Strada Isolanda, 26 - 43024 Provazzano (Parma) Italy Tel.: +39 0521 343011 Fax: +39 0521 342182 sales@vetromeccanica.it - www.vetromeccanica.it

Founded in 1992 in Parma, the heart of Italy’s packaging industry, Vetromeccanica is a key player with thousands of turn-key installations in over 70 countries for the food & beverage, pet food, chemical, and cosmetics industries. In-house production and management Vetromeccanica offers solutions for the Food & Beverage industry thanks to its rich product portfolio, including accumulation systems, conveyor belts, dividers, dryers, and other accessory machines, up to palletizers. Vetromeccanica’s engineering department leverages its experience across various sectors to devise the best solutions for each client. They meticulously consider the line’s production needs, such as accumulation type, alignment method, production speed, the criticality of the containers being handled, and space optimization. This allows them to select the most suitable systems for the production environment, ultimately aiming to enhance the overall line efficiency.

One of Vetromeccanica’s core tenets is 100% in-house production.

Managing all phases of the production cycle internally guarantees high product quality, fast delivery times, and competitive prices.

Over the past few decades, our company has invested significantly in strengthening all production departments. This includes the cutting, bending, and metalworking department, as well as the electrical and electronic department. The latter specializes in hardware/software design, the construction of electrical panels, and the hardware/software testing of the complete system. All our processes and products comply with international standards and the specific regulations required in various countries, such as UL, CE, and CSA.

In this way, Vetromeccanica is able to guarantee all phases of the production process.

Today, with three operational sites, Vetromeccanica stands in the market as a reliable and solid partner, capable of offering complete solutions for producers in the food & beverage sector thanks to its fundamental pillars: engineering, manufacturing, assembly, installation & start up, service.

Vetromeccanica at Gulfood Manufacturing

At Gulfood Manufacturing, Vetromeccanica will be delighted to welcome all clients to its Stand S2-F77 – Saeed Hall, in the Italian Pavilion. It will be there to discuss the feasibility of new projects or the revamping of existing lines. This year, among its most innovative solutions, Vetromeccanica features dynamic parallel-row accumulation tables equipped with a patent pending trolley. This allows for format changeovers without the need to replace mechanical parts, but simply by using special graduated handles. This is a fundamental advantage for managing different formats (round, square, oval) on the same line.

Another innovation from Vetromeccanica is an ultra-speed divider. This compact machine can continuously split containers from a single lane into multiple output channels, reaching speeds up to 80,000 bph. It’s designed to handle even the most varied, unstable, and difficult-to-manipulate shaped containers, such as square, rectangular, and oval. These – and many other excellent technological solutions – await you at Saeed Hall, Stand S2-F77 at Gulfood Manufacturing, from November 4th to 6th, 2025

Via Roma, 123 - 46033 Castel d’Ario (Mantova) Italy

Tel. +39 0376 57 001 - Fax +39 0376 66 05 56 export@unical-ag.com - www.unical.eu

Unical power

Industrial boilers Made in Italy.

A range aimed at large industrial sector, a complete range of boilers manufactured in Italy by highly skilled personnel, with unique technological details, some covered by Unical patent, like the special smoke pipes which significantly increase the boiler efficiency and control panels developed to ensure operator-free control, in total safety, up to 72 hours and with possible remote control.

The design of each boiler allows Unical to build special appliances, fulfilling any customer need.

Unical, an Italian company born in the 1972 to design and produce professional and industrial thermal groups for heating, has, subsequently, expanded its operating field, including air conditioning systems, thermal solar systems, integrated and hybrid systems, heat pumps, radiant panels, etc., coming to have one of the most complete catalogues in the entire sector.

Made in Italy is the focus of Unical.

5 the locations distributed on the national territory, between production and logistics, strategically connected and highly advanced for automation and robotization of the construction phases.

In the Borgocarbonara’s plant are manufactured industrial and steel boilers for jet burners (up to 15,000 kW), known for high-efficiency special boilers by virtue of special patented heat exchange pipes.

The range includes hot/superheated water boilers, up to 22,000 kW and boilers up to 25,000 kg/h of steam

In the Caorso’s plant are built wall and floor-standing boilers, both traditional and condensing (up to 1,500 kW).

The Unical Steamer department is the innovation of Unical power:

• Reverse flame steam boilers at low or high pressure,

genuine three pass steam boiler at high pressure, instantaneous electric steam boilers and all the necessary equipment for a medium or large system (industrial sector: food, canning for storage purposes, petrochemical, chemical, etc.).

• Hot water boilers and superheated water boilers, with high and very high power, for production cycles and/or large systems (hospitals. pasta factory, district heating).

• Turnkey thermal power stations.

In addition to the EC certification, Unical boilers have obtained numerous certifications that allow them to be exported all over the world.

Unical, in addition to the 5 Italian offices, has 4 foreign branches (France, Germany, Poland and China) and boasts prestigious presences in Australia - New Zealand - Russia - U.K. - the U.S.A. and South America, well as the Middle East. www.unical.eu

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (Bergamo) Italy

Tel. +39 0345 401 11 - Fax +39 0345 402 09

info@smigroup.it - www.smigroup.it

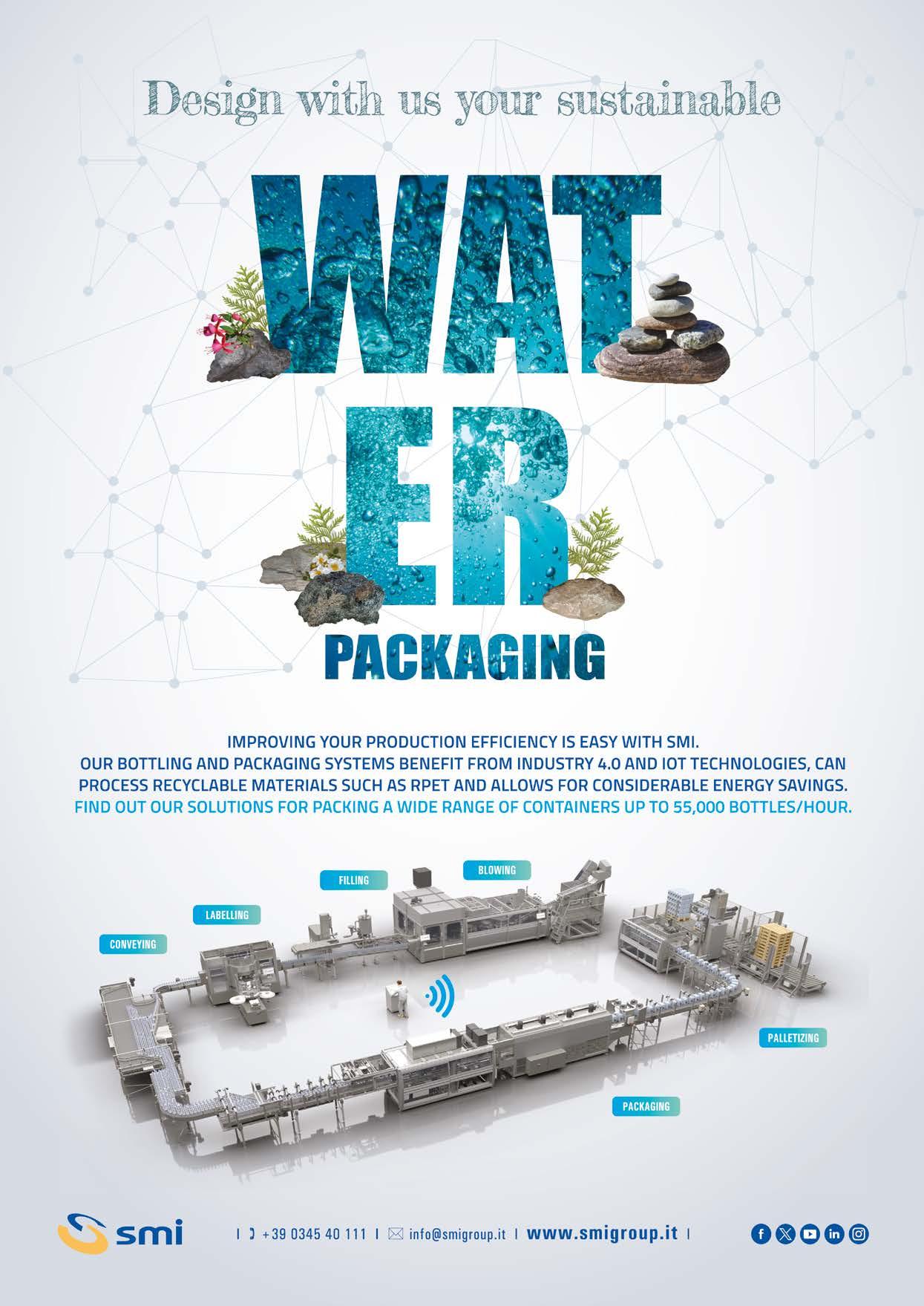

Label-free bottles: the new eco-design solution

In primary packaging solutions, sustainability is expressed through creativity, with the design of visually appealing containers that capture consumers’ attention, and through functionality, with the development of lightweight, rPET, and label-free bottles.

In Portugal, Carvalhelhos, a company that has always prioritized sustainability and environmental responsibility, produces new PET and rPET containers with and without plastic labels, thanks to the EBS 8 KL ERGON stretchblow moulder by SMI.

Carvalhelhos blow moulder not only produces traditional PET and rPET bottles that require label application, but it is also equipped with specialized moulds designed by SMIMEC for the stretch-blow moulding of 0.33 L, 0.5 L, and 1.5 L flat-bottom rPET bottles without paper or plastic labels. This eco-friendly solution eliminates the need for glue and additional paper or plastic materials, simplifying the recycling process and ensuring higher purity in recycled PET.

The area dedicated to the label has been removed, eliminating the ribs typically found in traditional bottles. Therefore, an innovative combination of embossed and debossed engravings on the bottle body provides additional space for the brand logo and essential product information, which would traditionally appear on a label. This approach also allows for the inclusion of information in braille.

Labels-free bottles. Advantages.

For the environment and the consumer:

• Eco-friendly solution, as the PET bottle is 100% recyclable.

• Better compliance with environmental regulations regarding recycling.

• Easier recycling process, since there is no label to remove. Even when made from recyclable materials, labels on traditional bottles must be separated from the container during recycling.

• No need for glue in label application.

• Reduced packaging waste, resulting in less material to recycle.

For the bottler:

• Reduced costs for raw material purchases (labels and glue).

• Lower storage costs for raw materials.

• Simplified and optimized production process, as a labelling machine is no longer required.

• Easier and more efficient PET recycling, since there is no need to separate the label from the container. SMI, through its subsidiary SMIMEC, takes care of the entire production phase of the moulds installed on stretch-blow moulding machines. To meet the needs of customers who wish to produce both traditional bottles intended for label application and bottles without labels, SMIMEC manufactures special couplings to be inserted in the moulds mounted on SMI stretch-blow moulders. Size changeover operations to switch from one type of bottle to another are extremely simple and fast as it is sufficient to replace the plug section in the mould.

The rotary stretch-blow moulding system from the EBS KL ERGON series is a state-of-the-art, intelligent and interconnected system, equipped with the most modern automation and IoT technologies, with strong ecocompatibility characteristics and different benefits.

Management and control benefits

The system supplied by SMI uses an advanced automation system called MotorNet System®, which ensures the constant maintenance of the optimal processing parameters during the entire production cycle, allows the direct modification of the machine settings from the operator panel, simplifies format change operations and offers the possibility of temporarily disabling one or more moulds if necessary.

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (Bergamo) Italy

Tel. +39 0345 401 11 - Fax +39 0345 402 09 info@smigroup.it - www.smigroup.it

Energy-saving benefits

The stretch-blow moulder is equipped with a system of energy-efficient thermo-reflective panels in composite ceramic material, positioned both in front and behind the lamps, which allow uniform heat distribution. The stretchblow moulding carousel is equipped with motorised stretch rods controlled by electronic drives, which guarantee precision in operations and energy savings (no compressed air is needed and the power consumption is lower than solutions with linear motors).

Production efficiency benefits

The EBS KL ERGON stretch-blow moulder is equipped with high-performance valves and low dead volumes (-50%) which ensure reduced pre-blowing and blow moulding times and better quality of the bottles produced. The blow moulding machine also adopts a series of measures capable of reducing the level of wear of the components to the benefit of production efficiency, such as the gripper handling system based on springless preform grippers/ bottles equipped with desmodromic cams and plastic bearings.

Benefits for operator flexibility

Thanks to the preform feeding system equipped with adjustments by means of numerical position counters, format changeover operations are simple and fast. Even the format change operations, to switch from the production of traditional bottles to bottles without a label, are extremely simple and fast as it is sufficient to replace the graft section in the mould.

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (Bergamo) Italy Tel. +39 0345 401 11 - Fax +39 0345 402 09 info@smigroup.it

QVision-Tech Srl was founded in 2015, with the desire to take advantage of more than 25 years of experience in the field of artificial vision by creating a company highly specialized and focused on the development of technologies for the automation of the quality control in industrial production.

With a specialized staff operating for years in the field, QVision offers:

• Experience gained over 25 years in the field

• Reliability, ensuring maximum availability and maximum personal commitment at all stages of cooperation, from the initial feasibility study to the realization of the product, its installation, training to the personnel working on the machines, the after-sales, and the possible update of the product over the years, also according to the changing needs of the customer.

• Attention to the specific needs of the customer, in the belief of the fundamental importance of a personal direct relationship, intended to transform the simple suppliercustomer duality in a constructive and proactive cooperation, aimed at achieving a common goal.

• Willingness to growth and innovation in the search for ever higher quality standards, putting in first place the study and the development of increasingly advanced projects, using the most modern technologies in the field of acquisition and image processing. The main field of activity of the company is the design and production of Artificial Vision Systems for the quality control in the packaging industry, mainly for the food and beverage sector. Basic products are the systems dedicated to the control of closures (plastic and aluminium) and the systems for the inspection of vials and bottles. These systems, using digital cameras and image processing systems, allow the automatic quality control at the end of the production line, with the ejection of defective parts, on the basis of the control tolerances set by the line supervisor / operator.

Via San Morese, 9 - 50019 Sesto Fiorentino (Firenze) Italy Tel. +39 055 4216422 info@qvisiontech.com - www.qvisiontech.com

In addition to the standard products, QVision also offers the possibility to supply “custom” systems, designed according to customers’ specifications, to allow performing special requests of inspection. Thanks to the know-how acquired in years of activity in the sector of industrial applications of machine vision, the use of the latest technology and a proprietary software completely developed in house, QVision is able to analyse specific issues and offer “turnkey” solutions, innovative and reliable.

Via I. Giordani, 10 - Z.I. Postumia - 46044 Goito (Mantova) Italy

Tel. +39 0376 689 707 - Fax +39 0376 68 96 44 info@newteclabelling.it - www.newteclabelling.it

Newtec Labelling Srl was founded in 1982 in Goito (Mantua), designs and produces linear and rotary labelling machines suitable for all user requests both in terms of production speed and type of packaging. Each model, thanks to the customization of the design, has specific characteristics designed to give maximum performance in every type of production. The result of a very long experience and constant updating of technologies, each model is designed to guarantee high production rates, absolute packaging precision and low operating costs. The materials used and the construction technologies allow these machines to support very heavy workloads. Thanks to their reliability and ease of use they are also successfully used in small and medium-sized businesses.

Panther is a high-level multi-label machine, ready to work with all application technologies: self-adhesive, hot melt, roll fed and wet-glue. Equipped with a complete control system for quality control, rejecting defective products and remote management.

Giotto is a latest generation Roll Fed labeller, compact and very simple to install, easy to use and maintain in perfect working order.

The modular structure of the machines, based on direct drive servo motors, is designed to help dramatically reduce all running costs. In addition to Panther and Giotto, the company also offers other models of rotary or linear labelling

machines, for the application of paper labels with cold glue, for the application of wrap-around labels in paper or plastic materials with hot glue, and for self-adhesive labels.

The company is present all over the world with its own agents and participates in the most important exhibitions in the sector.

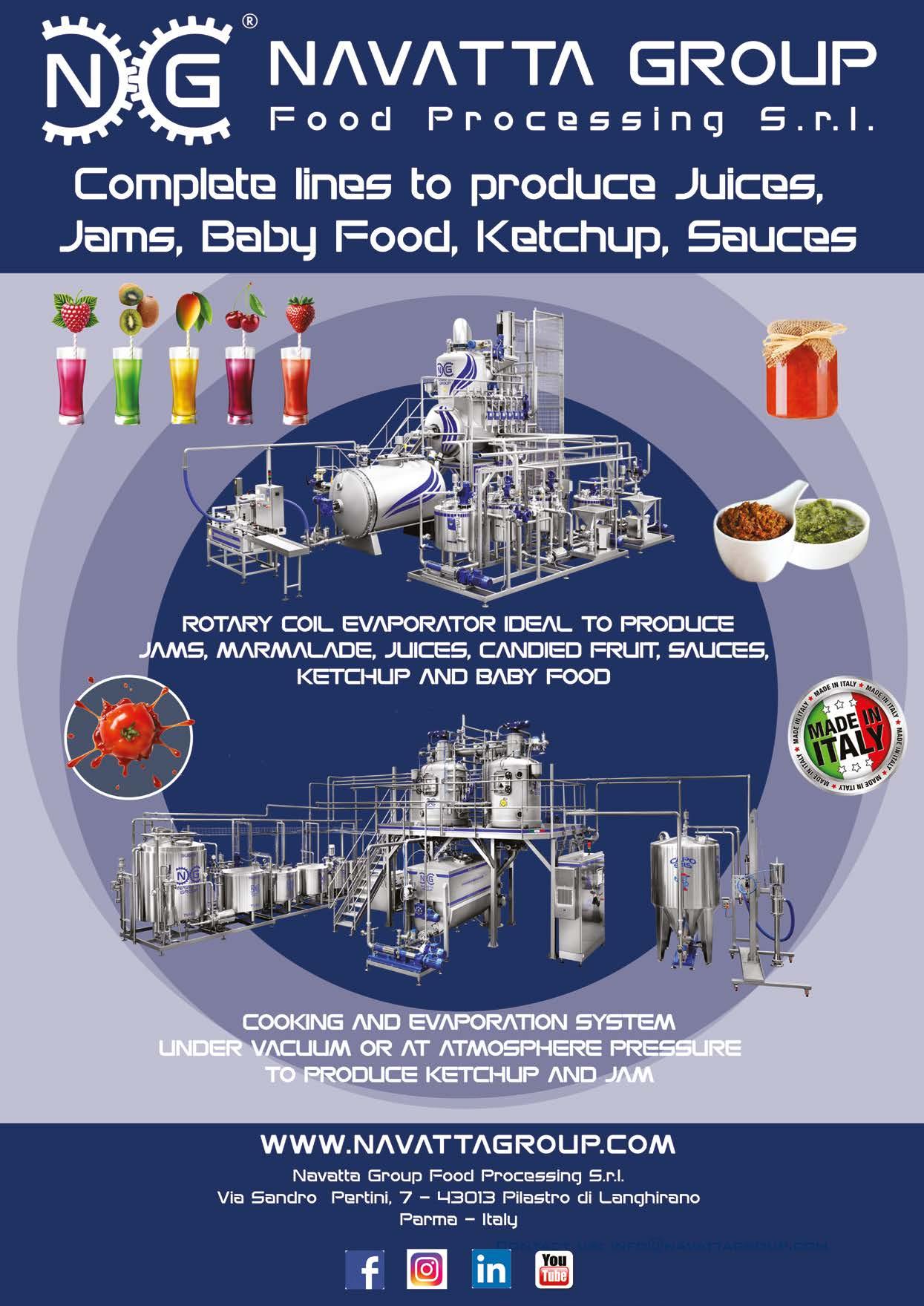

The history of Navatta Group begins in 1983, when Giuseppe Navatta founded the company in Parma. From a small workshop, Navatta Group embarked on a growth path, also thanks to the acquisition over time of historic high-quality brands in the sectors of handling and receiving raw materials, extracting and concentrating tomato juice and fruit puree, as well as in the production of sauces and condiments.

Today, the company is a solid and complete reality specialized in the production of machinery to process fruits and vegetables, involving around 100 collaborators and with a turnover that is constantly increasing. Navatta offers a wide range of production lines that includes:

• Complete lines for the production of tomato puree, concentrate, and diced tomatoes, from the reception of raw materials to aseptic packaging, glass jars, or pouches.

• Complete lines for fruit processing, from raw materials to the production of natural or concentrated puree.

• Production lines for formulated products such as mayonnaise, sauces, condiments, and gravies.

• Aseptic packaging lines.

The machines and systems proposed by Navatta Group guarantee greater energy efficiency, reduced operating

costs, and a lower environmental impact: for example, mechanical vapor compression evaporators allow a significant reduction in energy consumption thanks to heat reuse, with lower operating costs compared to traditional systems and a reduced environmental impact. In addition to the traditional products and services that have contributed to its success, Navatta Group continues to grow, demonstrating a strong inclination towards developing new ideas and a marked commitment to sustainability. Technology, innovation, and sustainability are the pillars of the company, which has always invested in updating its plants to maintain production excellence, with particular attention to environmental impacts. The headquarters in Pilastro di Langhirano, in the heart of the Food Valley, is an example: Thanks to solar panels, Navatta Group produces all the energy it needs and reduces its CO2 emissions.

“Passion drives us towards increasingly ambitious goals in terms of technologies, products, and services” is a key principle that inspires the company’s vision. During 2024, we concluded several important contracts and foresee a consolidation of business growth for the upcoming 2025 financial year.

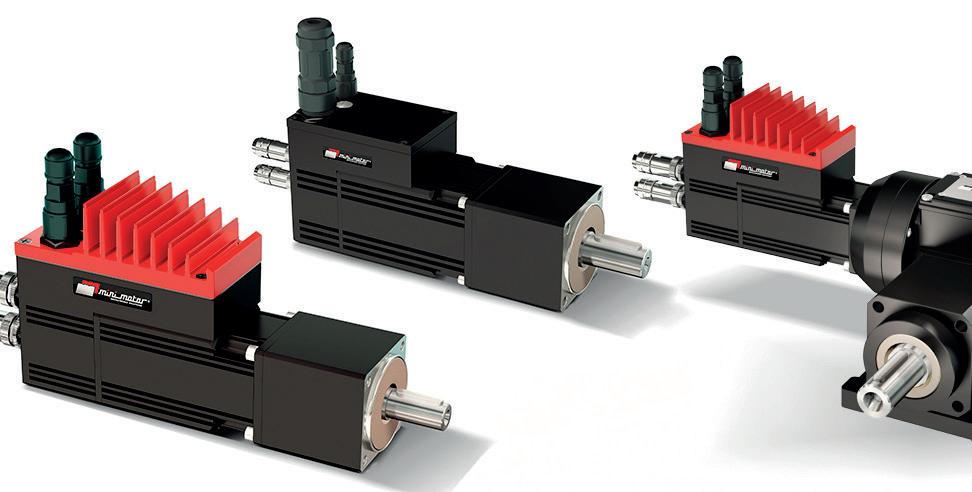

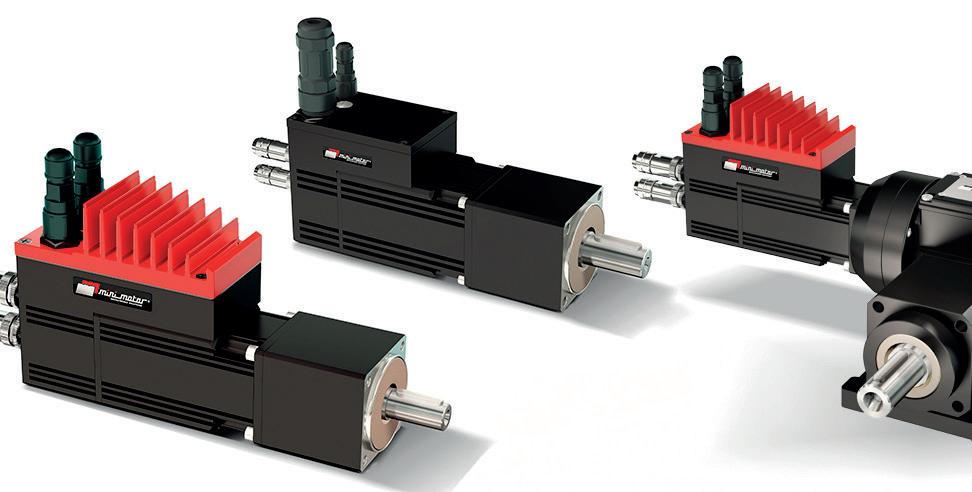

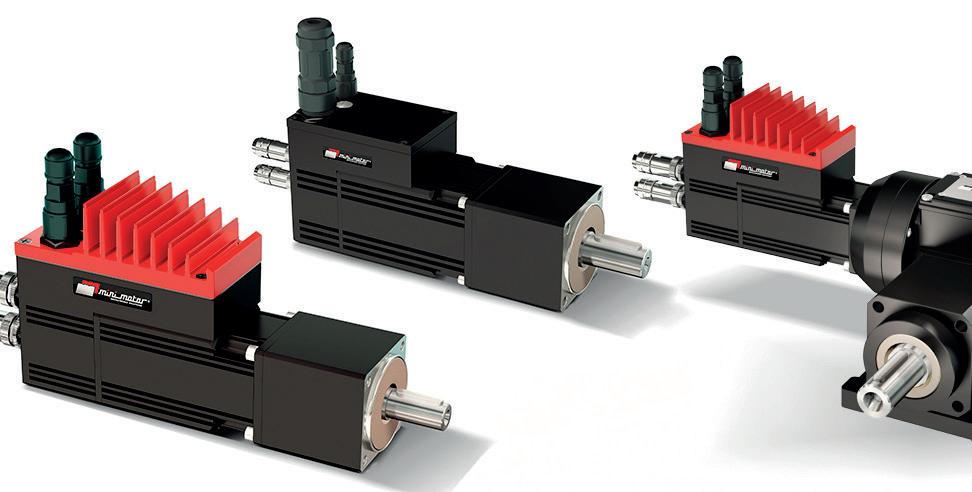

A lot has happened since 1965, when Gianfranco Franceschini embarked on his entrepreneurial adventure. Today, Mini Motor is a company with almost 100 employees and a global network that allows the brand to be present in 60 countries.

Innovation is the keyword that has guided the company over the last fifteen years and has allowed it to consolidate its role as a partner with some of the major players in strategic sectors for Italy. From packaging to ceramics, with a growing share in the food sector, Mini Motor has been able to take on the challenges of each sector and translate them into features for its products. Compactness and mechanical performance

With the same footprint, Mini Motor solutions guarantee higher torques and longer life cycles. The selection of materials, process-oriented design, and vertical

integration of the supply chain ensure a stable quality standard over time that is recognized internationally. All Mini Motor lines —Brushless/DBS, Gear, Clean, FC/ FCL— allow configurations with drives or integrated drives and digital communication. 97% of components are produced in-house or by selected suppliers with established relationships, allowing direct control over the quality and traceability of each unit manufactured. This focus on quality translates into thorough control over the reliability and performance of each product, which is individually tested and inspected.

Integration and simplification of system architecture

Mini Motor solutions are designed to integrate with the main fieldbus protocols (Profinet, EtherCAT, Ethernet/ IP, Powerlink, Modbus, CanOpen). The integrated drive eliminates the space required for electrical panels, reducing wiring and installation time.

The use of drivers allows for standardized management of

the entire power transmission range and is an advantage in hybrid topologies or mixed architectures.

In addition, the implementation of advanced logic configurations, such as Safe Torque Off (STO), digital outputs, and software parameter setting, allows for a high degree of customization based on the required behavior.

Wireless communication: A new design option

Mini Motor S.p.A. has introduced solutions that support wireless communication between the motor and the control system. The goal is to offer a concrete alternative to traditional wiring in applications where space constraints, mobility, or harsh environments make radio transmission a good choice.

Wireless technology simplifies installation on moving axes, reduces maintenance downtime, and improves the accessibility of operational data. It is an enabling technology for modular and flexible architectures geared towards interconnection and remote management.

Regione San Giovanni, 19 - 14053 Canelli (Asti) Italy

Tel. +39 0141 824206

sales@mondo-scaglione.com - www.mondo-scaglione.com

Innovative technological solutions that involve many packaging and packing aspects

Mondo & Scaglione was founded in Canelli (the capital of Asti Spumante) in 1969, since then the company has been designing and building packaging machines. At the beginning, Mondo & Scaglione worked especially for local wineries producing sparkling wines around its area (Gancia, Bosca, Riccadonna, Cinzano, Martini & Rossi…); these companies needed a local manufacturing company able to build case packers, case erectors, and palletizers, the so-called “end of line” machines as an alternative to German machine manufacturers that were dominating the market at the time.

After a few years from its establishment, Mondo & Scaglione spread its presence not only all over Italy but also to the foreign markets. Today, Mondo & Scaglione has customers all over the world and exports more than 85% of its manufactured machines. Thanks to this success, it has widened its market presence addressing not only its core business (wine and spirits) but also the beverage, food and chemical markets with machines that feature innovative technological solutions.

Mondo & Scaglione designs and manufactures all its machines entirely in-house, starting from the mechanical and electronic engineering, right through parts and components manufacturing for final assembly.

Besides the Design Office and the Electronic Office, Mondo & Scaglione has also a Welding Department to build in-house machine frames, and a Tooling Machines Department for the manufacturing of all the components that will be assembled on the machines.

Moreover, Mondo & Scaglione has also an important Electrical Department to create electrical cabinets and to completely wire in-house the machines, as well an assembly department that enables assembling the mechanical parts of the machines before testing and start-up before shipments.

In general, installation, start-up and commissioning of Mondo & Scaglione machines are operated by its specialized service engineers.

The company has also an after-sales and spare parts department suitable to help the customers worldwide supplying the necessary parts and components it keeps in its inventory or supporting them by phone, e-mail or via remote access to the machines PLC.

Mondo & Scaglione is a dynamic company that does not only build standard machines for its customers, but it also tries to understand customer’s requirements as to propose a tailored technological solution upon the product to handle, space available, and required production speed. Flexibility is for sure one of the major features that Mondo & Scaglione is recognized on the market for, and for this

reason it often manufactures “special” machines upon its customers’ needs.

That requires a strong “team effort” with engineers constantly exchanging ideas, as well as the considerable experience that Mondo & Scaglione can count on as a company that has been on the market for more than 50 years, a peculiarity that is hardly to be found in other companies of the sector.

In a few words, thanks to its experience and know-how gained in more than 50 years, the flexibility and strong motivation to always find new technical challenges, Mondo & Scaglione sees its future bright always looking for new market opportunities.

For over 75 years M.G.M. Motori Elettrici S.p.A. has been a global leader in the field of brake motors, with a solid presence in Europe, America, Asia and the Middle East. The heart of the company is located in Serravalle Pistoiese (PT), where its main production facility is based. In Italy the company is also present in Assago where it has a warehouse with commercial offices. Its global influence extends through subsidiaries in Montreal, Detroit, Chennai and Izmir, as well as a network of distributors for sales and assistance covering over 75 countries worldwide.

M.G.M. is synonymous with quality, innovation and reliability. The range of brake motors the company offers can be used in a wide variety of applications. The motor shaft heights range from 71 mm to 355 mm and the power outputs are between 0.09 kW and 250 kW. The brake motors can be supplied with a brake unit powered by either alternating current or direct current. Additionally the company is able to meet customer needs by providing customized products.

The company has always been at the forefront of technological innovation, with much of what we now know as AC brake motors having originated from M.G.M.’s research and laboratories. Since 2008 the energy efficiency

of its products has been continually evolving: the average amount of energy required for the operation of M.G.M. products has consistently decreased. All single-speed motors comply with the new European energy efficiency regulations and improvements in the electromagnets of the brakes - both AC BA series and DC BM series - have led to reduced energy consumption and a significant increase in performance.

The future of M.G.M. Motori Elettrici is focused on sustainability and environmental respect. With the goal of reducing environmental impact the company has committed to several initiatives. The geothermal system for

air conditioning, the reduction of plastic consumption and the ongoing search for solutions to reduce potable water consumption and the energy required to produce brake motors, along with a consequent reduction in greenhouse gas emissions, are just some of the actions undertaken.

In particular M.G.M.’s photovoltaic system, which originally covered 100% of the energy needs of the facility and offices, has recently been expanded to meet the growing demand for energy, partly due to the transition of the company’s vehicle fleet from combustion engines to electric motors. This commitment represents a concrete response to the energy and environmental challenges of our time.

M.G.M. Motori Elettrici not only makes eco-friendly choices within its own plants but also promotes sustainable practices with its suppliers and partners worldwide. It is only through collective effort that a greener and more sustainable future can be achieved. The company strongly believes that awareness and global collaboration are essential to making tangible change.

M.G.M. Motori Elettrici is not just a leader in the production of brake motors: it is a company looking to the future with a concrete commitment to technological innovation, energy efficiency and sustainability, ensuring cutting-edge solutions for a more sustainable world.

Via Giancarlo Puecher, 24 - 20842 Besana in Brianza (Monza Brianza) - Italy

Tel. +39 039 23 01 096 - Fax +39 039 23 01 017

customercare@magicmp.it - www.magicmp.it

Industrial Machine, model MET T80 double station for containers up to 280 litres

Industrial machines, the future is now!

Magic has presented during the Open House in November the revolutionary fully electric accumulating machine with patented head and clamping.

Even the field of industrial machines have been revolutionized, the innovative ideas of Magic will give its clients enormous benefits in terms of profit and process.

Principal benefits:

• Reduction of consumption equal to -53%,

• Maximum precision of the movements. Consequent efficiency equal to 99% with a perfect repeatability of the working cycles, potential reduction of the working cycle and potential reduction of the weight of the articles to be produced,

• Reduction of the maintenance costs equal to -52%,

• Machine completely oil free,

• Very silent machine since it is free of hydraulic pumps.

Magic MP S.p.A. is an Italian company founded in 1959, specialized in the conception and construction of extrusion blow moulding machines (EBM) and injection, stretch e blow moulding machines (ISBM) of plastic materials.

Thanks to its constant orientation to innovation Magic has become an excellence of the Made in Italy and a worldwide reference point for all the operators of this field.

MAGIC has been the first company in the world to conceive fully electric machines, revolutionizing the field of plastic and tracing a new technological greener and more sustainable road.

The clients recognize in the MAGIC machines patented technological benefits, which turn into real process improvements and consequent profit increases. Investments and efforts to give to their actual and future clients a unique and solid contact point in the production of bottles: machines, moulds and packaging solutions. Everything is internally developped and produced and commercialized with the best value for money on the market.

These investments confirm the continuity of principles, values and skills that has been distinguishing Magic Group for more than 60 years.

With his words reported below the President of the Magic Group, Mr. Ferruccio Giacobbe, devotes the moon’s landing of his company on the planet of industrial machines and he does it always in an innovative and futuristic way.

“Innovation is and always will be the engine that fuel growth and development of Magic. Up to date no one in the world has ever built a completely electrified accumulator head of big size, Magic, which always looks ahead and, driven by this philosophy, has understood that even in the field of industrial machines the complete electrification will become a determining and indispensable factor. We did it in the past with the continuous extrusion technology for machine up to 60 Tons for the production, per example, in 6+6 cavities for 5 litres containers; we do it today also with the industrial machines for containers up to 280 litres. Soon we will do in fact a second Open Day to show the world the new transfer machine with all electric technology of 80-100 Tons for containers up to 280 litres. This machine will have an incredible saving for our clients in terms of energy consumption equal to almost 180.000 Euro per year. We are led to think that electrification is all about the necessity of the energetic economy. But this is one of the aspects, even though very important. The electric motor means also more precision and repeatability in the execution of the movements, that impacts on the efficiency of the machine, in lighter articles and shortest working cycles and with less wastes. It will be easy for our clients to understand how advantageous and innovative is to produce with a machine which consume 50-60% less, that thanks to its stability allows shortest working cycles and allows to produce lighter articles and even more with reduced maintenance costs of 50%.”

We are sure that orientation to ’Green”, to be effectively implemented, must bring to our clients even advantages in terms of profit. In fact, in 25 years and 1800 electric machines sold as well as having “saved” almost 3 billions of Kg in CO2, our clients have saved more than 500 million euro in electric energy. To these many various millions must be added for the economy in maintenance costs.

We want our clients, with our patented technology, win the complex challenge of the market; we aspire to become their partner, grow with them and become their reference point in the field.”

Via Giancarlo Puecher, 24 - 20842 Besana in Brianza (Monza Brianza) - Italy Tel. +39 039 23 01 096 - Fax +39 039 23 01 017 customercare@magicmp.it - www.magicmp.it

Via dell’Artigianato, 5 - 46048 Roverbella (Mantova) Italy

Tel. +39 0376 75 10 11 - Fax +39 0376 75 10 12 kosme@kosme.at - www.kosme.it

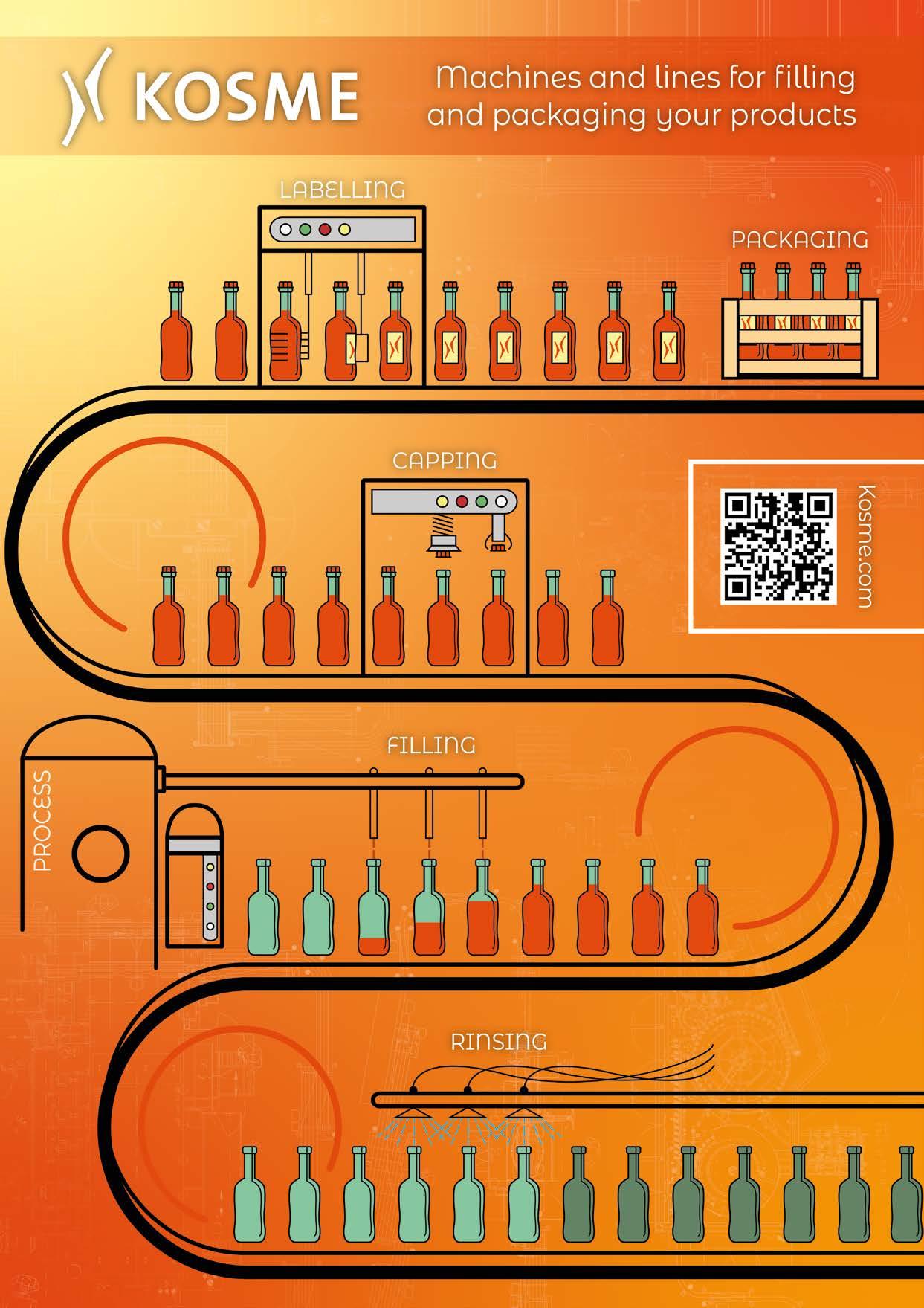

Engineering excellence in the Arab Region: Kosme solutions for water and oil production

From the bustling metropolises of the Gulf to the industrial zones of the Levant, the Arab region is a rapidly growing market for bottled water, soft drinks, juices, and edible oils. In this dynamic landscape, Kosme delivers integrated, sustainable, and tailor-made engineering solutions designed to meet local demands.

Smart design for a diverse market

Kosme develops high-efficiency, flexible production lines by integrating its proprietary technologies with those of the Krones Group and other partners. These systems are optimized to handle a wide range of packaging formats and product viscosities—whether PET water bottles in the UAE or oil jerrycans in Saudi Arabia.

Thanks to advanced automation and intelligent sensorequipped conveyors, Kosme lines ensure seamless transitions between machines. Each layout is customized to local conditions, taking into account available space, workforce, and hygiene regulations to guarantee optimal performance in any production environment.

Efficiency and sustainability at the core Kosme enhances operational efficiency through:

• Energy use rationalization to reduce consumption and optimize the reuse of water, steam, and electricity.

• Versatile machinery capable of processing liquids with varying viscosities and packaging formats.

• Simulation tools that predict line behavior and help prevent costly downtime.

These practices are especially valuable in regions with high energy costs or limited infrastructure, such as certain industrial areas in Oman and Bahrain.

Tailored solutions for water and liquid food Kosme addresses the growing demand for safe, sustainable, and high-quality products:

• Water: Kosme lines ensure hygienic filling for still, sparkling, and flavored water, preserving product quality and shelf life.

• Edible oils: From olive and sunflower to palm oil and blends, Kosme provides precise filling and capping systems suitable for bottles, flasks, and large-format containers. The company also supports reusable and bulk packaging, contributing to environmental impact reduction and sustainability goals.

Regional market focus

• Gulf Cooperation Council (GCC): High demand for automation, hygiene, and premium packaging. Kosme supports large-scale plants with advanced simulation systems and energy recovery solutions.

• Levant (Lebanon, Jordan, Palestine): Need for compact, modular solutions to fit limited spaces and complex infrastructures.

• Iraq and Yemen: Emerging markets requiring scalable and robust production systems. Kosme offers durable, easily adaptable lines.

Customer-centric innovation

Kosme embraces a collaborative, customized approach. By working closely with clients, it develops solutions that reflect local realities and long-term business goals. Real-time data collection, simulation systems, and continuous feedback allow production lines to evolve alongside customer needs.

Looking ahead

Kosme is proud to support the development of the beverage and liquid food sectors across the Arab region— from the industrial hubs of the UAE to new opportunities in Saudi Arabia, Kuwait, and Oman. With a steadfast commitment to innovation, sustainability, and bespoke solutions, Kosme empowers producers to meet today’s challenges and seize tomorrow’s opportunities.

At the same time, Kosme remains deeply rooted in traditional sectors such as wine, beer, spirits, and soft drinks, which continue to be a cornerstone of its identity. By combining innovative strategies with respect for tradition, Kosme stands as the ideal partner to support a wide range of industries with solutions that drive growth, efficiency, and lasting success.

Via dell’Artigianato, 5 - 46048 Roverbella (Mantova) Italy

Tel. +39 0376 75 10 11 - Fax +39 0376 75 10 12 kosme@kosme.at - www.kosme.it

Year Anniversary 1955-2025

For seventy years, IMCAR has been working in the design and production of machines for the processing of sheet metal and profiles, one of the long est-lasting on the market.

“With solutions for different fields of application, IMCAR manufactures machines for the production of tanks and plate bending machines to respond efficiently to the most complex needs, offering solutions with great simplicity of use and an Italian quality.”

IMCAR stands out as a benchmark in the design and distribution of sheet and profile processing machines, thanks to a production that can be considered among the largest on the market, and an exceptional ability to customize, distinctive of a clear made in Italy imprint. With one of the most solid know-how, IMCAR manufactures 2/3/4 roll plate bending machines with or without numerical control, variable geometry machines, automatic pallet and multi-pallet systems, single and double pre-bending profile bending machines, vertical systems and factory plants for tank production, welding systems and flanging machines. Customization and development are the core of every negotiation, sale and after-sale of this type of product as there is no standard, but each machine is something “tailor-made” for the customer, combining its experience with their requests and knowledge of the final product. After several years of experience in horizontal and vertical machines fed by sheet and coil for production of tanks of small and medium sizes, IMCAR has designed and produced an innovative technology to manufacture medium and large size tanks in vertical suitable for a wide range of industrial applications: petroleum,

Via del Lazzaretto 66 - 20873 Concorezzo (Monza Brianza) Italy

pharmaceutical, wine, water, beer, fruit juices, chemical products, liquid gases, etc

This technology, constituted by independent stations, is a fully integrated turnkey solution devoted to achieving high-level quality of manufacture, offering customers the best methods related to efficacy and efficiency both for workshop production and field application. The first station allows shell forming thanks to the bending, cutting, welding and welding cleaning processes; the second station allows circumferential welding between roof and shell and between shells through the alignment, welding, compression and welding cleaning processes. Several accessory machines can be added to complete the production of full tanks: flanging machine, manipulator for bottom cleaning, forming leg machine, semi-automatic and automatic forming and welding half pipe cooling system, cone forming and welding machine and door tank cutting manipulator.

All these latest items reflect IMCAR’s purpose to propose solutions that it studies, designs and manufactures for its customers’ satisfaction, a philosophy which let IMCAR achieve its 70-year anniversary.

Galigani Filtri is a leader in the design and construction of filter presses and relevant filtration systems.

Since 1958, the company has boasted over 3,000 installations in 5 continents, created with skill and professionalism, in order to offer a high-quality product and a support service for users, installers, and designers.

The company is based in Italy, located in a modern facility in the heart of Tuscany, where it makes use of the most modern systems of research, study, and design so as to best solve the problems of each individual application, as well as provide adequate pre- and post-sales assistance through its qualified technicians.

Furthermore, the company is also equipped with a laboratory for filtration testing on samples supplied by clients to determine all the necessary parameters required for sizing the filter press that is most suitable for their needs. Production includes filter presses and pumping units that feed the filter presses.

The wide range of filter presses varies from manual discharge machines to fully automatic machines run by modern PLCs.

Galigani Filtri manufactures filter presses for all types of applications: food, chemical, pharmaceutical, explosive atmospheres (ATEX), purifying waste water, acid filtration, aggregates, mining, galvanic industries, recycling industries, and so on. All machines are equipped with the most advanced safety devices.

The press filters and filtration systems that are manufactured by Galigani Filtri carry out “mechanical” filtrations, and therefore the liquid does not undergo chemical changes.

Filtration can occur on the synthetic filter cloth, which retains solid particles up to 1 micron, or on cardboard for

particles that measure less than or equal to 1 micron. When it comes to the most technologically advanced systems that Galigani Filtri can provide for filtration and clarification before bottling, the Diatom and the Clearness systems are in the forefront.

The Diatom system is comprised of a filter cloth for the filter press and is equipped with all the necessary parts (tanks, pumps, valves ...) that are required for filtration processes using various aids (fossil shell flour or cellulose flour, perlite...).

The Clearness system is a filter press with an Aisi304 or Aisi316 structure, which uses cardboard filters and a plate pack that is entirely sealed and protected from contact with the external environment.

Via del Lavoro, 14 - 24060 Telgate (Bergamo) Italy

Tel.: + 39 035 845908

info@enoberg.it - www.enoberg.it

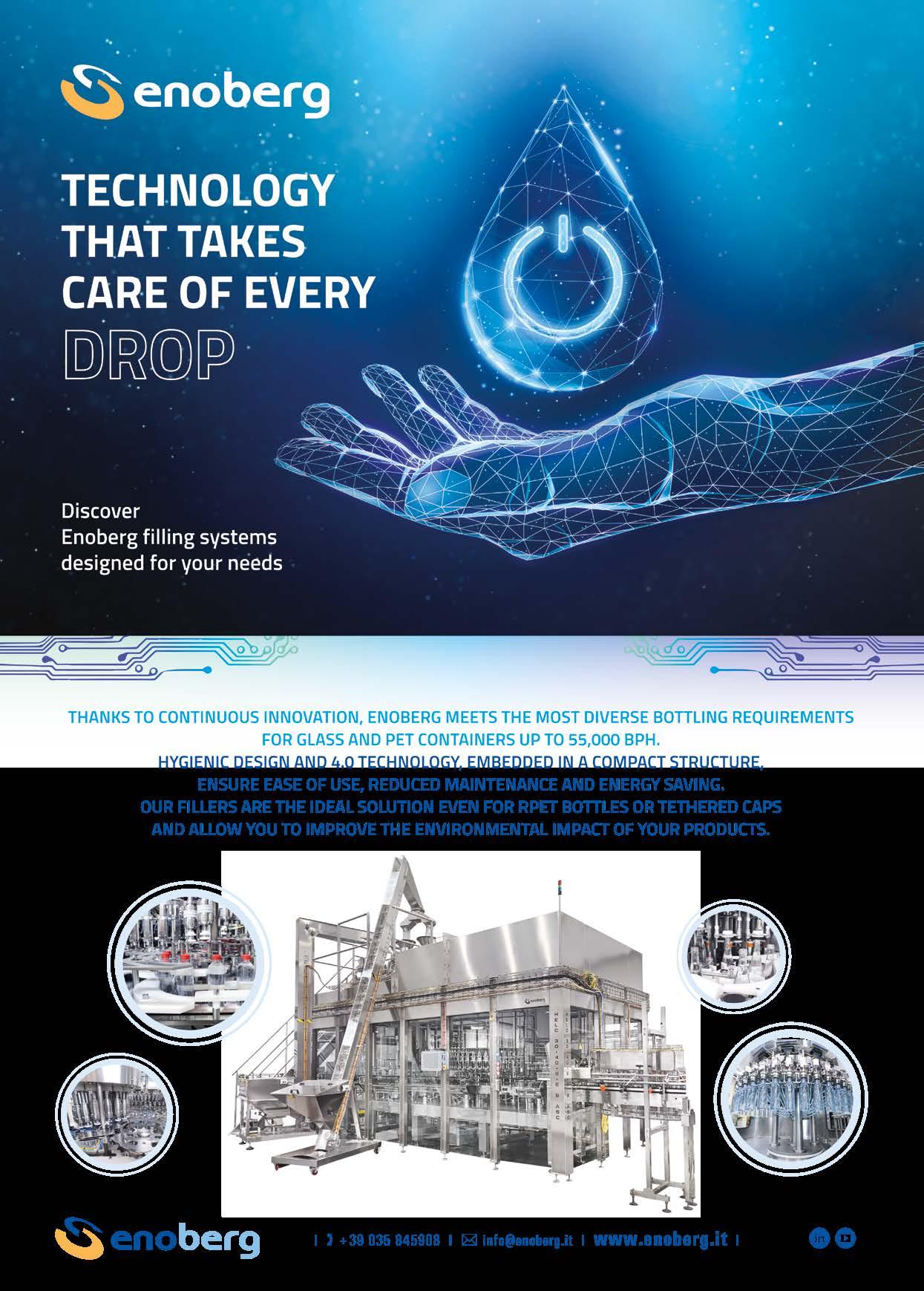

High-tech solutions for the beverage filling ENOBERG machines stand out for their reliability, solidity, ease of use and wide customization possibilities.

Beverage and liquid food industry has constantly been evolving to meet the several requirements of a market that keeps changing and that pays increasing attention to environmental issues.

The filling machines used for the beverage bottling adopt more and more sophisticated technologies to fill the containers in the fastest and most precise way, thus ensuring company competitiveness and improving production efficiency.

Present on the market since 1984, ENOBERG (company of the SMI Group) is one of the main producers of filling machines for still and carbonated beverages in the world. Reliability, solidity, ease of use and wide customization possibilities are features that distinguish the fillers supplied by ENOBERG.

The importance of the filling operation

Filling is the most important stage of the bottling process, since quality, hygiene and preservation of the product characteristics depend on this operation.

ENOBERG S.r.l. is aware of the importance of proposing cutting-edge solutions, capable of meeting the new requirements of customers all over the world; therefore, it has been investing in research and development of innovative, flexible and reliable solutions.

Suitable for the filling of PET, glass and aluminium containers, ENOBERG solutions perfectly adapt to the filling of still (water, isotonic drinks, juices, sauces, vinegar, spirits, oil) and carbonated beverages (water, soft drinks, beer).

HYPERCLEAN range. The response to continuous innovation

To meet the requirements of hygiene, safety and cleaning and to minimize the possibility of contamination of the product to be filled, ENOBERG has developed the HYPERCLEAN series that offers considerable advantages in terms of hygiene, reliability and maintenance.

The advantages in terms of hygiene

The structural parts of the machine are designed in order to avoid liquid stagnation; in particular:

• The inclined base plane ensures the continuous drainage of the liquids within the filling environment on the outside;

• The welded frame is made of AISI 304 stainless steel, without iron components, which ensures a solid structure, with no rust;

• The filling section is completely isolated from transmissions, that do not enter into contact with the liquid to be bottled;

• The filling valves are made of AISI 316 stainless steel. The advantages in terms of reliability

• Designed according to Industry 4.0 parameters, ENOBERG fillers ensure the complete process automation and the electronic management of the movements: all this is synonym for maximum reliability;

• The machine carousel movement is performed by robust gears positioned within the machine base;

• Fast format changeover of the bottle guide equipment;

• Parameters of each format manageable directly through HMI.

The advantages in terms of maintenance

ENOBERG HYPERCLEAN range allows to optimize the spaces of the production plant in order to have a more efficient and more performing line:

• Compact and easy-to-manage solution;

• Extremely safe access to the different components of the machine by the operator, with a subsequent reduction in maintenance times and costs

Innovative walk-in decomposed frame

The most recent developments in research and innovation have led to the creation of models of fillers equipped with a “walk-in” decomposed frame, which allows the operator to easily access the filling and capping sections.

The strengths of this new solution are:

• Minimum overall dimensions during the transport phase

• Solid and robust structure

• Full operator access to the filling block to facilitate all format change and machine maintenance operations

• Possibility of complete cleaning of the flooring under the base of the system

• Complete visability of the work area thanks to the large protective glass

• Available in various configurations, up to 114 filling valves

• Customisable with different options, including top cover, sterile air blowers and aspirators for corrosive vapours.

Since 1984, ENOBERG S.r.l. design and manufacture of high-quality filling machines for bottling both still and carbonated beverages to meet and satisfy the customer’s needs for speeds from 1,000 up to 55,000 bottles/hour

The achievements reached through 40 years of activity result from the cutting-edge machines supplied by ENOBERG, from people’s passion and expertise and from high attention to customers’ satisfaction. The latter has allowed the continuous development of customized and reliable filling systems of the latest generation that meet countless customers’ requirements.

In 2016 Enoberg became part of SMI Group, one of the world’s largest producers of bottling plants and packaging machines. In the same year, Enoberg started a complete refurbishment of its facility.

Via del Lavoro, 14 - 24060 Telgate (Bergamo) Italy Tel.: + 39 035 845908 info@enoberg.it - www.enoberg.it

Purification control technology

Since 1961, BEA Technologies has been a reference point in the design and production of filters and automatic filtration systems. Headquartered in Italy with a strong focus on innovation, the company has developed solutions capable of purifying liquids, air, and compressed gases, with quality and safety at the core. Continuous research on materials and technologies has enabled the company to offer advanced and reliable products that meet the needs of constantly evolving markets.

Market sectors

The company’s experience spans through many strategic sectors. In Life Science, it produces filters for the pharmaceutical, medical, and cosmetic industries, manufactured in Clean Rooms. In Food & Beverage, it develops filtration systems for bottling of beverages and syrup production. For Air & Industrial Gas, it offers high-efficiency solutions capable of removing solid, liquid, and aerosol contaminants. In the Industry sector, it provides filter elements and housings for a wide range of manufacturing applications, while in Energy Oil & Gas, it produces automatic systems designed for refineries and chemical plants according to customer specifications.

Production and control

BEA Technologies does not only produce filter elements, but it designs and manufactures them in strict compliance with current regulations. Microfiltration takes place in controlled environments to ensure the absence of contamination. Every stage, from intermediate inspections to final tests—carried out either on a sample basis or 100% of the production—is documented and archived, ensuring traceability and quality assurance.

Quality and traceability

The company’s quality system is certified according to ISO 9001 and ensures consistent standards and compliance with major regulations in the food and pharmaceutical sectors. Each batch is recorded at the time of shipment with a barcode that allows tracking of the entire production chain. Periodically, the Quality Department performs traceability

checks on both finished products and raw materials, providing additional assurance for customers and markets.

Commitment to sustainability

In 2024, BEA Technologies was recognized among Italian companies awarded the “Sustainability Award” promoted by Kon Group, acknowledging companies capable of combining competitiveness and sustainability. BEA Technologies invests in renewable energy to reduce environmental impact; recently, it installed 700 square meters of solar panels on the roof of the new production unit to generate electricity from renewable sources. This path demonstrates that environmental protection and technological innovation are integral parts of the company’s development strategy.

Frazione Diolo, 15/D - 43019 Soragna (Parma) Italy

Tel. +39 0524 59 90 97 - Fax +39 0524 59 90 12 info@akomag.com - www.akomag.com

SIRA, the washing, rinsing, filling and capping monoblock

The monobloc washer for gallon bottles SIRA has been designed by AKOMAG for washing and sterilizing PET or PC gallon bottles or other bottles of various sizes, to be filled with still water. The washing cycle adapts to the various production needs of the end customer and is very effective. For this machine AKOMAG has designed and produced a special spraying and brushing device for gallon bottles that ensures total cleanliness. Through the use of special mobile nozzles furniture (penetrating and rotating), the machine washes the bottle internally at high pressure (5 bar). While the outside is brushed by means of nylon brushes. The machine can be quickly adapted to the different bottle formats by simply setting the type of container to be handled on the control keyboard. The stainless steel control board installed next to the monobloc is easily accessible for the operator. The panel is equipped with a touchscreen for the complete management of all line functions, and the display of operating parameters and alarms. The monobloc features an automatic de-capper in stainless steel: A pneumatic system grips the bottle neck while ejecting the cap. The system is safe, but it can be equipped with a system for the selection and ejection of gallon bottles that have not been properly de-capped. The bottles are then filled by means of special inverter- controlled pumps.

A valve designed by AKOMAG guarantees a laminar flow and no contact between the valve and the bottle. The filling is carried out by means of a special metering device that ensures extreme filling accuracy. The capper consists of soundproof vibrating hopper, a descent channel, and a tear-off pick-up head.

The closure of the bottle is guaranteed by an inclined pressure belt characterized with adjustable pressure. All adjustments are automatic and managed from the control panel.

Località Piana, 55/D - 12060 Verduno (Cuneo) Italy

Tel. +39 0172 47 02 35 - Fax +39 0173 61 56 33 info@watersystems.it - www.watersystems.it

WS is a company, founded in 2005, working as process equipment supplier for the beverage industry. During these years, WS has achieved a very good reputation in the beverage industry field, managing to cooperate with the major global players, such as Coca Cola, Pepsi Cola, Nestlé Waters and OranginaSchweppes, and with private investors installing new production facilities, quite often green fields, in emerging Countries.

WS has met new standards for product quality, energy saving and maximum plant output while complying with the strictest criteria for hygiene and safety

All the devices are entirely conceived and designed to guarantee the best requirements in terms of microbiological, physical-chemical and organoleptic properties; the entire production process and software development are managed internally, as well as installations and commissionings which are carried out with WS’s own resources. WS’ products for beverage industry are:

• water purification plants (mechanical filtration, microfiltration, reverse osmosis, UV disinfection, sterilisation) designed according to the customer’s exigencies and the chemical analysis;

• sugar dissolving systems (single batch, double batch and continuous up to 35.000 l/h);

• semiautomatic and automatic syrup rooms;

• premix units;

Località Piana, 55/D - 12060 Verduno (Cuneo) Italy

• flash pasteurising units;

• ozone generators;

Tel. +39 0172 47 02 35 - Fax +39 0173 61 56 33 info@watersystems.it - www.watersystems.it

• carbonating equipment (water, wine, beer, soft drinks);

• in line syrup blending systems and ingredients mixing systems;

• steam sterilisable microfiltering systems (juices, beer, wine);

• mineralising equipment;

• equipment for preparation of non-chemical bottles rinsing and disinfecting solutions (such as ozone) and chemical solutions preparing devices (peracetic acid, hydrogen peroxide, chlorine, etc.);

• equipment for the preparation of sterile water;

• manual and automatic CIP systems

Thanks to its skill and process expertise, today WS is widely present worldwide even with turnkey solutions including ancillary equipment (cooling equipment, boilers, etc.).

WS’ philosophy is to manufacture high-quality and reliable equipment, equipped only with top brand components: ALFA LAVAL, ENDRESS+HAUSER, PALL, ANTON PAAR, SIEMENS, FESTO, SPIRAX SARCO are the typical components our Customers will find on Their plants.

The choice of providing only state-of-the-art solutions has brought us to be appointed as officially authorized integrator by ALFA LAVAL

Between main technical references, WS can list the supply of two fruit juice tubular flash pasteurizers for aseptic filling to ORANGINA-SCHWEPPES in France; furthermore, it’s significant to point out that WS is included in NESTLÉ WATERS’ authorized suppliers list for water purification systems: recently an important contract for the supply of a toptechnology water treatment plant in the far East has been finalized. Amongst last supplies (early 2016), WS also boasts a complete line for soft drinks production in Las Vegas – USA (Coca Cola co-packer): from water treatment to hot fill pasteurizer, through sugar syrup preparation and ingredients mixing, also including CIP equipment. WS considers Customer Service one of the greatest keys to success: entire business, marketing, sales and profits depend on customers’ satisfaction so the after sales team is constantly trained to perform the simplest solution in the shortest possible time to support the customer’s business.

“BLENDSYSTEM M”

The growing market’s confidence gained by process plants manufactured by WS, allowed a continuous development of blending technology for carbonated soft drinks (CSD) production to such an extent that We reached a very high level of specialisation in manufacturing mass controlled blending systems, named BLENDSYSTEM M.

BLENDSYSTEM M is a piece of equipment for preparing beverages, completely preassembled on a skid for an easy and quick shipment and installation, conceived mostly for the production of carbonated soft drinks (CSD), but also carbonated mineral water (CMW) and still water (charged with nitrogen in order to increase the mechanical resistance of the bottle). The required quantity of ingredients (water, syrup, and CO2) is carefully measured and dosed in an electronically controlled continuous process.

The whole system, realized to guarantee the highest qualitative standards and a qualitatively constant production, also running in conditions of considerable format change, is completely preassembled on stainless steel circular-section skid for an easy and efficacious cleaning. It usually includes the following subsystems:

• inlet water deaeration: a vacuum pump removes incondensable gases; the pump is conceived to maintain the dissolved oxygen level below 1 ppm values;

• carbon dioxide dosing (or nitrogen in case of still mineral water production): a modulating valve and a mass flow rate transmitter inject carbon dioxide in quantity that is proportional to water quantity loaded to the deaeration tank; the water flow rate is usually measured by a magnetic flow rate transmitter, which may be replaced with

a mass flow rate transmitter in case water presents a very low electrical conductivity level. A special gas injecting and mixing system - specifically developed by WS - performs a careful mixing with the water to be treated and, hence, best results in terms of product perlage; the carbon dioxide contents is maintained constant in the product receiving tank by a supervising software, which checks possible fluctuations in feeding

Località Piana, 55/D - 12060 Verduno (Cuneo) Italy

Tel. +39 0172 47 02 35 - Fax +39 0173 61 56 33 info@watersystems.it - www.watersystems.it

water temperature and product buffer temperature; the effective dissolved carbon dioxide contents in the product is checked using a carbometric unit, installed in by-pass on the filling machine feeding line;

• syrup dosing and mixing: at first syrup is stored in a small buffer tank, whose atmosphere is modified and enriched with carbon dioxide in order to avoid oxidation occurrence. Syrup injection is made by a

sanitary design modulating valve and a mass flow rate transmitter in a quantity which is proportional to the water amount fed from the deaeration tank; furthermore, using the mass flow rate transmitter, it is possible to check constantly the effective density of the inlet syrup and therefore to compensate immediately for the dosing and to stabilize the sugary concentration in the end-product within established bounds (usually ±0,05 °Bx). A specific refractometer installed in bypass on the filling machine feeding line, allows the constant check of the product and, if necessary, its adjustment; similarly, the instruments minimize waste of both syrup and product during transitory phases of production, such as start and stop.

Furthermore, customized solutions for product cooling are also available, depending on the environmental conditions of the system installation.

The supervising software loaded on the mass premix unit

- BLENDSYSTEM M - is conceived to guarantee the best results in terms of dosing, offering at the same time an easy control by a friendly user interface; this software enables on one hand to set the main production parameters and visualize their state graphically and on the other hand to set the statistics parameters (ca, cp e cpk) connected to that kind of production.

Using a more advanced version of this software, associated with specific instruments, it is also possible to control automatically saccharose inversion, so that the need of intervention by laboratory technicians is reduced.

The equipment is equipped with field buses (MPI, Profibus or Ethernet) for a complete integration in the bottling line and the control of production, cleaning and sanitizing processes.

TecnAlimentaria supplement N°8/9 August/September 2025 - Year XXX

Publisher

Fabiana Da Cortà Fumei

Editorial Staff & Design redazione@tecnalimentaria.it

Sabrina Fattoretto

Claudia Bosco

Elena Abbondanza

Veronica Menegazzo

Marketing and Advertising

Anita Pozzi anita.pozzi@edftrend.com

Franco Giordano franco.giordano@edftrend.com

Management, Editorial Office

Editrice EDF Trend srl

Corso del Popolo, 42 31100 Treviso – Italy

Tel. +39 0422 549305

Fax +39 0422 591736 www.tecnalimentaria.it www.TecnAmagazines.com

Translation into Arabic

Ann Nasr

Printing L’Artegrafica Srl

Autorizzazione Tribunale di Forlì n. 5 del 19.01.1996 N° iscrizione ROC (Registro degli Operatori di Comunicazione): 22054

In questo numero la pubblicità non supera il 45%

Sped. in abbonamento postale 45%Art. 2 Comma 20/B Legge 662/1996 DCI-TV All right reserved. Reproduction in whole or in part without written permission is prohibited.

The Publisher is not responsible for any materials, nor for writers’ nor contributors’ expressed or implied opinions. Informativa ex D.lgs 196/03

Ai sensi dell’art.2 comma 2° del Codice Deontologico dei giornalisti si rende nota l’esistenza di una banca dati di uso redazionale presso la sede di Corso del Popolo, 42 - Treviso. Responsabile del trattamento dati è il direttore responsabile a cui ci si può rivolgere presso la sede di Treviso - Corso del Popolo, 42 per i diritti previsti dalla legge 675/1996. TecnAlimentaria is a

Member of:

Beverage Industry www.watersystems.it I^ - 2^ Cover, 8-11

Beverage & Food Industry www.aeraque.com 13

Beverage Industry www.akomag.com 14-15

Beverage Industry www.bea-italy.com/it I^ Cover, 5, 16-17

Beverage Industry www.enoberg.it 19-21

Beverage Industry www.galiganifiltri.com 4, 22-23

Beverage & Food Industry www.giordaninox.it 3, 25

Beverage Industry www.imcar.it 26-27

Beverage & Food Industry www.kosme.it I^ Cover, 2, 29-31

Beverage Industry www.magicmp.it 33-35

Beverage & Food Industry www.mgmrestop.com 36-37

Industry www.mondo-scaglione.com 39-41

Beverage & Food Industry www.minimotor.com I^ Cover, 42-43

Beverage & Food Industry www.navattagroup.com I^ Cover, 44-45

Beverage Industry www.newteclabelling.it 46-47

Beverage Industry www.qvisiontech.it 48-49

Beverage & Food Industry www.smigroup.it I^ Cover, 50-53 SMI SPA

Beverage & Food Industry www.smipack.it 12

Beverage & Food Industry www.unical.eu I^ Cover, 1, 55-57

Beverage & Food Industry www.vetromeccanica.it I^ Cover, 58-59