Sustainability

Beko Remains Committed to Sustainability

ABOVE:Beko has implemented 332 energy efficiency projects across its global production sites. These projects saved 59,901GJ of energy and avoided 5,800 tons of CO2e emissions.

At Beko, sustainability is not only about the products Beko creates – it’s also about the way the company engages with its people, communities and partners around the world. Over the last two years, Beko’s teams have been deeply involved in initiatives which reflect Beko’s values of resilience, responsibility and global citizenship.

“We believe businesses, more than any other actors, hold the power to turn the tide,” said Beko CEO Hakan Bulgurlu.

“At Beko, we have embraced that responsibility. Our goal is to become a net-zero company by 2050, fully aligned with the 1.5°C pathway. The Science Based Targets initiative (SBTi) has validated both our 2030 and 2050 targets, ensuring they meet the highest scientific standards.

“We are committed to reducing absolute Scope 1 and 2 emissions by 42% by 2030, using 2022 as a baseline. We also aim to reduce absolute Scope 3 emissions – primarily from the use of our products –

by 42% by 2030. In the long term, we are targeting a 90% reduction across all three scopes, with the remaining emissions removed through credible carbon removal solutions.

Bulgurlu added: “Scope 3 emissions account for 99% of our total footprint, as approximately 80% of its Scope 3 GHG emissions stem from the use phase. That’s why we are focused on energy efficiency, durability and lifecycle performance in everything we design.

“Throughout 2024, we implemented 332 energy efficiency projects across our global production sites. These projects saved 59,901GJ of energy and avoided 5,800 tons of CO2e emissions. We also saved 223,650m³ of water through efficiency upgrades and rainwater harvesting. Our waste recycling rate reached 98.5%, and we are targeting 99% across all facilities.

“Electrifying everything is one of the clearest levers for rapid decarbonisation, and we are acting accordingly. As of 2024, 60.5% of the electricity we use in manufacturing comes from renewable sources. Our goal is to reach 100% by 2030 in every country where we operate. Our installed renewable energy capacity reached 90.2MWp last year, significantly reducing our emissions and operational costs.

Our parent company ranks 17th on TIME’s global list, holding the 1st place in our industry for the second year running.

“The International Energy Agency estimates that renewables will account for 95% of the growth in global electricity demand by 2027. This shift is not only vital for the climate – it also increases energy security and drives down volatility. As electricity demand surges globally, scaling clean power will be essential for every sector.

“To all our colleagues, partners, and customers, thank you. Your trust, passion, and perseverance make this journey possible. We are no longer in the decade of awareness. We are in the decade of delivery. And we strive to lead,” added Bulgurlu.

PROGRESS TOWARDS NATIONAL PACKAGING TARGETS

According to Beko Marketing Manager ANZ, Amanda Hart, Beko is strongly committed to meeting and exceeding Australia’s National Packaging Targets, with a particular focus on the phase-out of Expanded Polystyrene (EPS) packaging by July 2025. She said that while regulation sets the timeline, Beko has chosen to go further, delivering EPS-free packaging solutions ahead of schedule to create better outcomes for our customers and the environment.

“

Through our EPS-Free Packaging Pilot Project, Beko has already rolled out compliant packaging across several categories.

– Murat Dora, Beko ”

“For us, the EPS phase-out is not just about compliance, it’s about leadership,” she added. “We’ve brought together our local Product, Marketing, Operations, Sales and Logistics teams to assess, test and implement alternatives that don’t just meet the regulations, but deliver smarter, more sustainable solutions for Australian and New Zealand consumers.”

As well, Murat Dora, Beko Head of Product, noted: “Through our EPS-Free Packaging Pilot Project, Beko has already rolled out compliant packaging across several categories. Cooktops and rangehoods, for example, are already using EPS-free packaging, with production completed in 2024 and full compliance well ahead of the March 2025 deadline. Built-in ovens will transition with new pyrolytic models in early 2025, and additional categories including washing machines and dryers are undergoing further testing for future rollouts.

“Beyond EPS-free innovation, Beko continues to reduce packaging volume and weight, increase recycled content and prioritise materials from sustainable sources. In 2024 alone, we used 30,165 tonnes of recycled cardboard globally, saving more than 512,000 trees from being cut down,” he added.

Amanda Hart continued, saying: “We’re fortunate to have a global R&D team which has been focused on sustainable packaging since 2020. Their work on alternatives such as moulded pulp and recycled cardboard, gives us the confidence to make the transition early, without compromising product protection or quality.

“For Beko, sustainability isn’t just embedded in our products and operations, it’s also a core part of how we tell our brand story. One of our proudest achievements this year has been our recognition →

Sustainablilty leadership,

TOP: Eddie Gaymer and Larry Waldron unpack EPS-free Beko products at Bi-Rite Underwood.

ABOVE: Beko CEO Hakan Bulgurlu.

in the TIME and Statista ‘World’s Most Sustainable Companies’ ranking, where Beko rose from 44th place to 17th globally in 2025, and secured the #1 position in the Retail, Wholesale & Consumer Goods category.

“The ranking is especially meaningful given the evaluation process was even more rigorous this year, covering more than 20 environmental, social, and governance (ESG) indicators, from emissions reduction and renewable energy to transparency, diversity, and circularity. In a year when many global brands slipped backwards, Beko not only advanced but achieved an impressive score of 81.53 out of 100,” Hart said.

“By proudly showcasing our TIME ranking in both consumer-facing and trade communications, we’re giving retailers a powerful story to share with shoppers, reassuring them that when they choose Beko, they’re choosing a brand independently recognised as one of the most sustainable in the world.”

STEPS TOWARDS GREATER SUSTAINABILITY

Beko has taken steps towards sustainability across each stage of the organisation’s value chain –from product design to packaging, durability and repairability. Here are some more examples.

MATERIAL REDUCTION & CIRCULARITY

Beko has progressed in material reduction and the use of alternative materials. For example, by optimising product design in 2024, Beko reduced total raw material use by 17,163 tonnes, including 15,915 tonnes of plastics and 743 tonnes of metals, preventing more than 20,220 tCO2e emissions.

At the same time, Beko continues to increase the use of recycled materials in its products. In 2024, Beko used 27,835 tonnes of recycled plastics, including innovations such as plastics made from waste PET bottles, discarded fishnets and recycled packaging waste. Beko’s goal is to reach 40% recycled plastic content by 2030 and 50% by 2040.

ABOVE: Beko has taken steps towards sustainability across each stage of the organisation’s value chain – from product design to packaging, durability and repairability.

BELOW: Beko designs durable appliances, tested under EN 45552 endurance standards, and improves repairability by ensuring accessible spare parts and clear repair instructions.

PACKAGING INNOVATIONS

Beko has also invested in more sustainable packaging. Since 2020, the Beko Sustainable Packaging Project has focused on reducing volume and weight, increasing recycled content, and replacing materials such as Expanded Polystyrene (EPS) with more sustainable alternatives.

DURABILITY, REPAIRABILITY & REFURBISHMENT

Another crucial pillar to Beko’s commitment to sustainability is product longevity. Beko designs durable appliances, tested under EN 45552 endurance standards, and improves repairability by ensuring accessible spare parts and clear repair instructions. This supports the growing ‘Right to Repair’ movement while extending product life. Through material reduction, recycled content, sustainable packaging, energy-efficient technologies, and the company’s focus on repairability and refurbishment, Beko is committed to building a more circular, low-carbon future. These initiatives not only reduce environmental impact but also deliver confidence to consumers and retailers that Beko products are designed for both performance and responsibility. AR

Winning Group receives two sustainability milestones for Kemps Creek distribution centre

Winning Services, the logistics arm of Winning Group, has been recognised for its sustainability credentials for its NSW distribution centre at Kemps Creek.

The building secured a 6 Star Green Star –Design as Built v1.3 rating from the Green Building Council of Australia as well as a Carbon Neutral certification for upfront embodied carbon under the Climate Active Carbon Neutral Standard.

The 66,610sqm facility, the largest in the Winning Group’s history, also boasts of a 650-kW solar PV system, EV charging infrastructure, and advanced environmental monitoring systems.

“We were delighted to partner with Mirvac on our NSW Winning Services distribution centre, which supports the growth of our retail entities Appliances Online, Winnings and third-party logistics partners, and operates our award-winning take-back and recycling program,” Harry Boileau, General Manager at Winning Services, said.

“Our desire to use our business and ecosystem as a force for good, is why achieving a 6 Star Green Star rating and Carbon Neutral certification for our largest-ever distribution centre was so important.

“Achieving the 6 Star Green Star rating for our Kemps Creek DC was really important to us, especially from a solar perspective, as it reduces our operational carbon footprint and supports our net-zero goals,” Alice Kuepper, Head of Sustainability and Industry Impact at Winning Group, said.

Richard Seddon, CEO of Investments at Mirvac, noted that Winning’s recent sustainability achievements also reflect Mirvac’s shared and continued commitment to sustainability and innovation.

“Our commitment to top-tier sustainability standards has been longstanding at Aspect Industrial Estate, with two of the completed warehouses having both already achieved Carbon Neutral certification for the building’s upfront construction carbon emissions,” Seddon said. AR

TOP: Winning Services has been recognised for its sustainability credentials for its 6 Star NSW distribution centre at Kemps Creek.

ABOVE: The 66,610sqm facility, the largest in the Winning Group’s history, also boasts of a 650-kW solar PV system, EV charging infrastructure, and advanced environmental monitoring systems.

Photo Credit – Chris Hung

JB Hi-Fi shares goals in 2025 Sustainability Report

The JB Hi-Fi Group brings together three of Australia’s iconic retail brands – JB Hi-Fi, The Good Guys and e&s. The Group as a whole, operates from over 340 stores and websites in Australia and New Zealand.

This year, the JB Hi-Fi Group published its sixth Sustainability Report which reviews the group’s sustainability performance from 1 July 2024 to 30 June 2025. As the Group’s Chief Executive Officer, Terry Smart, said: “FY25 has been a year of continued focus on delivering value for our customers, supporting our team members and progressing our sustainability commitments.”

Smart added: “At JB Hi-Fi Group, we believe in doing business the right way — by supporting our people, engaging with our communities and reducing our environmental impact. This year we welcomed e&s into the Group. With its long history and strong reputation in the communities it serves, e&s is a great cultural fit and brings a complementary offer to our existing JB Hi-Fi and Good Guys businesses. We look forward to growing together and continuing to integrate our sustainability practices across the Group,” he said.

In reference to the Sustainability Report, Smart added: “This report outlines our continued efforts to make a positive

contribution in the areas that matter most. From investing in our communities, to emissions reductions and ethical sourcing. This year we surpassed $44m in workplace giving donations, thanks to the generosity of our team members. We also made good progress on reducing emissions.

“Forty percent of the Group’s energy now comes from renewable sources, which has resulted in our emissions decreasing by 18.7% from the prior year, or 32% compared to our base year of FY20,” he said.

As well, Smart thanked the Group’s 16,000 team members for their ongoing support and he added: “We are committed to continuously improving the way in which we operate and working with our team members and partners to help shape a more sustainable future for our business and the communities we serve.”

HIGHLIGHTS FROM THE JB HI-FI SUSTAINABILITY REPORT FOR FY25

` 32% decrease in scope 1 & 2 emissions since FY20 baseline year.

` 9632 tonnes of customer e-waste collected and recycled.

` 92% of the core private label range now has 100% recyclable packaging.

` 165 suppliers engaged on modern slavery, packaging sustainability and emissions targets.

WORKING WITH THE ENVIRONMENT

The JB Hi-Fi Group recognises the urgency for climate action and the importance of limiting global temperature increases in line with the Paris Agreement. The Group aims to minimise the impacts that its operations may have on the natural environment and be pro-active in reducing its waste, energy consumption and emissions.

CLIMATE ACTION

The JB Hi-Fi Group monitors its energy consumption and reduces its greenhouse gas emissions, with the goal of achieving net zero (scope 1 and 2) carbon emissions by 2030. Scope 1 emissions relate to direct emissions from the companyowned vehicles and usage of natural gas in the stores. Scope 2 emissions relate to purchased electricity to power the stores, warehouses and support offices.

The Group is reducing its scope 1 and 2 emissions by reducing energy consumption where possible, pursuing energy efficiency upgrades, investing in solar power generation and increasing the use of renewable electricity.

In FY2025 the Group completed 6 new solar installations and in FY24, 7 new sites had solar power generators installed, which takes the total number of sites with solar power generators to 36.

This year, the JB Hi-Fi Group published its sixth Sustainability Report which reviews the group’s sustainability performance from 1 July 2024 to 30 June 2025.

The Group progressively increased its procurement of renewable electricity through the year, which resulted in 27% of the Group’s energy needs being sourced from renewable energy in FY25. In the month of June 2025, this increased to 40% of the Group’s energy needs and the Group is working proactively to increase the use of renewables to reach the net zero target by 2030.

THE JB HI-FI GROUP’S APPROACH TO PACKAGING SUSTAINABILITY

The Group is committed to working closely with its suppliers and team members to improve packaging sustainability and to optimise recycling of operational waste. The Group aims to achieve this by combining packaging compliance and ensuring product packaging is as sustainable as possible.

THE GROUP’S ETHICAL SOURCING POLICY OUTLINES THE MINIMUM STANDARDS IT EXPECTS ALL SUPPLIERS TO ADOPT INCLUDING:

1. Working towards 100% recyclable packaging.

2. Use of at least 50% recycled content.

3. Use of Forest Stewardship Council certification where practicable.

4. Elimination of unnecessary single-use plastics.

5. Clear consumer labelling.

THE 2025 NATIONAL PACKAGING TARGETS

The Group is a member of The Australian Packaging Covenant Organisation (APCO) and submits an Annual Report and Action Plan which tracks the progress the Group is making toward achieving the 2025 National Packaging Targets. So far, progress has been made and the Group is on-track to align with the National Packaging Targets for packaging over which they have operational control. Achievements so far are:

` 82% of the Group’s packaging is now 100% recyclable.

` 59% of the Group’s packaging is now made from at least 50% recycled material.

` 83% of the Group’s packaging is free from problematic and unnecessary single use plastics.

As well, in FY25, the Group continued to expand the use of recycled materials in the JB Hi-Fi private label products, with an additional 12 XCD cables made from 80% recycled PVC and 7 chargers made from at least 33% recycled rubber and plastic.

Over 220,000 used plastic bottles were used in the production of private label camera bags, laptop bags and sleeves that were sold in FY25.

Both JB Hi-Fi and The Good Guys offer paper bags which are 100% recyclable and certified by the Forestry Stewardship Council (FSC) to be made from 100% recycled material.

All cardboard shipping cartons utilised for fulfilment, contain a minimum of 50% recycled content, are 100% recyclable and are Certified FSC Mix, which means the materials used in its production come from responsible sources. The Group’s Ethical Sourcing Policy requires brand owners to use sustainable packaging as well.

MANAGEMENT OF MOULDED EXPANDED POLYSTYRENE

Moulded expanded polystyrene (EPS) is widely used in packaging for large home appliances such as whitegoods and large-screen TVs, due to its lightweight and protective properties. If EPS isn’t recycled responsibly, it can pollute the environment for years to come. So, the JB Hi-Fi Group operates EPS recycling throughout the entire store and warehouse network, and a total of 478 tonnes of EPS was recycled last year.

COLLABORATION AND ADVOCACY

Many of the environmental issues facing the retail industry cannot be solved by any one company and they require collaboration across the supply chain and government to achieve broader industry impact.

With this in mind, the JB Hi-Fi Group is one of the founding members of The Coalition for Sustainable Solutions (COFOSS) – an industry not-for-profit organisation comprising some of Australia and New Zealand’s leading consumer electronics and home appliance retailers and suppliers.

In FY25, JB Hi-Fi attended 5 COFOSS Board Meetings and contributed over 40 hours of assistance to help COFOSS develop its 2025-2028 Strategic Framework. For more information, visit COFOSS –Coalition for Sustainable Solutions.

As well, in FY25, the Group continued to raise awareness about the importance of battery and e-waste recycling with the Group collecting 9,632 tonnes (FY24: 6,599 tonnes) of used batteries, small e-waste items and large domestic appliances for recycling. In FY25, JB Hi-Fi Business facilitated the re-use and/or recycling of 5,118 devices (FY24: 4,909). AR

Unless otherwise stated, metrics in this report exclude e&s, noting that the e&s business has only recently become part of the Group. Future Sustainability Reports will include more detail on the e&s business as it is integrated into the Group’s sustainability activities.

recycling with the Group collecting 9,632 tonnes of used batteries, small e-waste items and large domestic appliances for recycling.

JB Hi-Fi Group continued to raise awareness about the importance of battery and e-waste

Miele maintains passion for sustainability

When we look at sustainability in the appliance market, Miele has a reputation as being one of the passionate pioneers in this area – both here in Australia and globally.

Recently, Appliance Retailer spoke with Miele Australia’s Consumer Data and Product Engineering Manager, Matt Slater, and Miele’s Global Head of Sustainability in Germany, Max Wagner, to find out more.

“Miele has always been known for longevity, especially here in Germany,” said Wagner. “It always been like – if you buy a Miele appliance, you buy it once and then you’re good to go for the next 20 years.

“And this is still our main claim and our main point of difference in sustainability,” Wagner added. “We test our appliances for up to 20 years of lifetime – and especially now with the high energy efficiency we have in our appliances, it’s pretty clear the most sustainable appliance you can have is the one you already have. So, if you buy an appliance that lasts for a long time it’s the most sustainable choice you can make – and this is really our focus on sustainability. This is why this heritage of making appliances that last for a long time is also our biggest sustainability pillar.

“We remove the pain of having to repeat the process more frequently. And another key pillar of ours is the fact our machines are repairable and they’re

repairable for a very long time. That very much lends itself to them being sustainable as well.”

Miele has recently invested in sustainability through the consumption dashboard using the Miele app.

“The app is one of my babies,” said Slater. “It’s one of the things I’m responsible for here locally and we promote it as much as we can because we’ve seen, especially in Europe, when customers start engaging with the app and looking at their consumption, they tend to start changing their behaviour and use more economic programs and making smarter choices around their appliance usage.

“It’s a really powerful way to influence customer behaviour,” he added. “It’s very transparent. It’s very clear and easy to see what your consumption is and look at your historic trends. So, a customer themselves can see if they’ve made a change in behaviour and the benefits of doing that.

“Taking the global perspective,” said Wagner. “If you look at the CO2 scope of our company, 84% of it is the usage of our appliances. And then another 14% is the materials. So, the biggest lever we have is the usage of our appliances.

“The tricky thing is obviously we don’t want to tell our customers how to do it,” Wagner added. “It’s their appliance – we don’t want to dictate anything. We really

ABOVE: Miele has made substantial investments into its app including the sustainability benefits of eco programs and the consumption dashboard.

just want to educate them about what is possible. The app for us is the perfect tool to stay in contact with the customer after the purchase. Usually, as a manufacturer, you would lose the customer at the point where the appliance leaves the gate but not with our app and the consumption dashboard.

“And with the consumption dashboard we can do it in a fun way,” Wagner said. “It’s not like the app tells you – ‘hey, you have to use the eco program again, otherwise you are a bad person!’ It’s more like – ‘hey, you used it 50% of the time last week. That makes you one of the top 5% sustainability contributors.’ It’s more like a gamification point.”

When it comes to appliance sustainability – it is the consumer usage that has the highest impact. A lot of companies focus their sustainability messaging on the construction and manufacturing. Miele is changing the language around appliance sustainabiliuty and transferring the attention more on consumer usage.

“To be honest, this usage phase will get less and less critical with the energy mix of the countries,” Slater said.

“For example, in Germany, if the German energy grid is more and more renewable, that directly feeds into our CO2 footprint – because then our appliances run on green electricity and we don’t have CO2 anymore. And then obviously the material used becomes more and more important.

“As more and more households in Australia install solar panels or get better access to renewables, I think there’s going to be a shift and we might see an acceleration in the uptake of battery systems and things, much like what happened with solar panels ten or so years ago.

“They can actually do potentially a mathematical equation on the floor of the retailer and say this is actually going to hold me in a better position over the longer term.

ABOVE: In Europe, Miele achieves Class A energy efficiency across its entire range of dishwashers.

BELOW: When it comes to appliance sustainability – it is the consumer usage that has the highest impact and as a result Miele is changing the language around appliance sustainability and transferring the attention more on consumer usage.

“When customers start engaging with the app and looking at their consumption, they tend to start changing their behaviour and use more economic programs.

– Matt Slater, Miele ”

“Something that I’m quite proud of with our appliances is that we’re very transparent about their consumption,” added Slater. “Our manuals provide quite a lot of detail about how much energy and water the different programs use. Especially in the laundry and dishwashing space. That’s not always the case with other manufacturers.

“Another point is the fact that usually what people compare is the eco program which tells them how much energy they will use in the eco program. But then we look at the data of our appliances which are connected, we can see what kind of problems customers are actually having. For example, you buy a washing machine based on the eco program usage and then we look at what’s the percentage of eco program usage in washing machines in Germany?” he added.

“It’s only four percent. So, you buy a product based on a program that you’ll never use,” Wagner said. “So really, at Miele, we are very transparent about the actual consumption of all our programs. That way you can actually get an idea of what’s the actual consumption you will have.” AR

Hisense takes the guesswork out of sustainability

Sustainability is a central pillar of the Hisense brand according to Michelle Wee, General Manager, Marketing for Hisense ANZ. She explains that Hisense aims to “take the guesswork” out of sustainability for its customers with its 2025 Eco Vision range being designed to help customers be as eco-friendly and energy efficient as possible.

“This gives our customers more time and space to live life to the fullest,” Wee says.

“In 2025, Hisense evolved its Eco Vision sustainability standard. We know that nobody wants to spend a lot of time thinking about the ins and outs of home appliances. So, our Eco Vision range is designed to help customers be energy efficient effortlessly.

“Eco Vision means your appliance is the most efficient and sustainable machine we make, meeting or exceeding that standard set in the appliance’s category. This means that everything from the efficiency of the motor to the packaging it’s shipped in, is as low impact to the environment as possible.”

Wee adds: “In a world which is growing increasingly environmentally conscious, customers are choosing to seek out brands that align with their own values and this highlights the importance of sustainability credentials.

“We see our environmental social responsibility manifest throughout every stage of a customer’s purchasing journey,” she says, “from manufacturing to the shop floor, packaging recycling options and finally when products enter and adapt to their homes”.

“This year, we released a wide range of new products which delivered category leading energy efficiency and game-changing features which augment the ability of customers to monitor and manage their power consumption,” she said.

“With a proven track record of industry-leading innovation, we continue to evolve the ways that we can deliver environmental sustainability. We believe sustainability starts in the home, and by giving more power to our customers through innovations like our ConnectLife App and Smart-AI features, we’re able to help households optimise energy, streamline chores and make life more connected, efficient and creative.”

HISENSE’S THREE CORE SUSTAINABILITY PILLARS

1. Innovating towards product energy efficiency, utilising the latest technology and innovations to develop low energy consumer products and minimise the carbon footprint for our customers.

2. Minimising waste by ensuring our packaging/e-waste disposal processes adheres to industry best practice for a greener environment and that our products are designed to keep food fresh for longer plus minimising wear and tear and using the correct amount of detergents.

3. Promoting convenience, through thoughtful design and smart features which take the guesswork out of our appliances. Through ConnectLife, customers can gain even greater transparency to personalise appliance programs, sync washer and dryer cycles and monitor energy/water usage. AR

The Hisense 116-inch RGB MiniLED UX 4K 165Hz Smart TV is 30 per cent more efficient than previous models of its size category due to the powerful AI Eco features.

ABOVE: The Hisense Series 8i Washer has been awarded a 5 Energy Star and 4 Star Water rating. The Hisense Series 8i Dryer has been awarded a 10 Energy Star rating but takes sustainability a step further by exceeding the 10 Energy Star benchmark by a further 10 per cent.

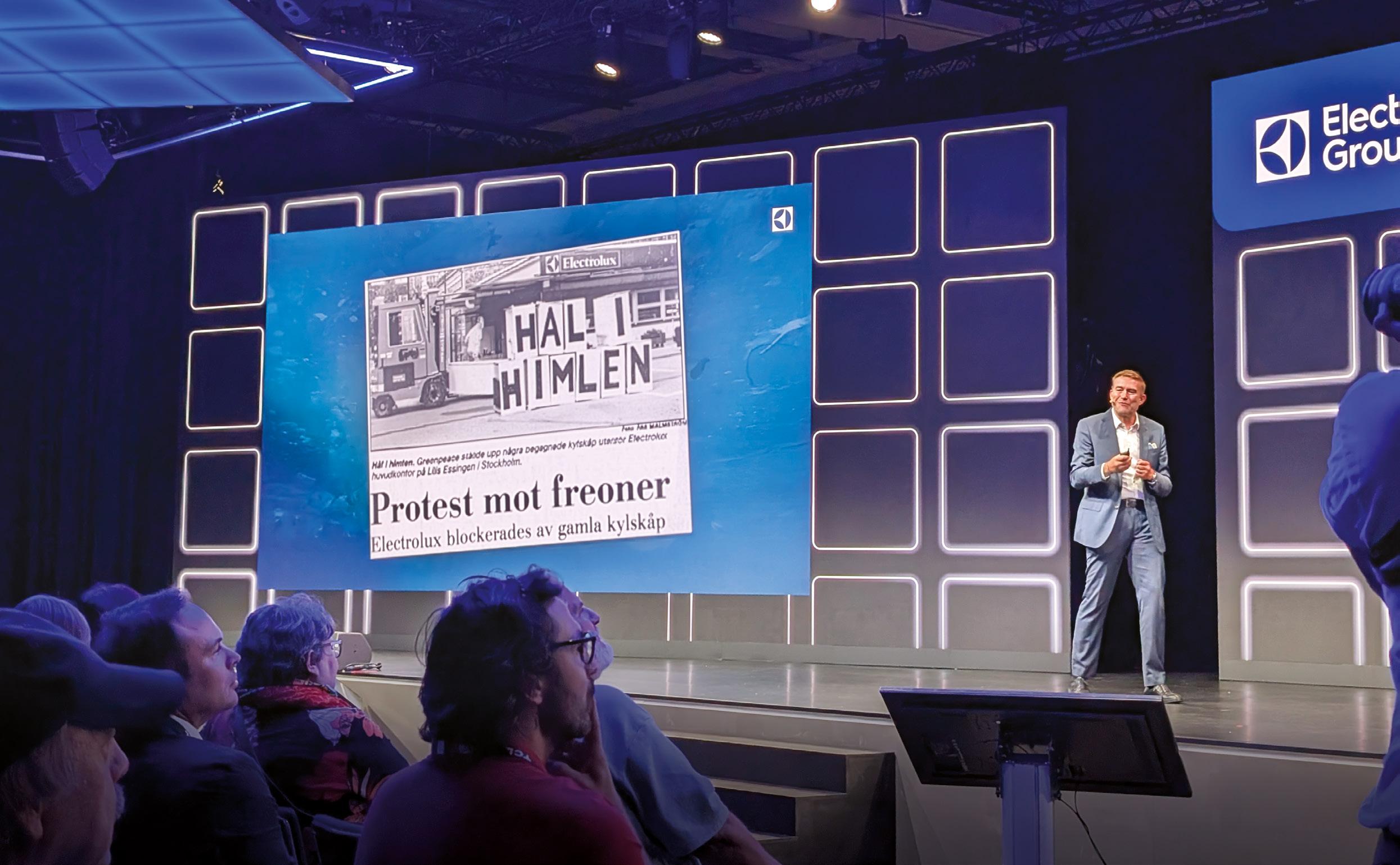

Electrolux CEO calls for more sustainability action

Yannick Fierling, CEO of Electrolux Group, led the first keynote of IFA 2025 in Berlin, giving both industry and politicians a firm sustainability push.

Fierling’s 27-minute-long speech touched on Electrolux’s extended history in not shying away from sustainability issues his own company experienced, including a Greenpeace protest in 1992 in Stockholm over the use of CFCs.

“In 1992, Greenpeace dumped a truckload of refrigerators with freon in front of our headquarters in Stockholm. That was a trigger for us. One year later, we launched the first refrigerator without CFC to protect the ozone layer,” said Fierling.

“In 2010, we launched a vacuum cleaner series using 70% recycled plastic, along with the campaign ‘Vac from the Sea’, where employees and volunteers collected plastic from beaches worldwide.”

Fierling, who spent close to nine years at Haier Group before joining Electrolux, said Electrolux has always been an early adopter of green goals.

“Electrolux was among the first 100 companies to set a science-based climate target in 2018. We reached it three years ahead of schedule.

“Between 2021 and 2030 we will reduce Scope 1 and 2 emissions by 85%, and Scope 3 by 42%. Looking from 2015 to 2030, we will reduce Scope 1 and 2 by almost 100%.

“In 2024, 94% of our electricity was green, and 64% of our overall energy came from renewable sources.

“Two out of three consumers now say sustainability is one of the most important drivers in buying appliances.”

TOP: Electrolux CEO Yannick Fierling, who spent close to nine years at Haier Group before taking his current role, said Electrolux has always been an early adopter of green goals.

ABOVE: Electrolux was among the first 100 companies to set a science-based climate target in 2018.

On stage, Fierling made a three-prong call to action for industry and policy.

“We all need to do more. I call for cross-industry collaboration on recycled materials. Every company must set clear targets.

“We need policymakers to streamline regulations, give incentives for recycling, and support research and development.

“And, we must empower consumers with clear information on recycled content and energy tags on every appliance.

“Let’s make shaping living not just a strategy, but a shared ambition. When we work together, we all move forward faster, in a prosperous manner, to shape living for the better.” AR

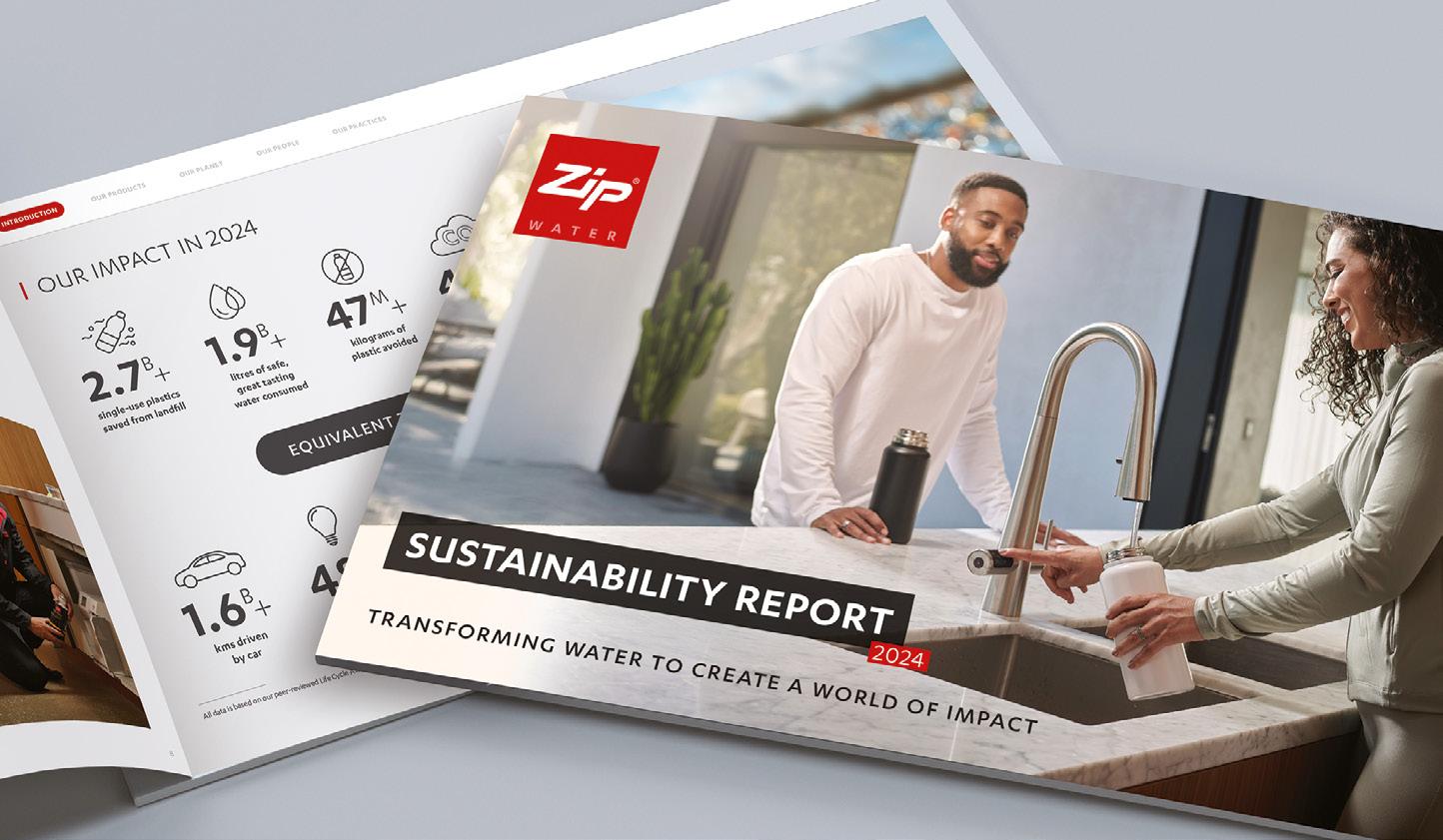

The latest Zip Water Sustainability Report shows the company’s commitments to reducing its environmental

Zip Water releases Sustainability Report

Zip Water has released its 2024 Sustainability Report, outlining its progress on environmental, social, and governance (ESG) initiatives across product development, manufacturing, and corporate operations.

The report reflects the company’s ongoing efforts to align with five key commitments tied to the United Nations Sustainable Development Goals, including cleaner drinking water, plastic waste reduction, climate action, diversity and inclusion, and responsible business conduct.

The reporting period covers January 1 to December 31, 2024, and documents Zip Water’s push to reduce its environmental footprint while expanding access to high-performance hydration solutions for homes, workplaces, hospitality venues, and public spaces.

Among its notable milestones is the launch of its most sustainable HydroTap model to date, featuring low Global Warming Potential (GWP) refrigerants that comply with emerging climate regulations. The company also transitioned to dry manufacturing for its core product line, eliminating wastewater from the process entirely.

Additional environmental initiatives include further investment in renewable energy, with a solar power expansion at Zip’s New South Wales manufacturing site, as well as improvements in packaging, with a focus on reducing unnecessary materials and increasing recyclable content.

On the consumer side, Zip introduced an upgraded filtration system to better protect users from harmful contaminants. In addition, it expanded its suite of sustainability tools, including the HydroTap Impact Calculator and verified Environmental Product Declarations (EPDs) that offer transparent lifecycle data.

The report also emphasised Zip Water’s social impact work, including its partnership with SOURCE Hydropanels to deliver clean drinking water to remote Australian communities.

Today, Zip Water products are used by more than 25 million people globally each day and contribute to preventing over 2.7 billion single-use plastic bottles from entering landfill or waterways annually.

“We’re proud of how far we’ve come – from sustainable design to clean manufacturing and everything in between,” said Mike Abbott, Managing Director of Zip Water Australia and New Zealand.

“Whether it’s a workplace fit out or a residential kitchen upgrade, we want to give people smarter, more sustainable choices when it comes to water.” AR

Breville invests in Sustainable Brown Box initiative

In 2023, Breville Group – under its global Breville | Sage brands – launched the companywide Sustainable Brown Box initiative.

This is part of the company’s commitment for the packaging of all products in Australia and New Zealand to be 100 per cent reusable, recyclable or compostable.

According to Breville general manager –Australia, Nick Moore, the Sustainable Brown Box initiative transitioned the business to a more sustainable packaging solution.

“These changes reflect our commitment to best-in-class sustainable packaging practices across our entire range,” he said.

“The Sustainable Brown Box initiative is a company-wide project, through which we replaced our coloured packaging with a recyclable outer box, fully eliminated EPS (expanded polystyrene) and minimised soft plastics.

“This transition underscores our commitment to reducing environmental impact while maintaining the premium quality our customers expect, and we would like to thank our retail partners for their support for this initiative,” Moore said.

In addition, the new Brown Box will carry simplified on-pack communications with the rollout of a new product information and sticker strategy. This will allow the Breville Group to streamline its sustainable packaging supply chain for its three theatre, multi-region production.

It is expected the full transition to Sustainable Brown Box packaging globally will be completed by FY2030. AR

Examples of the Breville Sustainable Brown Box packaging.

footprint.

Amazon’s Melbourne sustainable sort centre achieves Australian-first certification

Amazon’s sort centre in Craigieburn, Melbourne, has made history as Australia’s first-ever warehouse to earn a Zero Carbon Certification from the International Living Future Institute. It’s the fourth project in Australia to receive a Living Future certification.

The site designed with sustainability at its core enhances delivery speed for customers and is another step in Amazon’s Climate Pledge commitment to reach net-zero carbon emissions by 2040.

In addition to being fitted with innovative technology that helps the site use less energy, the sort centre plays a strategic role in making Amazon’s logistics network more efficient. It sorts orders by delivery destination, before they are shipped to Amazon delivery stations or last mile carriers. This can reduce the number of trucks on the road moving parcels from site to site and enhances delivery speeds for customers.

The certification is the world’s only performance-based standard for buildings that examines both emissions released during construction as well as those released during operation – with targets needing to be met over a 12-month performance period. Alongside the Zero Carbon Certification, the sort centre has also achieved a 5-Star Green Star rating from the Green Building Council of Australia.

“At Amazon, we are laser focused on The Climate Pledge – our commitment to reach net-zero carbon emissions by 2040 — and our buildings are a big piece of this puzzle. According to the Carbon Leadership Forum, buildings and construction account for 40% of the world’s greenhouse gas emissions. Our building designs not only consider the materials and methods used in construction, but also the energy consumption throughout a building’s lifecycle, and we apply those principles across our network,” said Sandra McNeil, Amazon Australia Director of Operations.

Buildings are just one of the areas we are innovating and investing in to make every day better for our customers, employees, communities and the planet. We recently stopped packing products in singleuse plastic delivery bags in our Australian distribution network, replacing them with recyclable paper alternatives.

The Craigieburn sort centre is the first Amazon site outside of the US to achieve the Zero Carbon Certification and joins a sortation centre in Liberty, Missouri, a Same-Day Delivery site in Sacramento and an Amazon Fresh grocery store in Seattle. Additionally, Climate Pledge Arena, which Amazon helped renovate and restore through our collaboration with the Oak View Group, is the first ILFI Zero Carbon Certified arena in the world.

Amazon now has eight renewable energy projects in Australia including two solar farms in New South Wales, one in Queensland and a wind farm in Victoria. Once fully operational, together with the company’s warehouse rooftop solar initiatives, these projects are estimated to generate the equivalent energy needed to power more than 175,000 Australian homes. AR

Amazon Craigieburn sustainable sort centre features

100% Renewable Energy: Powered by solar and Amazon’s offsite renewable investments.

Solar Power: Over 3,000 solar panels generating 1MW, covering up to 80% of energy needs.

Fully Electric: No fossil fuels used in operations.

EV Charging: 12 stations now, with capacity for 30 more, covering 20% of parking spaces.

Water Efficiency: 22,000-litre rainwater recycling system and waterefficient fixtures reduce mains water use.

Amazon now has eight renewable energy projects in Australia including two solar farms in New South Wales, one in Queensland and a wind farm in Victoria.

The Craigieburn sort centre is the first Amazon site outside of the US to achieve Zero Carbon Certification.

Amazon’s commitment to reach net-zero carbon emissions by 2040 relies on the sustainability of its buildings.

The site is designed with sustainability at its core for everyone including employees.