6-11 Update

A news roundup from the world of print

12 Vivad celebrates 25 years

Vivad marks 25 years with open house and facility expansion

16 Konica Minolta Australia hits the road Konica Minolta takes innovation on tour with UnPacked national roadshow

18 Lamont Print & Signs hosts VIBE Conference Business leaders gather in Townsville for third annual VIBE conference

20 Jacinta Allen shares printing insights from Japan

Geoff Selig Scholarship recipient shares study tour highlights

24 Cover story: Dragon Printing unleashes Gallus

One Digital Press

Dragon Printing boosts capacity and capabilities with the Gallus One Digital Press

28 Feature: Sustainability in print

How industry leaders are driving the green movement:

28 Ball & Doggett

30 Currie Group A/NZ

32 Durst Oceania

34 Koenig & Bauer Australia

36 Konica Minolta Australia

38 Ricoh Australia

40 Spicers

43 Comment: Charles Watson

Employer compliance to employee flexible work requests

43 Comment: Andrew Ash

What’s quietly killing your cashflow?

44 ProPrint Diary

Keep up-to-date with the latest industry events

This edition of ProPrint is focused on sustainable printing – a movement that continues to gain traction across as the industry strives for smarter, cleaner, and more responsible ways of operating.

Sustainability has become a core driver of investment, innovation, and purchasing decisions. Across the supply chain, accountability and environmental stewardship are reshaping how materials are sourced, how machines are powered, and how waste is managed.

Traceability and compliance are also becoming nonnegotiables. Leading suppliers are ensuring their product ranges carry validated certifications and meet regulatory standards – from sourcing and safety to recyclability.

In this issue, we take a closer look at how the print sector is stepping up to the challenge –redefining processes, rethinking materials, and embracing

innovation to create a more sustainable future. We spotlight some of the organisations leading the charge towards greener printing.

Also in this edition, Jacinta Allen, graphic prepress coordinator at Breen Printing and winner of the Geoff Selig Scholarship at the 2024 ProPrint Awards, reflects on her recent experience as the inaugural recipient of the program.

The scholarship, awarded to an Emerging 50 finalist, is in honour of the former IVE Group chairman’s passion for nurturing emerging talent within the print industry. Jointly funded by ProPrint and IVE Group, the scholarship offers up to $10,000 in financial support for personal and professional development.

As part of her scholarship experience, Allen attended PacPrint in Sydney before heading to Japan, meeting with leading industry organisations to explore the future of print from a global perspective. In this issue, she shares key insights and takeaways from the study tour.

Plus, we bring you highlights from Konica Minolta’s recent UnPacked roadshow series and Vivad’s impressive 25th anniversary open house celebration.

Editor Claire Hibbit, chibbit@intermedia.com.au

Editor Hafizah Osman, hosman@intermedia.com.au

Design and Production Manager Sarah Vella, svella@intermedia.com.au

Managing Director James Wells, james@intermedia.com.au

Subscriptions (02) 9660 2113, subscriptions@intermedia.com.au

Printed by Hero Print Alexandria, NSW, 2015

Mailed by D&D Mailing Services Wetherill Park, NSW, 2164

The oOh!media-owned printing company

Cactus Imaging has described the development of Ecobanner as “nirvana” by creating a closed loop recycling process for a PVC-free substrate for printed billboards.

Cactus Imaging general manager Nigel Spicer believes Ecobanner is a landmark product for the local printing industry, delivering a truly environmentally friendly and sustainable substrate.

“This is printing nirvana. We have produced a product that is specifically for printing, that can be recycled in Australia, and be used specifically for printing substrate again – and that is exactly where we want to be,” he said.

“This is a true world first. We are aware of other PVC-free substrates, but there is nothing like this when it comes to recyclability and closed loop manufacturing processes.

“We came up with the concept and approached Gale Pacific with an opportunity – they have been keen to help us develop the product.

“There is no financial gain for Cactus –what we are trying to do is the right thing for the industry – we understand where the world is heading. We want to make the world a better place once we are gone, and this is our company legacy knowing we have done the right thing. That is particularly important.

“We are currently producing billboards using Ecobanner – but our next step is to take this to the entire market to ensure that 100 per cent of billboards are

Investment firm Straight Bat has acquired Fleetmark, a specialist branding and signage solutions business for Australian fleet commercial and digital markets.

Fleetmark said this partnership was forged to capitalise on its “solid platform for growth”, and to better serve its customer base.

Fleetmark has been providing innovative branding and signage solutions in fleet graphics and PVC fabrication, wide format digital print, and digital displays for more than 30 years.

Fleetmark’s nationally scaled facilities across Victoria, NSW, and Queensland allow for a unique proposition where fleet

recyclable across the entire industry, and not just oOh!media. We want to include the entire out of home market as we know that being environmentally friendly is something that can work for everyone.

“There is a premium cost for the substrate, but this is expected for a fully recyclable product. The cost of this product is certainly not prohibitive – but it is about doing the right thing for the industry.

“We understand that to get the volumes we need to meet the market expectations on price, and we want to do that, and we want to also get the volumes up as well.

Ecobanner is available through Ball & Doggett in back lit (white/white) and front lit (grey/white) banner options in both 1.6m and 3.2m sizes.”

According to Ball & Doggett general manager, Rob Brussolo, Ecobanner underscores the company’s commitment to providing innovative, high quality and sustainable solutions for its customers.

“Ecobanner not only meets the rigorous demands of flexible banner advertising but also sets a new standard for environmental stewardship in our industry,” Brussolo said.

“Ecobanner is part of a traceable full circular loop program, allowing for the complete recycling and repurposing of used banners. This contributes to a sustainable lifecycle and minimises environmental impact. Unlike greenwashing claims, this closed loop program is already in full swing, and its impact is measurable, demonstrating a genuine commitment to sustainability.”

signage is designed, manufactured, and installed on site by Fleetmark’s design team, sign writers, and installers.

Generating more than $40 million annually, the company’s success is underpinned by a blue-chip customer base made of the largest transport and quick service retail companies in Australia. Recent branding projects have included the Team Global transport signage, KFC digital signage, and many other well-known and highly visible logistics businesses.

Part of the businesses’ success is attributed to its ability to source and implement state-of-the-art printing technologies. These technologies include a Canon Colorado M5W from Currie Group and an EFI VUTEk D3r.

“We are delighted that a business with such an outstanding track record and legacy has chosen to partner with us,” Straight Bat Private Equity managing

partner Steve Gledden said.

“Fleetmark has a great reputation for trusted service and quality results which has endured for over 30 years.”

Fleetmark founder Dean Coates continues to work alongside the Straight Bat team as a shareholder and operator.

Stuart Farrow, who was Fleetmark general manager, retained his position within the company following the acquisition, but is now a self-employed strategic business consultant as of May.

Former Cleanaway Waste Management executive Karl David has been CEO since February – around the same time the acquisition of Fleetmark was confirmed.

Fleetmark is the ninth portfolio addition to the Straight Bat Perpetual Legacy Fund portfolio, which comprises investments in varied industries such as building and construction, rubber, food manufacturing, marketing services, smoke alarms, and more.

Easy Signs co-founder and director

Adam Parnell has been appointed treasurer of the FESPA Australia board.

Parnell’s appointment follows the resignation of long-serving treasurer Mark Brooks, who has served on the FESPA Australia board for more than 17 years.

Aside from Brooks’ departure, all other board members have been reappointed to their roles. The board consists of: Nigel Davies, president; David Asker, vice-president; Adam Parnell, treasurer; Keith Ferrel, honorary secretary; Matt Ashman, supplier director; and Bianca Martin, public relations director.

“I’m excited to welcome Adam Parnell to the board,” said Nigel Davies, FESPA Australia president.

“His industry knowledge, strategic thinking, and relationships will strengthen our leadership team and help us deliver

even greater value to our members. I’d also like to thank Mark Brooks for his dedication and work as treasurer over the last few years.”

“I’m excited and grateful to be elected to the board,” Parnell said.

“I’m very much looking forward to contributing in a positive and meaningful

An expertly restored 1857 Imperial Press owned by Tony Wolf & Son has been generously loaned by Ian Wolf for display at the Penrith Printing Museum.

Manufactured in England and imported into Australia in the late 1850s, the historic press was used by the Wimmera Mail Times in Victoria.

Traded to settle a debt, it was later discovered in derelict condition at an antique dealer in Horsham, Victoria, in 2002.

The historic press was used by the Wimmera Mail Times until 1974.

The press was acquired by well-known industry figure Barry Toombs, who restored it before selling it to Ian Wolf’s father.

The Penrith Printing Museum is in the grounds of Penrith Paceway, corner of Mulgoa Road and Ransley Street, Penrith, NSW and is open to the public every Sunday from 10am-2pm.

way to our print community.”

FESPA Australia also unveiled its strategic vision for 2025 at its AGM.

“We are financially stable and growing, but complacency is not an option,” Davies said.

“Organisations need to innovate and reinvent themselves continually, and FESPA Australia is no exception. The incoming board will face challenging years ahead as we navigate a dynamic industry environment and face the uncertain effects of AI on our members, sponsors, and the way we work.

“It is a time for collaboration with other associations, while also recognising that our membership has grown because there is meaning in what we do.

“We must maintain our identity and hold true to our values as a people-centric organisation that empowers our members, both printers and suppliers, through global connections. We must lead through this time of uncertainty.

“The new FESPA brand tagline ‘Connect, Inspire, and Support’ is the essence of who we are and what we stand for,” Davies said.

“Association work is rewarding, and we have a lot of work ahead of us.”

• Thriving and long-standing print and signage family business located in Central Queensland.

FY25 revenue of $6.6m+ and EBITDA of $1.9m, with compelling growth prospects.

• Reputation for quality, supported by fit-for-purpose machinery that consistently delivers reliable commercial print work.

• Strong exposure to coal, underpinned by long-term supply ties with major mining clients.

Loyal client base with recurring revenue across print and signage.

• Operates from two adjoining freehold lots (1,616 sqm) with 1,239 sqm of office, print and warehouse space.

• Leased from a related entity; available to purchase with the business.

For more information or to review the Information Memorandum, please contact:

Guyomar

CMYKhub has provided a sneak peek at its soon-to-be-opened, state-of-the-art headquarters in Melbourne, releasing a new video that showcases the scale, innovation, and modern design of the new facility.

The 7000sqm purpose-built facility, located in Keilor Park near Tullamarine Airport, will represent twice the space of its current premises in Heidelberg, which is spread over six separate locations. The new headquarters on Wright Road will also feature 500sqm of office space across two levels.

The newly released video captures the reactions of CMYKhub staff as they explore the expansive space and witness the installation of industry-leading equipment, including the Komori Lithrone GX40RP and the Canon varioPRINT iX3200.

The new CMYKhub headquarters, which is scheduled for occupancy in September, also aims to set a new benchmark for sustainability.

“The solar applications for us alone will reduce our consumption by around 30 to

40 per cent,” Michael Ellis, HSEG manager at CMYKhub, said.

“And, coupled with everything else we can do on this site compared to what we were doing in Heidelberg, we have great scope for improvement here.”

Speaking at CMYKhub’s networking event during PacPrint in May, Dayne Nankervis, CEO of CMYKhub, said the new site reaffirms the family-owned business’ commitment to the wider print industry.

“We’ve built a new factory that will take a long time to pay off. We have a brandnew press and a new offset press being

installed, a new digital machine being installed in the coming weeks, and we’ll be moving around 60 machines in a few weeks’ time,” Nankervis said.

“But the point of this is that it’s a 10-to-20-year investment for us to get a return and we’re doing it. This investment shows that we believe in the industry and we’re staying here, and we hope everyone comes along for the ride with us.”

Nankervis said the new facility will enhance operational efficiency and secure supply chains, reinforcing the message that print remains a viable and thriving industry.

“In the last five years we’ve invested $20 million in print equipment, which is equipment for every printer in Australia to use – it’s not our equipment, it’s everyone’s,” he said.

“This factory solidifies that because this is our factory. We’ve never had the ability to have a workflow that is pre-designed. Our ability to consistently get the work out for Australia-wide is just going to be incredible and this should, we hope, improve everyone’s ability to supply their clients everywhere in Australia.”

Take a look at CMYKhub’s new facility

Durst Group appoints Johann Strozzega as Durst Graphics director of global sales

Durst Group has announced a change in leadership with the promotion of Johann Strozzega as Durst Graphics director of global sales.

Strozzega succeeds Christian Harder, who served as chief sales officer (CSO), with overall sales responsibility for all business units of Durst Group since 2021, and who also headed the graphics business unit.

With the official handover to Strozzega, Durst Group CEO and co-founder Christoph Gamper said an important step has been taken in the strategic development of the global sales organisation.

“With this new appointment, Durst Group is strengthening its leadership structure in a key business area and laying the foundation for sustainable international growth. The company’s management sees this as a clear signal of continuity, customer focus, and future

security,” he said.

“With Johann Strozzega, we are bringing an experienced manager with a strategic compass to the top. My thanks go to Christian Harder – for his strong commitment and for actively shaping this transition. We do not fill leadership roles based on status but on substance and future viability – for our customers and the sustainable success of Durst Group.”

Durst Oceania managing director Matt

Ashman said, “We are so pleased to have Johann in such a strategic and important role within the business. Johann is a real Durst’ler with a perfect understanding of the graphic business”.

Harder and Strozzega share a long and successful history of collaboration, particularly in the ceramic printing market segment of the Durst Group. This shared history has created a foundation of trust for a seamless transition and consistent strategic development.

“In recent months, I had the privilege of mentoring Johann. Our long-standing and successful collaboration in the ceramic printing segment has shown me early on that he has the strategic instinct and leadership skills to further expand our market share in graphics,” Harder said.

“This move allows me to focus even more strongly on group-wide strategic topics in the future – and to prepare the next growth steps together with our business units.”

“It is a great honour for me to take on this responsible leadership role. I thank Christian for his support and trust; and Christoph Gamper for the opportunity to shape this role in such an important market segment. Together with my team, I will do everything to further expand our strong market position and actively contribute to the global growth of Durst Group,” Strozzega said.

Sydney will host the Visual Impact Conference & Expo in September 2026, with event organisers Visual Connections saying the reimagined event promises a “new concept, new vision, and new opportunities” for exhibitors and visitors alike.

The show is booked for Wednesday 2 September 2026 until Friday 4 September 2026 at the Sydney Showground, with the timing deliberately pushed back from its traditional May timeslot to avoid clashes with the global shows which are typically held mid-year, explains Visual Connections executive general manager, Karren Challoner-Miles.

Since joining the supplier association late last year, Challoner-Miles has been clear about her intention to review and assess all the association’s activities and initiatives to ensure they align closely with the needs and values of both Visual Connections members and the wider industry.

“Industry businesses are facing a raft of challenges,” Challoner-Miles said.

“It’s hard to get away from the workplace; time is tight, and money tighter. Yet it’s imperative for business owners to keep pace with technological changes, evolving trends and new market opportunities if they want to build success and stay ahead of their competition.

“On the supplier side, marketing budgets are as tight as ever, and trade shows take a real commitment in terms of

stand builds, staff allocations and promotion. As show organisers, we need to make sure that our exhibitors can maximise the value of every square metre of space, and every moment they spend on stand.

“In short, the onus is on us to deliver trade shows which are sharper, more focused and more valuable than ever before – and we are embracing that challenge in 2026.”

Visual Impact has long been regarded as the leading expo for the sign, graphics and visual communications sector in Australia.

The 2026 iteration, which is expected to draw some 4,000 visitors, will not only feature some exciting new initiatives, but is also perfectly timed to allow industry businesses to make the most of both local and international opportunities.

The co-located conference will enhance the value for visitors by bringing together leading experts, visionaries and thought

leaders to provide vital information and insights on economic conditions, industry trends, business leadership and the big issues which can impact the market and create new challenges and opportunities.

“This will be a tightly focused show, designed to bring the best of the world’s innovations in digital, wide-format and textile printing; engraving, routing and laser cutting; conventional, digital and illuminated signage; promotional gifts, awards and trophies, and more, to the iconic Showgrounds Dome,” said Challoner-Miles.

“The daily conference program will have a broad scope, bringing together information and insights which will inform and equip business owners to understand the global market, identify opportunities, learn about Australian and international sustainability requirements, and capitalise on emerging markets and new technologies.”

Mimaki Australia strengthens SA and WA footprint with new hires

Mimaki Australia has appointed Troy Craigie as its new sales channel manager for Western Australia and South Australia.

Craigie brings more than 20 years of experience in sales and service within the Perth market and is widely respected and trusted by customers across the region.

Kohei Kobayashi, managing director of Mimaki Australia said, “Since our establishment in Sydney in 2013, we have expanded operations to Melbourne in 2015 and Brisbane in 2018, steadily growing our business through close community engagement and regional support. With the addition of Troy to our

team, we are excited to extend that same commitment to customers in WA –delivering Mimaki’s innovative solutions and helping businesses thrive.”

Following Craigie’s appointment Mimaki Australia has also announced additional authorised service agents in WA and SA.

MTech Serviced WA in Perth and a second agent in Adelaide have been added to strengthen Mimaki’s service operations nationwide.

“As our customer base grows across metropolitan and regional areas, we recognise the need for a scalable service model that maintains quality while improving accessibility,” said Kobayashi.

“To support this, we continue to invest in our authorised service agent network and reinforcing our national call centre.”

These additions complement Mimaki Australia’s internal service team, which includes more than 13 highly skilled engineers operating from three strategic locations nationally.

Konica Minolta Australia has been officially certified as a Great Place to Work for 2025, recognising the company’s ongoing commitment to fostering a positive, inclusive, and supportive workplace culture.

The award is based on employee feedback say on their experience working at Konica Minolta Australia.

This year, 72 per cent of employees said it’s a great place to work – 12 per cent higher than the average Australian company, according to the Great Place To Work 2024 Australia National Employee Engagement Study.

Great Place To Work is the global authority on workplace culture, employee experience, and leadership behaviours proven to deliver market-leading revenue, employee retention, and increased innovation.

Gabrielle Stevens, chief people and culture officer, Konica Minolta Australia, said, “Being certified by Great Place To Work is more than an endorsement; it’s a meaningful recognition of the inclusive, empowering, and values-led culture that Konica Minolta Australia works hard to cultivate. This certification validates that

Konica Minolta Australia is a workplace where everyone feels supported, respected, and able to thrive. It reflects Konica Minolta Australia’s long-standing commitment to listening to its employees and creating a culture built on equity, inclusion, and opportunity”.

According to Konica Minolta Australia, the company’s employee experience and culture programs are designed with a clear focus on consultation, authenticity, and continual improvement. Its diversity, equity, and inclusion (DEI) committee is employee-led, with members selected through expressions of interest to support broad representation across teams, backgrounds, and lived experiences. This group drives grassroots input into key initiatives and plays a central role in shaping the company’s strategic focus across disability inclusion, gender equity,

LGBTQIA+ representation, and cultural awareness. Its work is complemented by a long-running annual engagement survey, which tracks how employees experience the workplace and identifies where change is most needed. High scores year after year, including consistent results in the DEI category, reinforce the effectiveness of this approach and guide areas for further investment.

Sarah Lewis-Kulin, vice-president of global recognition, Great Place To Work, said, “Great Place To Work Certification is a highly coveted achievement that requires consistent and intentional dedication to the overall employee experience. By successfully earning this recognition, it is evident that Konica Minolta Australia stands out as one of the top companies to work for, providing a great workplace environment for its employees”.

Ball & Doggett, Australia’s largest distributor of printable materials, press consumables, and equipment, has announced a new strategic partnership with Kongsberg Precision Cutting Systems, a global leader in digital cutting solutions.

As part of this partnership, Ball & Doggett will now offer state-of-the-art digital cutting systems from Kongsberg Precision Cutting Systems (PCS) across its national sales network and will also provide Kongsberg accredited trained engineers for servicing.

In addition, Kongsberg Systems will be available for demonstrations within selected Ball & Doggett showrooms.

Ball & Doggett is also making significant investments in its technical and application services team, expanding its

footprint with new hires in South Australia, NSW, and Queensland.

“We are excited to welcome Kongsberg Precision Cutting Systems into our expanding digital finishing portfolio,” said Rob Brussolo, general manager sign, display and digital at Ball & Doggett.

“This partnership ensures we can support our customers with cutting-edge solutions that match the demands of modern production workflows. Kongsberg PCS’s innovation and reputation for reliability add a powerful new dimension to our digital cutting offer for the Australian sign and display industry.”

Founded in Norway in 1965, Kongsberg

PCS has built a global reputation for developing high-performance digital cutting tables. Serving packaging, signage, and display markets worldwide, Kongsberg PCS’s solutions are known for their robust build, advanced automation, and consistent precision, making them a top choice for converters and manufacturers looking to optimise production and reduce turnaround times.

David Preskett, vice-president EMEA and APAC, Kongsberg Precision Cutting Systems said, “We’re looking forward to partnering with Ball & Doggett, a company that shares our commitment to innovation, quality, and customer-centric service, to further strengthen our existing network and support in Australia.

“We’re also proud to back this partnership with the regional guidance from our team, ensuring customers receive the highest level of knowledge and expertise. Working with Ball & Doggett, we can further support Australian print and packaging businesses to enhance their finishing capabilities, expand production possibilities, and unlock new growth opportunities with world-class digital cutting solutions.”

Velflex, a leader in Australian heat transfer solutions, has announced the acquisition of Stahls’ Pacific and Flexi-Print, with the move establishing Velflex as the largest supplier of traditional heat transfer decoration in the country.

Velflex, led by managing director Ben Carroll, is a leading specialist supplier of heat transfer equipment and premium vinyl products.

“By combining the strengths of these businesses, we’re building something truly unique,” said Ben Carroll, founder and managing director of Velflex.

“The team at Stahls’ Pacific are some of the most experienced in the industry, and Flexi-Print’s heritage goes back to 1972, when my great uncle Noel Wighton and Ray Black helped pioneer heat transfer technology in Australia. Uniting these companies under Velflex means our customers will benefit from deeper expertise, faster service, and access to the world’s most advanced decorating solutions.”

The integration of Stahls’ Pacific brings the globally renowned Stahls’ range of heat transfer vinyls and Hotronix heat presses directly into Velflex’s supply chain, expanding its offering and strengthening its ties with international partners.

Carleen Gray, CEO of the Stahls Group, said, “Velflex is an ideal partner for continuing the Stahls’ mission in the

Imagination Graphics has celebrated the contribution of two long-serving employees, Kim Rogers and Brad Sly, who are marking 20 years and 25 years of service within the business, respectively.

“In an era where professional longevity is becoming increasingly rare, it’s extraordinary to find employees who dedicate decades of service to one organisation,” said Imagination Graphics director Emmanuel ‘Budgie’ Buhagiar.

“Today, we celebrate two individuals whose steadfast loyalty, tireless work ethic, and enduring impact have helped shape the heart of Imagination – marking 20 and 25 years of service, respectively.”

Located in an industrial estate in the

region. With their strong reputation, local technical expertise, and deep understanding of the decorator’s needs, we’re confident the future is bright for the Australian and New Zealand markets”.

Meanwhile, the acquisition of Flexi-Print adds decades of technical knowledge and manufacturing experience to Velflex’s operations, further enhancing its ability to serve both high-volume manufacturers and small-scale decorators with premium custom transfer solutions.

According to Carroll, the acquisition will combine the full range of Flexi-Print’s long-

inner west of Sydney, nestled between some of the most popular craft breweries, Imagination Graphics offers digital printing, offset printing as well as graphic and web design services.

Buhagiar said Rogers is an “invaluable cornerstone of the team”.

“Two decades ago, Kim stepped through our doors with determination and fresh ambition. Over the years, he has evolved from a promising newcomer to an invaluable cornerstone of the team.

“Taking on everything I have thrown at

established product offerings including die-cut sports numbers, high-quality plastisol transfers, and specialised heat transfer vinyl (HTV), with Velflex’s solutions such as UltraColour and UltraColour Max. Flexi-Print’s capabilities in direct-to-film (DTF) transfers will also be integrated.

“We’re bringing together the best transfer manufacturing businesses in the country with the company range to be able to service as one business – a one-stop shop for [the industry],” Carroll said.

“We’re going to have manufacturing in Wodonga, Victoria, as well as in Brisbane, which means our Velflex customers can all truly benefit from the products Flexi-Print has specialised in for many years.

“Also, Flexi-Print customers that had access to all those traditional products are going to be able to have in-house support and access to Ultra Colour and our Ultra Colour Max, and other various licensed products that we do as well.”

Shane Black, general manager of FlexiPrint and son of founder Ray Black, who established Flexi-Print in 1972, said the merger offers customers the opportunity to streamline product access.

“You want customers to have the easiest options to supply all the products, and this makes it very simple for them. Going forward, we want to make sure that all Flexi-Print and Velflex customers come together, and we can provide a solid product for them.”

Watch Ben Carroll discuss the new Stahls acquisition and distribution in Australia

him, going from pre-press to digital printer and then our main KM-1 printer and production manager, Kim’s consistent pursuit of excellence has become part of our company’s DNA.”

Buhagiar said Sly “represents the very essence of commitment and growth”.

“His career has mirrored the evolution of our industry, and has continually adapted, led, and innovated along the way.

“From doing our basic artwork job, Brad learned pre-press, digital printing, guillotining, celloglazing, then wide format printing with an ability to design and install Covid screens at a time of innovation and looking outside the box,” said Buhagiar.

“Both these remarkable employees remind us that long-term commitment isn’t just about tenure – it’s about evolution, resilience, and purpose. Their service has shaped not just our organisation’s past, but its future. We thank them for their unwavering loyalty and look forward to the chapters yet to be written in their careers.”

Vivad opened its doors to the industry with an exclusive event, unveiling a major facility expansion and offering a glimpse into the future of large-format printing.

Melbourne-based Vivad has marked a major milestone – its 25th anniversary – with a stylish celebration and exclusive open house event, showcasing both its rich history and ambitious future.

The event followed a major expansion of Vivad’s production facility, which has grown significantly from 4,000sqm to an impressive 7,500sqm.

To celebrate the occasion, the company welcomed clients, suppliers, and industry peers to its state-of-the-art premises for a behind-the-scenes look at its enhanced print capabilities.

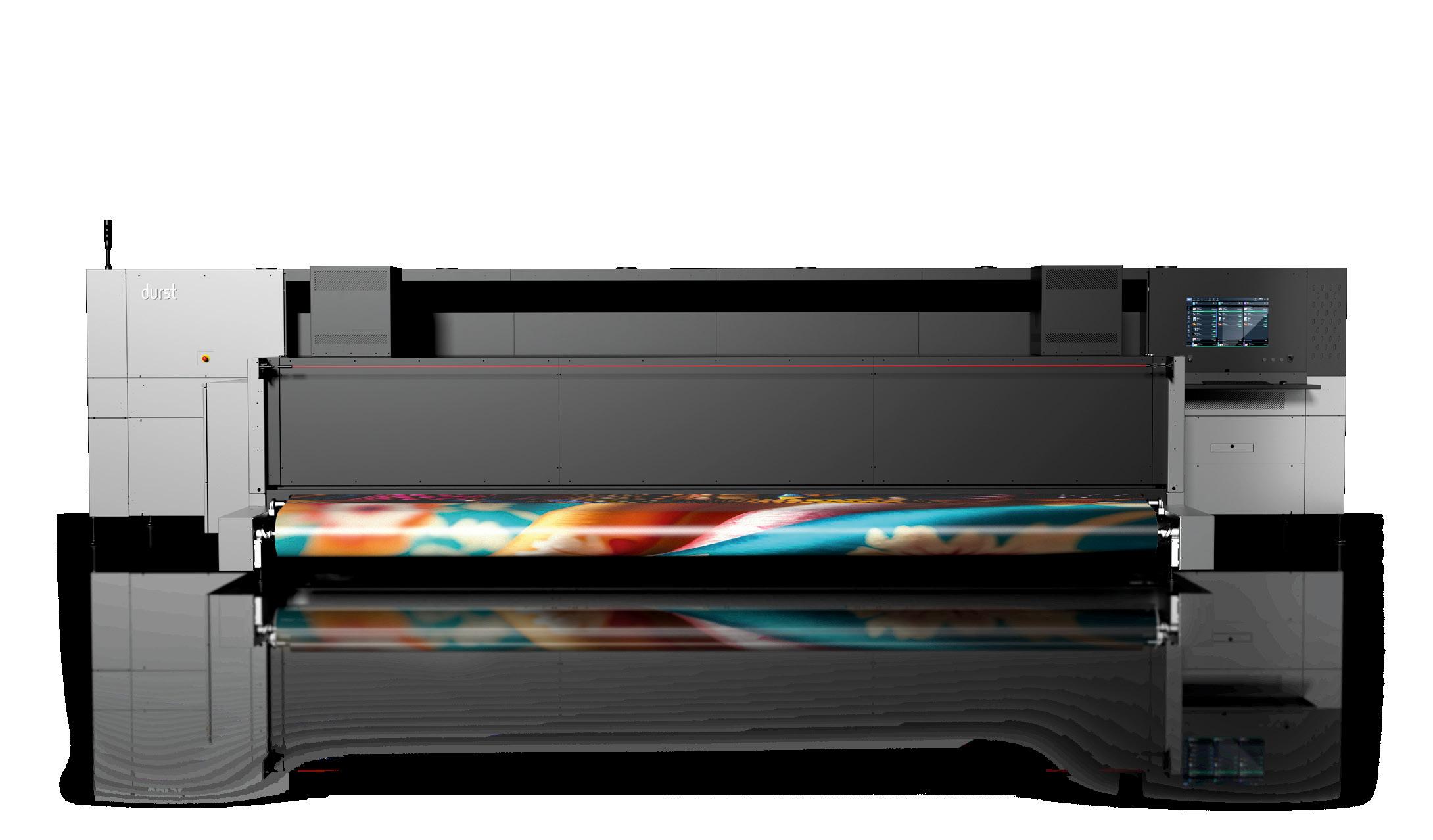

Guests were treated to a guided tour of the expansive large-format print facility, now housing an extensive suite of advanced machinery, which includes an impressive

fleet of five Durst machines, including a P5 Tex iSub dye sublimation printer and a P5 350 HS hybrid printer.

Attendees also took part in the VivTrack Web-to-Print Games – an interactive live showcase of the company’s Web-to-Print system. Events included the Carr Group Dye Sublimation Steeplechase, the Spicers Vinyl Banner Velodrome, the Currie Group SAV Print Shot Put, and the Corex Corflute Challenge, with the Installation Gymnastics performed by Peak Install. Guiding each team through the games were Vivad account managers – aptly dubbed team captains – who kicked off the race by scanning QR codes to initiate ordering the print online.

Festivities continued in the newly acquired adjacent warehouse, which featured live entertainment including a DJ,

a

and

“It’s been an incredible journey over the last 25 years,” said Ewen Donaldson, Vivad founder and managing director.

“It’s a long time, but not a long time at the same time and I sometimes wonder where all that time has gone.

“I remember thinking when I started Vivad, ‘I wonder what Vivad will be like in 25 years’, and I think that if the 29-yearold version of myself could look at today, he would be pretty happy; probably more relieved than anything!

“Starting a business in the printing industry can be fraught with danger and risk. Back then, I bit off more than I could chew, and I chewed very hard. I think that

formed a bit of a habit when you look at this amazing [new] space. So, I’m up for another 10 years of chewing very hard.”

During his speech, Donaldson acknowledged and thanked his entire team as well as Vivad’s customers.

“We’re an organisation of people and everybody has an important role to play. We wouldn’t be able to do the things we do without the hard work and the dedication of everybody,” he said.

“I want to thank our customers. It’s because of you that we get to do the things that we do. You bring us challenges and opportunities. You entrust us with your projects, and for that, we are very grateful. We’re driven by your success, and we strive to serve you better.”

He also extended appreciation to suppliers, competitors, and the wider industry.

“I want to [thank our suppliers] for your support in assisting us to deliver on our commitments. Thank you for bringing us new technologies, new substrates, and more sustainable alternatives,” he said.

“I also want to thank our competitors. Thank you for motivating me to get up in the morning. You set the bar higher, which motivates me to set the bar higher again. You keep us on our toes, and you keep me sharp and agile.

“I also want to acknowledge the industry. There’s an incredible amount of camaraderie in this industry. Everybody works with each other in a positive way. When you look at the growth over the last 25 years, when we started with our first 5m solvent printer, it’s amazing how much print there is around.

“Print is everywhere. There are so many applications and so many new applications. This industry provides purpose, opportunities, and livelihoods for thousands of people. I’m particularly excited about the younger people who are just getting started. This is fertile ground for emerging leadership, and I hope that Vivad can provide part of the journey.”

So where to from here for Vivad?

“Vivad has been growing and continues to grow. We have been on a growth trajectory

of 12 per cent since we moved into the factory next door [1958 Sydney Road] 10 years ago,” Donaldson said.

“We’re now three and a half times the size we were in terms of staff and turnover and we were running out of room. So, when [the factory next door – 1960 Sydney Road] became available, we thought, well, we have to back ourselves and bite off another 10 years of excitement.

“Am I up for it? Absolutely. In fact, we are just warming up. This new space is really a blank canvas. We’ve got new frontiers, new horizons, and ideas that we haven’t had yet. This is a great space to grow and to innovate – particularly in sustainability.

“We’ve made significant progress in the past offering sustainable alternatives, recycling and upcycling everything we can through our polyester, corflute, our cardboard and aluminium, moving away from solvent inks to low VOC water-based inks, reducing energy demands by installing 100 kilowatts of solar and more energy efficient lighting. However, whatever we have done so far, it’s not enough. We must continue to improve and

innovate. This new space gives us more room for initiatives such as product stewardship programs and take-back initiatives, and I hope one day soon we can even develop upcycling processes in-house.

“At Vivad we use the latest technology to deliver high quality, cost effective, large

format, digital printing. We transform ideas into impactful visual experiences. Committed to excellence, we cultivate strong relationships with our customers, suppliers, and industry partners,”

“Our team thrives in an innovative and productive work environment where merit is rewarded, accountability

is paramount, and people are valued. As responsible corporate citizens, we strive to reduce our environmental impact and also fulfil on our social responsibilities.

“Grounded in our core values and inspired by our future vision, together, we are passionate about delivering incredible outcomes.”

Konica Minolta Australia recently hosted a national roadshow that delivered innovations and insights to customers across the country.

Konica Minolta Australia took its latest innovations on tour with the ‘UnPacked’ national roadshow – an engaging six-state event series that brought the excitement and technology of its PacPrint showcase directly to customers across the country.

UnPacked visited Victoria, Western Australia, South Australia, Queensland, New South Wales, and the ACT, giving attendees an exclusive opportunity to see Konica Minolta’s latest production and industrial print technologies up close.

“Konica Minolta’s philosophy is known as Kankei, a Japanese term that loosely translates to ‘relationship’. In Japanese culture, it refers to a mutually beneficial relationship – something that forms the foundation of how we engage with our customers in this space. We wanted to build on that philosophy through our PacPrint UnPacked evenings,” Dean Hosking, chief sales officer of Konica Minolta Australia, said.

“By taking these events on the road, we aimed to make them more accessible recognising that not everyone is based in Sydney. For those in other states, attending major events like PacPrint can be more challenging, so we wanted to bring the key insights and experiences from PacPrint to a wider audience in a welcoming, relaxed setting.”

Andrew Cocker, general manager, production and industrial print at Konica

Minolta said, “[UnPacked] is all about sharing valuable information and insights, showcasing recent product launches, and offering a virtual introduction to some of our new systems.

“We were proud of what we presented at PacPrint. We made several major announcements during the event, including celebrating 20 years in the production print space.

“We’re committed to delivering leading edge technologies that are relevant to the industry and that support our customers in growing their businesses and exploring new revenue streams.”

The UnPacked events featured presentations of new product launches unveiled at PacPrint including the AccurioPress C14010S, the AccurioPress C12010S, the AccurioJet 30000, as well as the AccurioShine 3600, which was first launched at drupa last year.

Konica Minolta Australia product marketing managers Grant Thomas and James Rolland provided insights into how these solutions are redefining productivity, versatility, and print quality.

The AccurioPress C14010S and C12010S aim to deliver exceptional performance, achieving print speeds of up to 140 pages per minute (ppm) and 120 ppm, respectively. The AccurioPress C14010S and C12010S feature seven Intelligent

Media Sensors, that identify paper type, weight, and size instantly for optimal print settings every time without additional operator input.

The AccurioJet 30000 is a successor model to the AccurioJet KM-1/KM-1e series, which has been widely acclaimed in the market since its release in 2016 and has sold more than 350 units worldwide.

The AccurioShine 3600 is an inkjet spot UV coater that incorporates innovative varnish technology by MGI. It enables digital spot UV varnishing and digital hot foiling in a compact solution that forgoes the need for screens, plates, or dies. The fully digital solution features artificial intelligence (AI) registration technology and an eco-friendly LED curing system.

Konica Minolta Australia industrial print sales specialist Paul Sanelli also presented an industrial print mini-masterclass which explored how industrial print is reshaping what’s possible – from high-capacity print innovation, to labels, embellishment, automation, and workflows.

“If you look at a commercial printer today, they don’t just do commercial print. They have diversified into either signage with wide format flatbed printers, label printing, bindery equipment, and even have digital embellishment. They’re diversifying to be more relevant and to capture a larger share of their customers’ wallets,” Sanelli said.

With a focus on innovation and growth, Lamont’s VIBE Conference continues to establish itself as a must-attend gathering for North Queensland’s business community.

Lamont Print & Signs hosted its third annual Visual Industry Business Education (VIBE) Conference, bringing together business leaders, entrepreneurs, and industry professionals from the sign, print, and display industries.

Held at C Bar in Townsville, this year’s sold-out, one-day conference brought together professionals from across the region and beyond for a full day of networking, education, and inspiration – offering a valuable platform to gain insights and stay ahead of industry trends.

“Lamont VIBE brings together industry experts and thought leaders through a comprehensive conference program delivering a platform where they can connect, learn, and lead,” said Stephen Lamont, founder of Lamont Print & Signs.

“Lamont VIBE delivers the opportunity to connect with like-minded individuals, exchange ideas, and form valuable connections the lead to future

collaborations and partnerships and better ways of doing business.”

VIBE 25 featured a distinguished line-up of speakers, each bringing expertise across leadership, marketing, and business performance.

This year’s speakers included Stephen Lamont, founder of Lamont Print & Signs; Vincent Nair, CEO of Smartech; Andrew Action, director and founder of Explore Property Townsville; and Dr Jo Lukins, author and performance psychology coach.

These industry leaders delivered impactful sessions on topics such as marketing strategy, staff acquisition and retention, and developing a high-performance mindset for business leadership.

“Each presenter brought unique perspectives that left us challenged, inspired, and better equipped to lead our businesses forward,” Lamont said.

The event also included engaging workshops and networking opportunities.

“VIBE 25 was crafted for forward-thinking businesspeople seeking to grow scalable and sustainable enterprises. Through interactive workshops and networking opportunities, attendees gained actionable insights and real-world strategies ready to implement in their own organisations,” Lamont said.

With the success of VIBE 25, Lamont has confirmed that VIBE 26 will return in August 2026, promising another milestone event for the industry.

“Lamont Print & Signs continues to strengthen Townsville’s position as the northern hub for industry innovation,” he said.

“The VIBE conference series has become synonymous with not just education, but with fostering a vibrant community of likeminded professionals.

“We’re already excited for what’s next –but for now, thank you again to everyone who made VIBE 25 a standout event for the signage and display industry.”

RELIABILITY

•Dependable performance

•Trusted platform

•Easy maintenance

PRODUCTIVITY

•High machine uptime

•High volume label printing

•Consistently high print speed

AUTOMATION

•Seamless integration

• Streamline production

• Maximum efficiency

Breen Printing graphic prepress coordinator Jacinta Allen travelled abroad to explore

the future of printing, sharing highlights from her time in Japan.

As the inaugural recipient of the Geoff Selig Scholarship, awarded at the 2024 ProPrint Awards, Breen Printing graphic prepress coordinator Jacinta Allen used the opportunity to travel to PacPrint in Sydney, then Japan to visit leading suppliers and explore the future of printing.

In this article, she shares highlights from her time in Japan:

After a couple of days adjusting and sightseeing in Tokyo, I officially began my study tour with a visit to the Canon Customer Experience Centre.

I met my host, Tiger, in the afternoon, who gave me a guided tour of the facility. We had a great conversation about current and emerging trends in the print industry, as well as the types of printed materials that are popular in both Japan and Australia.

Between chatting and asking lots of questions, I mentioned I wasn’t as familiar with inkjet printing since I predominantly

use a toner machine. In response, Tiger and one of the technicians gave me an in-depth demonstration of machines they offer, highlighting the unique strengths of each machine. I had the chance to see live demonstrations, handle print samples, and learn more about the processes behind achieving such impressive print quality.

My second company visit was to the incredible Ricoh Technology Centre. The visit began with warm introductions and a photo, followed by a presentation by Yuki.

Yuki, Mitsu, and Ayako had prepared drinks and snacks, ensuring I felt comfortable and welcome.

At Ricoh, I learnt about their company values, including the Japanese term ‘Gemba’ and how important it is to Ricoh to work with their customers to find solutions for specific needs.

Following the presentation, I was guided through a range of both inkjet and toner machines by various team members,

each explaining the unique features of the models. After a quick coffee break, Junpei delivered another interactive presentation, during which we were constantly getting up and moving around the room to explore different machine features – it was hands-on, informative, and a lot of fun!

The third stop of the study tour was the Printing Museum Tokyo, which showcased the rich history and evolution of printing in Japan – going back as far as the 700s!

The main exhibition was arranged chronologically and highlighted the profound influence printing has had on Japanese society through the Ancient Times, Early Modern Times, Modern Times, and Present Age. It highlighted how printing shaped various aspects of life, including politics, religion, education, art, and entertainment. There was plenty of information written in English, but thanks to trusty Google Translate I could read a little deeper!

During my visit, there was also an exhibition titled The Art of Black: Gutenberg and German Publication Printing Culture. Although photography wasn’t allowed, the display was beautifully curated and focused on Gutenberg’s invention of letterpress printing.

Next stop was the Konica Minolta Customer Engagement Centre, where I was welcomed by Ayuka and Ken. They introduced me to the fantastic team who would guide me through the day.

We began with an impressive showcase of printed materials and products produced on Konica Minolta machines (I spotted a Revolution Print sample which was super cool!)

As we were browsing the samples I learnt about Goshuinchō, a traditional Japanese stamp book used at temples and shrines. Then to my surprise I was gifted with my very own! Such a thoughtful gift I will cherish.

The tour continued with a walkthrough of their printing technologies, including inkjet, toner, and embellishment machines. Michiyo demonstrated the foiling process and shared her beautifully foiled business card that she made for herself! I also received a lovely sample pack to take home.

We wrapped up in the meeting room, where Kenny presented Konica Minolta’s background, values, and innovations in digital label printing. A truly inspiring and informative visit.

The final stop on the study tour was the Fujifilm Business Innovation Ebina Center –and what a knowledge-packed day it was!

We kicked off with an introduction to Future Edge and an overview of the Innovation Print Awards. Afterwards, I had the chance to view – and hold – the award-winning printed pieces on display.

Next, we headed to the demo room, but not before getting a firsthand look at Revoria XMF PressReady, Fujifilm’s workflow software that connects and controls all their machines. Nifty!

In the demo room, we explored the machines behind those stunning print

samples. Two standouts for me were the clear toner, which left a watermark effect and then the pressure adhesive toner, which was peelable! I’d never seen that before!

From there, we toured through the manufacturing line. It was incredible to see machines being put together. It was inspiring to see so many women working in manufacturing!

Back in the presentation room, I was shown three presentations that delved into the Revoria XMF PressReady software, digital marketing initiatives, and Fujifilm’s commitment to sustainability.

It was a fantastic last stop on the study tour journey!

This study tour has been incredibly valuable to both my personal and professional development. It challenged me in many ways and pushed me well outside my comfort zone – in the best possible way.

I’m so grateful to everyone who helped organise the trip, as well as those I had the pleasure of meeting along the way. The insights, experiences, and connections I gained have been truly unforgettable.

To the 2025 Emerging 50 finalists – I encourage you to apply for the Geoff Selig Scholarship. It’s a once-in-a-lifetime opportunity that will expand your perspective and inspire your future in print.

The Geoff Selig Scholarship is dedicated to former IVE Group chairman Geoff Selig and his passion for encouraging emerging talent within the industry. The scholarship provides a financial value of up to $10,000 for personal and professional development and is funded jointly by ProPrint and IVE Group.

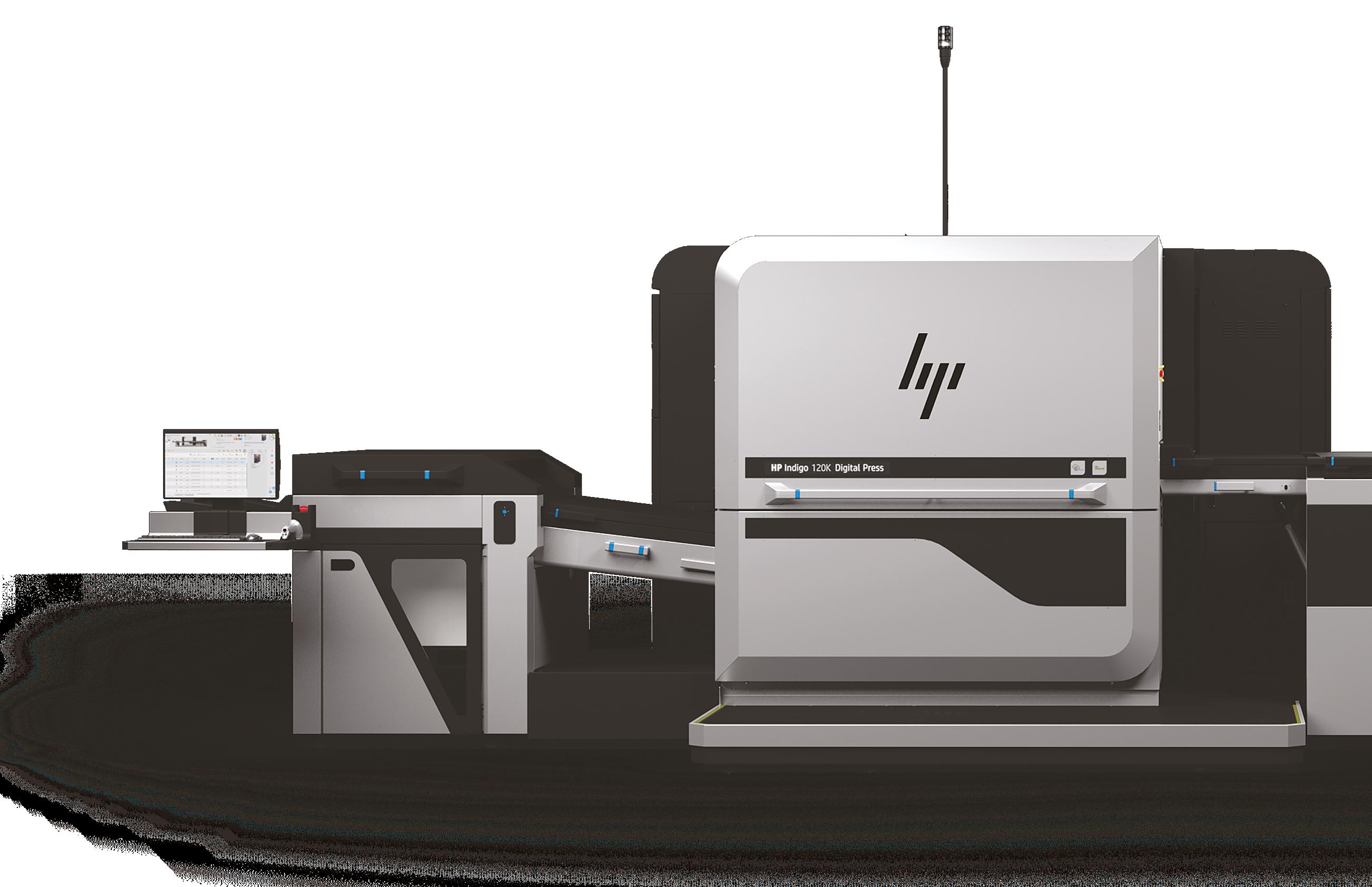

With the addition of a Gallus One to Dragon Printing’s existing fleet of high-performance presses, the Sydney-based business is stepping into a new era – boosting capacity, expanding capabilities, and reinforcing its position as a leader in premium label production.

With the new Gallus One Digital Press fired up at Sydney-based Dragon Printing, the company has entered a new phase – one that gives its clients even better options, while greatly increasing the workload the company can handle.

Investing in advanced technology is a signature move of Dragon Printing, keeping the business at the forefront of label manufacturing and enabling it to deliver an exceptional range of highquality work.

Dragon Printing prides itself as a company that moves forward with the times, having shown a willingness to invest in innovation

and give itself an edge over its competition. Already boasting a fleet of Gallus presses, there’s almost nothing it can’t do.

This has meant that the presses are fully loaded. Though it’s a good problem to have, it has created the need for faster, more agile systems that truly harness the power of digital press systems.

“Today, so much more of our work is suited for digital press systems,” explains Paul McCullum, director of Dragon Printing.

“We saw the need to alleviate the workload on our current presses, using them for more hybrid work. What we

needed was a press that would fit with our existing systems well but also be a natural progression in terms of the work we are doing, where the market is heading, and still be able to deliver the standard of work we are known for.”

As with any significant investment, McCullum and the team at Dragon Printing did their due diligence, looking at multiple options from selected manufacturers.

“We did look at all the available presses that might suit our needs,” McCullum said.

“We have seen them running and know what they’re best suited for. We were obviously already very familiar with

– and extremely happy with – the Gallus Labelfire presses that we have in operation. After speaking with Dierk Wissmann and the team at Gallus, and seeing what the Gallus One could do, we knew it was the right fit for our business and the work we need it to handle.”

The Gallus One is a unification of all Labelmaster modules. The press is built around the idea of ‘modularity’, so that it can adapt to changing needs and market trends.

Businesses operating the Gallus One can easily add, remove, or replace units up and downstream, including flexo and screen printing, cold foiling, die-cutting, and more. This level of flexibility means print manufacturers can expand their services as their business grows, but without having to make significant investments in other types of printing systems and presses. It can all be done on the one press.

“A press with this level of flexibility is perfect for us because of the ‘hybrid’ work we do,” McCullum said.

“We handle a lot of cosmetics, pharmaceuticals, food, and wine labels that we do as one long pass on our Gallus Labelfire. At the same time, we are also running a lot of very simple jobs that are just die-cut and varnished. So, we now split the work between the systems, doing

the more complicated jobs on the Labelfire, while the more straightforward jobs are done on the Gallus One. Because of the speed and print capabilities of the Gallus One, it will become the ‘workhorse’ of our operations.

“The options with the Gallus One are nearly endless. You can start your journey with a simple roll-to-roll configuration with CMYK+W and later expand the machine according to your needs.”

“The running speed of the press is one of the significant features that attracted our interest, and of course, we know the technology and we know the inks. We won’t be wasting valuable time colourmatching jobs; it’s a straight swap from one press to the other. We will achieve huge time savings because this press is an all-in-one process.”

The Gallus One can print up to speeds of 70m/min, even with high-opacity white of 85 per cent. With a printing width of 340mm or 430mm, the press can run a variety of self-adhesive materials such as papers, plastics, and unsupported materials.

As impressive as the stats are, it’s the modularity of the press that is really something special.

“The Gallus One represents the dawn of a new era,” said Dierk Wissmann, national

sales manager – Australia at Heidelberg Australia and New Zealand.

“The options with the Gallus One are nearly endless. You can start your journey with a simple roll-to-roll configuration with CMYK+W and later expand the machine according to your needs. This new ‘system to compose’ allows business owners to add to or change the composition of the machine system at any time of the journey.”

Options include the expansion of the colour gamut by adding orange and violet, flexo printing units, screen printing units, RDC Top, SDC ABG, and RDC quick diecutting solutions, as well as a cold or hot foil, rotary embossing, web turn bar, de-lam re-lam, mono and PS laminating and MR touch.

“In Dragon Printing’s case, it is a Gallus One CMYK+W with a flexo unit for varnish or lamination, as well as a semi rotary diecutting unit at the end. And of course, all of this comes with the highest print quality in 1,200 dpi by 1,200 dpi and at 70m/min –including white!” Wissmann said.

“The new Gallus One ‘system to compose’ allows business owners to add to or change the composition of the machine system at any time of the journey.

“In addition to high print quality, high speed, and high flexibility, to be truly successful, there is one more important piece of the puzzle – high machine uptime.

“We have taken everything we have learned from our clients using the Labelfire systems and poured all that knowledge into the development and design of the new Gallus One press.

“We have added new automated features such as automatic ultrasonic print-head cleaning, for example, to reduce downtime. The overall new design comes with many improvements to extend the life of vital parts and thus increase the machine uptime to a new level.

“In addition, Heidelberg Australia and New Zealand has a very strong service team on the ground, ready to jump in and offer support should it be required. Finally, there is no purging required; therefore nearly 100 per cent of the purchased ink is used to produce labels with virtually no ink waste.

“Which brings us to the final puzzle piece – high affordability. With its lower entry price, high quality, speed, and uptime, and nearly 100 per cent ink utilisation, the new Gallus One truly tears down the TCO barriers there might have been in the past.

“Driving the press is our market-leading Prinect workflow system from Heidelberg. This was jointly developed by Heidelberg and Gallus and combines the digital printing and software know-how of Heidelberg with the extensive expertise of Gallus in label printing. The Gallus One is the perfect solution for Dragon Printing who need a very fast, versatile press that still delivers exceptional print results.”

The abilities of the Gallus One press were not the only reason why Dragon Printing chose to re-invest with the company. The company has a strong partnership with Heidelberg and knows it can rely on service and support if, and when, needed.

“We’ve been dealing with Heidelberg for more than five years now,” McCullum said.

“Right from the start, we insisted that any servicing was done by Heidelberg, which it has done, and we always have access to online support. If we need to, we can always pick up the phone and speak to the team directly.

“For us, being able to rely on the manufacturer is extremely important because we cannot afford unnecessary downtime.”

Market competition, and the developing trend of shorter, more varied runs in faster time, means that label manufacturers such as Dragon Printing cannot afford downtime. They must be able to perform when the customer needs them and to a level that befits their reputation.

“Despite the capabilities we have and the results we can achieve, what we are really known for is our honesty,” McCullum said.

“Our customers deal with us because they know we are straight up. If there’s a problem, we will say it. With a press like the Gallus One, and the service and support we get from Heidelberg, we know we can promise our customers exceptional results with very short turnaround time.”

The Gallus One has been up and running for a few months now at Dragon Printing’s Sydney headquarters. Finished jobs are already flowing because the installation time to learning curve was minimal as the Dragon Printing team was already familiar with the Labelfire press.

“We are very happy with how things have gone and the results we are getting,” McCullum said.

“The new Gallus One ‘system to compose’ allows business owners to add to or change the composition of the machine system at any time of the journey.”

“It hasn’t taken our people long to adapt to the new press because it shares some basic similarities with the Labelfire, and we are already very familiar with Prinect. You can certainly notice the speed difference; that’s something we are still getting used to. We can run a large volume of work through the Gallus One and still have room for more because it is so quick.”

The Gallus One represents a significant leap for digital press label manufacturing. The combination of speed, print quality, automation, and the ability to grow with the needs of the manufacturer, means Dragon Printing has the firepower necessary to handle any job.

Content and images supplied by Labels Plus Magazine and republished with permission.

At the heart of everything we do is a commitment to innovation, quality, and reliability — values that have driven us for 175 years, and will continue to guide us into the future. As a leader in the packaging and printing industry, we develop solutions that set new standards, looking far beyond our core sector. Thanks to our expertise built on 175 years of experience, we are constantly providing new impetus and actively helping to shape the future. We would like to thank all the customers, partners, and staff accompanying us on this journey. heidelberg.com/175

UNRIVALLED PRECISION. UNMATCHED PERFORMANCE. KONGSBERG HAS ARRIVED

Ball & Doggett is now your trusted partner for KONGSBERG Precision Cutting Systems starting with the powerful C24

Engineered for speed, accuracy and versatility, it’s the new benchmark in digital cutting for signage and print professionals.

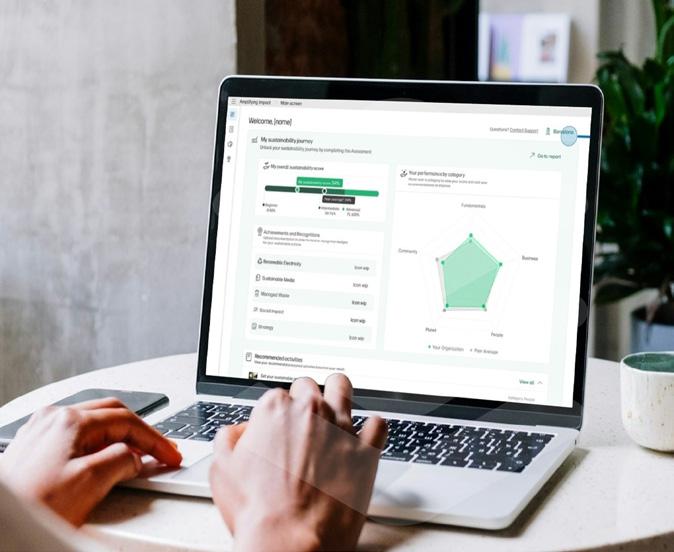

HP Indigo empowers converters to win business from sustainability-driven brands, while helping them hit critical KPIs in waste, carbon, and circularity.

Sustainability is no longer a side initiative – it’s a core business imperative. Brands, governments, and consumers alike are demanding greater environmental accountability. In response, HP Indigo has reimagined what’s possible in digital printing, offering a powerful blend of efficiency, compliance, and circularity to drive measurable sustainability gains.

With the print industry facing mounting pressure around Scope 3 emissions, waste reduction, and material circularity, HP Indigo offers proven solutions backed by independent certifications and measurable outcomes.

HP Indigo’s digital presses are manufactured with carbon neutrality from cradle to gate, and the company committing to operate with 100 per cent renewable energy by 2025. These milestones are aligned with HP’s global goals, which target net-zero carbon emissions by 2040 and a 50 per cent use of recycled, reused, or renewable materials in shipments by 2030.

HP Indigo digital presses are engineered to reduce setup media waste by up to 90 per cent compared to analog methods. For example, the HP Indigo 6K press running 300 jobs per month can save up to 70km of media – the equivalent to $9,000 per month in material savings and significant carbon footprint reduction.

Through on-demand printing with no minimum orders, brands and converters can reduce overproduction, inventory waste, and transport emissions. A full CO₂ impact calculator is available upon request to support customers in measuring their emissions by press, job, and country-specific energy sources.

HP Indigo is investing in sustainable design, not just efficiency. The presses feature:

• Reused parts through a growing Certified Pre-Owned (CPO) program

• Recycled Imaging Oil (RIO) systems to minimise consumable waste

• Take-back programs for ink cartridges and press components across EU, UK, Australia and New Zealand

• Support for FSC-certified and postconsumer recycled substrates

In FY22, 17 per cent of all HP Indigo press sales were CPO units, and more than 1,600 tonnes of consumables were diverted from landfill through HP Planet Partners.

HP Indigo enables printing on a wide range of eco-certified substrates, including recyclable labels, compostable flexible packaging, rPET liners, and reducedweight label stocks. This flexibility supports brands’ goals to comply with EU circular economy regulations and achieve recyclability, compostability, or reuse without redesigning packaging supply chains.

HP Indigo is proactive about meeting evolving regulatory frameworks. Its inks:

• Contain no hazardous air pollutants (HAPs)

• Meet the French mineral oil (MOAH/ MOSH) ban taking effect in 2025

• Are transitioning to PFAS-free formulations in advance of US and EU bans in 2026–2027

• Have built-in VOC capture systems for emissions control and site compliance.

HP Indigo’s PrintOS Suite delivers measurable gains in sustainability through automation and analytics. Tools such as Color Beat and Substrate Manager reduce setup time and media waste, while Site Flow enables distributed printing and minimises shipping-related emissions.

With PrintOS, converters and brands can optimise energy usage, consumables, and logistics – further aligning print operations with ESG goals.

The shift to sustainable printing is not only about compliance – it’s about creating value.

HP has developed a solution for this as part of its Print OS production operating system – the HP Sustainability Amplifier. Available to anyone with a Print OS account, this programme is designed to empower printers and converters to achieve environmental goals and deliver more sustainable prints to their own customers.

“Sustainability is no longer optional; it’s a business imperative,” said Carlos Lahoz, head of sustainability strategy at HP Industrial Print.

“HP Sustainability Amplifier is here to help you lead with purpose, offering tools, insights, and recognition to advance your sustainability journey. HP PrintOS Sustainability Amplifier helps you assess your current sustainability status and provides actionable insights to boost your impact. At the same time, you can tap into additional resources and get recognised by HP for the work you’re doing in this area.”

HP Indigo empowers converters to win business from sustainability-driven brands, while helping those brands hit critical KPIs in waste, carbon, and circularity.

By printing on demand, consolidating SKUs, and choosing sustainable substrates, brands using Indigo are wellpositioned to meet both internal ESG targets and external regulations without compromising quality or flexibility.

Durst’s industry leading and data driven approach to sustainability ensures the company not only meets but exceeds environmental standards in all aspects of its operations.

Durst Group is reinforcing its position as a global leader in sustainable print technology, with environmental stewardship at the core of its Environmental, Social, and Governance (ESG) strategy.

Durst Group, a third-generation familyowned business co-owned by Harald Oberrauch and CEO Christoph Gamper, has been a leader in digital printing technology since its founding in 1929.

Today, the company employs more than 1,100 people globally – an increase of 10 per cent over the past year – and is renowned for the quality and reliability of its advanced solutions across the global graphics, ceramic tile, labels, packaging, and commercial corrugated packaging sectors.

“At Durst, sustainability is deeply embedded in the company’s DNA,” said Matt Ashman, managing director of Durst Oceania.

“Our approach to sustainability is deliberate and data-driven, ensuring that we not only meet but exceed environmental standards in all aspects of our operations. We substantiate our commitment with certified, measurable actions that drive lasting impact.”

Durst Group adheres to a robust environmental management system certified under ISO 14001. This certification allows the company to systematically track, measure, and improve its environmental footprint across all areas of the business, from product design to operational efficiency.

“Our goal is to continuously evolve, guided by measurable targets, and supported by both internal audits and external reviews,” Ashman said.

Durst Group has achieved carbon neutrality for Scope 1 and Scope 2 emissions for its production facilities in Brixen and Lienz, with plans to electrify its vehicle fleet by 2030.

Durst Oceania has already achieved this milestone in Australia, deploying a 100 per cent electric vehicle fleet in 2023.

“The transition to an entirely electric fleet was a key first step in our sustainability journey,” said Ashman.

“It reflects our alignment with the global Durst vision – to explore every avenue to become more sustainable.”

Looking ahead, Durst Oceania is planning a move to a new, larger facility that will feature on-site solar panels, a recycled water system, battery storage, and EV charging stations – aligning with the ecofriendly infrastructure already in place at Durst’s Brixen headquarters.

The Brixen site also offers solar-powered car charging and free e-scooters for staff and visitors, highlighting the company’s holistic approach to low-impact mobility.

Durst’s commitment to environmental sustainability also extends to its products.

“From water-based ink systems to energyefficient LED UV drying technology, we aim for innovative solutions that enable our

customers to operate more sustainably,” Ashman said.

Earlier this year, the Durst Group finalised its acquisition of Aleph SrL, a pioneer in sustainable digital solutions for textiles and interior and exterior decorations.

With this strategic move, Durst Group is set to further enhance its position in water-based and sustainable printing technologies.

“In recent years, markets for digital printing technologies with water-based ink applications have experienced rapid growth, driven by increasing demand for environmentally friendly and customisable products,” Ashman said.

“Aleph’s water-based technology and sustainability solutions align perfectly with Durst’s current and future professional values, aims and objectives. It marks the start of very exciting times for Durst.”

Through its sustainable innovations, Durst Group helps clients achieve their own environmental goals.

“Whether it’s reducing energy consumption with advanced LED technologies or minimising resource use through our Ink Save software, our solutions substantiate the claim that sustainable practices can drive both environmental and economic success,” Ashman said.

“We aim to lead by example, creating a blueprint for sustainability that the entire industry can follow.”

Backed by a five-pillar sustainability strategy, Koenig & Bauer is redefining sustainable printing with cutting-edge technology and a commitment to lasting impact across the industry.

Koenig & Bauer is pushing the boundaries of sustainable innovation in the printing industry.

Anchored by a comprehensive sustainability strategy built on five key pillars: employee responsibility, customer responsibility, industrial environmental protection, social responsibility, and integrity and compliance – the company is committed to making a lasting, positive impact across the value chain.

“Your partner in printing excellence –Koenig & Bauer leads the way in printing technology, delivering high-performance solutions for every application,” said Rayne Simpson, sales manager for Koenig & Bauer Australia and New Zealand.

Engineering sustainability: Eco-design and energy efficiency

As a supplier of sustainable solutions to the industry, Koenig & Bauer sees itself not just as a supplier, but as a technology partner dedicated to helping reduce ecological footprints across the printing industry.

To support this mission, Koenig & Bauer has developed a range of eco-components and innovative technical solutions that contribute to cutting carbon emissions by reducing

energy consumption, waste and the use of other resources such as inks and coatings.

Some examples of Koenig & Bauer’s innovative technical solutions include:

For sheetfed offset presses, VariDryBlue drying systems cuts energy consumption of the dryers by up to 35 per cent, while QualiTronic inline measuring and inspection systems reduces the use of substrates and consumables by up to 30 per cent in conjunction with the ink workflow.

“Your partner in printing excellence – Koenig & Bauer leads the way in printing technology, delivering high-performance solutions for every application.”

For metal decorating presses, HighEcon dryer cuts gas costs by up to 70 per cent and for Intaglio presses for banknote printing, reduction of up to 25 per cent in ink consumption with a special ink apply.

Within the framework of an overall strategy process, Koenig & Bauer has elaborated goals for sustainable development of the company group. With these strategic ESG goals, it is seeking to

fulfil its ecological, social, and community responsibilities even more effectively.

Koenig & Bauer is a participant in the UN Global Compact and has identified seven of the 17 UN Sustainable Development Goals as priorities and backed them up with strategic sustainability initiatives. These include Health & Wellbeing (3), Quality Education (4), Gender Equality (5), Decent Work & Economic Growth (8,) Sustainable Consumption & Production (12), Climate Action (13), and Partnerships to Achieve the Goals (17).

Koenig & Bauer is also a partner of the VDMA’s Blue Competence environmental initiative and is a member of the Healthy Printing Initiative, the 4evergreen Alliance, and a member of the Holy Grail 2.0 Project.

As Koenig & Bauer continues to align innovation with environmental responsibility, the company emphasises the importance of tailored solutions that meet each customer’s unique requirements.

“We invite our customers to discuss and explore our comprehensive portfolio of printing presses and related equipment to find and build a niche press that’s a perfect product for your individual needs,” Rayne said.

Exceeding Print – because there is still so much more to discover.

The future still holds so much worth discovering. To help preserve it, Koenig & Bauer is committed to protecting the environment through sustainable printing processes and increasingly e cient machines. Non-ecological packaging can be replaced, waste reduced, and resource-saving practices advanced.

Alongside supporting numerous initiatives and projects, Koenig & Bauer's roadmap includes achieving complete CO₂ neutrality across its production plants by 2030.

Koenig & Bauer (AU)

Rayne Simpson +61(03) 9548 7277

rayne.simpson@koenig-bauer com.au

koenig-bauer com

Sustainability has been central to Konica Minolta’s innovation for more than 20 years – and continues to remain a key focus for the future.

Sustainability is vitally essential for all print businesses today.

Embracing a clear environmental vision is the only way forward.

The world today is still firmly focused on mass production, mass consumption, and mass disposal. Unsurprisingly, this is causing significant problems, not least of which is the depletion of natural resources.

For obvious reasons, there has been an increased focus on environmentally responsible sourcing, supply chain management, and manufacturing within the print industry. This is something that customers are increasingly demanding too, actively seeking to reduce their carbon footprint with manufacturers that embrace long-term environmental responsibility.

With Mintel’s latest Global Outlook on Sustainability: A Consumer Study 2024-25 reporting sustainability as the most critical issue concerning brands, it’s clear this is a key concern facing the wider print industry.

The challenges

Here’s a quick overview of the main environmental challenges in production print:

Energy consumption

Production print processes consume large amounts of energy, especially with older, traditional equipment. From powering large presses to the drying and curing processes, the energy demand is substantial and often relies on nonrenewable sources.

Waste generation

A substantial amount of waste is produced, including excess paper and setup sheets used for calibrating and adjusting presses.

Misprints, overproduction, and leftover materials all play a big part too.

Recyclability

Coatings, lamination or complex substrates, like composites or metallic inks, mean that some printed materials are challenging to recycle. While these features may improve the durability or aesthetic value, they can make recycling much harder.

In short: addressing environmental issues is no longer optional for print providers.

Here’s why it really matters:

Reputation and responsibility

Environmental challenges affect all of us today. As businesses and consumers become more conscious, it’s vital to be transparent with our own commitments and actions towards sustainability. This demonstrates print providers understand their customers’ needs and are actively helping them reduce their impact.

Cost and time savings