Portable Abrasive Blasting Shelter

Efficient Contained Cost-Effective

Scan or click here to see video

Efficient Contained Cost-Effective

Scan or click here to see video

Traditional abrasive blasting and coating works often require scaffold-built or fixed enclosures, or the removal of components to off-site facilities, each adding days of labour, high transport costs, and disruption to live sites.

The Portable Abrasive Blasting Shelter eliminates those inefficiencies.

It is a fully engineered, certified, and relocatable enclosure that brings controlled abrasive blasting, surface preparation, and coating directly to site, creating a compliant, contained workspace wherever it’s needed.

Each unit delivers fixed-shelter performance with mobile efficiency, combining environmental control, safety, and flexibility without the cost or complexity of conventional structures.

Designed for demanding industrial environments, the Portable Shelter integrates structural strength, full environmental containment, and rapid deployment in one engineered system.

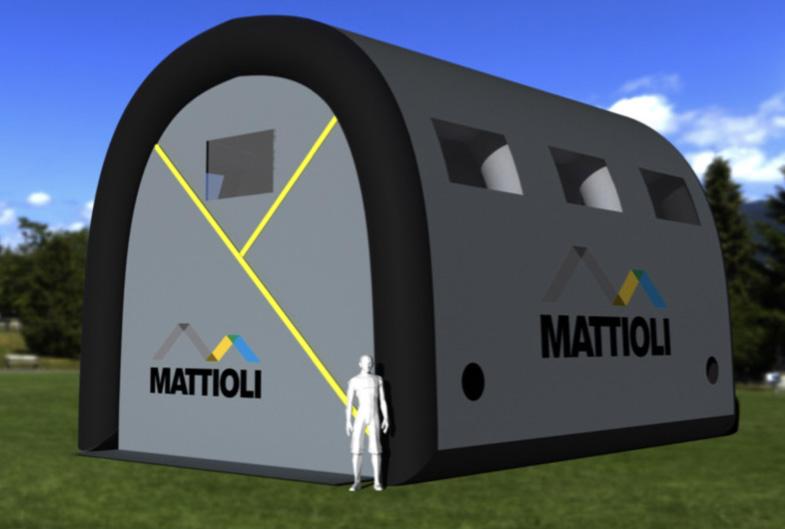

Available sizes from 10 m (L) × 8 m (W) × 6 m (H) up to 20 m (L) × 10 m (W) × 8 m (H)

Its air-supported frame and heavy-duty PVC construction create a large, unobstructed workspace suitable for blasting, coating, welding, or surface treatment , indoors or outdoors.

3-metre blast-protection screens with integrated dust tray

High-velocity negative-pressure extraction and media-recovery system for compliant dust and contaminant control

Heavy-duty PVC-coated fabric, fire-retardant and UV-resistant

Transparent welded windows provide natural light while maintaining waterproof, dustproof integrity

Built-in safety flooring with non-slip rubber topping for improved operator safety

Reinforced duct ports and optional crane-lift lugs for precise positioning

Fully enclosed structure with emergency exits and venting

Certified as a permanent engineered system, eliminating the need for re-certification or re-engineering upon relocation

High-velocity negative-pressure extraction

Operational within hours; adaptable for confined, open, or hard-to-access areas and easily redeployed between sites.

Eliminates scaffold hire, freight, and lengthy setup cycles.

A Certificate of Compliance confirms permanent engineering and safety certification for each deployment, eliminating the need for recertification when relocated.

Sealed, negative-pressure workspace for uninterrupted operation.

Integrated extraction and media recovery ensure containment.

Reduces work-at-height and material-handling risk.

7.

Enables in-situ treatment of one-off or critical components; no transport risk.

Factor

Deployment Time

Setup & Engineering Requirement

Cost Efficiency

Safety

Environmental Control

Operational within hours; dismantled in under an hour by a small crew.

Fully engineered and certified system; relocates without reengineering or site-specific certification.

Reusable system; upfront investment delivers measurable savings from the first deployment.

Eliminates work-at-height and heavy-handling risks.

Fully sealed, high-velocity negative-pressure workspace with integrated dust extraction and media recovery, delivering fixedshelter performance in a portable system.

Multi-day scaffold build, wrapping, or off-site scheduling delays.

Fixed or scaffold-built shelters require design, certification, and construction time for each deployment.

Ongoing scaffold hire, freight, and engineering certification per project.

Involves scaffold erection and double-handling of materials.

Achieves similar control only through purpose-built or engineered fixed enclosures, requiring extensive time, cost, and certification.

Asset Protection

Project Downtime

Quality & Consistency

Enables in-situ blasting and coating of one-off or critical components, avoiding removal, lifting, and reinstallation.

On-site operation removes freight delays and accelerates shutdown schedules.

Stable, weather-proof environment ensures consistent coating quality across multiple sites and conditions.

Requires removal, loading, transport, and reinstallation, adding cost, time, and risk of damage.

Off-site works extend timelines through transport, staging, and reassembly.

Quality consistency depends on site conditions and enclosure build quality.

Unlike conventional methods, the Mattioli Portable Shelter delivers fixed-shelter performance without the cost, complexity, or downtime. It brings controlled blasting and coating directly to the work front, faster, safer, and fully compliant.

Across Australia, asset owners and operators are achieving 30–50% reductions in total project hours and costs through the use of the Mattioli Portable Abrasive Blasting Shelter.

The shelter is now a proven asset within major maintenance and refurbishment programs across:

• Water and Wastewater Infrastructure

• Power Generation and Energy

• Petrochemical and Industrial Facilities

• Defence and Government Assets

• Civil and Transport Infrastructure

Measurable efficiency gains, stronger safety performance, and long-term cost advantages across every industry it serves.

Each deployment is managed through a defined and repeatable framework that ensures safety, efficiency, and full compliance from planning to delivery.

We review target assets, access constraints, and containment requirements to determine the optimal configuration.

Structural verification, anchoring, and environmental controls are planned and certified for site conditions.

The shelter is delivered, installed, and operational within hours, with all safety and quality, and compliance controls verified onsite

Operators are briefed on setup, use, and relocation protocols to ensure safe, repeatable operation across future projects.