Water & Wastewater

Capability Statement

For over 50 years, Mattioli has safeguarded Australia’s critical infrastructure and built environment — protecting the assets that keep communities, industries, and essential services running.

We deliver remediation, protection, and preservation solutions that restore integrity, control deterioration, and mitigate operational risk.

Each solution is designed to meet operational and compliance demands, ensuring durable, risk-controlled outcomes against challenges such as corrosion, water ingress, and chemical exposure.

The result: longer-lasting assets, predictable costs, and compliance you can rely on.

Concrete Remediation

Protective Coatings

Engineered Systems

Waterproofing

Floor Coatings

Heritage Restoration

Infrastructure & Utilities

Water & Wastewater

Petrochemical

Power Generation

Road, Rail & Transport

Ports & Marine

Commercial & Residential Retail

Commercial Buildings & Architecture

Venues & Hotels

Body Corporate & Strata

Educational Facilities

Health, Sport & Recreation

Hospitals

Aged Care Facilities

Stadiums & Arenas

Aquatic & Recreational

Facilities

Commercial Painting

Asset Management Plans

Industrial & Resources

Mining & Resources

Manufacturing

Food & Beverage

Public Sector & Government

Defence

Government &

Councils

Civil Engineering & Infrastructure

With offices in Melbourne, Sydney, and Brisbane, Mattioli provides comprehensive coverage across Australia. Our network enables rapid mobilisation of expertise, equipment, and resources to metropolitan, regional, and remote locations — ensuring projects are delivered safely, efficiently, and on time.

Our network enables rapid mobilisation of expertise, equipment, and resources to metropolitan, regional, and remote locations

Preservation where failure isn’t an option.

Water and wastewater facilities are among the nation’s most critical assets. They are essential to public health, environmental protection, and industry. Yet they operate in some of the harshest conditions in infrastructure. Corrosive gases, sewage acids, chemical by-products, and constant abrasion attack steel and reinforced concrete every day, accelerating deterioration, shortening service life, and heightening the risk of failure.

Beyond these physical realities, the sector faces broader pressures. Demand is rising. Regulatory obligations are becoming stricter. Opportunities for shutdowns are limited. At the same time, operators must integrate smarter systems into ageing infrastructure. Together, these factors expose the limits of routine maintenance. Short-term fixes may delay problems, but they do not deliver resilience, compliance, or long-term cost control.

This is where Mattioli’s approach makes the difference. With decades of experience in the water and wastewater sector, we deliver remediation, protection, and lifecycle solutions built to perform in harsh environmental conditions and under strict operational constraints. Our strategies extend service life, reduce reliance on short-term fixes, and provide cost-effective alternatives to replacement — ensuring critical infrastructure remains safe, reliable, and resilient well into the future.

With decades of experience in the water and wastewater sector, we deliver remediation, protection, and lifecycle solutions built to perform in harsh environmental conditions and under strict operational constraints.

Water and wastewater infrastructure operates under relentless pressure. Corrosive gases, chemical attack, constant wear, and limited shutdown opportunities combine to accelerate deterioration and heighten risk.

For operators of treatment plants, pumping stations, transfer infrastructure and reservoirs, these threats are a daily reality— jeopardising service continuity, compliance, and financial control. When failures occur, the consequences are immediate: disruption, penalties, environmental harm, and escalating costs.

Left unaddressed, these risks compound — shortening asset life, increasing operational risk, and driving up cost.

Mattioli addresses risk across three focus areas —

• Asset condition,

• Lifecycle demands

• Safe delivery

Together, these focus areas ensure nothing is left unmanaged, and each is tackled with precision so every intervention delivers measurable, lasting value.

• Control corrosion & restore concrete integrity

• Seal leaks, waterproof & protect against chemical attack

• Rehabilitate assets to extend service life

• Embed compliance & sustainability at every stage

• Balance capital & operational expenditure

• Monitor & optimise to sustain performance

• Execute safely in live, process-sensitive environments

• Meet strict WHS & regulatory requirements

• Overcome access challenges with engineered solutions

Outcome: The result: assets that are safer, stronger, and ready to perform for decades.

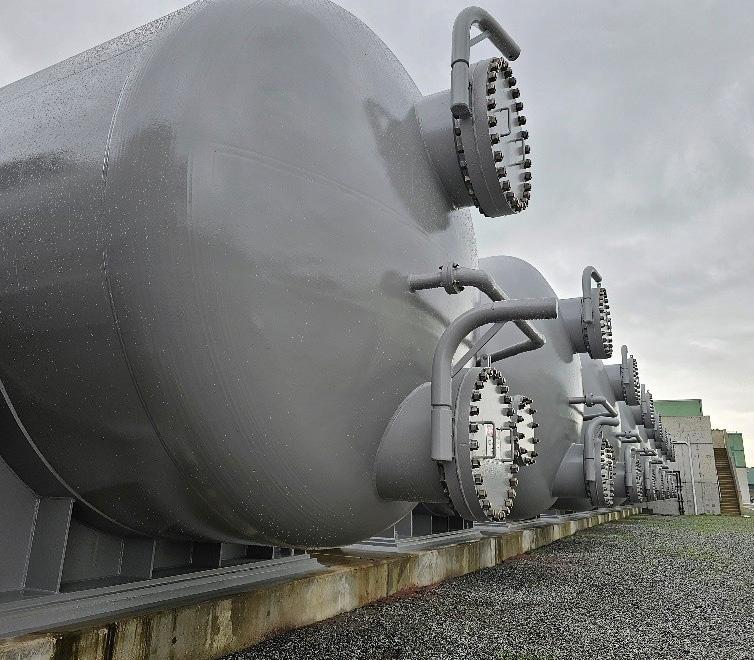

The water and wastewater sector depends on a mix of core facilities — treatment plants, reservoirs, and pumping stations — supported by environments such as chemical storage and control facilities.

Each facility type presents its own challenges, from aggressive chemicals and confined access to strict shutdown limits and compliance obligations.

Drawing on sector insight, Mattioli develops facilityspecific strategies that address these pressures — protecting performance, ensuring compliance, and sustaining long-term reliability.

• Water & wastewater treatment plants

• Desalination & filtration facilities

• Recycling & reuse centres

• Pumping & valve stations

• Reservoirs, dams & storage tanks

• Chemical storage & handling areas

• Stormwater & sewer systems

• Monitoring & control facilities

Water and wastewater networks rely on a wide range of critical assets — from pipelines and reservoirs to clarifiers, digesters, and dosing systems.

Each asset faces different challenges, from corrosion and leaks to chemical attack and mechanical abrasion particularly in highuse areas, any of which can compromise performance if left unchecked.

Our knowledge of asset vulnerabilities allows us to deliver targeted solutions that restore integrity, extend service life, and ensure asset safety, compliance and reliability.

Core Systems Supporting Infrastructure

1. Conveyance Systems

• Pipelines and valves

• Pumping and booster stations

• Flow measurement and control structures

2. Treatment Assets

• Clarifiers and sedimentation tanks

• Biological treatment systems (aeration tanks, activated sludge, MBRs, trickling filters)

• Filtration and disinfection systems (sand filters, UV, ozone, chlorination)

3. Storage & Containment

• Reservoirs, dams, balancing tanks

• Process basins and tanks

• Chemical storage tanks and bunded areas

4. Sludge & Residuals Management

• Digesters (aerobic, anaerobic, lime stabilisation)

• Thickening and dewatering facilities

• Sludge storage and transfer systems

5. Operational Infrastructure

• Administration buildings, laboratories, workshops

• Minor civil works (slabs, walkways, signage, barriers)

Our knowledge of asset vulnerabilities allows us to deliver targeted solutions that restore integrity, extend service life, and keep every asset safe, compliant, and performing reliably.

In water and wastewater environments, fragmented approaches heighten risk. Assets are vulnerable to concrete deterioration, corrosion, water ingress, chemical attack, and access limitations — each capable of shortening service life, increasing cost, or triggering compliance breaches.

Mattioli eliminates fragmentation through a fully integrated approach. Our expertise spans remediation, protection, and preservation across all core disciplines, allowing us to deliver coordinated solutions that close scope gaps, reduce risk, and maintain consistent quality.

The result: safer assets, predictable costs, and compliance you can rely on — all under a single, accountable warranty.

Concrete structures inevitably deteriorate under the effects of age, load, environmental exposure, and chemical attack. Left untreated, issues such as cracking, spalling, and reinforcement corrosion compromise safety, function, and compliance — and can lead to premature asset failure.

Services include:

Structural Repairs

• Crack injection

• Spall repairs

• Joint reinstatement

• Strengthening solutions

Surface Preparation

• High-pressure water blasting

• Mechanical treatment

• Specialist cleaning

Concrete Protection

• Corrosion inhibitors

• Patch repairs

• Protective coatings

• Passive Cathodic Protection

Reinstatement Systems

• Application of repair mortars grouts and resurfacing solutions

Mattioli delivers comprehensive concrete remediation solutions that restore structural integrity and extend service life. Our works are carried out to strict quality and durability standards, ensuring reliable performance in even the most demanding environments.

Protective coatings provide a critical barrier against deterioration, extending the service life of assets exposed to corrosive, chemically aggressive, or high-wear environments. Left untreated, these conditions can undermine steel and reinforced concrete structures, compromise compliance, and accelerate costly deterioration.

Mattioli delivers comprehensive coating solutions where corrosion control is a core outcome, complemented by protection against chemical attack, water ingress, fire and heat exposure, and everyday wear. Each system is engineered for the specific asset and environment and verified through stringent quality assurance — from AS/ NZS 4020 compliance for potable-water infrastructure to on-site testing such as holiday detection and dry film thickness checks.

Services include:

• Advanced surface preparation & cleaning

• High-build epoxy coatings

• Chemical-resistant linings

• Elastomeric membranes

• Fire-resistant systems (including intumescent coatings)

• Slip-resistant and safety coatings

• Integrated repair and recoating systems

• Anti-corrosion treatments

Each system is engineered for the specific asset and environment and verified through stringent quality assurance.

Uncontrolled water ingress is one of the leading causes of asset deterioration, structural damage, and service disruption. In water and wastewater infrastructure, reliable containment and waterproofing are essential to maintain compliance, safety, and long-term performance.

Services include:

• Liquid-applied membranes

• Sheet and roll-applied systems

• Cementitious coatings

• Geotextile-reinforced linings

• Polyurea and polyurethane spray-applied systems

• Tank and reservoir linings

• Joint sealing and waterstops

Mattioli delivers advanced waterproofing and lining systems tailored to resist hydrostatic pressure, chemical exposure, and environmental stress. For potable-water applications, all systems are certified to AS/NZS 4020, ensuring compliance and safety. From basements and tunnels to tanks, reservoirs, and treatment facilities, our solutions are designed for durability, watertight integrity, and cost-effective asset preservation.

Water and wastewater facilities place extreme demands on flooring systems. Constant moisture, chemical exposure, heavy equipment, and high foot traffic can quickly degrade unprotected surfaces, creating safety hazards and maintenance challenges.

Services include:

• Epoxy and polyurethane flooring systems

• Slip-resistant coatings for wet and high-traffic areas

• Chemical and abrasionresistant floors

• Antimicrobial and hygienic coatings for controlled environments

• Line marking and demarcation systems

• Rapid-cure flooring systems to reduce shutdown times

Mattioli delivers specialised flooring and safety coating solutions designed for these environments. From chemical-resistant finishes in treatment areas to slipresistant surfaces in wet zones, line marking for safety and demarcation, and rapid-cure systems that minimise downtime, our solutions ensure durability, compliance, and long-term performance.

Mattioli’s engineered systems are developed for situations where conventional approaches cannot deliver the required outcome. These systems are custom-designed and validated to address severe deterioration, highly aggressive environments, or access constraints that make standard applications impractical.

Services include:

• Advanced Encapsulation and Hazardous Waste Containment

• Fabric-Reinforced and Engineered Linings

• Thermal and Insulation Systems (Including Intumescent and Thermal Spray)

• Advanced Surface Preparation Solutions

• Rope Access and Specialised Application Methods

• Designed and Fabricated Solutions for Challenging Environments

By combining engineering design, rigorous testing, and controlled execution, these solutions restore integrity, minimise risk, and extend service life — often turning assets once considered unserviceable into reliable, compliant infrastructure. This approach avoids costly replacement, reduces downtime, and supports longterm sustainability goals.

Contaminants such as biofilm, mineral scale, corrosion by-products, and mould not only affect appearance but also accelerate deterioration, compromise coating performance, and threaten compliance.

Services include:

• Sodium Bicarbonate Blasting

• Dry Ice Blasting

• Drone-Assisted Cleaning for Confined or Elevated Areas

• High-Pressure Water Washing

• Targeted Mould and Mildew Removal

Mattioli delivers specialised cleaning systems engineered for operational environments where conventional methods are often impractical or unsafe. Our approach removes contamination without damaging underlying substrates, enabling effective remediation, coating adhesion, and long-term protection.

Structured. Integrated. End to End.

Water and wastewater infrastructure operates under conditions where reactive maintenance is costly and short-term fixes quickly fail. The Mattioli Asset Management Plan (AMP) provides a clear, structured approach to managing and preserving assets across their lifecycle — connecting assessment, planning, delivery, and long-term care in one coordinated process.

Each stage informs the next, ensuring risks are controlled, interventions are timely, and investments deliver maximum value. By closing the gaps between assessment, specification, and works, the AMP keeps maintenance aligned with asset condition and budgets predictable. Continuous monitoring and amortised cost models provide transparency and confidence, supporting better decision-making at every stage.

Whether managing ageing infrastructure, compliancesensitive facilities, or large portfolios, the AMP provides a scalable approach to maintain reliability, control cost, and extend asset life.

The outcome: timely interventions, predictable budgets, and assets that remain safe, compliant, and resilient well into the future.

Assets are managed strategically from assessment through to optimisation.

Rigorous processes identify risks early and address them effectively.

Condition-based interventions preserve asset value, minimise downtime, and maximise longevity.

Facilities remain aligned with regulatory, safety, and industry requirements.

Amortised models provide predictable budgeting and financial certainty.

Investment, time, and effort are directed where they achieve the best outcomes.

A systematic process of review and refinement—driven by performance insights, innovation, and stakeholder input—to extend asset life, improve outcomes, and enhance overall service delivery.

Structured, transparent reporting that communicates progress, insights, and performance data—enabling informed decision-making and supporting long-term planning and accountability.

Ongoing performance tracking and analysis to ensure maintenance activities remain effective, efficient, and aligned with changing asset conditions—maximising reliability and lifecycle value. 6

C O MMUNICAT

A structured long-term program that delivers ongoing asset care—embedding monitoring, reporting, and refinement within a coordinated approach. Includes the option to amortise project costs to support financial planning and long-term performance. 5

1

A detailed evaluation of the asset’s condition, accurately identifying deterioration, root causes, and performance risks–forming the diagnostic foundation for all subsequent planning and intervention.

2

Detailed, standards-aligned specifications that translate assessment findings into clear scopes of work—ensuring maintenance activities are targeted, compliant and technically sound.

3

Clear definition of the proposed works, supported by structured cost modelling that aligns scope, priorities, and delivery strategy—forming the foundation for either standalone project delivery or transition into the AMP Maintenance Program.

Coordinated execution of defined works—aligned with the scoped plan and delivered with a focus on safety, quality, and minimal disruption—whether as a one-off project or within a broader asset strategy.

Available as part of our Asset Management Plan, cost amortisation affords asset owners the option to structure maintenance costs across the service life of assets.

By avoiding large, upfront expenditures, this approach creates financial stability, simplifies budgeting, and ensures maintenance can be carried out when it is most effective.

Budget limitations are one of the main reasons maintenance is delayed or deferred. By smoothing costs over time, our cost amortisation model removes this barrier, enabling asset owners to sustain high standards of care without compromising financial health. The result is predictable funding, better decision-making, and the ability to prioritise long-term reliability over short-term constraints.

Structures costs across the service life of assets, improving budget accuracy, long-term planning, and cash flow management.

Aligns resources with critical needs, extending service life and ensuring maintenance is delivered at the right time.

Minimises exposure to major one-off costs, stabilises budgets, and supports compliance with financial and regulatory obligations.

Encourages adoption of advanced, sustainable technologies by lowering upfront costs and unlocking long-term savings.

In water and wastewater environments, there is little margin for trial and error. Assets operate under chemical extremes, confined access, and live operational pressures that push conventional methods to their limits. To succeed in these conditions, solutions must perform first time, safeguard compliance, and deliver measurable long-term value.

Mattioli’s innovation is proven in the field. We adapt and engineer systems to work where standard approaches cannot — restoring assets once considered beyond recovery, reducing lifecycle costs, and ensuring reliability under the sector’s toughest conditions

Innovation demonstrated through practical outcomes:

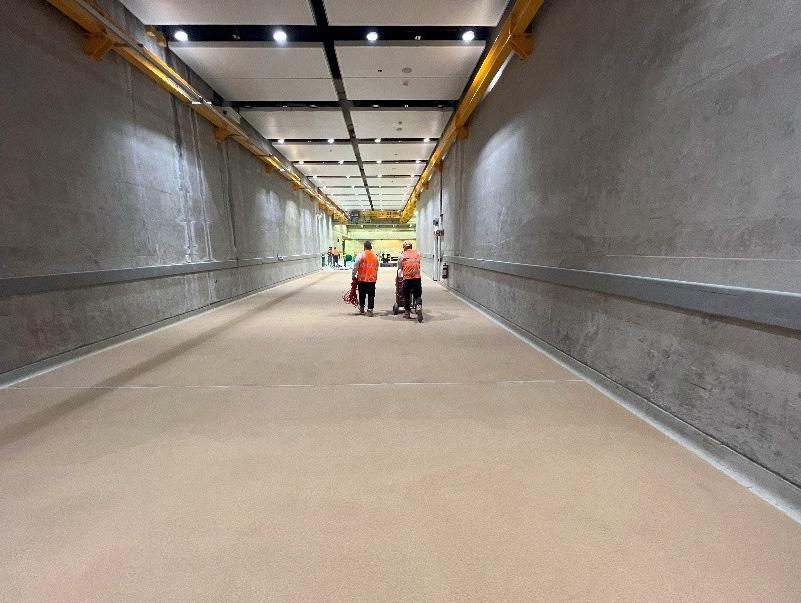

Robotic Precision for Safer, Cleaner Refurbishment

Project Context

This project involved the full coating refurbishment of a 65-metre diameter water storage reservoir, including the removal of hazardous internal and external coatings under highly restricted access conditions. The works were performed while ensuring safety, environmental compliance, and minimal disruption to the surrounding facility operations.

Mattioli utilised a remote-operated spider robotic system to remove hazardous coatings from the reservoir’s external surfaces. This eliminated the need for scaffolding, reduced working-at-heights risks, and enabled precision cleaning in difficult-to-reach areas. Ultrahigh-pressure (UHP) water was used in a fully controlled, closed-loop process to capture all waste material and prevent contamination.

Inside the reservoir, a mast climber robotic system was deployed to carry out coating removal on vertical surfaces under confinedspace conditions. This solution minimised manual handling, eliminated airborne contaminants, and maintained worker safety. UHP water was again used in a closed-loop system with full recapture and treatment.

A purpose-built water treatment and recycling plant was established on-site to process all captured UHP water from both internal and external works. The system enabled complete treatment and reuse of water with zero discharge to waste, meeting stringent environmental requirements.

By combining advanced robotic systems with on-site water recycling, Mattioli delivered a safer, faster, and environmentally sustainable refurbishment. The approach reduced labour risks, maintained full compliance, and allowed the reservoir to return to service sooner — with no environmental discharge and a fully refurbished coating system. This project was recognised as a finalist for the Australian Water Association’s Water Industry Safety Excellence Award for its innovation and sustainability outcomes .

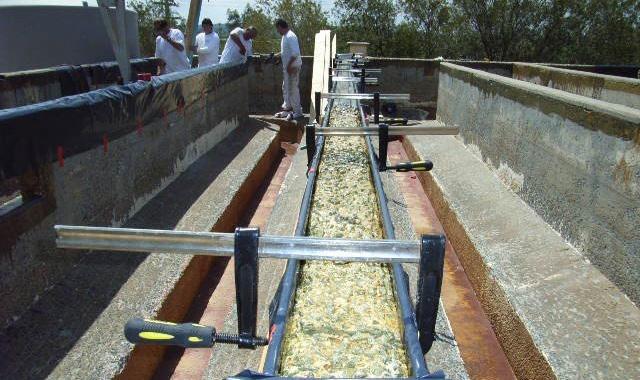

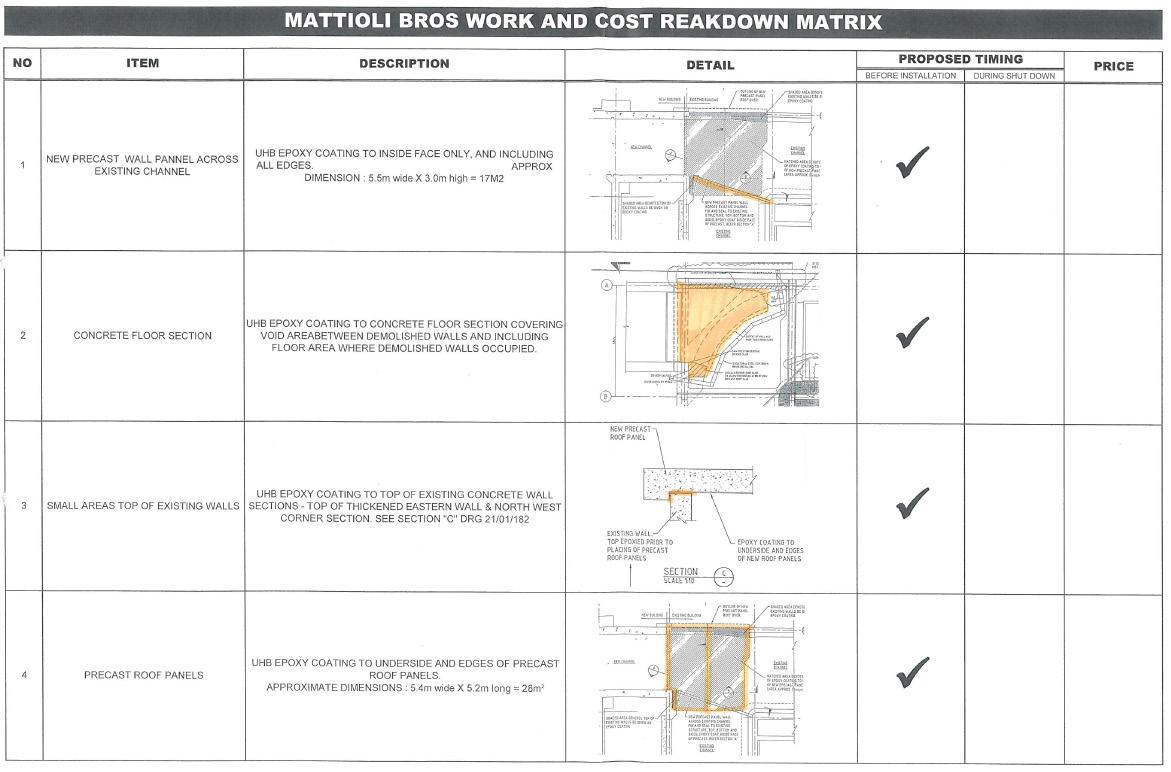

As part of a major facility upgrade, a critical tie-in project was required to integrate new treatment plant infrastructure with the existing system. The works had to be completed with restricted access and under strict operational constraints to avoid extended shutdowns or service interruption.

Mattioli designed and installed an in-house engineered geotextile-reinforced lining system that not only protected the internal concrete surfaces but also bridged across moving stainless-steel plates and an HDPE liner interface — an approach rarely attempted in live plant conditions. This bespoke solution was engineered to withstand the chamber’s hydraulic loads, chemical exposure, and dynamic movement without compromising seal integrity.

This innovative approach:

• Reduced project costs by 40% compared with conventional alternatives

• Minimised downtime risk by avoiding full system shutdown

• Extended service life of the chamber and improved overall reliability

• Demonstrated a novel application of geotextile technology, setting a precedent for similar assets

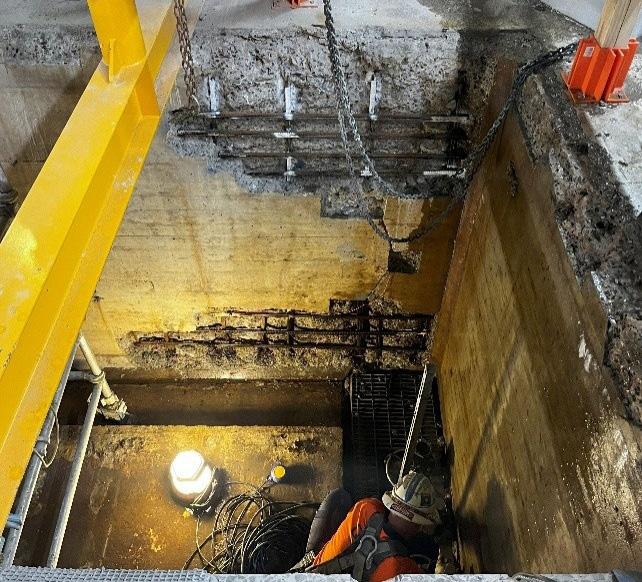

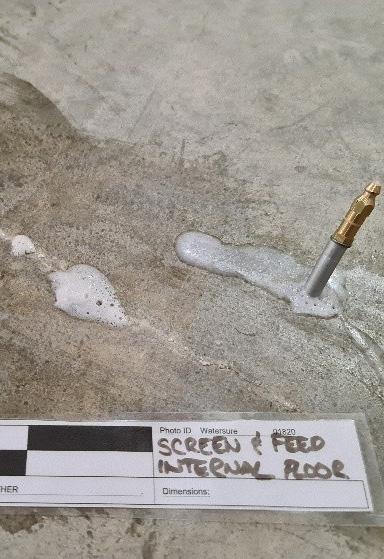

A critical sewage inlet chamber at a wastewater treatment facility had experienced severe concrete degradation and high-pressure leakage, leaving it close to decommissioning. The client required a solution that would avoid full replacement, restore structural integrity, and extend the asset’s service life.

Mattioli delivered a comprehensive, in-house engineered rehabilitation solution that combined three key techniques:

• Precision Crack Injection – sealed high-pressure leaks to restore watertight integrity.

• Concrete Refurbishment – reinstated the structural capacity of severely degraded sections.

• Geotextile-Reinforced Lining System – provided a robust, chemical-resistant barrier to protect the structure long-term.

This integrated approach formed a complete containment and protection system, purpose-designed for the inlet chamber’s hydraulic and chemical demands.

The solution extended the chamber’s service life by 25+ years, avoided the need for demolition and costly asset replacement, and returned the structure to full service. This innovative, multi-layer approach set a new benchmark for sustainable rehabilitation in wastewater infrastructure.

Our partnerships and industry associations strengthen the foundation of everything we deliver.

By aligning with respected organisations worldwide, we access specialised expertise, proven technologies, and global best practice. These relationships enhance our capabilities, reinforce our commitment to quality and compliance, and position us to set new benchmarks of innovation and performance across the industry.

By aligning with respected organisations worldwide, we access specialised expertise, proven technologies, and global best practice.

Mattioli’s capability is built on more than certifications — it is reinforced by decades of delivering complex projects in live, compliance-critical environments. Our accredited teams and ISO-aligned systems combine technical expertise with sector-specific experience, ensuring every intervention is delivered safely, to specification, and with long-term performance in mind.

Our key credentials and experience include:

• AMPP (NACE) Level 1 & 2 Certified Inspectors

• Applying international best practice in corrosion management and coating verification, backed by decades of project experience.

• ACRA-Accredited Concrete Repair & Protection Personnel

• Delivering remediation programs proven to restore integrity and extend the life of critical concrete assets.

• Specialised Training for High-Risk Environments

• Including confined space entry, chemical handling, and live-site operations — enabling safe, efficient work in process-sensitive facilities.

• ISO-Aligned Competency Frameworks

• Supported by ISO 9001, ISO 45001, and ISO 14001 management systems that ensure quality, safety, and environmental control on every project.

Together, these credentials and systems ensure every project is delivered with precision, compliance, and measurable performance outcomes.

Backed by ISOaligned systems and accredited expertise, every intervention is delivered to specification and built for enduring performance.

Delivering certainty through rigorous standards

At Mattioli, quality is embedded in every stage of our work. From planning and specification through to inspection, testing, and final verification, we maintain processes that ensure all outcomes meet the highest standards of performance and compliance.

Our quality systems include:

• ISO 9001-Certified Quality Management System

• Comprehensive Inspection & Testing Regimes Including surface preparation checks, DFT verification, adhesion and holiday detection testing.

• Traceable Project Documentation Ensuring accountability and transparency at every stage.

• Continuous Improvement Practices Driven by lessons learned and client feedback.

These controls provide confidence that every project is delivered as specified — safe, compliant, and built for long-term durability.

In water and wastewater environments, quality assurance is critical. For potable-water assets, every coating and lining system is tested to AS/ NZS 4020, with inspection and verification ensuring compliance at every stage.

Zero Harm — Every Project, Every Day

Safety is central to Mattioli’s culture. We operate under strict Health, Safety, and Environmental (HSE) protocols to protect our people, our clients, and the communities we work in. These measures allow us to deliver works safely in live, high-risk, and process-sensitive environments.

Our HSE framework includes:

• ISO 45001-Certified OH&S Management System

• Zero Harm Commitment

Underpinned by rigorous risk management and compliance with WHS legislation.

• Comprehensive Training Programs Including confined space, working at heights, and hazardous environments.

• Safe Systems of Work

Supported by permits, monitoring, and emergency response planning.

• Environmental Safeguards Waste management, spill prevention, and pollution controls embedded in every project.

This framework underpins our commitment to zero harm, ensuring every project is executed responsibly and in full alignment with client and regulatory expectations.

Our HSE systems enable safe delivery in confined spaces, live plants, and chemically aggressive environments — protecting people, assets, and the environment.

Preservation over replacement — driving innovation in sustainable outcomes

Sustainability sits at the heart of Mattioli’s approach to asset preservation. By focusing on extending the life of existing structures, we reduce waste, minimise embodied carbon, and provide long-term value for asset owners.

Our sustainable approach includes:

• Remediation-First Approach Reducing the need for demolition and rebuilds.

• Durable, Low-Intervention Systems Minimising future interventions and extending service life.

• Alignment with Client Sustainability Goals Supporting environmental frameworks and compliance obligations.

• Responsible Procurement & Local Engagement Driving energy-conscious practices and regional benefits.

• Commitment to Innovation Applying new technologies and sustainable methods to set the benchmark in asset preservation.

These strategies ensure every project supports both immediate performance needs and long-term environmental responsibility.

Our remediation-first approach extends asset life, reduces embodied carbon, and avoids unnecessary replacement — with durable systems and responsible practices delivering both environmental and financial sustainability.

Contributing towards global climate targets

Delivering biodiversity net gain and positiive environmental impact

Moving to the circular economy and effective waste managment

Driving fairness, inclusion and respect.

Promoting health and wellbeing

Maximising local benefits and community engagement

Developing careers from within and investing in local recruitment

Incorporating social enterprises and small businesses into our supply

To extend the life and resilience of essential infrastructure, keeping it safe, reliable, and sustainable for generations to come.

Resilient assets. Sustainable outcomes. Lasting value.

Please