STOCEXPO PREVIEW

Get a glimpse of the exhibitors and speakers behind StocExpo 2024 and why it’s a must-attend event

THE TERMINAL OF THE FUTURE

Euro Tank Terminal explains how it has become a modern, future-thinking, multi-customer terminal

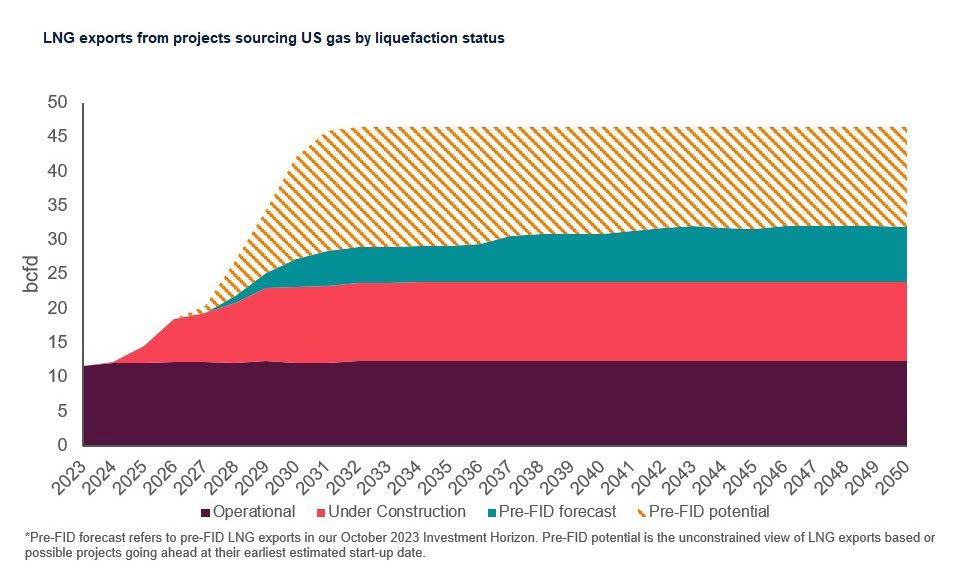

USA SPECIAL

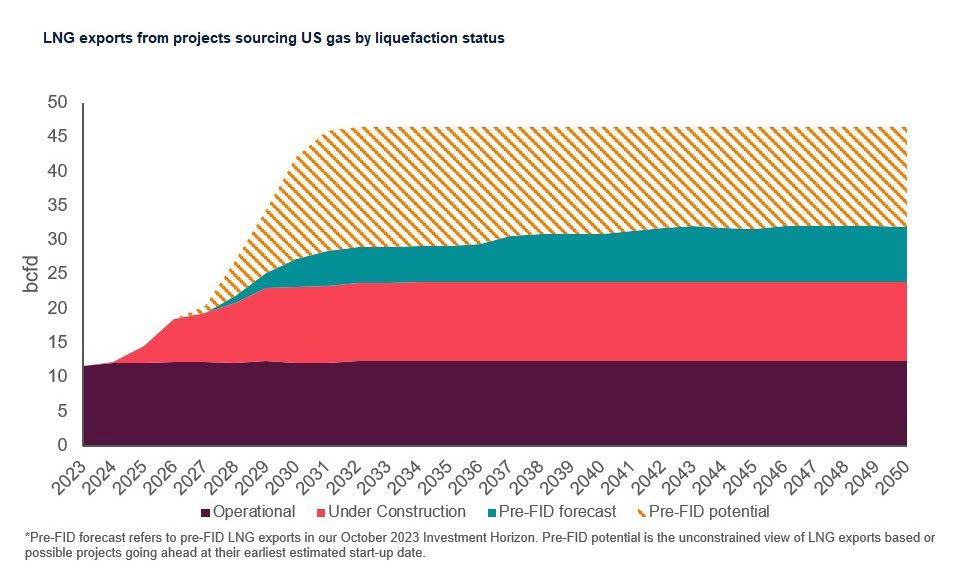

We delve into updates from US terminals, look at LNG exports and upcoming events

Spring 2024 | Volume 20 | Issue 01

Established 2005. Trusted. Valued. Influential.

• OIL & CHEMICAL TRANSFER HOSES • HOSES FOR LIQUEFIED GASES SUCH AS LPG, AMMONIA & LC02 • IN PLANT TRANSFER HOSE www.dantec.com +44 (0)151 678 2222 sales@dantec.com WORLD LEADER IN COMPOSITE HOSE TECHNOLOGY

UP FRONT

GLOBAL NEWS UPDATE

MARKET ANALYSIS

38 Reducing GHG emissions

Ravi Bhatani, executive director at FETSA shares the group’s response to the European Commission’s 2040 GHG reduction target

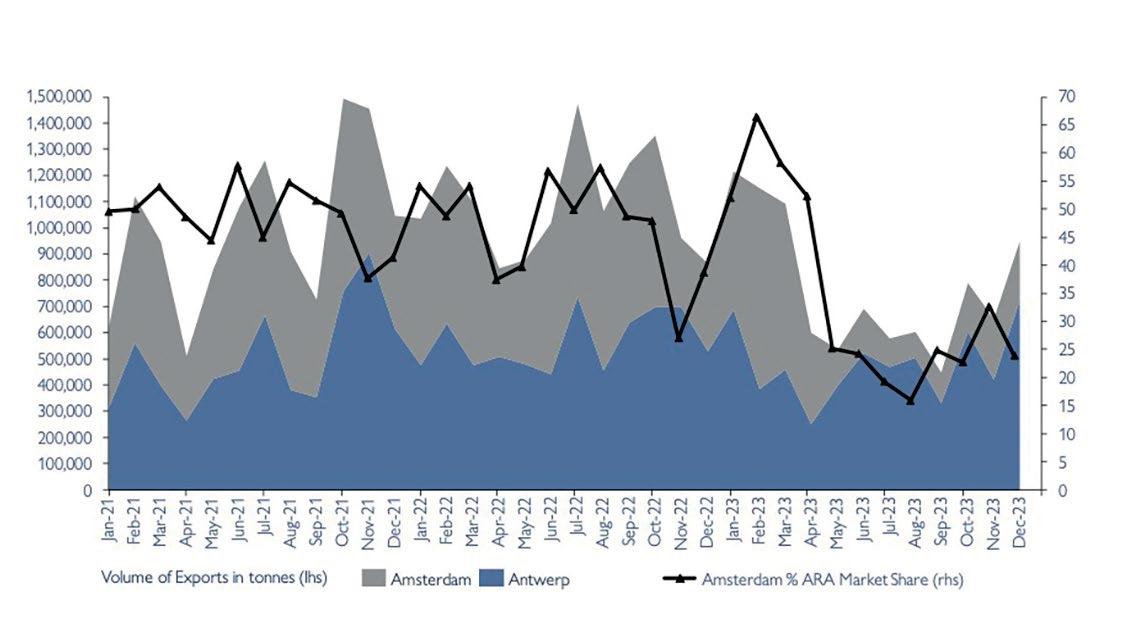

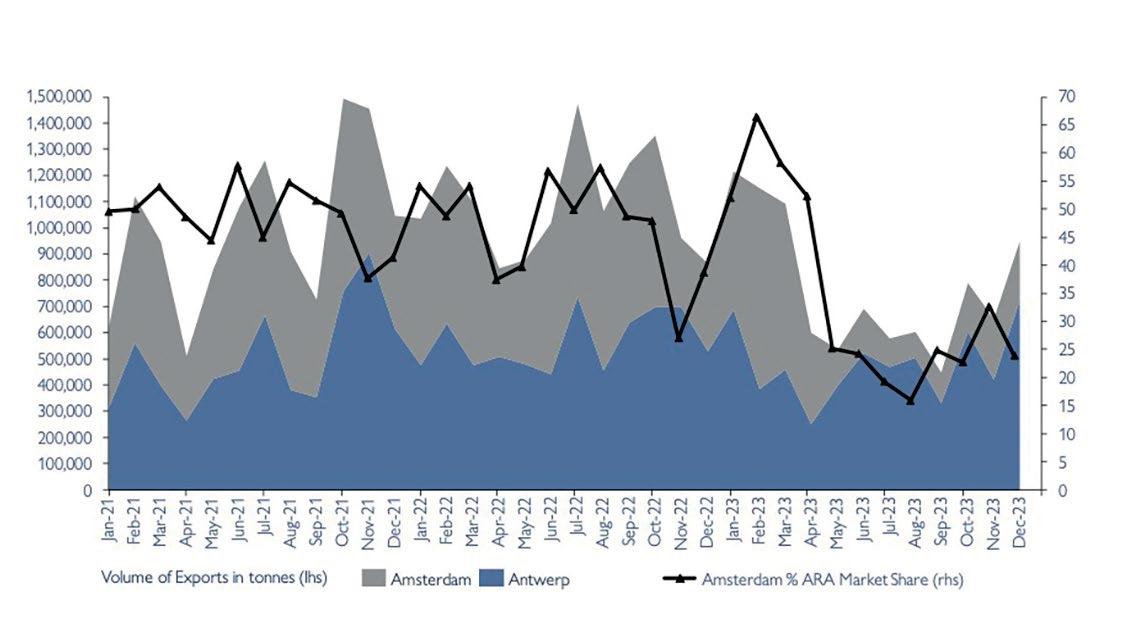

56 ARA gasoline blending terminals: Time for a strategic review

Jonathan Martland at Energex Partners explores the evolving role of the Amsterdam-Rotterdam-Antwerp (ARA) region

58 Safety best practices for terminal owners

Executive director of the Tank Storage Association, Peter Davidson, discusses the importance of good leadership in process safety

60 The path to carbon neutrality for terminal owners

EXCLUSIVE INTERVIEWS

34 A complete, multi-customer terminal

Tank Storage Magazine speaks with Frans Jan Hellenthal, commercial manager at VTTI, about Euro Tank

48

LBC Rotterdam’s terminal manager, Mathias Potvin, tells

54

Sandra

David Tassadough, infrastructure associate at GRESB, discusses how working parallel with current EU legislations will help companies reach net zero

64 Navigating the evolving landscape of fuels

Jonathan Feys, CCO of at Ghent Transport & Storage discusses the current crossroads of traditional and alternative fuels in transport

65 Becoming a future fuels hub

Tank Storage Magazine hears from Port Tarragona on how its energy transition strategy is working to decarbonise the port and turn it into a future fuels hub

66 The forgotten link in the energy transition

Rafael Rengifo and Iván Parra Tepedino from Becht explain the role the midstream sector plays in the energy transition

USA SPECIAL SUPPLEMENT INSIDE PAGE 112 CONTENTS Spring 2024 | Volume 20 | Issue 01

and its exclusive

at StocExpo

Terminal

tour

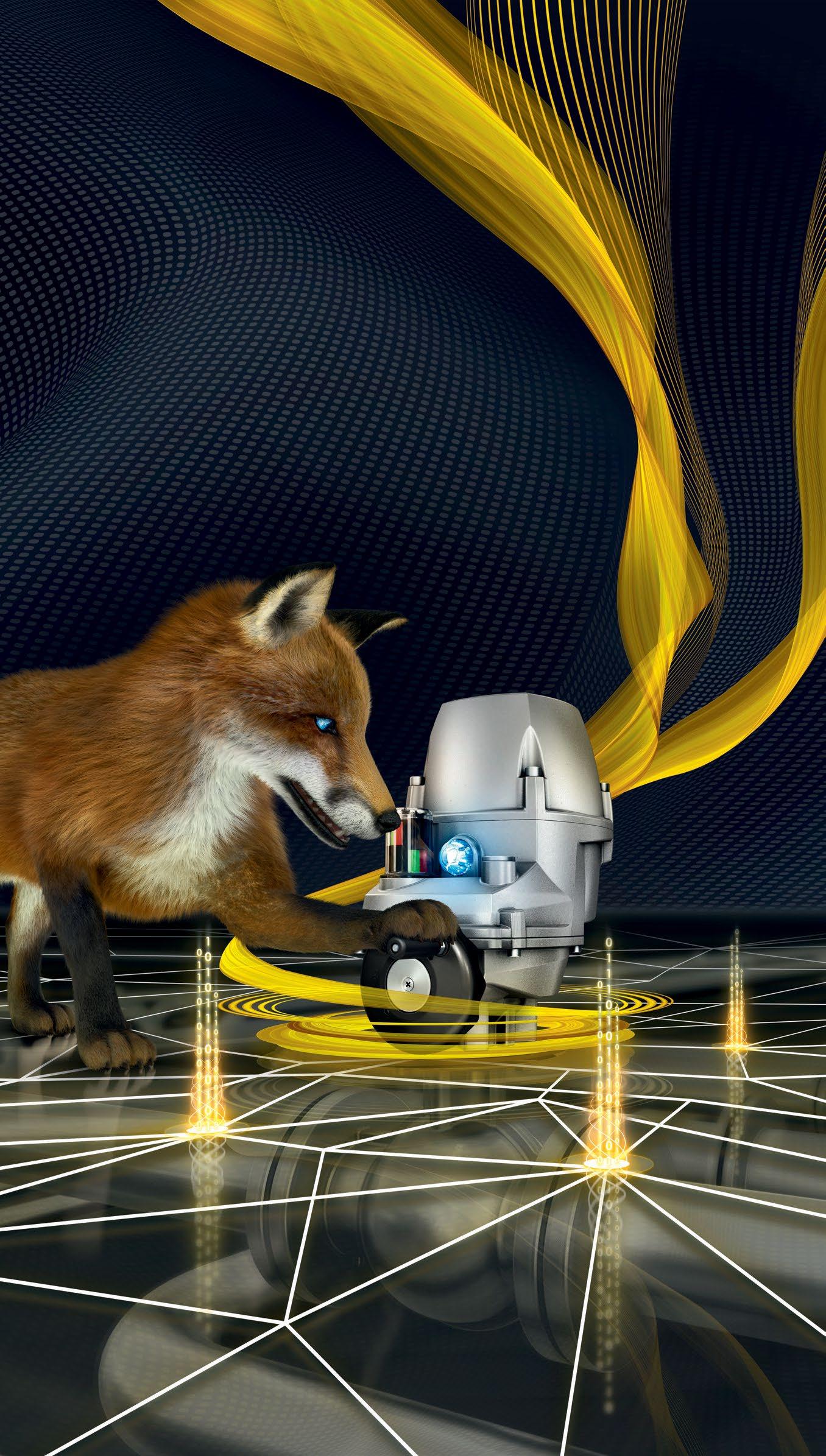

Stay moving, stay ahead

Tank

Magazine

company

positioning itself ahead of the curve

Championing a safety-first mindset Global functional safety manager at Emerson, Akansha Gupta, tells Tank Storage Magazine about why she chose tank storage

Staying the course Gary Kalmin, CEO at Aquarius Energy tells Tank Storage Magazine about the company’s past year in business and what’s ahead for 2024

Storage

how the

is

50

52

Prioritising performance, teamwork and skills

Fernandez Gigirin, project development manager at Advario, tells Tank Storage Magazine about the empowerment gained from working in the storage and logistics sector

12 Energy transition 22 Company announcements 26 Technical 30 Incident Report 32 Tank Terminal Update

06 Contributors 08 Advertiser index & Social storage 10 Editor’s Note 34 58 UP FRONT CONTENTS PAGE 01

TECHNICAL FEATURES

68 LOHC technology: strengths and weaknesses to overcome

Ion Agirre and Laura Barrio from the SherLOHCk project discuss the challenges of storing and transporting hydrogen

70 Innovation in ammonia terminal design

Proton Ventures provides a summary of the PGS-12 standard ahead of the panel discussion at StocExpo 2024

72 Cryogenic storage & its role in future fuels

Ahead of speaking at StocExpo, the experts at Chart Industries explain how cryogenic storage will be key to the energy transition

74 Radar’s solutions for LPG storage

Tomas Hasselgren at Emerson explains how integrating non-contacting radar level gauges into tank gauging systems provides an accurate solution

76 A world on the move

Bart Muijtjens, engineering manager at BM Process Management discusses energy-efficient, carbon neutral and NOx-free emission control

78 Reducing emissions at green facilities

The experts at Assentech explain how it’s pioneering solutions for engineers in quantifying and mitigating methane emissions in biogas sites

80 How waste can be a profitable output

Tecam explains why terminals should be making the most of their waste

81 The age of PTFE-coated hose fittings

The team at Dantec explain how new fittings are improving petrochemical safety

82 Enhancing fire safety at modern terminals

The team at ThinkTank explain how the use of fusible link valves in modern firevprotection systems can improve safety and efficiency on site

84 Controlling dust explosions

The experts at Newson Gale explain how static electricity has the potential to cause fires and how to prevent them

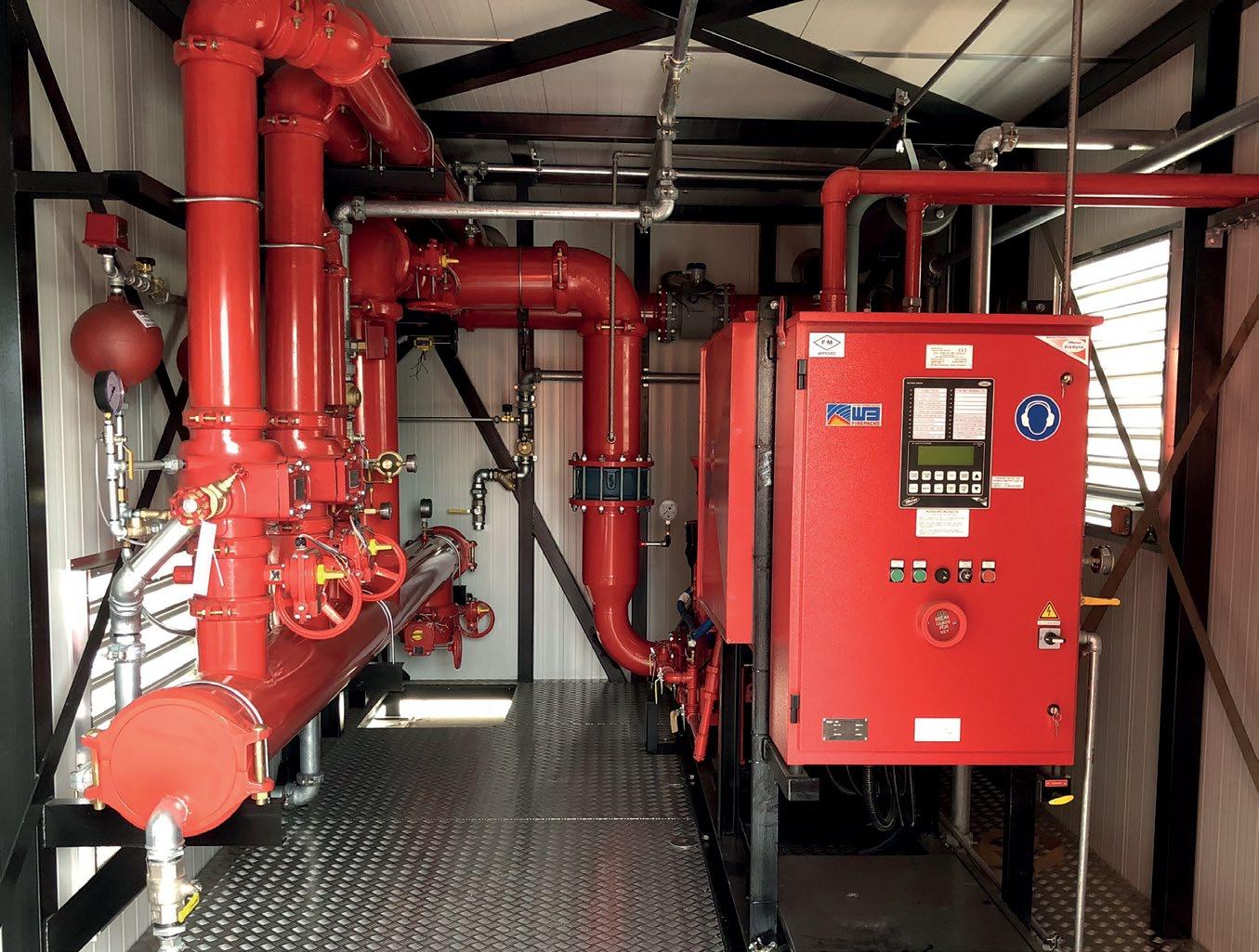

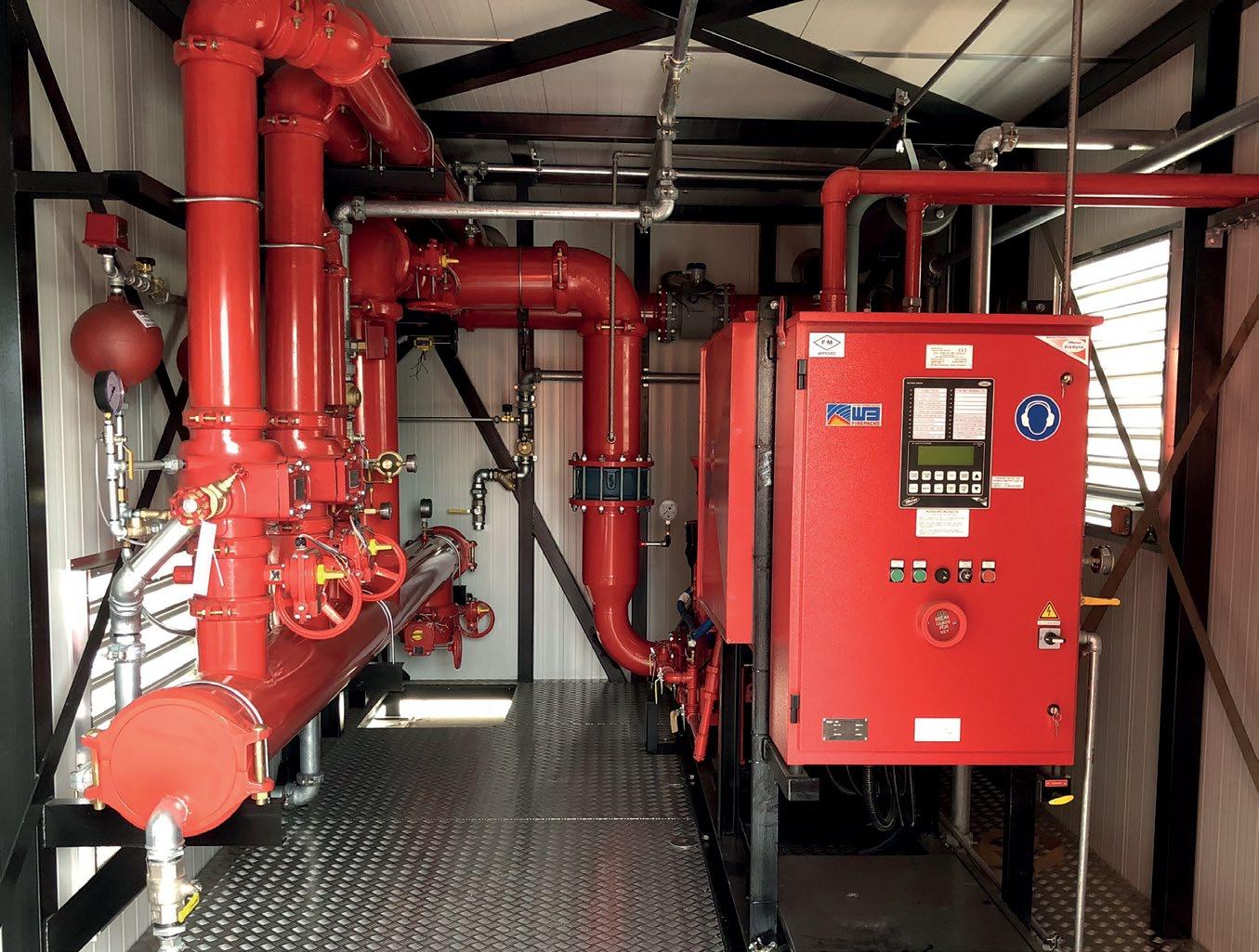

85 Why choose a pre-fab pump and valve room?

Learn how a Crea Construct prefabricated unit can benefit your terminal

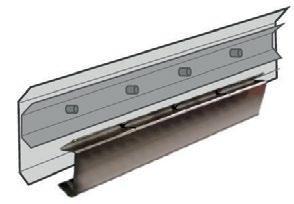

86 New guidance for tank operators

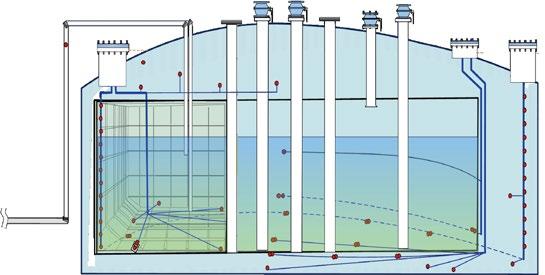

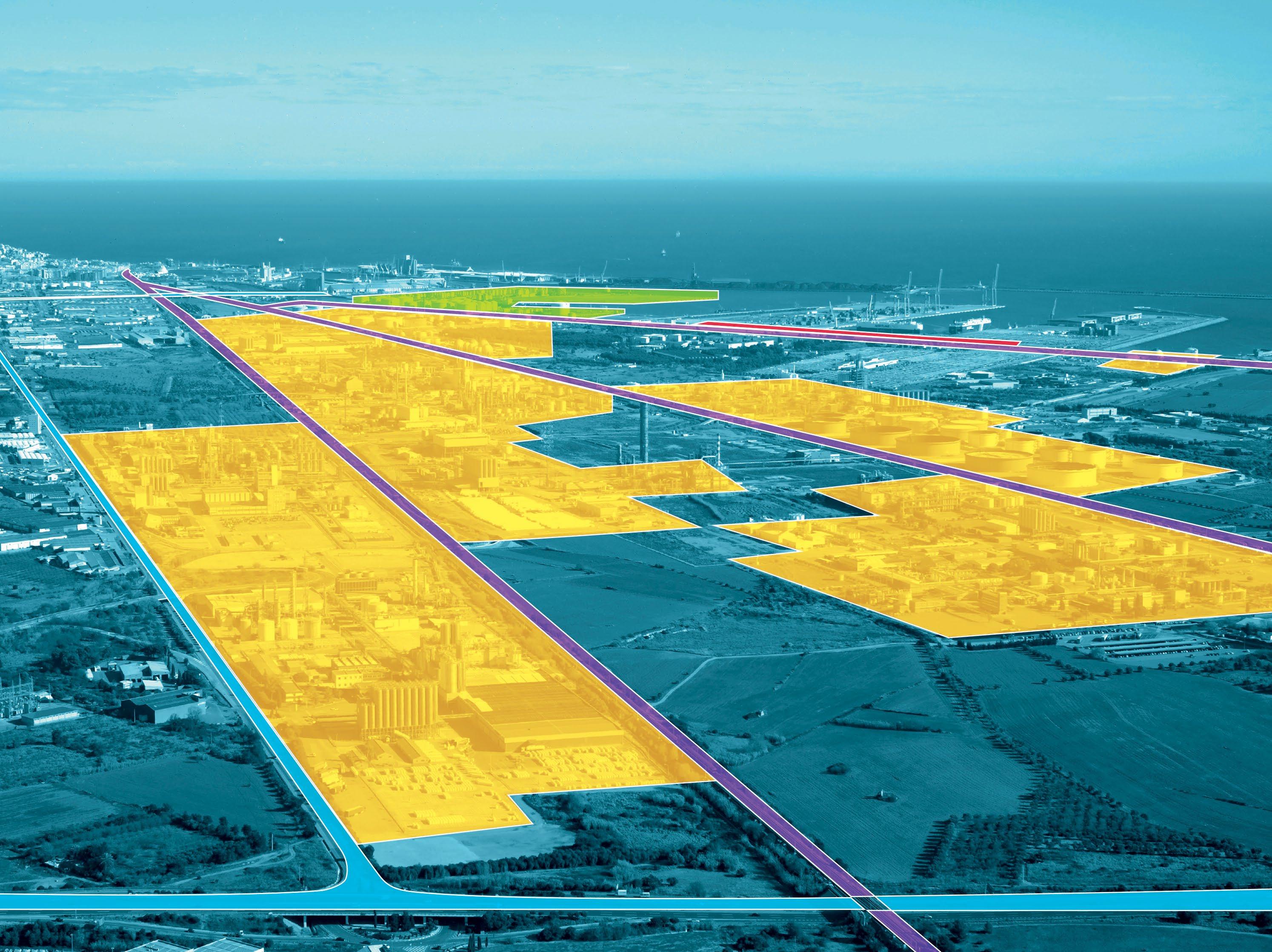

Ahead of EEMUA’s session at StocExpo, the team discusses new guidance on above ground horizontal rectangular metallic storage tanks

87 Glass fiber reinforced polymer floating roofs

The experts at EPT discuss how its approach to GRP roofs reduces maintenance costs and minimises environmental risks

88 Repair, not replace

Theexpertsat3XEngineeringshareause-casefortheir ReinforceKitpatchtankroofrepairandreinforcementsolution

90 Protecting asset integrity

The experts at Ferrous Protection discuss the importance of proper tank linings

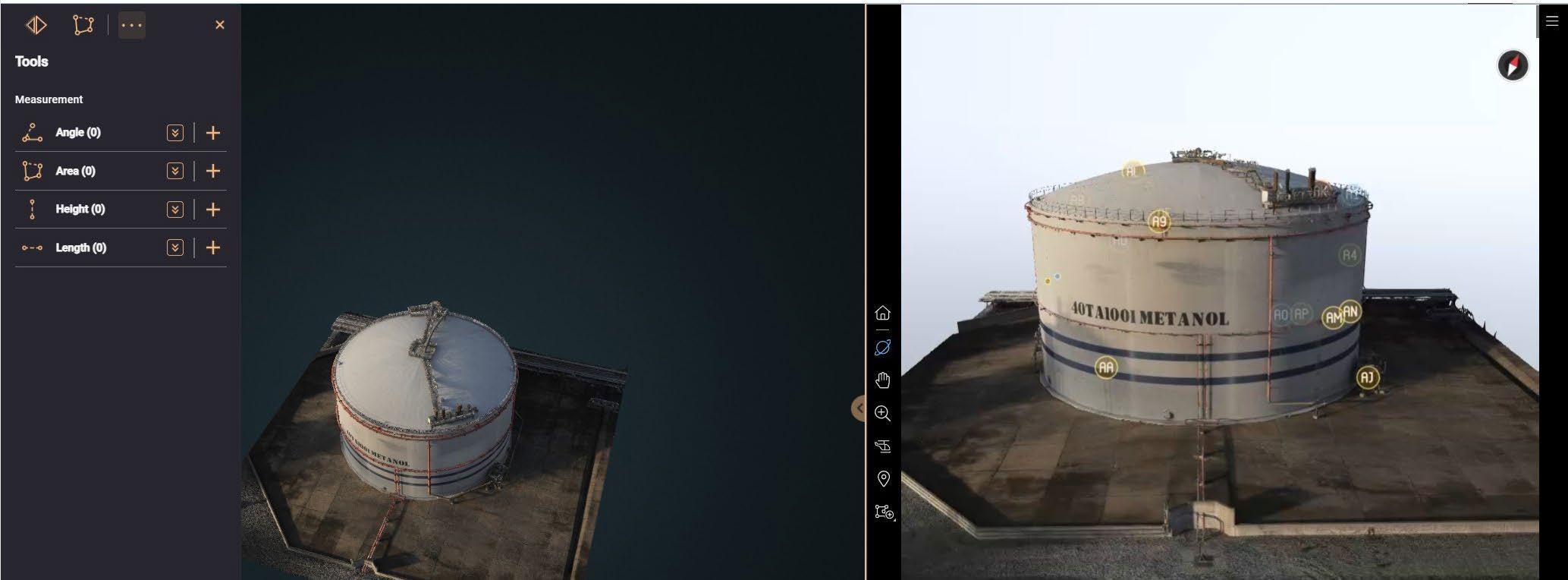

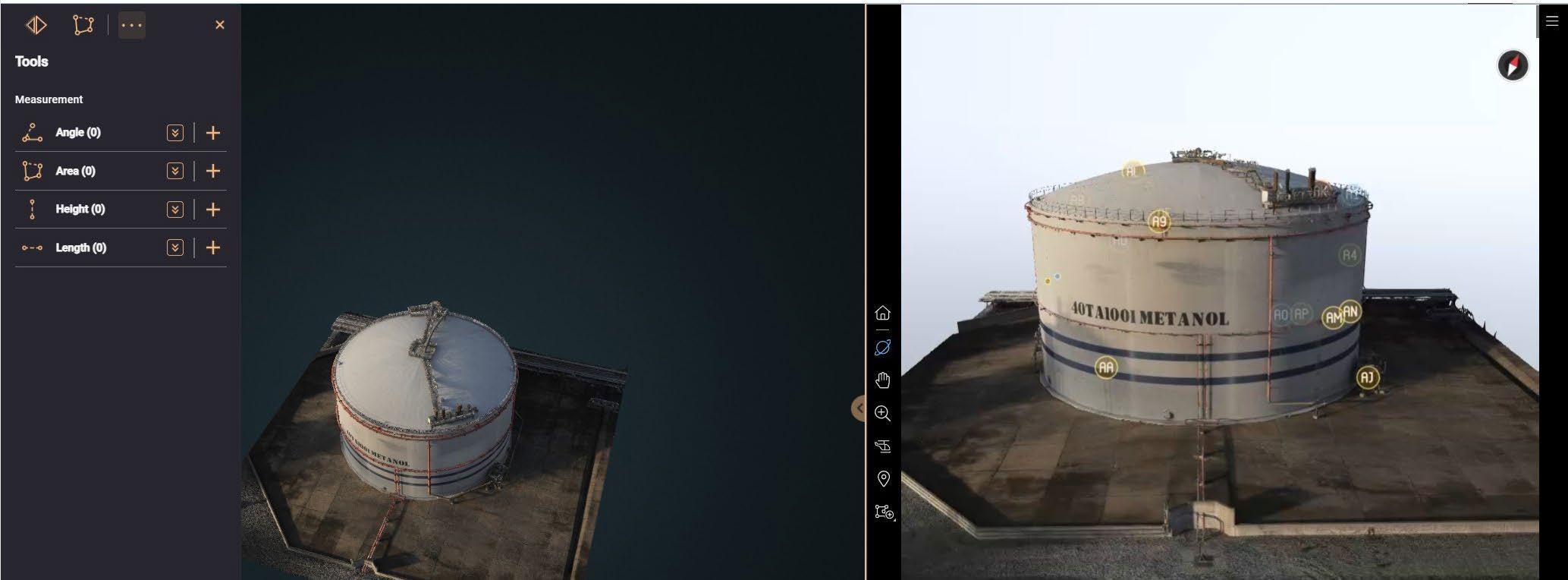

92 Optimising assets on site

The team at Advanced 3D Laser Solutions explain how laser mapping assets can benefit your tank terminal

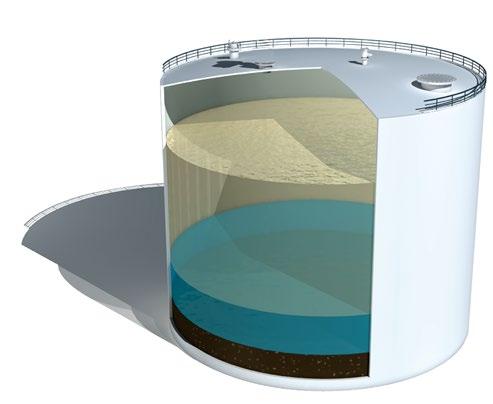

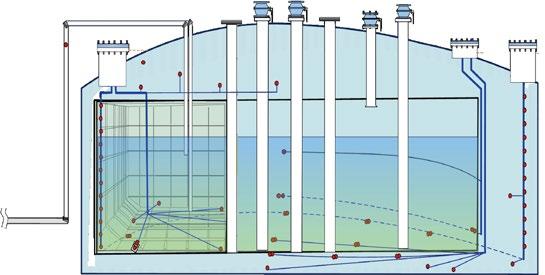

93 No-man entry for oil storage tank cleaning

The experts at Scanjet explain how its new tank cleaning machine improves safety and efficiency on site

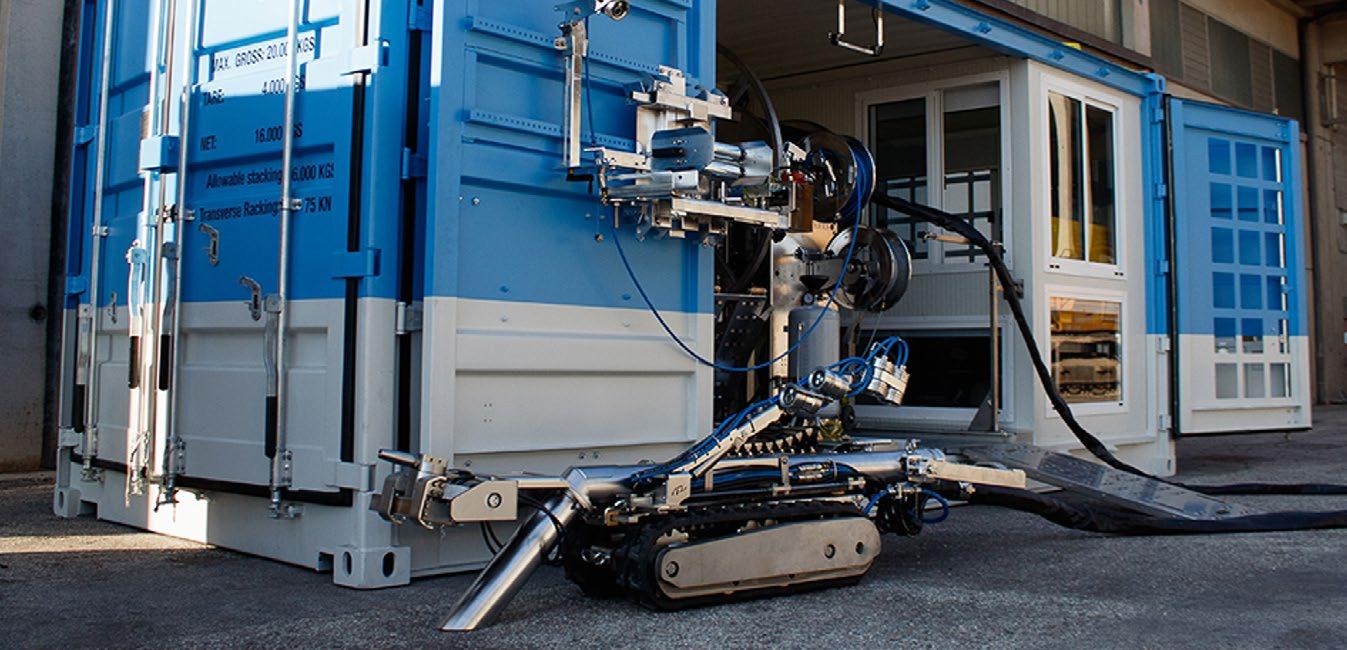

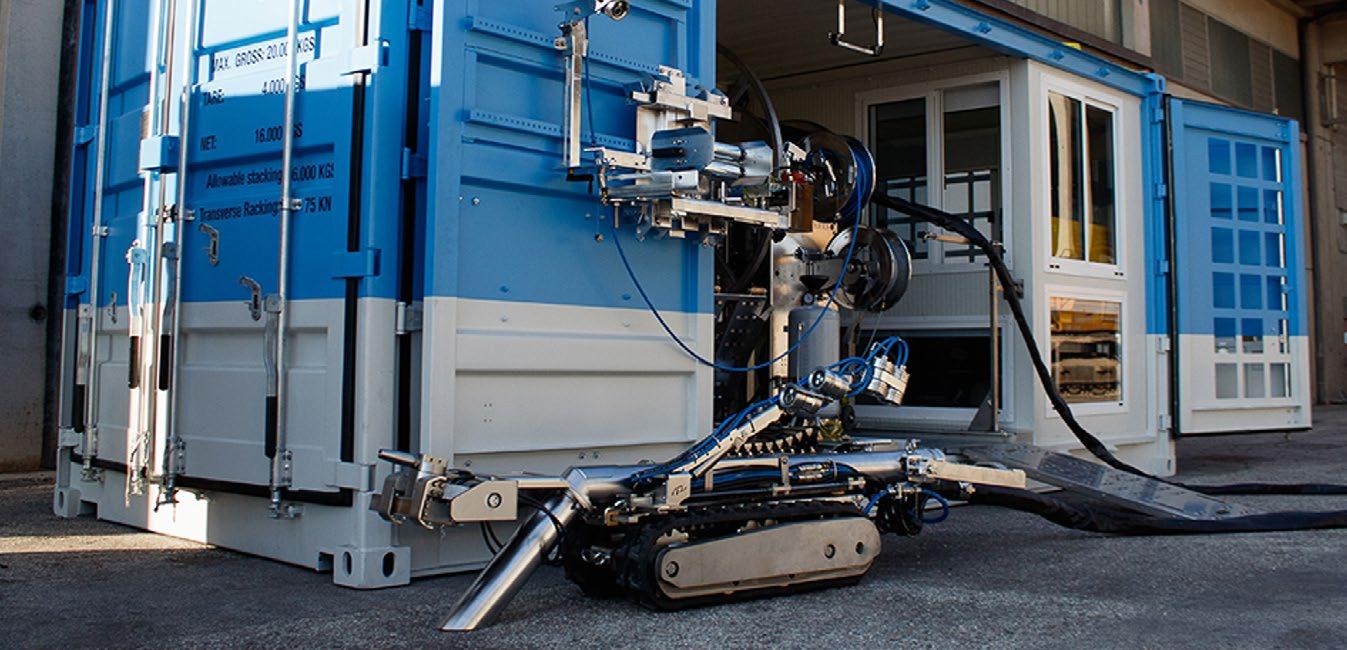

94 Ensuring safety with robotic tank cleaning

Gerotto examines how the use of robots can make desludging an external floating roof crude oil tank easier

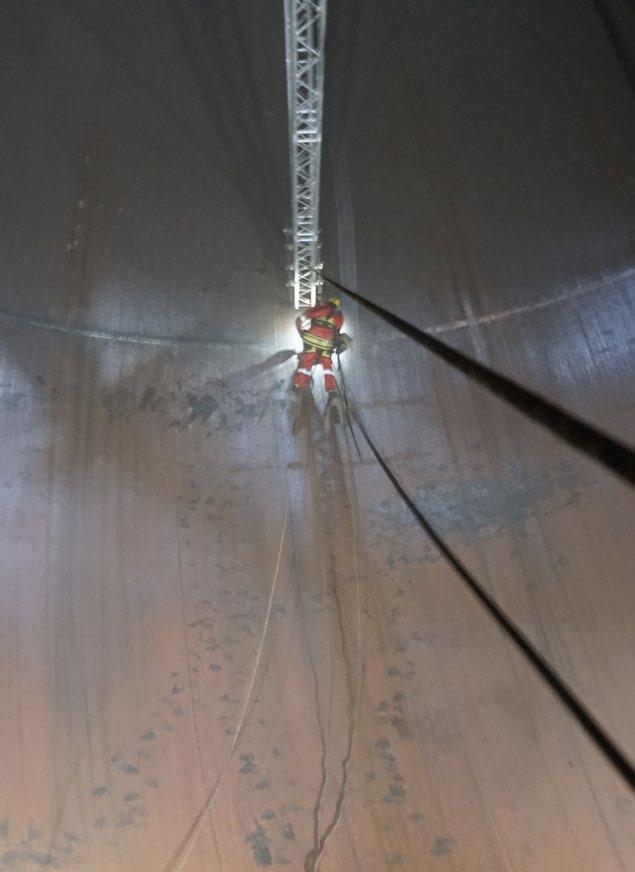

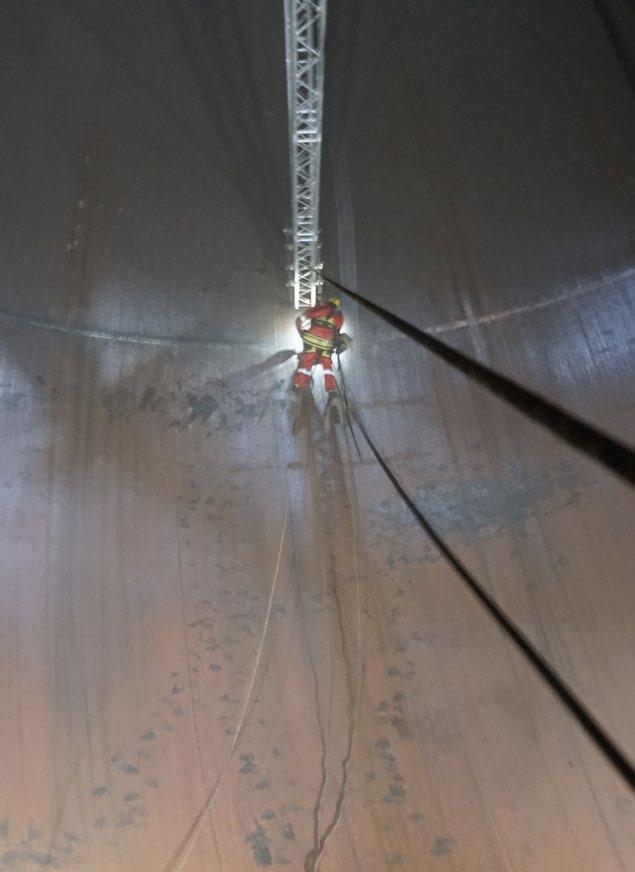

96 Synergy in inspections

Marin van Oorschot, technical director at Sky-Access explains how the right skills are key to tank maintenance challenges

98 Accurate reporting through modelling

Ahead of his session at StocExpo, Axess Digital’s Ole-Erich Haas explains how its web-based interface is improving reporting on site

99 Decarbonisation starts at the terminal

Ahead of his presentation at StocExpo, UAB-Online’s CEO Hans Bobeldijk explores how tank storage can reach net zero

100 Where the heck is my document?

Viewport.ai’s Radboud Grijpma explains how proper data management can optimise terminal efficiency

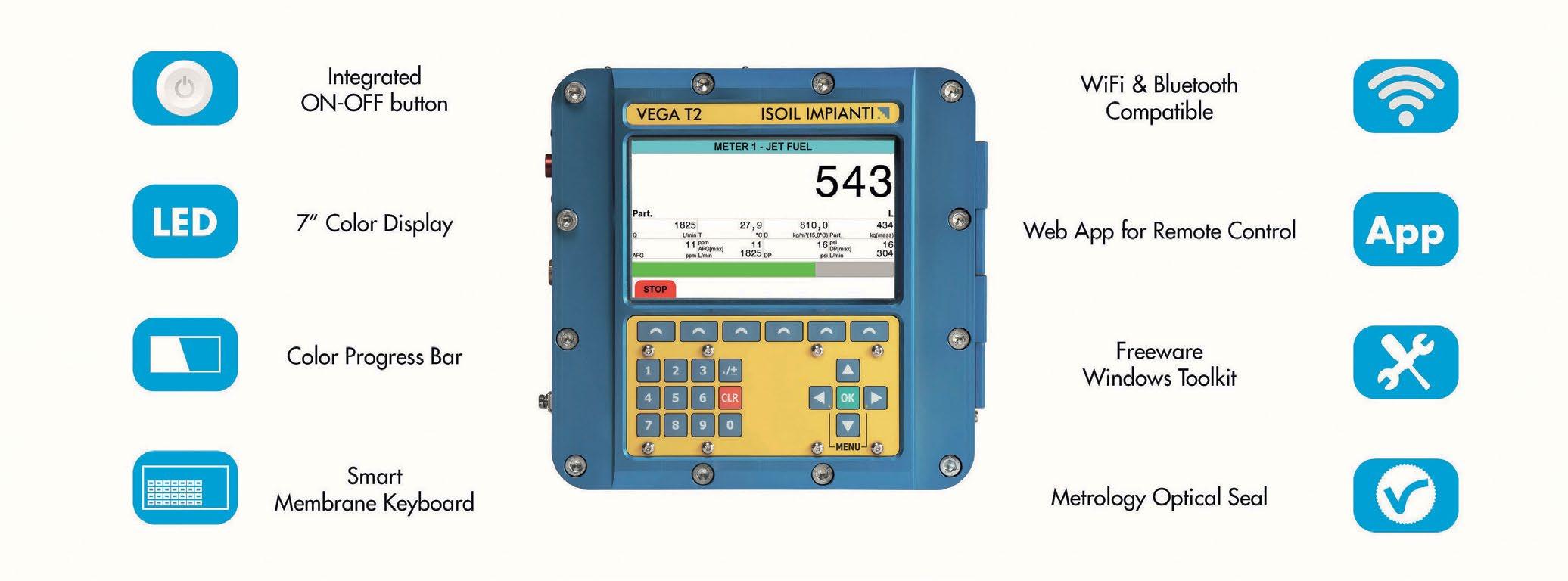

102 Automated loading for better speed & safety

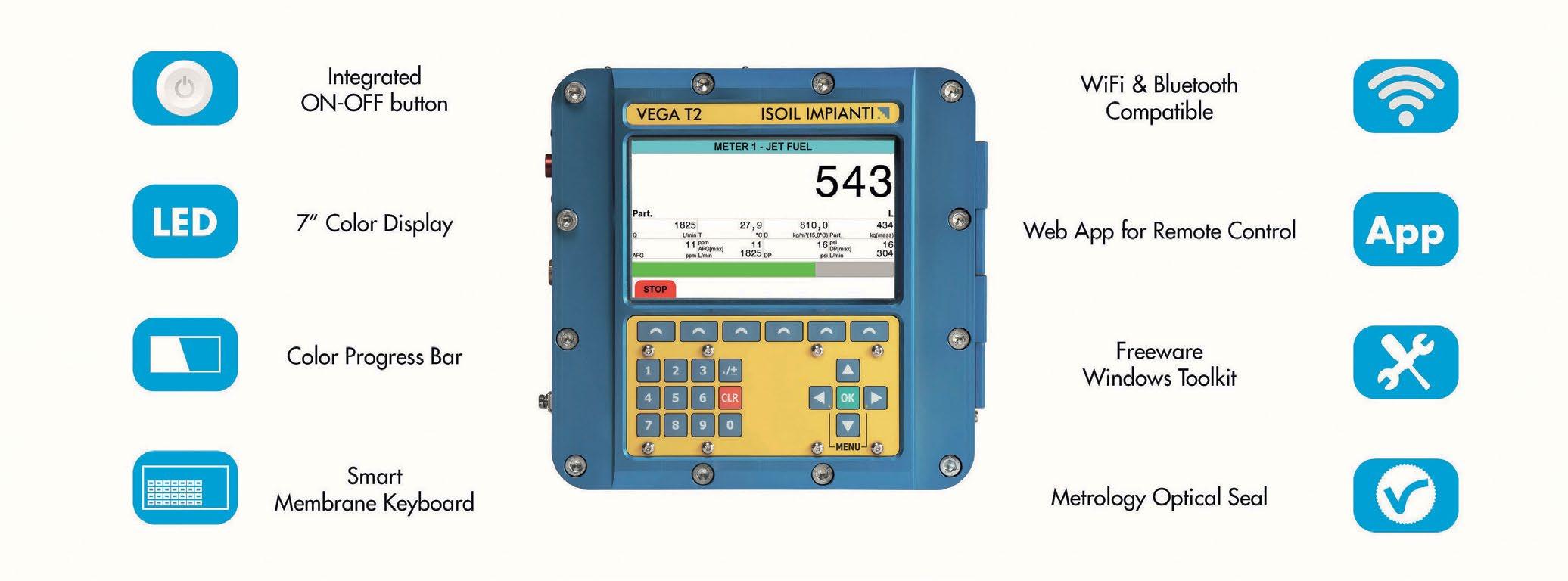

Discover how Isoil’s latest innovation is improving operational efficiency at the terminal

104 Ensuring efficient loading operations

Discover how Scully Signal Company helped an oil terminal in Belfast that needed to replace its loading equipment without impacting operations

106 Taking charge in Africa, one terminal at a time

The experts at Soliflo explain how its evolving liquid control products have transformed terminals across Africa

108 The analysis is only as good as the sample

UK Sampling Gauges’ founder Reg Kimonides explains how modern sampling methods can vastly improve product analysis

110 Six things to consider when insulating storage tanks

The experts at Owens Corning explain how to properly manage the risk of corrosion under insulation

EVENTS

41 Global Tank Storage Awards Preview

62 It’s all about work ethic

Managing director at EWFM, Guy Curtis discusses winning the Rising Star Award and working his way up in the tank storage sector

126 The AI revolution in tank storage training

Frederik Haentjens, COO at TankSkills, explains why the industry needs to be utilising AI vocational training

AT THE BACK

129 Events 2024

41 UP FRONT CONTENTS PAGE 02

EDITORIAL

ANAMIKA TALWARIA

Anamika is the editor for Tank Storage Magazine. She curates all the fantastic content in every edition and online.

MOLLY COOPER

Molly is a journalist for Tank Storage Magazine. She’s been busy sourcing exclusive speaker interviews from StocExpo for this month’s edition.

CONTACT

T +44 (0)20 3196 4300

F +44 (0)20 8892 1929 anamika@tankstoragemag.com www.tankstorage.com

Easyfairs

2nd Floor, Regal House

70 London Road Twickenham TW1 3QS United Kingdom

ISSN 1750-841X

MEMBERSHIP RATES

A one-year Elite Membership costs €299. Premium Membership costs €199.

CONNECT WITH US

@tankstorageinfo

Tank Storage Magazine

Tank Storage Magazine

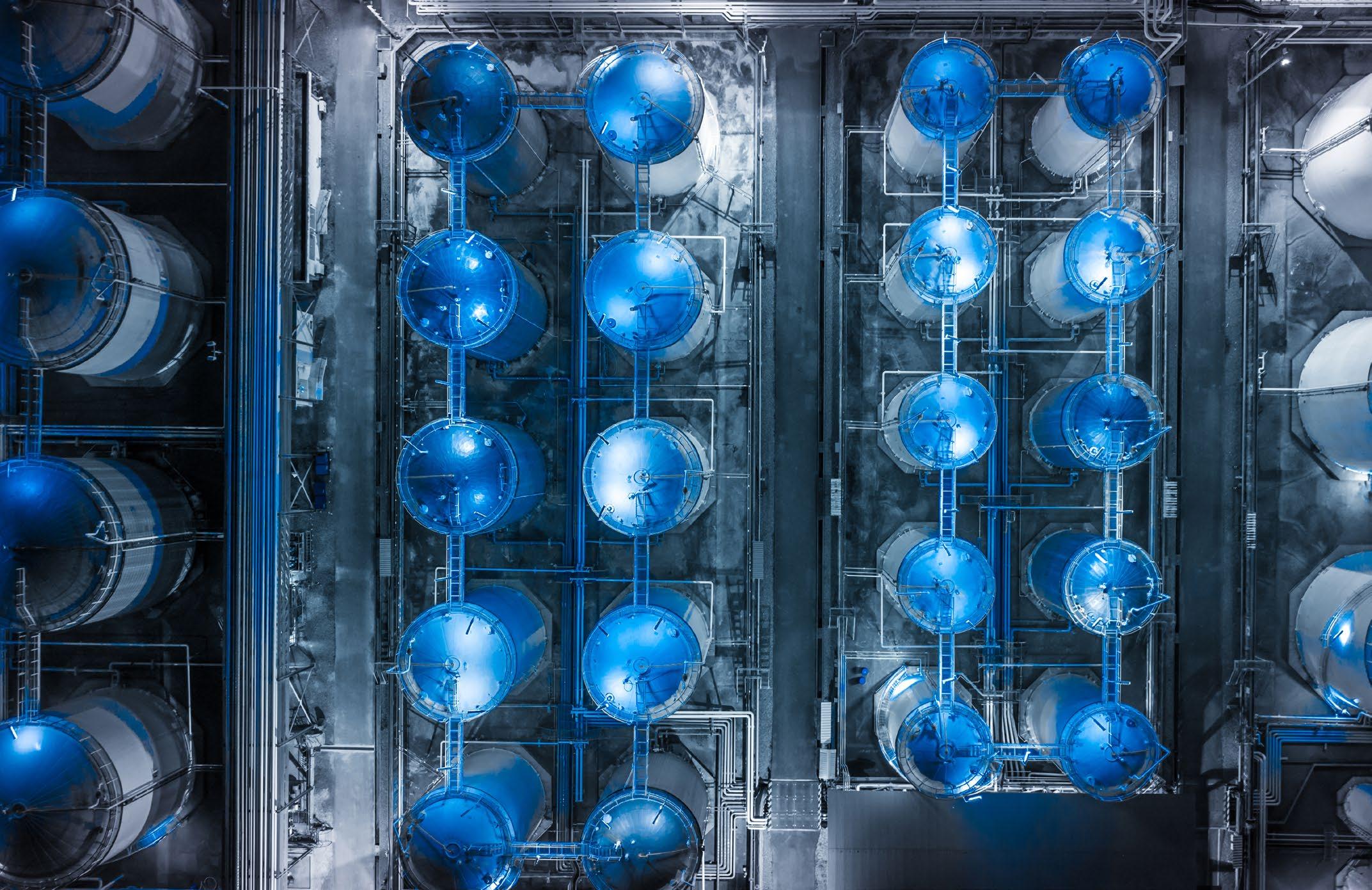

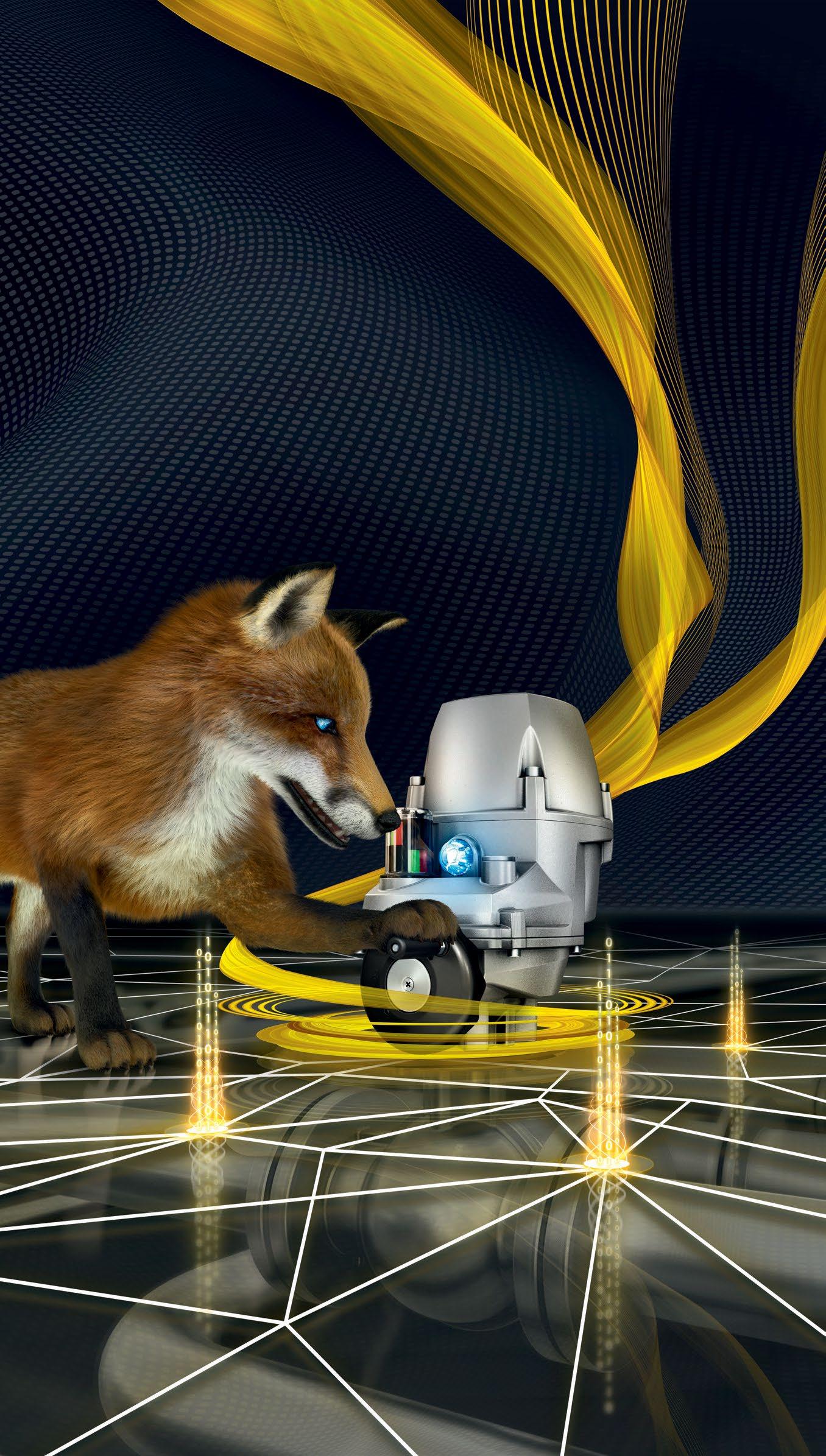

Front cover courtesy: Emerson

SALES & MARKETING

PORTFOLIO DIRECTOR

Margaret Dunn

+44 (0)20 3551 5721 margaret@tankstoragemag.com

SALES MANAGER

Josh Lyle

+44 (0)20 3196 4364 josh.lyle@easyfairs.com

KEY ACCOUNT MANAGER

Gary Kakoullis

+44 (0)20 3196 4248 gary.kakoullis@easyfairs.com

INTERNATIONAL

SALES MANAGER

David Kelly

+44 (0)20 3196 4401 david@tankstoragemag.com

MARKETING MANAGER

Eleanor Gravette eleanor.gravette@easyfairs.com

HEAD OF DATA

Beth Welcomme beth.welcomme@easyfairs.com

CEO EASYFAIRS UK & GLOBAL

Matt Benyon matt.benyon@easyfairs.com

Anne Lafère anne.lafere@easyfairs.com

Spring 2024 STOCEXPO PREVIEW Get a glimpse of the exhibitors and speakers behind StocExpo 2024 and why it’s a must-attend event THE TERMINAL OF THE FUTURE Euro Tank Terminal explains how it has become a modern, future-thinking, multi-customer terminal USA SPECIAL We delve into updates from US terminals, look at LNG exports and upcoming events Established 2005. Trusted. Valued. Influential. CONTRIBUTORS

UP FRONT CONTRIBUTORS PAGE 06

An independent storage company for bulk liquid products, focused on the marketing, renting in and renting out of storage capacity at bulk liquid terminals worldwide. Our representatives have more than 200+ years of experience in the bulk liquid storage industry.

Connect

info@vtankstorage.ch

KNOWLEDGE &

Nordics l Baltics l UK l Europe l Asia l USA l UAE l Carribbean

with us:

+41 79 595 99 00 EXPERIENCE,

SKILLS YOU CAN TRUST

- Tank Storage SA

PAGE 08 ADVERTISERS INDEX SOCIAL STORAGE Most liked posts since January: UP FRONT ADVERTISERS INDEX & SOCIAL STORAGE Emerson Front Cover Dantec Inside front cover Aquarius Energy 3 Port Tarragona 4-5 V-Tank Storage 7 Exolum 9 ILTA 11 Joyo 13 Borsig 15 SGB 16 Krantz 17 LBC Tank Terminals 18 EEMUA 19 UK Sampling Gauges 20 Koerting 21 Netzsch 22 Auma 23 Saval 25 Reynolds Training 25 Unimat 27 FabriConsult 28 Isoil 28 EEMUA 29 Protego 30 USA DeBusk 31 Standic 33 StocExpo 36-37 FETSA 40 Odfjell 45 North Sea Port 48-49 Emerson 51 ChemUK 67 Proton Ventures 71 Chart 73 Assentech 79 3x Engineering 89 Ferrous Protection 91 Scanjet 93 Gerotto 95 Sky Access 97 Ferbeco 101 Kanon 103 Scully 105 Soliflo 107 Pittsburgh Owens Corning 109 TopTech USA Special 02 Qmax USA Special 04 MESA ETP USA Special 08 Sandborn USA Special 10 NISTM Orlando USA Special 14 AntwerpXL 127 Tank Storage Association 128 Zwick Outer Back Cover Tank Storage Magazine, (ISSN 1750-841X) is published five times a year by Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK. A one-year, 5-issue membership costs €299. The US annual subscription price is $243. Airfreight and mailing in the USA by agent named WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Periodicals postage paid at Jamaica NY 11431. US Postmaster: Send address changes to Tank Storage Magazine, WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Subscription records are maintained at Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK. Tank Storage Magazine 13,312 followers 2w Tank Storage Magazine 13,056 followers 1mo • Edited Tank Storage Magazine 13,056 followers 1w • Edited From countless entries, down to just 85 shortlisted companies; the shortlist for the #GlobalTankStorageAwards 2024 has been announced Are you on the shortlist? Click the link to find out! https://lnkd.in/epx-TwpJ Plus, don’t forget to book your ticket to the ceremony and connect with these industry giants on 12 March 2024 #TankStorageMagazine #TankTerminal #StorageTerminal #OilAndGas #BulkLiquids #FutureFuels #Hydrogen #Ammonia #EnergyTransition #TankStorage #StorageTank #TankStorageAwards #StocExpo #ExcellenceinIndustry Terminal Outlook 2023/24: Exolum CEO Jorge Lanza Perea shares the company’s journey, reflecting on 2023 achievements and 2024 plans, focusing on sustainable energy and aviation success. Become a member to read the feature in full now: https://lnkd.in/eHxRnjjv #TankStorageMagazine #Publication #TankTerminal #StorageTerminal #OilAndGas #BulkLiquids #FutureFuels #Hydrogen #Ammonia #News #EnergyTransition #TankStorage #StorageTank A warm welcome: Advario has announced that snehashish chatterjee is joining the Advario leadership team, in the new chief projects and safety officer (CPSO) role: https://bit.ly/4bwquC8 #TankStorageMagazine #Publication #StorageTerminal #OilAndGas #BulkLiquids #FutureFuels #EnergyTransition #TankStorage #StorageTank #LNG #News #Company Shortlist revealed for the Global Tank Storage Awards Terminal Outlook 2023/24: Exolum Advario welcomes Snehashish Chatterjee as CPSO 58 reactions • 35 comments • 18 reposts impressions 3,024 42 reactions • 1 repost impressions 2,183 86 reactions • 2 comments • 1 repost impressions 4,140 Like Like Like Comment Comment Comment

Making the world move Europe’s leading bulk liquid logistics provider exolum.com

EDITOR’S NOTE

KEEN READERS of TankStorage Magazine might notice that the weight of the edition you hold in your hands is indeed the largest we’ve ever produced. And it’s been no easy feat to get so much in-depth analysis, high-level interviews and interesting technical articles to you all –but we’ve managed an absolute whopper of a magazine this Spring.

First, let’s address the elephant in the room: StocExpo 2024. Many of you will be reading this before the show starts on 12 March, so you’re in for a treat as we’re offering up sneak previews of so many of the talks and tech that will be on display at the show.

The TankStorageMagazine will also be on site – of course – so you can swing by our stand C35 to speak to the team, renew your membership, enjoy a drink and join our Membership Mixer at 11:00am on 13 March to network with other titans in the industry. We’ll be conducting interviews on site, bringing you breaking news, and compiling the StocExpo Daily –so get in touch if you have a story to tell!

Staring on page 34, we’ve got exclusive interviews with key figures at StocExpo, including Euro Tank Terminal’s commercial manager Frans Jan Hellenthal, VOTOB Academy’s Sandra de Bont (page 54 and LBC Tank Terminal’s terminal manager Mathias Potvin (page 48). All three will be speaking at the FETSA Tank Storage Conference, and you can take a tour of ETT’s facility on 11 March (day zero of StocExpo).

You’ll find even more exclusive market insights from other speakers, such at the Tank Storage Association’s Peter Davidson – focusing on safety best practices on page 58 – and David Tassadogh from GRESB’s advice to terminals trying to reach net zero (page 60).

The technical articles throughout this edition pair nicely with StocExpo’s focus on future fuels, too. Say hello to hydrogen with articles from Chart ( page 72) and SherLOHCk ( page 68) – both of whom will be delivering insightful presentations at StocExpo. Proton Ventures will be covering ammonia on page 70, and don’t miss them teaming up with Vopak for a panel discussion at StocExpo.

Further into the magazine, we’re looking at emissions reduction at the terminal (pages 76-79), focusing in on fire safety (pages 82-84) and tank maintenance (pages 86-91) – as well as how far robots and drones can go when it comes to tank inspection and cleaning (pages 93-98).

As well as future fuels, a key theme in the tank storage industry is digitalisation and AI. StocExpo’s conference will be covering these topics on day two in particular, and we’ve got sneak previews from Axess Digital (page 98), UAB-Online (page 99) and Viewport.ai (page 100).

And that’s not all! StocExpo is, of course, the biggest event of the year for our team – as the event’s sister publication. But you can pick up this copy of Tank StorageMagazine at a number of events happening worldwide this Spring –including NISTM Orlando this April.

That’s right, our team is heading across the pond again for another fantastic event – and you can read all about it in our brandnew-for-this-year USA Special, starting on page 112. We’ve got exclusive analysis into the USA’s LNG market, terminal

profiles and technical articles, curated special for our partners in the USA.

And if you can’t wait to get your hands on even more North America content, you won’t have to wait long. With another huge event scheduled in May, TankStorage Magazine’s Summer edition will be back for ILTA, with exclusive delegate bag distribution – so make sure you get your brand in the hands of every single attendee. Contact the team to advertise and share your story. For a full run-down of every upcoming event we’re heading to this year, check out page 129

We can’t wait to keep connecting with the tank storage industry – so come and say hello if you spot any of the team at an event this year!

Look forward to seeing you on site!

Anamika

Best wishes,

Anamika

PAGE 10

UP FRONT EDITOR’S NOTE

2024

Conference & Trade Show

May 6-8

HOU TX

ILTA 2024, the leading conference and trade show for the bulk liquid terminal industry, is set to be our biggest yet!

Join thousands of terminal industry professionals from around the world for:

Inspiring keynotes plus in-depth educational sessions featuring expert speakers

The ILTA exhibit floor packed with hundreds of industry solution providers

World class networking including a special celebration of ILTA’s 50th anniversary

All in Houston, TX—the Energy Capital of the World!

ilta.org

Register Now!

GLOBAL NEWS UPDATE

UNIPER AWARDS TECHNIP ENERGIES & AKER CARBON CAPTURE DESIGN STUDY CONTRACT

Uniper has awarded Technip Energies and Aker Carbon Capture process design package (PDP) contracts to deliver its technology and design studies for the Grain Carbon Capture project.

Both companies will participate in a competition to engineer the carbon capture technology and plant design needed for the project to move to the front end engineering and design (FEED) phase, ahead of a final investment decision, which is expected to be taken in the mid-2020s.

The project is a proposal to retrofit post combustion carbon capture technology on up to three units of the existing 1,326MW combined cycle gas turbine (CCGT) plant at Grain power station, in the southeast of England, United Kingdom. It has the potential to remove over 2 million tonnes of CO2 per year during the electricity generation process, representing over 7% of the UK government’s 2030 target to capture up to 20-30 million tonnes of CO2 per year across the economy, to help meet the UK’s target of net zero by 2050.

Ian Rogers, head of asset improvement and making net zero probable, says: ‘The award of the PDP contracts is a significant milestone in the development of our plans to decarbonise electricity production… It would not only help meet Uniper’s ambitious strategy to generate more than 80% of our installed power capacity from carbon free sources by 2030, but could also help to support the UK’s transition to a net zero future by removing millions of tonnes of CO2 per year whilst continuing to provide flexible and reliable power to the national grid.’

ADVARIO & FLUXYS PARTNER FOR ANTWERP-BRUGES AMMONIA TERMINAL

Fluxys has teamed up with Advario Stolthaven Antwerp and Advario Gas Terminal to study the feasibility of building an open-access green ammonia import terminal at Belgium’s Port of Antwerp-Bruges.

Located at a future green energy gateway, the terminal is expected to be operational in 2027. It will deliver storage and multimodal logistics solutions for ammonia (train, truck, barge and possibly ammonia pipelines connected to local industrial sites) and place Advario and Fluxys at the forefront of the energy transition.

The terminal will also be able to convert ammonia back into hydrogen and is due to connect to Fluxys’ hydrogen network to ensure supply throughout northwest Europe.

The project aligns with the REPowerEU programme, which has set a target of 20 million tonnes of green hydrogen consumption by 2030, one-fifth of which should be covered by ammonia imports.

Pascal De Buck, CEO of Fluxys, comments: ‘We are delighted to launch this green ammonia import terminal project with our Advario partners. Combining and leveraging our

terminalling and technology expertise will enable us to fast-track the development of key solutions for importing low-carbon energy and feedstock. Fluxys aims to be a decarbonisation driving force and this project is a landmark venture in helping build the infrastructure to carry the molecules needed for a carbonneutral society.’

During the Hydrogen Council’s tour of Advario Gas Terminal, Nancy De Groof, Advario’s vice president Belgium says: ‘It was a pleasure to host the council, and I am grateful for their input and kind words. We believe in ammonia as a cornerstone of the clean energy mix, as an enabler of the hydrogen ecosystem, and are in advanced stages of a feasibility study, executed together with our partner Fluxy. The study explores the build of an ammonia import terminal in Antwerp.’

VOPAK PARTNERS WITH NESTE FOR SUSTAINABLE FUELS

Vopak recently commissioned tanks at its Penjuru terminal in Singapore, storing Neste renewable fuels for road transportation and renewable feedstock for polymers and chemicals. Neste is the world’s leading producer of sustainable aviation fuel, renewable diesel and renewable feedstock solutions.

‘We deeply value this long term partnership and collaboration with Neste. Our customers recognise the value of our network, innovative infrastructure solutions and high safety standards. We are excited to support regional and global acceleration towards the use of alternative energy and sustainable feedstocks,’ says Neeraj Kumar, director of commercial chemicals & business development new energies, Vopak Business Unit Singapore.

United Kingdom

Belgium

Stay informed with our round-up of all the news hitting the tank storage sector

PAGE 12 NEWS UPDATE ENERGY TRANSITION

Singapore

BJLM Series Tank Gauging System

Smart Tank Gauging System

BJLM-80H servo level gauge with a smart displacer forms a smart TGS in which multiple measurement functions are integrated in a single gauge, including the liquid level, density, temperature, oil-water interface. It provides accurate density measurement and custody transfer based in both volume and mass.

HIMS Tank Gauging System

The Hybrid Tank Measurement System conducts the measurements for the liquid level, temperature and density via several discrete instruments that are working together in one system. It provides the online temperature data via the MPT, and the average density data by the hi-precision pressure transmitter.

BJLM-80H Tank Gauging For LPG

BJLM-80H tank gauges with the MPF smart displacers are designed to set up a TGS for high pressure liquid stocks. It features with multiple functions being integrated in one gauge, especially for measuring density for a vaporized liquid, which is included in the calculation of the tankage inventory in mass, providing a more accurate data for the custody transfer.

BJLM Tank Gauging For LNG

A whole LNG tank gauging system from JOYO consists of the primary and secondary level gauges, primary and secondary thermometers, the extra LTD gauge and a radar level gauge as the HH alarming instrument. All the instruments including LNG manager& Rollover Predictor software are all manufactured by JOYO.

TM-80N LTD

TM-80N LTD gauges are designed mainly for the LTD (Level + Temperature + Density) measurements of cryogenic bulk stocks. With one integrated instrument in which multiple measurement functions are involved, aiming at providing a detailed and accurate LTD profile measurement.

O-W interface Density & Temp 2 Level Tank Bo�om Density & Temp 3 Density & Temp 1 Level BJLM-80H BJZT-IV MPT Water Probe SF Displacer Pressure Sensor Temperature Water Level Liquid Density& Temp 2 Vapor Density& Temp 1 Tank Bo�om Liquid Density& Temp 3 Liquid Density& Temp 1 Vapor Density& Temp 2 Level Oil-Water Interface Water Probe LTD Gauge Measuring Tape Smart MPF Displacer Density Sensor Temperature Sensor TP LTD TS A S SIS system DCS LSHH/LSLLL LSHH/LSLLL LSHH/LSLLL Modbus RTU Loop1 Modbus RTU Loop2 TS-I CIU P Roll over monitoring system CIU LNG Tank Gauging Management System JOYO M&C TECHNOLOGY CO., LTD www.joyo-mc.com info@joyotec.com

VTTI TO STORE MABANAFT HVO

VTTI’s terminal in Antwerp, Belgium is due to store store Hydrotreated Vegetable Oil (HVO) for its customer, Mabanaft. This HVO is destined to be transported to Germany and other parts of Europe.

HVO is a type of biofuel produced from waste, residue oils and fats, such as used cooking oil. Biofuels like HVO play a key role in the decarbonisation of mobility. The move is in line with VTTI’s strategy to support customers in the energy transition.

UNIPER TO DEVELOP HYDROGEN STORAGE

Uniper has announced plans to develop hydrogen storage in Germany with a capacity of up to 600 GWh by 2030.

The project will both investigate the possibility of converting existing underground facilities, as well as developing new facilities along the planned hydrogen core network.

‘Hydrogen is expected to play a key role in the energy transition, but in order to ensure reliable supply to the market, new storage is urgently needed. At Uniper we are investing in meeting that need, and today announce plans to develop salt caverns in north-west Germany for large volume hydrogen storage. The facilities will have an envisaged capacity of 250600 GWh by 2030,’ the company says in a post on LinkedIn.

With a total of more than 80 TWh of underground gas storage capacity for natural gas in Germany, Austria and the UK, Uniper is one of the largest energy storage operators in Europe.

In order to better forecast the demand for hydrogen storage capabilities as well as potential future projects, Uniper is also launching a comprehensive market consultation until the end of March 2024.

ROSEN RESEARCHES INDUSTRY KNOWLEDGE FOR ENERGY INSTITUTE

The Rosen Group has developed a research report commissioned by the Energy Institute to identify current knowledge gaps regarding repurposing natural gas infrastructure for hydrogen. The report is based on a literature review of all ongoing technical work, joint industry projects, and research in this field worldwide.

The goal is to consolidate all knowledge into a guidance document to enable pipeline operators and other energy companies to safely introduce hydrogen into existing natural gas infrastructure. The research report focuses on pipelines and certain associated installations from (but not including) the hydrogen production plant up to inlet valves.

Neil Gallon, principal engineer at Rosen says: ‘The conversion of existing natural gas infrastructure to the transportation of hydrogen is an important element of the energy transition. While the threats operators face with natural gas infrastructure are still relevant, there are certain characteristics of hydrogen that may increase the risk of some threats more than others. As hydrogen is a relatively new energy source, there are at this time some knowledge gaps that need to be addressed in order to safely use the existing assets while transitioning to a decarbonised future.’

H2MED PROJECT ENTERS NEW PHASE OF DEVELOPMENT

Enagás, GRTgaz and Teréga, in coordination with OGE, have awarded WoodCo contracts to conduct essential preliminary engineering studies for the BarMar project.

The scope of work includes analysing the various potential routes for the offshore pipeline to connect Barcelona to Marseille across the Mediterranean Sea. This comprehensive evaluation will allow to identify a preferred corridor for BarMar, and will consider technical, economic, environmental, and societal perspectives, emphasising the commitment of the three Transmission System Operators (TSOs) to a wellrounded and sustainable approach.

Given the cross-border and multidisciplinary nature of the BarMar project, the societal and environmental impact will be conducted by Tecnoambiente, supported by Francom and Natural Power. BarMar is part of the H2Med project. The H2Med project is composed of a hydrogen connection between Portugal and Spain (Celorico da Beira – Zamora) and a maritime pipeline connecting Spain to France (Barcelona – Marseille).

HYDROGEN COUNCIL DIRECTORS VISIT ADVARIO BELGIUM

The Hydrogen Council’s team of directors visited Advario’s facility in Antwerp, Belgium to see hydrogen working in action.

Steven Libbrecht, interim executive director, Daria Nochevnik, director policy and partnerships, and Andrei V.

Belgium

Switzerland

Germany

Spain

PAGE 14 NEWS UPDATE ENERGY TRANSITION

Belgium

Membrane Technology. For processes and environment.

→

Think. Create. Change.

The conscious and responsible use of energy and resources is already the basis for a sustainable and environmentally friendly circular economy.

Saving, recovering and recycling from industrial production processes are among the core competences of BORSIG membrane technology.

We offer modern, intelligent and innovative solutions for your processes. We guarantee the highest safety and quality standards, maximum efficiency and resource conservation for

- emission reduction

- minimised energy requirements

- sustainability

- environmental protection. BORSIG

Visit us at StocExpo 2024 in Rotterdam, Stand F30. www.borsig.de

Membrane Technology GmbH

VAPOUR RECOVERY TECHNOLOGY

SEPARATION & RECOVERY SYSTEMS

ORGANIC SOLVENT NANOFILTRATION (OSN) & PERVAPORATION

→ GAS

→

Tchouvelev, director safety and regulatory, toured the Advario Gas Terminal (AGT) and discussed the important role hydrogen carriers as ammonia play in the development of a hydrogen economy and the European need for import and export facilities for ammonia.

United Kingdom

TECHNIP ENERGIES TO PROVIDE FEED FOR VIKING CCS PROJECT

Technip Energies, supported by its subsidiary Genesis, has been awarded a Front-End Engineering Design (FEED) contract for the UK-based Viking CCS project, led by Harbour Energy and BP.

The project is expected to play a pivotal role in creating a globally leading CCS sector in the UK, contributing to the government’s target for net zero emissions by 2050. The project is focused on the transportation and storage of the captured CO2 into the depleted Viking gas fields. The initiative aims to reduce UK emissions by 10 million tonnes annually by 2030, increasing to 15 million tonnes per year by 2035.

Technip Energies, supported by its subsidiary Genesis, will provide FEED services for the CO2 transportation system, including the CO2 handling station, onshore and offshore pipeline and a NPAI (Not Permanently Attended Installation) platform.

Harbour Energy’s Viking CCS project director Graeme Davies says: ‘We’re delighted to be working with Technip Energies to help deliver another important milestone for the Viking CCS project.’

Jim Todd, BP JV manager for Viking CCS, adds: ‘After three years in development, the Viking CCS project is now entering the FEED phase. This is a significant step in the journey of any project, and we are excited to welcome Technip Energies as the FEED contractor, paving the way for large-scale CCS in the South Humber and North Lincolnshire region.’

PAGE 17 TERMINAL NEWS XXXXXXXXX NEWS UPDATE ENERGY TRANSITION

United Kingdom

VTTI’S BIO-ENERGY FACILITY REACHES FINAL STAGES

VTTI’s bio-energy facility in Tilburg, Netherlands, is now in the final stages of construction. The facility represents a significant contribution to the biobased circular economy and renewable energy transition. It is the most modern VTTI facility to date, incorporating the best available technologies.

At VTTI bio-energy Tilburg, the focus is on sustainability and innovation. The facility will primarily utilise organic side streams from the agricultural sector and food industry such as potato peels and animal manure minimizing environmental impact and maximising resource value.

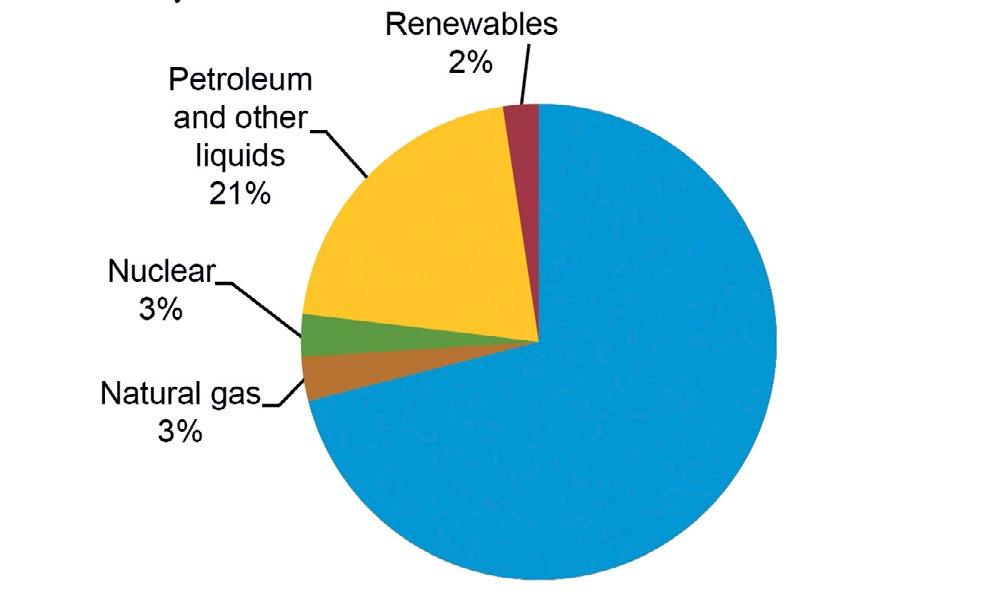

As highlighted in the Energy information Administration (EIA) Renewable Report 2023, the utilisation of biogas and biomethane plays a crucial role in building a circular economy around residue and waste. This approach not only fosters rural economic development and creates employment but also aligns with the emissions reduction objectives of the Global Methane Pledge, signed by 155 countries as of January 2024.

ESSAR OIL UK BECOMES EET FUELS

Essar Oil UK has become EET Fuels as it delivers on its plan to become the UK’s first low carbon refinery, setting the global benchmark for lower emitting refineries and industrial decarbonisation.

For a century, the refinery based at Stanlow, on the River Mersey, has provided the fuel and chemical building blocks that people rely on for their everyday lives. EET Fuels remains committed to sustainably meeting the energy needs of the country.

EET Fuels is investing €1.11 billion to support industrial decarbonisation, with the ambition to deliver a 95% cut in carbon emissions associated with its production processes by 2030.

Deepak Maheshwari, CEO, EET Fuels, says: ‘This is an exciting time for our business. We are delivering on our plan to be the world’s first low carbon process refinery and world’s first low carbon process fuel producer. It is world leading and we’re pleased that it is happening now, in the North West.’

‘EET Fuels is a key part of EET, which is building Europe’s foremost integrated energy transition hub. Leading by example, Essar Energy Transition is a major catalyst for region-wide industrial decarbonisation. We are playing our part to ensure that the UK delivers on its climate change goals, enhances energy security, and maintains a strong, secure manufacturing base for fuels,’ adds Prashant Ruia, chair, EET Fuels and CEO, Essar Energy Transition.

France

EXOLUM AWARDED TENDER FOR FUEL TERMINAL AT PARISCHARLES DE GAULLE INTERNATIONAL AIRPORT

Exolum has announced it has been awarded the tender for the operation and maintenance of the fuel terminal at Paris-Charles de Gaulle international Airport, in Paris, France. The concession, granted by Groupe ADP (Aéroports de Paris) and for which operations are expected to start in April

YOUR CONNECTED PARTNER FOR SUSTAINABLE STORAGE SOLUTIONS Connect with us

www.lbctt.com

Netherlands PAGE 18 NEWS UPDATE ENERGY TRANSITION

Specialist Training for the Storage Tank Industry

Classroom, live online, blended, in-house, and e-learning

Gain or renew up to 5-year Certificates of Competence* Courses based on EEMUA 159

In English, Dutch, German and French Courses each year, including:

TankAssessor courses *

26-29 February 2024 – in Dutch –live online

18-21 March 2024 – in French –classroom – Près de Paris, FR

15-18 April 2024 – in German –classroom – Hanover, DE

20-23 May 2024 – in English –classroom – London, UK

27-30 May 2024 – in English –live online – KSA time zone

TankInspector courses *

4-6 March 2024 – in Dutch –live online

8-10 April 2024 – in French – classroom – Paris, FR

16-18 September 2024 – in English –live online – CSA time zone

28-30 October 2024 – in English –classroom – London, UK

TankBasics courses

16 September - 25 October 2024

–in English – blended learning (live online, e-learning, and more)

S torage Tanks e-learning On-demand – in English and in Dutch

In-house courses

By arrangement for your choice of: time, language, location

Also... Meet EEMUA at StocExpo 2024 Main Conference Seminar 11 am on 12 March and EEMUA's Stand – F45

More choices, information and registration at www.eemua.org

Above ground flat bottomed storage tanks A guide to inspection, maintenance and repair Pub icat on 159 Edition 5 . . . .

heating transition,’ says Arne Hauner, director of innovation at Uniper.

The project is an interplay of various components. The production facilities at the Herne site generate waste heat in varying quantities. The cooling water required in the processes heats up in the plants and now serves as a heat source.

The waste heat is not released into the environment unused, instead it is raised to the required temperature level of over 100°C for the district heating network by the high-temperature heat pump and with the help of renewable energy.

Around 1,000 households in Herne benefit from the heat pump. The CO2 savings amount to around 1,750 tonnes per year.

United Kingdom

EXOLUM TO CONSTRUCT GREEN HYDROGEN PRODUCTION PLANT IN TEES VALLEY

Exolum is going to construct a green hydrogen production plant and refuelling station at its Riverside terminal in Stockton-on-Tees, UK

as part of the Tees Valley Hydrogen Vehicle Ecosystem project.

Exolum has been awarded £2 million as part of the Tees Valley Hydrogen Transport Hub, which is funded by the Department for Transport and delivered in partnership by Innovate UK, to construct the hydrogen refuelling station.

Exolum’s consortium partners have been awarded a further £5 million under the same scheme to deploy at least 20 hydrogen fuel cell trucks in the region.

The project will lead to a first-of-a-kind coordinated deployment of hydrogen refuelling infrastructure and fleets of fuel cell trucks in the Tees Valley and is a vital step towards the development of a nationwide network of hydrogen refuelling stations.

The planned project will feature the construction of a water electrolyser and a hydrogen refuelling station. The electrolyser will produce green hydrogen using renewable electricity and will supply both the refuelling station, with a capacity of 1.5 tonnes per day.

The Tees Valley Hydrogen Vehicle Ecosystem is a vital first step towards the development of a nationwide network of hydrogen refuelling stations, serving as a model for other regions to deploy similar hydrogen mobility ecosystems. This project will help accelerate the UK’s

transition to zero- emission fuel cell vehicles and reduce carbon emissions in line with the UK’s net zero ambition.

Andrés Suarez, clean energies lead at Exolum says: ‘This project in the UK comes in addition to others we have under development and others already fully implemented, such as the first hydrogen plant for mobility in Madrid, Spain.’

Australia

AUSTRALIA TO DEVELOP PILBARA HYDROGEN HUB

The Australian government has announced a AUD$140 million (€85 million) agreement with the Western Australian government to progress a hydrogen hub in the Pilbara region of western Australia. It is the seventh hydrogen hub funded by the Australian government, with more than $500 million (€303 million) invested to support the development of the hydrogen industry.

The Pilbara Hydrogen Hub will serve as a prominent centre for hydrogen production and export, with potential to emerge as a global gateway for Australiamanufactured green steel and iron. It

UK Sampling Gauges Ltd

Our manual sampling equipment, for liquids, are not only operator friendly, but environmentally friendly too! Our unique design of the samplers ensures representative samples are taken time after time.

Reliability is a key feature of UK Sampling Gauges Ltd equipment that will help to avoid repetitive sampling saving time and money! The analysis is only as good as the sample. With a range of ATEX and IECEx approved open and closed sampling systems, contact us to discuss your sampling requirements, training needs or to book a demonstration (at the UKSGL factory or on customer site).

sales@samplinggauges.com I www.samplinggauges.com

sales@samplinggauges.com I www.samplinggauges.com

Download our free UKSGL app to access to our product videos and

brochures.

PAGE 20 NEWS UPDATE ENERGY TRANSITION

is expected to be operational by mid2028, with construction of necessary infrastructure and road intersections commencing this year.

The Australian and Western Australian governments will each contribute $70 million to the project, primarily directed towards building essential infrastructure supporting hydrogen exports and renewable energy production. Funds will be allocated for the establishment of a Clean Energy Training and Research Institute, focusing on practical, job-oriented training in renewable energy and hydrogen for Pilbara residents, including First Nations peoples.

CEO of the Australian Hydrogen Council Dr Fiona Simon says: ‘We would like to congratulate the Australian government, state governments and industry for investing in the Australian Hydrogen industry through seven regional hydrogen hubs strategically positioned across Australia. These hub projects are being led by world-leading developers and partners, and will need continued support from all levels of government to address common user infrastructure, social licence and regulatory requirements. Hydrogen has a clear role to play in meeting Australia’s net zero ambitions especially for the hard-to-abate sectors, so we now need to focus on implementation and continue to share and learn from these large-scale projects to accelerate the transition and drive down the cost of hydrogen.’

VOPAK USA INVESTS IN ELECTRICITY

Vopak is investing in new infrastructure for electricity in the USA. Vopak will own and operate two stand-alone lithium-ion battery energy storage systems near Houston, Texas.

This project marks Vopak’s first entry into electricity storage in the US, and is part of Vopak’s strategy to accelerate towards new energies.

In March 2024, the first 10MWh is expected to be placed into service. The second 20 MWh project, is planned to come into service in Q4 2024. This project is part of its strategy to accelerate towards new energies.

Customised tank mixing solutions

Essential advantages with Körting tank mixing systems:

• low energy input

• no sealing problems

• low investment costs

• no unmixed dead zones

• wear-resistant operation

• no maintenance in the tank

• complete mixing of tank content

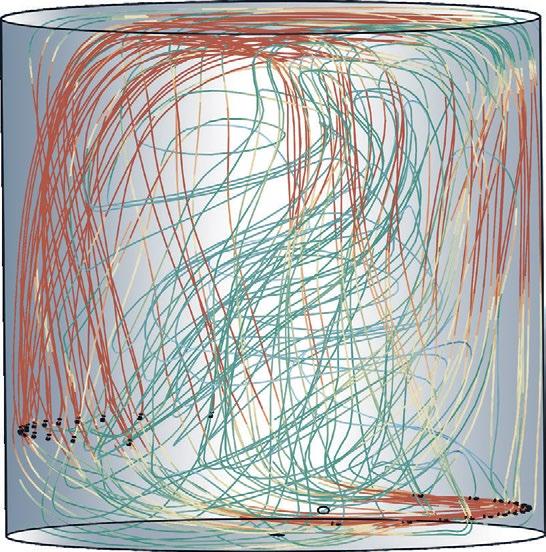

• optimisation with (CFD)

Computational Fluid Dynamics

+49 511 2129-221 | sales@koerting.de | koerting.de

USA

United Kingdom

TSA APPOINTS NUNZIA FLORIO AS COMMUNICATIONS DIRECTOR

The Tank Storage Association (TSA), the trade association representing all aspects of the UK’s bulk storage and energy infrastructure sector, has announced the appointment of Nunzia Florio as communications director.

Florio brings to the role a wealth of experience in communications, media and external affairs and has led the association’s communications functions since 2019 as communications specialist.

Peter Davidson, executive director of the Tank Storage Association, says: ‘Nunzia’s expertise will be invaluable in supporting us to further develop our communications vision for the future, deliver the exciting new initiatives we are setting out for the months and years ahead, continue to build on our relationship with influential external stakeholders, and champion the value and benefits of a thriving, resilient bulk storage and energy infrastructure sector in the UK.’

Florio says: ‘I am delighted to join the TSA in this capacity and privileged to have the opportunity to champion our sector and the key contribution it makes to complex supply chains, growth, mobility and resilience. I look forward to continuing to work closely with our members to share our industry’s ambitions for the future.’

Malaysia

TECHNIP ENERGIES UPDATES ON PETRONAS MELAMINE PROJECT

In February 2022, Technip Energies was awarded the engineering, procurement, construction, and commissioning (EPCC) contract for a new Melamine Plant at Gurun, Malaysia, by Petronas Chemicals Fertiliser Kedah. In a post on LinkedIn, the company provided an update on the progress of the project.

Technip Energies has made significant progress in the installation of key equipment, including the crystallizer and hydrolyzer. The team has demonstrated its commitment to safety, reaching 2.4

million safe man-hours by the end of 2023. Technip Energies is committed to delivering a new plant that will utilise advanced melamine technology and existing interconnections with the existing urea plant to minimise its CO2 footprint.

Apart from progress on the plant, the project team demonstrated its commitment to the local community by sponsoring the installation of the town signage for Gurun. This was launched in a special ceremony in October 2023.

Netherlands

ADVARIO WELCOMES SNEHASHISH CHATTERJEE AS CPSO

Advario has announced that Snehashish Chatterjee is joining the Advario leadership team, in the new chief projects and safety officer (CPSO) role. As CPSO, Chatterjee is responsible for the safe and timely execution of Advario’s projects, across its global portfolio. He also leads various procurement organisation, and drives excellence in safety.

Higher suction capability and dry run

Pump multiple products with a wide range of viscosities with only one pump

From light fuels to heavy crude, asphalt, bunker n.6, molasses, palm oil and more. Contact us, we will find the optimal solution for your application.

We support you from commissioning, maintenance, repair and to modernization of your pump.

Partnership

does not end with the purchase

Your local US Manufacturer for pumping complex fluids NETZSCH Pumps USA Exton, PA, Tel: 610-363-8010 Houston, TX, Tel: 346-445-2400 npa@netzsch.com www.pumps-systems.netzsch.com Empty your tanks faster and e ciently with a Positive Displacement Pump

Exchange centrifugal pump technology to positive displacement technology to realize:

Tank emptying with reduced dead volumes

Tank Storage 175x120 print quarter page.indd 1 10/9/2023 1:58:31 PM

PAGE 22 NEWS UPDATE COMPANY ANNOUNCEMENTS

Chatterjee has been with the company and its predecessor Oiltanking for 25 years starting his career as a trainee engineer in his home country India. In the years that followed, he has held a variety of roles, across a variety of countries. He has been instrumental in building the team and terminal in Oman, led projects in Indonesia, before spending years as VP of Advario’s Southeast Asia cluster. In 2023, he moved into the VP commercial role, located in its Rotterdam HQ.

EXTENSION GRANTED FOR DRIFTWOOD LNG TERMINAL

US LNG terminal developer Tellurian has secured more time from the US FERC to complete the construction of its Driftwood LNG project in Louisiana, USA.

In April 2019, the FERC authorised Driftwood LNG to site, construct, and operate facilities for the liquefaction and export of natural gas in Calcasieu Parish, Louisiana. The project scope includes a 27 million tonnes per annum LNG terminal and 48-inch interstate natural gas pipeline system.

Authorisation was on the basis that the Driftwood terminal and pipeline should be fully completed and made available for service within seven years.

However, Driftwood requested an additional 36 months to complete construction of the LNG terminal and the pipeline and place the entire project in service.FERC granted the extension, giving both Driftwood LNG and the pipeline until April 18, 2029.

‘Because we find that Driftwood has demonstrated good cause for delay and progress in developing the projects, we will grant the requested threeyear extension of time to complete construction of the Driftwood LNG terminal and Driftwood Pipeline project,’ the FERC says.

PROFOX-X Learn more about our smart actuators PROFOX-X ACTUATORS SAFETY THANKS TO CERTIFICATION profox.auma.com

AUMA

PAGE 23 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE COMPANY ANNOUNCEMENTS

USA

INTERNATIONAL ENERGY WEEK ANNOUNCES ED MILIBAND AS SPEAKER

International Energy Week 2024 welcomes Ed Miliband, the UK’s Shadow Secretary of State for Energy Security and Net Zero, as keynote speaker on the opening day of the event.

With a UK general election on the horizon, the former and prospective Energy Secretary will outline how a future Labour government would address the challenges posed by the energy and climate crises, both domestically and internationally.

Miliband has been MP for Doncaster North since May 2005 and, between 2010 and 2015 was Leader of the Labour Party. From 2008-2010 he was UK Secretary of State for Energy and Climate Change, a brief he now covers again in opposition as Shadow Secretary of State for Energy Security and Net Zero.

He is also a co-chair of IPPR’s Environmental Justice Commission and the chair of Doncaster’s Climate Change Commission, both helping to develop ideas and policies to bring about a rapid green transition that is fair and just.

USA

MESA INDUSTRIES PROMOTES ADAM VANCE TO GENERAL MANAGER

Mesa Industries, the parent company of Mesa ETP and Gunite Supply & Equipment, proudly announces the promotion of Adam Vance to the newly created position of General Manager.

Adam Vance, an experienced leader, technical expert, and innovator in the petroleum industry, has been an invaluable asset to Mesa Industries since joining in 2018. Previously serving in a senior management role at Mesa ETP, Vance led business innovation, engineering, and quality, overseeing the design of top-quality customengineered solutions for aboveground storage tanks and the construction industry. Vance played a key role in the successful integration of industry leader WG Seals into Mesa ETP’s Engineered Tank Products division. With

15 years of engineering, operations, and management experience, Vance brings a wealth of knowledge to his new position as general manager.

‘I am honoured to take on the role of general manager at Mesa Industries,’ says Vance. ‘I am committed to building on our successes, fostering innovation, and ensuring the continued growth and success of our company.’

Mexico

VOPAK’S COATZACOALCOS TERMINAL CELEBRATES 24 YEARS INCIDENT FREE

Vopak’s Coatzacoalcos Terminal in Mexico has achieved a impressive milestone of 24 years free from reportable incidents. This means that no one has been seriously injured while working at the terminal in the past 24 years, and there have been no spills.

In a post on LinkedIn, Vopak congratulated the team on this safety achievement. The post states: ‘Safety is Vopak’s highest priority, we strive to ensure that everyone can return home safely at the end of each working day.

EXOLUM OBTAINS ‘TOP EMPLOYER 2024’ CERTIFICATION

Exolum has received the ‘Top Employer 2024’ certification, a recognition that places it as a company with the best practices in human resources management.

This certification positions Exolum as one of the 2,300 companies across the globe and 137 in Spain that stand out for their excellence in people management practices after undergoing a rigorous evaluation process.

Top Employers Institute, the organisation granting the recognition, values the efforts made by the company in HR, after the successful completion of three stages consisting of an HR best practice survey, validation and audit which are required in order to be eligible for the certification. For such purpose, 20 different topics were analysed and assessed during the process, including workforce planning, talent acquisition, employee wellness programmes and social learning, among others. These qualities were assessed following a process audited by an independent body.

Cristina Jaraba, Exolum’s global people lead, says: ‘We are extremely proud of this recognition, which positions us as a Top Employer for 2024. This certification proves Exolum’s efforts in managing its workforce by promoting values such as diversity and equality and favouring work-life balance, talent attraction and professional and personal development.’

United Kingdom

Global PAGE 24 NEWS UPDATE COMPANY ANNOUNCEMENTS

FIRE DETECTION FOR INNER FLOATERS MAINTAINABLE WHILE OPERATION CONTINUES

INNOVATION FOR DOME-ROOF

TANK PROTECTION

NEW! CLEARVIEW VISIT US AT STAND C4 systems@saval.nl SAVAL.NL Ad ClearView-CFI-StockExpo-A5-2024_drukwerk.indd 1 8-2-2024 15:02:04

EMERSON NAMED ‘INDUSTRIAL IOT COMPANY OF THE YEAR’

Technology and software company, Emerson has been named IoT Breakthrough ‘Industrial IoT Company of the Year’ for the sixth time.

The 2024 award recognises Emerson’s advances in sustainability-enabling technologies and software, efforts to accelerate the development and delivery of life-saving drugs, and the company’s Boundless Automation vision of a nextgeneration, software-defined industrial automation architecture.

Lal Karsanbhai, president and chief executive officer of Emerson says: ‘We are honoured to receive this award that recognises the value Emerson delivers to help customers in so many critical industries achieve their maximum performance.’

The award also recognises Emerson’s leadership in developing digital technologies aimed at accelerating drug development. The company recently announced One-Click Technology Transfer software that will convert today’s life sciences manufacturing recipe transfer process into a digitalised production platform, helping get new drug therapies to patients faster.

‘Emerson is a consistent winner of our Industrial IoT Company of the Year award because of how effectively it leverages its decades of expertise in digitalisation and automation to help industry leaders transform their operations to address the needs of the future,’ adds Steve Johansson, managing director at IoT Breakthrough.

GLOBAL ENERGY TALENT INDEX EXAMINES AI IN OIL AND GAS

The eighth annual Global Energy Talent Index (GETI), has released a report which has highlighted a cautious approach to AI adoption in the oil and gas industry, wide interest in AI skills development, and a slowing of salary growth.

According to the report, produced by Airswift, 24% of oil and gas professionals already use AI – somewhat behind the industry average of 27%. A further 10 % are expecting to adopt AI within six months. Nearly half (47%) of

professionals feel very optimistic about the future impact of AI, with many anticipating an uplift in their personal productivity (71%), improved career progression opportunities (58%) and increased job satisfaction (58%). Over 53% believe it will positively impact time spent with family and friends.

Nearly all respondents to the GETI 2024 report say AI will increase demand for skills, with two thirds (62%) of oil and gas professionals expecting AI to increase pressure on them to acquire new skills.

Reflecting on the findings of the GETI 2024 report, Janette Marx, CEO of Airswift, says: ‘Our report underscores the need for a delicate balance between technological advancement and nurturing the skills of our workforce.

As we see a modest stabilisation in salaries and a high willingness for global mobility, the area to watch now is how companies embrace AI.’

The report also indicates a flattening in salary growth, with 48% of professionals reporting a pay rise this year, a modest increase compared to previous years. 69% of professionals are optimistic of a pay rise next year, a sentiment that is shared by hiring managers.

With an international pipeline of new projects, 83% would consider relocating, compared with 81% in 2023. Asia enters the top three desirable destinations for relocation, behind Europe and the Middle East. The demand for oil and gas skills remains strong, both within and beyond the sector, with 81% having been headhunted in the past year. However, there is a hesitancy to join other industries, with only 19% considering such a move.

ESSAR TO PARTNER WITH TOPSOE AT STANLOW REFINERY

Essar Oil UK has selected Topsoe as a second key licensor technology provider for the planned EET Industrial Carbon Capture (“ICC”) facility based at Stanlow, UK.

This is a pivotal step towards Essar’s $1.2 billion (€1.1 billion) investment in decarbonising the Stanlow refinery, by reducing around 2 million tonnes of CO2 emissions, making it the world’s first low-carbon refinery and a producer of low carbon fuels.

Topsoe will provide its sustainable fluegas treatment technology SNOXTM.

Deepak Maheshwari, CEO of Essar Oil UK, says: ‘The industrial carbon capture facility, combined with our upcoming hydrogen fuel switching project, will reduce the refinery’s CO2 emissions by 95%. Topsoe is a valuable partner in this endeavour. With Topsoe’s SNOM technology we are getting a proven and highly sustainable flue-gas treatment.’

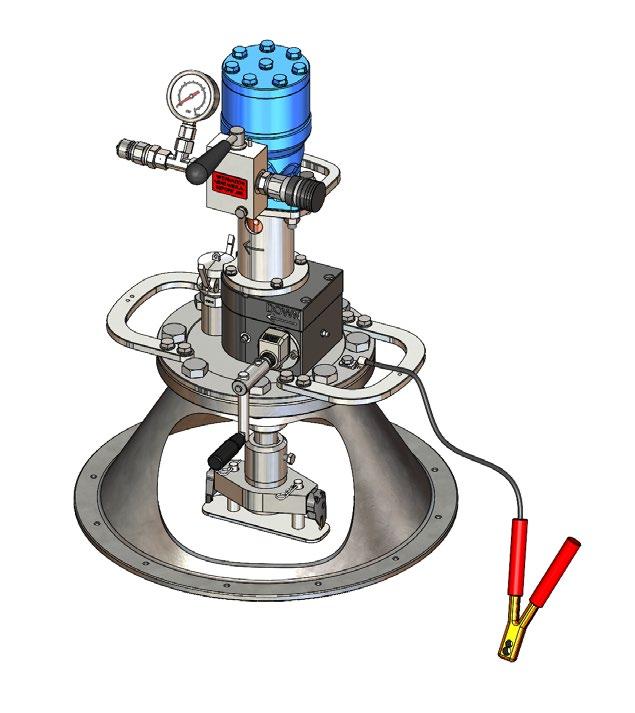

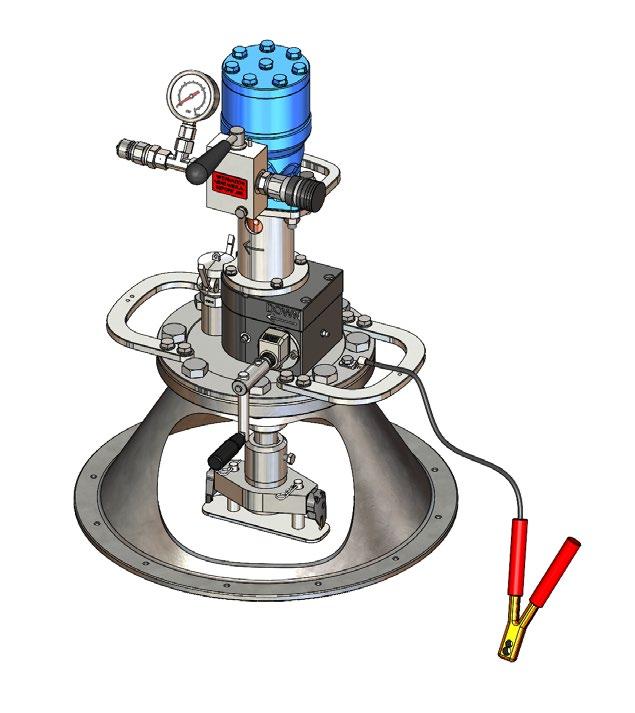

EMERSON LAUNCHES PILOT-OPERATED RELIEF VALVE

Emerson has introduced the Fisher 63EGLP-16 Pilot Operated Relief Valve for installation on pressurised bullet tanks used to store liquid propane and anhydrous ammonia.

The new pressure relief valve (PRV) is certified under UL132 and American Society of Mechanical Engineers (ASME) Section VIII.

With a pre-installed national pipe tapered (NPT) thread standard 2-inch male hex

Global Energy Talent Index (GETI)

Emerson

Emerson

Essar Oil UK

TERMINAL NEWS XXXXXXXXX PAGE 26 NEWS UPDATE TECHNICAL NEWS

nipple, this new product serves the need for a solution with a 2-inch connection that provides the same benefit as traditional multi-ported valves, but with simplified installation and maintenance. For this application, the PRV must be connected directly to the tank, with no isolation valve between the tank and the PRV. This National Fire Protection Association (NFPA) 58 code requirement presents challenges when testing the PRV while the tank is pressurised and in operation.

The Fisher 63EGLP-16 Pilot Operated Relief Valve addresses this and other issues because it is the only pilotoperated relief valve on the market designed specifically for this type of service. Operation is implemented with a dual pilot array, providing redundancy, and allowing for removal of one pilot for testing while the other is operational.

Because this is a critical safety-related application, reliable operation over a long lifecycle is needed. This requirement is met by the 2-inch PRV because it is similar in design to the Fisher 63EGLP 4-inch CL300 model, which has been proven in use over the past 10 years.

GEROTTO ANNOUNCES IECEX CERTIFICATION PROCESS AND UL COMPLIANCE FOR ROBOTS

Italian company Gerotto, has begun a process that will lead – by the first half of 2024 – to the UL compliance, valid in North America, and to the international IECEx certification of its robotic systems for cleaning tanks inside refineries and tank terminals.

Alessandro Gerotto, CEO of Gerotto says: ‘This project is a key step in our industrial growth plan, which includes a deeper penetration in strategic oil and gas markets. Our company’s international vocation leads us to face technological challenges with a focus on operator safety and improving the working conditions of women and men around the world.’

‘IECEx certification and UL compliance are a key step in strengthening our positioning in markets where we are already present such as Australasia, North America and Africa. Thus, the range of tank cleaning robots becomes even more versatile and allows us to meet cross-cutting needs of contractors and asset owners and we are confident that it will bring added value to our customers and partners,’ adds Daniel Devò, Gerotto’s export sales manager.

TERMINAL NEWS AFRICA & THE MIDDLE EAST

Gerotto

PAGE 27 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE TECHNICAL NEWS

VEGA T2 Electronic Batch Controller Wi-Fi & Bluetooth Compatible Freeware Windows Toolkit ATEX- IECEx Approved Large Colour Display ISOIL Impianti S.p.A. - Italy Tel. +39 02 91988 5 - Email: sales@isoil-impianti.it - www.isoilmeter.com for Loading Operations Flow Metering and Automation Solutions for the Oil Industry Specialising in Downstream Oil and Aviation, Fabri Consulting Engineers provide Clients with the requisite engineering and management expertise to safely and effectively deliver Projects to existing and new terminals throughout the UK, Europe, Asia and Africa. Fabri project managers and engineers work closely with clients, contractors and suppliers to ensure the projects are delivered trouble free. FEED Studies | Process Design | Project Management | EC&I/Mechanical and Civil Design | Procurement, Scheduling and Cost Control | ATEX Inspections and Compliance | HAZOP/LOPA Studies | 3D Surveying/Modelling | Commissioning In summary, all aspects of an operational downstream terminal, from minor works to complete terminal redevelopment. Contact us at info@fabriconsult.com to discuss your requirements. To learn more visit www.fabriconsult.com or call us on +44(0)141 95 45 991

ANDERSON PROCESS ACQUIRES TIGHEZEMAN EQUIPMENT LLC

Anderson Process, one of the US Midwest’s leading suppliers of process equipment, repair and services, has acquired long-standing manufacturer’s representative TigheZeman Equipment LLC.

Since 1952, Tighe-Zeman Equipment has been providing solutions throughout Wisconsin and the Upper Peninsula of Michigan. For over 70 years, the company has specialised in mixers, pumps, tanks and engineered systems. Its target markets are general process, food and beverage, biopharma, pulp and paper, power, chemical and municipal. This acquisition capitalises on complementary product offerings between the two companies. It also strengthens relationships with customers and offers them leading brands, including SPX mixers, WatsonMarlow pumps and Belding Tank Technologies.

‘Tighe-Zeman Equipment is very pleased to have become a part of Anderson Process,’ says Tighe-Zeman Equipment owner Dan Tighe. ‘This provides us with the opportunity to utilize our well-known knowledge and experience of mixers, tanks and peristaltic pumps and provide expanded coverage and penetration into the marketplace. This will provide better support for our customers and coverage for our principals.’

Anderson Process has warehouse and service locations in Wisconsin, Illinois, Indiana, Michigan, Ohio and Minnesota. With physical locations in those US states and a sales team spread across eight states in the Midwest, Anderson Process can provide the physical presence necessary to specify and supply a comprehensive line card of process equipment.

With the acquisition of Tighe-Zeman Equipment, Anderson Process now has 175 fluid-handling professionals.

EEMUA Training for Mechanical Integrity with reality built

in…

Developed and verified ‘for industry, by industry' , Mechanical Integrity courses come with reality bu industrial engineers at every career stage. For effic with primary containment – to prevent loss of haza

• Satisfy industry requirements at each competency level – Awareness, Basic application, Practitioner.

• Certificated courses – through robust examination, valid up to 5 years.

• CPD-approved courses.

•Flexible delivery to suit learners and companies

– Blended, Live online, Classroom, E-learning, In-house

• Available to all – free or discounted to EEMUA Members.

• Select from courses throughout each year, including:

Mechanical Integrity Practitioner Certificate (MIPC®) – blended, live online learning for on-site application of EEMUA 177, 231 and 232 guidance, and the PSSR ACOP –certificated for 5 years via a proctored exam and portfolio assessment – the Next course begins on 4 March 2024 and runs for 27 weeks, at 4 hours per week. The MIPC course adapts to the engineering needs of each Learner, company and site through a 2-hour induction to fit work from 5 February 2024

EEMUA 231 Mechanical Integrity Basics – certificated via exam –blended, online learning – at the Basic application competency level –4 hours of learning per week for 3 weeks – Next course starts 26 February 2024

EEMUA 231 Mechanical Integrity e-learning – set at the Awareness level – immediately available on-demand – course with Continuing Professional Development approval.

EEMUA 231 Mechanical Integrity In-house training – running over a whole-day or 2 half-days – set at the Awareness level – by arrangement, for your choice of time, location, and learning method – Certificated, Continuing Professional Development approval

online-learning@eemua.org

+44 (0) 20 7488 0801

www.eemua.org

TERMINAL NEWS AFRICA & THE MIDDLE EAST

MeetEEMUA atStocExpo2024 StandF45

PAGE 29 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE TECHNICAL NEWS

Anderson Process

INCIDENT REPORT

A summary of the recent explosions, fires and leaks in the tank storage industry

19 February

MALAYSIA

Ammonia gas geak at Shah Alam factory

10 factory workers have been rushed to hospital following an ammonia gas leak at a factory in Jalan Keluli 1 at the Bukit Raja Industrial Area, Malaysia.

State Fire and Rescue Department deputy director (operations)

Ahmad Mukhlis Mukhtar says: ‘Preliminary checks suggested that there was a valve leakage from a tank storing ammonia gas. Works to shut off the valve is being done by the hazmat (hazardous materials) team.’

2 February INDIANA, USA

Power outage at BP Whiting, Indiana US oil refinery

A power outage hit the BP oil refinery in Whiting, Indiana, on Thursday 1 February, prompting increased burning and flaring to manage excess product.

The outage resulted in burning and flaring from the refinery stacks as BP addressed the surplus product. Despite lifting the evacuation order late Thursday, road closures continued and BP aimed to restore power by 10 pm that evening with gradual system restarts on Friday morning.

29 January

MONGOLIA

LNG tanker crash in Mongolia

Three firefighters died when a truck transporting 54.5 tonnes of liquefied natural gas (LNG) crashed and exploded in Ulaanbaatar, Mongolia’s capital.

The incident occurred early on January 24 after the vehicle collided with a car. Emergency responders, numbering in the hundreds, fought the resulting blaze which spread to nearby structures, injuring at least 11 individuals. The blast hit three nearby buildings.

PAGE 30

INCIDENT REPORT

+ Robotic sludge removal

+ Chemical treatment

+ Water washing

+ Material processing

+ Waste minimization

+ Emission controls/degassing

+ Nitrogen services

+ Hydro cutting

+ Vacuuming

+ In-plant transportation

+ Robotic surface preparation

+ Coating & painting

+ More

844.243.5557 • sales@usadebusk.com • www.usadebusk.com • Follow us: Advanced technologies for safety and savings. Coker Services | Controlled-Volume Pigging | Emission Controls | Field Services | Hot Catalyst Services Hydro Blasting | Hydro Cutting | Hydro Excavation & Vacuum Services | Inert Catalyst Services Nitrogen Services | Pigging, Decoking & Filtration | Pipeline Integrity Management Reactor Cleaning | Tank Cleaning | Transportation, Storage & Transloading | Turnaround Services Unit Decontamination & Chemical Cleaning Get the savings, efficiency, and enhanced safety of a single multi-service provider for tank cleaning, resource recovery, and waste mitigation. USA DeBusk – one source, unlimited value.

…THAN USA DEBUSK NO ONE PUTS MORE INTO YOUR TANK…

the focus is on sustainability and innovation. The facility will primarily utilise organic side streams from the agricultural sector and food industry such as potato peels and animal manure minimizing environmental impact and maximizing resource value.

LANZAJET

Products: Ethanol to SAF

Construction: LanzaJet has joined government officials, industry leaders, partners, and supporters to open LanzaJet Freedom Pines, the world’s first ethanol to sustainable aviation fuel (SAF) production facility.

Comment: LanzaJet CEO Jimmy Samartzis says: ‘Our novel LanzaJet ethanol to SAF process technology is now deployed at our commercial plant in Georgia which will convert ethanol into drop-in SAF. As we start-up the plant, we will continue to refine our technology, while launching our efforts to advance new sustainable fuels projects globally.’

Greenergy, says: ‘We are constantly looking at how we can increase efficiency across our own operations, and the commissioning of these expansion works in Amsterdam and on Teesside is key to our strategy to support the energy transition through waste-derived fuel products.

PORT OF ANTWERP-BRUGES INTERNATIONAL

Products: Industrial hub

Construction: Port of Antwerp-Bruges International (PoABI) and Perbadanan Kemajuan Negeri Perak (PKNP), a state development agency, have formed a strategic partnership to develop the port of Lumut in Perak state, Malaysia.

Comment: Kristof Waterschoot, managing director PoABI: ‘The official establishment of this development company underlines our commitment to the development of LUMIC. Together with our partner PKNP, we are ready to create a sustainable industrial cluster, which will not only boost the local economy, but also contribute to the broader vision of progress and innovation for the state of Perak in Malaysia.’

chains for new sustainable energy vectors such as ammonia and green methanol, both of which are hydrogen derivatives. This operation, Exolum’s first in the U.S., will enable us to continue strengthening our position in strategic ports. It also allows us to further promote the energy transition and the decarbonisation of mobility, which are central to our sustainability master plan.’

TECHNIP ENERGIES

Products: Petrochemicals

Construction: Technip Energies have announced that start-up has begun at its Long Son petrochemical complex in Vietnam. This project that uses naphtha and liquefied petroleum gas (LPG) to produce olefins products is Vietnam’s first Olefins plant.

Comment: In 2018, Technip Energies were awarded a contract for the petrochemical complex licensing, engineering, procurement, construction, commissioning, start-up, training, interim operation, and maintenance.

PAGE 32

Georgia, US

Malaysia

Vietnam

US ENERGY

Products: Refined products

Acquisition: US Energy acquired two refined product terminals in Mount Prospect and Rockford, Illinois. With the addition of these facilities, US Energy now owns and operates 37 terminals across nine states with a collective storage capacity of over eight million barrels.

Comment: ‘We are excited to welcome four legacy employees from these facilities to the U.S. Energy team. Across our terminal network, we pride ourselves on our customer service, safety record, site uptime, and throughput turnaround. We are confident these team members will help us replicate this at our new locations,’ adds Dan Morrill, vice president of operations at US Energy.

HIAP SENG ENGINEERING

Products: Petrochemicals

Construction: Hiap Seng Engineering Limited FZC, UAE, has been awarded a significant contract by Intrakat Societe Anonyme Technical and Energy Products, Fujairah Branch for the engineering, procurement, construction, and commissioning (EPCC) of the Ecomar Storage Terminal Phase I Project, located in the Fujairah Oil Industry Zone, UAE.

Comment: ‘This award demonstrates how, through strong collaboration and consistent project execution strategy, we continue to build our relationship with Ecomar,’ says Murugesan Chidambaram, Managing Director of Hiap Seng. ‘To ensure project execution excellence, we will leverage our “One Hiap Seng Way” operating model to safely and efficiently deliver the Ecomar Storage Terminal Project with the highest quality.’

We’re growing so fast we didn’t even have time to come up with a new ad...

PAGE 33 TANK TERMINAL UPDATE

Illinois, US

However, with a stroke of luck, we hope to meet you on March 12th and 13th at StocExpo 2024. There, we will be delighted to share what’s been keeping us bustling in Dordrecht and Antwerp. We are also eager to hear your story. See you there? www.standic.com

UAE

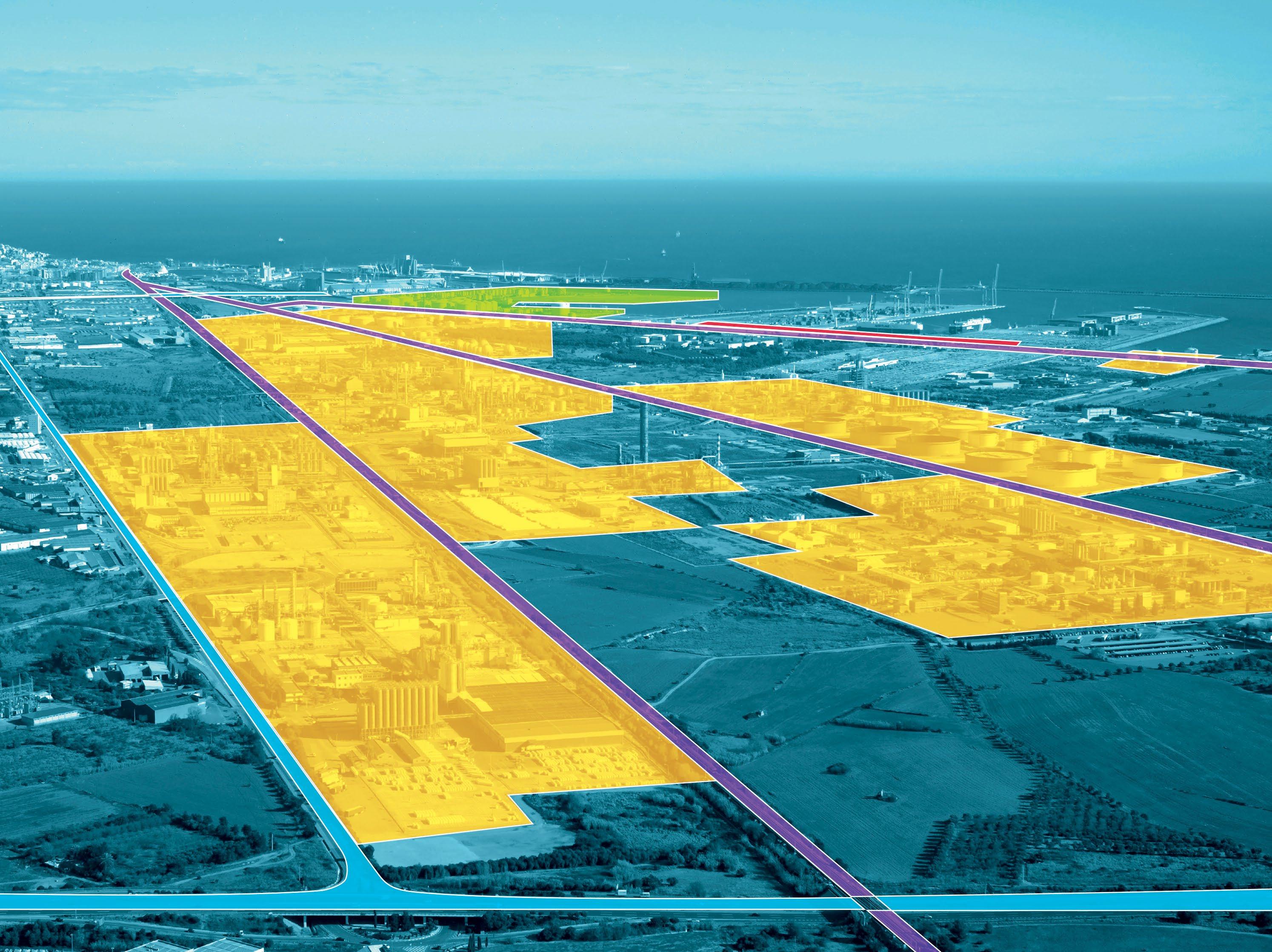

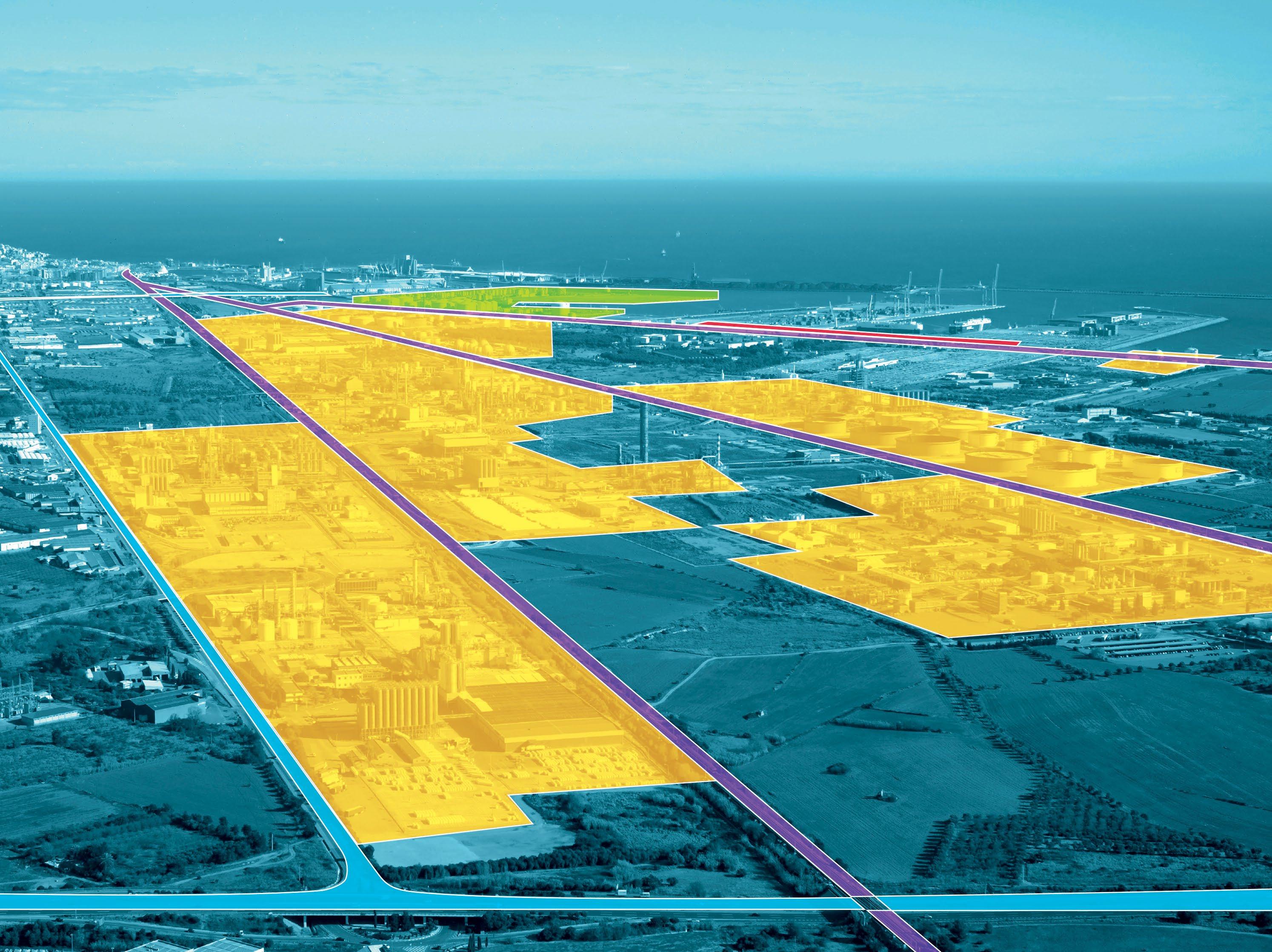

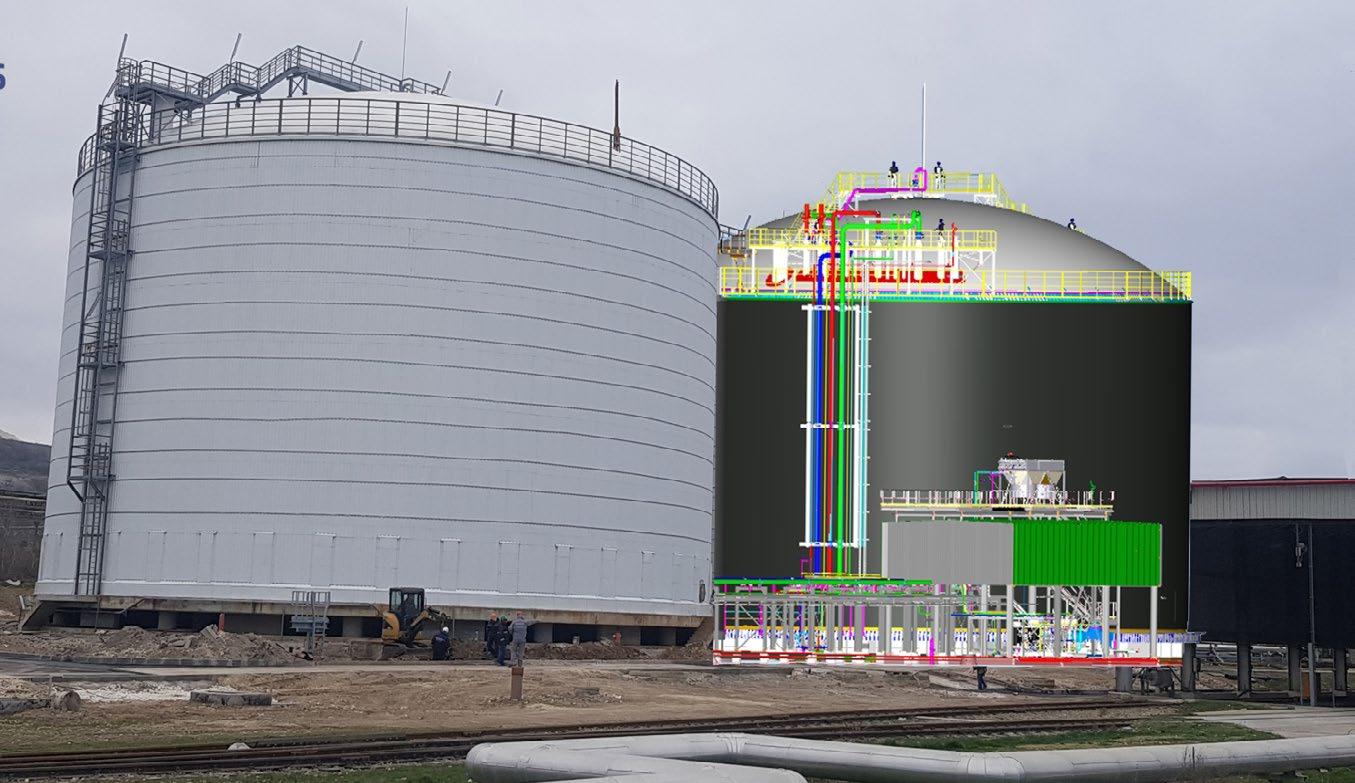

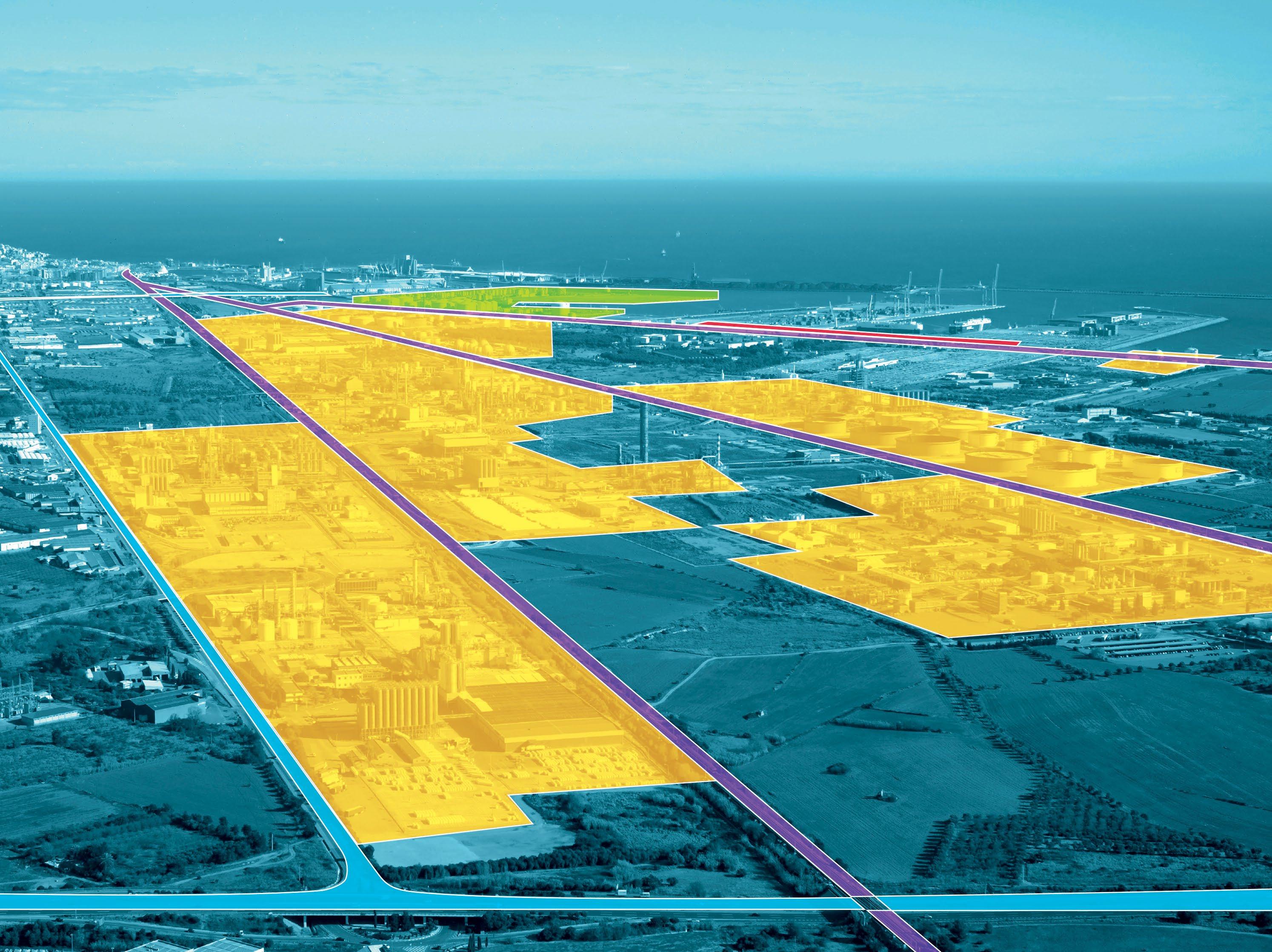

A COMPLETE, MULTICUSTOMER TERMINAL

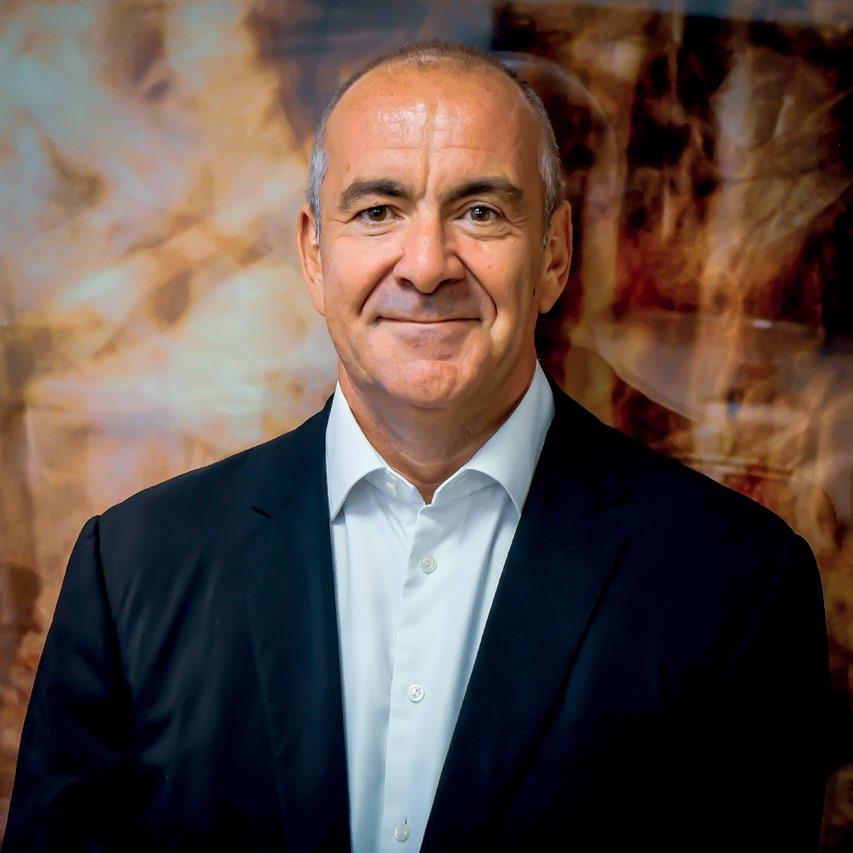

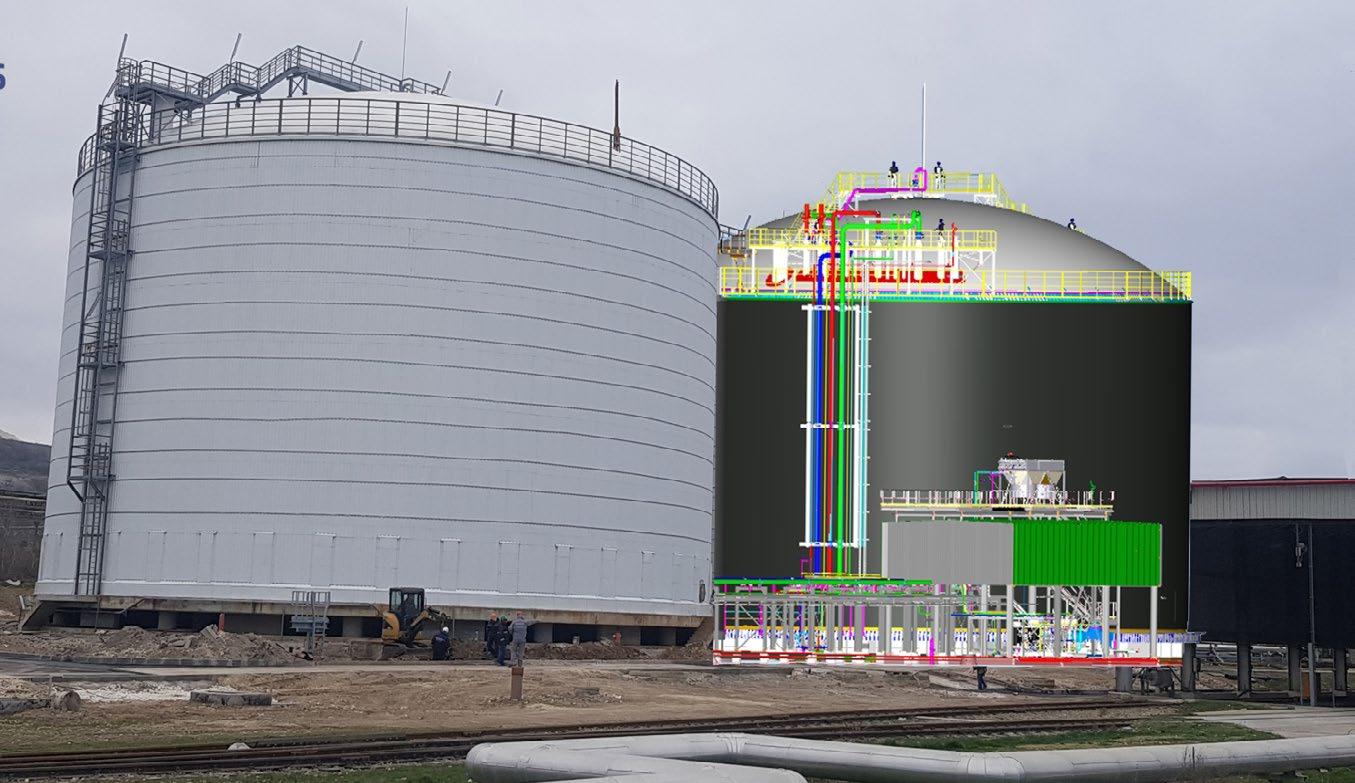

Tank Storage Magazine speaks with Frans Jan Hellenthal, commercial manager at VTTI, about Euro Tank Terminal and its exclusive tour at StocExpo 01

EURO TANK Terminal Rotterdam

in the Netherlands, also known as ETT, was founded in 2006 and originally started with one tank pit for fuel oil storage. During the first few years, the focus of the terminal was on making bulk and storing fuel oil. The product would come from several origins, primarily for export to Asia.

‘Vitol was one of the founders of VTTI and ETT was one of the first terminals of the group as part of this development. Overtime, VTTI diversified, both in terms of shareholder base and customers.

Currently, the company is composed of three shareholders, two of which have an equal stake and one minority shareholder,’ explains Frans Jan Hellenthal, commercial manager at VTTI. Several tank pits were developed over the next 15 years, and many new customers came along with this, transforming ETT into a complete, multicustomer terminal. It is now capable of handling the largest seagoing vessels as well as smaller coasters, barges, trains, trucks and pipeline connectivity.

CENTRAL LOCATION

ETT is located on the deep-water channel of the Port of Rotterdam in the middle of the port complex, ensuring it is in close proximity to refineries and adjacent industries. The site also offers options to connect to infrastructure, such as road, rail and pipelines, which all run close by the site and are connected to the terminal too.

‘A key advantage of the terminal is that it can handle a wide range of ship sizes, from VLCC-size, to coasters and barges. The fuel storage sector will still need both large vessels as well as smaller parcels coming in, even with all the changes

‘Further improvements and projects are underway to push forward our own energy use and emissions, enabling the terminal to reach net-zero by 2042.’

to come due to the energy transition and from changes in product flows worldwide,’ says Hellenthal.

The terminal handles products from various nearby sites and industries as ETT is as well connected to the panEuropean aviation fuels pipeline system, further enhancing its position as aviation fuels hub for European airports.

ADAPTING TO MARKET CHANGES

The handling of sustainable aviation fuel (SAF) is the most recent addition to the terminal and Hellenthal views it as a promising market. ‘ETT has always been evolving with the market and adapting itself to new realities. Starting with fuel oil and later gas oil, the terminal currently stores a variety of products including methanol, ethanol, jet fuel, and SAF,’ Hellenthal says. Looking towards the likelihood of mandated blending of SAF into the jet fuel market, this helps put ETT ahead of the curve.

Existing connections could not be used, as handling SAF is not the same as handling regular jet fuel. So, to

PAGE 34

PROFILE EURO TANK TERMINAL

accommodate these more sustainable projects involving storing and blending SAF, ETT has been adapting its own infrastructure to ensure appropriate connectivity.

LEADING TOWARDS NET-ZERO

ETT prides itself on being on the cutting edge of change and is taking steps to ensure it is ready for net-zero. ‘We have the ambition to have at least 50% of our business coming from transitional and renewable energies by 2028.

ETT is preparing itself for this both by focusing on its own footprint as well as by selecting customers which fit this purpose and mission of our business,’ says Hellenthal.

Most companies have experienced large volatilities in energy prices, so ETT has put a strong focus on decreasing its own energy use at the terminal. As well as reducing costs, this also has a positive impact on its emissions.

ETT is contracting its on-site energy from sustainable sources, such as wind and solar power. The facility has its own solar capacity installed at the main pump room, as well as a contract with an external electricity company, generating power via wind, to provide sufficient energy to run the terminal.

‘As of now, further improvements and projects are underway to push forward our own energy use and emissions, enabling the terminal to reach net-zero by 2042,’ explains Hellenthal. ‘Next to that, our main drivers are pushing into the future fuels and new energies space in which we leverage our global knowledge and experience.’

FUTURE-THINKING

Euro Tank Terminal is highly automated, which makes it efficient and flexible. This, in turn, enables further digitalisation to take place. ETT intends to leverage this by making maximum use of existing and new to be developed tools and software. ‘These tools and software can be both developed in-house as well as contracted by third parties. Digitalisation is a great tool, not only for internal administration purposes, but also enabling us to make data transparently available to our customers and stakeholders,’ explains Hellenthal. This enhances its customers’ operations and streamlines the overall logistics processes through the terminal jointly with all other parties in the logistics chain.

It’s a crowded market in Rotterdam, but ETT has earned its position. ‘We will build on that strong base to stay on top for our customers and develop opportunities for future business,’ say Hellenthal.