GARANT MATADOR BAG MACHINE

Labelexpo SEA 2025 sees success The tradeshow delivered its largest ever exhibition this year

Labelexpo SEA 2025 sees success The tradeshow delivered its largest ever exhibition this year

From uncoated to laminated to UV or foils - Hero Print has you covered

AUSTRALIA’S BEST TRADE PRINTER

Orora hires at Global Glass P05

Emmanuel Ladent to fill executive role in July

Innovation at RollsPack P06

Kirk Group, XSYS, and Hybrid partner

ABG retrofit sales go up P06

Company sees uplift of 239 per cent

Easy Signs enters roll labels P08

Installs HP Indigo and ABG machines

Changes at Koenig & Bauer P08

Spins off digital unit from the holding company

Durst and OMET success P10

More than 20 hybrid machines sold in 2024

Pact Group to delist from ASX P10

Delisting “to be in the company’s best interests”

New technology from Gallus P11

Makes available the new Gallus MatteJet tech

Jet Technologies Open House P11

Open House event in Indonesia a huge success

Excel gets new Century 1670Q die-cutter from Graffica P12

The Century 1670Q die-cutter has boosted Excel’s production capacity and profitability

New Garant Maschinen Matador NXB for Charters Paper P14-16

The machine includes a four-colour LINAFLEX NL inline printing for paper packaging

Labelexpo SEA delivers largest ever exhibition P18-22

More than 190 exhibitors participated in the recent Labelexpo Southeast Asia edition

Labelexpo Europe includes folding cartons category P23

The categorywas created based on inline and digital technologies disrupting the industry

All the scoop from Dscoop P24-26

Dscoop Edge Long Beach showcased the power of connection, idea sharing and innovation

2025 PIDAs winners named P28

A significant number of unique designs were recognised at the recent 2025 PIDAs

Nekkorb Solutions reinforces AVT partnership P30

AVT returns to its core operations, moving away from its Danaher’s Esko integration

Dantex relaunches PicoColour P31

It is a compelling solution for businesses seeking to enter digital production

Brick Lane creates ultimate can design using Orora Express P32

Orora Express will be further enhanced once Helio comes online in a few months’ time

The gap between promise and progress P33

Jet Technologies’ Daniel Malki focuses on Australia’s sustainable packaging challenge

Mattingly P34

The rise of ex-industry specialists

Smithers P36 Key trends and drivers in brand protection

Aquapak P37 The categories that fare poorly in consumer perceptions around packaging recyclability

A guide to the upcoming events

What a whirlwind month it has been. In the past few weeks, the pmg team was at several tradeshows including Fespa, China Print, Labelexpo Southeast Asia, and PacPrint.

There were even a few events which fell on the same dates, including Dscoop Edge Long Beach, but just because we couldn’t attend doesn’t mean we don’t have the latest information. This issue deep dives into the showcase at Dscoop, along with our extensive coverage of Labelexpo Southeast Asia.

For more Fespa 2025 and PacPrint content, read the June issue of ProPrint. China Print content will be published in the July issue of Australian Printer, and details about the 2025 Australasian Packaging Conference will be published in the August issue of ProPack.pro.

We hope you enjoy the read.

Orora (ASX: ORA) has announced that after eight years of leading the Saverglass business and 16 months leading the global glass business, Jean Marc Arrambourg will retire from his role as president, global glass, at the end of calendar year 2025.

The company has also hired Emmanuel Ladent to take on the role, effective 1 July.

Ladent will join Orora’s global management team, reporting directly to Orora CEO and managing director Brian Lowe, and will be based at Saverglass’ head office at Feuquières, France.

Ladent brings a wealth of experience leading large-scale industrial premium businesses. With a strong background in sales leadership, his career includes almost 30 years at Michelin, where he held senior executive roles including president – global automotive, president – global agricultural and managing director, passenger car and motorcycle.

More recently, he was CEO of green tech company Carbios, where he built a team and led the creation of strategic partnerships instrumental to the growth of the business.

Arrambourg will work alongside Ladent until 31 December 2025 to ensure a smooth transition.

Brian Lowe said, “We are grateful to Jean Marc for having led the Saverglass business through the transition of ownership to Orora. He is a respected leader who has achieved much to

be proud of during his career. He has led major initiatives including the launch of Saverglass’ Acatlán site in Mexico and the acquisition of the Ghlin site in Belgium.

“I appreciate his support in the coming months as we manage a transition in leadership of the global glass business.”

Commenting on Ladent’s appointment, Lowe said, “I look forward to welcoming Emmanuel to the global management team at Orora from 1 July.

“A seasoned leader, he brings an excellent track record of leading international premium businesses and driving growth in listed company environments, with a strong focus on sales excellence, innovation and sustainability. Emmanuel is the ideal successor to lead Orora’s global glass business into its next chapter”.

Sydney-based reprographics company Kirk Group has partnered with XSYS and Hybrid Software to deliver new flexo plate innovation to Melbourne’s RollsPack.

When long-term customer RollsPack challenged Kirk Group to find a more cost-effective and sustainable way to print high value flexible packaging, it carefully considered the combination of plate and specialised screening technologies necessary to achieve the desired outcome.

It leveraged the versatility of the ThermoFlexX imaging system and Catena+ automated processing line to implement these solutions:

• ThermoFlexX Woodpecker Nano – the finest surface micro pattern available for LAMS plates, suitable for platemakers and printers who need high frequency surface screens to increase quality and efficiency while reducing costs.

• Nyloflex NEF D – a high durometer printing plate for flexible packaging developed by XSYS for the efficient creation of flat-top dots and reproduction of surface screenings with UV LED exposure.

• Velvet Screening – a new screening type from Hybrid Software created to meet flexo requirements. As the successor to hybrid XM screening, it uses an

AB Graphic International (ABG), has seen an uplift of 239 per cent in its retrofit sales, completing more than 170 retrofit installations in 2024.

ABG’s portfolio of machines is designed to be retrofittable, offering customers the flexibility to upgrade their existing equipment, from adding new physical modules to enhancing software and beyond.

With many of ABG’s machines being modular, they can be reconfigured to suit the evolving needs of businesses.

One of the most popular retrofits is the Flat Bed Foil Module, which is available in two options: the 25-tonne and 50-tonne Big Foot units. These units can be used for foiling, embossing, or a combination of both, creating striking effects and premium finishing.

advanced dot removal algorithm to reduce harsh edges, leading to smoother and higher-quality prints.

In this scenario, advanced screening technology and dedicated plate surface structures simplified the challenging task of controlling the dots and the ink behaviour on press. ThermoFlexX Woodpecker and Velvet Screening proved their individual strengths, to deliver a successful outcome for RollsPack.

The nyloflex plates with Velvet Screening and Woodpecker micro surface patterns provided by Kirk Group ticked all the boxes for RollsPack, meeting its demands for quality, sustainability, and costs.

“This solution offers a lot of potential. Set up times have been reduced significantly due to precise colour profiles, and longevity on press is comparable to other major players on the market,” RollsPack print manager Thanh Huynh said.

“There’s also a marked difference in the ink laydown on surface print; it’s one of the best

Also popular in the embellishment arena is the High-Speed Screen Module, enhancing labels and packaging with a range of varnish effects, ideal for transforming products with not just eye-catching matt and gloss

I’ve seen in flexibles. In addition, Velvet Screening holds the dots really well, ensuring that there are minimum hard edges.”

Kirk Group chief operating officer Robert Selvaggio said, “We were among the first in the market to realise the potential of this high performance, one-touch technology which tripled our capacity and elevated plate quality. We’re now in the process of installing a Catena+ line in Brisbane and a third one is already planned for Sydney”.

XSYS Asia Pacific vice-president Roy Schoettle said, “We are delighted that this partnership has been so successful and look forward to taking the next steps with the team, as they equip all their manufacturing sites with full Catena+ lines”.

Hybrid Software Australasia sales manager Brenton King said, “In this collaboration, Kirk Group simply applied Velvet Screening and then added the Woodpecker surface patterns during imaging. It’s a very clever combination”.

varnishes but tactile finishes too. Among ABG’s most in-demand retrofits is the re-register lamination upgrade: this allows customers to produce multi-layered labels for peel and reveal products by laminating a pre-printed web to the main web in perfect register, illustrating the versatility of the retrofit upgrades on offer from ABG.

From a software perspective, ABG Connect is a key upgrade aiming to revolutionise automation in the labels and packaging market.

This solution provides unrivalled workflow efficiency by enabling automatic job set-up and changeover in just a few milliseconds, with minimal operator intervention, therefore improving production efficiencies.

ABG director of service Peter Redmond said, “Demand for ABG’s retrofit offering has risen over the last few years, allowing our customers to adapt their machinery as their business grows and changes. We’re proud to have such a dedicated team of engineers, trusted by our customers to enhance their production capabilities”.

durst-group.com/label

Easy Signs has started selling rolls of labels for the first time in the company’s history following the installation of a new HP Indigo and ABG finishing equipment purchased almost a year ago at drupa.

“We can finally say that this equipment has arrived, and we are up and running in the custom label rolls category,” Easy Signs co-owner Andy Fryer told ProPack.pro

“We literally turned on the Custom Label Rolls page on our website two weeks ago and we are already offering labels within 48 hours. Sales are already very strong, and we are looking to reach 24-hour turnaround in the near future.

“We have tested all our processes and systems and based on the orders we have received so far, we feel this will be a very good product line for us.

“Previously we were selling labels printed on our sheet fed Indigo that were being cut on our Zünd. This is a very labour-intensive process for labels, and we can now provide

Koenig & Bauer has announced that its digital unit, previously operating under the group’s umbrella, will be spun off from the holding company.

The result will be a wholly owned subsidiary, Koenig & Bauer Kyana GmbH, that will be part of the special and new technologies segment.

Sandra Wagner, previously vice-president of digitalisation at Koenig & Bauer, has been appointed managing director of Koenig & Bauer Kyana GmbH.

According to Koenig & Bauer, the spin-off of its innovation hub as an independent entity marks an important milestone in the consistent implementation of the company’s digital strategy. Koenig & Bauer Kyana GmbH will continue to concentrate on the development of digital business models as well as AI and data-driven solutions throughout the entire life cycle of print products.

“We are convinced that this strategic spinoff, combined with the concentration and consolidation of our outstanding expertise in the field of digitalisation, will make a significant contribution to the long-term success of our company,” said Dr Andreas Pleßke, CEO of Koenig & Bauer.

The digital unit was launched in 2022 as part of the consistent implementation of the

the same labels for approximately two-thirds cheaper – so we are now a real player in the label market and competing with the major companies in this space.”

Shortly after Easy Signs purchased the new equipment at drupa, the business was already targeting 24-hour production.

“One of our main points of difference in the market has been producing products within

group strategy, ‘Exceeding Print’.

Sandra Wagner, managing director of Koenig & Bauer Kyana GmbH said, “Our customers are at the heart of everything we do. With Koenig & Bauer Kyana GmbH, we are creating the necessary organisational structure of an agile software company, which enables us to respond even faster and more comprehensively to the needs of our customers”.

Koenig & Bauer said the transformation into an independent software company enables the targeted development and expansion of specialised areas such as digital sales, a dedicated onboarding and support team, and sustained customer care through customer success management.

The digital unit’s product portfolio already

a 24-hour production time and the new ABG DigiLase laser technology is a game changer,” Fryer said in June last year.

“Using traditional methods, it is possible to lose 24 or 48 hours with the shipping of dies and there is also a cost. The introduction of the ABG DigiLase laser cutting finishing equipment by the end of this year will be critical for us to meet the expectations of our customers.

“We realised that we needed to make a substantial investment with the HP Indigo 6K to compete on higher runs as we know our clients want their stickers or labels on rolls, but we have not been able to provide this until now.

“We will continue to do some of the stickers on the wide format table for UV stability when needed as well as for bigger stickers, but the smaller stickers will migrate to the Indigo and the ABG finishing equipment with DigiLase laser technology.”

Currie Group director of labels and packaging A/NZ Mark Daws told ProPack in June 2024 the sale to Easy Signs will help the company further enhance its labels and web-to-print business.

“It wasn’t an easy decision for them, we took Andy and Adam to visit a very similar operation in the UK. They spent a bit of time doing their due diligence. It gives them the most versatile solution on any media off the shelf and it complements their existing verticals that they operate in,” Daws said.

includes myKyana, the central portal for the digital product world; Kyana Assist, the AI-powered chatbot for fast assistance and problem solving; Kyana Data, the intelligent production data analysis tool, and VisuEnergy X, the energy management system optimised specifically for the print and packaging industry.

In addition to the products of the Kyana ecosystem, which are specifically tailored to the needs of traditional machine users, the digital product portfolio is being expanded by the Connected Packaging solution presented at drupa 2024.

The existing digital product portfolio of Koenig & Bauer Kyana GmbH is constantly being expanded with further pioneering AI and data-driven applications.

Christian Steinmaßl, who as a member of the group management is responsible for various business units in the newly created special and new technologies segment said, “Digitalisation is a central driver for innovation and progress in our industry. With Koenig & Bauer Kyana GmbH, we are able to bundle expertise in the field of digitalisation in a more targeted manner. Growth in this promising market segment will be further driven forward while maintaining close links with the group strategy”.

Koenig & Bauer Kyana GmbH said it will continue to “work closely with the other business units of Koenig & Bauer in order to leverage synergies and offer customers a holistic solution”.

Durst and OMET, who have been in a partnership for eight years, and strengthened their partnership in 2023, have announced their collaboration has seen the sale of more than 20 machines in 2024.

The jewel in the crown of the Durst and OMET partnership is the KJet, a new digital and flexo hybrid machine tailored for the label and flexible packaging market. It is the second joint development by the companies after the XJet.

The KJet combines the ‘cylinder-base dual-servo’ flexo technology from OMET with the robustness and reliability of Durst’s RSCi Digital printing engine. It also offers operators a seamless experience with its user-friendly interface and ultra-short web path. This design minimises waste and reduces setup times, showcasing the

Pact Group has issued a statement saying it is intending to delist from the ASX pursuant to ASX Listing Rule 17.11.

The delisting is considered by Pact’s board to be in the best interests of the company and its shareholders in light of:

• the very concentrated nature of the company’s register,

• the low level of trading of Pact’s shares on ASX,

• the cost of maintaining an ASX listing relative to the benefits associated with such ASX listing, and

• the burden associated with compliance with the regulatory regime applying to listed companies.

Additionally, it said the board and company management spends a considerable amount of time and resources on matters relating to Pact’s listing on ASX, and that a delisting would enable Pact to focus more on its business operations and on delivering on its long-term business objectives.

The possibility of Pact being delisted was canvassed extensively in documents sent to shareholders during the takeover bid for the company made by Bennamon Industries, a company associated with Kin Group and the company’s chairman (which closed on 7 June 2024).

advantages of digital printing.

In response to the announcement of the 20 machines sold, Durst Oceania managing director Matt Ashman said, “It is great to see the strengthening of the collaboration between two giants of the label printing industry.

“As the saying goes, we can achieve great things by sitting on the shoulders of giants. This partnership leverages the strengths of both businesses to bring much-needed

innovation to the label converters in the Oceania region.”

OMET said, “When innovation and mutual trust meet, great projects come into being. As a result of a long-lasting collaboration between OMET and Durst, 2024 saw the sale of over 20 hybrid machines – a true gamechanger in the printing market.

“[It’s] an incredible result, which celebrates not only our technology, but also a shared vision of two cutting-edge realities.”

Bennamon repeatedly stated that its intention was to delist the company as soon as it was able to do so. The independent directors highlighted this risk to shareholders as a reason to accept Bennamon’s offer and outlined that this could occur on certain conditions even if Bennamon did not reach 90 per cent ownership.

This means that shareholders who did not accept Bennamon’s offer (or who purchased shares subsequently) may be regarded as being on notice about the likelihood of delisting being pursued.

Pact intends to hold an extraordinary general meeting (EGM) of shareholders on 12 June to seek shareholder approval for the delisting by special resolution.

Subject to shareholder approval of the delisting by special resolution, it expects that the key dates for delisting will be as follows:

14 July 2025 – Pact’s shares suspended from trading on ASX at the close of trade.

As the EGM is proposed to be held more than 12 months after the close of the takeover, Bennamon and its associates will be entitled to vote on the resolution.

Bennamon and its associates, who together hold 88 per cent of issued shares, intend to vote in favour of the resolution.

Prior to delisting, Pact shareholders will be able to sell their shares on ASX. To provide its shareholders with an adequate opportunity to exit their investment, the delisting date will not be until at least one month after shareholders approve the delisting.

After delisting, the company’s shares will be capable of being traded by off-market private transactions, which will require shareholders to identify and agree terms with potential purchasers of shares in accordance with the company’s constitution and the Corporations Act 2001.

Gallus Group, a subsidiary of Heidelberg, has announced the global commercial availability of its new matte finishing technology for the Gallus One, Gallus MatteJet.

The technology allows converters to produce profitable digital labels inline with a high-end matte finish at the touch of a button, with the company saying it is set to boost digital adoption in the growing wine label segment.

Initially unveiled as a research breakthrough at Labelexpo Americas 2024, strong market demand led Gallus to fasttrack the development of Gallus MatteJet.

Achieving a premium look by removing the traditional digitally printed gloss finish, historically one of the foremost barriers to digital label adoption, Gallus MatteJet paves the way for broader use in labels and packaging – particularly in high-end segments like wine and spirits where brands demand a sophisticated, premium matte finish.

Gallus Group CEO Dario Urbinati said,

Jet Technologies recently held its highly anticipated 2025 Open House in Jakarta, Indonesia, welcoming more than 200 industry professionals from across Southeast Asia.

The event served as a dynamic platform to showcase the latest innovations in flexographic printing, with a strong focus on enhancing efficiency, improving print quality, and adding tangible value across the labels and packaging sector.

The event marked the official opening of Jet Technologies’ new Indonesian headquarters, featuring a purpose-built 500sqm demonstration centre. This new space provides a permanent home for live demonstrations of technology, and for this occasion, the spotlight was on the Omet X6.0 – the flagship flexo press from Omet.

In a world-first, the press was equipped with the Versatex Print Bar, allowing for on-the-fly digital embellishment during label and lami-tube production, offering a compelling look into the future of hybrid

“Until now, matte finishing for digital inkjet has only been achievable through the addition of integrated flexo units or postprocessing equipment to utilise matte coatings – adding time, complexity and cost.

“Now, by eliminating the need for these types of varnishes, customers can unlock various efficiencies whilst retaining the surface texture of their desired substrate. This also in hand eliminates any required tooling and cleaning of coating machinery, adding up to a significant overall benefit.

“Three years ago, with the launch of the Gallus One, we addressed the TCO barrier to profitable digital labels. With MatteJet, we’ve taken this concept further, bringing all the advantages of digitally printed matte labels to premium brands – including short runs,

reduced inventory, enhanced sustainability, personalisation, and on-demand printing.

“These strategic developments demonstrate our commitment to closing the gap between the vast promise of digital technologies and the current reality for businesses across our industry. Making the embrace of digital solutions an accessible and profitable path for more converters and further supporting the drive towards ‘smart, connected, printing’, this innovation effectively completes the circle for premium digital labels.”

Gallus MatteJet is designed to integrate effortlessly with the Gallus One, the company’s flagship digital label press. The new innovation can now be incorporated into both the 340mm printing width and the newly-expanded 430mm web width, further enhancing the System to Compose concept and boosting performance and flexibility for businesses.

Offering a modular blend of workflow and service options as well as equipment, System to Compose provides compatibility across Gallus’ leading product lines and enables converters to cost effectively adapt their technology offering to meet changing market needs for long-term success.

Furthermore, this new addition to Gallus’ ecosystem is said to further strengthen the future of ‘smart, connected printing’ by embracing the shift towards new digital technological advancements and reinventing processes across multiple areas in the printing industry.

printing workflows.

To emulate a real-world production environment, the Omet X6.0 was complemented by:

• The JetiQ SRI450 slitter/rewinder with Luster inspection system

• A Jindali shrink-sleeve seaming machine

• A Flexo Wash anilox cleaning machine

Beyond live machinery demonstrations, the Open House featured keynote presentations and technical workshops.

Notably, ESKO delivered an in-depth session on Automation Engine, while Jet Technologies’ Marifel Dela Calzada led an engaging workshop on colour management, sharing best practices for achieving consistent colour reproduction across various print platforms.

The event was further enriched by the

participation of industry-leading material suppliers, including UPM Raflatac, Avery Dennison, and Ritrama, who contributed to both the technical discourse and the vibrant networking sessions.

Jet Technologies director Jack Malki said, “Jet Technologies has been operating in Indonesia for over 12 years, consistently investing in the local industry by bringing new technologies to market.

“Having a dedicated space like this allows us to host larger, more collaborative events that are valuable for our clients. We were thrilled by the strong turnout and are already planning the next one.”

Malki added the impressive attendance underscores the growing appetite for advanced print technology in Indonesia and the wider Southeast Asian market.

The Century 1670Q die-cutter has boosted Excel Packaging’s production capacity and profitability, brought its previously outsourced work back in-house, significantly improved its quality control, and reduced its lead times

Excel Packaging, a South Australiabased business specialising in the manufacture of cardboard packaging solutions, has installed a high-end Century 1670Q automatic flatbed die-cutter from Graffica, boosting its production capacity and bringing previously outsourced work back in-house.

The automatic flatbed die-cutter has significantly improved its quality control, reduced lead times, and boosted profitability. It has also increased revenue by an additional 20 per cent through enhanced sizing and output capabilities.

The proudly Australian-owned and run family business’ cardboard packaging solutions range from standard FEFCO designs to completely unique die-cut products. It focuses primarily on corrugated cardboard packaging, but also develops, converts, and supplies a wide range of box board products to meet diverse customer needs. Excel Packaging services a broad range of industries requiring cardboard packaging, holding a strong market share in the wine, FMCG, general manufacturing, export, and the fastgrowing e-commerce industry sectors.

Last year, the company reached its production capacity and needed to outsource a significant volume of work to keep up with demands. Additionally, there was a shortage of local partners capable

of handling the larger sheet sizes required for certain products. Excel Packaging realised it needed to bring its work in-house to alleviate these bottlenecks and streamline business processes.

After researching several options, the company found that Century and Graffica could deliver not only the best machine for its requirements but also the high level of local support it was looking for.

Excel Packaging general manager Daniel Zaniewski met Graffica director Neil Southerington, and a new partnership was forged, with the machine installed in March 2025.

“The Century 1670Q integrates seamlessly with our existing operations, pairing perfectly with materials printed by our flexographic printers or laminated by our partners and customers,” Zaniewski said.

“Despite the challenge of moving a 40-tonne piece of equipment, once positioned, Graffica and Century’s engineers had it connected and running jobs within two days. Training was completed by day three, making for a smooth transition into full production by day four.

“The Century 1670Q has strengthened our production capabilities and market position, giving us the confidence to plan for further machinery investments in the near future. The Century 1670Q is our first

machine from Graffica – but based on this experience, it likely won’t be the last!”

The Century 1670Q automatic flatbed diecutter is built for quick set-up, safety, wide stock range and reducing damage to print sheets. It has a maximum cutting force of 400 tonnes and a maximum mechanical speed of 5,000 sheets per hour.

Zaniewski said the Century 1670Q was selected for its larger sheet size capabilities – it takes a maximum sheet size of 1670mm by 1260mm – and its range of automatic features, including faster setups, full waste stripping and removal, an automated feeding and delivery system, and a vacuum system capable of handling a wide variety of materials, including warped and laminated board.

“One of the best features of this machine is the patented feeding system that easily handles bowed and warped materials, maintaining precise registration even on tricky printed and nested designs. The suction feeder also protects laminated materials from scratching,” Zaniewski said.

“Excel Packaging plans to continue its strong growth path with further investment in automation, specialty gluing, and storage solutions, while expanding its reach into the e-commerce market nationwide.”

Southerington said the demand for online is proliferating, and just about every company that makes something now is in e-commerce.

“As a result, packaging’s high on the agenda for our company direction and we’ll be looking to install more machines, such as the Century 1670Q, soon. Century is a well-known name in Australia and New Zealand, mostly in the larger formats, and in fully and semi-auto,” Southerington said.

“The Century 1670Q installed at Excel Packaging works seamlessly with the company’s other machines. Everything came together very well, and I look forward to keeping that relationship moving forward.”

See our range of folding box gluers, board slitters, creasing machines, auto loaders, unloading cutting tables and more.

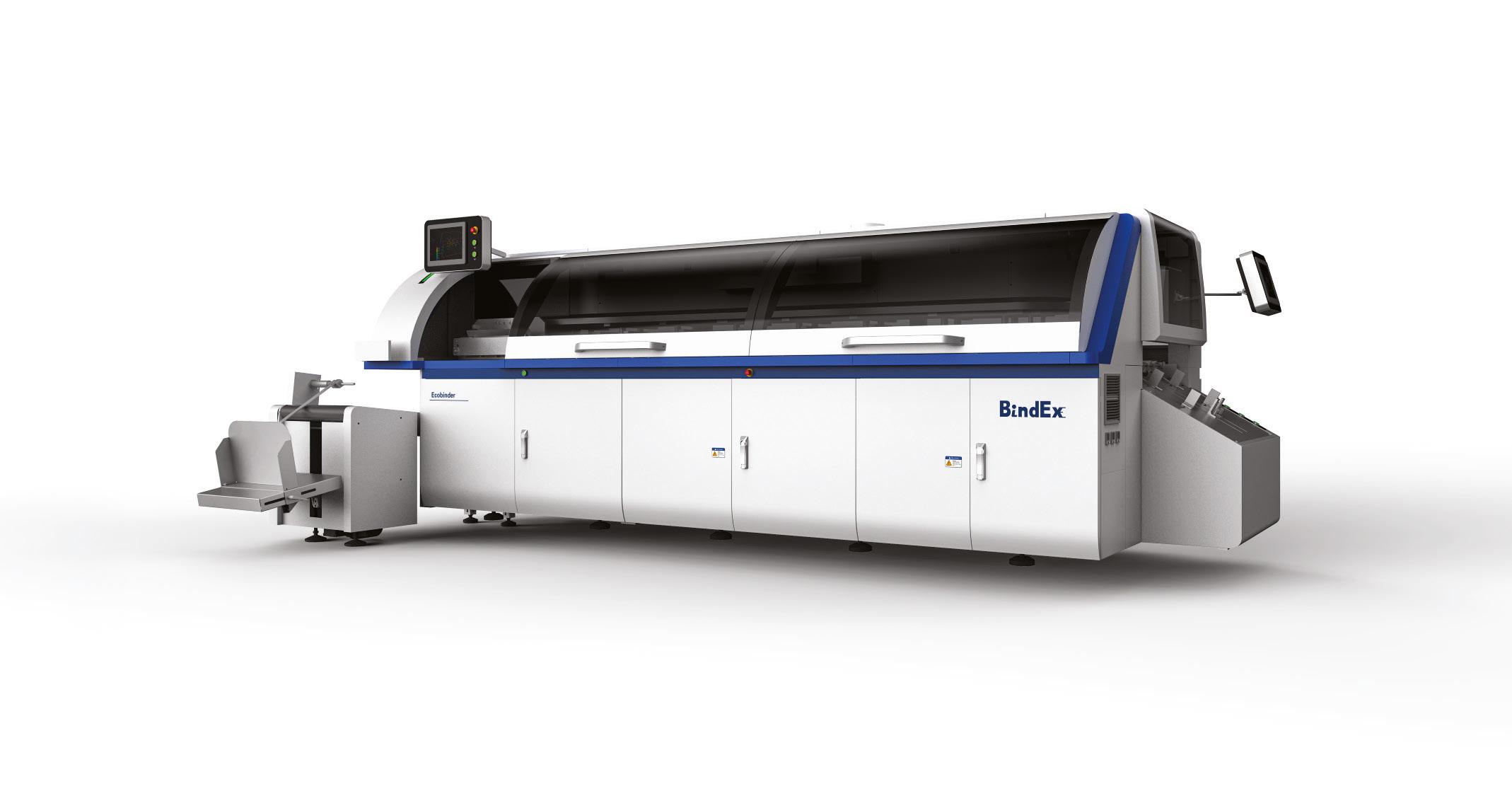

Charters Paper invests in a Garant Maschinen Matador NXB with four-colour LINAFLEX NL inline printing to strengthen its paper packaging capabilities

Charters Paper, an Australian family-owned and operated business established in 1991, has made one of its biggest investments to date – the purchase and install of a Garant Maschinen Matador NXB machine with four-colour LINAFLEX NL inline printing, boosting its recentlydeveloped packaging arm.

The arrival of the machine in January 2024 has already enhanced the company’s packaging offerings, providing its customers with better quality products and more sustainable options.

Charters Paper specialises in the manufacture, storage, and distribution of plain and pre-printed thermal receipt paper rolls, ticketing, and associated products for the retail, banking, hospitality, gaming, entertainment, medical, and transport industries. It has an exclusive distribution

agreement with the world’s largest supplier, Graphic Controls, for its thermal TITO Tickets and is licensee across Asia Pacific for StickyPOS linerless labels.

Based in Melbourne and employing 25 staff, Charters Paper’s headquarters houses its manufacturing, sales, customer support, logistics, and finance teams.

Even though the company retains market leadership in this space, it made the decision to diversify and branch out into the food packaging space to tap into new areas of play.

In response to the surging demand for ecofriendly packaging, Charters Paper invested in its paper packaging capabilities in 2022, when it expanded into the production of flat paper bags and grease-proof sheets, resulting in its exclusive agreements with major suppliers for innovative paper-based packaging products.

“For over 30 years, Charters Paper has been a trusted provider of thermal paper solutions to Australia’s top companies,” Charters Paper CEO Michael Sfetkidis said.

“Expanding our expertise into sustainable paper packaging was a natural progression for the business as we have been in the paper and printing industry for a long time, allowing us to better serve our customers and the environment.

“Our focus was to diversify the business into food packaging, specifically the production of paper-based packaging products. Most recently, we also signed a distribution agreement for 100 per cent paper bubble wrap.”

According to Sfetkidis, when Charters Paper first acquired equipment for food packaging, it procured the work of some

well-known bakery brands, providing a strong foundation for its entry into the field.

“At the time, we were able to ‘piggyback’ on this deal for all other paper bag jobs. The bans on single-use plastic bags across Australia further catapulted our strategy into paper-based packaging products,” he said.

When the business began in the food packaging space, it was using secondhand equipment. However, the company soon found it needed to improve its automation to meet growing demands.

“The strategy was always to start off with second-hand equipment, build the business, and then get the best available machinery for production,” Sfetkidis said.

“We saw a big demand very quickly since our first entry into the food packaging area. The volume of work multiplied fast. There was a need locally for fast turnaround ink on paper and ink on bags. Since we have a relatively small team, the need for us to operate as efficiently as possible arose.”

As a result, it purchased a state-of-the-art Matador NXB flat and satchel paper bag machine, configured with four-colour LINAFLEX NL inline printing, from Garant Maschinen, a German leader in paperconverting technology.

Charters Paper purchased the equipment direct from Garant Maschinen, which is a member of the Windmöller & Hölscher (W&H) Group. The local W&H agents helped Charters Paper through the purchase and install process.

“We did some research when we attended Interpack 2023. We saw a handful of machines at the tradeshow, but the Matador NXB stood out for us and was our pick of the bunch. From there, we worked very closely with W&H Australia and its headquarters in Germany to get the machine into our premises,” Sfetkidis said.

The Garant Maschinen Matador NXB boasts impressive capabilities. It can produce a wide range of flat and side gusset paper bags at speeds of up to 1,200 bags per minute. It runs a standard size two square bag in a dual-web production method.

Additionally, the machine offers fourcolour printing, creating a one-stopshop for efficient, customised paper bag manufacturing.

Sfetkidis said this investment enhanced the company’s flexibility, enabling it to offer faster turnaround times, and reduced setup and production times.

“This investment empowers us to deliver exceptional quality paper bags with guaranteed supply and faster lead times. We’ve got much more capacity, and it enables us to do longer runs in a shorter time,” Sfetkidis said.

“This allows for more flexibility within the business, especially for any urgent orders or quick changeovers. It gives us

a wide range of bag sizes that we can manufacture, on a standard machine.

“Several existing clients have already benefited from the Matador’s capabilities, receiving high-quality, branded paper bags. They’ve provided us with feedback, saying they’re impressed by the fast turnaround times, the quality of the bag, and the print that’s being produced.”

The four-colour configuration was chosen as Charters Paper has always been a believer of inline printing. The company also owns two other machines that it uses to print inline for thermal rolls.

“With the four-colour option, we get several accommodations. A lot of work is twocolour, but we can now set up the other two units while it’s running for quicker changeovers. It also gives us an advantage over our competitors that are probably limited to one or two colours,” Sfetkidis said.

“We can also deliver solutions to the market quicker than people that are buying in from China, where they’ve got to wait for eight weeks minimum.”

One of the standout features of the Matador NXB for Sfetkidis is the flexo chamber blade system, which allows Charters Paper to better control the ink laid down, resulting in a much clearer image.

“This machine has given us more flexibility than we have ever had before. Because of that, our go-to-market offering is unique and unlike many others. It has set us apart from the pack,” Sfetkidis said.

Putting sustainability at the forefront

The acquisition of the Matador NXB aligns with Charters Paper’s ongoing commitment to develop its sustainable packaging solutions and caters to the growing demand for eco-conscious alternatives.

Charters Paper’s sustainability strategy includes a waste management program where it works with suppliers to remove plastic out of its supply chain. It has been FSC Certified since May 2011, has held Sustainable Green Print L1/303670 certification since 2012, and is a Supplier Ethical Data Exchange (Sedex), and an Australian Packaging Covenant (APCO) member.

“The majority of our stock is FSC Certified. Our grease-proof papers and packaging papers are PFAS free. And with our thermal rolls, we are the only converter in Australia that manufactures coreless rolls – we only use coreless or cardboard cores, which support our customers in meeting their sustainability targets as there is less wastage and it gives us a competitive edge,” Sfetkidis said.

“The Matador NXB supports our sustainability strategy in that it promotes the use of paper and the move from single-use plastic bags to paper bags. The future for us is to move to Hazard Analysis Critical Control Point (HACCP) certified and we’ll continue to invest in equipment for the production of fibre-based packaging or paper-based packaging.”

What’s next?

Charters Paper will continue its investment into Australian manufacturing, especially paper-based food packaging products. It will also continue to innovate through its global network of contacts and suppliers.

“We’re always looking forward to innovation. That has been on the Charters

Paper agenda for years. Despite being in a commodity-based business, we’ve always looked to add some specialty products, which we will continue to do in the coming years,” Sfetkidis said.

“We’re looking into products like selfopening satchel (SOS) paper bags with inline printing as there’s a market for that. There are also opportunities for digital printing for paper-based food wraps, which can be used for labels as well.

“In addition to that, our plans involve increasing our range of products – either through distribution deals with global companies or manufacturing them locally. We want to be first to market and offer the market flexibility for printed products, with fast turnarounds.”

More than 190 exhibitors participated in the recent Labelexpo Southeast Asia edition, showcasing their latest innovations that shape the industry’s future

Labelexpo Southeast Asia (SEA) recently took place in Bangkok, Thailand, welcoming visitors and exhibitors to its largest edition to date.

More than 190 suppliers were at the show, unveiling innovations poised to shape the future of the industry. Live presentations and valuable networking opportunities were also present.

Labelexpo Global Series managing director Jade Grace said, “We are incredibly proud to share that this year’s show has grown by 40 per cent. The ASEAN label and packaging printing market is experiencing rapid growth, driving demand for more automated and sustainable packaging solutions.

“This year’s theme, Where Strength and Innovation Meet, speaks to the very dynamic nature of this space as people form more partnerships, share thinking, and adopt technologies that shape the future of this industry.”

Thailand Convention and Exhibition Bureau (TCEB) director Duangdej Yuaikwarmdee said Labelexpo Southeast Asia brings together the brightest minds, cutting-edge technologies, and latest innovations of the labelling and packaging sectors.

“We are really proud that Thailand has been chosen as the home country for this year’s Labelexpo Southeast Asia exhibition,” he said.

“The exhibition platform is a great meeting space for buyers and exhibitors, and is a place where invaluable opportunities exist for knowledge sharing and partnerships.

“Apart from the exhibition, we can learn that Bangkok is not just a venue but a city that has the energy to provide creativity and bring together people within the same industry. We are proud to support an event like Labelexpo Southeast Asia as it generates economic value for Thailand and fosters good relations between international countries.”

Here are some of the highlights from the event:

A B Graphic (ABG) International business development manager Floriana Montella shared her expertise on ABG’s finishing solutions including the DigiLase 4.0 and DigiJet.

Montella identified the benefits of ABG’s DigiLase 4.0 technology, saying the fully automated die cutting system requires minimal operator intervention and is highly efficient.

She said the technology enables fully automated job changeover and simple pre-press set-up, can be integrated with any Management Information System (MIS), requires no make readies and saved jobs can be set up for automatic repeats, and includes an intuitive interface with integrated inspection area and no need for hard tooling.

“What we’re seeing is that customers in this region aren’t moving from

conventional to fully digital as they have traditional customers who want traditional die cutting and want to keep that side of business,” Montella said.

“However, more and more customers are investigating what they need if they do invest in the digital side of their business for short runs and quick make ready and turnarounds. With ABG, they can deliver on the best quality and delivery times.

“ABG’s DigiLase 4.0 technology has new automated features. This laser die cutting machine is tool-less. It uses a laser beam to die cut at different depths according to the thickness of the material.

“It can produce labels in individual pieces, sheets, and roll-to-roll, and the laser knows what shape to cut at every single job change, which happens in a few milliseconds. Therefore, the customer can do very short runs quickly and efficiently.”

The DigiJet technology supports DigiLase as it’s a digital embellishment with inkjet technology that can achieve very fine details and tactile effect without the use of any tooling.

DigiJet gives an inline or offline fully digital system, allowing for multiple processes in one pass, including spot varnishing, cold foiling and tactile screen effect on any size of print run, all with no tooling.

“This is something you would probably only reach with screen printing and conventional hot/cold foiling. But we can do this with new equipment that only requires a single consumable, which is varnish,” Montella said.

“This can be used as a glue for digital cold foiling and as a varnish that creates a raised effect. This is where ABG’s expertise comes in as we can do this type of effects with the highest accuracy of 0.15mm.”

ABG is distributed by Currie Group in A/NZ.

Brother and Domino showcase N730i press in ASEAN first

Brother and its subsidiary Domino took the wraps off the new N730i digital colour label press at Labelexpo Southeast Asia,

in an ASEAN first, delivering on high quality output, high speeds, and printing efficiency. Built on Domino’s latest Generation 7 inkjet technology, the N730i delivers on 1,200dpi print quality, combining precision with speed. This digital label press is equipped with Brother’s BITSTAR printhead, ensuring exceptional print quality at the standard operating mode of up to 70m/min across all colours, including high-opacity white.

It is upgradable to the high-speed productivity mode, supercharging printing to a maximum speed of 90m/min – boosting productivity by 28 per cent.

Brother commercial Thailand digital printing senior business development executive Vuthilert Kanjanaharitai said the digital press enables businesses to streamline their production processes, reduce waste, and meet the evolving demands of their customers with precision and reliability.

“The upgraded N730i high-speed productivity mode allows users to increase print speeds with no perceptible difference in print quality, compared to the standard operating mode. Users will see a 28 per cent boost in productivity, or reduce production time by 22 per cent, all while reducing ink usage by up to eight per cent,” he said.

“These benefits reduce the cost per label and enable more jobs to be completed per shift, allowing users to maximise their return on investment and meet the growing demands of the label printing industry.”

At the event, Brother and Domino also provided more information on several of its other machines including:

• The N610i digital label press: A 600dpi label press for printing self-adhesive labels. It can be configured as either reel-to-reel, with priming for greater substrate support, with in-line finishing, or as a full hybrid press integrated into any flexo press line.

• The X630i digital corrugated press: A single pass digital press that enables corrugated converters to develop short and medium-run market opportunities.

• The K600i Variable Data Printer: A 600dpi module that integrates into an existing web or sheet handling system for digital imprinting or can be in the format of a monochrome digital press.

• The N610i-R digital retrofit module: A compact solution that seamlessly integrates into existing analogue equipment.

• The K300 digital printer: A 600dpi high-resolution monochrome variable data printer for late-stage customisation including 2D coding.

Domino is distributed by GMS Pacific in A/NZ.

Durst shared with attendees how its Tau 340 RSC sets the benchmark in productivity and flexibility. With print speeds of up to 80m/min for the upgraded version, a native resolution of 1,200dpi by 1,200dpi and up to eight colour stations, the Tau 340 RSC enables customers to achieve flexo like productivity in a 24/7 environment.

It also can be also equipped with the revolutionary Durst Hawk Eye technology to automate print quality.

The 340 RSC is available in two variants – RSC E and RSCi. The RSC E is Durst’s high spec entry-level variant, while the RSCi is the industrial version that accommodates wider media and can be hybridised with OMET embellishment or finishing.

The RSCi version is available in printing widths of 338mm, 420mm or 510mm. The printer can be equipped with the Tau RSC UV inks or with the new Tau RSC LED inks. Applications for the machine include variable data, industrial, and speciality packaging.

Durst Oceania labels and flexible packaging sales manager Graham Blackall said, “We’re seeing major growth in the market now with hybrid machines. The market, from a consumer perspective, is starting to merge between analogue and digital, so a hybrid machine lets customers have the best of both worlds.

“Durst is focused on quality, reliability, innovation, and serviceability. The Tau 340 RSC’s hardware and software help customers organise their production workflows to be more efficient and cost effective. There’s a lot of potential for this machine in Thailand as the country is a high-volume and diverse market.”

Durst Asia business development head Bernard Sun said the company is expanding and growing in the ASEAN region, with more than 90 inkjet units installed across Asia.

“Our biggest Asian market is Korea – we have over 40 inkjet units installed in the country since 2013. We’re seeing growth

in other parts of Asia as well, including Thailand, Malaysia, and Taiwan. There’s also massive growth in A/NZ,” he said.

“Durst delivers on the entire ecosystem and we are manufacturing not just the technology but also inks and software. This allows customers to deliver a wide range of applications. That’s what we are trying to show this region and at this show.”

Flint Group focuses on narrow web inks with EkoCure F

Flint Group showcased its EkoCure F ink for narrow web flexo technology. EkoCure F is a UV LED curable flexo ink based on bio-renewable resin technology, with high press performance supporting industry sustainability initiatives.

It can be used in all UV flexographic print units – provided the ink is cured with UV LED lamps. EkoCure F can also be used with doctor blade as well as in a chambered doctor blade system.

UV LED curing is an alternate way to cure UV inks as compared to the traditional mercury-based lamps on UV presses.

Some of its properties include high colour strength and excellent mileage, good press stability, fine printability and high printing speed, as well as excellent adhesion to a variety of substrates.

It is suitable for a variety of applications including self-adhesive labels (coated and uncoated papers, BOPP, PE, PLA and other synthetic films), carton boards, tags, and shrink labels.

EkoCure is developed using specially selected raw materials that match the narrow and targeted wavelength area that is typical for UV LED lamp output. The main advantages include:

• Economical benefits – energy consumption will be significantly reduced; quality assuredness brings increased productivity and press uptime; manufacturing space is increased; UV LED lamps are nearly

maintenance free; no mercury bulb replacement and disposal costs; expanded capability to run heat sensitive materials with less heat management costs.

• Ecological benefits – energy will be saved; UV LED lamps are ozone and mercury free (improved worker and environmental safety).

Flint Group narrow web assistant technical sales manager Thammakorn Klaypong said some key benefits include lower energy costs, improved print results, higher quality labels, improved productivity, and faster press changeovers.

“It saves energy and operating costs of up to 40 per cent, lowers heat emissions, increases press uptime as no bulb replacement or reflector cleaning is needed, and saves printers time and money,” she said.

Jet Technologies makes Labelexpo Southeast Asia debut

Jet Technologies marked its first appearance at Labelexpo Southeast Asia, demonstrating the OMET iFlex and Jet iQ machinery on its stand.

“This is the first regional show, outside of the countries that we operate in, that we’ve exhibited at. It’s very exciting as we’re trying to grow in the Southeast Asian region,” Jet Technologies director Jack Malki said.

The OMET iFlex 370 was on the stand and running live demonstrations, showcasing its ease of use and capabilities. The 14m, 10-colour configuration machine is a narrow web printing press with maximum speed of 190 m/min and printing repeat from 5.5-inches to 18-inches.

The machine is dedicated to the label market as it can produce all kinds of labels, including wraparound and shrink labels using its specific Film Asset.

A prominent feature of the OMET iFlex 370 is its iLight and iVision technology, which when combined, drastically reduces set-up time and waste, as the operator needs only a

few seconds to adjust the mark by watching the image on the dedicated display. At the tradeshow, a demonstration of the machine showed a mere one-to-two-minute changeover for 10 flexo units and rapid rebooting after job changes, simplifying setup and boosting productivity.

The OMET iFlex 370 is distributed in A/NZ by Currie Group, while Jet Technologies distributes it in the Southeast Asian region.

Malki said, “I think Currie Group will agree that OMET is a wonderful partner that is at the forefront of technology”.

As for the Jet iQ machinery, Jet Technologies had the Jet iQ M370 finishing machine and the Jet iQ SRI450 on show. This newly launched range of finishing solutions for the label and packaging markets is designed and built in partnership with Polly Automatics.

Attendees got a chance to explore the Jet iQ M370 with Versatex Print Bar, delivering high-build varnish, digital foil, and spot varnish on even, uncoated papers. With two semi-rotary flexo units and semi-rotary die cutting, the Jet iQ M370 offers a versatile and powerful finishing solution for any digital press.

The Jet iQ SRI450 demonstrated its highspeed label inspection, slitting, and rewinding capabilities. With a dual rewinder system and speeds of up to 450m/min, this advanced machine promises precision, efficiency, and seamless label finishing.

“We are always complementing printing with finishing, and in A/NZ, we’ve had a big focus on the Jet iQ range in the last year and it has been very well received,” Malki said.

“We’re just trying to show clients what a modern print shop would look like –your printing, finishing, inspecting and rewinding, all with a minimum of people.”

Konica Minolta showcases AccurioLabel 400

opportunities and production cost savings and reduce waste due to lower setup and startup material requirements with its high productivity AccurioLabel 400 press.

The AccurioLabel 400 is Konica Minolta’s newest dry-toner digital label press, allowing customers to expand their businesses in the growing markets of digital label production and packaging.

The AccurioLabel 400 incorporates all of Konica Minolta’s technology, including the Intelligent Quality Optimiser (IQ-520) colour management functionality for real-time colour stability and registration control.

The new press features a fifth station for white toner to expand creative label applications, plus resolution equivalent to 3,600dpi by 2,400dpi, and many automated control features for highly productive label output.

Important new developments include extended job opportunities with press runs up to 3000m, improved productivity with super-fast print speeds of up to 40 m/min (CMYK) and up to 20 m/min with optional white.

It also includes further running cost reductions thanks to even more durable parts life, as well as enhanced print quality.

The AccurioLabel 400 is available in 4- and 5-colour options.

The press is capable of printing on a wide range of substrates, including PP and PET, with media thickness between 81 to 256 gsm.

“We go beyond simply offering production innovations and technologies. We focus on creating value and providing Konica Minolta’s original solutions that genuinely address our customers’ challenges and exactly solve their problems,” Konica Minolta Thailand production print senior digital press consultant Nitikorn Thongdang said.

“The AccurioLabel 400 reflects our commitment, as evidenced by the rapid global sales growth of the AccurioLabel digital label press.

“From its first worldwide installation in 2017 to the countdown towards our 2,000th unit sale in the near future, we aim for the AccurioLabel 400 to be a key driver for label and converter entrepreneurs in today’s highly competitive market, offering endless business value.”

During live demonstrations of the AccurioLabel 400, show visitors saw the high colour quality with outstanding

white toner in action, supporting perfect white label printing in a single pass.

The company also showcased user-friendly functions, including automatic quality adjustment and control, that eliminate the need for highly skilled labour, and imposition software for automated label placement on the print layout.

Kurz outlines sustainability agenda

With consumers driving the demand for sustainability, the focus on greener solutions is increasingly crucial to futureproof businesses in the global market. Kurz was one of several exhibitors outlining its sustainability agenda.

Emphasising recyclable, sustainable, and compostable decorative products under the theme “Design and Sustainability. Sharing one Future”, the company aimed to inspire the labels and package printing community at the tradeshow.

Kurz Thailand managing director Boonchai Laohateerapong said the game changer for Kurz’s metallisation decoration cold foil/transfer film technology is now the same surface finish on a 50 per cent thinner carrier.

What used to be 12 microns as an industry standard was reduced to 10 microns in Thailand two years ago. As of last year, it has been producing cold foils in six-micron thickness.

He said this results in reduced materials usage, which in turn reduces carbon footprints. In addition, it weighs less, which enables easier handling. It also allows for the production of longer reels, meaning less changeovers are necessary.

“Kurz has been improving on its sustainability over the years and continues to do so. We don’t only think about the end product but also about the process. Our technology has developed, and we are proud of what we have achieved so far,” he said.

“Our customers are now looking for more sustainable solutions. Going green and reducing carbon footprints are leading

conversations, so we want to educate customers that Kurz is the first to make PET cold foil films at six microns.

“Customers can be confident that they’re using the latest, superior technology from Kurz in regard to the sustainability of materials. Customers that are already using the slimmer cold foils are happy with its performance.”

Kurz was also showcasing the capabilities of the DM-Uniliner 3D at the tradeshow. The machine is a spot coating, relief varnishing, and metallisation all in one operation machine, applied with digital technology.

The machine’s inkjet on substrate technology offers flexibility for the embellishment process, allowing for flat and haptic effects ranging from four to 100 microns.

Designs can be metallised either before or after CMYK printing. With a print resolution of 600dpi, the DM-Uniliner 3D ensures quality metallisation and varnishing, resulting in excellent surfaces and intricate structures, suitable for both thin and thick layers.

Moreover, the digital metallisation can be over-varnished and protected using digital UV spot varnish.

XSYS displays ThermoFlexX 30

XSYS showcased its ThermoFlexX 30 (TFxX 30) technology, designed for the narrow and medium web segment, targeting label printers who want an independent and efficient plate imaging solution.

Key benefits of the TFxX 30 include:

• Maximum plate size: 635mm x 762mm

• Steel back letterpress plates supported via optional Hybrid (vacuum/magnetic) drum

• Compact, single-footprint design suitable for tight spaces, with built-in air supply and filtered dust extraction

• Operates on standard single-phase electrical mains

• Offers multiple resolutions: 2400, 2540, 4000, 4800, or 5080dpi with automatic resolution switching

• High-resolution imaging up to 10,160dpi for security print applications

• Waste-reducing Vacuum Slider Concept (VSC)

• Easy, tapeless plate loading for any plate width

XSYS Asia Pacific vice-president Roy Schoettle said the machine is a seamless fit to any workflow.

“This machine is perfect for label printing as it handles small formats, which is the industry standard. It’s also versatile enough for other applications, such as letterpress, dry-offset, and direct engraving plates with the optional hybrid drum,” he said.

User-friendliness and high efficiency are priorities at XSYS to make workflows more productive and user operations easier.

XSYS prepress general manager Steven Vandevoorde emphasised the TFxX 30’s smart integration and usercentric design.

“The ease of integration comes not only from the compact form factor but also from the seamless integration into existing workflows. TFxX imagers support industry standard file formats and interfaces, avoiding proprietary constraints and ensuring compatibility with virtually all established workflow solutions,” he said.

“The system also operates at very high speeds – up to 3m² per hour – with exceptional resolution and quality.

“The machine is Industry 4.0 compliant, with an API module that connects the device to a customer’s MIS system. But we’re already thinking ahead – Industry 5.0 brings AI into the connectivity equation.”

Schoettle also noted the importance of serviceability and uptime.

“What’s great about this machine is that it allows for remote servicing via Catena ProServX, and troubleshooting as well. This is not only for the TFxX 30, but for all of XSYS’ equipment,” he said.

ProServX is a cloud-based, real time equipment monitoring tool designed to offer input for data driven decision making, proactive maintenance, ultimate quality follow-up and MIS/ERP connectivity.

Hybrid Software Southeast Asia technical sales manager Alan Tan was also present at the XSYS booth.

XSYS partners with Hybrid Software primarily to ensure seamless integration of its equipment and software within the Hybrid Software Cloudflow workflow, enhancing both ease of use and output quality.

From this year, Labelexpo Europe will be expanded to include folding carton technology. Andy Thomas-Emans, strategic director at Informa Markets’ labels & packaging group, explains how Labelexpo is evolving to include new categories

Labelexpo Europe 2025, held in Barcelona from 16-19 September, will now include folding carton technology alongside labels and flexible packaging.

This looks like a big change for the show, but in fact is more of a natural evolution based on inline and digital technologies which look set to disrupt the traditional folding carton industry in much the same way they did with flexible packaging.

As part of this move, Labelexpo has announced a strategic partnership with Brunton Business Publications, publisher of ‘industry bible’ Folding Carton Industry magazine. Folding Carton Industry has a comprehensive website ThePackagingPortal. This partnership will allow Labelexpo to communicate directly with the folding carton industry and brings on board the industry expertise of its managing director, Dan Brunton.

Labelexpo has constantly adapted to new package printing technologies. The early Labelexpo shows, starting in 1980 in Brussels, focused on what was then the new technology of self-adhesive labels converted inline on narrow web presses. As labels expanded into new formats, such as shrink sleeves, wraparound and in-mold labels, Labelexpo adapted to showcase these technologies.

The next big evolution for Labelexpo was the addition of flexible packaging, which happened around a decade ago with the launch of the 30-inch wide HP Indigo 20000 Digital Press.

Flexo press manufacturers then developed wider ‘mid-web’ presses in the 26-30-inch range better adapted to handling these larger packaging formats.

Label converters who diversified into flexible packaging – typically stand-up pouches – found this opened up new market opportunities which strengthened their label businesses. We are now seeing a similar convergence of print technologies between labels and folding cartons with the potential to open up new markets for label converters and other market disruptors.

Folding cartons are today overwhelmingly printed on sheetfed presses followed by further off-line operations such as creasing and die-cutting, hot stamping and embossing. These multiple process steps add to lead time and create a lot of work-inprogress (WIP) as pallets are moved between workstations. The technologies which could revolutionise this traditional workflow are core Labelexpo technologies: inline flexo and rotary offset, digital and hybrid.

Labelexpo could speed the adoption of digital printing for folding cartons, just as it did for labels and flexible packaging. The addition of folding cartons to Labelexpo is also likely to galvanise developments in short-run converting systems and digital embellishment.

We should also not forget that by far the biggest volumes of wet glue labels and in-mold labels are printed on sheetfed offset presses. One result of bringing folding cartons into Labelexpo will be an increased focus on the high levels of

automation on these presses as well as new in-line coating and foiling systems.

As well as overlapping print technologies, there are wider themes which unite labels, flexible packaging and folding carton converters at Labelexpo.

Sustainability is a key one, driven by the EU’s looming PPWR initiative. Labelexpo Europe 2025 will examine these trends at a feature area on the show floor, with daily presentations and interactive exhibits.

Automation is another common theme. Labelexpo exhibitors are already demonstrating process automation software and robotics systems, particularly focused on end-of-line material handling. The addition of folding cartons will no doubt expand this area of the show.

What might persuade a folding carton converter to visit Labelexpo? I suspect the same reasons flexible packaging converters now visit the show: a general interest in visiting co-suppliers; and a general interest in new print and decorative technologies.

Also, with the entry of Private Equity finance into the packaging sector we are seeing more big groups which include labels, flexible packaging and folding carton operations.

This is reflected in a growing visitor interest in both flexible packaging and folding cartons. At Labelexpo Europe 2023 over 25 per cent of visitors registered an interest in folding carton technology and 40 per cent in flexible packaging. This demonstrates that Labelexpo has transformed into a package printing show, albeit with labels at its core.

Labelexpo Europe 2025 will take place in Barcelona from 16-19 September 2025.

Andy Thomas-Emans is the strategic director at Informa Markets’ labels & packaging group.

Nearly 1,300 members gathered at Dscoop Edge Long Beach for a three-day event spotlighting the power of connection, idea sharing and innovation

Dscoop Edge Long Beach recently took place in California, bringing together nearly 1,300 members of the Dscoop global community, where they converged for three days of learning and connecting. This year, the flagship event, centered around powerful ideasharing within the Dscoop global community, celebrated its 20th year.

Dscoop is one of the largest digital print communities in the world, now comprised of about 22,000 HP Industrial and HP Large Format users and partners across 96 countries including Australia and New Zealand.

In Long Beach, as the event’s theme depicted, they confronted the industry’s “next waves” – major forces like AI and economic trends that will crash into businesses left unprepared, while uplifting others with incredible momentum.

“For two decades, HP and the Dscoop Edge community have been driving the transformation of digital print – raising the bar for quality, versatility, productivity, cost efficiency, and sustainability,” HP Industrial Print senior vice-president and division president Haim Levit said at the event.

“This year at Dscoop we celebrate that legacy and embark on a new journey – one in which AI will revolutionise the world of

print as we know it today – opening a new era where presses become autonomous and workflows are connected, automated, and orchestrated from creation to delivery.”

Australasian printers’ representation

A cohort of 18 print professionals from Australia and New Zealand, including staff from HP Indigo A/NZ distributor Currie Group, attended Dscoop Edge Long Beach, joining like-minded innovators at the event.

The trip was more than just a conference experience – the group embarked on a curated program of exclusive site visits to several high-performing Californian print businesses, gaining invaluable insights into the latest technologies, workflows, and business models shaping the future of print. These tours complemented the immersive Dscoop agenda.

The event also marked a proud milestone for the Australasian print community, with Kelvin Gage – an industry leader and longtime Dscoop advocate – being elected as global chairman of the Dscoop Global Board.

The energy, collaboration, and inspiration that came from the Long Beach experience left a lasting impression on all who attended. The A/NZ delegates returned home with fresh ideas, strengthened global connections, and a renewed

sense of momentum to help drive their businesses – and the broader regional print community – forward.

Currie Group labels and packaging A/NZ director Mark Daws said, “Dscoop Edge is always an inspiring experience, bringing together like-minded professionals from across the globe.

“It was fantastic to see so many of our A/NZ customers making the journey, connecting with peers and learning from the best. The site visits to high-performing print businesses really reinforced how technology and collaboration are shaping the future of our industry.

“We should be proud of the level of quality and automation we’re achieving here in Australia and New Zealand, as it truly stands out on the world stage.”

Rawson Print & Packaging managing director Andrew Price said, “It has been eight years since my last Dscoop in 2017 – this was my third Dscoop – having previously attended in 2010 (Dallas), 2017 (Phoenix), and now Long Beach.

“Dscoop is a fantastic experience, not just for connecting with like-minded professionals from across the print industry, but for the opportunity to collaborate with peers globally. We’re often facing similar

challenges, and it’s incredibly valuable to share ideas and solutions.

“I was eager to see what’s new in the industry and what opportunities we could leverage. I was also keen to explore the latest advancements in HP Indigo technology. My most valuable takeaway was the use of AI in the printing industry –particularly how it can help streamline and enhance both operational workflows and the sales and quoting process.”

Onpack managing director Michael Nankervis said, “This was my first Dscoop event. For anyone considering Dscoop for the first time, I’d describe it as a unique opportunity to gain practical insights, build meaningful relationships, and see what’s possible with new technology – all in one place.

“My motivation for attending this year was to stay ahead of industry trends and connect with peers and partners who are shaping the future of print and packaging. The most valuable takeaway from Dscoop Edge Long Beach was seeing firsthand the latest advancements in digital print technology, including AI for the industry, and how global operators are leveraging them to deliver more agile, efficient solutions for customers.”

Photo Create general manager Peter Barr said, “I’ve attended about 10 Dscoops. We find the people, content, and conversations deliver benefits (both short-term and long-term) for our business. If you attend, be open with others, and keep an open mind, you are almost guaranteed to unearth benefits that improve your business. Some improvements may be transformational.

“I found the conversations around AI crucial. AI is here and we need to start

using it. Just starting ‘somewhere’ with a curious mind is the best place to start.”

Peacock Group executive director Andrew Crump, who attended his eighth Dscoop event, said, “The industry is in a constant state of evolution, and Dscoop provides an ideal platform to gain clarity on how to navigate those shifts – particularly in responding to societal trends and generational change. It’s a strategically insightful event that ensures your business remains progressive, adaptive, and wellpositioned for future growth.

“The level of collaboration and openness at Dscoop is unmatched, and it’s always energising to exchange ideas with people who are equally passionate about the future of our industry.

“The most valuable takeaway for me was the rapid advancement in AI and its increasing relevance within our industry. It’s clear that AI is set to transform many aspects of print and packaging from automation and workflow optimisation to customer engagement, and staying ahead of these developments is critical to remaining competitive.”

Colemans Darwin CEO and chief experience officer Magdaline Coleman said, “I’ve attended several Dscoop events across APJ and the US. Each one

brings a different theme and unique energy. This year, I was especially motivated by the opportunity to attend site visits and gain fresh insights.

“Dscoop also offered a great chance to reconnect with our existing software and hardware suppliers, while exploring new technologies and engaging with new brands. I also appreciated the opportunity to connect, in-person, with leaders in the industry.

“The value of attending Dscoop truly depends on what you’re willing to contribute. If you’re open to sharing your own insights – your personal tips, habits, and ways of working – you’ll find that the return is exponential.

This year’s event showed how creativity, sustainability, and technology, especially AI and connected workflows, are converging to redefine what it means to be a print company. It’s no longer just about the output, but about the value we create the speed we deliver, and most importantly, how we make our customers feel while using the technology.

“It also became clear that even though we’re running family businesses grounded in strong values, we operate like elite sports teams – success comes from having well-trained key players, the best equipment, systems of play, and a culture of taking care of one another.”

The AI advancements that sparked attendees’ attention include:

HP Nio

Powered by HP’s PrintOS, HP Nio empowers businesses with data-driven intelligence to maximise printing resources, drive productivity, and unlock new avenues for growth.

HP Nio is a new chatbot that allows customers to ask questions about their print operations. It connects directly with HP PrintOS to deliver real-time data, production insights, and on-demand knowledge, all in one place.

By using tools like Print Beat and the Knowledge Zone, HP Nio provides expert, print-specific guidance. Soon, it will also

integrate with other HP PrintOS apps like HP Site Flow to support workflow automation and suggest smart, actionable next steps.

Ultimately, HP Nio will act as an intelligent co-creator, enhancing the PrintOS experience and helping automate the entire print workflow from start to finish.

AI inside HP Indigo presses

Introduced at drupa for HP Indigo presses, HP’s AI-enabled solutions –including Automatic Alert Agent (AAA 2.0), Print Mode Preflight, and PQ Maestro –were showcased in an end-to-end intelligent print workflow at Dscoop Edge Long Beach.

These innovations are estimated to be commercially available in July and are becoming core assets of HP Indigo’s AI technology, helping customers significantly increase print efficiency.

Enhanced features across HP PrintOS and HP Site Flow

HP has further enhanced the HP PrintOS Creativity Power Pack with new features in HP SmartStream Designer, including support for Adobe CC2025, integration of Amazon Transparency codes, and the addition of Bria.ai capabilities for generating AI images within variable data projects, allowing for the creation of highly personalised and scalable campaigns.

HP Quality Power Pack is also available for HP Indigo 120K and HP Indigo 18K Digital Presses enabling printers and converters to achieve colour industry standards in minutes – fully automated, with zero human touch points to increase press uptime.

New features in HP Site Flow will also help printers and converters efficiently track orders, for a more agile workflow including the ability to:

• Get data on reprint jobs with flagged items table

• Automate complex workflows with custom production plans

• Connect 100+ carriers in a matter of days with ShipStation API Integration

• Gain access to advanced intelligent picking and warehouse management capabilities by integrating with Mintsoft.

HP has improved HP Brand Centre, the platform designed to speed up on-boarding and improve order tracking, by connecting brands to printers and converters efficiently. The solution enhances the overall efficiency to

manage and share the brand’s product catalogue, simplifying their onboarding process to a few days, and allowing users to manage invoicing, production, and service agreements in one place.

At Dscoop Edge Long Beach, HP welcomed four new brands to the intelligent HP Brand Centre platform – Zazzle, Minted, Printerpix and Mixam.

HP also announced the launch of HP Business Centre, providing customers with enhanced finance management capabilities empowering customers to make informed decisions and to optimise their operations.

The new solution enhances the HP PrintOS ecosystem with features including online supplies lifespan score monitoring, impressions performance tracking and comprehensive invoice tracking – driving efficiency and automation for organisations to deliver smarter printer operations.

At Dscoop Edge Long Beach, HP also demonstrated full production lines powered by the HP Indigo 120K and HP Indigo 18K HD Digital Presses, showcasing the wide versatility and productivity. These presses, with their AI-based solutions, were released at drupa, and aim to redefine the shift from analogue to digital printing.