2024 / 2025 Supplemento a TecnAlimentaria N° 2 Febbraio 2024 Poste Italiane SpA - Spedizione in Abbonamento Postale D.L. 353/2003 (conv. in L. 27/02/2004 n. 46) art. 1 comma 1 NE/TV - Anno 29 N°2 - 2024 - ISSN 2498-9541 INTERNATIONAL MAGAZINES .it EASTERN EUROPE EDITION ITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY

Via Tretti Marotti, 4 Grisignano di Zocco 36040 (VI) - Italy T + 39 0444 41473 5 F + 39 0444 41471 9 E in f o@ t eknos t amap .c o m

SPIRAL MIXERS

TecnAlimentaria Supplement n. 2 February 2024 - Year XXIX

Publisher Fabiana Da Cortà Fumei

Editorial Staff & Design redazione@tecnalimentaria.it

Sabrina Fattoretto

Claudia Bosco

Elena Abbondanza

Marketing and Advertising

Anita Pozzi anita.pozzi@edftrend.com

Franco Giordano franco.giordano@edftrend.com

Autorizzazione Tribunale di Forlì n. 5 del 19.01.1996

N° iscrizione ROC: 22054 (Registro degli Operatori di Comunicazione)

In questo numero la pubblicità non supera il 45% Sped. in abbonamento postale 45%Art. 2 Comma 20/B Legge 662/1996 DCI-TV

All right reserved.

Reproduction in whole or in part without written permission is prohibited.

The Publisher is not responsible for any materials, nor for writers’ nor contributors’ expressed or implied opinions.

Informativa ex D.lgs 196/03

Ai sensi dell’art.2 comma 2° del Codice Deontologico dei giornalisti si rende nota l’esistenza di una banca dati di uso redazionale presso la sede di Corso del Popolo, 42 - Treviso. Responsabile del trattamento dati è il direttore responsabile a cui ci si può rivolgere presso la sede di Treviso - Corso del Popolo, 42 per i diritti previsti dalla legge 675/1996.

ITALIAN TECHNOLOGY FOR FOODTHEINDUSTRY ASIATIC & PACIFIC EDITION Supplemento TecnAlimentaria Novembre Italiane Spedizione AbbonamentoPostale 353/2003 (conv. 27/02/2004 art. NE/TV 28 2498-9541 2023/2024 INTERNATIONAL MAGAZINES.it FOOD INDUSTRY www.tecnalimentaria.it N°1 Dicembre Gennaio 2024 ITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY TECNOLOGÍA ITALIANA PARA LA INDUSTRIA ALIMENTARIA AMERICAS EDITION 2023 2024 AMERICAS EDITION Supplemento TecnAlimentaria Luglio/July Poste 353/2003(conv. 27/02/2004 Anno 2023 2498-9541 2023 2024 2023 2024 .it INTERNATIONAL MAGAZINES Supplemento TecnAlimentaria Ottobre Poste SpA D.L. (conv. 27/02/2004 commaITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY 2023/2024 www.tecnalimentaria.it www.edftrend.com Management and Editorial Office Editrice EDF Trend srl Corso del Popolo, 42 31100 Treviso – Italy Tel. +39 0422 549305 Fax +39 0422 591736 www.tecnalimentaria.it www.edftrend.com Printing L’Artegrafica Srl Member of 2024 / 2025 Supplemento a TecnAlimentaria N° 2 Febbraio 2024 Poste Italiane SpA - Spedizione in Abbonamento Postale D.L. 353/2003 (conv. in L. 27/02/2004 n. 46) art. 1 comma 1 NE/TV - Anno 29 N°2 - 2024 - ISSN 2498-9541 INTERNATIONAL MAGAZINES .it EASTERN EUROPE EDITION ITALIAN TECHNOLOGY FOR THE FOOD INDUSTRY INTERNATIONAL MAGAZINES .it

4G GHIDINI SRL www.4gghidini.it 8-9 FOOD INDUSTRY AM TECHNOLOGY www.am-technology.it 10-11 FOOD INDUSTRY BORGHI SRL www.borghigroup.it 2, 72 FOOD INDUSTRY CASEARTECNICA BARTOLI SRL www.caseartecnica.it I^Cover, 1, 12-13 FOOD INDUSTRY CLM BAKERY SYSTEM SRL www.bakerysystem.com I^Cover, 14-15 FOOD INDUSTRY CUOMO F.LLI www.cuomoind.it 73 FOOD INDUSTRY DEFINO & GIANCASPRO SRL www.defino-giancaspro.com 16-17 FOOD INDUSTRY DOLZAN IMPIANTI SRL www.dolzan.com I^Cover, 18-19 FOOD INDUSTRY ESCHER MIXERS SRL www.eschermixers.com I^Cover, 3, 20-21 FOOD INDUSTRY FERRARONI AFP SRL www.ferraroni.net 22-23 FOOD INDUSTRY FIC SPA www.fic.com 24-25 FOOD INDUSTRY GENERAL SYSTEM PACK SRL www.gsp.it 65 FOOD INDUSTRY GRUPPO FABBRI VIGNOLA SPA www.gruppofabbri.com 26-27 FOOD INDUSTRY IFP PACKAGING SRL www.ifppackaging.it 65 FOOD INDUSTRY INOX MECCANICA SPA www.inoxmeccanica.com I^Cover, 28-29 FOOD INDUSTRY ITALPAN www.italpan.com 30-31 FOOD INDUSTRY LANDUCCI SRL www.landucci.it I^Cover, 32-33 FOOD INDUSTRY LIVETECH SRL www.live-tech.com 34-35 FOOD INDUSTRY M.H. MATERIAL HANDLING SPA www.mhmaterialhandling.com 38-39 FOOD INDUSTRY MARVIL ENGINEERING SRL www.marvil.it 37 FOOD INDUSTRY MC² SRL www.mc2-srl.com 40-41 FOOD INDUSTRY MILLENNIUM ENGINEERING SRL www.me-foodsolutions.com 42-43 FOOD INDUSTRY MINI MOTOR SPA www.minimotor.com 45 FOOD & BEVERAGE INDUSTRY MOLITECNICA SUD SRL www.molitecnica.it 47 FOOD INDUSTRY OCRIM SPA www.ocrim.com I^Cover, 4-5, 48-50 FOOD INDUSTRY OLOCCO SRL www.olocco.eu I^Cover, 52-53 FOOD INDUSTRY ORION SRL www.orion-srl.it 46 FOOD INDUSTRY PND SRL www.pndsrl.it I^Cover, 54-55 FOOD INDUSTRY RE PIETRO SRL www.repietro.com I^Cover, 56-57 FOOD INDUSTRY SATINOX SRL www.satinox.com 58-59 FOOD INDUSTRY SIGMA SRL www.sigmasrl.com I^Cover, 60-61 FOOD INDUSTRY SILVESTRI SRL www.impastatricisilvestri.it 62-63 FOOD INDUSTRY TECNO PACK SPA www.tecnopackspa.it 65 FOOD INDUSTRY TEKNO STAMAP SRL www.teknostamap.eu I^ - II^ Cover, 66-67 FOOD INDUSTRY VIMCO SRL www.vimco.it 44 FOOD INDUSTRY Z MATIK SRL www.zmatik.com 68-69 FOOD INDUSTRY ZUDEK SRL www.zudek.com 70-71 FOOD INDUSTRY FOOD INDUSTRY INDEX

Via Ruca, 400 (Z.I)

25065 Lumezzane (Brescia) Italy

Tel. +39 030 892 59 53 info@4gghidini.it www.4gghidini.it

4G® GHIDINI Srl is specialized in producing stainless steel ball valves and fittings

Founded in 1978, with over 40 years of experience, 4G® GHIDINI has always set the product and service quality as its main objective. Product quality is ensured by using raw materials exclusively sourced in the European Union and by processing them entirely in the production site located in Lumezzane, Brescia. Service quality relies on prompt stock availability of all the proposed items, added value in terms of offer and timely deliveries.

All the products are designed, manufactured and 100% tested before being marketed, following a correct certified construction practice and with the aid of highly advanced machinery to guarantee end-users a highlevel product.

The company is UNI EN ISO 9001:2015 certified. Product traceability is guaranteed throughout the entire production process, from the entry of raw materials to subsequent processing, up to the finished product. 4G® GHIDINI product is 100% Made in Italy, no import particulars are used. 4G® GHIDINI products are used in the most varied industrial applications, including

Pharmaceutical, Biotechnological and Cosmetic industry; Food and Beverage; Chemistry, Process, Water treatment and Energy production.

Pharmaceutical industry needs the best technologies to meet the needs of its productions in sterile and aseptic environments. 4G® GHIDINI valves with integral seals without dead points eliminate the deposits of fluid inside them; high performances and certifications make them the ideal product for clean applications. The valves, easily removable, guarantee ease of cleaning and quick maintenance.

Food industry requires components such as ball valves and fittings that together with performance and reliability guarantee suitability for contact with foods through certifications such as “MOCA” 1935/2004/ CE and FDA. For this sector 4G® GHIDINI provides specific solutions, such as predispositions for washing with CIP system, for sterilization by steam and for PIG product

recovery systems. All 4G® GHIDINI valve models are available also in the version with heating jacket, ideal for the use in chocolate production.

For the chemical industry, the valves and fittings made entirely in Aisi 316L from bar ensure maximum compatibility with the most aggressive fluids and the most critical conditions of use; the possibility to configure them ad hoc allows to obtain the maximum yield.

The valves can be installed in hazardous areas given the ATEX II 2 G-D T4 certification. Products comply also with the technical regulation EAC TR CU 010/2011 and EAC TR CU 032/2013

The different types of connections allow 4G® GHIDINI to customize ball valves according to customer’s needs, making them suitable for installation on any system.

Strengthened of the past and present challenges, 4G® GHIDINI is ready for the future ones.

Turning 8 EASTERN EUROPE EDITION FOOD INDUSTRY

Laser Marking Welding Cut

4G Ghidini Srl

AM Technology Srl

Via Ferracina, 13

36043 Camisano Vicentino (Vicenza) Italy

Tel: +39 0444 41 02 21 info@am-technology.it www.am-technology.com

Tailor-made simplicity on your installations

AM Technology is an Italian company designing, manufacturing and installing industrial processing and handling systems specifically for the food sector.

Thanks to its great experience in the tech sector and a cutting-edge vision, the company has crossed the Italian border, consolidating its presence in the European market.

AM Technology solutions are not just systems, but customised technologies that allow companies to optimise their production processes and express their full potential.

Each company has its own vision of the production process, and this can be easily replicated thanks to the AM’s ability to customise the plant, with a focus on functionality and space availability, aiming for maximum performance and minimum maintenance

The concept of tailor-made simplicity is the cornerstone of AM Technology’s approach, born from the desire to break down the technological gap so as to provide the right solution to each company, because simplicity means designing a system from scratch using the essential components that, together, can achieve the best result, without complicated procedures. When the goal is to bring value to the food product through a solution that can solve complexities and guarantee constant and streamlined control and when simplicity becomes customisation, then the process becomes innovation

AM Technology operates in the food sector by designing different types of systems for: proofing, cooling, deep-freezing, pasteurization and handling, having as common thread the ability to put the product at the center, to gently respect its organoleptic properties while raising its quality.

Am Technology, the simpler better

10 EASTERN EUROPE EDITION FOOD INDUSTRY

Caseartecnica Bartoli Srl

Via Quintino Sella, 21/A 43126 Parma, Italy

Tel. +39 0521 98 23 81

Fax +39 0521 99 48 66

info@caseartecnica.it www.caseartecnicabartoli.it

Caseartecnica Bartoli: alongside the dairy company with automatic or semi-automatic solutions

A wide range of machines designed for the entire milk supply chain. From the professional packaging industry to the needs of small producers and traders.

Caseartecnica Bartoli offers cutting and packaging solutions for the dairy sector designed to work in line or stand alone, thus responding to the demand for effective, automatic or semi-automatic tools.

At CibusTec 2023, Caseartecnica Bartoli consolidated what had already been presented in the pre-Covid edition with the exhibition and presentation of a new milk processing agitator for the production in particular of Parmigiano Reggiano and Grana Padano. Completely oriented towards compliance with the hygiene and noncontamination requirements of the product that the market requires: it is an absolute novelty. The EVO Stirrer is equipped with a brushless motor with permanent magnets without a reduction gear and without oil

inside. The current situation of the market and the sector requires products that have the primary objective of energy saving and environmental sustainability. This is undoubtedly a turning point in the sector where Bartoli has been present for over 60 years with machinery that responds in real time to the needs of the sector. Caseartecnica Bartoli develops and assembles new machinery along this path, putting innovation and respect for the product first.

The offer of Caseartecnica is completed with cutting machines: the use of automatic and semi-automatic machines for cutting hard and semi-hard cheese and other products other than dairy products (ham slices, pumpkins, frozen products, etc.). The cutting machines - portioners and panel saws - have a vocation towards ever greater automation of the production cycle with ever greater performance speeds.

In the field of hard and semi-hard cheese cutting, the ROCK20 PLUS, the latest generation automatic machine, allows you to choose to portion both fixed and variable weights. Versatility and flexibility characterize this machine suitable for working alone or in

line with other Bartoli cutting machines allowing an entire portioning and packaging line.

The market trend and international customers allow Caseartecnica Bartoli to export 15% of its annual production abroad, mainly for Northern and Eastern Europe, in countries such as Austria, Germany, Switzerland, Hungary, Serbia, but reaches also nonEuropean markets such as Canada, the U.S.A. and Brazil and Albania and Russia.

The agitators are mainly placed on the Italian market: the production of cheeses in the Italian territory, in fact, guarantees a preponderant market share. Without forgetting, however, the expansion - precisely in the two-year period 2020-22 - with a supply to Brazil and the United States, Hungary, and Russia for a production of “grain-like”.

The current national and international context makes us hope for a positive, but not easy reaction for the next few years, certain of a consolidation of its presence on the national and international market. The return to presence for the entire trade fair sector will allow us to be present and available for new meetings and new markets in the coming months.

12 EASTERN EUROPE EDITION FOOD INDUSTRY

Caseartecnica

Caseartecnica Bartoli Srl

Caseartecnica Bartoli Srl

CLM Bakery System Srl

Via Val D’Aosta, 43

33080 Fiume Veneto (Pordenone) Italy

Tel. +39 0434 17 08 720

Fax +39 0432 16 92 077

sales@bakerysystem.com

www.bakerysystem.com

Quality of tradition in industrial quantities

CLM Bakery System designs and manufactures complete pizza and bread production lines, offering you modern and efficient production systems combining the requirements of industrial production with the quality of handmade products.

CLM Bakery System can automate the whole production process, and offers you turnkey solutions and tailor-made systems, building different solutions and equipment suited to your needs.

CLM Bakery System is leader in the world in the production of bakery lines for wood-fired pizza and wood-fired bread.

In CLM Bakery Systems wood-fired pizza lines the tunnel stone ovens marketed under the CLM Vesuvio brand, powered by gas and/or wood are equipped with the innovative patented embracing heat baking system and are accompanied by complementary equipment, such as the innovative automatic fermentation room for 24/48 hours sponge/biga fermentation and main dough fermentation in small bins of 25 kilos, the automatic dough balls proofer, crossing lamination and a special hot pressing technology which does not need any additional oil or flour.

The innovative process technologies of CLM Bakery System pizza lines give you unique selling points in your market;

- Open texture great alveolation

- Melt in the mouth texture – i.e. not tough/ chewy especially on the rim

- Great flavor

- Greater enzyme conversion of starch to sugars - leads to better colouration / rustic look and feel without a heavy bake

- digestibility/ lightness of eat

- reduced yeast levels

- crispness through life (retention of outer shell crispness).

Nowadays, we are used to seeing pizza baked in electric or gas ovens, but we should not forget that the real Italian pizza was created in 1889 in Naples with the characteristic of being baked in wood-fired oven at 450°C for no longer than 60 to 90 seconds. CLM Vesuvio wood-fired tunnel oven for pizza now offers all the advantages of traditional wood baking with direct flame, allowing the best handmade quality to be achieved in industrial pizza production.

CLM Vesuvio wood-fired tunnel ovens are completely built in stone and refractory material and thanks to these materials, CLM Vesuvio accumulates and emits heat uniformly, guaranteeing the best baking stability for any type of product and giving you the possibility to bring in your market the real Italian wood-fired pizza baked in a stone oven with the smokes embracing the product.

At the same time the automatic wood loading guarantees you high productivity and energy efficiency.

Not only wood is a renewable form of energy but you have also the possibility to improve the carbon footprint of your products baking carbon neutral.

Between the proving process and the baking process, there are various processes involved in preparing the pizza, which must be carried out using high quality equipment as to ensure a finished product that complies with the reputation that Italian pizza has built up all over the world.

CLM bakery System can offer you the innovative hot pressing system and the crossing lamination.

In the CLM Bakery System hot pressing system, the dough balls are picked up by servo controlled mechanical hands and transferred onto the plates of the hot press conveyor with precision. Upper and lower plates are heated by a controlled electrical resistance system, which always keeps them at the ideal operating temperature. The pressing plates are also shaped in such a way as to obtain the preferred pizza shape. By changing the shape, it is very easy to move from a flat pizza to a thick crust or rimmed one.

14 EASTERN EUROPE EDITION FOOD INDUSTRY

After the hot press step, the bases are picked up off the conveyor by a second manipulator, with vacuum-operated pick-up heads, and then placed onto the conveyor belt direction oven.

The hot pressing carried out by the CLM Bakery System procedure allows an even crispier pizza base to be obtained, so that the base absorbs the wetness of the tomato to a lesser extent, hence consistently improving the finished product.

As an alternative to the hot pressing CLM Bakery System offers you the crossing lamination: two laminators receive the proved dough balls and make them into oval shapes, which are lined up and handled by a dedicated phasing system. A retractable conveyor then gently transfers the ovals, creating a direction change. The ovals move through the third and fourth laminator, which creates the typical round shape. Flour dusters make sure a thin layer of flour is dusted to avoid dough sticking.

In CLM Bakery System wood-fired bread lines the CLM Vesuvio tunnel oven for bread will allow modern consumers to discover the ancient flavour of traditional bread baked in a wood-fired oven, enhancing the quality, taste, fragrance and authenticity.

Food marketing in recent years has focused greatly on making the most of tradition. Since the CLM Bakery System Vesuvio industrial tunnel oven is wood fired and thanks to the smokes that hit and embrace the products, it

allows the aromas and fragrances found only in few artisan bakeries to be rediscovered. For the proofing in wood-fired bread lines CLM Bakery System offers you the proofer CLM Libera with the following advantages:

- Independence from the oven: the suitable proofing time can be chosen regardless of the baking time needed for the product;

- Flexibility in the choice of proofing times at multiple intervals of a few minutes;

- Specific trays for each product: at one time, bread was proved on wood boards, wicker baskets, linen pockets or other natural materials. Nowadays, you can choose the ideal surface for exalting the flavour and development of your products; this customisation provides for specific stores for each type of tray, with automatic in-line changing of the actual trays;

- Quick and easy cleaning: The CLM Bakery System Libera proofer can be fully emptied of the trays and then cleaned very easily.

Experience in renewing tradition The experience, technology and professionalism that have always accompanied CLM Bakery System’s development make the company a trusted industrial partner for everything to do with the world of bakery.

Via Val D’Aosta, 43 33080 Fiume Veneto (Pordenone) Italy Tel. +39 0434 17 08 720 Fax +39 0432 16 92 077 sales@bakerysystem.com www.bakerysystem.com

EASTERN EUROPE EDITION 15 FOOD INDUSTRY

CLM Bakery System Srl

Defino & Giancaspro Srl

Via Archimede, 27/33

70024 Gravina in Puglia (Bari) Italy

Tel. +39 080 326 61 96

Fax +39 080 326 58 54

info@defino-giancaspro.com www.defino-giancaspro.com

Defino & Giancaspro “has its roots in the time of mills made by wood”. The company was founded in 1965 in Gravina in Puglia (Bari-Italy) thanks to some craftsmen, whose main occupation was the assembling of milling plants and whose only capital was the work of their hands and their commitment to the world of wheat and cereals.

The master-fitter Vito Antonio Giancaspro, the father of the current General Manager, had many skills in various fields such as carpentry, mechanics, plants and food technology. This “artisan” disposition, after more than 50 years, remains the cornerstone of the company philosophy and is one of its strengths. The company continues nowadays to provide its customers with all the experience and expertise of over one hundred employees with the same passion and enthusiasm.

The goal of the Defino &Giancaspro is not to simply offer a machine or a plant,

but to supply all the technologies and means to adapt them to the customer’s requirements.

Just like a high-quality tailored dress, the product meets the customers’ needs but always respect the company style with the unmistakable Made in Italy quality. Engineering, prototyping, research and continuous development ensure always the best solution to the customer. In Defino & Giancaspro design is meant with the overall conception of work planning, with the aim to turn ideas into product specification through the precious and constant sharing of information between young engineers and expert workers.

The company is a specialist in realization of carbon and stainless steel spouting and accessories, has a pool consisting of more than fifty types of machines in various sizes and operates construction and assembly of structures and silos. Its success lies in the precision and accuracy of working,

always realized within their own workshop, and in the use of forefront machinery and certified welding techniques, which offer an excellent finishing and quality.

The service does not end at the delivery of the supply, the relationship with the customer continues through the optimization and the implementation of the new product, ensuring support, maintenance and constant assistance, namely a complete turnkey product.

Plants and machines manufactured and assembled by Defino & Giancaspro are requested and appreciated all over the world. Almost daily and constant are collaborations not only in Italy and Europe, but also with Russia, the United States, Mexico and North Africa.

Proud of their work, everywhere, from the offices to the workshop, all the departments work daily to improve and expand the range of products and services to satisfy both historical and new customers.”

16 EASTERN EUROPE EDITION FOOD INDUSTRY

Via Roma, 260

35015 Galliera Veneta (Padova) Italy

Tel. +39 049 596 93 75

Fax +39 049 94 01 38

dolzan@dolzan.com www.dolzan.com

The company DOLZAN IMPIANTI srl, which has been working in the packaging field since 1962, owes its success to the long experience in the sector and the continuous technical refinement aiming at providing its clients with the best solutions available on the market.

The results of this passion, which has been lasting for over 55 years, take shape in a wide range of packaging machines whose main characteristics are the versatility, the reliability and the user-friendly aspect.

DOLZAN IMPIANTI has grown with its clients and created solid grounds with the great determination for a promising future.

Designed in a rational and essential way, suitable for the food, pharmaceutical, pet food, confectionary, chemical, mechanical industries and others, Dolzan vertical

packaging machines represent the best way to pack any type of products in bulk, be they granular, powdery or liquid, starting from flat foil reel.

They can handle any thermoplastic or polyethylene film, thermo sealable film or polypropylene and complex material.

Packaging lines with electronic weighers (linear and multihead weighers), volumetric dosers (volumetric cups or auger filler), with the possibility of combining two different dosers on the same machine, are available for packing into pillow pack, flat bottomed bags, gusseted bags, bags with handle, clip, doystyle bag and bags with vacuum.

Dolzan packaging machines can be equipped with a range of accessories, such as: bucket elevators for granular products, screw feeding systems for powders, synchronized elevators for counted products, printers, rotating collection tables and many more. Important equipment is

a nitrogen injection system that allows extending the product shelf life; the device acts on the air composition inside the bag, reducing the oxygen percentage replacing it with by nitrogen.

The wide range of packaging machines and dosers the company can offer, allows satisfying different demands in terms of product, bag shape and dimension.

Dolzan packaging machines are created by a qualified team whose aim is to provide a highly performing product. Its Made in Italy finds its expression in a high-quality product suitable for the most demanding customers’ needs.

The company’s customer-care service gives its clients a direct access to its specialized technicians in order to ask for information and solve problems in real time. Client care continues a tour customer site with timely and effective assistance by DOLZAN IMPIANTI’s qualified operators.

18 EASTERN EUROPE EDITION FOOD INDUSTRY

Dolzan Srl

Escher Mixers Srl

Via Copernico, 62

36034 Malo (Vicenza) Italy

Tel. +39 0445 57 66 92

Fax +39 0445 57 72 80

mail@eschermixers.com

www.eschermixers.com

Escher Mixers specializes in the production of mixing machinery for the bread and pastry-making sectors.

Over the years, Escher Mixers has gained specialized knowledge that has allowed this company to develop machines and solutions to meet the needs of a variety of clients and different types of markets.

Escher Mixers machines are renowned for their sturdiness, durability, accurate finishes, and for the quality of the dough they produce.

Bakery equipment

Escher Mixers proposes Spiral and Wendel mixing concepts. Both solutions can be with removable bowl through a patented® bowl locking and motion system MR-MW Line or bottom discharge system MD-MDW Line with conveyors belts or bowl lifters which can be matched with automatic solutions with linear system and storage of the resting bowls in vertical or linear storages, rotating automatic systems-carousel, scraps recovery

systems, transverse hopper systems and star-cutting/guillotine/roller with guillotine and other customized solutions.

Pastry equipment

The range of planetary mixers with double tool for the pastry industry is characterized by the lack of oil lubrication systems, improving hygiene and reducing machine maintenance. A wide range of interchangeable tools is available for different uses and doughs.

For industrial productions, Escher Mixers has developed the PM-D Line with independent tool movement, with individual speed regulation and the possibility to reverse the motion. While the PM-DB Line with the bridge structure allows automatic insertion of the ingredients, air insufflation to reduce mixing times and increase volume, dough processing with negative/positive pressure and cleaning through CIP washing system. Various bowl discharge options are available.

20 EASTERN EUROPE EDITION FOOD INDUSTRY

Ferraroni AFP Srl

Via Sardi, 31/A

43124 Alberi (Parma) Italy

Tel. +39 0521 648 742

Fax +39 0521 648 637 info@ferraroni.net www.ferraroni.net

EF 300, the new tilter that conquers the industry

Extensive experience, knowledge of materials, and qualified technical staff have enabled AFP Ferraroni to introduce EF 300 and conquer modern industries.

AFP Ferraroni has developed the new tilter and meets the needs and requirements of the modern, innovative food industry, where a design that ensures effective sanitation, easy handling and moving is the key, especially in food processing areas.

Cleaning design

• It allows for quick, easy sanitation

• Made of stainless steel AISI 304 Easy to use

• Two push-button panels, one on each side, to simplify activities in small food-processing environments

• A rechargeable battery with a waterproof socket mounted on the flipper shell and battery charger Ergonomic design

• Front spinning wheels

• Large lateral handles to facilitate movements.

22 EASTERN EUROPE EDITION FOOD INDUSTRY

55- year business activity in industrial mechanics sector

AFP FERRARONI is leader in design and production of centrifugal machines for butchery by-product processing. The machine range it produces also includes pneumatic conveyors and lift-tippers for any kind of container and product

AFP Ferraroni Srl

Via Sardi, 31/A – 43124 Alberi (Parma)

Tel. +39 0521 648742 - Fax: +39 0521 648637 - info@ferraroni.net

www.ferraroni.net

Via Trivulzia, 54

23020 Mese (Sondrio) Italy

Tel. +39 0343 410 51 fic@fic.com www.fic.com

The cool revolution: Exploring ICE WATER solutions in chilled water production

In the realm of industrial cooling systems, the demand for efficient and sustainable solutions has never been higher. As industries strive to meet stringent environmental standards while maintaining optimal performance, innovative technologies like ICE WATER systems are emerging as key players in the field. This article delves into the technical intricacies of three cutting-edge products — Everest ICE BANK, RED System, and Falling Film Chillers — each designed to meet specific industrial needs while promoting sustainability.

Everest ICE BANK: Chilling water with precision

The Everest ICE BANK by FIC is a gamechanger for those seeking precise chilled water production at +1°C through ice accumulation. This system shines when daily chilled water usage is limited or when a burst of heavy usage is required over a short period. The ice banks consist of an insulated tank with serpentines pipes heat-exchanger,

available in galvanized or stainless steel. The tank, filled with water, is cooled down to the freezing point using refrigerants like freon, glycol, CO2 or ammonia. Ice sleeves grow on the serpentines, reaching a set thickness controlled by special controllers. When the stored cold is needed, water flows into the tank, cooling down to the equilibrium temperature (+1°C) before being sent to users. The melting efficiency is enhanced by a unique air agitation system, ensuring rapid and controlled melting. The insulation minimizes thermal dispersions, and the system can be supplied with or without a refrigeration unit, with an accumulation capacity ranging from 38,000 kCal to over 2,000,000 kCal.

RED System: Continuous chilled water production

When continuous chilled water production is required for more than 10-12 hours a day, the RED System by FIC S.p.A. steps in as a robust solution. This insulated tank,

available in galvanized or stainless steel, houses a heat exchanger with Pillow Plates, ensuring efficient heat transfer. The cooling medium (freon, glycol, ammonia, CO2) flows through the plates, cooling the water inside the tank continuously. An air agitation system optimizes heat transfer, making RED an open system, eliminating risks associated with ice formation.

FIC SPA offers two versions of RED: RED Compact, entirely in stainless steel, and RED Blu, with a remote cooling unit and a tank available in stainless or galvanized steel. The open system facilitates easy cleaning procedures, and both versions provide costeffective and space-saving solutions.

Falling film chillers: Precision Cooling with Flexibility

The Falling Film Water Chiller by FIC offers a unique approach to water cooling, efficiently reaching temperatures as low as +0.5/+1°C. Constructed with materials like Aisi 304, Aisi 316, or SMO, these chillers utilize Pillow Plate batteries manufactured by FIC through

Everest ice sleeves

Everest ice sleeves

24 EASTERN EUROPE EDITION FOOD INDUSTRY

Falling film for hydrocooling

Fic Spa

Tel. +39 0343 410 51

www.fic.com

automated laser welding. The design ensures optimum refrigerant distribution and homogeneous cooling.

Operating as an open system, Falling Film allows easy cleaning and inspection. With low refrigerant content leading to low Global Warming Potential (GWP), these chillers are tailored to meet diverse customer and industry needs. The compact design is crucial for industrial refrigeration engineers working on plant replacements or expansions.

Falling Film excels in a range of capacities, from 50/60 kW for smaller applications to 1,000 kW or more for industrial setups. Larger projects can utilize multiple modules, customizing the cooling capacity to match specific configurations.

Compatibility with new refrigerants:

Embracing sustainability

All three ICE WATER solutions from FIC are designed to operate seamlessly with a variety of refrigerants, including HFC refrigerants, HCFC refrigerants, refrigerant blends, as well as brine. Falling Film, in particular, showcases its adaptability by operating with gravity systems, pump systems, or dx-expansion. Additionally, these systems are available for use with green refrigerants, such as R717 and R744, aligning with the global push for more sustainable industrial practices.

In conclusion, ICE WATER solutions are at the forefront of the cool revolution, providing efficient and sustainable alternatives for chilled water production. Whether through precise ice accumulation, continuous production, or falling film technology, these systems cater to diverse industrial needs while embracing the compatibility of new and environmentally friendly refrigerants. As industries continue to evolve, ICE WATER stands as a beacon of innovation, ensuring a cool and sustainable future.

Via Trivulzia, 54 23020 Mese (Sondrio) Italy

fic@fic.com

Evaporator - Hydraulic test

Evaporator - Hydraulic test

EASTERN EUROPE EDITION 25 FOOD INDUSTRY Fic Spa

Redcompact

Gruppo Fabbri Vignola Spa

Via per Sassuolo, 1863

41058 Vignola (Modena) Italy

Tel. +39 059 768 411

Fax +39 059 762 864

info@gruppofabbri.com

www.gruppofabbri.com

Over 70 years of active market experience make Fabbri Group a renowned leader in the manufacture and sale of machines and films for fresh and ultra-fresh food packaging (typically red meat, poultry, fish, cheese, fruit, vegetables, sauces, ready meals, sweets…).

Thanks to over 35,000 machines installed globally and thousands of tons of film produced per year, Fabbri Group advises and supports more than 2,500+ companies worldwide, and preserves the freshness of billions of packs commercialized every year on the total market.

Fabbri Group’s winning strategy comes from a combined supply of machines and films, completed by an extensive network of experienced, qualified, multilingual technical teams

The wide Fabbri portfolio includes automatic stretch wrappers, automatic, semiautomatic and manual tray-sealers, traditional, biobased and compostable stretch or lid films, which can be neutral and/or printed according to the different applications.

All Fabbri solutions can be used as standalone, in combination with all most popular packaging equipment on the market, or as a whole composite packaging system

Fabbri Group caters for everyone (retail, industry, brand-owners, and big to small food processors), covering with care all food markets: main objectives for Fabbri’s R&D Dept. are offering safe and effective solutions at improved sustainability and performance, as proven by the more than 130 active patents related to both machines and films projects.

Environment, we care!

Fabbri Group’s attention has always revolved around the concept of sustainability: since the beginning, the Company’s mission has always been “preserving without waste”.

Fabbri focuses on preserving food products and extending their shelf-life thanks to the most appropriate and environmentally sustainable packaging solutions. Related to films in particular, Fabbri Group recognises and protects the value of resources by developing different food packaging solutions in all the most required materials by the different markets worldwide, all of them in their most sustainable form and optimised thickness

Performance products for every need

• Elixa: This range of stretch wrappers is ideal for retail and small packaging centers (work rate from 14 to 35 ppm)

• Automac: These high-productivity stretch wrappers answer all most stringent needs from the food industry (work rate from 40 to 90 ppm) The Elixa and Automac equipment can be both optimally integrated with all major weigh-pack-label solutions available on the market. The new models Elixa SPE 21 and Elixa SPC 21 are the most recent example

coming from the newly-signed partnership with Bizerba.

• Stretch and lid films in different formulations, layouts (plain or printed) and materials (traditional, biobased, compostable) according to the various applications.

• Automatic tray-sealers for the food industry and retail. These machines can be adapted into complete customised lines for packaging solid, liquid and semi-liquid products, such as pasta, ready meals, hamburgers, fruit and vegetables, dairy products, olives, pickled vegetables, sauces, pizzas, desserts, candies...

Some new features of Fabbri’s offer:

• Fabbri Hybrid: All Fabbri Elixa and Automac stretch wrappers are now designed to handle any kind of packaging materials (traditional, biobased, compostable), being ideal for multiple productions or for a gradual transition to sustainable packaging.

• Nature Fresh and Nature Lid: The innovative stretch and lid films with compostability certifications according to EN 13432 European standard. In its “cutterbox” version for manual packaging, Nature Fresh is particularly appreciated by the Ho.Re.Ca. sector.

European-based Italian excellence requested worldwide

• 1 head office located in Vignola (Modena, Italy)

• 4 machine or film production plants (3 in Italy, 1 in Switzerland)

• 4 Italian seats and 5 foreign subsidiaries in the European continent for commercial and technical assistance

• Active in around 90 countries worldwide

• A hundred dealer companies and authorised service centres

Voluntary System Certifications: Quality, Environment, Health & Safety Companies within Fabbri Group also boast the following certifications:

• ISO 9001:2015 - Quality Management System (Gruppo Fabbri Vignola S.p.A., Gruppo Fabbri Svizzera S.A., Fabbri Group France S.A.S.)

• ISO 14001:2015 - Environmental Management System (Gruppo Fabbri Vignola S.p.A., Gruppo Fabbri Svizzera S.A.)

• EMAS Regulation EU no. 2018/2026 (Gruppo Fabbri Vignola S.p.A.)

• ISO 45001:2018 - Occupational Health and Safety Management System (Gruppo Fabbri Vignola S.p.A.)

For more information and offers:

• Info: www.gruppofabbri.com

• Offers: sales@gruppofabbri.com

• LinkedIn:

https://it.linkedin.com/company/fabbrigroup

• YouTube:

https://www.youtube.com/@Fabbri-Group

TrioPlus

Automac Industrial

Nature Fresh certified compostable cling film

TrioPlus

Automac Industrial

Nature Fresh certified compostable cling film

26 EASTERN EUROPE EDITION FOOD INDUSTRY

Gruppo Fabbri Vignola Spa

Inox Meccanica Spa

Strada Solarolo, 20/B-C-D

46044 Solarolo di Goito (Mantova) Italy

Tel. +39 0376 60 82 82

Fax. +39 0376 60 81 80 info@inoxmeccanica.it www.inoxmeccanica.com

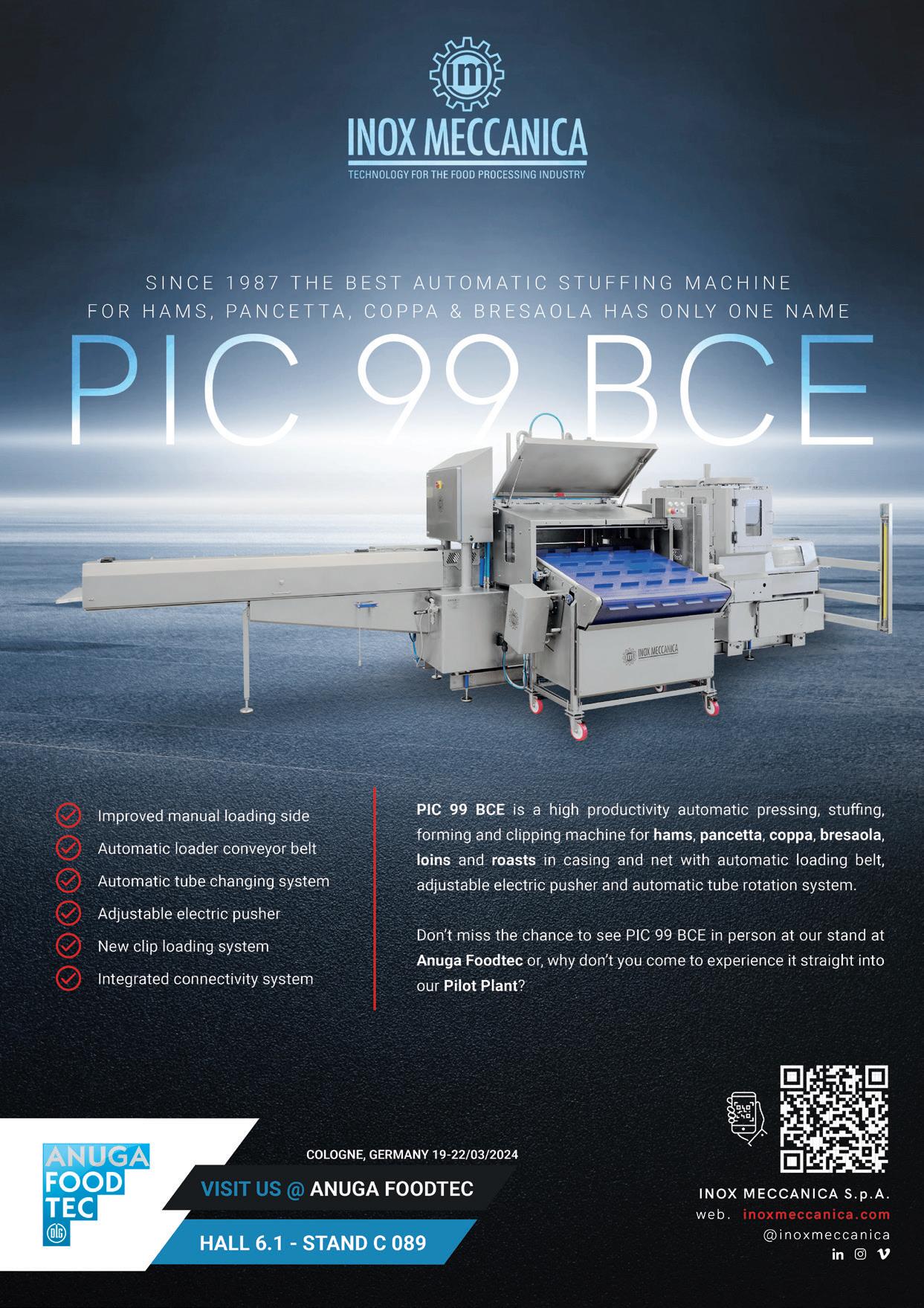

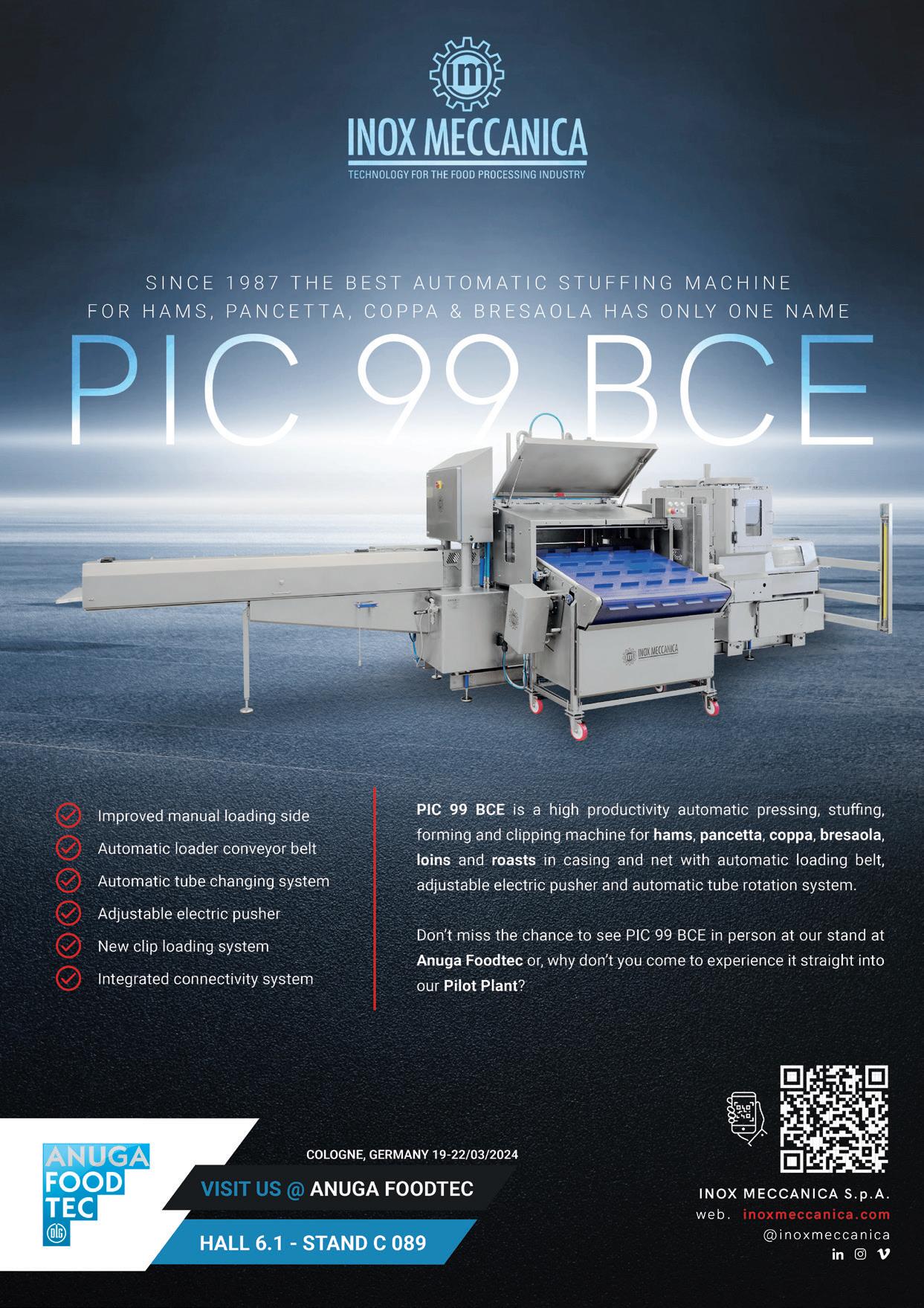

Inox Meccanica back to Anuga FoodTec

Since 1983, Inox Meccanica has been one of the world’s most important players in designing and manufacturing machines for automation in the processing and packaging of meat and cured meat products, as well as equipment for washing and sanitising equipment and foodstuffs produced, responding to the diverse and specific customer requirements.

This past year has been very meaningful for Inox Meccanica: Besides celebrating 40 years in business, Inox Meccanica changed its company name, turning into an S.p.A., which gave a strong and important message to the market as well as confirming how reliable and constantly growing the company

is. As an illustration of this, in 2023’s first months, Inox Meccanica opened a new sales company in Chicago (USA) to be even more present and efficient in a very important market such as the U.S. market.

Renewal is certainly the term that best describes what Inox Meccanica has always been. A company capable of constant renewal and innovation to provide customers with ever new technological solutions. Only a few years later, Inox Meccanica returns to Anuga FoodTec with high expectations and a lot of enthusiasm because Cologne is one of the most significant venues of the year.

Hall 6, Stand C 089: gateways to a mustsee. Along with an advanced PIC 99 BCE, which is displayed equipped with an automatic loading belt, an automatic tubechanging system, an 1100 mould as well as the adjustable stroke electric pusher you will come across Tumbler 4000 BT-S set up with a special smoking dedicated generator.

To achieve smoking, Inox Meccanica R&D department improved a process that relies on a friction generator, which by producing low temperature smoke duly alternated with vacuum phases, impregnates the product with greater speed. This combination is programmable and repeatable until the desired degree of smoking is achieved. Rounding out the picture will be Inox Meccanica now-famous TM 200 V inclined belt tying machine ideal for tying very different products from roasts to salmon slices and its legendary P600 semiautomatic bagging machine often used in small and medium production of pork belly, coppa, bresaola, hams, loins and roasts.

Inox Meccanica, though, is not just food processing but also washing and sanitation; therefore, there has been a focus on designing the best solutions to sanitize all those tools used in production processes. These are machines and systems with a strong transversality of use, just think of the meat, dairy, pet-food, pharmaceutical and cosmetic sectors.

The wagon washing machine, which will complete the exhibit, is one of many examples of how the company has actualized its commitment to research and development of new technologies for sanitizing and washing. Inox Meccanica team has evolved the previous model of wagon washer by equipping the washing cabin with two doors: one is used for the entrance of the container by an automated system with forks, and another frontal door from which the container is extracted clean and disinfected, again by automation.

Make sure you won’t miss the chance to experience Inox Meccanica’s multiversebranded innovative exhibition in Cologne; Inox Meccanica personally invites you to a show you cannot miss. Stay up-to-date!

28 EASTERN EUROPE EDITION FOOD INDUSTRY

Via Braglio, 68

36015 Schio (Vicenza) Italy

Tel. +39 0445 31 42 36

Fax +39 0445 31 42 37

info@italpan.com www.italpan.com

The success of Italpan is based on its attention to its clients’ needs and its ability to transform them into advanced technical solutions, as well as its great flexibility of operation. Growth has been constant since the company was founded in 1977, and the range of products it now offers on the market is further proof of its dynamism: machines for bread sticks and taralli, taralli boilers, loaf moulders and rollers, dough sheeters, bread cutters, flour sifters, crumbers and fully automatic lines for the production of bread sticks.

The Automatic Grissini Machine MOD. GR/25-A is a mass-supplied with adjustable press so as to make even the thickness of dough when entering in the die. The cut of dough can be carried out by manual electric control or through programming by timer for

continuous duty. All surfaces in touch with dough are in Stainless Steel. Output can achieve 50 kg per hour.

The Automatic Grissini Machine MOD. GR/25-L is a mass-supplied with adjustable press so as to make even the thickness of dough when entering in the die. The cut dough can be carried out by manual or electric control or through programming by timer for continuous duty. All surfaces in touch with the dough are in Stainless Steel, Teflon or treated through “Nihar Process” (American patent replacing the chromothickness). Output can achieve 50 kg/h.

Dies are easily interchangeable with the intervention of two knobs. The speed of the exit belt is adjustable to be adapted to every type of product in order to avoid stretching or accumulation of the dough. The assembling system on the trolley has been studied to take a minimum amount of space in a rest position.

The Sheeter Moulder I.T.P. 500/600Painted steel sheet bedplate, mounted on castors. Anodized aluminium sides. Ball bearings with double seal on all rotating parts. Ground and thickness chrome-plated steel rollers. A simple device stops the upper belt and the machine becomes a roll unit for the upper belt and the machine becomes a roll unit for the rolling of small quantities of dough. The machine is supplied with infeed belt for the automatic feed of the dough into the rollers.

30 EASTERN EUROPE EDITION FOOD INDUSTRY

Italpan

Landucci Srl

Via Landucci, 1

51100 Pistoia, Italy

Tel. +39 0573 53 25 46

Fax +39 0573 53 30 67

landucci@landucci.it www.landucci.it

Landucci: A reliable partner worldwide Landucci is known worldwide for the high quality of its dies and the technology and reliability of its pasta forming machines. However, in its operating model, this is only the starting point. The relationship that Landucci establishes with its customers includes impeccable after-sales and service. In fact, considering that pasta production represents a delicate balance between traditional processing methods and the need to maintain consistent production volumes, in a competitive industry landscape, technical assistance plays a crucial role in ensuring operational continuity and product quality.

Landucci is committed to always being at your side, wherever you are, offering a high-level service guaranteed by specialized and qualified personnel.

Continuous staff training

Landucci’s dedicated service personnel are constantly trained and updated on the latest technologies and methodologies used in the pasta industry. This commitment allows them to offer the highest level of technical assistance, ensuring quick diagnosis and timely solution to problems. Landucci’s goal is to minimize downtime, helping to keep your production at peak performance.

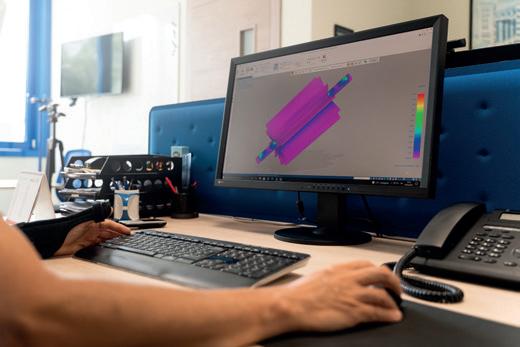

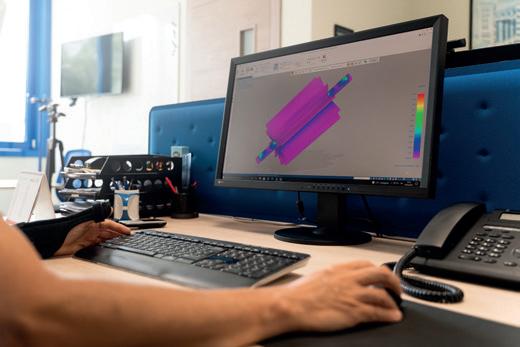

State-of-the-art technology

Landucci is constantly investing in technology, equipping its technicians with state-of-the-art instrumentation to make their work more precise and efficient. Experience is thus combined with technology, sensitivity and intuition to measurement; assistance is thus always a perfect combination of people and tools.

Upgrades and improvements

In addition to traditional assistance, Landucci also offers upgrade services to improve the performance of already installed machines. Landucci is able to optimize its machines in your pasta factory through software or hardware updates. The structured customer care office is always at your disposal to coordinate these interventions and schedule preventive maintenance visits.

A global presence

Landucci is proud to be a strategic partner of prestigious pasta factories around the world, and its presence and assistance are guaranteed in a timely and highly professional manner wherever you are. Its ability to intervene globally is one of the elements that distinguish it and make it a valuable ally in the pasta supply chain. In any country you operate, you can count on Landucci to meet all your needs.

Zamboni brand assistance

Landucci, with the recent acquisition of Zamboni, a leader in machines for the production of pasta Bologna, is now able to offer a

complete and qualified assistance service for every Zamboni machine in the world. In fact, it is guaranteed the same know-how and the same intervention capacity that is offered for the Landucci brand on these machines, providing support to all pasta factories that have owned this prestigious brand for a long time.

At Landucci, the staff takes after-sales and assistance very seriously. Landucci’s customers know that they have a constant and qualified presence at their side wherever they are. For Landucci, the sale is the beginning of a relationship of trust.

At Landucci, they are happy that customers feel close to them, always, wherever they operate in the world.

32 EASTERN EUROPE EDITION FOOD INDUSTRY

Live-tech Srl

Via Stazione, 65

12066 Monticello d’Alba (Cuneo) Italy

Tel. +39 0173 44 06 79

info@live-tech.com

live-tech.com

Livetech is an Italian company whose headquarters is located in Monticello D’Alba, between the hilly landscapes of Langhe and Roero, areas known all over the world for their products of excellence.

Livetech and its specialized divisions operate in complete synergy and are able to supply a wide range of products, from single machines to complete packaging systems and chocolate moulding lines.

Primary wrapping, secondary packaging, palletizing, chocolate moulding: Livetech offers cuttingedge solutions in each of these sectors. The products are oriented towards excellence, like those of its territory.

A customer’s unique product is the driving force for each project.

Thanks to close collaboration with its customers, Livetech can provide specific technical solutions focused on the fundamental aspects of marketing, cost optimization, process automation and sustainability. A fundamental added value that Livetech provides is the willingness to engineer customized solutions.

high performance and high customization, and E-Series, focused on simplicity, efficiency and energy savings. Livetech range includes multifunctional top loading systems, side loading systems, cases erectors, cases sealers, vertical formers, and much more: our solutions can handle any type of packaging. Among Livetech most popular

management, and primary packaging of several types of food products. Liveflow offers a wide range of products, ranging from horizontal flowpack packaging machines to X-fold systems, integrable with dedicated feeding systems.

Livepal offers palletizing systems, from simple systems with cartesian axes, to more complex systems equipped with industrial robots able to manage multi-channel lines. For instance, the palletizing unit LPA is a simple and compact cell capable of handling boxes coming from a single line, that can match any kind of layout and it can be equipped, accordingly to the requests, with a wide range of accessories.

Livetech’s traditional field of activity, namely automatic secondary packaging systems, now includes an expanded range of products. Robotic secondary packaging lines, in two versions: X-Series, focused on

solutions are the LWA-TH case packer, which can make wraparound and tray + hood boxes, and the new concept multifunctional systems based on the use of independent shuttles able to optimize forming, filling and closing of cases and boxes of various types in a compact design. The company also provides stand-alone machines dedicated to specific functions, which can be integrated into existing manual systems to introduce automation elements.

In the field of primary packaging, Liveflow is specialized in the design and production of automatic systems for the handling,

Livemould is the division of Livetech specialized in the design and production of machines, plants and equipment dedicated to the world of chocolate moulding Livemould also can offer a wide range of solutions. Complete lines to produce coupled subjects such as eggs, spheres, various figures. Lines for the production of semi-finished products such as drops and strips of chocolate. “One shot depositors”. Moulding systems for hollow figures, solid tablets, and chocolate bars. Consultancy is for Livetech a strategic element for the development of successful projects. Its specialists are involved in the creation of new blanks and the modification of existing ones in order to meet the needs of each customer. The direct interface of Livetech specialists with papermaking companies allows the formulation of the most suitable solution in a very short time. Livetech technological specialists, relying on their experience in moulding products and the related production processes, analyse and compare the latest technologies to help improving the quality of the processes and productivity of the systems.

Discover Livetech world at live-tech.com

34 EASTERN EUROPE EDITION FOOD INDUSTRY

M.H. Material Handling Spa

Via G. di Vittorio, 3

20826 Misinto (Monza Brianza) Italy

Tel.+39 02 96720176

Fax: +39 02 96720215

info@mhmaterialhandling.com www.mhmaterialhandling.com

High efficiency in a packaging line is the primary objective of any project manager, when he begins the design phase. In the present days, packaging machines have reached performance levels that were unthinkable just a few years back, but as much as a single machine can be efficient, the overall result when you put all the pieces together can be extremely different. The first result of a Google search with the keywords “Buffering System” is a Wikipedia page on the pH balancing system of the blood that is needed by the human body to maintain the proper functioning of the metabolism. A packaging line behaves in a very similar way, the different machines need to be connected to each other by an efficient circulatory system and that is able to balance the operating differences that may exist between them. Conveyors represent this circulatory system and are too often underestimated in the design phase with dramatic results on the final efficiency of the line.

Buffering systems, ensure that the packaging line operates smoothly and efficiently. They are able to compensate for any variations in the speed or performance of individual machines, preventing bottlenecks and ensuring that the entire line operates at maximum capacity. Some kind of buffering systems should always be present in the packaging line, as they can have a significant impact on the final throughput of the line. Providing consultancy in the identification of the correct solution and subsequently supplying the machines to the customer is exactly the core business of M.H. Material Handling SpA, an Italian company that has been operating in this market for almost forty years now, being founded in 1986.

There are a number of different buffering solutions available to cover any possible requirements, far from being a complete list we can point out the LIFO spiral systems Heliflex, that finds its sweet spot for long buffering requirements of thin products and the BAT-Buffer, a modular system that allow great flexibility to fit any kind of product. For naked products handling M.H. has a FIFO solution for the confectionery industry: The 5L multilayer belt, specifically designed for placement upstream rank distribution lines. Even if buffering systems are the easiest way to increase line efficiency, they are not the only important node: mergers, dividers, elevators and products manipulation systems are also part of the mix that allow to walk the path towards maximum productivity. M.H. has expertise in each of these devices, as well as the engineering capabilities to put them together in a layout that is fit every time to the customer’s needs. These last devices cover many needs in the line design: Some are mandatory features because there’s the need to connect different numbers of machines along the process, others are useful to optimize the use of floor space available in

the plant. Often the focus on efficiency is so high that brings to neglecting other aspects, like the ergonomics of the line, accessibility of machines for the operators, passages and storage areas for packaging materials and other utilities.

Balancing productivity, line ergonomics and return on investment is M.H. Material Handling’s mission.

M.H. operates in Easter Europe with the support of POLO-AG, for further contact you can reach them directly through website www.mhmaterialhandling.com or search for the responsible for machinery division in your country on Polo’s website contact page www.polo-ag.com/contact

38 EASTERN EUROPE EDITION FOOD INDUSTRY

Via Galliera, 62

40050 Funo di Argelato (Bologna) Italy

Tel. +39 051 46 83 268 info@mc2-srl.com www.mc2-srl.com

MC²: The ultimate solution to all industrial mixing needs

MC² produces top-quality industrial mixers with passion, care for detail and competence, for countless applications in virtually all industrial sectors, thanks to our extensive experience.

Whether you are dealing with dry materials only or in combination with liquids, whether your ingredients are fine and dusty or granular and irregular, abrasive, fragile, hazardous or inert...

Whether you handle food ingredients, or chemicals, plastics or industrial and municipal sludge, animal feed or building materials for the construction industry, pharmaceutical APIs or soils from quarries and mines...

Whether you are dealing with simple recipes or super-complex ones, whether it is straight-forward mixing or sophisticated processing (drying, cooling, granulating, reacting), whether you need to process small quantities or manage extra-large capacities... At MC² you will always be met with professionalism, competence and attention: but, above all, you will find the solution to your needs, developed together with you and for your specific situation.

40 EASTERN EUROPE EDITION FOOD INDUSTRY MC2 Srl

Millennium Engineering Srl

Via Martin Luther King, 12

35010 - Curtarolo (Padova) Italy

Tel. +39 049 96 24 258

Fax +39 049 96 23 823

info@me-foodsolutions.com

www.me-foodsolutions.com

ME FOOD SOLUTIONS: Scaling new heights and reaching unparalleled milestones

Millennium Engineering S.r.l. was established in 1996 and promptly gained recognition for its expertise in stainless steel processing, primarily focusing on AISI 304 steel. The company’s exceptional precision in metal sheet and tube laser cutting, punching, welding, and bending has been pivotal in forging significant partnerships for the manufacturing of food machinery. Their cutting-edge systems cater to various stages of food processing, including deepfreezing, cooling, leavening, pasteurizing, and conveying. With over 25 years of extensive research and development, ME Food Solutions has proven itself to be an innovative and dependable company. Additionally, its global distribution network, adept at facilitating the parent company’s ventures in the international market, attests to the company’s esteemed reputation.

ME is glad to offer customers the most suitable solutions for the entire factory line, starting from components preparation and finishing with packing and storage. A wide range of solutions for freezing, cooling, leavening, pasteurizing and conveying are available. All systems are designed with the aim to provide customers the best solution improving their business in terms

of quality, safety and hygiene. Every system is projected considering mechanical and thermodynamical aspect and considering the special features of the processed food. ME Food Solutions stands as a beacon of Italian precision, European technology, and global expertise. With 12 offices and 2 production plants strategically positioned to serve a worldwide clientele, the company’s reach is as expansive as the Italian vistas, reflecting their commitment to bringing their unparalleled food industry equipment and conveyor belts to every corner of the globe. Throughout their journey, ME Food Solutions has built 50 production lines and provided 50 turnkey solutions, distinguishing themselves as pioneers in the industry. Their unwavering dedication to excellence and attention to detail has propelled them to produce over 10 kilometers of conveyor belts in 2023 alone, setting new benchmarks for the industry. The remarkable accolade of creating a conveyor belt spanning 1.7 kilometers in length and 1.4 meters in width exemplifies their exceptional capabilities, marking them as industry front-runners in delivering comprehensive solutions to their clientele. This conveyor

spiral can operate in the temperature range from -40° to +140°.

Moreover, ME Food Solutions has continued to pioneer innovations in sustainability, leading the charge with their No CFC project. This groundbreaking initiative introduces green solutions by utilizing CO2 in freezing systems instead of the more environmentally harmful and non-green freon, underscoring the company’s commitment to eco-conscious practices and technological advancement. Their forward-thinking approach not only revolutionizes the industry but also sets a new standard for environmentally responsible production, emphasizing the fusion of Italian precision and European technology with global sustainability.

ME Food Solutions prides itself on its individualized approach to each client, recognizing that every food production operation has unique requirements. The company offers tailored temperature solutions to cater to different types of food products, ensuring optimal preservation and quality at every stage. With the capacity to create projects of any size, ME Food Solutions boasts the adaptability to meet the

42 EASTERN EUROPE EDITION FOOD INDUSTRY

diverse needs of their clientele, regardless of floor area. Their maximum production volume of 5 tons per hour stands as a testament to their commitment to efficiency and reliability, showcasing their ability to handle large-scale operations with ease. With their unwavering dedication and extensive expertise, ME Food Solutions takes on every challenge with confidence and aplomb, firmly believing that there are no impossible tasks for this visionary company.

Low and high capacity, automated and manually operated, medium and premium category, standard and customized designed: all these options are open to discuss with ME Food Solutions.

ME Food Solutions world-spanning experience extends further with successful project implementations on 4 continents, spanning more than 28 countries. This global footprint underscores their ability to adapt and cater to the diverse needs of the food industry across varied cultural and technological landscapes, solidifying their reputation as a leading provider of innovative solutions on a global scale.

With these extraordinary accomplishments, ME Food Solutions has proven that their expertise extends far beyond Italian borders, culminating in a truly global legacy. Their continued commitment to innovation, precision, and sustainability cements

Millennium Engineering Srl

their position as pioneers in the industry, embodying the ethos of Italian craftsmanship and European engineering on a global platform. ME Food Solutions is not just a company; it is a testament to the resounding success that arises from combining creative potential, European technology, and worldclass experience in the food industry. Looking ahead to the future, 2024 holds the promise of even greater achievements for ME Food Solutions. With a track record of groundbreaking innovations and a commitment to excellence, the company is poised to embark on another year of impactful advancements. As they continue to push boundaries and set new industry standards, 2024 is anticipated to be a year of unparalleled success, growth, and continued advancement in the global food industry. ME Food Solutions is primed to build upon their exceptional legacy and usher in a new era of innovation, sustainability, and global impact.

Via Martin Luther King, 12 35010 - Curtarolo (Padova) Italy Tel. +39 049 96 24 258 Fax +39 049 96 23 823 info@me-foodsolutions.com www.me-foodsolutions.com

EASTERN EUROPE EDITION 43 FOOD INDUSTRY

VIMCO’S PORTFOLIO

Level

Street E, Stand 225

Gran Via, Hall 3,

0,

Via Massarotti, 76

26100 Cremona - Italy

Tel. +39 0372 40 11

Fax +39 0372 41 26 92

info@ocrim.com www.ocrim.com

The company OCRIM, headquartered in Cremona, is globally renowned as a reliable partner for the construction and supply of milling, feed, and cereal processing plants, as well as end-of-line plants. Its commitment in research, customer care, training and communication has always been an incentive for innovative and productive teamwork.

In the city of Cremona, OCRIM boasts two sites: The original headquarters in Via Massarotti, which houses offices and parts of its production factories, and the premises at the canal port for some important production and logistics departments, and also for the Milling Hub created jointly with Bonifiche Ferraresi, is meant to strengthen Italian agrofood supply chain by offering food industries without milling plant the chance of using a customized plant, as well as the technical and technological knowledge of OCRIM team. Turnkey projects are one of OCRIM’s strong points, supplied in tailor-made solutions, increasingly welcomed by international customers who decide to rely on a single partner who can guarantee a high professional level and respect programmed time. OCRIM is an irreplaceable partner also

for the supply of machines only, and in milling plant upgrade/modernization.

The FBC department designs and manufactures end-of-line plants for palletization and packaging of bags and other packing, supplied turnkey and personalized upon customer’s requirements. Today, it is fully integrated in OCRIM and further piece to complete the industrial chain, which means internalizing all processes, thus guaranteeing a traced, controlled, and certified Italian Made product.

OCRIM’s versatility and seriousness have been further highlighted at the end of 2023, thanks to the acquisition of the company SIMA of Treviso, specializing in storage system design and construction for more than thirtyfive years. All that grounds on shared values, such as honesty, reliability, team feeling and availability, and above all, attention to Human Capital.

reduction of operating and maintenance costs down to the minimum.

In fact, as for strategies and management related to maintenance and improvement of technological results, OCRIM has introduced the Modular Mill Concept, an innovative technology that enables stopping some parts of the grinding section, for any reason (ordinary and extraordinary maintenance, or else), while letting another run, thus granting uninterrupted specific production. This solution is chosen and highly appreciated by many customers thanks to the benefits it generates.

OCRIM has always been an attentive and well-prepared supplier of storage plants, and this partnership adds further and crucial element not only to “The Italian Agri-Food Chain Choice”, of which OCRIM is one of the main players, but also to the increasingly complete production chain.

OCRIM’s reliability is also evidenced by an important agreement reached with Italian company Molitecnica Srl, to build nixtamalized flour plants for tortilla, snacks and chips production. These products are mainly part of Central and Southern America’s food culture, but also highly appreciated and consumed all over the world. OCRIM will supply its process machines for these plants, thus guaranteeing high performance in line with the targets set. With the goal of supplying long-lasting milling plants and efficient high-quality services, OCRIM proposes increasingly innovative solutions in terms of sanitation, reduction of energy consumption, maximization of technological results of the plants, and

As far as automation is concerned, OCRIM plays the role of direct reference, thus avoiding external bodies for the study and implementation of plant management systems.

The general automation package @mill, which includes many application packets, the innovative @rollermills, which enables controlling the mills remotely via tablet, and the Immersive Reality are futuristic solutions created to improve and simplify the work activities of those in the milling sector.

In addition, OCRIM also offers its customers comprehensive support with its innovative Service, and its customers can be granted specialised after-sales technical support in real time, and can easily and quickly require their own. This state-of-the-art approach to customer service sets this company apart in the milling industry, offering timely and customised solutions for every need.

OCRIM also excels in terms of training and higher education, in fact, thanks to the extensive

Cremona – OITheatre on OCRIM historical premises

Cremona – OCRIM historical premises

Cremona – OIMuseum at OCRIM historical premises

Cremona – OITheatre on OCRIM historical premises

Cremona – OCRIM historical premises

Cremona – OIMuseum at OCRIM historical premises

48 EASTERN EUROPE EDITION FOOD INDUSTRY

Cremona – roller mills assembly on OCRIM historical premises

Ocrim Spa

training experience of OCRIM International School of Milling Technology, active since 1965, and in line with the Milling Hub initiative, the Milling Hub Masterclass training hub has been established. This hub enriches the training with an innovative perspective. Access to the Masterclass is reserved to previously trained technicians only, with proven expertise, as to guarantee a high-degree training. 360° advanced training focusing on the knowledge of seeds, through cereal and pulses processing, to finished product sales.

On account of this corporate positive development, OCRIM’s R&D department is committed to experimenting new strategies and state-of-the-art projects can be broadly acknowledged as unique in the milling sector and in full harmony with the innovation the company has been experiencing. The partnership between OCRIM and some prestigious Italian universities is further strengthened, broadly contributing to get valuable results for the milling sector in general. OCRIM’s communication instruments mean to finetune the corporate language to the new trends.

The company boasts considerable visibility through both national and international sector publications, via its LinkedIn and Instagram

profiles, and three Internet websites: the corporate website www.ocrim.com, one dedicated to the company’s museum www. ocrimcore.com, one dedicated to the blog www.ai-lati.com, strongly wanted by OCRIM as a real information provider for the entire The Italian Agri-Food Chain Choice chain, and therefore for its member companies. In 2020, the company’s media department was greatly and successfully developed with the start of highly technical-scientifical Webinars into the milling world. Yet, the real novelty arrived at the end of 2022 with the new format O-News Live, a TV news hosted by three OCRIM employees, whose stage is the new O-Theatre, a space that OCRIM strongly wanted for events like this, as well as for meetings with customers. In addition to this, OCRIM also continues offering its customers tailored solutions featuring customized machines, participates in events such as “Wheat, flour, and …”, and welcome its guests at hO (Home OCRIM) and Farmhouse, a farmstead typical of the Cremona area, renovated and inaugurated on occasion of the company’s event “Wheat, flour and …” 2022). Those are the events and projects created to provide a close-up view of a company that is continuously and constantly evolving.

Via Massarotti, 76 26100 Cremona - Italy Tel. +39 0372 40 11 Fax +39 0372 41 26 92 info@ocrim.com www.ocrim.com

Cremona – conference hall on OCRIM historical premises

Cremona historic city centre – HO, the house that OCRIM puts at its guests’ disposal

Cremona canal port – FBC department

Cremona canal port –OIFarmhouse, the farmstead renovated by OCRIM

Cremona canal port – Milling Hub

Cremona canal port – Milling Hub –roller mills floor

Cremona canal port - OCRIM logistics warehouse

EASTERN EUROPE EDITION 49 FOOD INDUSTRY Ocrim Spa

Cremona - a meeting room on OCRIM historical premises

Via Massarotti, 76

26100 Cremona - Italy

Tel. +39 0372 40 11

Fax +39 0372 41 26 92

info@ocrim.com www.ocrim.com

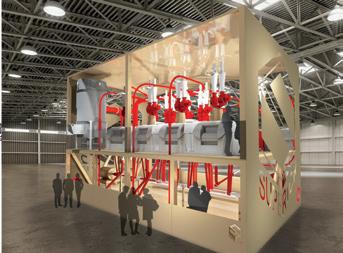

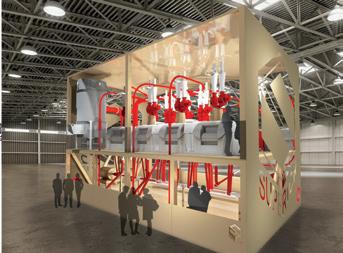

Superior – the compact mill by OCRIM

Superior is a compact mill representing a strategic and smart investment that offers safe and versatile productive solutions for an excellent final product. Pre-assembled at OCRIM warehouse, Superior reduces the costs of a dedicated multi-level building and

OBrochure dedicated to Superior

bureaucracy expense for urbanization works, and offers high energy performance for reduced production and management costs. Meant for customers with different entrepreneurial courses, Superior is suitable for people approaching the milling world for the first time as well as for those who want a compact plant to extend or diversify their

Superior 1948 Superior today

PARTS: Ocrim’s world is just a click away

OCRIM launched the innovative platform www.oparts-shop.com, an e-commerce portal with interactive catalogues where spare parts for milling plants can be bought.

The entire website has been designed with the customer in mind. The aim is to ensure the best user experience in terms of ease of navigation, speed, and intuitiveness.

The is available worldwide and allows customers to directly purchase milling products 24 hours a day via certified international payment circuits.

The portal is structured in two parts: a B2B e-commerce platform for the immediate and direct purchase of milling plant articles, and a customised section for loyal customers with interactive catalogues. In the latter area, the user’s machine catalogues are uploaded for browsing, with the relevant serial number, table, and bill of materials so that users can find and order both specific and custom-made spare parts. The reserved area has been specifically designed both for new and long-standing customers. The goal is optimising the flow of information and improving customer service when purchasing specific spare parts for OCRIM machines. Customers can browse the various catalogues in several ways, making the ordering process easier and quicker,

offer, without revolutionizing their industrial production.

Create in the 1950s, Superior is a stateof-the-art engineering icon that has highly contributed to OCRIM’s industrial development internationally.

The mill offers the possibility to personalize its technical, technological, and design equipment, with four different solutions available: Passion, Natural, Gold, and Style. Back to OCRIM home in a futuristic shape, from the technological and design points of view, Superior has generated great interest and significant demand, as to persuade OCRIM to create dedicated Internet website (www.ocrimsuperior.com) and e-mail address (info@ocrimsuperior.com) for information and request, accompanied by a as well as a brochure that fully conveys the elegance of this compact mill.

thus minimising the chance of error when searching for a specific component.

Thanks to this portal, with just a few clicks, the user can choose and order the spare parts he needs for his machine, by selecting them directly from the table and order, and also find dedicated promos in the “My Area” and keep track of requests and orders at all times.

For more information visit www.oparts-shop. com or e-mail to info@ocrim.com for more details and to receive a brochure about this service.

50 EASTERN EUROPE EDITION FOOD INDUSTRY Ocrim Spa

Olocco Srl

Via del Santuario, 41

12045 Fossano (Cuneo) Italy

Tel. +39 0172 69 25 79

Fax +39 0172 69 25 78

info@vdlolocco.com www.olocco.eu

Leader in the field of valves and components for pneumatic conveying and dosing of powder and granular products, Olocco has a strong market position in Europe, Asia, the Middle East, South and Central America.

Founded by Mario Olocco in 1970, in 2010 it was taken over by his sons Umberto and Andreana, and today it has 30 employees and a turnover of around 9 million euros in 2022.

A reality that becomes part of VDL Groep BV, a family-run group based in the Eindhoven Brainport region, the Netherlands.

Founded in 1953, since 2017 the third generation of the Van der Leegte family has been at the helm of the group with over 16,000 employees, operating in 19 countries, thanks to over 100 manufacturing operating companies in various fields of

specialization. In 2021, combined annual sales amounted to €4.995 billion. Umberto remains manager and managing director of the company which will be renamed VDL Olocco, which has become the 107th operating company of the group. Andreana will also remain active in the company as administrative manager.

The president and CEO of VDL Groep BV, Willem van der Leegte, says: “One of the ambitions is to further strengthen our position in the food industry. With Olocco we add specialist knowledge and skills, and high-quality machinery. The benefits of the synergy between VDL Industrial Products and Olocco will lead to a broader and more complete product package for customers around the world”.

“We have had a pleasant cooperation with VDL Groep BV for 30 years. It is great that they understand the ethics and dynamics of a family business, as well as the needs of the next generation. The diversity of sectors in which the various companies are active VDL will also offer many opportunities for our businesses. We look forward to further shaping and interacting with this newly initiated partnership,” said Umberto Olocco.

52 EASTERN EUROPE EDITION FOOD INDUSTRY

Via Brancaccio, 11

Via Brancaccio, 11