Canon Colorado and Arizona complement Currie Group’s Wide Format Portfolio.

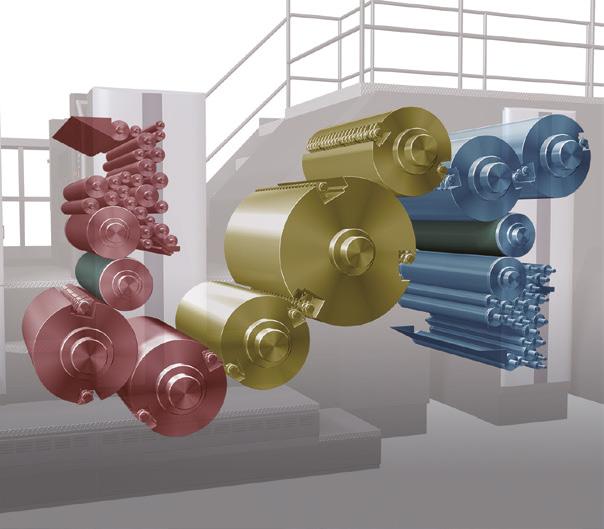

Currie Group has strengthened its partnership with Canon Production Printing, now supplying the Canon Colorado and Arizona wide format platforms in New Zealand.

Backed by Currie Group’s trusted nationwide service and support, the Canon wide format range will be delivered with the same confidence and commitment customers have come to expect. Craig Paul, Country Manager for Currie Group New Zealand, says, “This is exciting news for the local printing and sign and display sector. The awardwinning Canon Arizona and Colorado platforms deliver incredible results and, together with Currie Group’s proven service and support team, will empower our customers to thrive in their business.”

Currie Group has taken care to avoid “doubling up” when introducing new solutions to its extensive range of print technology. It has made it clear that adding Canon Arizona and Colorado technology to its wide format portfolio complements the solutions it already supplies without competing with them.

Paul Whitehead, Currie Group Business Unit Manager – Sign & Display, says, “This announcement rounds out Currie Group’s comprehensive sign and display portfolio.

It means we have a printer for every business in the sign and display market.

“For us, it is about delivering the best solutions and service that suit our customers, so we offer a diverse range of wide format technology ranging from smaller wide format options and roll to roll to super wide format solutions, hybrids and flatbeds; as well as our Elitron cutting systems.

For example, the Canon Colorado platform is unlike any of the other wide format printers Currie Group supplies, so we can confidently promote it separately from our other solutions.”

Since its inception in 2007, the Arizona has become the world’s largest selling flatbed printer. Whitehead points to a number of reasons for the Arizona’s ongoing popularity, which include:

High image quality: The Arizona series delivers exceptional image quality, making it suitable for demanding applications.

Versatility: It can print on a wide range of rigid and flexible media, allowing businesses to take on diverse projects.

UV curing technology: The UV curing process ensures durable and vibrant prints.

Scalability: The Arizona series offers various configurations, including different table sizes and ink channel options, allowing businesses to scale their production as needed.

Reliability and user-friendliness: Arizona owners attest to its robust architecture, reliability, and user-friendly design.

Continual development: The Arizona has continued to develop through its lifecycle, including recent innovations such as FLOW Technology which improves media handling and PRISMAelevateXL that allows customers to produce textured prints up to 4mm in height.

Recently, Canon brought the Arizona’s warranty into line with the Colorado warranty, The Arizona range of flatbed printers now come with a two-year manufacturer’s warranty as standard, providing customers with additional peace of mind and reinforcing Canon’s confidence in the reliability of its technology.

Canon’s UVgel technology

In 2017, the world first saw UVgel technology in use in the first Colorado printer, the 1640. Six years later, Canon introduced the Colorado M-series, which also uses UVgel technology.

Offering instant drying with LED lights, robust print quality with gloss and matte finishes, and stretchable ink that prevents cracking, UVgel technology, combines the advantages of traditional ink technologies while eliminating many of their limitations. The ink is essentially a gel, developed according to UV curing principles. The UVgel process has three distinct advantages:

Prevents coalescence: The solidified state of the pinned gel dot prevents coalescence, or merging, between

individual ink drops, delivering optimal control over the dot to prevent spread.

Smoother images: Because LED curing is performed later than with existing technologies, images have a more uniform, smoother surface.

Instant drying: Prints are instantly dry, requiring no evaporative drying process.

Colorado’s rapid rise

Since its introduction March 2023, the Canon Colorado M-series has helped

Currie Group customers take their business to new heights. The Colorado M-series offers a range of innovations and some key advantages over its competition.

These include:

Fully modular: You can upgrade the Colorado as your needs change. Infield upgradability means you can opt for white ink with just a service visit.

White ink without worry: The UVgel white ink is up to three times faster than comparable technology. And it requires no maintenance or printhead treatment.

Low operating cost: Includes automated roll feeding; easily refillable ink; an advanced highly automated new maintenance system; as well as reduced ink and energy usage.

Application range: Print in matte, gloss, or mixed matte/gloss. Create textured, transparent, coloured, and reflective media, and produce a range of output including self-adhesive vinyl and banners. Canon Prismaguide XL software supports the easy preparation of many multilayer print jobs such as underflood, overflood, and three or five layer print jobs.

Improved sustainability: Reduce energy consumption with the low-heat, energy-efficient LED curing system

and instant-on operation. Print on environmentally-friendly materials and use up to 40 per cent less ink.

Certification: Several certifications guarantee print quality including the 3M MCS Warranty, Avery Dennison ICS Warranty, and Greenguard Gold certification for safe indoor use in the most sensitive environments.

Recently Canon introduced enhancements to the Colorado portfolio. For the growing soft signage segment market, Canon has made the process of loading rolls of textiles into the Colorado much easier, reducing loading time from 10-15 minutes down to approximately three minutes. New software guides operators through the media loading,

Across the Tasman, Currie Group’s partnership with Canon Production Printing has enabled Aussie print and sign companies to benefit from the distinctive capabilities that the Arizona and Colorado platforms provide.

Since joining forces as a Canon Production Printing partner in September 2023, Currie Group has rapidly risen to become one of the top-performing partners globally.

Last year, Currie Group was named the top performing Canon Colorado partner in the Asia-Pacific region and seventh globally. The recognition came from Canon Production Printing headquarters, which annually celebrates its leading partners driving success with the Colorado Series. Year-to-date, Currie Group is leading the global partner leaderboard.

This achievement reflects the company’s dedication to delivering innovative print solutions and its commitment to helping customers maximise the benefits of Canon’s UVgel technology. Rob Mesaros, chief executive officer of Currie Group, said, “We are incredibly proud to receive this recognition from Canon Production Printing.

“This achievement is a testament to the strength of our partnership with Canon, the power of the Colorado M-series, and the dedication of our team in delivering best in class solutions to our customers. The

ensuring textiles are perfectly flat and properly positioned, preventing damage to either the printer or the media and improving the quality of the final output.

Two new print modes of Matte Density (two layers) and Backlit High Density (three layers), specifically designed for soft signage applications, enable printing in multiple ink layers. Canon says this delivers superior results for backlit applications such as silicon edge graphics widely used in retail environments.

Significantly expanding the range of materials for interior décor and wall covering applications, Colorado M-series customers can now print on roll to roll media up to 1.6mm thick; double the thickness previously printable.

demand for high quality, efficient and versatile print technology continues to grow, and we are excited to help more businesses unlock the benefits of UVgel.”

Canon Production Printing acknowledged Currie Group’s efforts in championing the Colorado M-series, highlighting their expertise in identifying ideal customer applications, showcasing the technology through demonstration facilities, and providing outstanding customer service. Craig Nethercott, managing director, Canon Production Printing Australia said, “Currie Group’s achievement is a clear indication of what is possible when the right technology aligns with the right partner. Their understanding of customer needs, combined with a proactive approach to showcasing the Colorado M-series and the advantages of UVgel technology, has made a positive impact here in Australia.

“This success is well deserved and highlights how effective collaboration can drive market adoption of technology.”

“Currie Group’s continued success underscores the power of the Colorado M-series.”

Paul Whitehead adds, “The response from our customers to the Colorado M-series has been exceptional. The modular design, productivity, and UVgel ink technology offer unmatched versatility and reliability. Our team has worked hard to demonstrate how this technology can transform print businesses, and this award reinforces our commitment to delivering real value to our customers. Currie Group is helping to set new benchmarks for excellence within the print industry.”

An updated Magnetic Media Kit, enabling the Colorado M-series to print on stronger magnetic media for car magnets, for example, is also available.

The Input/Output interface, another new enhancement specific to the Colorado’s UVgel Factory configurations, links the printer with inline finishing equipment and enables unattended printing by automatically stopping production if an issue arises with either the printer or the finishing equipment. This interface helps to meet tight production deadlines with fewer interruptions and can help prevent a substantial waste of valuable media.

Whitehead says, “These latest enhancements enable us to offer customers a high quality and highproductivity wide format printer of even greater value. For example, our customers can now enter the high-growth soft signage market while improving overall productivity and uptime.

He concludes, “The Arizona and Colorado platforms deliver exceptional value through a combination of quality, productivity, application versatility, operational efficiency and sustainability.”

Currie Group is inviting print professionals to the New Zealand Colorado Open House Event, which it will host at its Auckland Demonstration Centre.

The two-day event, running from August 27-28, culminating with an evening event on Thursday August 28 for customers and suppliers.

Craig Paul says, “Australian print and sign companies have benefited greatly from the advantages that UVgel technology provides. Now it is New Zealand’s turn.

“We are excited to demonstrate the capabilities of the Colorado M-series to Kiwi print and signage professionals. We will have our technical specialists available for specific appointment times on both days.

“To book your appointment visit: www.events.curriegroup.com.au We look forward to welcoming you to our showrooms and demonstrating these outstanding solutions.”

3-5 Currie Group: Strengthening its partnership with Canon Production Printing, Currie Group now supplies, and provides its exceptional service and support for, the Canon Colorado and Arizona wide format platforms in New Zealand.

12-13 Helping Hand: Steve and Natalia Morait have purchased Dash Design and Print, reports Iain MacIntyre.

14 Comment: Ruth Cobb says our workplace trainers put in the time, effort, and heart to help apprentices and trainees grow.

7 Heidelberg: Marking its 175th anniversary, Heidelberg hosted more than 1,500 guests from across the globe.

16 Konica Minolta: Automatic Quality Adjustment (AQA) is changing digital production printing.

18 Epson: Also celebrating an anniversary, Epson clocks up 50 years of innovation and success.

23 Printerverse: Meaningful messaging matters in marketing, says Deb Corn.

20 & 22 Fujifilm: Broderick Print has installed a Fujifilm Acuity Prime 30 printer with some impressive results.

24 Aarque Group: Epson solutions, supplied thoruugh Aarque Group, cater to sign, display graphics, fashion, promotional and label markets.

26 CCG: You are invited to attend the CCG Open House in Albany, Auckland on August 14.

28 Durst: Cactus Imaging is the first printer in the Southern Hemisphere to offer Durst Haptprint 3D technology.

30 & 32 Computaleta: Sign City has invested in Summa and HP technology to future-proof its business.

33 NZSDA Update: Mikayla Hopkins reports on the latest NZSDA happenings.

34 NZSDA President: Logan Sutton files his first post as our new NZSDA president.

35-48 NZSDA Awards: Whakatu Nelson welcomed NZSDA members for the 2025 Sign Display Awards of Excellence

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS: Ruth Cobb, Deb corn, Mikayla Hopkins, Iain MacIntyre, Logan Sutton

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE: Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz © Copyright 2025: Contents

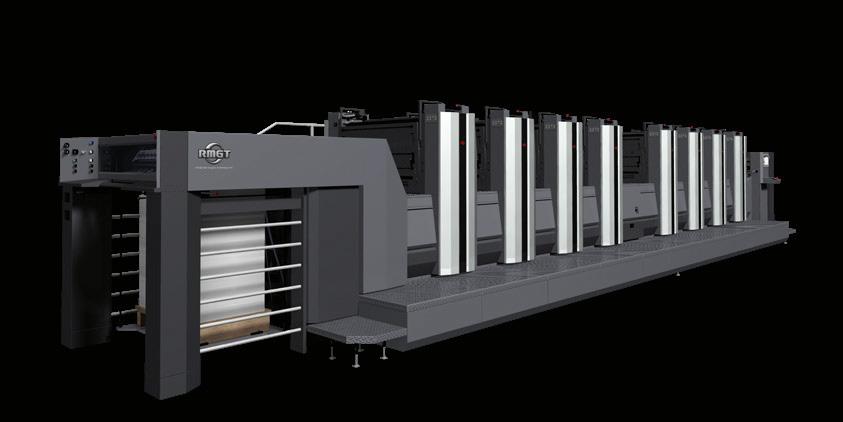

Offset press giant shows off its Print Media Centre in Germany.

Heidelberg marked its 175th anniversary with a week of celebrations at the company’s Wiesloch-Walldorf site in Germany, drawing more than 1,500 guests from all over the world.

The giant press manufacturer took the opportunity to show off its Print Media Centre. Greeting customers, suppliers, partners, politicians, and visitors, Jürgen Otto, chief executive officer of Heidelberg, said, “A warm welcome to Heidelberg and a warm welcome to our ‘Home of Print’, the printing industry’s largest customer experience centre anywhere in the world. We have now been the Home of Print for 175 years!”

Rebranded as the ‘Home of Print’, the redesigned Print Media Centre tracks the company’s growth strategy for its core business and presents future-proof and specific solutions that will appeal to all relevant target groups.

Heidelberg has made various end to end production systems available for customer presentations in collaboration with partners such as Polar and MK Masterwork. These include high quality folding carton production with

the Speedmaster series; high volume folding carton printing with the new Boardmaster flexographic web printing system; industrial label production using offset, digital, and flexographic printing; commercial printing; as well as hybrid print production using digital and offset.

The company has incorporated its entire portfolio into a single digital ecosystem comprising Prinect software, equipment including postpress solutions, robotics, consumables, service, training, and consulting.

In its data lab, Heidelberg offers a number of case studies to demonstrate how the company can harness its data expertise and use data analyses to help customers with their requirements and business model – when it comes to solving problems, integrating process steps, or boosting their performance, for instance.

Dr. David Schmedding, chief technology and sales officer at Heidelberg, said, “Our Home of Print reflects our growth strategy for our core business, which showcases Heidelberg as a collaborative total solution provider and end-to-end systems integrator for packaging and commercial printing.”

At the celebrations, Heidelberg unveiled the Cartonmaster CX 145 press for the very large format (105cm × 145cm, VLF, format class 6 . The company says focusing in particular on high volume folding carton production in the growing food, beverage, and consumer packaging segment, sees this system plugging a gap in the company’s portfolio.

The Print Media Centre will also showcase the Mastermatrix CSB 106 in the Heidelberg design. This high end diecutter presented at drupa 2024 operates at a speed of 9,000 sheets per hour. The company is incorporating the two new machines into the Prinect control software and will also interact with other components as part of a highly efficient end to end system.

Heidelberg calls the redesigned Print Media Centre ‘The Home of Print’. It covers an area of 9,000 square metres.

Each year, some 1,000 personalised presentations take place, with customers usually bringing along their own print jobs so they can thoroughly evaluate the machines based on their specific requirements. Heidelberg has 120 of its experts on hand to share their technical expertise and comprehensive application know how, offering advice and support from the initial preparations through to the follow up meeting after the presentations.

The company also organises open house events for German and international customers. These events focus on the key industry trends in packaging, label, and commercial printing.

In addition, Heidelberg provides around 100 guided tours of the Print Media Centre every year for visitors from brand manufacturers, schools, universities, and related sectors of industry. The Heidelberg service team receives regular training sessions.

Besides the Print Media Centre at the Wiesloch-Walldorf site, the company also operates a global network of customer demonstration centres in the USA, China, Japan, Indonesia, and Switzerland.

LANDA DIGITAL PRINTING is looking for new financial partners after it filed for court protection following its shareholders’ announcement that they would immediately stop financing the company. In a statement, the company attributed the situation to several factors, including “the geopolitical situation, as a result of the long war in Israel and regional instability, as well as commercial reasons, have made it difficult for the company, and the shareholders intend to stop financing the company immediately”.

EPS has partnered with carbon calculation specialist CarbonQuota to embed CarbonQuota’s automated carbon calculator into ePS’s software printing and packaging. The companies say this will drive sustainable production through verifiable accurate data and a new approach to scoring sustainability. Dominic Harris, co-founder of CarbonQuota, says, “Carbon footprints have become the universal metric for corporate sustainability. Our technology provides the most granular, trustworthy data needed to substantiate and accelerate organisations’ environmental goals.”

EPSON has unveiled its Direct to Shape Printing System, an inkjet printing solution for printing directly on 3D objects. The system combines Epson S800 PrecisionCore printheads with an Epson industrial robot. The S800 allows printing on complex shapes such as grooves and curves. The process uses a six-axis robot and lifting mechanisms to independently raise and lower the printheads to allow the system to print on objects from different angles with “outstanding quality and accuracy”.

The Christchurch Printing industry turned out in force recently for the Full Colour Trust Quiz Night.

BJ Ball sponsored the evening, which also received support from PrintNZ and many other print companies and suppliers in the Canterbury region. The Full Colour Trust raises funds to enable it to assist people from the local print and

Plockmatic Group has signed an agreement to acquire Renz, a producer of ring wire comb binding machines and supplies headquartered in Heubach, Germany.

The deal enables Plockmatic Group to enter the ring wire binding segment, which it sees as a natural complement to its existing offerings. Plockmatic Group also sees significant synergies with Renz within key areas such as sales, production, sourcing and research and development. It has an ambition to broaden its geographic footprint and

advertising industry when needed. The quiz night raised almost $2000 through entry fees and raffles. Many of the print companies and suppliers supplied prizes for the raffles.

Spectrum Print claimed first prize and bragging rights as top quizzers on the night.

Since its inception in 2006, the Full Colour Trust has assisted many people from the industry in Canterbury. It has raised funds through several

develop the next generation of automated professional ring wire comb binding equipment for calendar and book production.

Jan Marstorp, chief executive officer at Plockmatic group, says, “The acquisition of Renz will be a great opportunity for Plockmatic Group, where we see several opportunities and synergies between our organisations, and to further expand our value proposition as solution provider to our customers.

“With Renz becoming a part of Plockmatic Group, we will also get a strong and local sales organisation in Germany, which we have identified as an important growth market for Plockmatic Group going forward.”

Founded in 1908, Renz

functions organized by the trustees and PrintNZ. This includes the PrintNZ Charity Golf Day, where any profit is donated to the trust; Laser Strike evenings; Movie Nights and nights at the Court Theatre; as well as the successful quiz nights held annually.

The trustees include people from the industry plus an independent accountant. The trust does not have any overheads as it is all volunteer work, so all the funds raised are given back to people from the industry who apply for funding when no other funding is available.

The key function of the trust is to assist people to stay in work or to help them get back to work. The trust appreciates the assistance of suppliers and print companies in the area for support and assistance.

has clients in more than 80 countries. Its offerings include development and production of ring wire binding machines for the professional and office segments, as well as in-house production of premium quality wire binding consumables.

Michael Schubert, chief executive of Renz, says, “Becoming part of Plockmatic Group and finding a long-term solution for Renz, following some very challenging years, make us look at the future with confidence again.

“With the insolvency proceedings behind us and access to Plockmatic Group’s resources we will now be able to invest in new products and continue longterm partnerships with our customers and suppliers.”

The Flexible Packaging and Label Manufacturers Association (FPLMA) Forum and Gala Ball will take place in Melbourne next month.

The event, set down for August 21-22 at the Melbourne Exhibition and Convention Centre has a theme ‘Adaptation and Innovation’. Tony Dalleore, secretary at FPLMA, says, “We welcome labels, packaging, and printing professionals

Visual Connections has announced that a Visual Impact Conference & Expo will take place from September 2-4, 2026, at the Sydney Showgrounds.

Organisers say the reimagined event promises a new concept, new vision and new opportunities for exhibitors and visitors alike. Karren Challoner-Miles, executive general manager of Visual Connections, says organisers pushed the show back from its traditional May

from New Zealand to the event.

“We are thrilled to announce that the conference will have over 17 speakers, with eight coming from overseas.

timeslot to avoid clashes with the global shows which are typically held mid-year.

Since joining the supplier association late last year, she has made her intention clear to review and assess all the association’s activities and initiatives to ensure they align closely with the needs and values of both Visual Connections members and the wider industry.

She says, “Industry businesses are facing a raft of challenges. It is hard to get away from the workplace; time is tight, and money tighter. Yet it is imperative for business owners to keep pace with technological changes, evolving trends and new market opportunities if they want to build success and stay ahead of their competition.

“On the supplier side, marketing budgets are as tight as ever, and trade shows take a real commitment in terms of stand builds, staff allocations and

This will be one of the region’s biggest conferences dedicated to the industry.

“It presents a real opportunity to gain insights from thought leaders and industry innovators. You can discover the trends shaping the industry’s future. There is also the chance to network with other industry professionals.

“On August 22, we will present the 2025 FPLMA Awards at the Gala Dinner. These awards celebrate excellence in the packaging industry, spotlighting exceptional creativity, innovation, and technical prowess.

“The awards evening is spectacular and entertaining, a real highlight.

“Visit our website fplma.org.au to find out more. We look forward to seeing you there.”

promotion. As show organisers, we need to make sure that our exhibitors can maximise the value of every square metre of space, and every moment they spend on stand.

“In short, the onus is on us to deliver trade shows which are sharper, more focused and more valuable than ever before, and we are embracing that challenge in 2026.”

Organisers expect Visual Impact 2026 to draw some 4,000 visitors. They say it will feature exciting new initiatives. They add that the co-located Conference will enhance the value for visitors by bringing together leading experts, visionaries and thought leaders to provide vital information and insights on economic conditions, industry trends, business leadership and the big issues which can impact the market and create new challenges and opportunities.

Alexandra-based print company retains tradition of printing in the deep south.

Confident that print will remain a much valued commodity into the future and that their region needs large offset capability, Steve and Natalia Morait recently made the life-changing decision to purchase Alexandra-based Dash Design and Print (formerly known as ODT Print).

Having himself managed the now eightperson business for 30 years and with his wife also serving as graphic designer for over a decade, Steve says the couple were motivated when the opportunity came to acquire the firm late last year. He says, “In a nutshell, we believe the company wasn’t going anywhere unless it had investment put into it. Someone had to do it, and I think we owed it to the loyal staff that we’ve had to make a crack at it.

“We were fortunate enough that Fujifilm Business Innovation offered us a trip to drupa 2024 where we met, talked and got

feedback from other printers from around New Zealand and the world. It was just an amazing trip. When we returned, Natalia said, ‘We should put an offer in and try to buy the place’.”

Their strong belief in the future of print proved a fundamental driver for Steve and Natalia to make this, their first business purchase. Steve says, “I talk to a lot of people, and they don’t like reading from tablets or they get sick of using their phones. Sometimes you just want to pick up a bit of paper and read it. You want to be able to pick up and put down a book as you go along.

“I think the likes of magazines will always be around. We still print lots of brochures and people do paper diaries and notebooks all the time. We were told years ago that would all be gone, but for example, when the Covid-19 pandemic hit, people decided to write their memoirs

and family histories, and we ended up doing huge amounts of book work.”

The opportunity for the firm to service large offset work which otherwise would be headed out of the region, provided a key motivator. He explains, “No-one else has any A1 machines in Otago and Southland anymore. Dunedin doesn’t have any large printing presses at all; the biggest would be A3 digital. Southern Colour was the last company to have a large offset printing press in Dunedin.

“There is still a market for big printing gear down here, otherwise, all that work goes to Christchurch, Wellington or Auckland. It is a real shame for it to be sent out of the area.”

To reinvigorate the business and best position itself in the marketplace, they have invested in a range of new, upgraded equipment, including a Ryobi A1 LED UV

four-colour press; a Fujifilm Revoria Press PC1120; an A1 CTP platemaker; a large folder and an eight-station collator/stitcher.

Steve says, “We bought the business off Allied Press along with the stock and plant and basically, we’ve just gone through and updated just about most of it.

“Our main A2 offset machine was 20 years old. It was a great press and there was nothing wrong with it but with the new press, we can see the difference in the quality of the print, sharpness of the UV inks, the drying time and we don’t have any offset spray in the building anymore. With a lot of our jobs being A1, we also just do it twice as fast.

“I don’t think this company would have been around now in this form if Natalia and I hadn’t invested in it. We would just end up being another digital printing company and, while there is nothing wrong with that, there are just lots of them doing the same thing.

“There is still more machinery we need to upgrade, and we don’t want to have all our eggs in the one basket, just mainly relying on the big press. I mean, as soon as the four-colour turned up, Natalia said ‘make sure we make room for the eight-colour!’”

“We are looking forward to the future and hopefully putting ourselves in good stead.”

The company has also invested in new ePS Pace productivity software. Steve says, “This will see everyone equipped with a tablet and able to input all

information on each job as they go along, culminating in them taking a photo as it is despatched which will lead to an invoice being generated to the client and so forth.”

Dash’s capabilities range from short run, high quality digital printing and printing of high volume, multi-coloured laser forms right through to specialised, complex books and brochures.

Core services include offset printing; digital printing; graphic design; finishing and binding; and promotional products via Dash Promotions.

Steve says, “Because a lot of the smaller printing companies have decided not to invest in the big equipment, we do quite a bit of printing for them as well. This even entails export work. We probably ship two to three tonnes to an Australian printer each week.”

He considers the business’s team ethos one of its richest strengths. He says, “I literally can’t remember when the last person actually started. They have been here so long. We are like a family, and everyone just gets on and does their own thing.

“Though equally, we don’t have anyone who can only do the one thing. For example, people in the bindery can run the A1 press and vice-versa. Everyone has or is training so they can cover other jobs as necessary. Because we only have a staff of eight, everyone has to be able to cover for each other’s job.”

As well as cementing itself in its existing markets, Dash has ambitions to widen its offering. He adds, “The big press is still being fully commissioned, and we don’t know all its capabilities as yet. As mentioned, we hope to win a lot of the work that is usually going north now. It would be nice if work generated in our region stayed here.”

Does Steve have advice to other print business owners? He quips, “You should probably ask me that in a year’s time. There’s a lot to learn with buying equipment and bringing it in from overseas, that I’ve never done before. I would already do some things differently now, possibly borrowing more money to buy more equipment.”

He concludes, “It is like anything: you take a risk, and it will either work or it won’t. Often it just purely comes down to basic hard work and a wee bit of luck.”

Iain Macintyre

ODT Print has its origins in the gold rush days of the 1860s, when the Stevens family founded The Dunstan Times and The Alexandra Herald. Central Otago News formed in 1948, managed by Geoff Stevens. The commercial printing division began as an offshoot of the newspaper with the printing of local programmes, tickets, and small booklets as the main fare.

The commercial printing division growth made it necessary to separate it from the newspaper and it became ODT Print in 1999.

In 1975, two of the country’s oldest newspapers The Otago Daily Times and The Evening Star, merged to form Allied Press, which previously owned ODT Print. Allied Press operates newspapers, television stations, and printing operations, employing over 400 staff.

In November 2024, Steve Morait and Natalia Morait purchased ODT Print and subsequently renamed the business Dash Print and Design.

When we talk about industry training, much of the focus falls on apprentices – and rightly so. They are the future of our industries, bringing fresh energy, new ideas and a commitment to learning. However, behind every successful apprentice stands someone who quietly puts in the time, effort, and heart to help them grow: the workplace trainer.

These individuals are the unsung heroes of industry training. Seldom in the spotlight, they rarely seek recognition. But ask any qualified apprentice who helped shape their journey, and you’ll hear about the supervisor who showed them the ropes; the colleague who explained things again and again; or the mentor who believed in them when they didn’t yet believe in themselves.

Workplace trainers take on a responsibility that goes far beyond overseeing someone’s daily tasks. They are mentors, teachers, cheerleaders, and sometimes counsellors. None of them have the stand-alone title of workplace trainer. They are all doing this in addition to their own jobs, balancing their own workload while ensuring the trainee is learning, understanding the job, working with the team, and staying on target.

Their knowledge doesn’t come from a textbook. It is built from years of handson experience, problem solving, and real-

world application. Most of the workplace trainers in our businesses have been apprentices themselves and know that it takes more than just technical expertise to train someone. They must have the ability to be relatable, patient, empathetic (but firm), and to know when to step back and let someone try, fail, learn, and try again, all without judgment.

For many businesses, the quality of their training programmes, and the future of their workforce, hinges on the strength of these workplace trainers. They are the ones that can create the environment that ensures a trainee stays and grows. They can be the difference between someone completing a qualification and someone giving up part way.

Their impact is enormous and that is why it’s so important for employers to recognise and support their workplace trainers, not just with a thank you, but with time, resources, and professional development.

Ironically, many of them step into the role without any training about how to transition from the trainee to the trainer. Giving them the tools to train effectively is an investment in the entire business. It improves staff retention, builds team capability, and ensures the knowledge and values of the company are passed on. Courses like Train the Trainer and Team Leadership can help further unlock their own potential.

Print, Packaging and Sign have an 83 per cent completion rate for workplace training, the highest of any of the 36 industries managed by Competenz, who deliver our workplace training. Without our trainers that rate wouldn’t be anywhere near that. They lead by example and help their trainees develop skills they didn’t know they had in them.

They may not seek the spotlight, but workplace trainers certainly deserve it. So, this year, at our training graduations, we provided medals not just to the trainees that had graduated, but to their workplace trainers, in recognition of the role they played in getting the trainees to completion.

While we recognise the finalists and present an Award to the Trainer of the Year at the Pride In Print Awards each year, this was the first time we have acknowledged all workplace trainers and the work they have put in above and beyond to see their trainees succeed.

Every apprentice that earns their qualification, every new worker who finds their confidence, and every business that builds future capability, owes a great deal to the workplace trainer who helped make it happen.

This is our shout-out to these unsung heroes. Ruth Cobb

Konica Minolta has developed technology for performing maintenance and remote diagnosis to identify signs of defects in printed image quality.

Stating a clear objective to redefine print excellence with its latest AccurioPress printers, Konica Minolta has committed massive resources to research and development. One of the results of its efforts is Auto Quality Adjustment (AQA).

Chris O’Hara, national production and industrial print manager at Konica Minolta New Zealand, says, “AQA solves issues with image defects and that is important because it can increase uptime. For commercial applications, when quality defects force print companies to suspend printing operations, there are consequences downstream with loss of production hurting the bottom line.

“Having the latest bells and whistles is one thing, but consistency and reliability matter much more in printing. AQA addresses a major issue for print companies using digital solutions.”

To quickly solve problems with image quality, a key concern for its customers, Konica Minolta has developed a system called Auto Quality Adjustment (AQA) which combines an image diagnosis technology and an automatic restoration function.

Chris says, “This system regularly monitors the state of images and locates the causes of image defects, enabling presses to restore image quality. Furthermore, by remotely monitoring the diagnosis results and detecting signs of problems, print companies can optimise their own maintenance work, helping to

maintain the quality of printed matter and maximising the operating time of presses.”

Konica Minolta’s printed image quality diagnosis system automates the isolation of image problems, which conventionally customers have performed.

It prints and scans charts for measuring the quality of printed images, and quantitatively evaluates image noise inherent in presses, such as streaks, spots, stains, and uneven density.

Chris says, “Importantly, this system makes AI link quantitative evaluation results of image noises with image problems occurring on presses, and it learns from them. This means that presses can locate those parts that are causing problems through self-diagnosis.

“We believe that AQA, realised by combining AI for image diagnosis, will completely change the shape of after sales services in the printing industry. It is already saving time and money for businesses using this technology.”

Part of Konica Minolta’s solution for the issue of inconsistent image quality involved using technology to quantitatively evaluate printed image quality based on image analysis and statistical model.

Chis comments, “The digitisation and quantitative evaluation of the state of images

of presses has been an issue in performing maintenance at appropriate timing.

“Konica Minolta studied this issue, using a statistical model to analyse the relationship between the image features extracted by image analysis from the scanned images of printed evaluation charts for measuring image quality and the visual evaluation values of images, and developed a technology that can quantify the degree of image noise. With this technology, which accurately mimics the visual characteristics of the human eye, we can remotely monitor the state of images of presses.

“The next stage is the diagnosis of parts requiring maintenance by using the results of quantitatively evaluating printed image quality.”

Predictive maintenance a reality

Konica Minolta has developed a technology that locates parts causing image problems and requiring maintenance from image features analysed by the IQ-501 (Intelligent Quality Optimiser) and data on the operating state of the press.

Chris says, “This technology uses a classification model based on machine learning to learn the relationship between the results of quantitatively evaluating printed image quality and past image problems based on data collected from many presses operating in the market.

“By combining this image diagnosis technology with the abovementioned image state monitoring, our system enables print companies to perform predictive maintenance promptly before customers suffer image defects.”

Konica Minolta is working on expanding the range of target parts. Chris adds, “If you have any questions about AQA please contact us for a consultation. We look forward to talking with you about how AQA can help to keep your digital print production pumping.”

MINOLTA

More profitable business through a press that works smarter, not harder, with the AccurioPress C7100 series. You serve more customers and complete more jobs with innovative technologies that power your success.

Find out more at k konicaminolta.co.nz/C7100

Giving Shape to Ideas

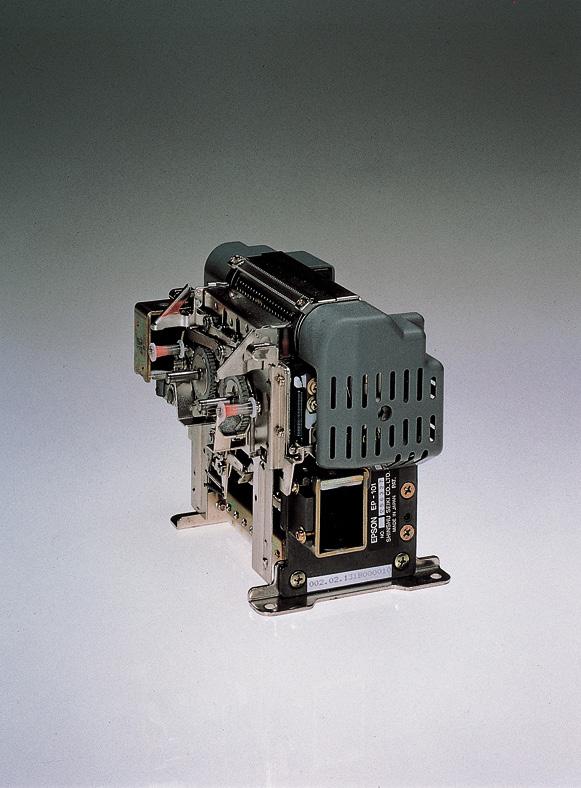

Digital pioneer looks back on half a century of success.

Epson has celebrated its 50th anniversary, marking decades of innovation and success as a brand.

Tracing its roots back to 1942 and the watchmaking industry, Epson says it has “continued to advance the efficient, compact and precise technologies first developed for watches, which have become a part of the DNA that has been passed down from generation to generation”.

The company adds that it has leveraged these core technologies and adhered to the founding principles of ‘Integrity and Effort’ and ‘Creativity and Challenge’ to innovate and create innumerable products and abundant value.

Company sales have expanded along with its sales network, which spans the world. Epson’s network of manufacturing sites and service and support organisations has also expanded globally.

Son of EP

In 1968, Seiko Epson launched its first information equipment product, the compact and lightweight EP-101 digital electronic printer. In 1975, this printer served as the impetus for the creation of the Epson brand. The brand name reflects the company’s hopes of preserving the value of the electronic printer (“EP”) while continuing to create many valuable derivatives (“SON”) – thus EP + SON = EPSON.

In 1969, with the goal of providing more accurate timepieces, Epson developed the world’s first commercial quartz watch. In 1982, it introduced a TV watch. And in 1988 the company developed a self-winding quartz watch that generated its own power and never needed battery replacement.

In 1975, Epson launched the MP-80, a compact and lightweight computer printer. The MP-80 was the first printer to come standard equipped with ESC/P, a printer control language created by Epson that would later become the industry’s de facto standard.

Epson’s first projector was the VPJ-700, a compact full-colour LCD video projector released in 1989. It followed this in 1994 with the ELP-3000, which delivered

triple the brightness of conventional models despite its portable, compact, and lightweight design. These projectors, coupled with a PC, became widely used in business.

Since its founding, the company has worked to enhance production efficiency by streamlining design and promoting automation. In response to the emergence of high-mix, low volume production in the early 1980s, it independently developed and designed industrial SCARA robots that serve as the core of a flexible production system.

After entering wide format printer market for professional graphic applications in 2000, Epson launched the Monna Lisa 160B, a digital textile printing machine in 2003. It offered the capability to produce a variety of products in small quantities with low waste and small environmental footprint, as well as rendering photographic details on fabrics.

In 2010, as production shifted toward short run print jobs and product life cycles shortened in industries such as food, beverages, and cosmetics, Epson launched the SurePress series of digital label presses to meet the diverse printing needs of the commercial and industrial sectors.

Also in 2010, Epson developed and launched the EcoTank series, printers equipped with high-capacity ink tanks. These high-capacity ink tank printers currently sell in 170 countries and regions around the world, and cumulative sales have surpassed 100 million units.

Micro Piezo technology has continued to evolve, with Epson developing next generation printhead technology called PrecisionCore. This has made it possible to develop a wide range of products, not only for the home and office but also for commercial and industrial applications.

For offices, Epson deploys PrecisionCore technology in high-speed linehead inkjet multifunction devices, delivering up to 100 pages per minute. Epson says that blazing speed, outstanding durability, excellent maintainability, and the unequalled energy-efficiency of inkjet systems make them a compelling replacement for office laser printers.

In 2016, with further miniaturisation of the optical engine and improved cooling performance, Epson launched a highlumen laser projector, the EB-L25000U. This projector boasted 25,000 lumens of brightness.

Today, the company and the Epson brand are recognised around the world for home printers, business printers, large format printers, projectors, and a wide range of other products. Epson says it has earned this recognition largely as a result of a staunch commitment to advancing the efficient, compact, and precise technologies that are an integral part of Epson’s DNA, and which contribute to a more sustainable future.

Epson adds that it will continue to take pride in its brand by living up to the corporate purpose: “Our philosophy of efficient, compact and precise innovation enriches lives and helps create a better world.”

North Shore print company welcomes advanced wide format printing technology.

Popular North Shore-based print company Broderick Print installed a Fujifilm Acuity Prime 30 wide format printer late last year.

Its compact footprint made an immediate impact. Grant Thorpe, general manager at Broderick Print, says, “We previously had the double bed Acuity, which took up a lot of room in our digital department. This new flatbed is very compact and fits the room far more suitably giving us more room for media handling around the machine.”

The Acuity Prime 30 hits speeds of up to 150 square metres per hour, offering a printable area of 2.5m x 1.27m on materials up to 51mm thick. Grant says, “We can turn around big jobs on the same day, if and when required. Due to the faster running speed of this machine,

we have doubled productivity, and the print quality is exceptional.

“It also gives us great colour vibrancy, colour consistency and accurate colour matching.”

Built from the ground up for improved print quality and productivity, the Acuity Prime 30 offers numerous innovations based on feedback that Fujifilm received from customers across the globe. Grant comments on some of the Acuity Prime 30’s major features:

“The introduction of the Media Registration Pins has, in essence, created a false lay edge, meaning it is much easier to get an accurate print position on the media. This is especially useful when

printing duplex sheets as it allows for a quicker and more accurate registration of the front and back image.

Vacuum zones

“A more varied and intuitive zoning system for the vacuum means that there is less time masking off for custom-sized media or sample prints, leading to higher productivity.”

“We opted for the five channel option (CMYK+White) as this was most suited to our requirements. The white ink has an increased opacity meaning that there is less need for multiple passes. The white ink allows us to print on a variety of substrates such as wood and

coloured stocks whilst still maintaining a vibrant and punchy four-colour image. Options above CMYK are white, clear and primer.”

Fujifilm Uvijet HM UV LED curable inks

“These inks have an increased adhesion level leading to a greater confidence in the longevity of the printed product particularly in the harsher New Zealand summer conditions. It also means that we can print on a wider range of substrates that would have previously needed a separate adhesion promoter applied prior to printing.”

Low energy LED curing system

“It is more economical in terms of run/power costs. Also, lower energy requirements leads to increased sustainability. That is better for the business and the planet.

“Lamps last for the duration of the machine, or up to 10,000 hours, so we no longer have the cost and waste of replacing the lamps every six months.”

Other features

Broderick Print is making the most of Acuity Prime 30’s advancements, which include a variable smoothing option and maintenance improvements.

Grant says, “The introduction of a variable smoothing option on the print has delivered amazing quality with less banding, sharper small type and smoother gradients. This gives us a greater control over the print quality depending on the end use and final product.

“Alongside the previously mentioned developments such as the media pins and vacuuming zones, the main way in which the Acuity Prime 30 is a noticeable improvement from our previous Acuity Advance is in the reduction of daily maintenance tasks.

“The Acuity Prime 30 includes an automatic head cleaning system which can be set to action periodically. This means that every few hours you can set the machine to do a full head flush and vacuum, thus preventing wasted production time from blocked heads. The heads generally are easier to maintain; one quick clean in the morning, and you are good to go.

“From an operator’s perspective, the greatest improvement is the automatic head adjustment/measurement. This enables me to automatically measure the thickness of the substrate at any point on the bed, which means that there is reduced risk of head strikes or scuffing on jobs. The new collision guards also mean

that if a strike does occur then the heads are not directly in contact with the media so there is less chance of costly damage. The height can also be adjusted on the fly/ mid print meaning there is less wastage due to variable stock thickness.”

Broderick Print has a reputation as a reliable long term partner with both its customers and suppliers. The company has partnered with Fujifilm for around 20 years.

Grant says, “They have good product knowledge, and they keep us updated with any new machines that might be of any interest to us.

“The service and training have been very good. They have checked up on us regularly and been on hand for any technical questions we have had.

“The Acuity Prime 30 is very user friendly, both in terms of software and hardware. As I had previously been running the Acuity Advance, the actual training needed was fairly minimal, approximately one afternoon.

“Fujifilm handled all the necessary training and technicians were on site throughout the transition period which made for a very smooth change over.

“Because the Acuity Prime 30 is significantly quicker per pass, our production rate has significantly increased without compromising on image quality.”

Broderick Print adapts and evolves

With a staff complement of only 10, Broderick Print completes an impressively

diverse range of print work for clients in various sectors, from design and print media to signage, packaging display, events, promotional, apparel and vehicle livery.

The company’s evolution from producing mainly commercial print to a business that serves the needs of multiple clients across multiple sectors is testament to its ability to adapt to an ever changing business and physical environment.

Grant says, “We have become a smaller outfit over the past few years. Several factors have contributed to this; the Covid-19 pandemic; severe flooding; some retirements; and a change of industry for some of our long-serving staff members.

“All our current staff are all multi skilled in all areas and have years of knowledge and experience in the print industry. We are all happy to roll up our sleeves and do whatever needs to be done, so we still meet clients’ deadlines without compromising quality.

“I still run jobs on the die cutting cylinder from time to time and jump on the guillotine when required. It is great to be able to help out in different areas. We all really do work as a team.”

Another major change for Broderick Print sees managing director Jonny Broderick making a major career change and moving into a different industry. He will retain his interest in the family-owned business but will leave its management to Grant and the team.

Grant says, “We are all excited for Jonny and have backed him 100 per cent in his new venture and we wish him all the very best.

“We have worked together for the past 24 years so it’s going to be different not seeing him every day. However, he will stay on the Board and keep up to date with what’s happening at Broderick Print.

“I will now oversee the day to day running of Broderick Print, nothing else will change, we will still hold the same high standards as we always have and continue our quality customer service.”

“Broderick Print still offers everything it has always offered, from offset to digital to signage; we do it all. We also do work for the trade.”

And what makes for a great week for the Broderick Print team? He says, “When we have a project that we are all working together on, once it is completed, we all feel a great sense of pride at what we have achieved as a team.

“We know that whatever challenges we come up against, we will rise to the occasion.”

The best marketing message is the one that resonates, drives results, and keeps print marketing customers coming back for more

We don’t need to talk to everybody; we need to talk to somebody – the right somebody.

Because in times of economic uncertainty, marketing and communication budgets are cut. Volume isn’t value. Reach isn’t results. And ‘spray and pray’ isn’t a strategy; it can be a waste of money and a results crapshoot.

Whether you’re a printer, a marketer, a brand, or wear all three hats, the name of the game is relevance. Relevance starts with knowing your audience and crafting messages that mean something to them.

Print marketing can break through the noise

Today’s consumers are surrounded by marketing messages every second of every day, and most messages are ignored as fast as they come in.

They fly past a screen when you scroll, get skipped, deleted, blocked, and relegated to spam in inboxes and texts, tossed in the trash from the mailbox, driven by on the highway… you get my point.

There is no reason to give meaningless messaging any attention. It’s not personal, timely, or relevant for the person receiving it.

According to McKinsey’s 2024 personalisation report, 71 per cent of consumers expect personalised

communication, and 76 per cent get frustrated when they don’t get it. That frustration leads to disengagement and lost opportunity.

People don’t want more content. They want content that speaks to them.

Email campaigns should make customers feel understood.

Direct mail should make them say, “This is for me”.

Relevant communication isn’t tied to a channel. It’s tied to a commitment to listen, learn, and respond with meaning. It’s about using every tool we have to communicate better.

It’s also about helping your customers maximise their return through data-driven print marketing and personalisation. Printing less and generating more results with targeted messaging at the right time is a winning strategy.

Here is an example:

A home improvement retail business can get a mailing list and send an offer for timber to every contractor within a reasonable driving distance and hope someone needs it at that time, or they can track purchase activity of contractors and send a relevant offer for items they need next when building a home.

With some basic knowledge of how long the construction process takes and the steps required, a contractor who bought a large amount of cement to lay a foundation will next need wood to frame the house.

Through customer communication and collaboration, printers and marketers can help the business get a relevant offer for wood, screws, nails, drills, saws, hammers, etc. into the hands of the contractor who needs these things for the next stage of the build.

Then comes the plumbing and electrical work, cabinets, and finishes. The print marketing and messaging plan writes itself with sales practically a given in this situation.

If you have customers with tight budgets and/or cutting back on print marketing spending until there is more stability with the global economy and supply chains, set up meetings and talk to them about a targeted messaging strategy.

Be prepared to talk about data collection and security, share case studies that show results from print marketing are improved with personalisation, and create a plan for reaching people before their decision making process.

Many businesses have this information, or they can figure it out, but they don’t know how to use it to create meaningful print marketing messaging and timely, relevant offers. Help them.

The best marketing message isn’t the one that reaches the most people. It’s the one that resonates, drives results, and keeps print marketing customers coming back for more.

Deborah Corn is the Intergalactic Ambassador to The Printerverse at Print Media Centr.

Aarque supplies a comprehensive range of Epson solutions which cater to sign, display graphics, fashion, promotional and label markets.

Unveiled at PacPrint 2025, the SureColor S7160 four-colour eco solvent printer incorporates advanced technologies such as Epson’s advanced 1.33-inch-wide PrecisionCore Micro TFP printhead, which facilitates faster printing and wider print width in a single pass, increasing the number of nozzles from 360 to 400.

Craig Harrison, national sales manager at Aarque Group, says, “A large four-colour UltraChrome GS3 800ml ink pouch system enables vibrant and accurate prints on a variety of media types, including vinyl, canvas, film, wallpaper, and other roll media up to 1626mm wide. Its 800ml ink bags reduce the frequency of ink replacement, while being 84 per cent lighter and generating 91 per cent less waste per bag than previous models.

“Built on a market-proven, robust chassis with an accurate media feed system, the printer also incorporates an air circulation system that removes ink mist, capturing it in filters. Its advanced auto tension control system and reinforced media feed roller deliver high precision media feeding.”

A printhead guard helps prevent media crashes while a new automatic head cleaning system ensures consistent performance.

The S7160 also has several other key functions including a carriage temperature sensor that quickly detects temperature differences, allowing for accurate temperature compensation to minimise colour variations. This feature maintains uniformity between the beginning and end of longer print jobs, compensating for changes in ink temperature and nozzle surfaces caused by the platen heater.

Its 4.3-inch user-oriented interface and touchpad allow operators to easily manage ink levels and other functions while its LED lighting feature improves visibility during printing operations, allowing easy status monitoring.

Also shown at PacPrint 2025, the SureColor S9160 is equipped with Epson’s latest user-replaceable 6.7cm PrecisionCore MicroTFP printhead, and features an integrated temperature sensor, nozzle verification technology and nozzle replacement. Craig says, “These advancements ensure reliable image quality and consistent colour output while significantly boosting productivity. This new PrecisionCore printhead makes the SC-S9160 a versatile and efficient choice for signage businesses of all sizes.”

The SC-S9160 utilises an advanced 11-colour ink set, including red, orange and an all-new green, as well as opaque white ink, which can be used on clear or dark substrates to add versatility and enhance colour. Craig adds, “This expanded ink set delivers a broad colour gamut and enables vibrant and accurate prints on a variety of media types, including vinyl, canvas, film, wallpaper and other roll media up to 1626 mm.

“Epson designed the S9160 printer with the user in mind. Its compact dimensions; flat-top and low profile design; as well as the clear top window ensure easy operation. The intuitive 4.3-inch tiltable

touchscreen offers more convenient operation with animated instructions to enhance the overall user experience.

The printer also features an advanced auto tension control system for highprecision media feeding and an included media lifter making media setup simple and easy.

In terms of eco-friendly innovation, around 30 per cent of the plastic used in its hardware is made from recycled materials; its UltraChrome GS3 eco-solvent inks used are low-VOC; and its 800ml and 1.5l ink bags reduce plastic waste.

Craig adds, “The 126cm SureColor S9160 delivers exceptional image quality; an expanded colour gamut; unparalleled productivity; and a compact, user friendly design

Both the SureColor S7160 and SureColor S9160 integrate with Epson Edge Print Pro RIP software and Epson Cloud Solution PORT. These tools offer comprehensive reporting, tracking and costing tools enabling businesses to streamline their operations.

Last year, Epson launched the Auto Table for the SD-10 spectrophotometer to make colour management easier and more reliable.

Craig says, “The Auto Table for the SD-10 spectrophotometer addresses and rebuffs the common perception that colour management is time consuming and requires high technical knowledge and skills.

“The SD-10 is an easy to use, full-featured colour measuring device that combines with the new Auto Table and Epson Edge Color Lite colour management software to offer a genuine colour management solution that addresses most colour management requirements and maximises print output quality.”

He adds, “Please contact us at Aarque for further information and demonstrations of our Epson range available in our Auckland showroom. We look forward to assisting you.”

E p s o n s ign a g e r a nge N o c om pr omis e s . The Epson SureColor signage range is built to meet the high demands of modern businesses with exceptional colour accuracy, job consistency and reliability. Equipped with advanced PrecisionCore printheads and a host of UltraChrome ink technologies – eco-solvent, resin and UV – these robust signage machines deliver vibrant, durable prints that hit the mark every time.

Learn more at www.epson.co.nz/signage

Invitation goes out for August 14 Open House in Albany.

Industry supplier CCG has put out an invitation for industry professionals to attend its Open House set for August 14 at the CCG showrooms in Tarndale Grove, Albany, Auckland.

Bryan Simpson, director at CCG, says the company is pleased with the advancements in the DTF technology that it supplies to the industry. He says, “There are two major factors: speed and quality. First, the speed of production has increased markedly. Second, the quality of the prints has also improved.

“Although the DTF garment process delivers photographic prints, an early issue that some end-customers had was the feel of the print on the garment. Some described it as a plasticky feel. However, with advances in technology, especially in relation to powders and film, the machines are producing garment prints that don’t have that plasticky feel. They have the feel closer to screen printed garments.

“At the Open House, we will have the latest software, nine colour ink systems, film and powder, and we will run demonstrations showing just how good the prints are.”

CCG supplies technology from DTF Station. Mark says, “Tony Lee, the owner of DTF Station, has accepted our invitation to the Open House. DTF Station is one of the biggest garment decorating digital

suppliers in the United States. Tony is not just a business owner. He is a hands-on garment printer who has a real interest in advancing the industry through innovative thinking as well as research and development. So we are really looking forward to his presence at the Open House.

DTF Station offers a range of printers from entry level to the advanced DTF Station Prestige XL4 60cm (24″) DTF Printer, which is the fastest and widest of its DTF printers.

Bryan says, “The Prestige XL4 has four Epson i1600 heads making it the ideal industrial level solution for customers who would like to lower the cost for their promotional business, have more options for their personalised business, and easier but better performance for their sign business.

“Another DTF Station printer you will see in operation at the Open House is the Prestige XL3 60cm CMYK & RGBO DTF printer, which also comes with NeoStampa Delta Software. It has three advanced Epson i3200 printheads that deliver stunningly vibrant prints with an expanded colour range thanks to the addition of Red, Green, Blue, and Orange inks. Designed for high demand environments, it offers maintenance

features like the White Ink Management System and automatic cleaning cycles, ensuring minimal downtime and maximum productivity.”

Once the graphic has made it onto the film, the next part of the DTF process involves placing powder on the film. Rhys Smith, account manager at CCG, explains, “The film then goes into the DTF Station Miro 36 DTF powder shaker and dryer. The powder is a glue adhesive that goes onto the film and then it undergoes drying until it resembles orange peel. This is the adhesive that will bond the film to the garment.

“The Miro 36 is built for easy setup, use, and maintenance. With a modular build and compact footprint, it fits easily into a production workflow. It is also easy to operate with a touch screen control panel, and its built-in purification system means you don’t need any extra equipment to run a safe workspace.

“The film is then ready for pressing on to the garment. We supply single, dual, four, and six station presses, depending on your needs. Once the film is pressed on the garment, the job is good to go.”

CCG also supplies DTF Station Arc 127 advanced roll to roll table cutter, the company’s first automatic roller cutting system. It has a maximum cutting width of 70cm and supports both sheet and roll cutting modes, with options for singleblade and dual-blade cutting.

Bryan says, “The DTF Station Arc 127 Advanced Roll to Roll Table Cutter is ideal for a wide range of materials, including DTF and UV DTF prints, it is a powerful tool for boosting productivity in DTF and UV DTF image production. Automation holds the key to improving productivity. The Arc 127 integrates seamlessly with DigiRIP RIP Software and DTF Station’s line of printers with a simple, userfriendly interface and an easy to use with intuitive control panel.

“We are excited to host the Open House and, we look forward to discussing the ways our solutions can take your garment printing to the next level.”

Innovative process delivers raised printing surfaces and simulated textures.

Sydney-based Cactus Imaging is the first printer in the Southern Hemisphere to offer Durst Haptprint 3D technology for its customers.

Durst Haptprint is a specific printing mode available on Durst P5 350 D4 high speed printers that delivers a printing process with up to 12 layers for raised printing surfaces and simulated textures, such as oil paintings, wallpaper and even brail.

Keith Ferrel, Cactus Imaging co-founder and general manager – operations, said, “We are excited to own the first Durst P5 350 D4 with varnish and white ink, which combined delivers the haptic 3D printing capability.

“What we can now offer our customers is something completely unique in terms of innovation. It is another opportunity for our high-end clients in sectors such as fashion, cosmetics as well as for artistic purposes as we can replicate the brushstrokes and texture of an oil painting for example.

“We can print with this new Haptprint technology on a multitude of substrates including PVC, Corflute, paper, alupanel, and even artist’s canvas and glass. We are experimenting all the time with this special option to investigate the opportunities it can deliver.

“The benefit of this investment in new technology is for our clients, so we can go

to them with opportunities that world first technology can deliver. We have always been known as innovators, and always been known as one of the first in the world to purchase new equipment that we know will be of immense benefit to our clients and enhance our client base.

“After we purchased the Durst P5 350 D4, we found out there was a new option available from Durst as an in-field upgrade to add the varnish and the white to an existing machine.

“We have now had the machine for 18 months, and we are pleased to able to offer this new feature to our customers. Our foresight knowing that this technology was coming to market is one of the reasons why we travel so frequently to these manufacturers and talk with them and understand what it is they are working on and how it can work for our clients base and enhance it.”

Matt Ashman, managing director of Durst Oceania, explained that the Haptprint technology is available with a specific configuration of both Durst hardware and software. He said, “To achieve this effect, Keith and the Cactus team have installed the white and varnish channels within the Durst P5 350 D4 machine as well as the Haptprint software which is part of the Durst software portfolio.

“With this configuration, the Cactus team can print with relief and texture as well as super high glossy prints. Cactus is also able to create ‘Lens-free Lenticular Printing’. Lenticular printing is a technology in which lenticular lenses are used to produce printed images with an illusion of depth, or the ability to change or move parts of the printed file as they are viewed from different angles.”

At drupa in 2024, Cactus Imaging confirmed it would undertake one of the largest Durst software implementation projects outside of North America. Matt said, “The installation of the Haptprint software and hardware at Cactus Imaging took place simultaneously as the global launch of this technology was demonstrated on the Durst booth during the FESPA Global Print Expo in Berlin this year.

“Durst is always associated with quality and speed, but the most important thing about the P5 is its versatility. Sometimes you need to be fast to be able to run a race and at other times you need to deliver a special job at high quality for special high value applications.

“This technology is part of Durst’s broader ‘Pixel to Output’ strategy that aims to deliver comprehensive solutions for printers including workflow, analytics, automation and the world’s best ink solutions, all ‘Made In Durst’ at the flagship HQ in Italy.”

How Sign City’s investment in Summa and HP Technology future-proofs its business.

For more than three decades, Sign City has been a trusted name in Auckland’s signage industry.

Now led by owner Mitch Keys, the business has undergone a transformation in recent years, expanding its capabilities through smart investment in production technology. With the addition of the Summa F Series 1612 flatbed cutter and the HP Latex R1000 printer, Sign City has eliminated outsourcing, improved turnaround times, and opened new doors for growth.

Mitch says, “We have always strived to be at the cutting edge to deliver quality signage products to the market. The Summa and HP platforms have not only improved what we can produce, but also how we operate as a business.”

Before installing the Summa F1612, Sign City relied heavily on manual, labour intensive finishing as well as outsourced cutting for more complex cutting of rigid substrates. Mitch explains, “We were manually finishing whatever we could in house and then outsourcing the more complex finishing jobs. This occasionally led to quality control issues, extended lead times, and added hassles transporting our jobs around risking damage and adding cost.

“Bringing in the Summa flatbed cutter has eliminated these pain points. With powerful tools like the oscillating knife and v-groove module, we can now prototype, test, and finish a range of materials in-house and on demand. This has not only reduced cost and risk but also improved workflow agility.

“We could not imagine now operating day to day without our F-series cutting table. Having a capable and reliable automated finishing workflow in house has changed the dynamic of our business and has only increased the responsiveness to our clients demands.”

Following the Summa investment, Sign City upgraded its ageing flatbed printer with the HP Latex R1000, a hybrid

Begin with cutting stickers, trimming wallpaper and graphics, then evolve to cutting and creasing packaging, cutting honeycomb boards for point of sale and even routing composite panels.

With an ever increasing arsenal of tools, the Summa F Series is designed to grow with your business.

Distributed by Computaleta 0800 505 600 help@clgroup.co.nz

platform that prints on both rigid and flexible media with water-based latex inks. This dual capability has become a core advantage.

Mitch says, “Every day we switch from rigid to roll and back again in minutes. It’s that easy. It’s effortless and simple, which matters in a versatile shop like ours.”

The HP Latex R1000 also introduced white ink printing for the first time in house at Sign City. He explains, “We used to shy away from white ink jobs or outsource at a margin loss. Now we can print beautiful white ink onto self adhesive films or rigid substrates such are acrylic or Kraft Reboard with ease.”

The HP Latex platform also brought in new capabilities that have added commercial value. Mitch says, “White ink printing is opening new doors for us. We can now go for jobs we wouldn’t have considered previously. Spot white, underflood, overflood. We’ve been really impressed with how quickly and cleanly it runs. Being able to load a white ink set on demand and print within a matter minutes is pretty incredible.”

Mitch also points to the benefits of HP’s water-based inks. He says, “The environmental credentials are a no brainer. More of our customers are demanding sustainable print solutions, and latex gives us a clear advantage. We’re winning business in retail and corporate spaces that prioritise sustainability. This demand will only continue to grow.”

The pairing of Summa and HP hardware is only half the story. The software powering

these machines has become equally crucial to Sign City’s success. Central to this is the Onyx Thrive RIP, which connects both devices with colour accuracy, speed, and automated workflows.

Mitch says, “We moved to Onyx when we installed the Summa, and that was great forward thinking from Computaleta. Summa has barcode-driven automation which appealed to fully utilise the cutter, and it laid the groundwork for integrating the HP Latex R Series later.”

Summa’s GoProduce software has been a standout for Mitch and his team. He says, “It’s easy to use for our operators with profiled materials and default tool settings. The Summa barcode workflow has improved our production and reduced spoilage and waste. Every job we print has a unique, automatically generated barcode at both ends of the job meaning we simply can’t load the wrong orientation or select the wrong cut data. It has really improved our operation and makes our finishing process very simple and reliable.”

The Summa’s ADC (Automatic Depth Control) and barcode-driven automation deliver exceptional cutting precision while optimising tool performance and machine safety. Mitch adds, “The system intelligently checks our tooling before each job, ensuring the correct tool and depth are set, so operators can proceed with total confidence.”

Mitch credits Computaleta not only for supplying the right hardware, but for delivering a complete solution. He says, “What stood out was the holistic

approach. Computaleta didn’t just sell us a machine; they helped us build a workflow that aligned with how we wanted to run our business.”

That partnership was put to the test early on when a hardware fault resulted in a damaged cutting belt. Computaleta stepped in quickly. He says, “They worked through the issue and stepped up to replace the belt at their cost and handled the situation professionally from start to finish. That kind of service built a lot of trust and made our decision easy when we came back to them to upgrade our print device.”

Since acquiring Total Sign Solutions in 2022, Sign City has expanded its capabilities further into retail point-ofsale and display work, making flexibility and speed even more important. The HP Latex R1000, with its ability to handle both signage and POS applications, has become the cornerstone of this evolution.

Mitch says, “We’ve had great growth over the past few years, and these investments have helped us consolidate that. The combination of HP and Summa lets us offer more to our customers, do it faster, and with a smaller environmental footprint. We feel really well positioned moving forward, with support and thanks to Computaleta.”