REASONS WHY HERO IS AUSTRALIA’S BEST TRADE PRINTER

14-16 COVER STORY: Böttcher Group celebrates 300 years serving the industry

T22

6-11 NEWS: Australian Printer’s comprehensive industry news

12-13 CASE STUDY: T22 powers Australian event signage with Canon innovation

14-16 COVER STORY: Böttcher Group celebrates 300 years serving the industry

18-19 75-YEAR ANNIVERSARY SPECIAL: Bernard Cheong, the silent entrepreneur

20 WOMEN IN PRINT: Kwik Kopy Eagle Farm centre owner Aleisha Gill

22-29 CHINA PRINT 2025 REVIEW: All the latest innovation and technologies on show in Beijing

30-32 THE EVOLUTION OF PRINT MATERIALS: The latest technologies and trends in this sector

30 Ball & Doggett 32 Konica Minolta Australia

OPINION: Meaningful messaging is the print marketing metric that matters most

OPINION: Uncovering the hidden benefits of eco-friendly print materials 37 OPINION: The physical permanence of print

38-39 DOWNTIME: Careers Expo & WorldSkills 2025 a huge success in Brisbane

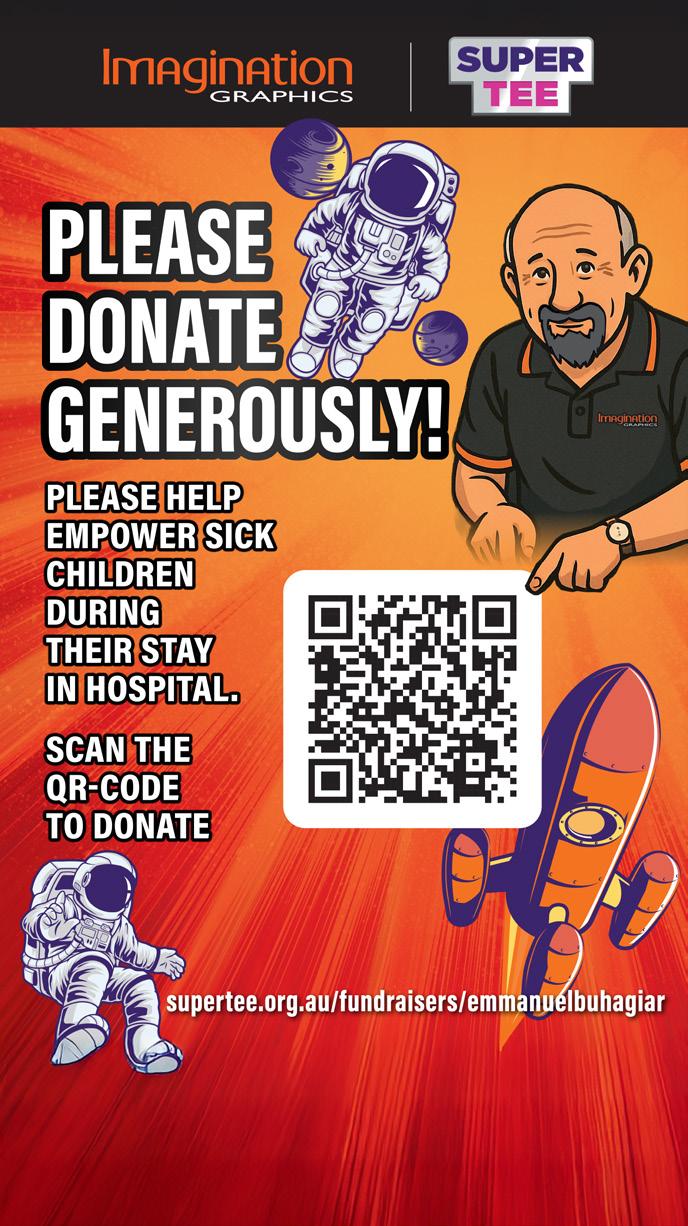

DOWNTIME: Imagination Graphics hosts fundraising BBQ in support of Supertee foundation

DOWNTIME: WA turns out in Perth for 2025

ASGA Sign & Print Golf Day

PRINT DIARY: All the upcoming events

45-50 CLASSIFIEDS: The Australian print industry’s biggest marketplace

To advertise call Carmen on 0410 582 450 or carmen@proprint.com.au

powers Australian event signage with Canon innovation

In the past few weeks, we’ve covered what just might be 2025’s biggest printing story of the year – Starleaton’s liquidation (more on page 8). We do come across such instances occasionally, where companies make promises, but fail to deliver.

These companies might have folded for their own reasons, but one theme is common across them all –customers get affected.

Customers are key; they remain at the heart of any printing business. Böttcher mentions this in the cover story (from page 14), Cyber Australia focuses on this in the AP 75-year special (from page 18), Kwik Kopy Eagle Farm lives by it, as detailed in our Women in Print feature (on page 20)... it’s the lifeline of any successful business.

Read more about these stories in this issue.

This issue also showcases the latest technological innovations that were on display at the recent China Print tradeshow in Beijing (from page 22).

Hope you enjoy the read.

Managing Director

James Wells / 02 8586 6101 james@intermedia.com.au

Subscriptions / (02) 9660 2113 subscriptions@intermedia.com.au

Subscription rate (5 issues) Australia $79

Cactus Imaging installs another Durst first with Haptprint 3D technology

Cactus Imaging is the first printer in the southern hemisphere to offer Durst Haptprint 3D technology for its customers.

Durst Haptprint is a specific printing mode available on Durst P5 350 D4 high speed printers that delivers a printing process with up to 12 layers for raised printing surfaces and simulated textures, such as oil paintings, wallpaper and even brail.

“We are excited to own the first Durst P5 350 D4 with varnish and white ink, which combined delivers the haptic 3D printing capability,” Cactus Imaging co-founder and general manager – operations, Keith Ferrel, said.

“What we can now offer our customers is something completely unique in terms of innovation. It is another opportunity for our high-end clients in sectors such as fashion, cosmetics as well as for artistic purposes as we can replicate the brushstrokes and texture of an oil painting for example.

“We can print with this new Haptprint technology on a multitude of substrates including PVC, Corflute, paper, alupanel, and even artist’s canvas and glass. We are experimenting all the time with this special option to investigate the opportunities it can deliver.

“The benefit of this investment in new technology is for our clients – so we can go to them with opportunities that world first technology can deliver. We have always been known as innovators, and always been known as one of the first in the world to purchase new equipment

that we know will be of immense benefit to our clients and enhance our client base.”

According to Durst Oceania managing director, Matt Ashman, the Haptprint technology is available with a specific configuration of both Durst hardware and software.

“To achieve this effect, Keith and the Cactus team have installed the white and varnish channels within the Durst P5 350 D4 machine as well as the Haptprint software which is part of the Durst software portfolio,” Ashman said.

“With this configuration, the Cactus team is now able to print with relief and texture as well as super high glossy prints. Cactus is also able to create ‘Lens-free Lenticular Printing’. Lenticular printing is a technology in which lenticular lenses are used to produce printed images with an illusion of depth, or the ability to change or move parts of the printed file as they are viewed from different angles.

“This technology is part of Durst’s broader ‘Pixel to Output’ strategy that aims to deliver comprehensive solutions for printers including workflow, analytics, automation, and the world’s best ink solutions, all ‘Made In Durst’ at its flagship HQ in Italy.”

Editor Hafizah Osman / 0431 466 140 hosman@intermedia.com.au

Printed by Hero Print Alexandria, NSW, 2015

National Sales Manager

Carmen Ciappara / 0410 582 450 carmen@proprint.com.au

Mailed by D&D Mailing Services Wetherill Park, NSW, 2164

Design and Production Manager

Sarah Vella / 0406 967 559 svella@intermedia.com.au

Cac tus Imaging installs another Durst first with Haptprint 3D technology

Redefine Commercial Printing Standards and elevate production with Next-Gen High-Speed Inkjet

PRODUCTIVITY

•High productivity

•560mm paper width

•High machine uptime

QUALITY

•New Inkjet 1200dpi PHs

•New saturated ink SC2

•Enhanced image quality

USABILITY

• Energy-efficient drying

•Easy operation

•Offset-coated papers

AGILITY

•Optimised integration

•Precision paper sensing

•Complete New Platform

It’s all over –Starleaton now in liquidation

Starleaton has failed to meet its monthly repayments promised to creditors and has been placed into liquidation. Australian Printer received a schedule of the payments Starleaton CEO Ben Eaton made, which was supposed to be $33,333.33 every month, for 24 months.

The schedule showed $800,000 was promised and $366,666.30 paid, with the last instalment of $33,333 paid on 28 February 2025. Starleaton only managed to complete 11 monthly payments of the 24 promised, resulting in a $433,333.70 shortfall.

Creditors were informed of the liquidation on the evening of Wednesday 11 June in a statement titled ‘General Update on the Deed of Company Arrangement’ issued by Simon Cathro and Andrew Blundell from Cathro & Partners.

“Pursuant to Clause 7.5 of the Deed of Company Arrangement (DOCA), the companies were obliged to make 24 equal monthly instalments in the amount of $33,333.33 into the Deed Fund on the last business day of each month, for the benefit of creditors,” the statement said.

“The Companies defaulted on this obligation and failed to make payment of monthly instalments as and when they fell due.

“The Administrators issued a default notice to the Companies pursuant to Clause 7.5 of the DOCA for the unpaid contributions required to be paid into the Deed Fund. The Companies failed to observe the default notice.

“Having regard to these circumstances, we write to advise that on 11 June 2025:

a) the Administrators terminated the DOCA due to the Breach, which the Administrators deemed was not able to be remedied within a reasonable time; b) the Companies have been placed into Liquidation; and c) the Administrators have been appointed as joint and several liquidators.

“The Liquidators will conduct investigations into the affairs of the Companies, including in relation to any potential recoveries.

“The Liquidators propose to issue a further report to creditors by 11 September 2025, including in relation to the likelihood of any dividend in the liquidation.

“Due to the liquidation, the Companies will cease trading shortly and the employment of its current employees will be terminated.”

“Pursuant to section 556 of the Corporations Act 2001, employee entitlements have a priority over unsecured creditors and even ahead of certain secured creditors when there are circulating assets. The federal government also has a scheme called the Fair Entitlements Guarantee (FEG) scheme which can assist employees if there are insufficient realisations in a Liquidation and FEG will then stand in the place of employees for any amounts paid.

“We suggest that all employees of the Companies lodge a claim with FEG for their unpaid entitlements. Further details to employees with their estimated entitlements values will be provided shortly.”

The FEG scheme can assist employees if there are insufficient realisations in a liquidation. The FEG will then stand in the place of employees for any amounts paid.

At the time, Starleaton employee entitlements were estimated to be:

• Wages

– $105,445.55 (28 employees)

• Superannuation

– $133,396.73) (35 employees)

• Annual leave

– $140,899.94 (24 employees)

• Long service leave

– $261,715.46 (14 employees)

• Pay in lieu notice – $190,635.36 (27 employees)

• Redundancy – $552,232.60 (26 employees)

Under a section titled ‘Next Steps’, the creditors’ statement also provided clarity on the timeline for the next stages of the liquidation.

There are key areas that will be addressed in any liquidation. A statutory report to creditors will be issued to creditors within three months of appointment as liquidators. Once the administrators have finalised our requirements in these areas we will proceed to finalise the liquidation, which will result in the company being deregistered.

The ‘Ongoing’ activities of the liquidators include: ‘Realise Assets’, ‘Investigations’, ‘Pursue Recoveries’, ‘Reporting’ and ‘Dividend’.

The estimated finalisation of the liquidation will be in two years from now – in June 2027.

In an open letter to the industry published in April 2024, Starleaton CEO Ben Eaton suggested “liquidation would have been an easier option” than undertaking the DOCA.

“In many respects liquidation would have been an easier option with the FEG scheme providing for the staff entitlements. However, this in my view was not an acceptable outcome as the result for all the other creditors would have been a NIL return,” he said at that time.

Prior to going into liquidation, Starleaton was first under voluntary administration from 19 January 2024. Eaton attributed the voluntary administration to several factors, including being mistakenly buoyed to the economic recovery of the pandemic, investing heavily in head count – particularly in its engineering team, inflationary pressure and a significant shift in the global financial landscape which caused a shift in spending habits across all three of its business units, impacts of rising costs due to the Ukraine crisis, and some significant changes to its level of insurance cover with key suppliers.

Starleaton CEO Ben Eaton

Westman Printing acquires Reacon Australia as creditors approve DOCA

Westman Printing has taken control of Reacon Australia following a recent vote by creditors. The creditors overwhelmingly voted in favour of the Deed of Company Arrangement (DOCA) that was proposed by Westman Printing co-owner Vik Gulati to acquire the Reacon Australia business.

At the same time, MMW3 Degrees was placed in liquidation and all employees previously employed by MMW3 Degrees were transferred across to Reacon Australia as part of the DOCA and the restructuring process.

Prior to the vote by creditors, Gulati had put forward an original DOCA, which he then updated to remove previous ambiguity around the entitlements for staff. These amendments were outlined in an updated Creditors Report.

“The DOCA has been updated to ensure the payment of all entitlements to all staff and also clears up any ambiguity identified during the first creditors meeting,” Gulati said, at that time.

“It is our intention to ensure all staff from the three trading entities will continue to receive the same benefits and will all retain their jobs if this is DOCA is approved.”

Prior to the vote by creditors, Reacon Australia was also placed back into voluntary administration by the Federal Court of Australia two weeks after being placed into liquidation.

Gulati said he is looking forward to the next stage of the Reacon Australia business.

“Reacon Australia will continue at Regents Park to operate as usual and we will work with the employees in the business over the next few months to see where we can add value and obtain efficiencies,” he said.

“We have continued to trade, and we have been heartened by the strong support we have continued to receive from our valued customers.

“The good news is that all transferring staff and their entitlements will be protected under the DOCA. We will also be paying all the transferring staff their outstanding superannuation that was not paid by the previous owners – so all statutory liabilities are all up to date.”

Everyone who remained employed upon entering the DOCA continues to be employed today. The two businesses – Westman and Reacon – will also be able to service customers more effectively driven by more production capacity, according to Gulati.

Technological powerhouse. ROLAND 700

The widely acclaimed ROLAND 700 EVOLUTION litho press deploys an array of innovative technologies to give unprecedented levels of efficiency, productivity and print

Vik and Manasa Gulati from Westman Printing

Snap Print Solutions Circular Quay offloads presses to ABC Copier Solutions

Snap Print Solutions Circular Quay has sold two presses to ABC Copier Solutions, which will dismantle and recycle the machines as part of its sustainabilityfocused equipment lifecycle program.

ABC Copier Solutions specialises in the purchase, dismantling, and removal of outdated equipment across Australia, ensuring it is recycled in an environmentally responsible manner. The recovered parts are shipped to Singapore for servicing, before being distributed for reuse in markets around the world.

“We purchase these machines, export them, and ensure they’re recycled in an environmentally responsible way,” said Jaxon Crocker, director of ABC Copier Solutions.

“In the past, many of these machines would’ve ended up in landfill, but we give them a second life and keep them in use for years to come. The machines get

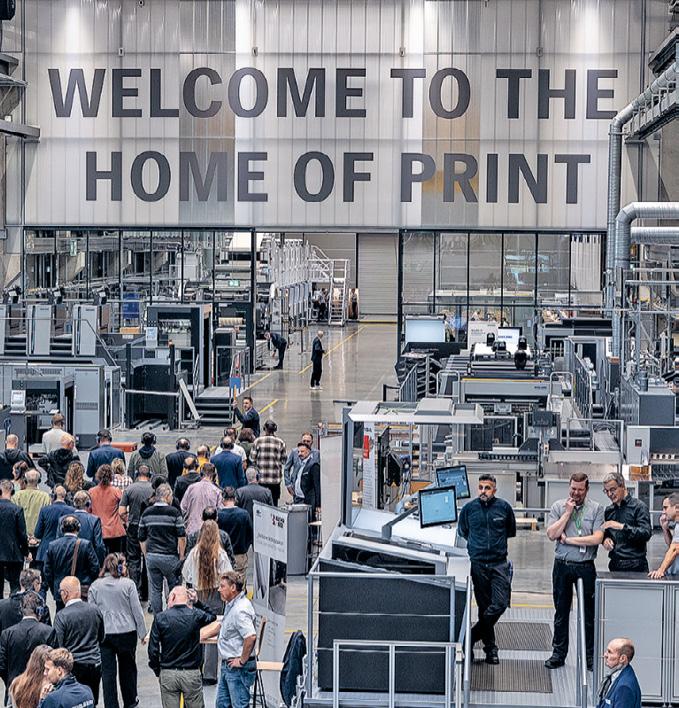

Heidelberg marks 175 years with launch of new print centre

Heidelberg marked its 175th anniversary with a week of celebrations at the company’s Wiesloch-Walldorf site in Germany, drawing more than 1,500 guests from all over the world.

The grand highlight was the opening ceremony of Heidelberg’s new Print Media Center (PMC), dubbed the ‘Home of Print’.

Jürgen Otto, CEO of Heidelberg, greeted the customers, suppliers, partners, politicians, and industry representatives attending the ceremony.

“A warm welcome to Heidelberg and a warm welcome to our ‘Home of Print’, the printing industry’s largest customer experience centre anywhere in the world. We have now been the Home of Print for 175 years!”

Rebranded as the ‘Home of Print’, the redesigned PMC tracks the company’s

sent to places such as China, Thailand, Vietnam, Hong Kong, Indonesia, and the Philippines, and they’re all reused in an environmentally friendly way.

“As part of our service, we handle everything – from dismantling to removal – making the whole process hassle-free for our clients. They don’t have to worry about a thing. We take the sting out of it, so to speak.

“We’ve bought machines of all ages – some just a year old, others five, 10, even 20 years old. It really depends on what’s available.”

growth strategy for its core business and presents future-proof and specific solutions that will appeal to all relevant target groups.

For example, various end-to-end production systems are available for the customer presentations in collaboration with partners such as Polar and MK Masterwork – from high-quality folding carton production with the Speedmaster series, high-volume folding carton printing with the new Boardmaster flexographic web printing system, and industrial label production using offset, digital,

As it services every part of Australia, ABC Copier Solutions has offices in Perth, Adelaide, Melbourne, Sydney, and Brisbane, along with storage facilities all over Australia.

“One of the key things we focus on is making sure our clients aren’t left without a machine. We coordinate everything so they can keep their production running smoothly. When the time comes, they just give us a call, and we take care of the rest,” Crocker said.

Richard Cook, managing director of Snap Printing Solutions Circular Quay, said the two machines sold to ABC Copier Solutions – a Xerox Versant 2100 Press and a Xerox Iridesse Digital Colour Production Press – were both around 10 years old.

“I had heard of ABC Copier Solutions through industry circles, which led me to reach out to Jaxon. The team was professional, responded promptly, and we were able to finalise a deal quickly – it was a smooth and straightforward process,” Cook said.

“By partnering with ABC Copier Solutions to responsibly retire our machines, we’re ensuring that even the end of a machine’s life contributes to a more sustainable future. There’s still life left in them, and this approach helps ensure that value isn’t wasted.”

and flexographic printing through to commercial printing and hybrid print production (digital/offset).

The entire Heidelberg portfolio has been incorporated into a single digital ecosystem comprising Prinect software, equipment (including postpress solutions and robotics), consumables, service, training, and consulting.

In its very own data lab, Heidelberg offers several case studies to demonstrate how the company can harness its data expertise and use data analysis to help customers with their requirements and business model – when it comes to solving problems, integrating process steps, or boosting their performance, for instance.

To coincide with its anniversary, Heidelberg also announced an important addition to its portfolio for packaging customers, unveiling the Cartonmaster CX 145 press for the very large format class 6, (41.34-inch by 57.09-inch) space.

By focusing in particular on high-volume folding carton production in the growing food, beverage, and consumer packaging segment, this system is plugging a gap in the company’s portfolio.

Jaxon Crocker (ABC Copier Solutions) and Richard Cook (Snap Print Solutions Circular Quay)

Heidelberg’s new Print Media Center in its new look as the ‘Home of Print’

FESPA Australia appoints Easy Signs’ Adam Parnell to board

Easy Signs co-founder and director Adam Parnell has been appointed treasurer of the FESPA Australia board.

Parnell’s appointment follows the resignation of long-serving treasurer Mark Brooks, who has served on the FESPA Australia board for more than 17 years.

Aside from Brooks’ departure, all other board members have been reappointed to their roles:

• Nigel Davies, president

• David Asker, vice-president

• Adam Parnell, treasurer

• Keith Ferrel, honorary secretary

• Matt Ashman, supplier director

• Bianca Martin, public relations director

“I’m excited to welcome Adam Parnell to the board. His industry knowledge, strategic thinking, and relationships will strengthen our leadership team and help us deliver even greater value to our members. I’d also like to thank Mark Brooks for his

Straight Bat acquires Fleetmark

Investment firm Straight Bat has acquired Fleetmark, a specialist branding and signage solutions business for Australian fleet commercial and digital markets.

Fleetmark said this partnership was forged to capitalise on its “solid platform for growth”, and to better serve its customer base.

Fleetmark has been providing innovative branding and signage solutions in fleet graphics and PVC fabrication, wide format digital print, and digital displays for more than 30 years.

Fleetmark’s facilities in Victoria, New South Wales, and Queensland provide customers with a unique proposition where fleet signage is designed, manufactured, and installed on site by its design team, sign writers, and installers.

Generating more than $40 million annually, the company’s success is underpinned by a blue-chip customer base made of the largest transport and quick service retail companies in Australia.

dedication and work as Treasurer over the last few years,” FESPA Australia president Nigel Davies said.

“I’m excited and grateful to be elected to the board. I’m very much looking forward to contributing in a positive and meaningful way to our print community,” Parnell said.

FESPA Australia also unveiled its strategic vision for 2025 at its AGM.

“We are financially stable and growing, but complacency is not an option. Organisations need to innovate and reinvent themselves continually, and FESPA Australia is no exception. The incoming board will face challenging years ahead

Recent branding projects have included the Team Global transport signage, KFC digital signage and many other well-known and highly visible logistics businesses.

Part of the business’ success is attributed to its ability to source and implement stateof-the-art printing technologies, which includes a Canon Colorado M5W from Currie Group and EFI VUTEk D3r.

as we navigate a dynamic industry environment and face the uncertain effects of AI on our members, sponsors, and the way we work,” Davies said.

“It is a time for collaboration with other associations, while also recognising that our membership has grown because there is meaning in what we do.

“We must maintain our identity and hold true to our values as a people-centric organisation that empowers our members, both printers and suppliers, through global connections. We must lead through this time of uncertainty.

“The new FESPA brand tagline ‘Connect, Inspire, and Support’ is the essence of who we are and what we stand for. Association work is rewarding, and we have a lot of work ahead of us.”

Building on the momentum of the highly successful FESPA Annual Conferences and the FESPA Leaders program, the association is set to “sharpen its focus on industry engagement, networking, and professional development”.

In collaboration with FESPA’s global network and the Leaders alumni, a new training initiative will also be launched to attract and retain fresh talent in the print and signage industry.

“We are delighted that a business with such an outstanding track record and legacy has chosen to partner with us,” Straight Bat Private Equity managing partner Steve Gledden said.

“Fleetmark has a great reputation for trusted service and quality results which has endured for over 30 years.”

Fleetmark founder Dean Coates continues to work alongside the Straight Bat team as a shareholder and operator.

Stuart Farrow, who was Fleetmark general manager, retained his position within the company following the acquisition, but is now a self-employed strategic business consultant as of May.

Former Cleanaway Waste Management executive Karl David has been CEO since February – around the same time the acquisition of Fleetmark was confirmed.

Fleetmark is the ninth portfolio addition to the Straight Bat Perpetual Legacy Fund portfolio, which comprises investments in varied industries such as building and construction, rubber, food manufacturing, marketing services, smoke alarms and more.

Adam Parnell at the 2024 ProPrint Awards

Fleetmark’s Michelle Porteous, Lance Singleton, Jennie Gan, Tony Beaumont, Andrew Bini, David Kerr, Jan Hade and Alf De Fazio outside the company’s Melbourne office

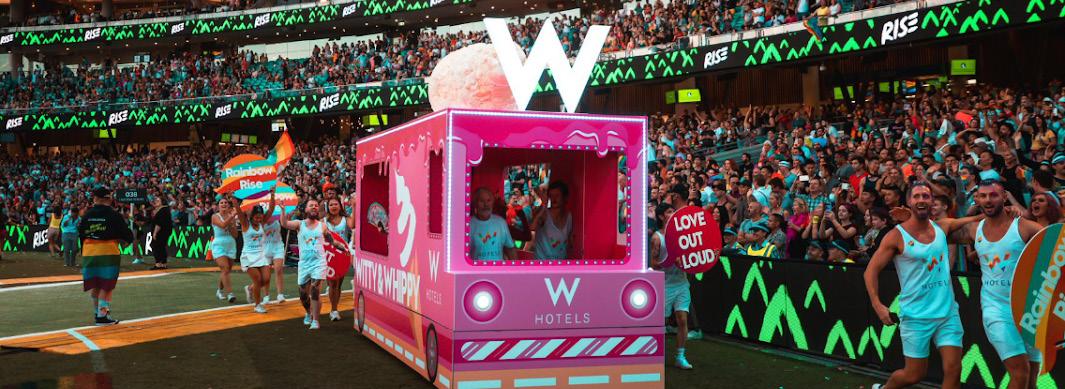

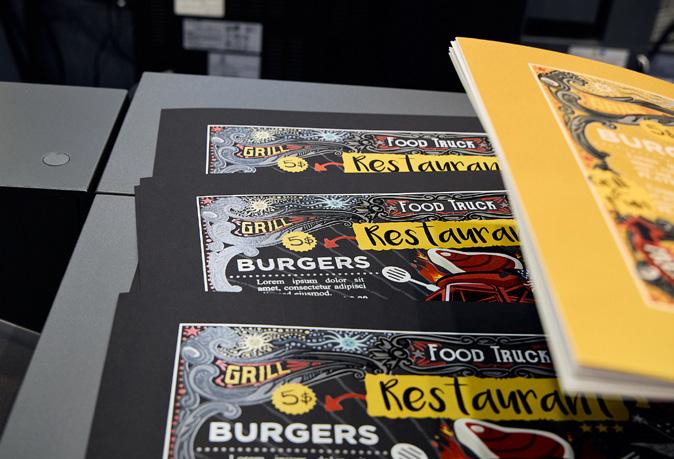

T22: Powering Australian event signage with Canon innovation

With Canon’s technology, T22 has seen a dramatic improvement in turnaround times and production efficiency, particularly for time-sensitive event signage

Melbourne-based T22 Pty Ltd is a leader in high-impact wide-format printing, trusted by some of the biggest names in events, retail, and commercial branding across Australia. Established more than 30 years ago as Signex Displays, the business evolved into the Signex Group after merging with Prologica Digital Print.

In 2022, general manager John Roberts acquired the business with the support of existing staff and major customers and rebranded it as T22, signaling a bold new chapter defined by innovation, speed, and elevated customer service.

From golf tournaments and marathons to corporate campaigns and custom fridge wraps, T22 produces a diverse range of applications – all from one dynamic production floor powered by a Canon Colorado 1650, an Arizona 2280 XT, and a Zünd G3 cutting table.

Challenges arose

With tight client deadlines and increasing demand for premium print finishes, T22

needed to replace its ageing solvent printers. The growing pressure from high-profile events like the PGA Tour made it clear: it needed faster, more reliable technology that wouldn’t compromise on quality.

A fast solution

T22 turned to Canon Production Printing for a complete technology transformation. The Canon Colorado 1650 was selected for its fast, high-volume roll-to-roll production and FLXfinish+ capability, delivering matte and gloss finishes in a single pass.

The Arizona 2280 XT added flatbed versatility for rigid media, while the Zünd G3 cutting system streamlined finishing with precision automation.

This setup provided T22 with unparalleled production flexibility, enabling the company to produce a wide range of items including POS signage, floor graphics, glass splash backs, wall decals, as well as time-critical sports and event signage – all within a single facility.

A deep dive into the technology

The Canon Colorado is a large format UVgel roll-to-roll printer that presents an industrial-level solution.

The super-fast 64-inch machine features print speeds of up to 159sqm/h as well as a heavy-duty drawer mechanism, which can hold up to two rolls of media at one time; supports a wide range of applications for both indoor and outdoor graphics; and offers between 30 and 50 per cent lower ink consumption compared to competing technologies.

UVgel technology allows for an outstanding colour gamut, colour depth and light fastness, while low-temperature, low-energy UV LED curing enables the usage of heat sensitive media. In addition, the machine’s FLXfinish+ technology expands application capabilities with options for more porous media, including uncoated papers, as well as soft signage materials such as polyester textiles and silicon edged graphics, allowing users to print matte and gloss prints in one single pass.

The Melbourne-based T22 team with its Canon Colorado 1650

The Canon Arizona family consists of true flatbed printers. Made in Germany to the highest engineering standards, they are designed for longterm reliable production and consistent, high quality output.

The printers include trusted technology and precision engineering for exceptional image quality and true-to-brand colour that customers expect.

With the power and productivity to respond profitably to today’s ultra-tight production deadlines, and the ability to sustain quality and speed when the pressure is on, Arizona remains the technology leader and multiple awardwinner in flatbed printing for more than 15 years.

The Arizona range comes with a vast range of choice in printing speeds (34 sqm/hr to 220 sqm/h), table sizes, media handling capabilities and software applications to cover different production needs. Users can choose between four and eight ink colour configurations, and add a roll media or FLXflow option.

The range can also handle a variety of media – up to 2-inches thick. Adding PRISMAelevate XL makes it easy to create amazing, high-value tactile and elevated applications. This is the “wow” factor for signage, graphics, décor, fine art prints, and promotional packaging as it enables embossing, textured effects, metallic accents, and raised lettering up to 4mm.

Arizona printers are built to last; to be the engines of profit in a business for years to come.

A great result

With Canon’s technology, T22 has seen a dramatic improvement in turnaround times and production efficiency, particularly for time-sensitive event signage.

This was especially evident during a major PGA event, where T22 was responsible for producing all the vinyl graphics for tee signs and wayfinding – all within just a few days.

“The Canon Colorado has transformed the way we work,” T22 managing director John Roberts said.

“Previously, we were limited by older printers that required high maintenance and could barely keep up with demand.

“With the Colorado, we’re now printing exceptional quality jobs – in both matte and gloss – faster than ever.

“Speed and reliability are absolutely critical when working on major events like the PGA or the Melbourne Marathon.

“We know we can deliver every time, even under pressure. That confidence has helped us grow stronger relationships with our clients.”

Canon partnership

Canon Production Printing has been more than a supplier – it has been a committed partner in T22’s journey.

From initial consultation and training to responsive service and ongoing support, the collaboration has enabled T22 to push boundaries and expand its offering.

“T22 is a fantastic example of a business that combines deep industry experience with the right technology to truly deliver for its customers,” Canon Production Printing head of sales and professional services Steven Badger said.

“What impresses me about John and his team is their relentless focus on quality and meeting deadlines. They’re delivering signage at the highest level for nationally broadcasted events – and Canon is proud to play a part in helping them scale their success. It’s a partnership built on trust, capability, and shared ambition.”

A large format rigid media created for a walkway

Signage boards created by the T22 team

Another angle of the large-format rigid media on a walkway

A solution for W Hotels created by the T22 team

Böttcher Group celebrates 300 years serving the industry

The Böttcher Group today stands on the foundation of 300 years of history – a long-standing past that gives the business confidence into the future

The Böttcher Group celebrates 300 years of operation this year, with its anniversary marking the company’s enduring success across multiple countries and industries.

Böttcher is now known as a leading supplier in elastomer-coated roller technology, especially in the coating of rotationally symmetrical bodies (rollers, sleeves) in industrial applications.

Additionally, Böttcher serves as a development partner to more than 400 machine manufacturers globally –around 70 per cent of all printing presses built worldwide are initially equipped with roller coatings from Böttcher.

The company also supplies customers from a wide range of industries with consumables such as washing agents, printing blankets, coating plates, dampening solution additives, and other printing aids. Böttcher holds a similarly strong position in the metal, plastics, and wood industries.

The foundations of today’s global Böttcher Group were laid by two companies: the

tannery founded by Jacobus Loosen in Cologne in 1725 and Felix Böttcher’s Leipzig-based company to produce gelatine rollers, which was established around 150 years later.

The two medium-sized companies merged in 1910, and elastomer roller coatings were used for the first time in 1952.

Today, Böttcher’s technology is used in all continents across 123 countries, 38 of which have their own employees and 27 production sites in 19 countries. Every day, 2,000 employees serve more than 50,000 customers around the globe.

“For 300 years – from 1725 to 2025 – Böttcher has written a success story in eventful times that is now recognised worldwide across many industrial sectors. We owe this to the commitment, work, and skill of all Böttcherians over the past 300 years,” Böttcher Group managing director Franz-Georg Heggemann said.

“During this time, a family business with a first-class reputation for its products and services has emerged that is independent of third parties.”

The Böttcher story

The origins of Böttcher date back to 11 July 1725 when Jacobus Loosen founded a business manufacturing high-quality leather in Rothgerberbach, located on what was then the outskirts of Cologne. This business continued for 100 years until his grandson Johann Georg Loosen took over.

He switched production to the manufacture of glue for bookbinders and woodworkers, which could be obtained from the waste from the tannery. In 1890, after returning from travels to England, Wilhelm Loosen convinced his father to switch to the production of gelatine roller mass.

The production process was very similar to the manufacture of glue and the industry experienced rapid growth. The roller compound was sourced from printers, who were still moulding their own rollers at the time.

Independently, Felix Böttcher started producing printing roller compound in Leipzig as early as 1878 and his successor, Ernst Herrmann, began casting his own rollers for printers in 1883.

Böttcher today stands on the foundation of 300 years of history – a long past that gives the business confidence into the future

Loosen had been offering this service since 1895. However, competition in the German Empire increased and so the two companies merged in 1910 and from then on, produced rollers together.

Foreign business was strengthened over the next few years and further sites were established. Herrmann’s financial and sales support for the first web offset press, built by VOMAG (now Manroland Web Systems), was revolutionary in 1912.

In the early 1930s, a new phase began with the entry into rubber roller production. After the Second World War, Böttcher managed to rebuild, but the company in Leipzig was expropriated and nationalised.

From the 1950s onwards, Böttcher experienced a strong upswing driven by innovative products and a welldeveloped supply network and became a close partner of printing press manufacturers. Despite the oil price crisis, internationalisation continued, with Böttcher also producing in England and Italy from 1973.

Over the decades, Böttcher expanded its global presence by opening new production sites and acquiring competitors. For example, rollers were manufactured in the US from 1987, in Thailand from 2002, and in China from 2005. This expansion was based on the new mixing plant built in 1990, which significantly increased the company’s production capacity for roller compounds.

Shortly after, the production of handrails began, rubber compounds were offered to external customers, and roller customers beyond the printing industry were established. The in-house development of production machines for the series production of OEM and exchange rollers gave Böttcher a decisive advantage over others. This was put into operation in Cologne in 2000. Böttcher grew to its current size and defied the financial

crisis in 2008 and the coronavirus pandemic in 2020.

Over the course of three centuries, Böttcher has developed from a small, German craft business into a globally active company, transforming from a traditional animal hide tanner to a leading supplier of rollers.

Böttcher’s entry into Australia

In 1998, Böttcher Group embarked on an expansion plan into Australia and New Zealand and approached Mitch Mulligan to lead the helm. Mulligan, who is currently managing director of Böttcher Australia, recalls the early days were exceptionally busy, with him having to juggle multiple roles within the business.

“Böttcher Group knew of my background, and I’d been involved in the rollers space previously. The chance for a

younger Mitch was great and I took on the opportunity to launch the Australian business,” he said.

“We started the business in Australia from my kitchen table 27 years ago. At that time, I was very hands-on, and I was involved in almost every role and function within the business – I was customer facing during the day, and then would head back to the warehouse to pack and dispatch orders.

“We transformed the landscape of rollers in Australia. We took them from a position where there was a high rate of replacement and failure, to restoring the longevity of rollers in machines.”

Forging ahead, Mulligan first set up a team of sales professionals in Queensland and Victoria, then grew the team across the entire East Coast.

“Year-on-year we grew the business. We got it to the point where we arrived as the market leader in the graphic arts market,” he said.

“In 2018, we acquired our competitor and merged the two businesses together, establishing manufacturing for Böttcher in Australia for the first time.”

1998 also marked the year Mulligan signed a distributor in New Zealand –Nova Inks & Chemicals. That company retains distributorship of Böttcher in New Zealand, but now under Huber Group.

The Böttcher we know today

Today, there are 20 staff at Böttcher Australia, with its local headquarters located in Smithfield, NSW.

“In the early days, we moved premises every five years – we started off in Rydalmere, then moved to a larger location in Castle Hill, and then again to another larger location up the road in Castle Hill. When we merged the two businesses together, we moved into a new site at Smithfield, which we operate out of today,” Mulligan said.

Whether for the production and processing of metals, plastics and cellulose, or textiles and wood, rollers from Böttcher has become an integral part of many industrial processes.

Böttcher rollers apply, dose, distribute, immerse, deflect, pull off, press, peel, emboss or squeeze. In addition, the durable and energy-saving roller coatings support the development of new, environmentally friendly packaging printing materials.

Its diverse range of solutions has enabled the business to reach an array of verticals,

Böttcher Australia’s admin, production and sales teams

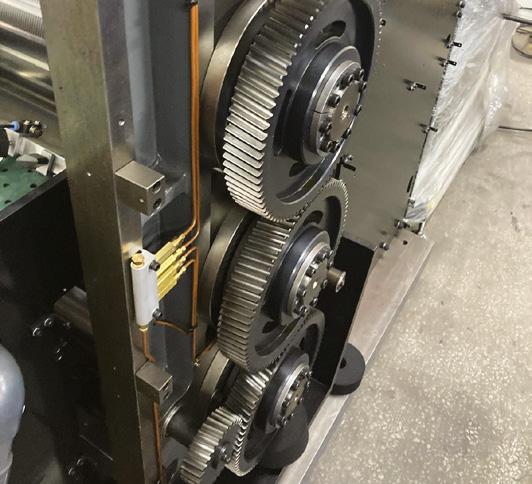

Böttcher Australia’s manufacturing site

Inside Böttcher Australia’s plant

including industrial packaging and industrial technical rollers.

“Launching into new verticals has enabled us with a continuous stream of new business. The growth in flexible packaging, gravure, and flexo printing has allowed us to have a greater focus in the industrial packaging vertical. As for the industrial technical roller vertical, it expands our presence in a variety of industries because they have a need for rubber covered cylinders doing different applications and work,” Mulligan said.

“Where we were heavily a graphic arts business about six years ago, we’re now 50 per cent graphic arts and 50 per cent industrial packaging and industrial rollers business. That’s really changed our business structure. The graphic arts segment is consolidating and we can’t be standing idle and need to grow our business, which is what we’ve done.

“We aim to continue growing into new verticals and expanding our vertical markets by investing into our own capabilities and adding new customers.

“We’re a long-term business, so our relationships with key clients go back many years. We want to further build on that success with new customers.”

Another important building block for the company’s success is the strong focus on in-house research and development expertise globally.

The 70 researchers at Böttcher Group develop and test materials that meet the high standards of measurable benefits for its customers. As the production of roller materials is a supreme discipline within the rubber industry, the Colognebased company operates its own mixing plant in Gelsdorf, Germany. This guarantees the high and consistent quality of its materials – no matter where in the world they are processed.

“We develop about 300 different compounds a year and bring on board about half a dozen into commercial reality. We always look forward to offering improved products to achieve greater efficiencies, lower cost of ownerships, and better productivity – that’s what drives us,” Mulligan said.

A strong future

At Böttcher, economic performance, social responsibility, and a considerate approach to nature are inextricably linked. Sustainability is also an integral part of its corporate policy.

By adopting a holistic approach, Böttcher takes responsibility for future

generations from the earliest stages of product development, through procurement, production, and sales. The goal is for Böttcher products to actively contribute to greater sustainability throughout their lifecycle.

According to Mulligan, Böttcher has a multi-pronged sustainability model that operates like a circular economy.

“Everything we do is generally aimed at reducing the consumption of our product – they’re now safer, have less VOC content in them, and have greater efficiencies. So, in a lot of our products, we try to get a ‘triple tick’ – a lower cost of ownership, lower consumption, and higher performance,” he said.

“We also refurbish and recover used rollers, saving them from going into skip bins. In addition, we look at our individual operations and come up with ways to reduce our carbon footprint – whether that be putting solar on the roof or changing the way the whole plant operates.”

Mulligan sees a strong future for Böttcher, fueled by digital drivers such as AI.

“Even as a manufacturing company, that sort of digital driver can be of great assistance. You’ve just got to work out what it is and where it fits, but I can see it being able to assist in everything from production right through to administration and customer experiences,” Mulligan said.

“We are so lucky to have a company that has such stability, is constantly evolving itself and its product lineup, and invests not only in product development but the people in it as well. Böttcher Australia sees organic growth and is cash positive, and having the backing of Böttcher Group gives us constant strength to keep evolving and growing.”

Böttcher’s milestones

1725 – Jacobus Loosen starts the tanning of animal hides for leather in Cologne, Germany

1825 – Glue production begins for the shoe, paper, and wood industries

1878 – Felix Böttcher starts with gelatine compound production in Leipzig, Germany

1893 – First gelatine rollers are made by Böttcher themselves

1910 – Loosen and Felix Böttcher merge to fight increasing competition

1912 – Böttcher starts production of “Böttcherin” roller washes

1933 – First rollers with rubber coverings are produced

1973 – First international production sites open in UK and Italy

1982 – Printing blankets become part of the product portfolio

1987 – First production site in America starts up in Belcamp, US

1987 – Foundation of joint venture company KBRT with Kinyosha

1990 – New rubber mixing facility opened in Gelsdorf

1995 – Rubber mixing for external customers starts 1995 – Beginning of Handrail production for escalators

1996 – Czech Roller production opens 2000 – Automated serial production of OEM and exchange rollers start

2002 – First production site in Asia established in Bangkok, Thailand

2005 – Roller manufacturing plant opens in Suzhou, China

2009 – Operations start in South America, Argentina and Brazil with own chemicals

2013 – Roller production in Brazil opens

2016 – Böttcher acquires three roller manufacturing sites in Hungary, Romania, and Serbia

2017 – Böttcher produces rubber rollers in India

2025 – Böttcher employs 2,000 employees in 38 countries and runs 27 production sites in 19 countries

Böttcher Australia managing director Mitch Mulligan at the 2022 ProPrint Awards

(l-r) The Böttcher Australia national sales team – Aaron Sidwell, Damon Timar, Neil Rose, Scott LeLievre, and Mitch Mulligan

Rolling on – 300 years and counting

In 2025 the Böttcher group celebrates its 300th anniversary – a remarkable achievement in a fast-changing world.

Today, Böttcher has grown to encompass all parts of the globe:

• employing 2,000 staff in 38 countries

• serving more than 50,000 customers worldwide

• a development partner to more than 400 machine manufacturers.

In Australia and New Zealand, Böttcher has been a direct supplier to the printing industry for three decades, making a significant contribution to the local industry.

Our progress over the past three centuries has been characterised by constant investment in research and development, the highest engineering quality standards and a willingness to take on new challenges. The group continues to diversify into new markets while remaining the global technology leader in the printing industry.

As a ninth-generation family-owned company, our stability and longevity provide the reassurance that businesses need to plan for the future.

Congratulations to all our customers, staff and industry partners for being part of this major milestone. We couldn’t have reached it without you.

Thank you for your ongoing support, now and in the future.

Here’s to another 300 years of building better businesses.

Talk to us about the journey ahead:

• bottchersystems.com.au

• info-aus@boettcher-systems.com

• Free call: 1800 204 102

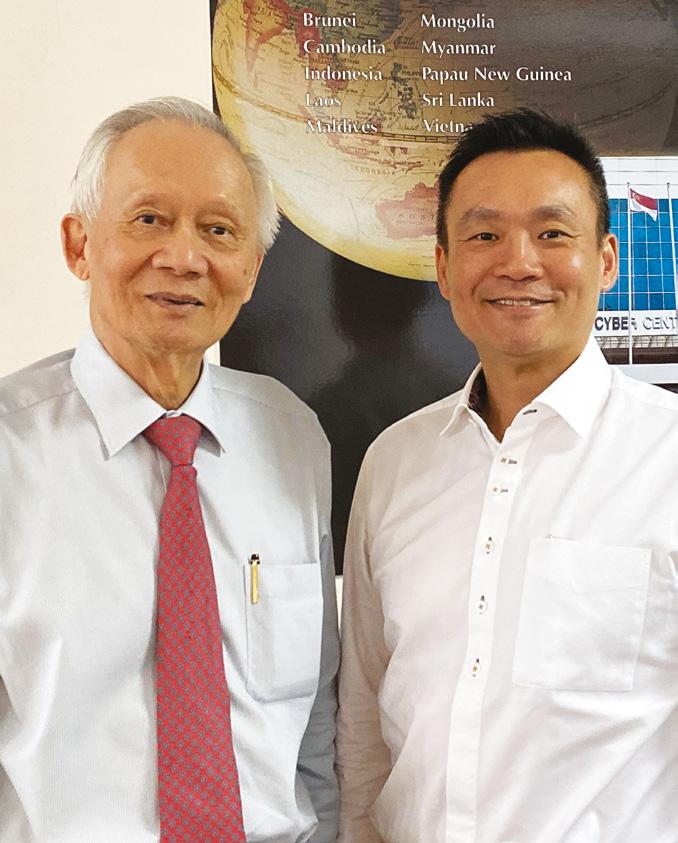

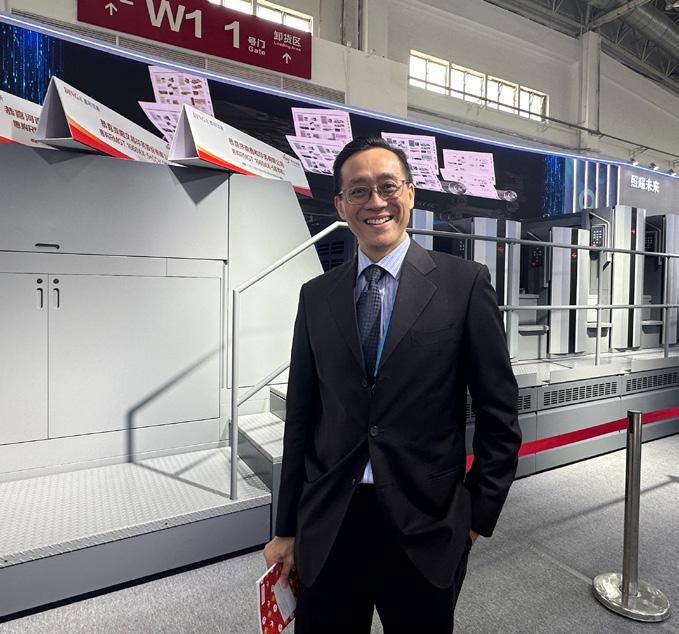

The silent entrepreneur: Cyber Australia managing director Bernard Cheong

Bernard Cheong shares how a conversation with Australian Printer influenced the birth of its Australian subsidiary – and what the company has been focused on since

Business leaders have varying personalities. While extroverted personalities are more visible in the public eye, they don’t necessarily have an advantage over introverted leaders. These silent entrepreneurs keep their heads down and work smart in gaining business.

Cyber Australia managing director Bernard Cheong is one of them. Within a span of more than 20 years, Cheong has silently and humbly turned Cyber Australia into one of the largest printing distributors in the Asia Pacific region.

Real estate is another of the company’s key assets.

In Singapore, the company recently relocated to a new office and began leasing out its former multi-story premises, which it owns.

“Cyber’s assets are mainly in real estate. We’re fortunate because we’re asset rich – we have our own building in Australia and the four factories we own in Malaysia for showrooms, a refurbishing centre, warehousing, and a candy plant spanning five hectares, are all owned by us. We don’t have any additional overheads for our real estate, allowing us to focus on what matters most – our customers,” Cheong said.

Cheong leads Cyber Australia, but his older brother John now heads up the wider Cyber entity ever since their dad Herbert took a step back from the business a few years ago due to health reasons. Cheong’s other brother, Paul, also works within the business as sales director.

It’s hard to speak of the origins of Cyber Australia without detailing the lesser-

known fact that Australian Printer is intertwined with the company’s first foray into this region.

It all started with a relationship between Brian Moore and Cheong. Moore, who was formerly publisher and sales director at Australian Printer, is a long-standing part of the magazine’s 75-year history – 24 years and counting, to be exact.

During his time with Asian Printer Magazine in Singapore, Moore established a strong working relationship with Cheong and Cyber, a then Singapore-based company. That professional partnership naturally fortified when Moore returned to Sydney to run the Printer Media Group, parent company of Australian Printer

A few months later, in what was just a simple discussion about the Australia and New Zealand printing markets between Moore and Cheong, Moore planted the seed to what has now grown into Cyber Australia, which holds the RMGT agency in this region.

“It was actually Brian who sparked my interest in setting up Cyber Australia,” Cheong recounted.

“I had known Brian from his time in Singapore, and we never miss an opportunity to catch up whenever he visits the country. We were once having a simple conversation about the A/NZ markets shortly after he returned to Australia, when Brian asked me if I knew much about that space.

“With Cyber having a big play in only the Asian market at that time, I replied that I didn’t know much about it; I thought Australia was a ‘sleepy town’. Brian then told me ‘You should check it out, because there’s a world of opportunity’.

“I did my research and made a few trips over to study the A/NZ printing landscape and true enough… there was an untapped opportunity for Cyber to make its mark in this region. The Ryobi distributorship was also available, so we took on the challenge.”

The rest was history.

Cyber Australia was established in 2004, with the company showcasing several Ryobi presses at PacPrint 2005.

Cyb er Australia managing director Bernard Cheong

“At PacPrint 2005, our first PacPrint, all major exhibits were sold,” Cheong said.

In 2009, Cyber Australia first unveiled the Ryobi 920 series in its Singapore showroom. The 925, a SRA1-size five-colour offset printing machine, was first purchased by CMYKhub in Australia sight unseen as a vote of confidence in Cyber and Ryobi.

“We truly appreciate the partnership and confidence CMYKhub has in us. The superior cost performance of the 925 led to more presses being purchased from the group over the years,” Cheong said.

“This includes Australia’s first 925D fivecolour with UV coater, the first 928P LED 8-colour convertible perfector with LED system, and the new 970PF-8 LED with PQS-D A1-plus-size 8-colour convertible perfector with LED and Smart-Automatic Printing (SAP), featuring non-stop automatic registration and colour control and inspection. CMYKhub bought a total of 15 offset printing presses from us.”

In 2010, Ryobi and Mitsubishi came together to form RMGT. The integration of the two product lines enabled Cyber Australia to bring to market the best of both worlds, giving the business an added advantage.

Through the years, order numbers increased, and Cyber Australia became a household name.

The Cyber of today

Cheong provided an update on Cyber Australia’s more recent business, saying the pandemic actually ended up being favourable for the company.

“In a single year, during the COVID period, we experienced the best business performance in our history in Australia,” Cheong said.

“Because shipping was an issue for printers during COVID, the Made in Australia movement resulted in more products being produced locally. This meant printers needed efficient machines to deliver quality solutions, and many turned to us as their trusted technology provider.

“Every cloud has a silver lining – you’ve only got to look for it in the right places.”

One of the more recent installations was at CCS Media Packaging, which installed a new RMGT Ryobi 970 seven-colour press with aqueous coating in 2024, bringing in the final piece of a 12-month, multi-million dollar investment.

“CCS is a unique client of ours. They used to print for record companies, but with music now going digital, the need for

prints for CDs and other related materials became obsolete. So, the company pivoted into the food packaging space and needed the machinery to support production,” Cheong said.

“But now, with record labels at boutiques making a comeback, it has become the icing on the cake for CCS because they have already been involved in the music industry.”

Of late, with the prolific growth in packaging, Cheong finds the number of print service providers purchasing machines from Cyber Australia specifically for packaging purposes has escalated.

“Half of our installations are now to companies that have taken on packaging work in addition to their printing capabilities,” he said.

“This was, again, brought on since COVID, when peoples’ purchasing patterns shifted from in-store to online.”

In New Zealand, the company is currently in the process of installing two presses.

“In New Zealand, a lot of print service providers’ equipment are getting old. Their hands are being forced to either update their machinery and continue operations, or close down,” Cheong explained.

Across Asia, most of the company’s sales come from Malaysia and Vietnam.

“There’s greater demand for machines in the developing markets in Asia as they invest a lot more than the developed markets. This is because most of the work is outsourced to printers in these countries,” Cheong said.

“When COVID hit in Malaysia, for example, business did stall momentarily but it was the first to pick up because the country sees a large production of latex and with the requirement for latex gloves,

our print service providers needed to print glove boxes rapidly.

“Since COVID until now, the Malaysia market hasn’t stopped – in fact, it’s been really strong for us. With Donald Trump slapping tariffs on China, I think it’s only going to fuel the Malaysian market to be even stronger.”

The move back to

offset

According to Cheong, Cyber’s customers are making the move back towards offset equipment as technology has made offset printing more affordable than before.

“For non-collated products, we have clients that were strong digital users for more than a decade embark on an offset journey because they find it cheaper to print on offset. Offset was dying because the last major adoption in that space was CTP. But now, with modern offset printing equipment, it is equally easy to print on it because everything is automated,” Cheong said.

“With digital, it’s all click charge – you pay for every sheet. With offset, you pay for the commodity, which is ink and plates. They’re cheap.

“So, RMGT’s R&D division focuses heavily on digitising offset equipment. The focus is very much on the mechanical engineering – improving reliability, increasing speed, and simplifying makeready times and staffing requirements.

“In fact, the company used to manufacture some digital machines, but when comparing the cost of print to automated offset presses, it found that printing on automated offset was still cheaper.”

One example that Cheong mentioned was US-based Pacific Printing. Previously, a lot of the company’s short-run work was digital. But, the ability to get to colour quickly enabled it to move a lot of that work over to offset, changing the capabilities for the business in terms of what it can gang-run and put on press in a short amount of time.

But even with the change in market demands, the core of Cyber remains the same.

“Our focus from when we first started until today is the same. We are very much a customer orientated business that evolves together with our customers. We are not fixated on any single market –whatever the customer wants, in whatever direction that they move, we are there for them,” Cheong said.

“Our customers are our compass for change – they show us the direction, and we adapt accordingly.”

(l-r) Cyber’s Herbert Cheong and Bernard Cheong

Gender isn’t a barrier to success

Aleisha Gill has cultivated strong relationships with customers and actively gives back to the industry, believing shared support is essential to the industry’s collective success

Building strong relationships with customers is one of the foundations of a successful print business. That, together with a love for production and customer service, is what drove Kwik Kopy Eagle Farm centre owner Aleisha Gill to purchase her own Kwik Kopy centre in Queensland.

Gill’s journey in the print industry began more than 20 years ago, when she started as a receptionist at JT Press. It wasn’t long before she became fascinated with the industry, and immersed herself in all things print – from estimating to quoting, through to production, and how offset printing worked.

“I developed a deep appreciation for the craftsmanship behind print, from how books are folded and produced to the precision involved in impositions,” Gill told Australian Printer

As she gained more experience, Gill moved into a role handling estimating and impositions – becoming the only female estimator among a team of men at that time – expanding her knowledge of the industry.

“While I loved the technical side, I wanted more interaction with customers. That led me to take on a position in customer service, where I found my true passion: working closely with clients, understanding their needs, and guiding projects from start to finish.”

This passion led Gill to Kwik Kopy, where she managed a local branch for eight years, allowing her to build strong relationships with customers while ensuring they received the quality and service they needed to keep coming back.

Then, about two and a half years ago, the opportunity arose for her to purchase her own Kwik Kopy centre.

“Purchasing my own Kwik Kopy centre was a big step, but I knew it was the right one. It allowed me to shape the business in my own way, build a strong team, take full ownership of our growth and success, and make a real impact in the industry I love,” Gill said.

With technology continuously changing the way print is produced, moving into the Kwik Kopy system introduced Gill to a more diverse range of printing methods – from traditional to digital and largeformat printing. Along the way, she also learnt graphic design.

“I wanted to have a well-rounded understanding of every element that goes into print production. Having this knowledge allows me to better support our clients, ensuring their designs are print-ready and advising them on the best way to bring their ideas to life,” she said.

“Learning never stops in this industry. We are constantly adapting to new technologies, materials, and techniques. There’s always something new to discover, and that’s what keeps me engaged and passionate about print.”

According to Gill, gender isn’t a barrier to success anymore. With the gender balance evening out over the past 20 years and more women taking up leadership positions in print, Gill finds it incredibly encouraging that more women are entering the trade.

“What matters most is being confident and secure in your skills. If you focus on doing your job well, continually improving your abilities, and making sure you deliver quality work, success will follow – regardless of gender. That’s the advice I’d give to every woman in print: Focus on mastering your craft and others will recognise your value,” she said.

Gill has never looked solely to women for inspiration. Throughout her career, she has been fortunate to learn from both men and women who have been willing to teach, mentor, and support her growth.

“The key has always been surrounding myself with the right people – those who are open to sharing their knowledge and genuinely wanting to see you succeed. This industry is full of knowledgeable, generous professionals who are willing to support others, and I’ve been lucky to have had many great mentors along the way,” she said.

Gill herself looks to give back to the industry through support, saying it’s crucial to the industry’s collective success. She has been involved in initiatives such as coaching programs that help people enter the workforce.

“Our team has supported initiatives like tours with the Youth Development Foundation, where we show young people how jobs are created and get them excited about the possibilities in the industry. By giving back, we can inspire the next generation and make the industry more accessible and inclusive for everyone, she said.

In addition, she said while supporting women in print is important, her broader goal is to support women in business.

“I want to help them build the right connections and network with other women in business, as well as with their customers. These connections are the foundation of a successful business. If you focus on relationships and not just transactions, that’s what truly drives success,” Gill added.

Some of her other aims include continuing to grow a successful Kwik Kopy business, building deeper connections with customers, and continuing to raise the profile of the wider print industry.

Kwik Kopy Eagle Farm centre owner Aleisha Gill

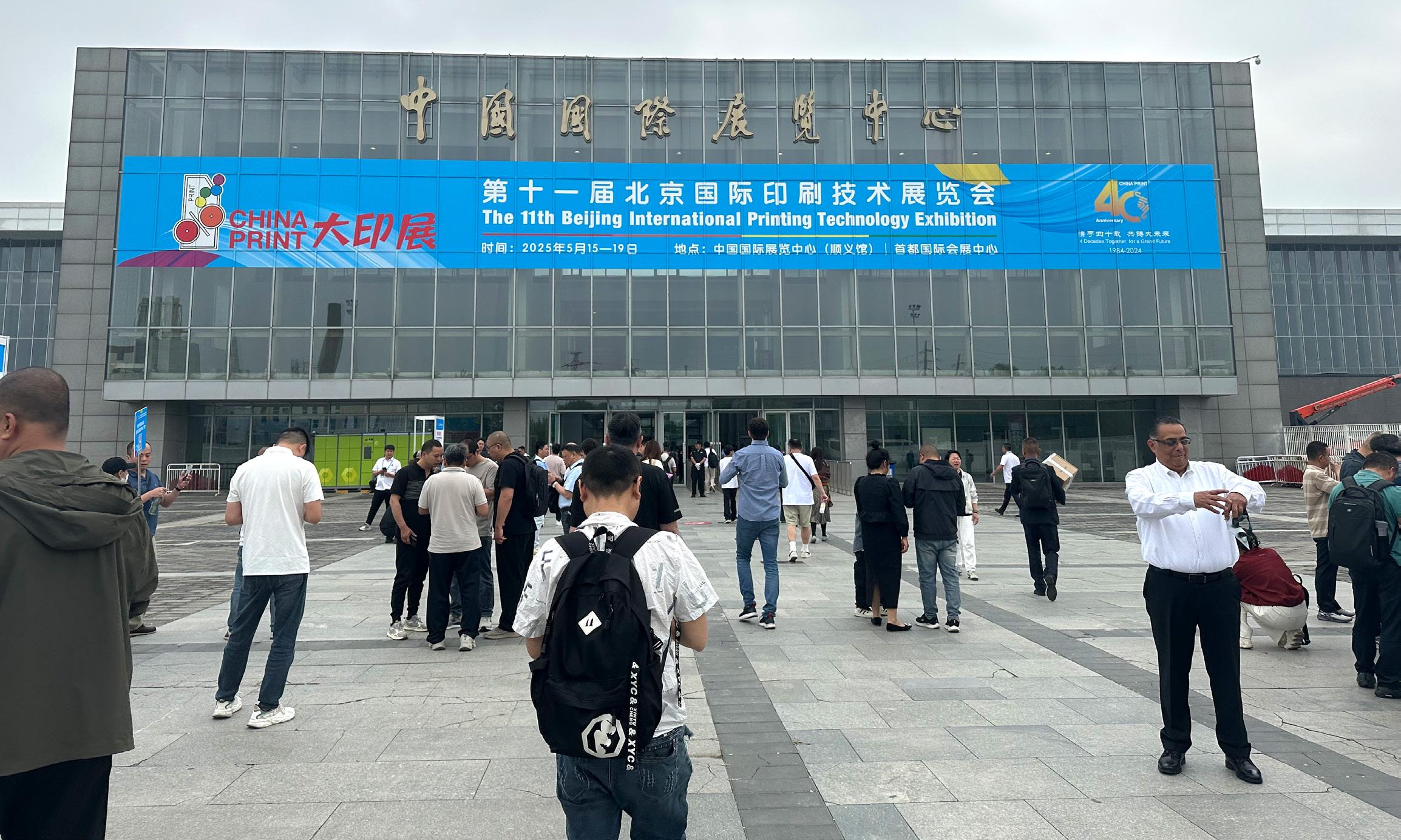

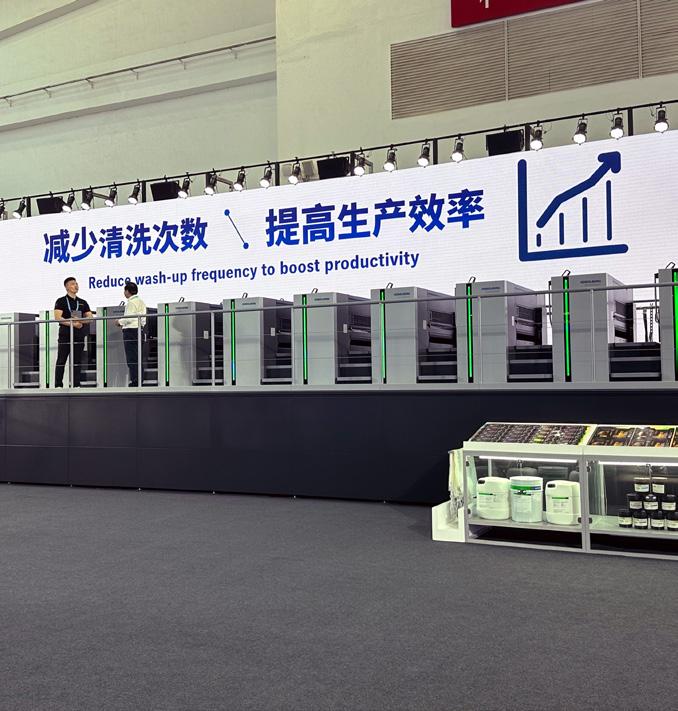

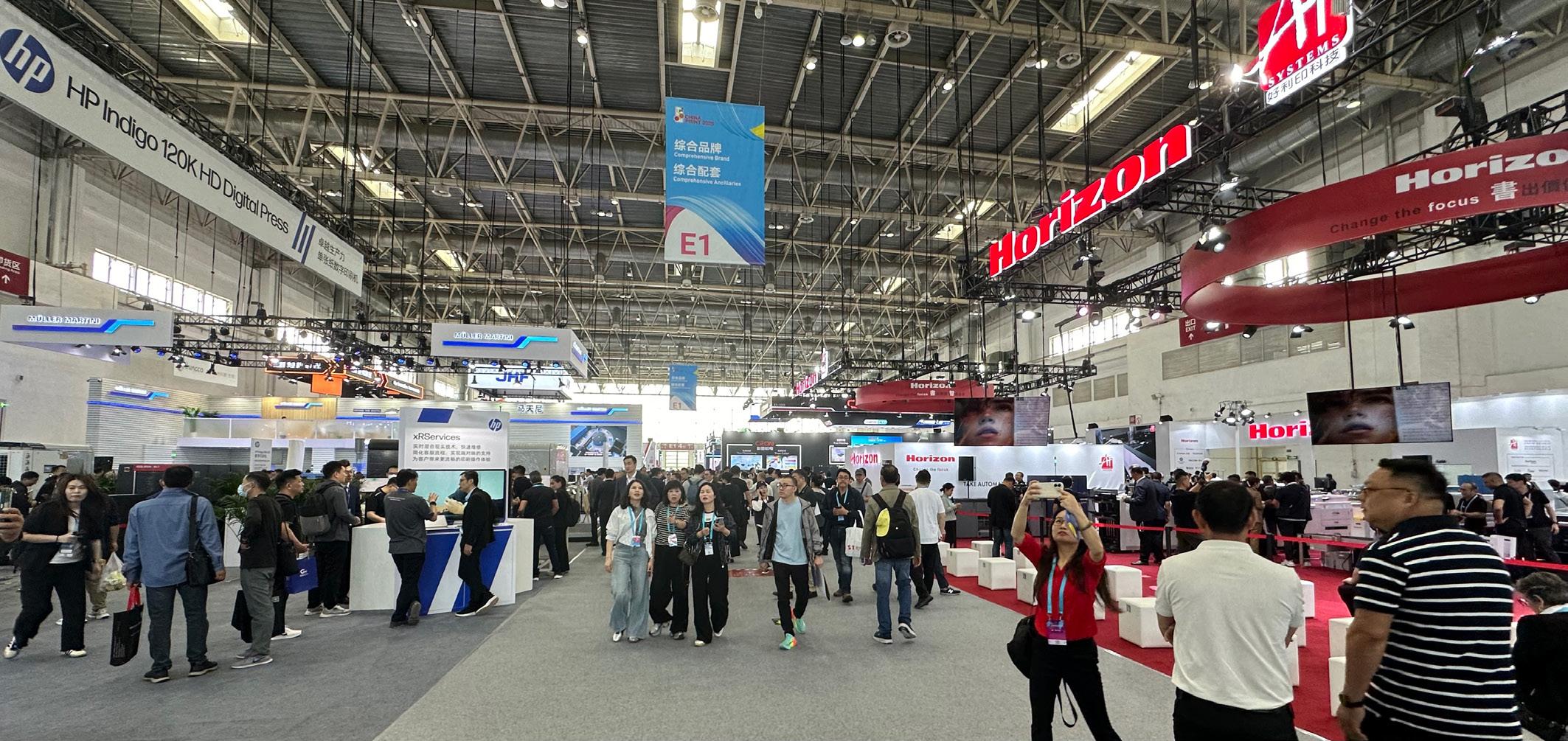

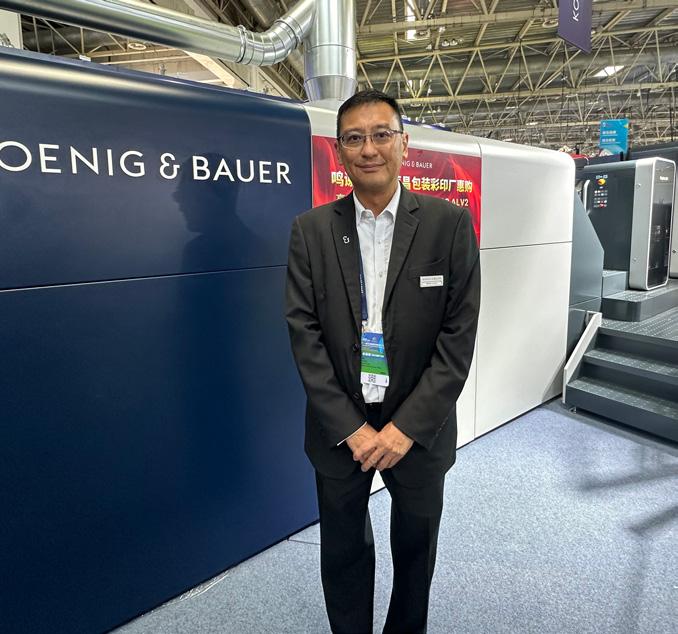

China Print 2025 sees huge success

One of the biggest tradeshows worldwide, China Print 2025 recently took place in Beijing and showcased the latest and greatest innovations in print

The 11th edition of China Print recently took place in Beijing, bringing together the global printing and packaging industry from more than 10 countries worldwide.

Spanning over eight exhibition halls and housing more than 1,300 exhibitors, the event not only brought together the world’s latest printing innovations, but also served as a barometer of the global developments and trends of the industry.

Here are some of the solutions leading manufacturers showcased:

Durst

Durst announced the sale of multiple Tau RSC machines to Chinese customers. On the first day of the tradeshow, the company celebrated the sale of seven Tau RSC E units and one Tau RSCi machine.

Deal signings and handshake deals were aplenty at the Durst stand, with company group CEO and co-owner Christoph Gamper and sales manager for labels

and flexible packaging Thomas Macina joining in the celebrations.

Durst also showcased on its stand the Tau 340 RSCi LED, which Durst Group labels and flexible packaging head of product management Martin Leitner said is growing in popularity in China.

“Durst has had a physical presence in China for about 10 years – 20 years if you include our days going to market with a distributor. The China market has been evolving over the last decade, and we have been fortunate enough to get a solid install base in the country,” he said.

“We are now very well known in the market with our customers and potential customers as our technology is disruptive.

“Bringing the Tau 340 RSCi LED lets us diversify in the market as the RSCi model is more high-end, and China is a high production market. It’s a machine that better suits the local market and is becoming more and more popular.

“Durst understands its markets really well and knows what the customers require for them to be successful. Automation, the adoption of digital printing, the importance of workflows, and stability of print runs are increasingly becoming important for this local region and Durst has integrated features within its portfolio to deliver on these needs.”

People heading towards the gates of China Print 2025

Durst management and three Chinese customers that purchased Durst Tau RSC machines

The Tau RSC platform sets the benchmark in productivity and flexibility. With print speeds of up to 80m/min for the upgraded version, a native resolution of 1,200dpi by 1,200dpi and up to 8 colour stations, the Tau 340 RSC enables customers to achieve flexo like productivity in a 24/7 environment.

It also can be also equipped with the revolutionary Durst Hawk Eye technology to automate print quality.

The 340 RSC is available in two variants –RSC E and RSCi. The RSC E is Durst’s high spec entry-level variant, while the RSCi is the industrial version that accommodates wider media and can be hybridised with OMET embellishment or finishing.

The RSCi version is available in printing widths of 338mm, 420mm or 510 mm. The printer can be equipped with the Tau RSC UV inks or with the new Tau RSC LED inks, which is integrated into the Tau 340 RSCi LED.

Applications for the machine include variable data, industrials, and speciality packaging.

Epson

Epson China celebrated the sale of six SurePress L-5034 units in the country and launched two new machines.

The SurePress L-5034 is a new commercial inkjet label press enabling high-speed printing thatʼs ideal for short- to mid-run jobs, producing labels with outstanding scratch and weather resistance.

The newly developed PrecisionCore linehead and centre drum system deliver high-quality images. The space-saving, compact design integrates all the functions required for label production.

Epson also took the wraps off its SureColor P9380 and SureColor P7380 at the event.

The 10-colour pigment ink machines add to Epson’s high-end imaging

series and include Nozzle Verification Technology (NVT), micro-spraying technology, the addition of violet as a spot colour, and the latest generation 2.64-inch Epson PrecisionCore MicroTFP print heads capable of ejecting a minimum ink droplet size of up to 3.5 microliters.

Epson China LFP product manager Xin Longhao said these machines are focused on the photo category as Epson has a huge market share in this space.

“The SureColor P9380 is a 44-inch machine, while the SureColor P7380 is a 24-inch machine, but their specs are totally the same,” he said.

“The colour gamut of these machines is 97 per cent as a result of the 10-colour pigment ink and addition of violet as a spot colour. Their speed is almost double of previous models, because of new and improved printheads. They are very stable machines that produce very vivid images.”

The SureColor P9380 and SureColor P7380 are referenced locally as the SureColor P9360 and SureColor P7360 respectively.

The Epson CW-6530A was also on display, integrated with post-processing die-cutter, demonstrating a total solution.

The Epson CW-6530A, which is the company’s first 8-inch wide format colour label printer, uses a PrecisionCore print head with resolution up to 1,200dpi by 1,200dpi and four-colour pigment ink.

The CW-6530A is known locally as the ColorWorks C6510A.

Fujifilm BI

Fujifilm Business Innovation (BI) featured the new Revoria Press SC285 and Revoria Press EC2100, which both made their Australian debut at PacPrint the following week.

Fujifilm BI graphic communications marketing deputy general manager

Toshiaki Okada stated, “what sets these two machines apart is that the high print quality is the same as our flagship model.

“Even as mid-range machines, these units boast fast speeds and include a new generation of technology. They are five-colour machines, which present a wide gamut of colours,” Okada said.

With the help of Super EA-Eco toner used in high-end models, both the Revoria Press SC285 and Revoria Press EC2100 enable users to experience high-quality CMYK printing and achieve shiny metallic colour and gloss.

Their compact high-quality LED print head can provide high-resolution output of up to 2,400dpi x 2,400dpi to achieve highdefinition printing with clear lines and images.

The Revoria Press EC2100 allows for high-speed printing of uncoated paper (52gsm to 400 gsm) and coated paper (72gsm to 400 gsm). Its A4 productivity is up to 100 pages/min, while its A3 print productivity is as high as 55 pages/min. It features an automatic optimisation function using Revoria Flow, of neon pink toner to achieve a wider colour gamut.

The Revoria Press SC285 supports a wide range of paper types and sizes, including various paper sizes as small as 90mm by 46 mm and as large as 330mm by 660 mm, and supports optional long paper printing (single-sided) up to 330mm by 1,300 mm.

Its production efficiency of A4 is up to 85 pages/min, while the production efficiency of A3 printing is as high as 47 pages/min.

Heidelberg

Heidelberg displayed the new Speedster CX104 A1 format press in a CX 104-8+LYY-1+L configuration, stating it is the “longest 13-unit offset machine in exhibition history”.

Epson China LFP product manager

Xin Longhao with the SureColor P7380 (SureColor P7360 locally)

The Heidelberg Speedster CX104 A1 format press in a CX 104-8+LYY-1+L configuration

The new Revoria Press SC285

The Speedmaster CX 104 can handle all materials from lightweight paper up to carton stock for packaging. It enables users to flexibly switch between conventional and instant drying UV colours – supported by the additional washing cycle for the inking unit, blanket, and printing cylinder.

It allows for high performance ranges with speeds of up to 16,500 sheets per hour, uses intelligent assistance systems like Intellistart 3 and Intelliline, which revolutionise job changes with time optimised automation and complete transparency, and features an improved anilox roller change in the coating unit that makes setting up noticeably easier, safer, and faster.

The LYY-1+L configuration consists of an extended double coating system.

In addition, Heidelberg also showcased its Jetfire 50 with a complete digital print ecosystem, making its debut at an Asian tradeshow. The machine, which was announced at drupa 2024, is based on inkjet technology from Heidelberg’s cooperation partner Canon and marks its expansion into industrial digital commercial printing.

Heidelberg said customers from the packaging sector invested in primarily its sheetfed technology, with a total of just under 350 printing units sold at the event.

“The huge interest in the innovations and displays at our booth provides impressive proof that Heidelberg is a leading market player in China,” the company’s chief technology and sales officer Dr. David Schmedding said.

“We won over a large number of customers with our integrated solutions for packaging and commercial printing from a single source, many of which are manufactured locally. The resulting incoming orders have given us a strong start to the new financial year, which began in April.”

HP

HP took the wraps off two new HP Indigo presses that made their Asian debut at China Print.

The HP Indigo 120K HD and 18K HD presses are built to support the transition from analogue to digital, with high-speed, AI-driven automation, and offset-quality output.

The HP Indigo 120K HD delivers on productivity and offset-matching print quality, setting a new standard for highvolume production and automation, at speeds of 6,000 sheets per hour.

True digital continuous operation enables non-stop paper feeding, non-stop colour measurement, and continuous stacking. It saves time, with multiple input and output paper sources, allowing a seamless and automated switchover process for jobs and paper on-the-fly.

AI-based technology aid in image quality troubleshooting, predictive press care and maintenance capabilities, and end-to-end line efficiencies and reduced paper waste.

It allows users to boost productivity by 33 per cent while reducing operating cost per sheet and save 25 per cent of energy consumption per sheet while printing on the HP Indigo Enhanced Productivity Mode (EPM).

Users can also print more economically and more sustainably with the new ECO 4-colour print mode option, which helps reduce carbon footprint by 11 per cent.

The HP Indigo Recycling Imaging Oil (RIO) technology lets users reuse imaging oil and reduce up to 35 per cent waste.

HP Industrial Print Asia-Pacific and Japan head of products and solutions Yoav Lotan said, “The HP Indigo 120K HD is 30 per cent faster than the 18K HD. It goes up to five colours and is mainly made for general commercial print applications that are high-quality, short-run jobs. It’s really about automation and productivity with this machine”.

As for the HP Indigo 18K HD, it is a B2 digital press that supports more than 2,000 certified substrates, 75 per cent of which are sustainable media, ranging from 75 to 600 microns. It produces unlimited colour combinations with seven ink stations, featuring 12 specialty ElectroInks and a countless array of spot colours.

Innovative Photo-Pro Mode eliminates the need for a photo specialist by automatically using CMYK+LLK inks on demand. AI-based automation is also

used for image quality, PQ Maestro troubleshooting, and diagnostics.

It also includes LEP Print Technology and PrintOS’ data-driven solutions.

“The HP Indigo 18K HD is the most versatile platform that you can buy today in the market. Its digital prints are of offset quality. It can support a range of applications, using anything from very thin paper – like for book publishing or catalogues – to rigid boxes, folding cartons, trading cards, and even credit cards. This machine can literally print on anything,” Lotan said.

“It’s a workhorse – it is a very robust, productive, and versatile printer that delivers on HD definition with its unique spot colour, UV, invisible, and security inks. It’s very popular.”

The company also had a portfolio of products on display, including the HP Indigo 200K, 6K, V12, and PageWide A2200 presses. These machines demonstrated solutions for short-run packaging, high-volume label production, and commercial print.

In addition, HP also showcased smarter production with HP PrintOS, educating attendees on new tools such as Production Beat and PQ Maestro that streamline workflows, boost efficiency, and save hours each day.

At the event, HP also celebrated its 100th flexible packaging press installation in Asia Pacific and Japan –in a major milestone for HP Indigo, Dongguan Honggan Packaging installed an HP Indigo 200K Digital Press.

“China has been one of the leading countries for us in labels and shows a good acceptance of the Indigo technology,” Lotan said.

“The main challenges that we previously noticed in China, that impacted the way we designed our products, was 1. the need for data processing and digital content that has resulted in more computing power in our platform today, and 2. colour management, accuracy, and repeatability, especially for customers with multiple sites that must serve the same brand across sites.

“We’ve identified these needs quickly and incorporated them into our designs. They have been very productive for HP Indigo customers in China, especially as they expand into new verticals of play. The fmcg, beverage, high-end tobacco, liquor, and cosmetics markets have skyrocketed here, and the HP Indigo technologies allow them to see the benefits of digital for these industries.”

HP Indigo is distributed in A/NZ through Currie Group.

The HP Indigo 120K HD press

Hybrid Group

Hybrid Software participated in China Print, where it educated attendees about its product portfolio, including PACKZ and CloudFlow.

PACKZ is a PDF editor for labels and packaging that makes designs print-ready for any printing process. PACKZ aims to enrich designs with priming and finishing separation, handles ink sets and objectbased screening, applies trapping and generates dynamic marks and panels.

The application also produces unique seasonal packaging and personalised labels with the VDP wizard, produces warp and 3D visualisations, and optimises substrate utilisation using numerous step and repeat solutions.

CloudFlow is a modular production workflow suite for file processing, asset management, soft proofing and workflow automation. It is a web-based application platform specifically tailored for the packaging graphics with support for PDF, colour separation, trapping, screening, and proofing.

It utilises Hybrid Software’s Workspace technology which indexes file repositories while respecting the existing directory structure, automatically extracts relevant metadata and creates accurate thumbnails. It stores all its information in a database to make it available and searchable and allowing for centralised configuration and backup.

Hybrid Software labels and packaging vice-president and general manager Bert Van der Perre said, “In Europe, we see a lot of automation happening, and that automation is always linked to an ERP or MIS system. It’s good to see that this is also a trend coming into China.

“We are still a relatively young company in China, but we are expanding our footprint in the country and adding on more staff. We are looking forward to growing our base here, in China.”

Kodak

as well as its Sonora Xtra Process Free Plate.

The Trendsetter Q800 is an eight-page model that now offers more speed and labour-saving automation options.

Semi-automated plate loading/unloading comes standard, or can be upgraded for additional automation features, including inline punch. The high-capacity, fully automated Multi-Cassette Unit (MCU) and top W-speed deliver optimal productivity and reliability with minimal manual intervention.

Trendsetter Platesetters aim to bring cost savings on several fronts. The automation features speed up platemaking and reduce errors from manual handling, saving time, labour, and costly remakes.

Plus, they require only 770 watts while imaging – up to 92 per cent less power than other CTPs – for lower resource usage and environmental impact, especially when paired with Kodak Sonora Xtra Process Free Plates.

Sonora Xtra Plates deliver high performance along with all the standard perks of going process free. It lets users eliminate plate processing, extra equipment, chemicals, water, and energy. They are also designed to keep up with the fastest platesetters, like the Kodak Magnus Q800 Platesetter, at up to 84 plates per hour.

The Kodak Magnus Q800 Platesetter is what the company calls the “industry’s fastest eight-page CTP”. It can be configured to multiple automation options, delivering up to 84 consistently imaged plates per hour.

Kodak Asia WW operations and alternate channels program director Anita Yiu said, “Both machines that we are showing at China Print are the most popular in China based on the volumes they produce daily. They are the market standard.

Kodak presented live demonstrations of the Trendsetter Q800 and Magnus Q800 SCU Platesetters,

Kodak Asia WW operations and alternate channels program director Anita Yiu

Bert Van der Perre (third from left) and the Hybrid Software China team at China Print 2025