From uncoated to laminated to UV or foils - Hero Print has you covered

AUSTRALIA’S BEST TRADE PRINTER

Pozitive sign & graphic supplies hosts large open house at its new premises

WOMEN IN PRINT BREAKFAST SERIES: Hundreds join the 2025 series across Australia

Print’s real strength lies in communicating, and moving people

Why offset printing remains the gold standard for large-scale projects in 2025

Print-to-table: The best business idea you haven’t tried (yet!)

All the upcoming events The Australian print industry’s

Redefine Commercial Printing Standards and elevate production with Next-Gen High-Speed Inkjet

PRODUCTIVITY

•High productivity

•560mm paper width

•High machine uptime

QUALITY

•New Inkjet 1200dpi PHs

•New saturated ink SC2

•Enhanced image quality

USABILITY

• Energy-efficient drying

•Easy operation

•Offset-coated papers

AGILITY

•Optimised integration

•Precision paper sensing

•Complete New Platform

AP celebrates 75 years in existence this year. When you think about mastheads going digital-only, it’s an honour to have a publication such as ours run for as long as it has in both print and online formats, and that too in delivering news about the booming print industry (who says print is dead?).

In celebration of AP turning 75, we tell the story of an industry veteran, who is well loved by all, in this issue. He too turns 75 years old this year – it’s none other than Cactus Imaging’s Keith Ferrel. He shares his inspirational story, leaving no stone unturned.

This issue also provides a peek into Konica Minolta’s upcoming AccurioPress C14010S and C12010S next-generation production presses, which will be making their debuts at PacPrint 2025. Learn more about how you can unlock new creative opportunities with these upcoming presses in our Cover Story pages.

We hope you enjoy the read.

Durst Group has acquired callas software, one of the leading providers of prepress automation and PDF technologies that plays an essential role in many print workflows – either directly or as an OEM component in prepress products.

Durst Group confirmed the acquisition will strengthen its software strategy and focuses on openness and connectivity within the printing industry.

callas will play a key role in connecting isolated solutions and enabling print service providers worldwide to achieve greater efficiency, scalability, and flexibility.

Durst Group’s objective is to create intelligent, seamless automation between machines, software, and print processes. At the same time, callas will remain autonomous in its management and product development.

Durst Group said for callas customers and OEM partners, the acquisition brings stability and new technological opportunities, including:

• Long-term security: callas continues to operate as an independent company.

• Guaranteed advancement: With the resources of Durst Group, callas can continuously improve its technology.

• Unchanged OEM contracts: Existing customer relationships remain unaffected.

• New opportunities: Expanded integration options through access to Durst Group’s software technologies.

“Maintaining callas’ independence was a central requirement for joining Durst Group. Our customers must be able to trust that callas will continue as a reliable partner – while also gaining a new foundation for long-term

innovation,” callas software CEO Dietrich von Seggern said.

In the coming months, the collaboration between callas and Durst Group will deepen, leveraging synergies and accelerating the development of an open, vendor-independent software platform for the print industry.

“This is not just another step towards digitalisation – we are actively shaping the future of digital printing. With callas at our side, we are making print software smarter, more connected, and more powerful. The best solutions arise when strong partners work together toward a shared vision,” Durst Group CEO and co-owner Christoph Gamper said.

Managing Director

James Wells / 02 8586 6101 james@intermedia.com.au

Subscriptions / (02) 9660 2113 subscriptions@intermedia.com.au

Subscription rate (5 issues) Australia $79

Editor Hafizah Osman / 0431 466 140 hosman@intermedia.com.au

National Sales Manager

Carmen Ciappara / 0410 582 450 carmen@proprint.com.au

Printed by Hero Print Alexandria, NSW, 2015 Mailed by D&D Mailing Services Wetherill Park, NSW, 2164

Design and Production Manager

Sarah Vella / 0406 967 559 svella@intermedia.com.au

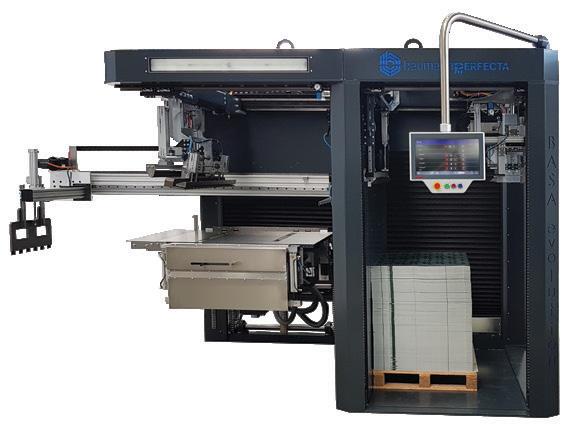

Currie Group has announced a new partnership with baumannperfecta, which will see the company become the exclusive A/NZ supplier of the German OEM’s range of automated cutting systems and related peripheral equipment.

baumannperfecta is a manufacturer of post-press and automation systems including high-speed cutters, cutting systems and three-knife trimmers, pile hoists, loaders and pile turners, automatic joggers and jogging systems, and buffering and unloading devices.

baumannperfecta provides a range of highly automated solutions which encompass the entire process including fully automated jogging and cutting, barcoding and peripheral logistics, and which can be customised to individual requirements thanks to their modular and expandable design.

Epson and Currie Group have announced a new partnership which will see Currie Group add Epson solutions to its product range for the sign, graphics, and wideformat print sector.

This will include the Epson SureColor ecosolvent models in the 64-inch size range, as well as resin and dye-sublimation solutions, providing productive solutions for a diverse range of market requirements. Since the launch of the Epson branded printers in both sign and graphics and fabric markets, Epson has seen consistent growth and has developed a strong customer base.

To help meet increasing demand and drive growth, the company had been looking to expand its network of dedicated and capable partners, and this coincided with Currie Group’s desire to expand into the more traditional signage market and round out their existing offerings with eco-solvent, resin and dye-sub technologies.

Epson A/NZ managing director Craig Heckenberg said, “The sign and display and textile markets are key to Epson’s

The baumannperfecta cutting solutions fall in the 80cm to 225cm range, ideally complementing the offerings of Currie Group’s other finishing solutions, providing complete coverage for digital and traditional printing applications.

Currie Group CEO Rob Mesaros said the new partnership aligns perfectly with Currie Group’s commitment to meeting the needs of its customer base.

“baumannperfecta not only has a longstanding reputation for exacting quality and robust, reliable equipment construction, it is known for its innovation, offering future-proof cutting and finishing

global strategy, making our partnership with Currie Group a natural fit. With a strong reputation for delivering advanced digital printing and finishing solutions, supported by a nationwide service team, Currie Group is an ideal partner for us. We look forward to a successful collaboration with the Currie Group team for many years to come”.

Currie Group CEO Rob Mesaros said, “As a company, our growth has always been driven by the needs of our customers, and we are delighted to be partnering with Epson to extend our range of solutions for this important market sector. As with all our partnerships, decisions are made very carefully and after long discussions

solutions to print service providers worldwide,” Mesaros said.

“Just as importantly, baumannperfecta is, like Currie Group, a family-owned business with a long-established commitment to supporting its customers; its slogan ‘Together Successful’ sums up its approach.”

Currie Group’s representation for baumannperfecta cutting systems began in March and, at the time, had already made its first sale in Australia.

“The positive response we have had to this new addition to our product portfolio validates our view that the market is looking for superior, new-generation cutting solutions that bring the best of digital cutting and advanced materials handling technology to the mid-to largeformat cut sheet market,” Mesaros said.

Olaf Gerber, sales manager at baumannperfecta, said, “Currie Group has extensive experience and a deep understanding of the Australian and New Zealand markets, which makes the partnership a promising combination. Together, baumannperfecta and Currie Group will be able to offer customised solutions that meet specific customer requirements”.

to ensure that we not only add the best products to our portfolio, but that we build strong and positive relationships with partners whose values and philosophies align with those of Currie Group and our customers.

“Epson really stood out during the evaluation process because of its strong commitment to customer-led innovation, high-quality manufacturing and sustainable, responsible operations.”

Commenting on how the new partnership will benefit the market, Romano Bacci, business manager – professional print solutions at Epson said, “Epson focuses on quality, reliability and above all delivering a positive experience for our customers. When we looked to expand our network, Currie Group was not only a perfect fit in terms of business strategy, but a natural choice given its reputation for outstanding customer service and a shared commitment to customer satisfaction”.

Paul Whitehead, business unit manager – sign and display for Currie Group, said, “We have worked to understand exactly what our customers need and carefully assessed the available technologies and manufacturers to find the perfect fit to complement our existing offerings. That’s exactly what Epson provides”.

Rawson Print & Packaging has acquired Sydney-based commercial printer Megacolour, saying the acquisition “marks a significant milestone in Rawson’s continued growth and expansion”.

“The addition of Megacolour to the Rawson family brings an exciting opportunity to expand product offerings and tap into new market segments. By combining Rawson’s cutting-edge technology and processes with Megacolour’s proven expertise, the company aims to set a new standard of excellence in the printing industry,” Rawson Print & Packaging said.

Based in Camperdown in Sydney’s inner west, Megacolour was established in 1992 and specialises in offset printing, digital printing, as well as finishing and binding.

Megacolour owner Michael Fang will retire in a few months; however, Fang will work closely with Rawson group account director Gavin Smith and other members of the Megacolour team during the transition.

Rawson directors Andrew Price and Lachlan Finch said, “We are thrilled to welcome Megacolour into the Rawson family. This acquisition will allow us to enhance our capabilities and offer even greater value to our customers. Our commitment to delivering high-quality service remains our top priority, and this partnership will further strengthen that commitment”.

Finch confirmed to Australian Printer Megacolour will be consolidated into Rawson Print & Packaging, with some of Megacolour’s equipment to be integrated into Rawson to expand its product offering. Finch also confirmed Smith will remain as group account director “focusing on a seamless integration of all Megacolour clients”.

In November 2024, Rawson Print & Packaging announced the retirement of co-director Shane Wildash.

At the time of the announcement, Rawson Print & Packaging confirmed to Australian Printer that following Wildash’s retirement, there will be no changes in management except its head of operations Gary Pool working more closely with directors Lachlan Finch and Andrew Price to manage the operational aspects of the business.

The widely acclaimed ROLAND 700 EVOLUTION litho press deploys an array of innovative technologies to give unprecedented levels of efficiency, productivity and print quality.

- Australasia Tel: +61-2-9645-7900 info.au@manrolandgoss.com

HP large format senior vice-president Michael Boyle has taken on a new role in the company as of May 1, as its senior vice-president and managing director of the Central and Eastern European market.

Boyle has been with HP for almost 10 years, starting off as its vice-president of Asia Pacific and Japan, based in Singapore, before taking up the position of vice-president and managing director in A/NZ and relocating to Sydney.

He was then appointed to the large format senior vice-president role in August 2022, based in Barcelona.

Before joining HP, he spent five years

FUJIFILM Business Innovation (BI) Australia has launched four new midrange production presses in the Revoria Press series. The machines include the Revoria Press EC2100S and Revoria Press SC285S, which are equipped with a specialty toner station in addition to the four-colour toners, enabling five-colour printing in one pass.

They also include the Revoria Press EC2100 and Revoria Press SC285 four-colour presses. All four products are designed to be compact with the ability to print with speed and maintain high quality outputs.

FUJIFILM BI Australia head of Oceania and graphic communications senior general manager Yoshitaka Nakamura said, “As industry demands continue to evolve the efficient printing process, we are thrilled to introduce the next-

at Canon and eight years with Océ, which Canon acquired in 2010.

Boyle reflected on his time leading the HP large format business, saying, “I am incredibly grateful for the amazing team I’ve had the privilege to work with here in Barcelona. Your dedication and support

generation machines, bringing even greater possibilities to the local market.

“Since the Revoria Press series launched in July 2021, its impact on the professional printing industry has been profound. It has set new standards in Europe, the US, and the Asia Pacific region, empowering print professionals to push creative and technical boundaries like never before.

“With its combination of image quality, productivity, and specialty colour printing, we believe the Revoria Press series has redefined what’s possible in production printing. Now, with the latest advancements, we are excited to see how these next-generation machines will further transform businesses in the region, with the aim to unlock new levels of efficiency, creativity, and competitive edge.”

These new products boast the option of an in-line Smart Monitoring Gate, which performs real-time detection and correction of any colour density variations or front-toback registration, during printing.

Taking it one step further is the optional Print Inspection System, which incorporates the Smart Monitoring Gate and powerful

have been instrumental in our collective success, and I am deeply appreciative of each and every one of you.

“As I step into this new role, I am filled with excitement and optimism. I look forward to driving innovation and growth in the Central and Eastern European market, and I am confident that together, we will achieve great things.

“Special thanks to my colleagues and family that continue to support me in this journey. Cheers to new beginnings and reaching new heights!”

In January 2024, Boyle shared his professional goals and new year’s resolutions with Australian Printer, saying they included inspiring creativity in others, having the courage to take more risks, and learning more about the opportunities AI will bring in the future.

software which compares printed material with Print Server images, to detect print anomalies. This system helps streamline the laborious task of checking for print irregularities, with the view to save significant time and effort.

The Revoria Press EC2100S and Revoria Press EC2100 print at a high speed of 100 pages per minute and are primarily utilised for an extensive range of commercial printing and quick printing, while the Revoria Press SC285S and Revoria Press SC285 have a printing speed of 85 pages per minute and are utilised for quick printing and in-house printing.

All four products are designed to be compact through the newly developed Vertical Toner Development Technology. They are also designed to incorporate the technology that enables high image quality printing, which is a feature of the flagship model, the Revoria Press PC1120.

The products can handle an expansive range of paper weights, from lightweight 52gsm to heavyweight 400gsm, and paper sizes from a minimum of 90mm x 146mm up to 330mm x 1300mm without reducing its printing speed.

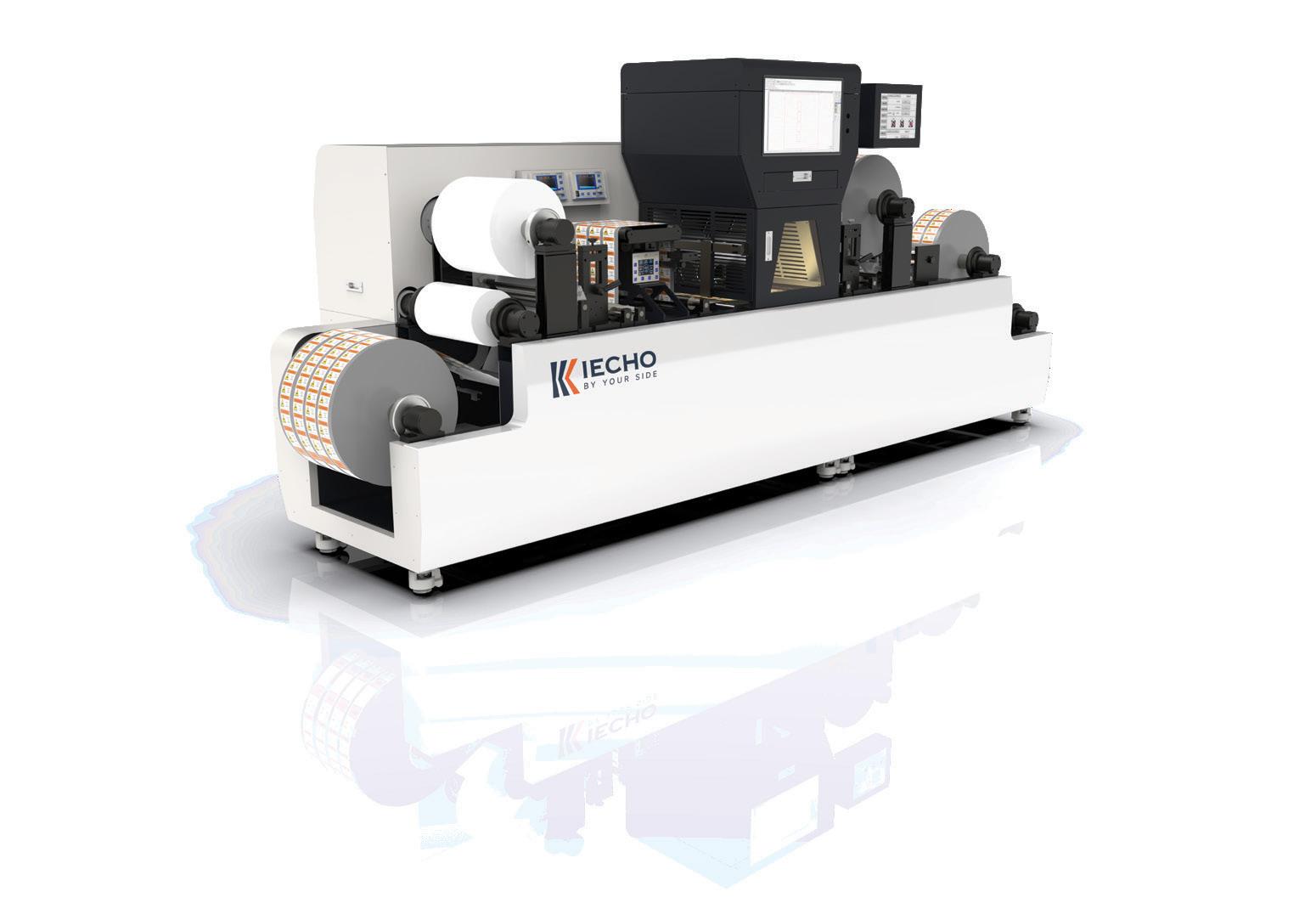

From signage to packaging, IECHO’s innovative technology ensures precision, adaptability, and simplicity. Here’s a closer look at three standout products now available at Ball & Doggett:

The ultimate label cutting device. A high-performance digital laser processing platform integrating automatic feeding, automatic deviation correction, lamination, laser flying cutting, and automatic waste removal. This platform is ideal for processing adhesive label materials, including paper, PVC, PET, and more.

Ideal for businesses of all sizes, the BK4 handles diverse materials like vinyl, foam board, and corrugated sheets. A wide range of tooling and intelligent print/cut registration ensures accurate and flexible operation, perfect for signage, displays, and packaging.

Compact yet powerful, the PK cutter is a cost-e ective solution for smaller print shops. It combines intelligent features with cutting and creasing capabilities, perfect for signs, printing, and packaging needs.

Explore the IECHO range to save time, reduce waste, and enhance your workflow. Whether you’re in printing, packaging, or design, IECHO brings e iciency and precision to every project.

Visit Ball & Doggett today to learn more and request a demo!

Mimaki Australia has signed a distribution agreement with Shann Australia, an Australian-owned business that has been supplying a diverse range of industries for more than 60 years.

Mimaki Australia national sales manager Jason Hay said, “Shann is highly regarded by top customers for its 3.2m to 5m wide printing media. As an innovative leader in the Australian market, Shann has introduced high-performance media brands such as Drytac, Heytex, and Beaver Paper.

Wildstone is set to become one of the biggest outdoor media asset owners in Victoria after agreeing to buy Total Outdoor Media’s (TOM) entire portfolio of regional billboards.

The deal marks Wildstone’s first Australian portfolio acquisition and includes 38 classic sites and 14 digital sites.

The acquisition is the second agreement the company has struck in Australia since launching in the country last year, with it having agreed a sale-and-leaseback deal to fund two new digital spectacular sites for Alliance Outdoor Media Group in October.

Under the terms of that agreement, Wildstone leases the sites back to the operator, which continues to manage media sales.

With the TOM portfolio, Wildstone will take full ownership of the assets and enter into new partnerships with media operators interested in managing advertising for the sites.

Noel Cook, managing director for Wildstone Australia said, “We’re thrilled to have completed our first acquisition in the Australian market and especially pleased to have secured such a strong regional portfolio. Through this deal, we are enabling regional centres to

“With a team of knowledgeable professionals across Australia, we are confident that, together, we can provide our customers with the best possible solutions.”

As a result of this deal, Mimaki will leverage Shann’s extensive distribution network to expand the availability of Mimaki products across Australia, ensuring a broader market reach and enhanced customer support.

Mimaki Australia managing director Kohei Kobayashi said the partnership marks a significant step forward in strengthening Mimaki’s presence in Australia.

“We look forward to continuing our commitment to delivering high-quality printing solutions through Shann’s nationwide network,” he said.

In March, Mimaki appointed Australian DTF Servicing as a new authorised service agent in Brisbane. The company also recently introduced a major update to its service fee structure, transiting to a two-tiered pricing model: metro and non-metro areas.

take advantage of digitisation as we know the regional audience is a growing and critical part of many outdoor campaigns.

“We will continue to support media operators and look for further opportunities in regional areas, as well as also being very much open to metro locations. We see the value in having billboard inventory across a diverse range of Australia markets and this acquisition is just the beginning, with more exciting announcements on the horizon as the company continues to expand its footprint.”

Ged Hart, managing director of TOM said, “We’re delighted to have reached this agreement with Wildstone Australia and are incredibly proud of the premium regional assets TOM has built in Victoria. The strong demand from advertisers underscores the growing importance of regional out-of-home media. With Wildstone’s vision and expertise, we’re confident these sites will continue to thrive, unlocking even greater opportunities for advertisers in key regional markets”.

Wildstone’s Australian expansion forms part of the company’s broader strategy for international growth. In addition to the Australian acquisition, the business has also recently announced new acquisitions in both Germany and Spain.

These add to Wildstone’s current portfolio of more than 5400 billboards across six countries. In its home market of the UK, Wildstone has emerged as the leader in both OOH asset ownership and the digitisation of classic OOH assets.

Over the past four years, the company has digitised more than 1000 billboards across the country, in the process facilitating the growth of several key media operators.

In August 2024, Wildstone made two significant executive hires – Mitch Cook as its commercial director for Australia and Amber Burbidge as a commercial executive. Both of them previously worked for oOh!media.

The new AccurioPress C14010S and C12010S, debuting at PacPrint 2025, are the future of digital print as they unlock new creative opportunities for printers

Konica Minolta is set to redefine the digital print landscape with the Australian launch of the AccurioPress C14010S and AccurioPress C12010S.

These next-generation production presses, debuting at PacPrint 2025, mark a significant leap forward in print speed, media versatility, automation, and colour capabilities. With the introduction of highopacity CMYK + white toner, these presses are engineered to provide print businesses with enhanced creativity, expanded service offerings, and greater profitability.

Konica Minolta general manager of sales Andrew Cocker said he is excited about more than just the technical specs of the new presses.

“Innovation in digital print isn’t just about speed; it’s about unlocking new creative opportunities. The AccurioPress C14010S and C12010S set a new standard for what’s possible in the print industry,” he said.

Unlocking new business potential with white toner

One of the most anticipated features of the AccurioPress C14010S and C12010S is the introduction of white toner, a transformative addition for businesses looking to elevate their print applications.

The ability to print in white unlocks a range of creative possibilities, enabling printers to produce high-impact designs on dark, coloured, and transparent media.

“White toner is a game-changer for creative design. It empowers print businesses to differentiate themselves and offer premium, high-margin applications,” Cocker said.

By incorporating white toner, print providers can establish a unique position in a competitive market, add high-value print services, and expand their revenue streams.

Unrivalled performance for high-volume production

Built for efficiency, the AccurioPress C14010S and C12010S deliver exceptional speed and quality, with production rates of 140ppm and 120ppm respectively.

Designed to handle demanding workloads, these presses integrate seamlessly into commercial and specialty print environments, helping businesses meet tight deadlines and maintain consistent quality.

Key performance features include:

• Advanced IQ-601 Intelligent Quality Optimiser – Ensures real-time colour control and precise registration adjustments for flawless prints.

• Expanded media handling – Supports a wide range of substrates, including textured, synthetic, and heavyweight stocks up to 450gsm.

• High-capacity input and output – Reduces downtime and boosts productivity by enabling continuous, uninterrupted printing.

• Versatile finishing options – Includes inline booklet making, perfect binding, creasing and folding, streamlining production for various applications.

“For print providers, efficiency is key. These presses allow for greater throughput, reduced waste, and superior quality control, making them a must-have for high-volume environments,” Konica Minolta Australia production print product marketing manager Grant Thomas said.

The print industry is undergoing rapid transformation with increased demand for short-run, customised, and high-quality print solutions. The AccurioPress C14010S and C12010S offer:

• Enhanced automation – Reduces operator intervention and increases production efficiency.

• Exceptional colour consistency –Konica Minolta’s imaging technology ensures precise colour reproduction across all print jobs.

• Seamless integration – Works effortlessly with existing workflow and print management software, simplifying operations for businesses of all sizes.

Konica Minolta continues to pioneer intelligent print solutions with features that minimise manual adjustments and optimise press uptime.

For larger and more demanding projects, the systems accommodate long sheets of up to 1300mm simplex and 900mm in duplex, providing unrivalled flexibility to meet customer demands.

Whether it’s for banners, book covers, or specialty items, the AccurioPress C14010S and C12010S let customers rethink possibilities in production printing and explore additional opportunities for business growth.

Graphic arts customers such as print service providers, offset printers, digital printers, and direct mail will benefit from the AccurioPress C14010S and C12010S models.

Other potential market segments include enterprise document printing, such as central print rooms and in-plant print operations.

“Konica Minolta’s AccurioPress C14010S and C12010S are engineered for efficiency, streamlining operations with advanced smart innovative technology,” Thomas said.

“These new print solutions help operators to work smarter, reduce manual adjustments for unattended, uninterrupted printing, and deliver flawless print results faster with reduced touchpoints and exciting new colour options with the addition of white in the new high-opacity CMYK + white toner.”

Features such as the Intelligent Quality Optimiser Unit, IQ-601, including a new inline spectrophotometer for precise colour profile creation, and Intelligent Media Sensors (IM-104 and IM-105) support consistent, high-quality output with minimum user intervention.

The IM-105 measures the paper size of the substrates and detects even the slightest variations in paper cutting size and, together with the Intelligent Quality Optimiser IQ-601, automatically adjusts image positioning to eliminate front/back alignment errors for professional quality and consistency with every print run.

Other key benefits include automatic print quality adjustments with Automated

Quality Adjustments (AQA) and Automatic Inspection Technology (AIT), with an intelligent overall design to maximise press uptime.

The AccurioPress C14010S and C12010S models underpin Konica Minolta’s mission to support the digital transformation of its clients’ companies by sector and industry, predicting potential challenges and creating solutions together.

Its human-centric partnership approach lets customers streamline their businesses through fewer human touchpoints and higher productivity with tangible benefits including high-quality output with less print waste.

“Konica Minolta is committed to enhancing its customers’ creativity and digital transformation. The new five-colour AccurioPress C14010S and C12010S print systems build on 20 years of digital printing expertise, innovation, and leadership, backed by the dedicated professional support that Konica Minolta is known for,” Thomas said.

“New operator assistance tools and fewer touchpoints let Konica Minolta customers optimise workflows and reduce downtime. This leads to greater creativity that empowers customers to rethink opportunities and identify new, profitable revenue streams.”

showcase the power and versatility of the AccurioPress C14010S and C12010S.

one session with our experts. Whether you’re looking to expand your business,

At 75, Cactus Imaging co-founder and general manager of operations Keith Ferrel reflects on his time in the industry including the importance of vision, risk-taking, continuous innovation and investments in automation

There’s no one in this industry quite like Keith Ferrel. At 75 years of age this year, he is one of the few remaining seniors that works fulltime – and he has no plans of stopping anytime soon. His peers describe him as a visionary; a calculated risk-taker; an extremely hardworking but humble person; a gentleman that wants to make a difference in the printing world.

Ferrel has also experienced it all in business – from helping start up a company in printing with no prior print knowledge, to being held at gunpoint when he demanded payment from a procrastinating client, visiting an international client during a coup, and seeing one of his sites impacted by tragedy.

The business, Cactus Imaging, is a huge part of his life, and having helped run it from its inception, he says it is one of his prides and joys. Ferrel, who is originally from New Zealand, has not only taken Cactus Imaging from strength to strength, but he has also come a long way since his foray into the world of print.

Widely recognised in Asia Pacific as one of the most influential people in the print industry, Ferrel has several accolades under his belt. A FESPA Hall of Fame inductee, Ferrel was also the 2014 FESPA World Printer of the Year and the 2021 Media Super Lifetime Achievement Award winner.

In addition, Ferrel has constantly topped the ProPrint Awards list since 2022 –he won the Printer 50 category in 2022, came runner-up in 2023, and topped the list again in 2024.

“People think I’m a visionary but to me, it’s just business sense. You’ve got to have foresight and take advantage of opportunities; otherwise, you’re just wasting time. But you’ve got to know when to jump off the bus and jump back on another one,” Ferrel said.

Ferrel co-founded Cactus Imaging in Auckland in 1992, together with Warwick Spicer. The duo met when Spicer was CEO of the now-defunct Auckland Star,

while Ferrel was group sales director. The idea of starting a business emerged when Spicer was intrigued by electrostatic printing technology at a tradeshow when looking to buy a newspaper press. He found the technology to have commercial potential and approached Ferrel with the proposition.

Ferrel bought into the idea and they both set the business up in Auckland. At that time, Ferrel was only 42 years old, and Spicer was 54 – with no prior printing experience whatsoever.

“We ended up buying an electrostatic printer, which was the first of its kind in the southern hemisphere, and potentially the first outside of the US,” Ferrel said.

However, after 12 months of running the company, the pair realised the New Zealand market alone was not big enough for what they were anticipating for the business. So, they made the big move to Sydney in 1993 and set up the sales arm of Cactus Imaging Australia. Their New Zealand operations was printing what they were selling in Australia.

“We got to the stage where we were selling more in Australia and printing in New Zealand, than printing and selling in New Zealand,” Ferrel said.

They also saw the potential for paper billboards, which was very common back then, to be replaced by vinyl. After researching Vutek vinyl printing technology in 1995 and meeting Dan Griesemer, whose company, Impact Imaging, was doing grand-format vinyl printing, the pair decided to play in that space – which was largely dominated by MMT in Australia.

However, as Cactus Imaging didn’t have sufficient funds for a vinyl printer, Spicer and Ferrel outsourced production to Impact Imaging. Very quickly, the vinyl billboards business skyrocketed, and the duo were soon looking to own their own 3.5m Vutek Sprayjet in Australia.

Griesemer took a 50 per cent stake in Cactus Imaging and helped Spicer and Ferrel establish a full-scale production plant at Lane Cove, Sydney, in 1996.

With the new Vutek Sprayjet installed in Australia, Cactus was able to introduce seven-day turnarounds.

“When we were printing on vinyl billboards in America, turnarounds were between six to eight weeks. But, when we got a machine here, we could turn them around in a week. It was a game-changer,” Ferrel recalled.

“I still remember the very first billboard that we printed – for Balmain Rugby Leagues Club. It was about an 8m by 3m billboard, and it took nearly six and a half hours to print.”

Cactus Imaging’s expansion into Asia followed shortly when it purchased machinery through the now-defunct Israeli-based NUR. Cactus owned the second NUR Blueboard HiQ Plus machine in the world, which was also an Asia Pacific first.

The NUR rep at that time, suggested Cactus Imaging go offshore to which Ferrel replied, “We’re only just starting to make headway here, let alone go anywhere else”. The rep then suggested a joint venture.

Austrade helped Ferrel and Spicer organise appointments with potential joint venture partners right through Asia, including India, Pakistan, and the Middle East. In 2000, they eventually signed a deal with Chennai’s Bee Vee Graphics to set up what Ferrel said was India’s first digital grand-format operation.

“It just went off from there. Then came about this opportunity in Pakistan with a company called Lakson Tobacco, through Philip Morris. We thought we could service Pakistan using our Indian factory, not knowing the feud between India and Pakistan,” Ferrel said, candidly.

“I’m not going to tell you exactly what we did to get around it; they’d probably hunt me down.”

Another memorable incident for Ferrel was when a Pakistani client owed the company money and was procrastinating to pay. When Ferrel visited his operations in India, he decided to make the trip over to Karachi to retrieve what this client owed him.

“They lied that they’d got the money, not realising I was in India and was only an hour and a half flight away. I landed there that afternoon, got a cab from the airport to the hotel, and he gave me a cheque. The deal was for cash,” Ferrel said.

“I was furious and got closer to him. The next thing I knew, I had a shotgun to my head. I ended up getting the money anyway, but the challenge then was getting US$50,000 through the Karachi airport. Those days, we had to be at the airport five hours before a flight, so I checked in and hid in the toilet.

“They kept calling my name and I exited the toilet at the last minute possible and told the airport staff I had been violently ill. They put me on a buggy and raced me through customs and onto the plane.

“On the plane, I thought to myself, ‘I have all this money on me, how am I going to manage when I disembark in India?’ Thankfully I had been going in and out of the country so often that the guy at customs knew me and let me through quickly.”

After six years in India, just as Ferrel was returning to Sydney from visiting its Chennai operations, tragedy struck. Ferrel knew something was off when Spicer was at the Sydney Airport to receive him.

“Warwick was at the airport and as soon as he saw me, he said ‘mate, go home and get changed because you’re getting back on a plane this afternoon to Chennai – the place is six metres under water,” Ferrel said.

“The Chennai site was backed onto a river and there had been huge storms. The banks had broken, affecting the entire industrial area including our factory. It was an absolute disaster.”

As nothing was salvageable, the company lodged an insurance claim, which he calls the biggest insurance payout in Chennai of that time, because Cactus Imaging was insured for loss of business as well.

Cactus Imaging saw no reason to rebuild the business, so it sold its stake in the joint venture and exited India. The Pakistani business also drifted off.

Through its time, Cactus Imaging serviced clients in other Asian countries as well, including Malaysia, Singapore, and Cambodia.

“When I was doing some work for a company called Sena Jaya in Singapore, its boss Simon Loong was talking to someone named Calvin Pereira in Cambodia – I had not even heard of the country at that time!” Ferrel said.

“Calvin was using MMT in Malaysia to print his billboards, so Simon suggested he use Cactus Imaging. Calvin was happy to meet me for a chat, so I jumped on a plane not knowing anything about Cambodia, apart from it being about two hours away from Singapore by flight.

“When I got on the plane, you wouldn’t believe it. I was the only person in civilian clothes. The rest were in army uniform. When we landed in Phnom Penh, it was right in the middle of a bloody coup!

“I disembarked the plane and didn’t have to clear customs or anything. There was a car at the bottom of the stairs, waiting for me. I got into the car and surprisingly ended up at the royal palace in Cambodia. Phnom Penh Media was owned by representatives of the royal family at that time, so I stayed at

the palace and met with someone named Dien Douk, whose father was the King of Cambodia.”

Cactus Imaging still retains Phnom Penh Media as a client to today, with Ferrel and Douk becoming good friends –he was even invited to Douk’s wedding.

All eyes were on Cactus Imaging’s growth, and in 2007, Ferrel and Spicer received an acquisition proposal from New Zealand private equity company, Knox Investment Partners, also a major shareholder in Opus Group. Knox Investment Partners had previously purchased Cactus Imaging’s New Zealand operations.

“Warwick and I didn’t want to sell the Australian business as it was our cash cow. The business was doing very, very well so we refused their first offer,” Ferrel said.

However, when the investment firm came back with a counteroffer, it was a deal they could not refuse. By this time, Spicer was close to retirement age – he left the business within a week of its purchase by Knox Investment while Ferrel and Nigel Spicer (Warwick’s son) continued with the business.

“Warwick’s leadership, his business acumen, his inspiration, and more importantly, his continued friendship has had such an enormous impact on both my life and career,” Ferrel said.

Opus Group went on to purchase several other top printers of its time including McPherson’s Printing in Melbourne, CanPrint in Canberra, and Ligare in Sydney. However, Opus started facing revenue declines.

“When this happened, several of Opus’ acquisitions including Cactus Imaging were ‘bailed out’ by CK Lau in Hong Kong. Following that, he put Cactus Imaging up for sale as large format wasn’t his thing and he wanted to focus on book printing, which was more in tune with the offerings of Ligare and McPherson’s Printing,” Ferrel said.

“I discussed it with Brendon Cook, the founder and then CEO of oOh!media before he retired, and the company bought Cactus Imaging for a very good price. This provided, and still provides today, surety supply and reinvestment in equipment for Cactus Imaging.”

With such a strong history backing it, Cactus Imaging has become a market leader today. It owned – and owns – the latest and greatest printing and finishing equipment and has spent millions on automation to support its clients and staff.

Previously, along with the NUR Blueboard HiQ Plus machine, Cactus Imaging had a few other firsts when it came to technology. The innovation-forward business owned the world’s first HP Scitex TurboJet 8500, fourth HP Scitex XP5100, and second HP Scitex XP5500 in its heyday.

It was also the first in the southern hemisphere to go from solvent to UV.

In more recent years, Cactus Imaging purchased the southern hemisphere’s first Durst Rho 512R roll-to-roll UV-curable printer in 2017 and a high-speed Durst P5 350 HS D4 hybrid press in 2023, which was also the second one in the world. Cactus Imaging also recently invested more than €300,000 in a new MIS system with Durst last year.

In 2019, Cactus Imaging installed Australia’s first Fujifilm Acuity Ultra 5044, one of the first five of its generation in the world. It also installed its predecessor, the Fujifilm Acuity Ultra, in 2018, also as an Australian first. The Fujifilm Acuity R2 was installed at Cactus Imaging in 2023 – the first of several installations for this technology following its showcase at FESPA Munich that year.

In 2020, Cactus Imaging also installed an Australian-first Fotoba trimmer.

“We’re always at the forefront of technology. One of our big benefits – which has been built up over years of trust and working with manufacturers – is our ability to help them help us. We’ve been to beta sites, we’ve tested various equipment, and we’ve always put our toes in the water where new technology is involved,” Ferrel said.

“Because of this trust, we can sometimes gain knowledge of what technologies are in the works from manufacturers, which allows us to forward plan.

“I’m not interested in going to tradeshows and buying what anybody else can buy today because we bought that two years ago. What I’m looking at is the manufacturers’ future inventory because we don’t just want to be competitive; we want to be market leaders.”

A prime example of Cactus Imaging’s market leadership is the development of its environmentally friendly printing option for outdoor advertising billboard skins, where the substrate is not only recycled, but turned back into boards for use again. Led by Nigel Spicer, Cactus Imaging partners with Gale Pacific on these projects.

This idea started taking root in 2019, when Cactus Imaging developed Smart Skins –a world first outdoor advertising banner –in conjunction with oOh!media. Smart Skins allowed the substrate to be turned into high grade polymer products like park benches and bollards when no longer needed.

“We’ve been working on our environmentally friendly printing option for more than 10 years and we’re 98 per cent of the way there. Unless you’re doing things like these, you’re going to be yesterday’s man,” Ferrel said.

Ferrel has no intentions of stopping or retiring, saying he is more focused than ever and wants to pass on his immense knowledge and experience to the industry.

“I love what I do, the people I work with, and this industry. I’d hate to put it in all this work for nothing and hopefully, others can benefit from it. I’m still going at this age because it’s mind over matter for me. Maybe one day I’ll wake up and think I’ve had enough, but until then, I’ve got more than enough enthusiasm to want to be a part of print,” he said.

Having been in the industry for 33 years, Ferrel said the growth of innovation and technological shifts in print has been “mind boggling”.

“In the past, your machines would allow you to print for one segment of the industry. They were also slower and lacked in detail and quality for prints,” Ferrel said.

“Machines today are super-fast, allow us to print on a variety of substrates, are so detailed in their print quality, have short changeover times, and allow us to play in markets we haven’t done before.

“For example, our Durst P5 allows for hapt printing – you can use it to print braille and raised effects and its many other features. We’ve just completed a big job for an artist using the hapt feature, and the prints will go into the New York Art Gallery.”

What’s also happening is the growth of digital billboards – but Ferrel finds it’s not as bad as some make it out to be.

“Digital billboards haven’t impacted anywhere near as much as people think.

I don’t deny there is growth in digital outdoor, but that has given recognition to outdoor media. So, while there are fewer static billboards now, the volume of changeouts of static ads have increased, allowing printers to produce more,” Ferrel said.

“One of the advantages of static billboards is it’s availability 24/7. Digital billboards rotate advertising, so each ad is only shown for about 10 seconds at a time,” he said.

“You can drive past your billboard on a freeway five times a day for five days and never see your ad. Also, with static billboards, research shows retention rates are much higher than with digital billboards.”

Ferrel’s efforts extend beyond the doors of Cactus Imaging. He gives back to industry and society, plays as hard as he works, and makes sure he sets aside time for family.

“I’ve reached a stage in life where I have the experience to give back. If I keep everything to myself, there’s no legacy left. My knowledge is there to spread so hopefully others can be better, or better equipped,” he said.

Within the industry, Ferrel advocates for Women in Print, the FESPA Future Leaders Program, and the ASGA apprenticeships and traineeships programs, to name a few.

He was also a past HP Customer Advisory board member, past board chairman of the Asia Pacific Japan Dscoop board, is currently a board member of the Asia Pacific Japan Dscoop board, and a current board member of FESPA Australia.

Cactus Imaging supports Camp Quality, Cure Our Kids, the Endeavour Foundation, and the Humpty Dumpty Foundation, along with many other charities. Ferrel, who loves his rugby, has also made sure the company backs charities founded by former Wallabies including the George Gregan Foundation and Matt Rogers’ charity, 4 ASD Kids.

A true sports lover, Ferrel also has a soft spot for horse racing – he currently owns far too many racehorses but has been lucky enough to have a Melbourne Cup runner.

“Three of them recently raced at Rosehill, and all three came second. I guess that’s better than nothing,” he said with a chuckle.

The family-focused man also finds himself spending valuable time with his family.

“My family is everything to me. I’ve been married for 43 years now, have an amazingly supportive wife, three wonderful daughters and four beautiful grandchildren,” he added.

Flexible conditions and a supportive environment are beneficial for both women and businesses, according to Ricoh Australia national customer service manager Rachel Zidan

‘Idon’t know how she does it’ is a sentiment that often comes to Ricoh Australia national customer service manager Rachel Zidan’s mind when she observes women in her team juggling the regularly competing demands of work and family.

“They do so capably and with effortless composure, ensuring they’re giving their all to the assorted parties making demands on their time and energy,” Zidan said.

“While making the difficult look easy –or manageable, at the very least – may be their super-power, I’m perpetually conscious of the importance of not making their lives more stressful and challenging than they already are.”

For that reason, Zidan has long been an outspoken advocate for work-life balance, and for flexible conditions that enable employees whose duties and responsibilities permit it, to split their working week between home and the office.

At Ricoh, many of the company’s customer care specialists were benefitting from such arrangements, well before COVID rendered them unremarkable.

“In the age of hybrid work, flexible arrangements offer advantages to both men and women. While women often bear most caregiving responsibilities, these flexible options also empower men to take on caregiving roles, fostering more balanced family dynamics,” Zidan said.

“As part of our commitment to supporting employees in achieving this balance, Ricoh offers a gender-neutral parental leave policy, encouraging men to share in caregiving duties that have traditionally been seen as women’s roles.”

What’s good for female employees can be good for business too, said Zidan. She believes that being treated as an individual with unique needs – someone whose priorities and responsibilities aren’t confined to the nine-to-five workday week – is empowering and motivating in equal measure.

“Employees who feel seen and heard in this way are more likely to become high achievers who are focused on getting amazing results for the businesses they serve, than those who believe themselves to be mere cogs in the system,” she said.

“They’re more likely to stick around longterm too. At Ricoh, where I’ve worked in progressively senior customer service roles since 2017, I’m proud of the fact that 60 per cent of our primarily female team has been with the company for more than six years.

“That’s far from the norm in the contact centre and customer service sector. In our line of work, the hours can be unsociable and the work stressful and thankless. Agent burnout is a common phenomenon and, consequently, staff churn rates of more than 100 per cent are common in some segments of the market.

“Organisations in the latter cohort typically struggle to deliver standout customer experiences because they’re trapped in revolving door recruitment mode; perpetually sourcing and upskilling new staff, only to see them move on in a matter of months.

“Flexible working conditions aren’t the whole answer to this problem but, in my experience, they can go a long way towards creating a more enjoyable –and sustainable – employee experience, for female and male workers alike.”

According to Zidan, offering support in the form of an Employee Assistance Program and – just as importantly –encouraging staff to use it when they’re experiencing professional and life challenges is important.

“During the time I’ve been in the workforce, I’ve seen businesses and organisations make great gains in this regard. Mental health issues have been systematically and significantly de-stigmatised over the past decade and formerly taboo subjects, such as domestic violence, brought into the open,” she said.

“At Ricoh, I’m proud we have a company and a team culture in which individuals have no issue with disclosing, for example, that they’re having anxiety issues and may need to take some time off for self-care.

“As a leader, I see it as my responsibility to advise my team members that resources are available to help them navigate this and other major issues. And I strive to make whatever accommodations are possible to support them on their journeys – to create a safe space in every sense of the word.

“Knowing their employer has their back and will repay their support and loyalty in kind is enormously reassuring for high performing female employees, especially those previously accustomed to working for organisations where the boundaries between personal and professional were defined stringently.

“As we celebrate the progress we’ve made towards equity and inclusion here in Australia, it’s worth remembering that one of the best ways businesses can help us continue to advance is by putting practices in place that help us survive and thrive through all sorts of times.”

Discover how Ricoh’s digital services can revolutionise your business operations. With decades of experience in workplace technology, we provide comprehensive solutions that free you up to focus on what you do best – delivering exceptional products and services to your customers.

From cloud and security solutions to managed IT services, Ricoh has the expertise to keep your business running smoothly and efficiently.

Learn more about how Ricoh can support your digital transformation.

Avon Graphics has put its own modern spin on traditional embellishment methods, solidifying its leadership in this key area of play for the business

Having established itself as one of the key finishing houses to turn to when Australia’s print providers want their prints embellished, acclaimed embellishing house Avon Graphics has perfected its traditional embellishment techniques and has created imaginative ways to enhance the artistry of printing.

The company found itself excelling in the niche market of finishing, foiling, laminating, and embellishment some 40-odd years ago and through dedication and business smarts, has long ridden the wave in this space.

Today, Avon Graphics offers trade services in foil stamping, embossing and debossing, die making, laminating, UV coating, hologram build and application, large format digital printing, and finishing services in Melbourne, Sydney, and Brisbane. It also offers tradeonly bookbinding in its Brisbane plant.

Avon Graphics’ fleet of foil stamping equipment includes flatbed high speed equipment, clamshell quarter, half, and full-size cylinders at all three of its sites. It also owns water-based laminating machinery in Melbourne and Sydney, and can run up to 1480mm sheets (with full sheet options available) in Queensland. Its UV coating equipment also goes up to full sheet with both screen coating and flexographic coating processes on offer.

Avon Graphics has built up its capabilities over the years through organic growth, forward-thinking business strategies, the adoption of new technology, and by acquisitions. Its most recent acquisition was Melbourne-based foil stamping and embossing specialist, Lorimier, in 2022, in a move that brought together 200 years of finishing excellence together under one brand.

Avon Graphics managing director Tate Hone said offering its clients superior quality, personalised service, and fostering long-term relationships is key to the company’s success.

“At Avon Graphics, we believe that service comes first. Our ongoing investment in the future of embellishment helps us and our customers stay ahead of the pack,” Hone said.

As Avon Graphics offers a large range of equipment across many different finishing processes, it helps printing companies have one point of production.

“We typically find that some finishing technologies can be utilised in-house by print providers, such as thermal laminating, but a lot of the more specialised processes have remained with finishing companies,” Hone said.

“Specialist trade finishing providers like Avon Graphics can offer various styles of equipment for one process as certain jobs suit certain presses to get the best results.”

Avon Graphics’ capabilities don’t end there. It has found ways to blend the traditional ways of embellishment with today’s market needs. With a larger focus on the environment and recyclability these days, Avon Graphics has been busy creating new processes in specialty finishing to keep up with demand.

Its Ecolux product, under its Ecoembellish banner, launched in early 2024 with great success. Ecolux is a curbside, fully

recyclable foil coating that Avon Graphics can apply in silver for digital or offset overprinting, creating a true print over foil finish. It also offers a range of colours and holographic finishes and patterns.

“The feedback about Ecolux has been overwhelming. Years of research and development has allowed Avon Graphics to create Ecolux – and we are proud to bring it to the market,” Hone said.

“Ecolux gives a smooth, high gloss metallic finish without any plastic film, so the end result is a foilboard that can be used for packaging and a wide variety of printed material while meeting the recycling requirements of today’s marketplace.”

Avon Graphics’ Ecoembellish brand has been around since 2022. Since then, it has allowed Avon Graphics’ customers to better understand the recyclability of their products and guarantee the use of recyclable embellished products to their clients.

Avon Graphics’ embossing, UV coating products, hot foil stamping, and Alumma raised foil falls under the brand, marked by the Ecoembellish logo to guarantee recyclability.

“As a society, we are becoming more aware of the processes and manufacturing involved, as well as the types of materials and packaging used for the products we consume,” Hone said.

“Traditionally, some printing processes have not been recyclable. This creates a problem today as more consumers, in particular millennials who are quickly becoming the largest consumer group, care deeply about their impact on the environment.

“While it has been previously assumed that high-class embellishment is not recyclable, Ecoembellish is here to disrupt the industry, creating stunning visual effects from 100 per cent recyclable material.”

According to Hone, the industry can continue to expect Avon Graphics to keep innovating in this space.

“We are currently investing in and developing further new processes to again strengthen our offering to the Australian print trade,” Hone added.

With print embellishment captivating the industry, Color-Logic has invited users to develop their marketing strategies by using this dynamic world

As the world of printing continues to evolve, print embellishment is rapidly becoming the buzzword captivating many in the industry. For the past 16 years, Color-Logic has positioned itself as a leader in print embellishment software solutions, providing printers and designers with the tools they need to stand out in a competitive market.

Print embellishments can range from simple additions, such as specialty inks or clear varnishes, to more complex techniques involving silver ink/toner as an underlay to CMYK on paper or white ink/toner as an underlay to CMYK on metallic stocks.

These advanced techniques can dramatically transform the look and feel of printed materials, making them more appealing to clients and consumers alike.

To support printers and designers seeking to harness the full potential of their fifth or sixth colour digital presses, Color-Logic has developed the QuickStart landing page. This resource is designed for anyone seeking to explore or utilise existing embellishment techniques, offering insights into what Color-Logic solutions provide in the print embellishment landscape.

Color-Logic develops colour communication systems and software

tool sets for a variety of special effect printing applications, providing brand owners, product managers, corporations, and their advertising agencies the ability to differentiate themselves and their clients with a simple print production process that delivers dramatic results.

Color-Logic’s decorative effects utilise the existing workflows of printers and designers, yielding dynamic results without the use of special equipment. Color-Logic supports the value of print and works with designers and printers to enhance their printed media.

‘All Print Starts with Design’ has been the guiding Color-Logic mantra for more than a decade, emphasising that no press can deliver quality results without a solid design foundation.

Designers need to understand the capabilities of the press on which their work will be produced, as well as the design techniques which will produce stunning effects. The Color-Logic QuickStart page not only showcases these capabilities but also educates designers on how to create effective files for metallic printing.

The Color-Logic QuickStart page is a vital tool enabling printers to visually grasp what their press can achieve,

while also demonstrating how quickly effects can be implemented, thus ensuring the designer’s original intent remains intact.

One of the standout features of the ColorLogic QuickStart page is the Test Form File, which any printer can use to test their press.

This form demonstrates 21 of the Color-Logic 924 metallic colours, and showcases various embellishments, including Gradation-FX, Dimensional-FX, Watermark-FX, Image-FX, and Pattern-FX. Each embellishment is accompanied by QR codes that link to tutorials on how they are created using Adobe Creative Cloud.

Color-Logic is committed to providing a predictable system for printers, complete with design tools, training, and educational resources that licensed printers can share with their internal teams, external designers, agencies, and brand clients.

Although videos showcasing physical samples are abundant online, few address the time, effort, and trials involved in achieving those results. The Color-Logic QuickStart page seeks to change this dynamic by offering not just Test Form files for printing, but also instructional videos that illustrate how Color-Logic tools operate, including a demonstration of its FX-Viewer.

This innovative feature allows designers to visualise effects on their monitors before committing to print, eliminating trial-anderror and saving valuable press time.

Once a user has printed the test form, Color-Logic encourages them to consult with their press manufacturer or dealer to explore how they would replicate these effects without the Color-Logic system.

Although print embellishments can be highly profitable, a comprehensive understanding of design time, proofing processes, colour palette creation, and the integration of metallics into images is essential to maximise the investment.

Color-Logic believes in a ‘show what is possible and how it was done’ philosophy, which is why it has created the QuickStart page.

Ricoh supplies Color-Logic in Australia.

Currie Group has always been a leader in finishing and embellishment in Australia and New Zealand, and has further intensified its reach into this space

As an industry print equipment provider, Currie Group helps print service providers with all their needs throughout the entire printing process – from file preparation to finishing. Finishing and embellishment is and has been one of the main offerings from Currie Group, and the company has now amplified its presence in this space.

In a move to further strengthen its foothold in the finishing and embellishment space, Currie Group recently inked a new partnership with baumannperfecta, becoming the exclusive A/NZ supplier of the German OEM’s range of automated cutting systems and related peripheral equipment.

“Currie Group already represents leading brands in A/NZ for over 75 years. Historically, Currie Group has offered smaller cutting machines, but now, the partnership with baumannperfecta enables us with a fully scalable automated offering,” Currie Group equipment category manager Alan Tam said.

“We love the modern state of the art design, ease of use, and quality German build.”

baumannperfecta’s range of cutting and materials handling solutions encompass the entire process – from single machines to fully automated lines, lifters, joggers and cutters, to full robotic systems which can be customised to individual requirements thanks to the modular and expandable design.

These robustly-engineered and technologically advanced systems offer precision, high-performance automation, and intuitive digital operation – delivering on the needs of today’s customer expectations and future-proofing their cutting and finishing solutions.

“The market is looking for superior, new-generation cutting solutions that bring the best of digital cutting and advanced materials handling technology to the mid- to large-format cut sheet market,” Currie Group CEO Rob Mesaros said.

Cutting can often be a bottleneck and an overlooked area in the print production process, whether that be for offset, cut-sheet digital printing, or high-growth areas such as labels and packaging.

The baumannperfecta cutting solutions fall within the 80-225 cm range, ideally complementing the offerings of Currie Group’s other finishing solutions, providing complete coverage for digital and traditional printing applications.

baumannperfecta sales manager Olaf Gerber said, “Only those who care about trends today can offer their customers future-proof solutions for the future. baumannperfecta was the first and only manufacturer within the graphics industry to fully automate the jogging process as well as the cutting process, ensuring automated, three-shift operation around the clock.

“Moreover, in 2018 baumannperfecta launched the RC Robotic system – the first robotic solution based on today’s industrial robots within the finishing area of the graphic industry”.

In his recent trip to Australia, visiting more than 20 print service providers of varying scale, Gerber saw very similar trends in finishing compared to baumannperfecta’s customers in Europe:

• Labour and skilled shortages: Skilled labour is hard to find and expensive. Cutting is skilled, labour intensive

and a very physically demanding activity, making it even harder to find good operators.

• Short-runs and on-demand printing: Increasing demand for flexible printing solutions for smaller quantities and quick turnarounds. Necessitating the need for efficient workflows.

• Digitalisation: Integration of digital technologies to optimise workflows and shorten production times. Connectivity through the entire production process is essential.

• Automation: The use of automated systems to increase efficiency, reduce errors in production, and reduce the physical ‘heavy lifting’ required enables a wider range of workers to operate the cutting systems.

• Sustainability: Using eco-friendly materials and processes to reduce the environmental footprint of the printing industry.

Tam outlined the business case for print service providers investing in premium finishing technologies.

“These solutions deliver labour savings, ease of use, and reduced training requirements. Safety features, automation, and less manual handling also help minimise the risk of injury. On top of that, premium finishing technologies that are built to last, with modular designs that grow alongside our customers’ needs, and tailored solutions to meet specific requirements,” he said.

“The result is consistent, on-time delivery of high-quality finished products – all supported by Currie Group’s extensive national service network and a leading European manufacturer known for its quality solutions.”

The print industry is constantly evolving, and an exciting development in recent years is the rise of specialty finishes. From eye-catching foils to velvety laminates, these premium enhancements are no longer exclusive to high-end brands – they are becoming mainstream thanks to advancements in finishing technology.

For print providers, the opportunity to incorporate specialty finishes isn’t just about aesthetics; it’s about increasing value, driving demand, and boosting profitability.

Today’s market demands more than just ink on paper. Customers want their prints to stand out, and specialty finishes provide the tactile and visual appeal that enhances brand perception. According to Hilton Laminating, some of the most sought-after finishes include:

• Velvet touch and anti-scuff laminates

– These soft-touch laminates add a premium feel to printed materials, creating an immediate sense of luxury. Anti-scuff properties ensure the finish remains pristine, even with frequent handling.

• Foiling and holographic effects

– Gold, silver, and rose gold foils remain classic choices, however, Hilton Laminating is seeing increasing demand for illusion (pearlescent silver) and holographic finishes. These elements bring an interactive, high-end appeal to packaging, invitations, and marketing materials.

• Spot UV – Spot gloss UV adds contrast by highlighting specific areas of a design, perfectly isolating and enhancing logos and emblems.

• Celloglazing – Glossy coatings elevate print materials, allowing brands to achieve distinctive, high-quality finishes.

According to Hilton Laminating, investing in specialty finishing technology

is no longer just for large-scale print operations. Even small and mid-sized printers are recognising the value of bringing these capabilities in-house, Hilton Laminating said.

This is due to several reasons, including:

• Higher profit margins – Specialty finishes command premium pricing. Adding foil, embossing, or spot UV to a print job can significantly increase its value without dramatically raising production costs.

• Increased customer retention –Clients who experience the impact of high-end finishes are more likely to return for future projects, appreciating the quality and uniqueness of the final product.

• Faster turnaround times – Outsourcing specialty finishes can lead to production delays. By investing in the right equipment, printers can streamline workflows and meet tight deadlines without compromising quality.

• Greater creative control – In-house finishing allows adjustments in real-time, ensuring every detail aligns with the client’s vision.

• Market differentiation – Offering specialty finishes helps print providers stand out in a crowded industry, giving them a competitive edge.

The demand for specialty finishes is growing and print providers who embrace these enhancements stand to benefit in terms of both revenue and reputation. Whether investing in high-end laminators, foiling machines, or spot UV technology, the right finishing solutions can transform ordinary prints into extraordinary pieces

While outsourcing specialty finishes has been the norm for many years, bringing finishing technology in-house has become increasingly viable.

Some of the benefits of outsourcing include cost-effectiveness if specialty finishes make up a small percentage of a business and they are working with a specialist finisher. It also eliminates the need for capital investment and ensures high-quality results from experienced professionals.

For print shops handling frequent specialty jobs, investing in laminating, foiling and equipment in-house can lead to significant cost savings, faster turnaround times, and increased control over quality.

The decision ultimately depends on a printer’s volume, customer base, and investment capacity.

As a leader in finishing solutions, Hilton Laminating offers a wide range of specialty films and equipment to meet diverse industry needs.

One of its standout machines is the M-560Y embossing laminator which sets a high standard for in-house finishing with its innovative features and precision. It features advanced electromagnetic heating that maintains an exact temperature within one degree Celsius, a durable chrome roller, delivers 6.2 tonnes of hydraulic pressure, and provides an impressive selection of embossing options.

Some of Hilton Laminating’s other products include:

• Foiling and holographic films – The company’s toner transfer foils are available in classic gold, silver, and rose gold, as well as eye-catching holographic and illusion finishes. These can be applied effortlessly with a laminator equipped with an uptake or rewind roller.

• Velvet touch and anti-scuff laminates – Designed for high-end packaging, brochures, and business cards, these films enhance both durability and aesthetics.

• Spot Gloss UV – Ideal for highlighting logos and design elements, these films add texture and shine to printed materials.

• BOPP films and PET laminates – Its Superstick and PET films provide versatile finishing options suitable for a range of applications.

• Binding solutions – A recent addition to its lineup, Rilecart Binding enables seamless production of booklets, manuals, and presentations.

The M-560Y Embossing Laminator sets a new standard in in-house finishing with its cutting-edge technology and precision. Featuring advanced electromagnetic heating that maintains an exact temperature within 1°C, a durable chrome roller, and delivering 6.2 tonnes of hydraulic pressure, it makes finishing effortless. With an impressive selection of embossing options, this laminator is sure to make its mark on the Australian market.

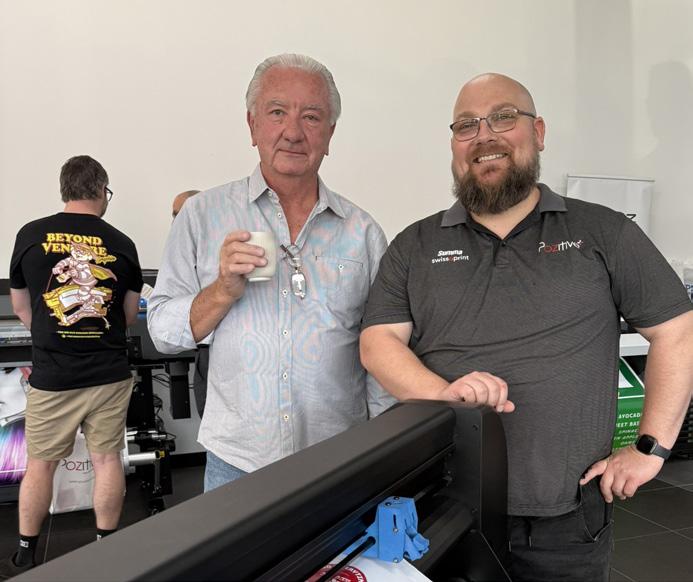

Pozitive sign & graphic supplies welcomed customers, partners, and suppliers to its recent open house at Emu Plains, which showcased its full print-to-finish process in action

Pozitive sign & graphic supplies has hosted one of the industry’s largest ever open house events, resembling a small industry exhibition. The grand opening of the company’s new premises at 152 Russell St, Emu Plains in Western Sydney featured a packed open house event attended by dozens of industry buyers, showcasing more than 10 different products from some of the largest brands in the market.

On display were products from brands exclusive to Pozitive sign & graphic supplies including swissQprint UV printers, Summa flatbed and roll cutters, and Valiani die cutters, as well as brands including Epson, Mutoh, Roland DG, B-Flex, and Ritrama among others.

Pozitive sign & graphic supplies owner and managing director Philip Trumble said the open house event and official launch of the new Emu Plains head office, warehouse, and showroom exceeded expectations.

“Overall, it has been a really busy day and has certainly exceeded our expectations,” Trumble said.

“We had a large number of registrations and normally, we would be happy with a 70 per cent turnout. But not only did we have everyone who registered turn up, we had another 30 per cent more show up as well.

“Since moving in last November, we have put in a lot of work into the new premises. We are very pleased to open our doors and show the industry our new home and what we have to offer. We have enjoyed showing printers and manufacturers how they can be more efficient and competitive, and it has been fantastic to be able to host this showcase with some our partners.

“Compared to our Eastern Creek site, which was 1150sqm, we now have 1500sqm. However, the difference with our new premises is the size of the showroom and office area, while the warehousing remains about the same.

“We didn’t really need more office space, but what wanted was a nice showroom to display all the great equipment from our brands including swissQprint and Summa that we represent exclusively.

“Trying to find a building wasn’t easy, but when I found this building, I thought, ‘wow – this is what I have always dreamed of’.

“In our Eastern Creek premises, our ink storage was built into a cool room that was attached to our warehouse. What we have done here is build an entirely new ink room so our customers can be assured that when the ink is shipped, it is stored at the correct temperature, remains fresh, and is in good condition when shipped.

“We also have a 54kW solar power system on the roof and we have lots of power for the products on the floor. The building lends itself well to our needs – very few people want an office, a warehouse, and a showroom. We have a meeting room downstairs, and we also have a beautiful boardroom upstairs with a video conferencing system.

“Trying to do all of this within our former premises was impossible. There is no way we could have showcased this many brands and technologies, and it’s great to be able to bring it all under one roof.”

Huge crowds recently gathered in Melbourne, Perth, Hobart, Brisbane, Sydney, Adelaide, and Canberra, as the annual event grows year-on-year

The 2025 Women in Print Breakfast Series saw hundreds joining the much-anticipated events in Melbourne, Perth, Hobart, Brisbane, Sydney, Adelaide, and Canberra.

The series kicked off in Melbourne, with a huge crowd gathering to hear leading presenter, writer, educator, podcaster, and media personality Craig Harper explore the topic of potential – how to recognise it and how to work towards achieving it. It was the perfect start to the nationwide program, designed to offer insight, empowerment and connection under the ‘Nourish to Flourish’ theme.

In Perth, Sharon Gleeson, a certified health, nutrition, and life coach, discussed ways to create simple, sustainable habits – and most importantly, keeping the goals realistic and attainable.

Tasmania patron Rita Karagiannis hosted a casual lunch, allowing for ample opportunities for networking.

Women in Print Australia chair Stephanie Gaddin said, “This year’s program focuses on the things which we can do to refresh and refuel, so that we can continue to be the best version of ourselves, not only at work but in all of life”.

Sponsors of the event included: Ally sponsors Durst Oceania, Media Super, and Ricoh Australia; Breakfast Series Champion sponsors Access Print Holdings and Cactus Imaging; as well as national association supporters and media partners including ASGA, FESPA Australia, LIA, Visual Connections, Visual Media Association, and Printer Media Group.

Individual community and print sponsors included Ball & Doggett, IVE Group, Signright Australia, Cactus Imaging, Total Digital Solutions, Rocking Rose, NJ Creative and FramptonPR.

Adelaide’s networking event, held at The Terrace Hotel, featured Brenda Snyman, mental health and wellbeing therapist and founder of Wildflowers Unite Living Systems Therapy.

Snyman’s keynote ‘Get back on the happiness track – happiness to accelerate success’ explored the relationship between happiness and success. In this session, Snyman challenged counterproductive beliefs

about success and happiness while walking attendees through six researchbacked steps – rooted in happiness, resilience, willpower, creativity, and mindfulness – to help get people back on track.

In Sydney, the event featured a panel that spoke about their life experiences and how they impacted their work.

The panel featured Samantha Flook, strategic psychotherapist and mindset coach at The Core Health; well known industry mental health advocate and founder of Anchor Health Group Steven Gamble; Que Nhi Makar, national

marketing manager at Ball & Doggett; and Carmen Ciappara, national advertising manager at the Printer Media Group.