office being the basement of

1963: First project at McIntyre’s Lorraine Mine, Belleterre (Québec).

1990:

1982:

1980s

1990s

1988:

1993:

INNOVATION

1965: Awarded Creighton #9 Shaft Project (Ontario), in partnership with Shaft Sinkers Pty Ltd. of South Africa. It becomes the deepest, single-lift circular concrete-lined shaft in North America.

1967: First mine development project at McIntyre Mines, Mines des Madeleines (Québec).

INNOVATION

1968: First use of jumbo drill in Canadian Mining.

1969: First work in the Arctic at Nanisivik Mine for Texas Gulf Sulphur (Nunavut).

1969: J.S. Redpath Limited moves to North Bay.

Design of the Redbore 40 drill is completed, with two units produced.

INNOVATION

1989: Full-face, Long Round, shaft sinking introduced to Americas at TL shaft for Falconbridge in Sudbury (Ontario).

INNOVATION

1995: Pioneers and introduces Programmable Logic Controllers (PLC’s) for use on mine hoists.

REDPATH REDPATH - A 60-Year History

First work at Freeport in Indonesia, Redpath’s longest continuing association with a client.

Redpath Manufacturing Limited (now known as Redpath Raiseboring Ltd.) is established to manufacture and sell raisebore machines.

Photo from 2011.

Kidd Creek Xstrata) mine expansion This project continued (Ontario).

First contractor Canadian diamond Kennecott’s DO-27 Northwest Territories.

4 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 / redpathmining.com

HISTORY

Creek (Falconbridge/ expansion begins. continued until 2009

INNOVATION

2003: Redbore 50 is designed and built.

1990s

contractor into the diamond fields –DO-27 project in the Territories.

1996: Raglan Mine Development Nuvumiut for Falconbridge/ Xstrata/ Glencore begins (Québec).

2004: Pogo Mine (Teck/Sumitomo), production development begins (Alaska). Underway until 2019.

INNOVATION

2004: Redpath Mongolia LLC is the first contractor to establish in Mongolia. Previously, there were exploration teams only. 2005: Work commences on Shaft 1 at Oyu Tolgoi for Ivanhoe Mines (now Rio Tinto), (Mongolia).

2005: Redpath’s proprietary training program “Pathways to Excellence” for supervisors and managers is introduced.

2000s

2006: ATON GmbH acquires Deilmann-Haniel International with its six subsidiaries, including The Redpath Group.

2007: DeilmannHaniel South Africa is purchased and rebranded as Redpath Mining South Africa Pty. Limited.

2008: EROC is acquired and rebranded as Redpath Australia Pty. Ltd., based in Brisbane and with a branch office in Perth.

INNOVATION

2008: Redbore 100 becomes the world’s most powerful and largest capability raisebore machine.

“The Queen Louise”

INNOVATION

2010: Development of VDSL WIFI communications, monitoring and data collection system begins for shaft-sinking operations.

INNOVATION

2011: Develops and deploys tunnel shield to establish a ramp portal through deep-running sands at the Ghaghoo Mine in Botswana.

2012: 50th anniversary is celebrated company-wide.

2012: Acquisition of DeilmannHaniel Shaft Sinking GmbH (later becoming Redpath Deilmann GmbH) in Germany, which integrated into The Redpath Group.

2010s

2012: Global employee count reaches 6,000.

2014: Redpath Zambia Pty Ltd. is established.

2015: Dayan Contract Mining LLC (DCM) is established as a joint venture between Redpath Mongolia LLC and Hasu Megawatt LLC. Becomes a major contractor for the Oyu Tolgoi Mine (Mongolia).

INNOVATION

2016: Design & implementation of ‘Shaft Controller System’ to provide fully integrated instrumentation, controls and communications in shaft.

INNOVATION

2018: Shaft Boring Roadheader (SBR) designed alongside Herrenknecht and deployed at Nezhinsky Mine (Belarus).

2019: Joint venture Redpath Thonket Mining Services Ghana Limited is established.

2019: Redpath installs the world’s largest friction hoist at Oyu Tolgoi Shaft 2.

2020: Redpath Deilmann GmbH achieves outstanding performance at Nezhinsky Mine (Belarus); 7.4 metres/day and more than 140 metres/month. The company applied experience gained at a freeze shaft completed for Uralkali Ust-Jaiwa Mine (Russia).

2020: Despite the disruptions and changes to regulations related to the COVID-19 pandemic, Redpath was able to cope and thrive.

2020s

2021: Raiseboring records at Niobec and Macassa Mines (largest bored raise in the Northern Hemisphere and longest raise in the Americas, respectively).

2021-22: Redpath designs, builds, and commences testing of the S-100 hydraulic shaft mucker (Germany).

2021: Redpath Africa and Redpath Australia form a joint venture to complete mine development work at De Beers’ Venetia Mine, South Africa’s largest diamond mine.

2022: Redpath Canada and AESA form a joint venture and secure the Yanacocha project in Peru.

REDPATH - A 60-Year History

redpathmining.com / REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 5

What one man started sixty years ago is now a multinational company with over 6,000 employees.

In Jim Redpath’s own words:

I was raised in Val d’Or, born in 1936, the same year the town was founded. My father, a mining engineer from Pincher Creek, Alberta, was mine superintendent and later mine manager at the Sigma Mine, an underground gold mine.

We lived about 100 yards from the mine’s bunkhouse. Prospectors, diamond drillers, and miners were the men I was exposed to from birth.”

The text and photos in this article have been adapted from “Redpath – the First Half-Century 1962 – 2012.”

BEHIND COMPANY THE

This company started with one man’s desire to build his own business in an industry that is predictable in only one way: good times will evaporate overnight and without warning.

Although so many other companies in this business are no more, Redpath has not only survived this turbulent environment for decades but thrived. Forty-five years after he set up in the basement storage locker with a subscription to The Northern Miner as his only business aid, Jim Redpath observed, “It’s an interesting thing about this company: that it survived all the things that I would not have done.”

THE MAN REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH REDPATH THE MAN BEHIND THE COMPANY - Jim Redpath

6 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMME R 2022 / redpathmining.com FEATURE

JIM REDPATHTHE MAKING OF AN ENTREPRENEUR

SUMMER WORK as a teenager at Sigma Mine; in exploration in Cape Breton; and in prospecting in Hudson Bay.

FIRST JOB as an underground miner at Giant Yellowknife.

ENROLLS AT MCGILL UNIVERSITY in the Mining Engineering program.

SUMMER WORK at Inco Garson Mine in Elliot Lake. Also visits mines and tunnels in Europe and attends a Commonwealth Mining Congress tour of Canadian mines coast to coast.

GRADUATES FROM MCGILL UNIVERSITY as a Mining Engineer in 1958.

TIMBERMAN’S HELPER at Kerr Addison Gold Mine. Becomes a stope miner and, in 1960, a shift boss.

SHAFTMAN for Boland Development Co. in the East Malartic winze, and as a shaft leader in Butte, Montana.

NIGHT CAPTAIN at the Kelly Shaft. Is sent to Québec to start the Joutel shaft.

FOUNDS

J.S. Redpath Limited at age 26, and manages the company for 25 years (1962-1987). Serves on the company’s Board of Directors until 1997.

The green pickup truck was Redpath’s first vehicle.

THE MAN BEHIND THE COMPANY - Jim Redpath

2022: Jim Redpath lives in St. John’s, Newfoundland with his wife, Bobbi.

redpathmining.com / REDPATH’S ADVANCE - 60TH AN NIVERSARY EDITION - SUMMER 2022 7

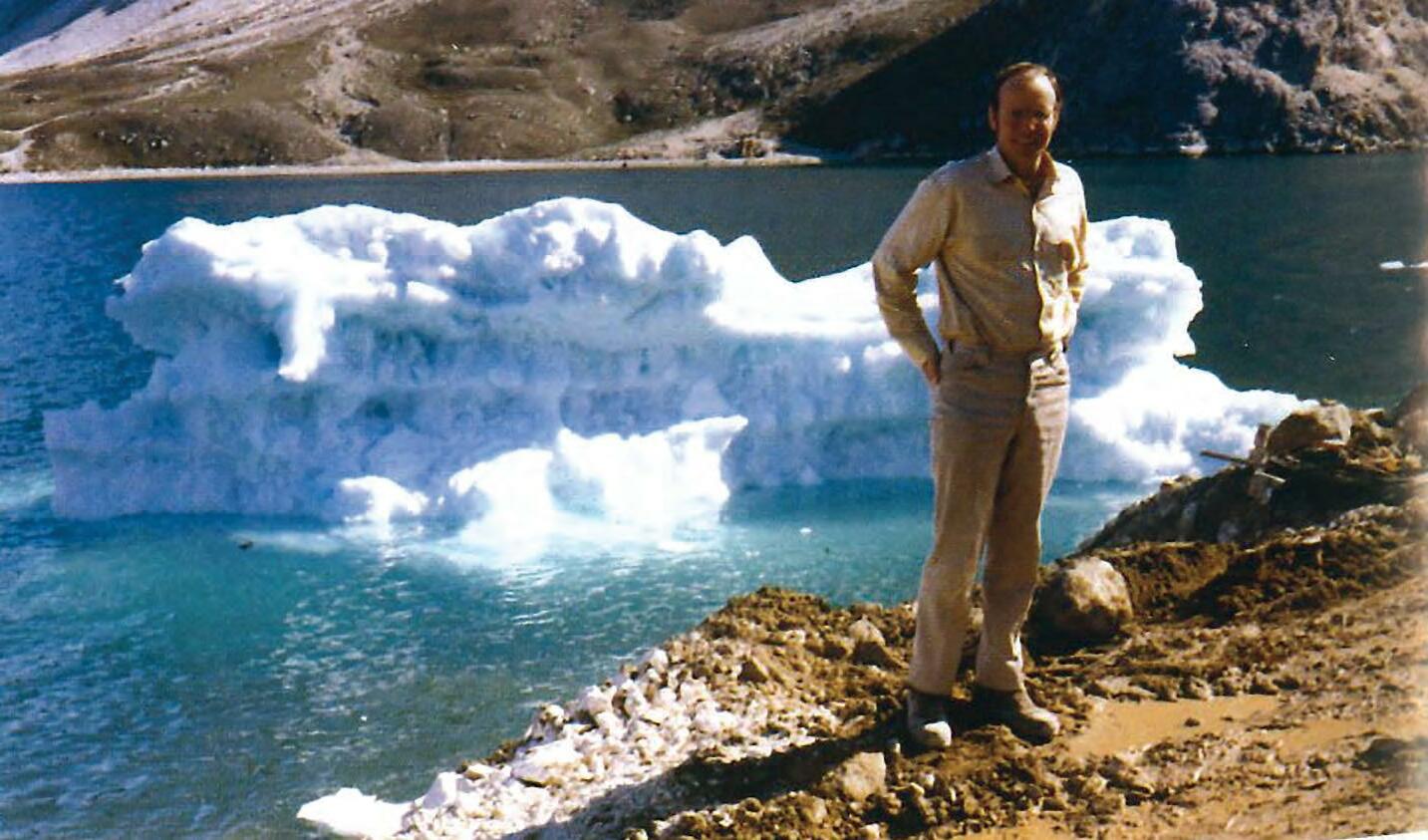

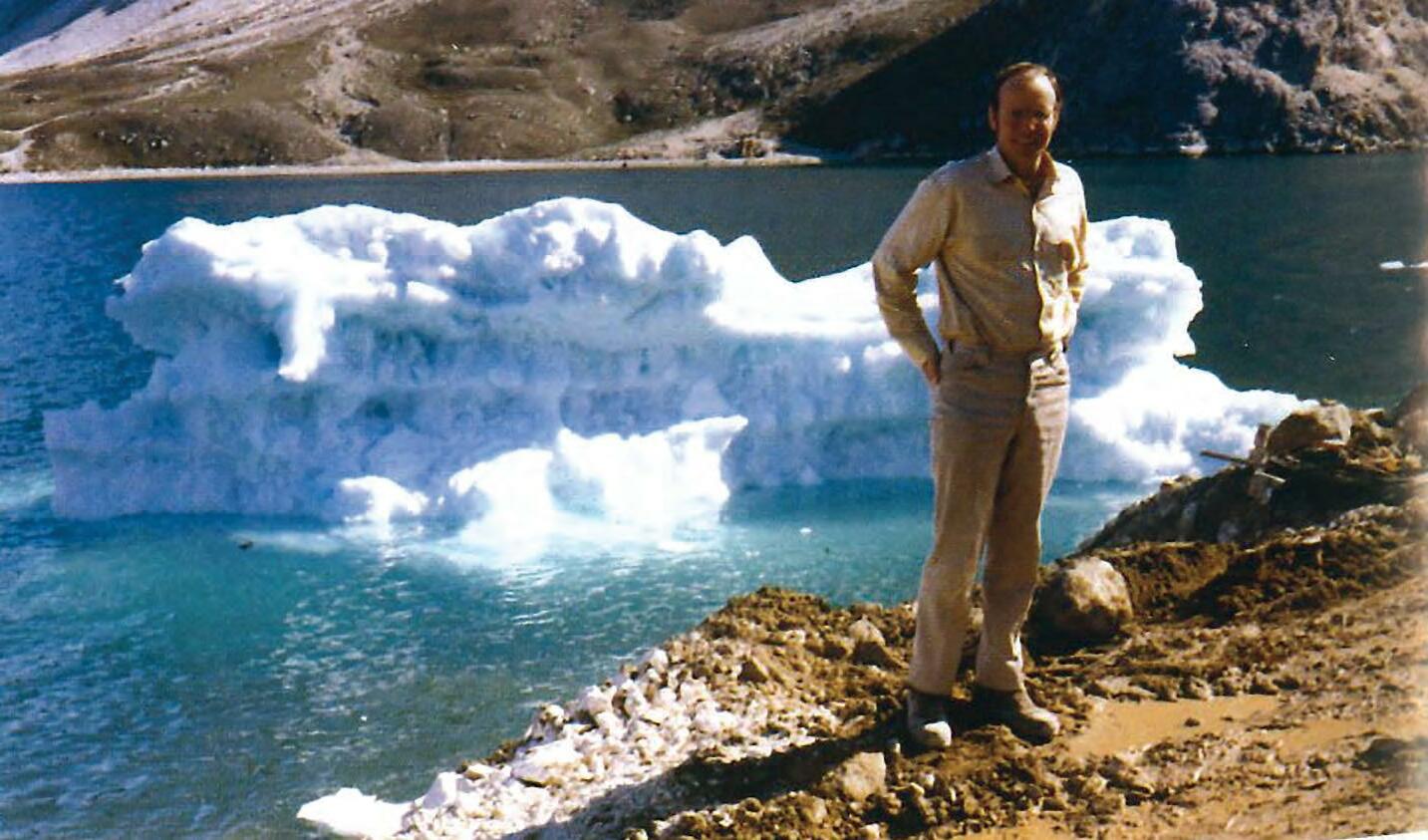

Jim Redpath at Black Angel Mine in Greenland. The company built an early reputation for successfully tackling projects in extreme climates and locations.

GUIDING PRINCIPLES

PENNED BY JIM REDPATH IN REDPATH'S EARLY DAYS:

OUR PHILOSOPHY

The Redpath Group Philosophy makes a commitment to: provide a level of service to the mining industry which will exceed normally accepted standards; create a desire in the industry for our continuing services; provide scope and challenge for our employees; control growth in order to maintain a high calibre of service to the industry. This philosophy has served Redpath well since 1962, and it will continue to support our belief that, at Redpath, “Challenge is an important part of life.”

GUIDELINES FOR SUCCESS

We are honest, fair and responsible. We make accurate schedules and budget forecasts that are managed and met to the best of our abilities without surprise.

We work by our principles of “Safety - First, Last And Always.” We never criticize our competition. We give and publish well-written technical papers. We do not overcommit. We ask if we don’t know the answer. We remember that our goal is to serve our clients well. Excuses are unacceptable. We act in the long-term interest of our company and our clients. We do not take advantage of short-term situations.

To see our Philosophy and Guidelines for Success, take a photo of this code with your phone’s camera and click ‘open site’.

Many people, either now retired or still working for the company, rode out the turbulence of repeated downturns in the industry because they believed so deeply in Redpath. Employees do

A PASSION FOR ART

Hundreds of pieces of art from Jim Redpath’s art collection adorn Redpath’s Canadian offices; watercolours and oils, lithographs and etchings, sculptures, prints, and artifacts in every style by artists both renowned and unknown from around the world. Jim Redpath’s interest in art took him to Sotheby’s in New York City for a ten-month sabbatical to study American works of art in 1986.

not feel like the proverbial cogs in a machine. Rather, they marvel at the way a company can grow to such a size but still feel like family.

In Jim’s own words:

If, in today’s world, you find yourself bored, you just aren’t paying attention. I don’t want anyone working with me who’s not paying attention.

The halls of Redpath’s Global Headquarters in North Bay are adorned with hundreds of original works in a variety of mediums.

8 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022

THE MAN BEHIND THE COMPANY - Jim Redpath

redpathmining.com

redpathmining.com

The first Redbore 40 raisedrill used at LAC Minerals’ Macassa Mine in Kirkland Lake, Ontario. Left to right: Dan Charbonneau, Kevin Anderson and Jim Redpath.

Redpath’s board of directors in 1978. Standing: Bob Dengler, Jim Redpath, Jim Proudfoot. Sitting: David Taylor and John Thompson.

GLOBAL REVIEW

From a small Canadian mining contractor to a multinational corporation serving the global mining industry.

From humble beginnings to the global organization it is today, Redpath’s journey has been filled with hard work, breakthroughs and challenges. The last few years have seen Redpath teams busy at projects around the world. With advanced technologies, new partnerships and groundbreaking records paving the way for continued strong performance, Redpath managers reflect on the last 10 years and new opportunities ahead.

GLOBAL REVIEW - Reflecting on the Last 10 Years Across the World

Uralkali Ust-Jaiwa Mine, Russia

Nezhinsky Mine, Belarus

K2 Mine, United States

Grosvenor Mine, Australia

Mogalakwena Mine, South Africa

Oyu Tolgoi Mine, Mongolia

REDPATH

Mt. Lyell Mine, Australia

Evolution Bateman Mine, Canada

redpathmining.com / REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 9

PT Freeport Indonesia Mine, Indonesia

Headquartered in Johannesburg, South Africa, and incorporated in Mauritius, Redpath Africa Limited has grown leaps and bounds in the last ten years, having extended its footprint from Southern Africa into East and West Africa. With subsidiaries in South Africa and Zambia and a joint venture partnership (Redpath Thonket) in Ghana, Redpath Africa Limited has completed numerous sophisticated and technically challenging mine development and construction projects across sub-Saharan Africa, some of which include impressive world-firsts.

The hiring of locals, coupled with a focus on skills development, training, and sourcing materials from local suppliers, speaks to our company’s commitment to add social and economic value in the areas in which the company operates. Redpath Africa Limited also plays an active role in supporting local social programs related to health, wellness and education through donations, fundraising, knowledge-sharing, and employee participation. Examples include Redpath Africa

At the Ghaghoo Sand Tunnel in Botswana, Redpath tunnelled through the desert to reach the orebody.

Redpath’s Ghaghoo Sand Tunnel Project in Botswana, for example, deployed a decline tunnelling method, utlizing a specially-designed, 96-ton Open Face Tunnel Shield to develop a sand tunnel at -8º in the Central Kalahari Desert, an exceptionally remote area characterized by its expansive, deep, and unconsolidated sand cover. This project was an unprecedented world first at 6.1 m in

ONE OF THE LARGEST diameter holes in Africa. Impumelelo Mine, South Africa: The Redbore 90 EX piloted and reamed two ventilation shafts, 7.3 m Ø x 186 m.

diameter and 473 m in length. Redpath’s work at the Mindola Deeps Vertical Shaft in Zambia between 2013 and 2020 saw the company complete one of the longest raisebored shafts in the world, measuring 6.1 m in diameter and 1,986 m deep.

AFRICA

Redpath Africa Limited has grown leaps and bounds in the last ten years, having extended its footprint from Southern Africa into East and West Africa.

PEOPLE AND COMMUNITY

Limited’s support of numerous socio-economic development programs e.g. Mvelaphanda preschool project in Tembisa, as well as enterprise-development programs across Gauteng. The programs, which are overseen by The Entrust Foundation, are aimed at providing resources to underprivileged schools and communities, creating jobs and nurturing entrepreneurship.

Redpath Africa Limited staff members are at the heart of the company’s success. Underpinned by the belief that there is power in having a diverse workforce that is indicative of a country’s demographics, staff members are recruited from various regions and backgrounds. The result is a staff complement that is diverse in terms of culture, experience and ideas.

This was completed in four separate lifts of approximately 500 m per lift, and the shaft was equipped with a total of four underground access stations.

In 2017, at Impumelelo Mine, the company reamed one of the largest diameter holes in Africa.

BENNIE BURGER General Manager, Mining and Raiseboring, Redpath Mining South Africa

GLOBAL REVIEW - Redpath Africa

10 REDPATH’S ADVAN CE - 60TH ANNIVERSARY EDITION - SUMMER 2022 / redpathmining.com

Twenty twenty-two will be the sixtieth-year anniversary of Redpath’s creation. Global expansion continues but Redpath maintains a powerful base in North Bay, overseeing and supporting projects in North and South America, Mongolia, and Indonesia.

The company’s service offerings have changed significantly over the past decade to support the changing requirements of our clients.

These changes have included development of sophisticated project management tools, implementation of new business systems, continued productivity initiatives, and innovation on project performance. The result is continued success in winning new work, executing projects effectively and fostering lasting client relationships.

Over the past decade, Redpath Americas has completed projects in

Canada for many of the major mining houses, including Newmont, Vale, Glencore, Alamos Gold, BHP, Kirkland Lake Gold (now Agnico Eagle), Rio Tinto, Hudbay Minerals, Canadian Royalties and Anglo American. Internationally, the team continues to support major works for Freeport in Indonesia and Rio Tinto in Mongolia.

In addition, Redpath has brought its offerings to new markets, sinking a shaft for Pan American Silver in Mexico and soon to construct the underground mine at Newmont’s Yanacocha project in Peru.

The past decade has also seen the fostering of strategic partnerships with local Canadian stakeholders: Nuvumiut Development Inc. and Tawich Construction in Québec, Nunatsiavut Group and Innu Development in Labrador, and Wahgoshig Resources and Three Nations Group in Ontario. These partnerships have benefitted Redpath with the supply of local services and staffing, and have provided the local communities with training and employment opportunities.

Ensuring best-for-project results led to several collaborations, including the formation of TRL, a partnership with the Ledcor Group and Thyssen Canada for work at BHP’s Jansen project in Saskatchewan; a joint venture with AESA Infraestructura Y Minera, a Peruvian underground contractor for mine development at Newmont’s Yanacocha project; and finally a joint venture with Redpath Deilmann for shaft sinking at Anglo American’s Woodsmith project in the United Kingdom.

PEOPLE

The company’s evolution and sustained success over the past decade can be attributed to the people of Redpath. Recognition is due to recently retired leaders, including:

• Bruce Dunlop

• Phil Hickey

• Gerry Ouellet

• Martin Hunka

• Rick Jylha

• Chris Cobbledick

All of these leaders were longterm Redpath employees, who were instrumental in Redpath’s past success and in mentoring a new, core leadership team. Their contribution, in conjunction with all past and current employees, has put Redpath in a position of continued success for the next decade and beyond.

PAUL HEALY President, Americas

AMERICAS

Redpath has evolved from a small regional contractor in Canada into one of the largest, most diverse underground mine constructors in the world.

GLOBAL REVIEW - Redpath Americas

Pogo Mine, USA.

Second-generation hydraulic mucking system at shaft bottom in Saskatchewan, Canada.

Split-feed jumbo bolter at Goldcorp’s Borden Gold Mine.

redpathmining.com / REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 11

CANADA

SCOTT HAYNE Senior Vice President, Redpath Americas

As our business in Canada continues to trend in an upward direction, each of our Area Managers have been tasked with the challenge of starting new projects. We are currently mobilizing five new projects spread across four clients: Eleonore and Musselwhite (Newmont), Macassa

Material Handling (Kirkland Lake Gold, Agnico Eagle), Alamos, and CC030 Construction (Vale).

We continue to intensify our “Start Well On Time” efforts, to ensure efficient project management from the very beginning - a belief pioneered by our founder, Jim Redpath, which is ingrained in our DNA. Additionally, we continue with front-end engineering activities in preparation for two new shaft jobs that will commence before the end of 2022.

Other projects across our Canadian portfolio continue to flourish under strong metal prices, lending to project

expansions and contract extensions. We are in the final strokes of winding down two technically challenging projects: the Kemano project in British Columbia is scheduled for “water up” in June, and the rehabilitation of Vale’s South Mine shaft in Sudbury is scheduled to be commissioned in early Q3 of 2022. I commend both project teams, as their perseverance through challenging technical execution resulted in very successful projects. Both projects are testament to the Redpath mantra: “Challenge is an important part of life”.

MARK IMMONEN Vice President, Redpath USA Corporation

The last decade for Redpath USA Corporation (RUSAC) has included record-high revenues, the end of several long-term anchor projects, the first shaft work in 20 years, a long run of infrastructure projects, and multiple mine development contracts. With senior leadership’s focus on a strong safety culture, RUSAC achieved a significant safety milestone working 7.2 years and 3.2 million workhours without a lost time accident.

RUSAC’s largest and longest contract at Sumitomo’s Pogo Mine concluded in 2019. The project saw 15 years of stable, large-scale success, providing RUSAC with business stability through mining’s cyclical years. This dynamic environment produced many of RUSAC’s current leaders, while engraining Redpath as the contractor

of choice for work in Alaska. The decade also saw relationships continue with Barrick at their Storm, Banshee, Meikle and Bazza Mines and, more recently, at the Golden Sunlight Mine in Montana. Golden Sunlight brought four years of safe, challenging work in a geotechnically and operationally complex environment. The projects’ success can be credited to leadership’s ability to recruit and train a predominantly local workforce, developing employees into well-rounded miners that remain with Redpath today.

One significant infrastructure project was the Waneta Expansion Project in Trail, British Columbia, Canada. The project’s entire hourly workforce was unionized and hired locally, with many workers never having worked underground.

RUSAC also continued to win smaller hydroelectric projects, including Allison Creek Hydro Access tunnel, Eklunta Tunnel Rehabilitation, the Blue Lake Expansion and the Jackson Hydroelectric project. The two latter projects won national awards for their success and positive environmental

impact involving optimizing powergeneration capacity and supporting fish-spawning habitats.

In the United States, Redpath Raiseboring led by Mat Perkins, completed all projects without a lost time incident. The company was successful in winning and executing most of the available work in the Elko region throughout the decade.

RUSAC’s Nevada Copper Pumpkin Hollow project is worth final mention as this has been the first USA shaft project Redpath has worked on in nearly 20 years. Project successes include the completion of main shaft sinking, final shaft outfitting for production and the continued ramp-up to sustainable production. The successful team, including Paul Anderson, Carl Graham, Ty Cortner, Michael Walters and Eric Stoll, to name just a few, has led the project through the challenges of moving into steady state production.

RUSAC’s future is optimistic with large, previously delayed projects coming online, promising relationships with clients and a long-term leadership team committed to future success.

12 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 / redpathmining.com GLOBAL REVIEW - Redpath Canada and USA

UNITED STATES

This year will mark a decade for me since I started working in Mongolia. During 2012, The Redpath Group celebrated 50 years of successful operations in the underground mining industry. Redpath Mongolia LLC had been in operation for 8 years and had successfully completed two shafts (Camel Well, 75 m, and Shaft 1, 1,385 m) at the Oyu Tolgoi Mine in the South Gobi region. Redpath was actively sinking two more shafts (Shafts 2 and 5) as well as undertaking a large lateral development program to enable long-hole drilling to better define the Hugo North orebody.

the government of Mongolia and Rio Tinto signed an agreement to restart the underground construction for the mine. Redpath was awarded a small construction-readiness program to bring the shafts and underground work headings back to a state where we could restart the development operations.

A further challenge was when our client indicated that all future substantial work packages would only be awarded to Mongolian majorityowned companies. After an extensive search for a potential Mongolian partner, our executive management team eventually selected one of our long-term subcontractors, Hasu Megawatt LLC, a heavy industrial fabrication and electrical service contractor. Thus, Dayan Contract Mining LLC was incorporated in 2015.

REDPATH/DAYAN CONTRACT MINING AT OYU TOLGOI

In August 2013, we were notified that the underground portion of the mine was to be shut down due to a dispute with the Mongolian Government. This was a very challenging time for Redpath, having to lay off most of our workforce. We were able to maintain a small, seconded workforce for the open-pit operation and underground care and maintenance program. The shutdown lasted until mid-2015, when

Through Dayan, we were awarded the underground mining and support services contract to resume sinking Shafts 2 and 5, in addition to restarting the underground lateral development (UDS) in 2016. Our seconded Care & Maintenance team continued under Dayan, as well as with the Mine Support Service project. In 2018, the sinking of shafts 2 and 5 was complete. Both projects reached world-class performance and quality standards, while achieving the lowest all-injury frequency rate of any Redpath shaft project in their final 18 months of sinking. The same mining crews went on to complete the

sub-level Shaft 2 vent fan, installation, the sinking of Ore Bin 11, Shaft 2 Barrel Equipping, and the rope-up and Chairing Steel installation of Shaft 2. Our lateral development crews have gone on to complete over 70 km of development.

On January 25, 2022, I witnessed the Oyu Tolgoi underground mine opening ceremony. The ceremony included Rio Tinto and the Government of Mongolia jointly firing the first blast for the block cave mine development. Working in Mongolia has been the most exciting and challenging experience of my mining career. I’m looking forward to

ANDY MCPARLAND General Manager, Mongolian Operations

MONGOLIA

Both Shaft 2 and 5 at Oyu Tolgoi reached world-class performance while achieving the lowest all-injury frequency rate of any Redpath shaft project.

GLOBAL REVIEW - Redpath Mongolia

FIRST Mongolian company to hire UG staff with recognized disabilities

4 MAJOR PROJECTS -1,300 employees

30+% of staff hired locally from South Gobi region

LOWEST injury frequency rate of all Redpath shaft projects

Redpath’s lateral development crews have completed over 70 km of development.

redpathmining.com / REDPATH’S ADVANCE - 60TH ANNIVER SARY EDITION - SUMMER 2022 13

Nyamdulam Yadamsuren, engineer with Redpath Mongolia / Dayan Contract Mining, was the first female shotfirer in an underground mine in Mongolia.

I t’s exciting to be part of this edition of the Advance and to celebrate Redpath’s 60th anniversary. It’s also a privilege to represent PT Redpath Indonesia (PTRI), where we are celebrating our 40th anniversary of providing services to the PT Freeport Indonesia “PTFI” project.

safety and training, engineering, MCM, electrical, project controls and administration. We diligently supported PTFI with their existing UG mine operations while remaining in the shadows of the huge Grasberg surface mine operation. Combined daily tonnage was >200,000 tonnes of which more than 75% came from the surface mine.

engineering and leadership, PTRI management under Nicky Herault, skilled National leadership, other PTFI support partners and a hard-working and determined workforce. Together, this team has consistently delivered safe development, construction and production.

Through my 30 years with the PTFI project, there have been many opportunities and challenges. None have been more gratifying than the past 10 years, which have seen the GBC and DMLZ* block cave mines be developed and come into production.

Looking back to PTRI’s first 30 years, we worked hard to develop a strong multinational workforce to service PTFI. We focused on developing National talent in operations, mid and senior management. We focused on sharpening our skills in all areas of mine development – production, tunnelling, mass excavations, raisebore, mechanized raise climber, and construction. We also focused on critical support departments including

PTRI was ready when PTFI announced that their surface mine operation would transition to what has become the largest underground block caving operation in the world. This announcement set into motion a journey which has allowed PTFI, with PTRI’s support and other PTFI support partners, to reach

Through this, PTRI remains committed to the Indigenous community in Papua. Employees from the surrounding villages and regional Papuan community make up one third of our employees. PTRI participates in and supports Papuan local arts and artisans from the Kamoro-Asmat region.

Examples

many milestones in the GBC and DMLZ Mines over the past 10 years. These achievements required PTFI

There remains more work to be done with the recent announcement of the DMLZ PB4 mine expansion and Kucing Liar mine development. We are excited about these opportunities

INDONESIA

PTRI was ready when PTFI announced that their surface mine operation would transition to what has become the largest underground block caving operation in the world.

GLOBAL REVIEW - Redpath Indonesia

± 40,000 ‘D’ equivalent metres / yr. tunnelled 176,000 m2 undercut at GBC Mine 46 M tonnes production at GBC since Jan. 2019 ± 3,300 metres / yr. of raise development

*Grasberg Block Cave and Deep Mill Level Zone Mine

and

over the past

years.

of milestones in the GBC

DMLZ

10

Grasberg Block Cave at PT Freeport Indonesia Mine.

Indonesian and Papuan employees 14 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 / redpathmining.com

BRUCE MENNIE Vice President, International Projects

>90%

When I look back at the last 10 years, there have been many notable achievements in our Australian business, including innovative and market-leading initiatives implemented by our divisions.

Starting with our Mechanical Excavation Division, in late 2012 through to May 2015, we undertook the Grosvenor Coal Mine Project with the development of two surface-toseam drifts using a flame-proofed tunnel boring machine (TBM). This was the first time a TBM was used in a Queensland coal mine. Then in 2017, we developed a shaft-lining jacking system for the installation of a steel-liner support system following the raiseboring of a shaft. We have gone on to use this on other projects following its initial implementation. These projects are examples of innovations applied in our Mechanical Excavation Division and demonstrate our commitment to offer clients unique solutions to their challenges.

led to contract extensions at existing projects, as well as new project successes, that have drawn on our significant ground-support experience and production-mining capabilities. And somewhat recently in the 10year reflection period, our partnering with Redpath Africa to secure two new projects in South Africa, has allowed us to provide scope and new challenges for our Australian employees who want to undertake international projects.

LARGEST SINGLE RAISEBORE CONTRACT in

In our Metalliferous Division, projects such as Cannington, George Fisher, Olympic Dam and Lady Loretta have provided us with a solid foundation for growth, confirming our capability across our service offering. This has

And lastly but by no means least, our Raisebore Division. From its inception in 2010 to celebrating 10 years in 2020 and then, in 2021, securing the largest raisebore contract in Redpath’s history, it truly has been an incredible journey! I look at the achievements of the division, and for me, what has been key to the success, was developing the large diameter raisebore capability within the division. During our first large-diameter shaft project at Olympic Dam, whilst debate

GAVIN RAMAGE Managing Director,

can be had on the success, we learned a lot, which provided a platform for success at Granny Smith, George Fisher, Narrabri, Broadmeadow and Cadia x 3. When we complete our current scope in 2023 at Cadia, we will have completed more than 8,000 m of raiseboring in a 5-year period at this mine, a significant achievement in anyone’s books.

In highlighting the achievements of the above projects, they could not have been accomplished without the support of the staff in our corporate offices. I send a big thank you to all the employees who have supported our success during this time.

AUSTRALIA

When I look back at the last 10 years, there have been many notable achievements in our Australian business, including innovative and market-leading initiatives implemented by each of our divisions into our projects.

GLOBAL REVIEW - Redpath Australia

Redpath Australia has been mining at Lady Loretta since 2018, providing nearly full mine-to-mill service at the mine.

Redpath history

Cadia: Redpath’s Redbore 100, Redbore 90EX and Redbore 90 are contracted to complete eight holes, totalling 5.3 km.

Redpath Australia’s first Reconciliation Action Plan (RAP) was recently endorsed by Reconciliation Australia. The plan outlines the commitment to developing relationships and partnerships with Traditional Owners and local community groups in areas where the company operates, and providing employment and sustainable business opportunities for Aboriginal and Torres Strait Islander peoples.

Redpath Australia

15 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 redpathmining.com /

Mt. Lyell Mine, Australia.

Redpath Deilmann (until 2019 Deilmann-Haniel), headquartered in Dortmund, Germany, is the European business unit of The Redpath Group. Our territory is Europe and the Commonwealth of Independent States (CIS), mainly Russia, Belarus and Kazakhstan.

Founded in 1888, Deilmann-Haniel, was for decades the leading mining contractor in Germany and Europe, predominantly active on lateral development in the German coal mines and in shaft sinking. The company has sunk more than 530 shafts, almost 200 of which are freeze shafts.

the company and our focus is to make sure our employees feel comfortable and, of course, safe every day. Our three-year apprenticeship program employs 25 young miners and is well known in the industry.

There are numerous highlights in the almost 135-year history of Redpath Deilmann / Deilmann-Haniel. One example is the first composite liner in a shaft, which was carried out in the early 1960s. Another example is the first deployment of a Robbins tunnelboring machine in an underground coal mine in the early 1970s, followed by the application of ground freezing in civil tunnelling, and the construction of a freeze shaft in China in the 1980s.

7+ METRES PEAK DAILY ADVANCE (140 metres peak monthly advance)

In the last two decades, Redpath Deilmann has been predominantly active in shaft sinking, shaft rehabilitation and other shaft-related works. Our slogan “any mineral, any geology, anywhere” speaks for itself. We also offer ground freezing to the tunnelling industry all over Europe and Northern Africa, mainly to build crosscuts between twin tunnel tubes. Our key asset is our employees, many of whom have worked for Redpath Deilmann for decades. We do promote the “family attitude” within

The company won the first major international project in Russia in 2011. Two freeze shafts for a new potash mine owned by Uralkali were successfully sunk, using conventional methods in the northwestern part of the Ural Mountains. The team consisted of 40 to 45 German site managers, engineers, miners and craftsmen, and about 250 local Russian employees, more than 60 of whom were women, many of them hoist operators.

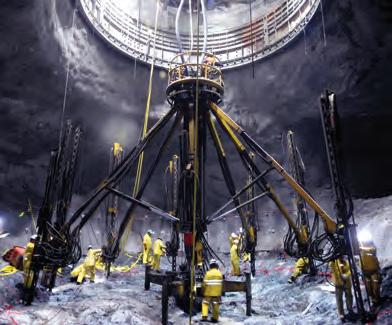

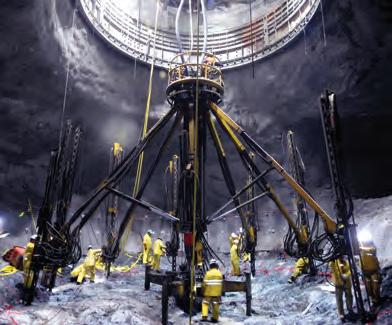

The follow-up project was of a similar scope: two freeze shafts, 8 m finished diameter and 750 m deep. However, in this project, the innovative Herrenknecht Shaft Boring Roadheader (SBR) technology was

used. The SBR is a mechanized sinking system for soft to medium hard rock. The excavation is done by a roadheader-type cutting head, and the mucking from the face to the bucket is done with a pneumatic mucking system, a giant vacuum cleaner. The client for this project was the Belarussian potash company Slavkaliy. On this project, the Redpath Deilmann team was driving the SBR technology to great performances. On average, 3 m/day of finished shaft were sunk, with peak daily advances of more than 7 m and peak monthly advances of more than 140 m.

In the last forty years, the Redpath Deilmann team has also gained lots of skills and experience in building new mines or rebuilding existing mines to become underground repositories for nuclear waste. The Gorleben Mine and the Konrad Mine, both in northern Germany, are examples of these highly demanding

GREINACHER

EUROPE

In the last two decades, Redpath Deilmann has been predominantly active in shaft sinking, shaft rehabilitation and other shaft-related works.

GLOBAL REVIEW - Redpath Deilmann

530+ SHAFTS sunk on 5 continents

Konrad Mine Germany

16 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 / redpathmining.com

JOCHEN

Managing Director (Chairman), Redpath Deilmann

60 YEARS OF SHAFT SINKING

KEVIN MELONG Vice President, Shafts and Technical Services

It seems like we were just celebrating 50 years of history, and now 60 has come along in what appears like a moment. The last 10 years represent some of the most innovative and transformational years in shaft sinking in our company’s history.

Highly complex shafts, requiring Redpath teams’ ever-present outof-the-box thinking, have been sunk around the globe.

During this period of success, projects have been carried out in Canada, the United States, Germany, Russia, Belarus, South Africa, Zambia, Mexico, England, and Australia, with shaft-related consulting conducted in many more countries. This, once again, highlights Redpath’s place as one of the preeminent shaft sinkers in the world attracting some of “The Best and Brightest”.

While this edition of the Advance does not allow for the complete story of these innovative approaches, a cursory review leaves one in awe of the many accomplishments.

The fact that these achievements were accomplished within a short span of 10 years is truly impressive and a testament to our people.

Redpath continues its innovative pace. We are a partner on a “hard rock” shaft-boring system in Germany. We are also currently conducting trials of the S-100 shaft mucker, set to change the sinking market considerably. I think it is safe to say that the future is bright in our business.

The participation of women in this traditionally male-dominated sector is on the rise. Redpath benefits from the work of many female professionals, including engineers, safety leaders, office and underground workers. This is a trend that has been

supported by changes in legislation, with more countries allowing women to work in underground mines.

In Mongolia, Redpath was the first company to hire female underground workers after it became legal in 2016. Today, the company has female jumbo operators, blasters and a growing number of truck drivers, which has resulted in reduced equipment damage and has significantly improved workplace order. In Africa, Redpath Africa takes in graduates every two

years to provide them with practical training opportunities. Preference is given to previously disadvantaged groups and women. At the Uralkali project in Russia, where Redpath Deilmann sunk two freeze shaft, 24% of the workers were women.

The work to achieve gender diversity continues and aligns with Redpath’s broader strategy of building and nurturing an inclusive and diverse work environment for all current and prospective employees.

WORLD’S LARGEST friction hoist at Oyu Tolgoi in Mongolia SMART PLANT PATENTED COMMUNICATION SYSTEMS DEEPFREEZE SHAFTS SHAFT BORING ROADHEADER technology LARGEST FRICTIONHOISTING PLANT in the world SHAFT SINKING / REDPATH’S WOMEN IN MINING

Examples of Redpath’s shaft-sinking accomplishments in the last 10 years.

REDPATH’S WOMEN IN MINING

redpathmining.com / REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 VERSARY EDITION - SUMMER 2022 17

STAGEMOUNTED HYDRAULIC MUCKER introduction

REDPATH’S LONG-SERVING EMPLOYEES

The talent, commitment and loyalty demonstrated on a daily basis and throughout the years by Redpathers around the world continue to be instrumental to the company’s success.

A limited group of people, in Germany and Canada, have followed the company for over four decades. Meet our most long-tenured colleagues.

GERMANY

REDPATH DEILMANN’s 40-YEAR CLUB

•Jürgen Fischer (40 years) retired

•Michael-John Frediani (40 years)

•Peter Messing (40 years) retired

•Michael Petri (40 years) retired

CANADA

•Dirk Schelkmann (46 years)

•Reinhard Swazinna (41 years)

•Karsten Tittes (40 years)

•Dieter Zemelka (47 years)

Redpath

Guy Julien 40 years

REDPATH AMERICAS 40-YEAR CLUB

•Phil Hickey (44 years) retired

•Dave Hansman (46 years)

• Robert Menard (42 years) retired

•Mike Kelly (42 years)

18 REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 / redpathmining.com REDPATH’S PEOPLE

Michael-John Frediani Manager 40 years

Dirk Schelkmann Area ManagerDesign Department 46 years

Reinhard Swazinna Supervisor 41 years

Dieter Zemelka Designer 47 years

Deilmann hosted an anniversary lunch with some of their employees who have served for 40+ years.

From left to right: Frank Otten, Thomas Ahlbrecht, Michael-John Frediani, Karsten Tittes, Jochen Greinacher, Peter Messing, Darius Kazior, Ralf Böttcher and Werner Siedentopf

From left to right: Phil Hickey, Dave Hansman, Robert Menard, and Mike Kelly.

Deilmann completed a 90 m vertical shaft for tourist access via elevator to the Altena Castle in Germany.

THE BRONZE CANNON located on the front lawn of Redpath Canada Limited on McKeown Avenue, North Bay, was raised from the Geldermalsen, a Dutch East Indian company vessel that sank in 1752 in the South China Sea.

INAUGURAL PROJECT

In 1963, J.S. Redpath Limited’s first project was to build a shaft collar for McIntyre’s Lorraine prospect near Belleterre, Québec. It was approximately 40 feet deep and concrete-lined – the cost was approximately $6,000.

REDPATH QUIZ - JUST FOR FUN

In 1969, Redpath moved to North Bay from Québec, with a mere four employees. Today, Redpath employs 6,000+ people globally.

The Queen Louise

The Redbore 100, aka Queen Louise”, the largest proven capacity raisedrill in the world, was completed and introduced in 2008.

CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS CELEBRATING 60 YEARS DID YOU KNOW?

Redpath raisedrilled horizontal ventilation tunnels under the Library of Parliament in Ottawa during its renovation in 2003.

5308 96 78 49 15 6 ARE WORKING ON AT FOR IN ON PROJECTS SITES CLIENTS COUNTRIES CONTINENTS CURRENTLY EMPLOYEES REDPATH IN NUMBERS JUL. 2022 How long did Jim Redpath manage the company? 1 A) 45 years Which project was Redpath’s first? B) 25 years C) 37 years 2 A) Lorraine Mine What was the diameter of the Ghaghoo Sand Tunnel in Africa? B) Dome Mine C) Asbestos Hill 3 A) 5.4 m How many hours were worked LTI-Free at Redpath USA? B) 7.2 m C) 6.1 m 4 How much development has been completed by Redpath

LLC, to date, at Oyu Tolgoi Mine? 5 A) 2.8 million A) 70+ KM B) 3.2 million B) 63+ KM C) 2.5 million C) 60+ KM

2. A, 3.

4.

redpathmining.com / REDPATH’S ADVANCE - 60TH ANNIVERSARY EDITION - SUMMER 2022 19

Mongolia

1.B,

C,

B, 5. A

Nezhinsky Mine, Belarus

Nezhinsky Mine, Belarus

redpathmining.com

LOOKING AHEAD TO A BRIGHT FUTURE.

GEORGE FLUMERFELTChief Executive Officer, The Redpath Group

GEORGE FLUMERFELTChief Executive Officer, The Redpath Group

Nezhinsky Mine, Belarus

Nezhinsky Mine, Belarus