SPEARHEADING THE DIGITAL REVOLUTION

Discover how Odfjell Terminals US is progressing with its digitalisation projects

OFF-GRID ENERGY & MEETING TARGETS

Flogas Britain shares how it is keeping up with changing energy demands

VIRTUAL REALITY PROCESS & SAFETY TRAINING

The experts at Oak Tree Consulting explain how VR applies to tank storage

June/July 2023 | Volume 19 | Issue 03

Established 2005. Trusted. Valued. Influential.

Clearwater, Florida, USA l www.lightningmaster.com l 1-800-749-6800 We wrote the book on lightning and static protection for process and storage tanks Structural lightning protection | Bypass conductors | Bonding | Grounding LIGHTNING AND STATIC PROTECTION FOR PROCESS AND STORAGE TANKS

EXCLUSIVE INTERVIEWS 30 32 36 34 30 Spearheading the digital revolution Fresh from his ORBIE award win, Aldrich Varilla, IT director for Odfjell Terminals US tells Tank Storage Magazine about the company’s digital initiatives 32 Off-grid energy and meeting targets Flogas Britain’s business development director, James Rudman tells Tank Storage Magazine how it’s keeping up with the ever-changing energy market 34 World-class facility Leading regional player for processing industry chemicals in the GCC region, AquaChemie, inaugurates its new petrochemical terminal at Jebel Ali Port 36 ‘Do not call me a diversty hire’ Embracing and encouraging diversity in the industry leads to endless possibilities, says Smartflow’s Stefana Sopco

ANALYSIS 38 Legislating for alternative fuels FETSA’s executive director, Ravi Bhatiani, looks at what’s needed from political leaders to enable the energy transition 39 Hydrogen’s role in the energy transition Madana Nallappan, EIC analyst, Asia Pacific region, discusses the emerging developments of hydrogen supply chains and the need for policy changes 40 Virtual reality-based process and safety training Karthik Govindarajan, president at Oak Tree Consulting, tells Tank Storage Magazine how VR and AR technologies are changing training procedures TERMINAL NEWS 08 Europe 14 The Americas 18 Middle East & Africa 20 Asia & Pacific 27 Tank terminal update UP FRONT 04 Contributors 06 Editor’s note CONTENTS June/July 2023 | Volume 19 | Issue 03 UP FRONT CONTENTS PAGE 01

MARKET

TECHNICAL FEATURES

42 Biofuels of the future, leading the change

Cyann Fielding asks biofuels experts to share their predictions for the future of tank storage and sustainability

46 Hydrogen takes centre stage

Molly Cooper investigates the factors involved in the transition to storing hydrogen as an industrial fuel

50 Versatile tank linings meet diverse needs

Lab tests and field studies identify coatings that streamline tank cleanings, adhere under pressure and withstand aggressive chemicals

52 One size does not fit all

Tank Storage Magazine looks at how leak detection equipment is embracing the digital transformation

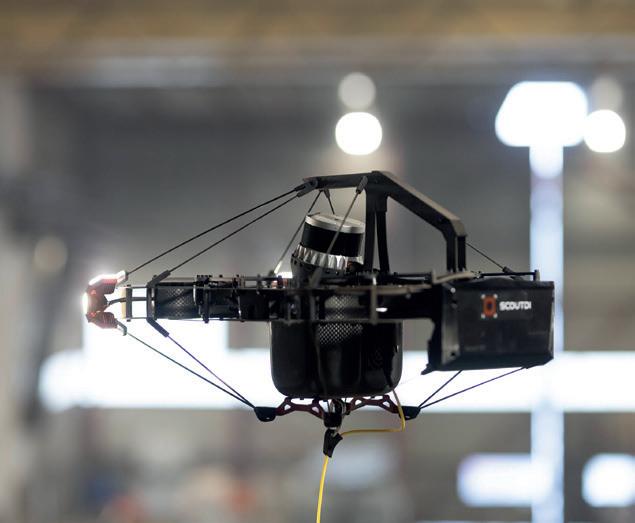

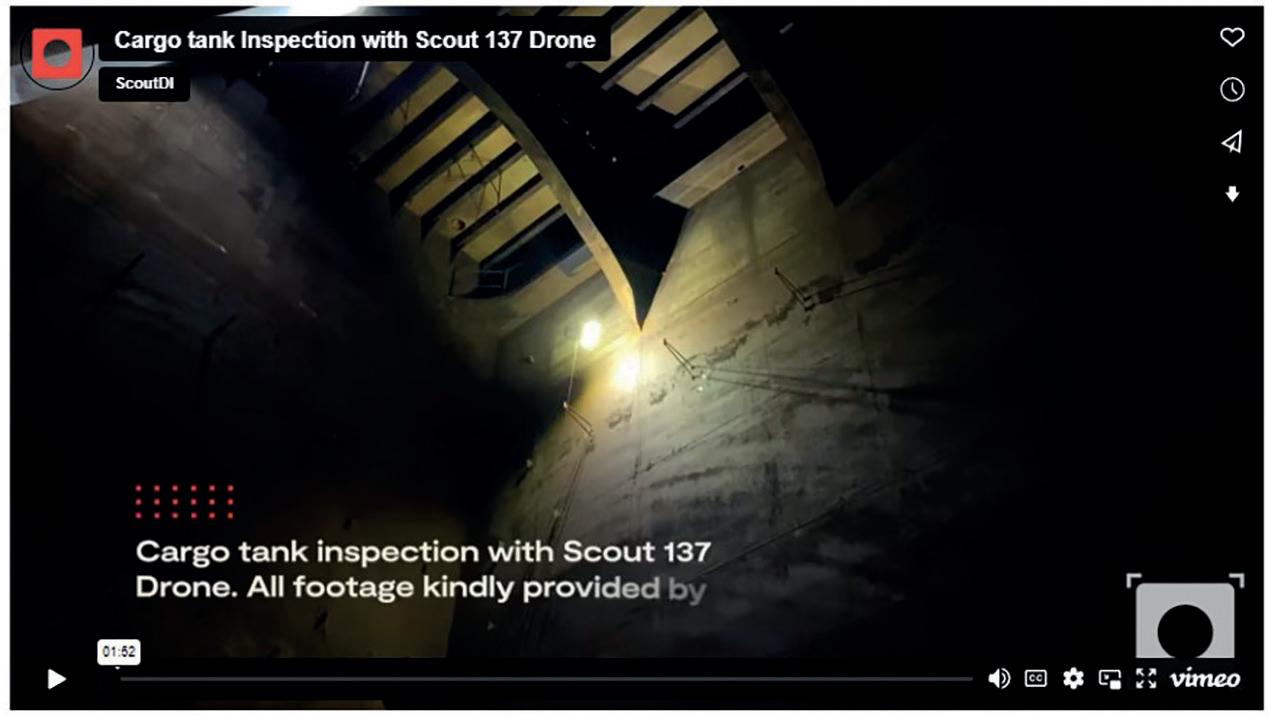

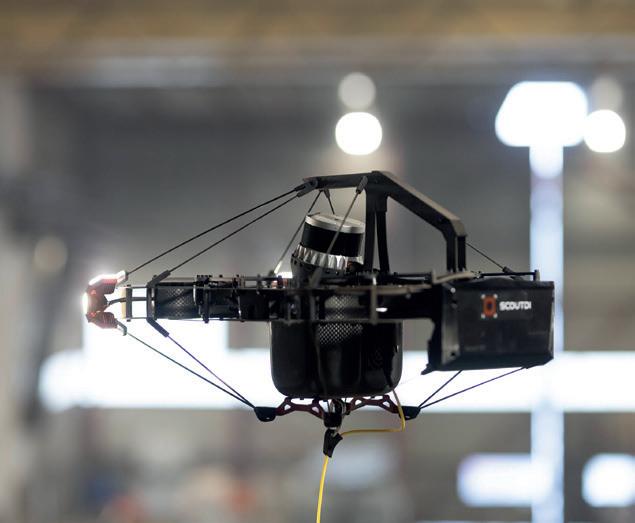

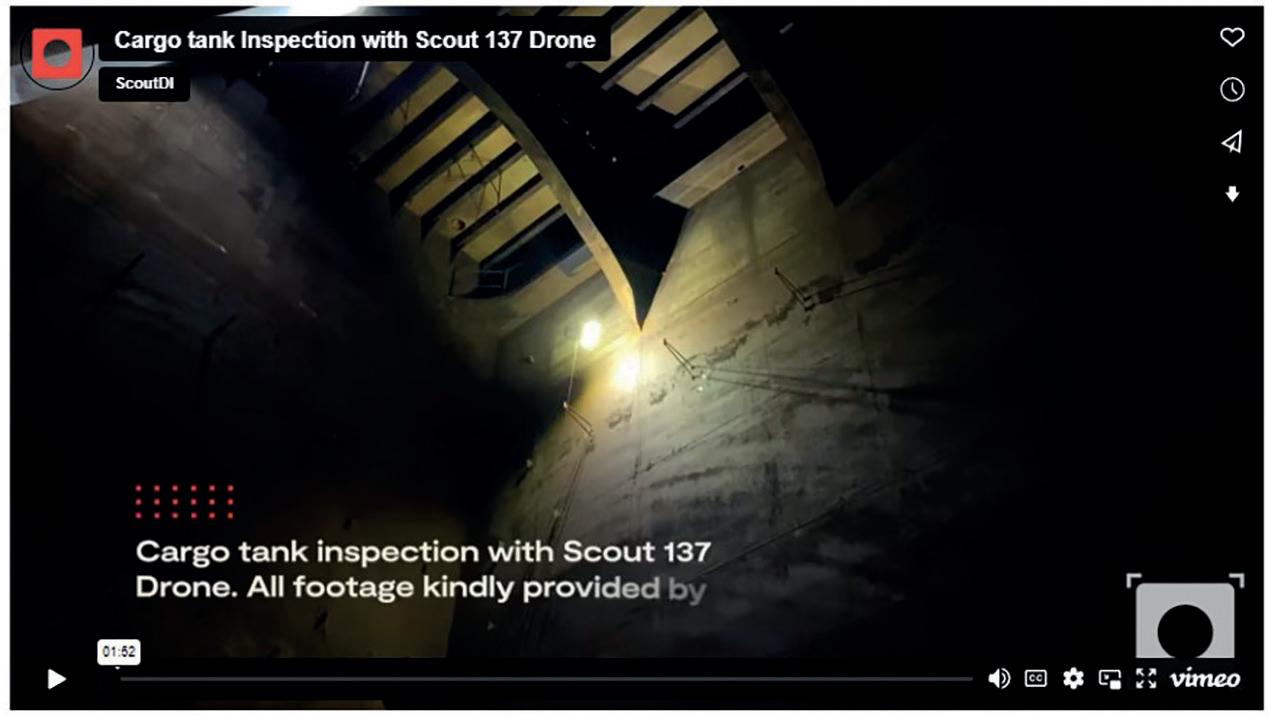

56 Cargo tank inspection: the right people and the right tools

To Simon Ruddick at Marine Inspection Services, a combined visual and UT drone platform could mean a welcome goodbye to rope access and scaffolding

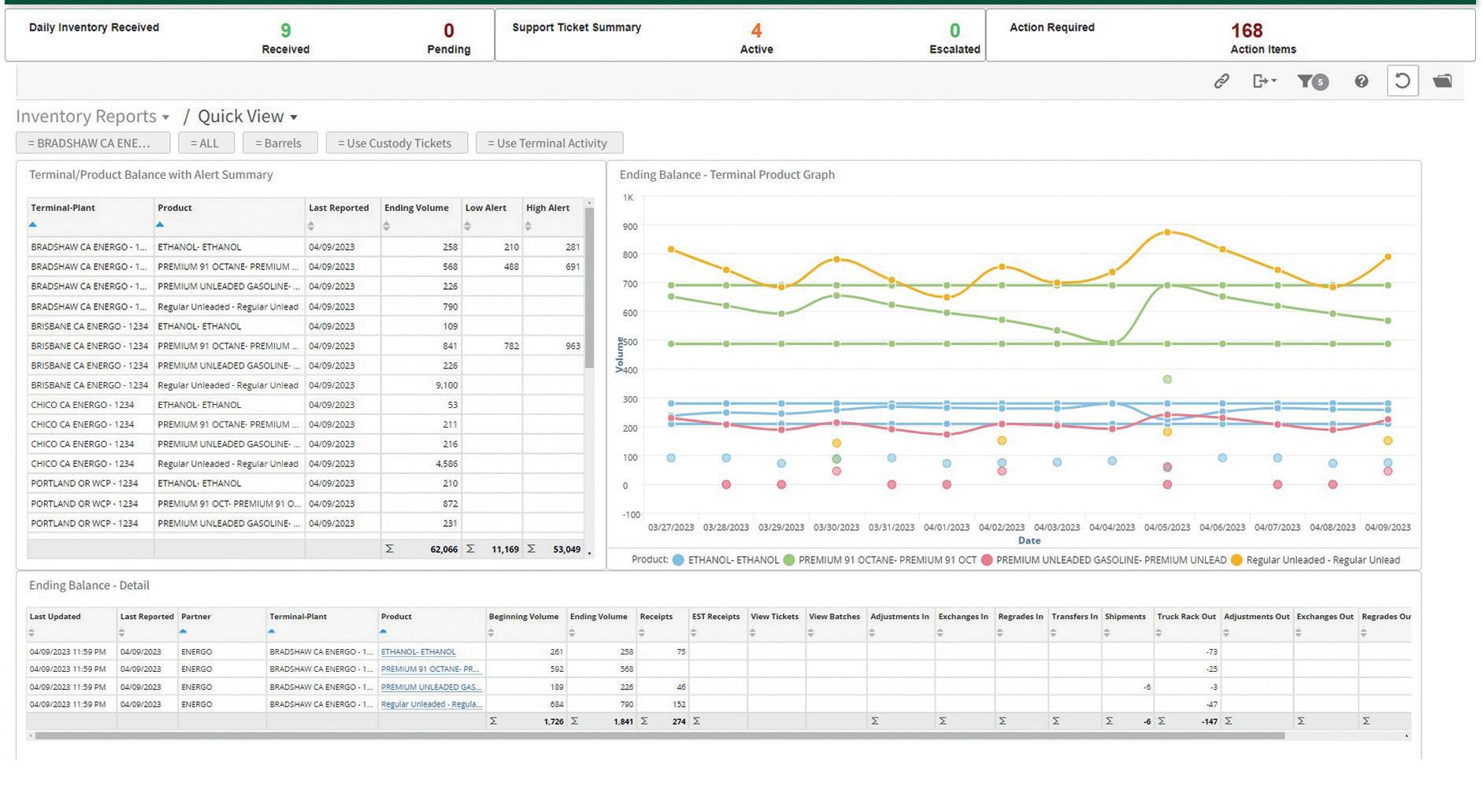

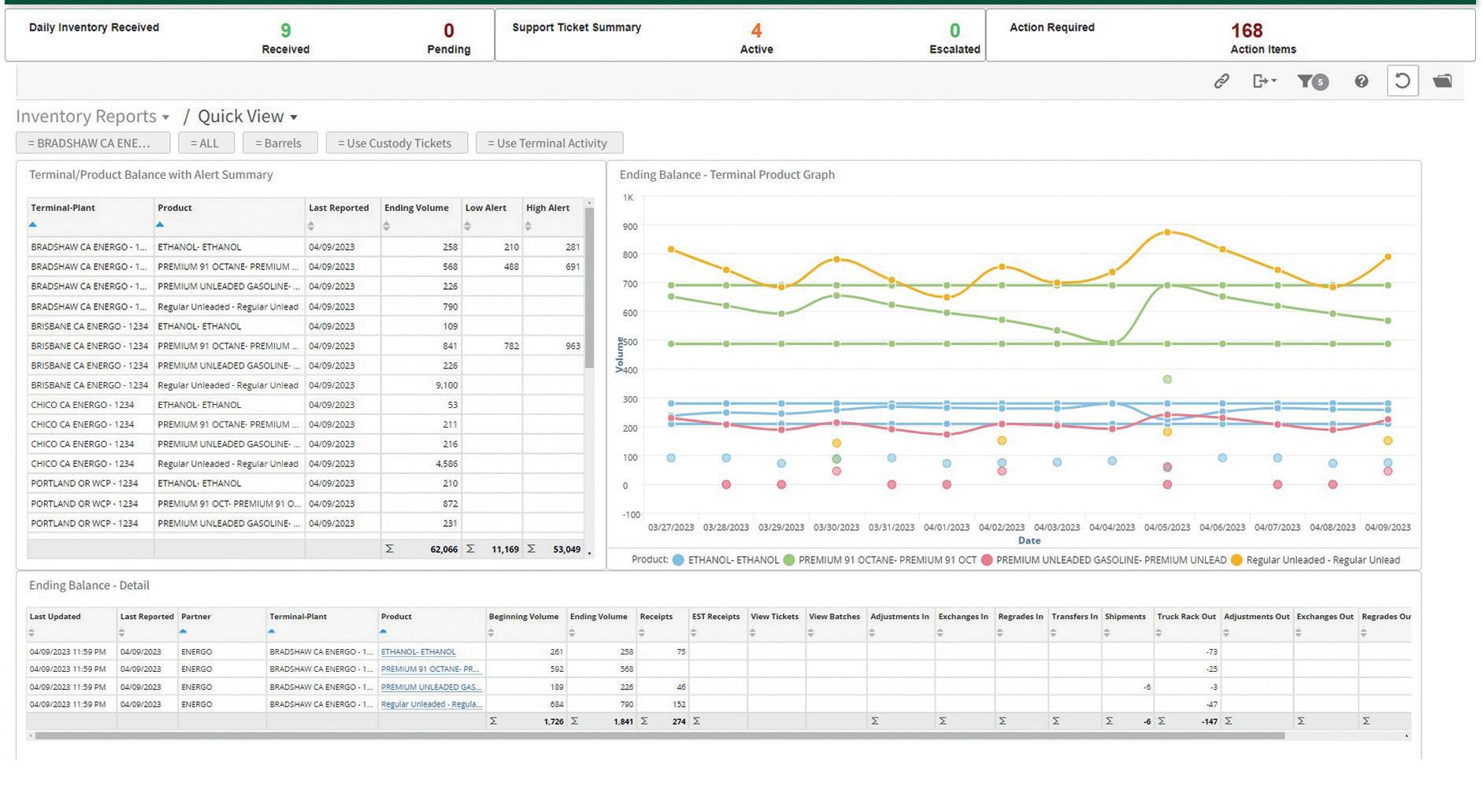

59 Updates in automated terminal management

Cyann Fielding finds out how digital processes are changing terminal operations

62 End-to-end digitalisation and decarbonisation

Diamond Key International shares how its proven solutions can achieve terminal optimisation through a strategic approach

64 EPC tank building: approaches & concerns

Major EPC companies share their man areas of focus when carrying out projects

68 Lightning can always strike twice

Tank Storage Magazine explores the latest lightning protection and mitigation techniques for tank storage facilities

70 Technical news

EVENTS

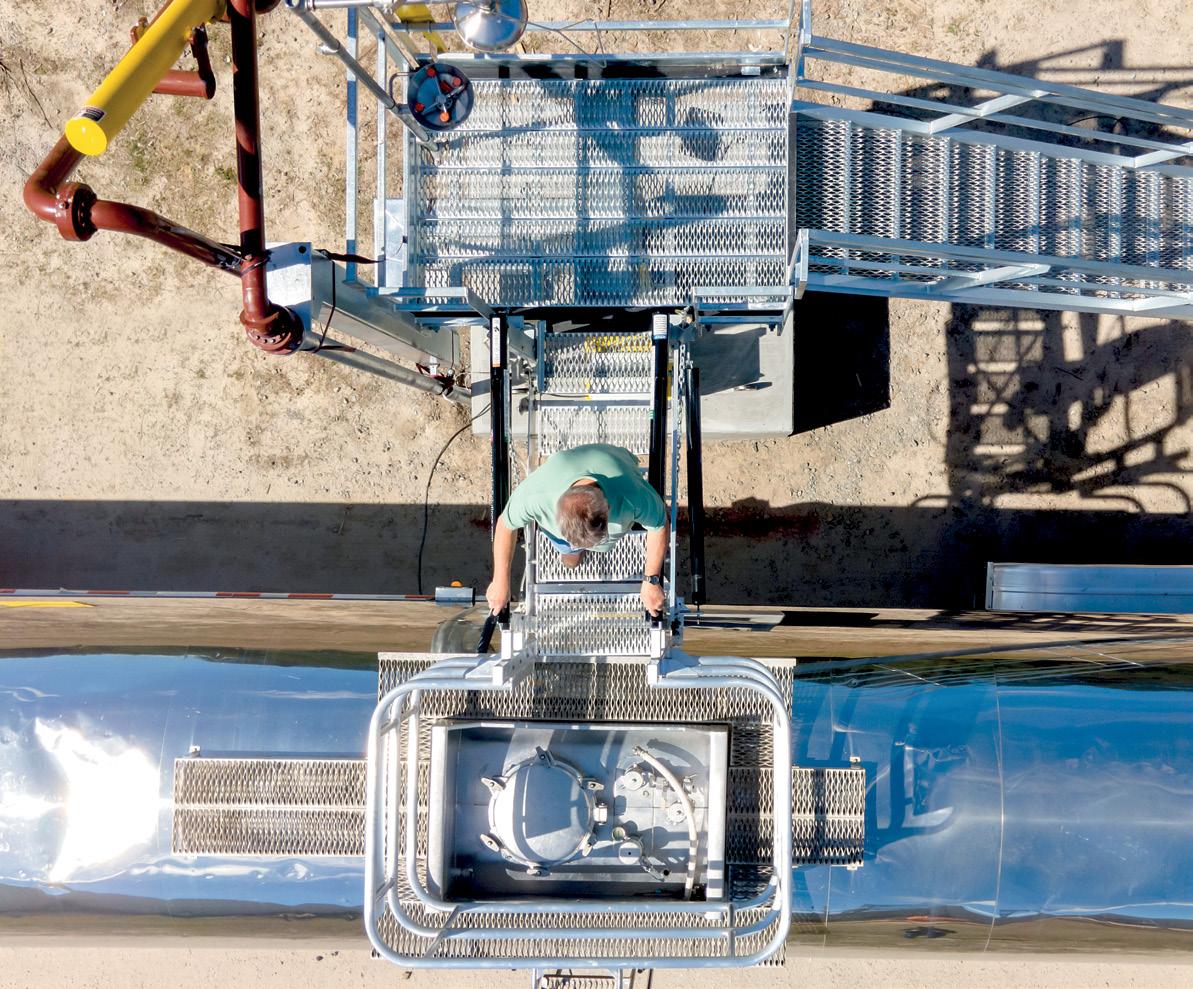

72 Keeping people safe where they walk

CEO of Real Safety, Torben Farup, discusses winning gold at the Global Tank Storage Awards and taking their technology into the tank storage sector

74 Houston-bound for ILTA

The Tank Storage Magazine team is heading off to Texas for the ILTA conference on May 22-24. Here’s a preview of what’s in store

76 We do it as a team

Commercial manager at North Sea Port, Sandra De May, tells Tank Storage Magazine how it feels to win gold at the Tank Storage Awards

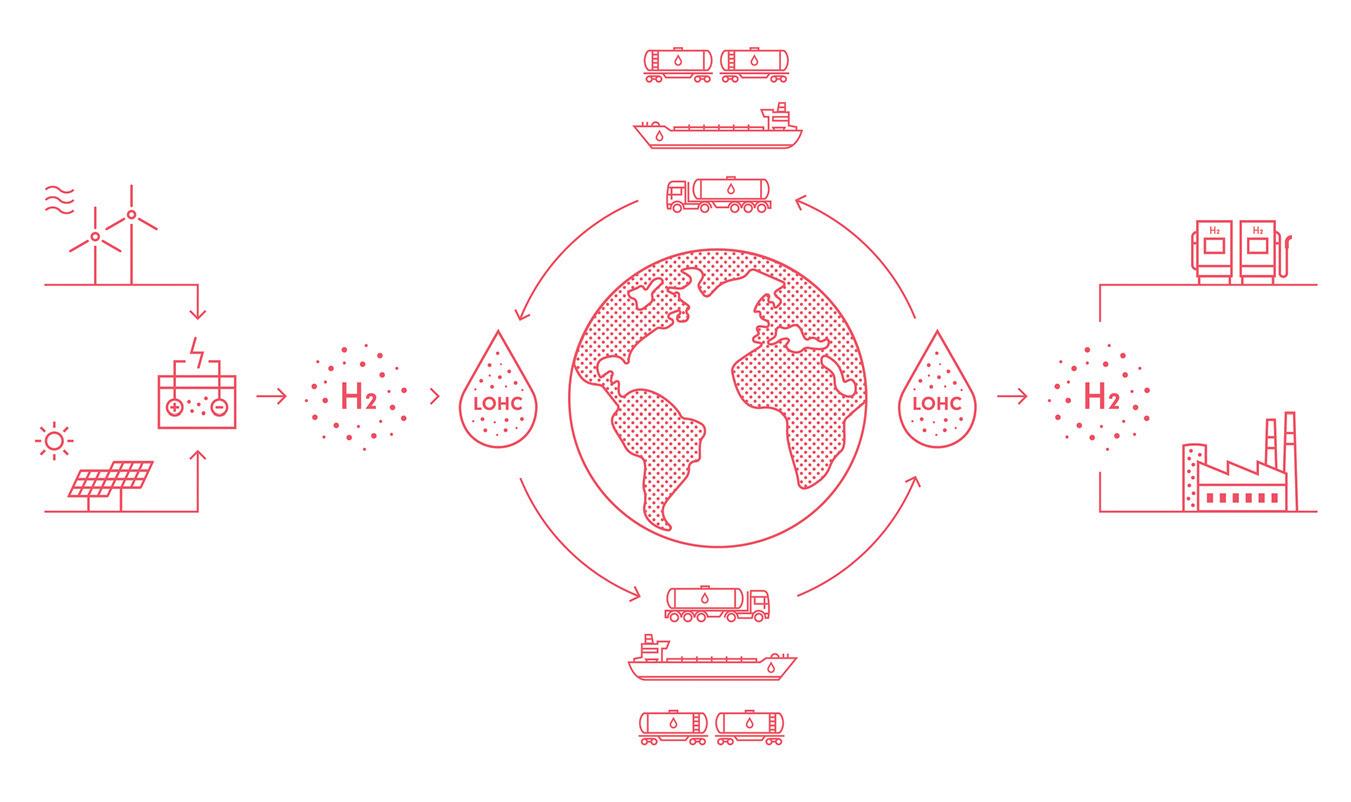

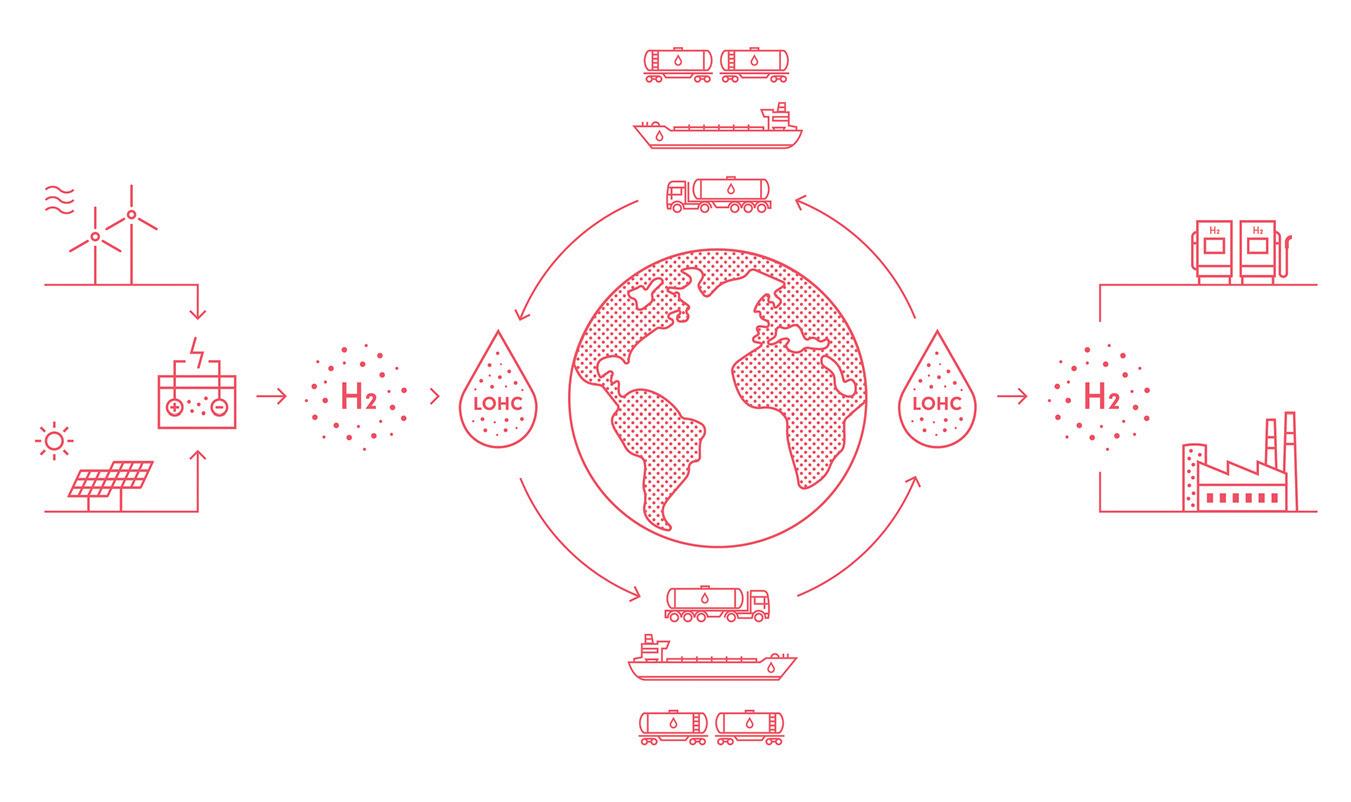

79 Storage tank industry meets in Florida

Editor Anamika Talwaria shares some of her favourite innovations from the 25th annual NISTM Trade Show and Conference

AT THE BACK

80 Advertisers index

80 Social storage: Most liked posts since April

81 Events Listing 2023

42 56 59 64 76 UP FRONT CONTENTS PAGE 02

ATEC Steel, 1000 W. 5th St., Baxter Springs, KS 66713 877.457.5352 877.404.8206 info@atecsteel.com WWW.ATECSTEEL.COM For your Next Tank Project, DISCOVER THE ATEC ADVANTAGE Quality, Safety and On-time Completion you can rely on For your Next Tank Project, DISCOVER THE ATEC ADVANTAGE Quality, Safety and On-time Completion you can rely on

CONTRIBUTORS

June/July 2023

PORTFOLIO DIRECTOR

Margaret Dunn +44 (0)20 3551 5721 margaret@tankstoragemag.com

EDITOR

Anamika Talwaria +44 (0)20 3876 9339 anamika.talwaria@easyfairs.com

JOURNALIST

Cyann Fielding +44 (0)20 3196 4416 cyann.fielding@easyfairs.com

JOURNALIST

Molly Cooper

+44 (0)20 3196 4263 molly.cooper@easyfairs.com

HEAD OF SALES

Sophie McKimm

+44 (0)20 3196 4356 sophie.mckimm@easyfairs.com

INTERNATIONAL SALES MANAGER

David Kelly

+44 (0)20 3196 4401 david@tankstoragemag.com

KEY ACCOUNT MANAGER

Gary Kakoullis

+44 (0)20 3196 4248 gary.kakoullis@easyfairs.com

MARKETING MANAGER

Ream Demnati

+44 (0)20 3196 4282 Ream.Demnati@easyfairs.com

HEAD OF DATA

Beth Welcomme +44 (0)20 3196 4345 beth.welcomme@easyfairs.com

CEO EASYFAIRS UK & GLOBAL

Matt Benyon matt.benyon@easyfairs.com Anne Lafère anne.lafere@easyfairs.com

SUBSCRIPTION RATES

A one-year, 7-issue subscription costs €250. Individual back issues can be purchased at a cost of €45 each.

CONNECT WITH US @tankstorageinfo

Tank Storage Magazine

Tank Storage Magazine

CONTACT

T +44 (0)20 3196 4300

F +44 (0)20 8892 1929 margaret@tankstoragemag.com www.tankstoragemag.com

Easyfairs

2nd Floor, Regal House 70 London Road Twickenham TW1 3QS United Kingdom

ISSN 1750-841X

UP FRONT CONTRIBUTORS PAGE 04 Tank Storage Magazine, (ISSN 1750-841X) is published seven times a year (in February, March, May, August, September, October and November) by Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK. The US annual subscription price is $243. Airfreight and mailing in the USA by agent named WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Periodicals postage paid at Jamaica NY 11431. US Postmaster: Send address changes to Tank Storage Magazine, WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Subscription records are maintained at Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK. Aug / Sep 2019 Volume 15 Issue 04 AN INTERNATIONAL CONCEPT IN A CAPTIVE MARKET Oiltanking matola explains how it is introducing the independent storage model in sub-saharan africa. AN INTERNATIONAL CONCEPT Oiltanking matola explains how it is introducing the independent storage model in sub-saharan africa.

| Volume

Issue

19 |

03

EDITOR’S NOTE

AS I TYPE THIS, the Tank Storage team is gearing up for our second US show of the season. Having just come back from NISTM, Orlando, I’m still battling jetlag while working to get this fantastic issue, packed to the brim with original editorial content, out to you. And all in time for the ILTA conference in Texas!

You can read a sneak preview of what’s coming at the ILTA trade show and conference on page 74, complete with the highlights that our team is looking forward to. From tank storage developments to stories of space travel, this iteration of the event is sure to be one to remember. And as my first time in Texas, I’m certainly looking forward to experiencing the American hub of tank storage.

As well as the Tank Storage team, Odfjell Terminals US’ IT director, Aldrich Varilla, will be in attendance. You can read our exclusive interview with him on page 30 as he discusses winning an ORBIE, and his digitalisation strategy for OTUS.

Speaking of winners, we’ve interviewed the gold winners at the Tank Storage

Awards and will be sharing their developments with you through the year. Starting with Real Safety for Safety Technology (page 72) and North Sea Port, for Port of the Future (page 76). Plus, Diamond Key International explains its winning Omega Digitz platform on page 62.

Innovative technology and digitalisation strategies really are key topics at the conferences I’ve attended this year. So, it’s only right that we give this topic proper attention in the magazine. Turn to our market analysis section, and you’ll see how digitalisation is changing training procedures at tank terminals, with an explainer into virtual reality on page 40.

And the rest of this edition is equally forward-looking, with in-depth, wellresearched articles put together by our editorial team on the future of biofuels (page 42), hydrogen storage (page 46), terminal automation (page 59) and more. Embracing the digital world is something we’re passionate about at Tank Storage Magazine and our webinar series is yet another way we’re connecting the tank storage industry all over the world. So, once you’ve had your fill of the words in our magazine and the in-person events happening in the next few weeks, make sure you’ve signed up to Tank Talk. Our next webinar session is on 22 June, sponsored by Foamglas.

As always, if you think your company has a particularly interesting insight into a trend, data point, or you have an exciting case study to share with the industry, please do get in touch with us. Please

swing by the Tank Storage Magazine booth 223 to have a cup to tea (or coffee) and talk about your latest products, projects or just about the football (soccer).

Best wishes,

PAGE 06 UP FRONT EDITOR’S NOTE

Anamika

MORE TECHNOLOGY FOR TANKS

Advances in automation, robotics, chemistry, and procedures are making aboveground storage tank cleaning safer, faster, and more cost-effective than ever before.

Clean & Fast. We remove material using track-drive and magnetic vertical-drive ROVs, remote-control manway cannons, tank sweeps with continuous slurry and removal, submersible pumping systems, and more.

Maximum Recovery. Minimum Disposal. Phase separation and treatment options use high-speed centrifuges, filter and belt presses, and chemical treatment to reclaim valuable hydrocarbons and minimize waste.

SEE THE STATE-OF-THE-ART AT ILTA BOOTH 413!

844.243.5557 • sales@usadebusk.com • www.usadebusk.com • Follow us: Advanced technologies for safety and savings. Automation & Technology | Catalyst Handling | Chemical Cleaning Controlled-Volume Pigging | Emission Control | Hydro Blasting Hydro Cutting | Mechanical Rental | Pigging, Decoking & Filtration Pipeline Integrity | Reactor Cleaning | Tank Cleaning Unit Decontamination | Vacuum Services

TERMINAL NEWS: EUROPE

EXOLUM SECURES CONTRACT TO MANAGE FUEL TERMINAL AT SHANNON AIRPORT

Exolum will operate the fuel storage terminal located at Shannon airport, Ireland, as the successful bidder of a tender process organised by the Shannon Airport Group. The company will manage the terminal with facilities for the receipt of fuel by vessel, as well as storage and dispatch. It will also be the only agent to provide into-plane fuelling services to the different airlines operating at the airport. Exolum will manage the terminal under a twoyear agreement.

Shannon Airport offers UK, European and transatlantic flights for both passengers and goods, and will operate 35 routes to 11 countries this year. In addition to a hydrant system, the storage terminal has a capacity of over 42,000 m3

This transaction consolidates Exolum’s presence in Ireland, where it already operates at Dublin airport, and represents another step in the company’s internationalisation strategy within the aviation fuel supply sector.

DRAX HALTS $2.5 BILLION BIOMASS CARBON CAPTURE PLANS

British power generator Drax has announced it will pause its planned £2 billion (€2.26 billion) UK investment in bioenergy with carbon capture and storage (BECCS) until it receives more clarity on government support.

Drax welcomed the UK government’s recent budget support for carbon capture and storage (CCS) but confirmed the company requires a firm commitment to BECCS before it could invest the cash to install the technology at its 2.6 GW biomass power plant in Yorkshire, northern England.

The US Inflation Reduction Act (IRA) is offering $85 (€78) per tonne of stored greenhouse gas removal using BECCS

while Britain has not yet established a market mechanism for the technology. An existing subsidy scheme for biomass plants, which provide about 6% of the country’s electricity, runs out in 2027, which a Drax spokesperson said could make them unviable.

‘Until we have this clarity, we are pausing our multimillion-pound investment programme in the UK BECCS project,’ Drax CEO, Will Gardiner, says.

UK TO PARTNER WITH KOREA ON ENERGY TRANSITION

The UK and the Republic of Korea are to collaborate more closely on the development of renewable energy sources and move towards energy independence.

Energy security secretary, Grant Shapps has joined forces with the Republic of Korea to collaborate on accelerating the move towards a cleaner, more energysecure future, including renewables and nuclear.

UK companies already represent 60% of Korean offshore wind engineering contracts, and Korea is already investing in projects supporting the offshore wind industry in the UK.

Shapps will also encourage the Republic of Korea to join the 168-strong ‘Powering Past Coal Alliance’ and commit to bringing forward its own 2050 coal power phaseout date towards 2030, with support from Britain’s own expertise in offshore wind.

ENFINIUM AND NAVIGATOR TERMINALS SIGN MOU FOR CARBON CAPTURE RAIL PROJECT

Enfinium, one of the UK’s largest energy from waste operators, and Navigator Terminals, leading bulk liquid storage provider, have announced they have signed a memorandum of understanding (MoU) to collaborate on the development of the UK’s first ‘Rail to

Zero’ carbon capture rail corridor, that would enable dispersed industrial sites to permanently store their emissions. They plan to develop options to transport carbon dioxide (CO2) captured at Enfinium’s Ferrybridge waste facilities in West Yorkshire, UK to Navigator’s proposed multi-model carbon dioxide terminal in Teesside, UK using rail freight. The CO2 would then be transported safely from Navigator’s carbon dioxide terminal for permanent storage. Bechtel, a global leader in engineering, construction, and project management, has been selected to support the feasibility work underpinning the concept.

The announcement follows the decision by the chancellor in the Spring Statement on 15 March to support the scale-up of the UK carbon capture and storage industry with up to £20 billion of investment.

EXOLUM INVESTS IN GREEN HYDROGEN START-UP H2VECTOR

Exolum is taking another step forward in its decarbonisation and diversification strategy by becoming a shareholder of H2Vector – a technology start-up, based in Asturias, Spain. H2Vector aims to provide energy solutions to enable the decarbonisation and electrification of society, based on renewable hydrogen. The company is conducting research into new forms of storage and transportation of green hydrogen based on the use of organic liquids, a field that coincides with one of the strategic lines of Exolum.

The investment in H2Vector is part of an ambitious Open Innovation plan through which Exolum seeks to establish strategic agreements that will enable it to incorporate new technologies and new talent in its business areas related to decarbonisation.

The company is investing in and cooperating with emerging companies from around the world that offer proposals to add differential value and provide innovative solutions in projects linked to the development of new energy vectors such as renewable hydrogen, biofuels and synthetic fuels, energy storage, sustainable mobility and the circular economy.

Ireland United Kingdom

Spain

United Kingdom

United Kingdom

TERMINAL NEWS EUROPE PAGE 08

EVERYTHING UNDER ONE ROOF

ATMOSPHERIC

PRESSURE SPHERES LOW TEMPERATURE

CRYOGENIC TERMINALS

www.cbi.com

VISIT US AT ILTA #701

HÖEGH LNG AND WÄRTSILÄ RECEIVE

FUNDING FROM NORWEGIAN

GOVERNMENT FOR CLEAN ENERGY INITIATIVE

Investor relations, Höegh LNG and technology group Wärtsilä have received €5.9 million in funding from the Norwegian government’s green platform programme to develop a solution using ammonia as a hydrogen carrier for the energy market. The project will seek to increase the viability of using hydrogen as a replacement for fossil fuels. A system will be developed to convert ammonia to hydrogen in a process that can be installed onboard a floating terminal to be owned and operated by Höegh Floating Terminals offer benefits including greater flexibility for relocation and minimal use of coastal land. They may also provide lower overall costs, improved safety and competitive hydrogen prices.

Belgium

INEOS-LED CONSORTIUM ANNOUNCES BREAKTHROUGH IN CCS

Crown Prince Frederik of Denmark officially initiated a world first with the safe injection of carbon dioxide from Belgium into a depleted oil field in the Danish North Sea.

Project Greensand, a consortium of 23 organisations, showcases the feasibility of CO2 storage from being captured at an INEOS Oxide site in Belgium, to being transported cross-border and finally safely and permanently stored in the INEOS operated Nini field in the Danish North Sea.

By 2030, Project Greensand aims to store up to 8 million tonnes of CO2 per year in this area while continuing to make significant contributions to our understanding and growth of carbon storage technology. The CO2 injected into the Nini field is stored at a depth of about 1,800 metres below the seabed and will be closely monitored.

Specialist Training for the Storage Tank Industry

Classroom , live online , blended, in-house , and e-learning

• Gain or renew up to 5-year Certificates of Competence*

• Courses based on EEMUA 159

• English, Dutch, German and French language options

• Select from courses throughout the year, including:

TankAssessor courses*

22-25 May 2023 – in English

–classroom – London, UK

5-8 June 2023 – in Dutch –classroom – Rotterdam, NL

2-6 October 2023 – in French –classroom – Près de Lyon, FR

6-9 November 2023 – in German –live online

TankInspector courses*

22-24 May 2023 – in Dutch –classroom – Rotterdam, NL

16-18 October 2023 – in English –live online

TankBasics courses

25 September - 3 November 2023 –in English – blended (live online and e-learning)

Storage Tanks e-learning

On-demand – in English and in Dutch In-house courses*

By arrangement – to suit your time, location, language

More choices, information and registration at www.eemua.org

Kenilworth, UK

PAGE 11 TERMINAL NEWS EUROPE

Norway

Above ground flat bottomed storage tanks A guide to inspection, maintenance and repair Pub icat on 159 Edition 5

Meet EEM U A at I LTA booth # 769

VITOL ANNOUNCES THE DELIVERY OF FIRST LNG TO INKOO TERMINAL

Energy and commodities company, Vitol has announced the delivery of the first LNG cargo into Finland’s new Inkoo terminal. The cargo was ordered by Elenger, the largest privately owned energy company in the Finnish-Baltic region.

The cargo originates from Vitol’s portfolio of US origin LNG and was transported in the Vivit Americas LNG, a modern LNG tanker which is part of the Vitol fleet. The tanker, sailing under the flag of Malta and built in 2020, is 299 meters long and 46 meters wide and can hold 174,062 m3 of liquefied gas.

Pablo Galante Escobar, head of LNG and European gas and power at Vitol said: ‘Vitol is delighted to deliver the first LNG cargo to Elenger via Finland’s Inkoo terminal. The opening of the terminal will enhance energy security in Finland and the Baltic region, facilitating the flow of LNG from around the world to European industry and consumers.’

STOLT-NIELSEN REPORTS UNAUDITED RESULTS FOR FIRST QUARTER

Stolt-Nielsen Limited has announced its unaudited results for the first quarter ending February 28, 2023. The company reported a first-quarter net profit of $99.8 million (€91.1 million), with revenue of $708.7 million (€646.9 million), compared with a net profit of $95.3 million (€86.9 million), with revenue of $732.5 million (€668.6 million), in the fourth quarter of 2022.

Niels Stolt-Nielsen, CEO of Stolt-Nielsen says: ‘The first quarter continued where 2022 ended, with a solid performance from all businesses during what is typically the seasonally weakest quarter of the year. Stolt Tankers improved on the prior quarter results as we began to see the impact of contract renewals on our earnings. Results at Stolthaven Terminals improved on the back of continued high utilisation, although throughput volume was down slightly.’

NAFTOGAZ PROMOTES GAS STORAGE AND PRODUCTION COOPERATION

The head of Ukraine’s state-owned oil and gas company Naftogaz Group, Oleksiy Chernyshov is promoting Ukraine’s competitive underground gas storage (UGS) facilities and production cooperation opportunities for Europe, during a two-day trip to Brussels.

Chernyshov says: ‘Our goal is to strengthen cooperation with our European partners, including storing European gas reserves in Ukrainian underground gas storage facilities and launching joint gas production projects in Ukraine.’

The CEO of Naftogaz has also met with James Watson, secretary general of the European gas industry association, Eurogas.

Finland Europe

Ukraine PAGE 13 TERMINAL NEWS EUROPE

TERMINAL NEWS: THE AMERICAS

YARA AND ENBRIDGE PLAN $2.9 BILLION AMMONIA PLANT

Norway’s Yara, the world’s largest ammonia distributor, and Canadian energy infrastructure company, Enbridge, plan to invest up to $2.9 billion (€2.6 billion) to build a lowcarbon blue ammonia production plant in Texas, USA.

The plant is to be built at the Enbridge Ingleside Energy Center near Corpus Christi. It will use carbon capture and storage (CCS) technology to ensure the removal of most carbon emissions.

The production facility will be capable of supplying low-carbon ammonia to meet growing demand and has an expected capacity of 1.2 million to 1.4 million tons (1.42 million tonnes) per year.

Around 95% of the carbon dioxide generated from the production process is anticipated to be captured and transported to nearby permanent geologic storage.

IMTT ANNOUNCES PLANS FOR NEW JERSEY OPERATIONS

Bulk liquid storage and logistics company, IMTT has announced plans to consolidate its existing bulk liquid storage operations in Bayonne, New Jersey, USA. This will free up approximately 130 waterfront acres for redevelopment on its 450acre property.

The consolidation will enable IMTT to serve its bulk liquid customers more efficiently and attract additional economic development opportunities to the Bayonne area. Even after the anticipated reduction in storage capacity, IMTT’s Bayonne terminal will continue to be the largest bulk liquids storage terminal in the New York Harbor area.

Carlin Conner, IMTT chairman and CEO says: ‘We are pleased to announce that IMTT is consolidating a portion of the Bayonne terminal and embarking on a transformational development process

for the eastern portion of the property. This will allow us to continue providing high-quality storage and logistics services on the west side of our property and pursue sustainable development opportunities on the east side.’

BUCKEYE PARTNERS ANNOUNCES LAUNCH OF ENERGY TRANSITION DEVELOPMENT COMPANY

Buckeye Partners has announced the lauch of BAES Infrastructure, a diversified energy company that will focus on the development, construction, and operation of energy transition projects. BAES Infrastructure will pursue new energy transition-related opportunities, with its seed assets being Swift Current Energy, OneH2, Bear Head Energy, a low carbon hydrogen and ammonia project under development in South Texas, USA and other advancedstage solar development projects.

Todd Russo CEO of Buckeye says: ‘The launch of BAES Infrastructure represents another step in our energy transition strategy, reinforcing our commitment to investing in growth that aligns with our customers’ current and evolving needs, while facilitating the decarbonisation of the broader economy. This new company will allow us to leverage existing and new relationships and focus on investment and development activity in the energy

BEAR HEAD ENERGY RECEIVES APPROVAL FOR GREEN PROJECT

Subsidiary of BAES Infrastructure, Bear Head Energy has announced it has received environmental assessment approval for the company’s green hydrogen and ammonia production, storage, and loading facility in Nova Scotia, Canada.

Bear Head is permitted for up to two gigawatts of hydrogen electrolysers. Bear Head could produce up to 350,000 tonnes of hydrogen and two million tonnes of ammonia per year, positioning Nova Scotia to be a leader in the production of green hydrogen and ammonia and a critical part of the global energy transition.

Paul MacLean, managing director of Bear Head Energy says: ‘We are grateful to have achieved this enormous milestone for Bear Head…We believe green hydrogen and ammonia will play a fundamental role in facilitating the global energy transition, and this approval demonstrates that Canada and Nova Scotia are at the forefront of making this a reality.’

Bear Head will be developed in phases and is expected to commence deliveries of green hydrogen and ammonia by 2028.

USA Canada USA USA

PAGE 14 TERMINAL NEWS THE AMERICAS

transition space without compromising our focus on safely and reliably operating our critical petroleum products infrastructure.’

AUMA World Discover your valve automation solution anzeige_halbe_Seite_tsm_2022.indd 1 23.02.2023 17:04:21

SEMPRA REACHES FINAL INVESTMENT DECISION ON PORT ARTHUR

USA power and gas utility Sempra Energy has announced that the first phase of its proposed Port Arthur liquefied natural gas (LNG) export terminal will move ahead with investment firm KKR & Co agreeing to a minority stake in the project.

Sempra Infrastructure Partners, the 70% owned unit of Sempra, would target 20% to 30% of indirect ownership interest in the project, subject to the closing of the KKR sale.

Additionally, Sempra Infrastructure announced the closing of the project’s $6.8 billion (€6.3 billion) non-recourse debt financing and the issuance of the final notice to proceed under the project’s engineering, procurement and construction agreement.

Sempra’s unit has also finalised its joint venture with ConocoPhillips. The USA oil producer in November 2022 had said

it would acquire a 30% non-controlling interest in the Port Arthur Phase 1 project in Texas through the JV. Sempra estimates the total capital expenditure for the 13.5-million tonnes per annum (MTPA) plant’s Phase 1 at $13 billion (€12.5 billion).

ConocoPhillips, units of Poland’s Polski Koncern Naftowy Orlen SA, INEOS, ENGIE and Germany’s RWE AG would together buy about 10.5 MTPA LNG from the Port Arthur plant under longterm agreements.

BP STARTS OIL PRODUCTION AT ARGOS PLATFORM IN THE GULF OF MEXICO

BP has successfully started oil production at its Argos offshore platform, delivering more energy at a critical time and strengthening BP’s position as a leading producer in the deepwater USA Gulf of Mexico.

The semi-submersible platform aims to increase BP’s gross operated production capacity in the Gulf of Mexico by an estimated 20%. BP expects to safely and systematically ramp up production from Argos throughout 2023.

BP chief executive, Bernard Looney says: ‘The start-up of Argos is a fantastic achievement that helps deliver our integrated energy strategy – investing in today’s energy system and, at the same time, investing in the energy transition. As BP’s most digital facility worldwide, applying our latest technologies, Argos will strengthen our key position in the Gulf of Mexico for years to come.’

USA USA

PAGE 16 TERMINAL NEWS THE AMERICAS

Argos is the centrepiece of BP’s Mad Dog Phase 2 project, which extends the life of the super-giant oil field discovered in 1998. It is one of nine high-margin major projects that BP plans to start, by the end of 2025.

ENERGY TRANSFER ACQUIRES LOTUS MIDSTREAM OPERATIONS

Midstream energy company, Energy Transfer and independent energy company, Lotus Midstream have announced that they have entered into an agreement in which Energy Transfer will acquire Lotus Midstream Operations. This acquisition will cost approximately $1.45 billion (€1.33 billion).

Lotus Midstream owns and operates Centurion Pipeline Company, an integrated, crude midstream platform located in the Permian Basin. The transaction is expected to close in the second quarter of 2023.

More for Engineering from EEMUA...

People in engineering work to make businesses, the environment, and everyone’s future prosperous and safe - EEMUA’s publications and other resources help people in engineering to get that work done.

EEMUA is the industrial engineering community’s not-for-profit association that, free of shareholders and owners, invests all revenue into sharing guidance resources, events, training, and more.

Practical Resources...

All EEMUA’s resources are developed ‘for industry, by industry’, as practical aids for engineers in their work, as they work, wherever they are, whatever time they have.

Available to all in industry

All publications and many other resources are downloadable from EEMUA’s Shop - where you can also register to take part in EEMUA events and training.

Members help yourselves...

Many EEMUA resources are free or discounted for members, so please log in and help yourself to guidance notes, training, e-learning, checklists, live webinars, recordings, and much more.

Join in...

New Corporate Members are always welcome to share EEMUA’s knowledge and influence.

Call on EEMUA...

www.eemua.org

ask@eemua.org

+44 (0)20 7488 0801

USA

A

and disposal 225 Edition 1

Above ground plastic tanks

guide to their specification, installation, commissioning, inspection, maintenance,

154

3 Meet us at ILTA booth # 769

Demolition of vertical cylindrical steel storage tanks and LPG spheres

Edition

PAGE 17 TERMINAL NEWS THE AMERICAS

TERMINAL NEWS: MIDDLE EAST & AFRICA

and other products, including 1.4 million litres a day of petrol and 1.1 million litres a day of diesel.

SHARJAH NATIONAL OIL CORPORATION (SNOC) EXPANDS GAS STORAGE FACILITIES

The latest expansion of SNOC’s gas storage capacity includes two high-pressure compressor trains and associated tie-ins to its existing brownfield facilities at Sajaa.

SNOC set a 10 month schedule from award to completion and successfully completed the project ahead of schedule. The project involved efforts from SNOC’s in-house project team and the EPC contractors Enerflex Ltd and ALUCOR.

The critical project construction achievements were welding 2180 inch dia, erection of 30 tons (27.2 tonnes) of steel, 360 m³ of concrete, 510 m of E&I cables and a safe heavy lift of 87 tons using a 500 ton (453 tonnes) capacity crane.

The project was completed without any operational or environmental incidents and achieved a milestone of 82,000 manhours without lost time incident (LTI).

ABSA GROUP AIMS FOR NET ZERO CARBON EMISSIONS BY 2050

South African lender, Absa Group, aims to cut its net carbon emissions to zero by 2050 by curtailing lending to coal, oil and gas projects and instead increasing its exposure to renewable projects.

‘While we recognise Africa’s particular vulnerability to climate change, our approach to net zero also takes cognisance of the development needs of Africa’s people,’ says Punki Modise, Absa Group’s chief strategy and sustainability officer. The company’s loan portfolio’s exposure to coal would reduce to 0.03% by 2050, from 0.2% in 2023. Oil exposure would reduce to 0.32% from 1.41%.

ACTAD ANNOUNCES OPENING OF GREENFIELD LIQUID BULK TERMINAL

ACTAD has announced the opening of its new greenfield liquid bulk terminal in Khalifa Port, Abu Dhabi, UAE, and will commence operations on July 1, 2023.

The state-of-the-art terminal offers facilities and services for storing and transporting liquid bulk, ensuring high levels of safety, efficiency, and sustainability.

ACTAD’s mission is to provide customers with unparalleled service and expert advice, ensuring their cargo is always in safe hands.

COMMISSIONING BEGINS AT TECHNIP ENERGIES’ KARBALA REFINERY

Commissioning has begun at Technip Energies’ Karbala refinery PMC project in Iraq.

Located approximately 100 km (62 miles) from Baghdad, Iraq, Karbala is Iraq’s first new refinery in decades and is the first refinery in Iraq to meet Euro 5 fuel standards, which will greatly reduce emissions. The project is moving ahead and is scheduled to reach its full capacity of 140,000 barrels per day (bpd) by the end of July 2023.

LIBYA SIGNS SOUTH REFINERY CONTRACT WITH HONEYWELL

A subsidiary of Libya’s state-owned National Oil Corp (NOC) has signed a contract with Honeywell for The project will be carried out in two phases. NOC has previously said South Refinery will produce cooking gas, jet fuel

Libya is seeking to bring foreign investment back into its energy sector after two and a half years of comparative peace following years of conflict. It hopes to take advantage of increased demand for its oil and gas following supply concerns in Europe resulting from the war in Ukraine.

ERBIL-BAGHDAD TEMPORARY DEAL TO RESTART NORTHERN OIL EXPORTS

Iraq’s federal government and the Kurdistan Regional Government (KRG) have signed a temporary agreement to restart northern oil exports through Turkey, as part of a broader deal to end decades of political and economic disputes.

Turkey stopped pumping about 450,000 barrels per day (bpd) of Iraqi crude through a pipeline from the Fish-Khabur border area to its Ceyhan port on March 25, after Iraq won an arbitration case. Under the deal, Iraq’s state-owned marketing company SOMO will have the authority to market and export KRG oil, and the revenues will be deposited in an account at the Iraqi Central Bank under the control of the KRG.

The deal is temporary until the budget law passes in parliament.

Crude flows are yet to restart.

United Arab Emirates

United Arab Emirates

South Africa

Iraq

Libya

PAGE 18 TERMINAL NEWS MIDDLE EAST & AFRICA

Iraq

International Operating Conference & Trade Show

HOU TX

ILTA 2024 is the largest event focused exclusively on the business and technology of liquid terminals. Packed with opportunities to connect with thousands of industry professionals, learn key best practices and discover the latest equipment and real-world industry solutions.

Plan now to attend!

2024

May 6-8 ilta.org

TERMINAL NEWS: ASIA & PACIFIC

IMPALA TERMINALS OPENS TERMINAL AT KWINANA BAY

Impala Terminals has officially opened its first Australian energy import, storage and distribution terminal, Kwinana Bay, western Australia.

Strategically located next to the Kwinana Bulk Jetty (KBJ), Impala Terminals Kwinana will bring fuel distributors alternatives to serve Perth and the surrounding region, creating a more resilient energy market and greater supply security.

The new terminal, which has been in operation since last October, has a storage capacity of 225 million litres/1.4 million barrels, with 11 bulk tanks, four day tanks and a butane tank. The facility includes a diesel express lane which significantly reduces loading time for delivery vehicles, and is equipped with the latest equipment and automation systems. The terminal is currently handling diesel and gasoline, as well as butane for blending, and is supported by a strategic anchor customer.

INPEX REVISES PLAN FOR ABADI LNG PROJECT

Japan’s Inpex Corp has submitted a revised development plan to the Indonesian government authorities for the Abadi liquefied natural gas (LNG) project, now incorporating a carbon capture and storage (CCS) component.

Japan’s biggest oil and natural gas explorer submitted the revised plan of development on behalf of its joint venture with Shell after amending it to include plans to neutralise all carbon emitted from natural gas production at the Abadi gas field through CCS.

Inpex expects to sequentially resume activities associated with the project, including various on-site activities, with an aim to reach a final investment decision in the latter half of the 2020s and commence production in the early 2030s.

STOLT NIELSEN ANTICIPATED TO WIN CONSTRUCTION BID

Stolt Nielsen looks likely to win a development contract for a storage project which will involve the construction of 4 million barrels of petrochemicals at Jurong Prot in Singapore, according to Reuters. The deal, which includes storage and terminal work, is expected to be worth about $300 million (€228 million) and is part of the development being built on the western edge of Singapore.

The contract was meant to have been handed out in December but now the decision on what company will be awarded it is expected to be made within the coming few months.

Included in the new project plans is 3.15 million barrels of oil storage, while the remaining 750,000 barrels will hold chemicals.

NESTE TO START PRODUCTION AT SINGAPORE RENEWABLE FUELS EXPANSION

Finnish biofuel producer Neste plans to start commercial production at its renewable fuels expansion project in Singapore in the coming weeks after trial runs.

Neste plans to inaugurate the 1.3 million tonne-per-annum (tpa) plant next month. The plant will boost Neste’s sustainable aviation fuel capacity by up to 1 million tpa, in addition to a 500,000 tpa project at its Rotterdam plant.

The Singapore expansion and production from a new joint venture plant in California with Marathon Oil Corp hopes to increase Neste’s biofuels capacity to reach 5.5 million tpa by end of 2023, up from 3.3 million tpa.

JERA AND KOGAS SIGN MOU FOR LNG

Fuel energy company, JERA has announced that it has entered into a memorandum of understanding (MoU) with Korea Gas Corporation (KOGAS), regarding cooperation in the LNG business.

Under this MoU, for the sake of securing supply stability of LNG, JERA and KOGAS agreed to discuss opportunities for mutual collaboration in the LNG business including LNG swaps, trading, ship optimisation, and market view exchange.

Russia’s invasion of Ukraine has created a severe energy environment, such as the reduction of pipeline gas supply to Europe, and the uncertainty regarding global energy supply is drastically increasing. In response to these circumstances, under this MoU, JERA and KOGAS will strengthen their strategic relationship and consider developing schemes of cooperation regarding their LNG supply and demand, to enhance stable energy supply in Japan and Korea.

Indonesia

PAGE 20 TERMINAL NEWS ASIA & PACIFIC

Australia

Asia

Singapore

Singapore

We commit to simplify your project, with an e ective heating solution, with every BTU in mind. QMax Tank Heating Solutions are designed to maintain specific process temperatures or provide rapid heat-up inside Tanks, Vessels and other containers using internal tank heating or external tank heating.

qmaxindustries.com • +1 704-643-7299 • sales@qmaxindustries.com Call to find out how together we can save the world 100 Trillion BTUs by 2029

Practical Solutions Globally Recognized Expertise Owner Operator Perspective Asset Improvement • Strategic Investment • Digital Transformation

TECHNIP ENERGIES AWARDED CONTRACT

BY JUHUA

Technip Energies has been awarded a contract by Ningbo Juhua Chemical & Science Co (Juhua) for a 1.3-propanediol (PDO) plant with a capacity of 72 kta(1) and a 150 kta polytrimethylene terephthalate (PTT) plant in Zhejiang, China.

These two products are based on Technip Energies’ proprietary Zimmer PDO and PTT technologies to strengthen and expand Juhua’s petrochemical new materials business.

PDO technology was originally developed by Shell and Shell Catalysts & Technologies will be the catalyst supplier to the PDO plant.

Bhaskar Patel, SVP sustainable fuels, chemicals and circularity of Technip Energies, says: ‘We are very pleased that Juhua has selected two of our polymer technologies for the expansion of their facility in Ningbo. This is the first commercial scale application of our PDO technology, which produces a high quality monomer with excellent raw material utilisation as feedstock for our PTT technology.’

PDO is a colourless, odourless organic chemical that can be used in the pharmaceutical, cosmetics and plastics manufacturing fields. It is also the feedstock for PTT, a high performance and versatile polyester, used in the manufacturing of high quality carpet and textiles.

India

HPCL AND BPCL SIGN MOU FOR HYDROGEN SYNERGY

A memorandum of understanding (MoU) has been signed between HPCL Mumbai Refinery and BPCL Mumbai Refinery for the purchase and sale of hydrogen.

The MoU is a one-of-a-kind strategic partnership between two companies to create synergy for mutual aid during emergencies and towards environmental impact by minimising valuable hydrogen flaring.

The initiative aims to achieve cooperation and collaboration in the areas of hydrogen exchange between refineries for sustained refinery operations and uninterrupted product availability.

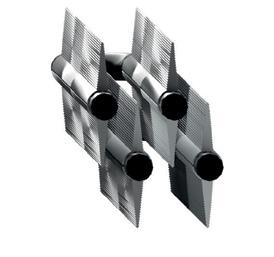

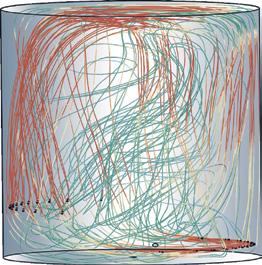

Customised tank mixing solutions

Essential

advantages with Körting tank mixing systems:

• low energy input

• no sealing problems

• low investment costs

• no unmixed dead zones

• wear-resistant operation

• no maintenance in the tank

• complete mixing of tank content

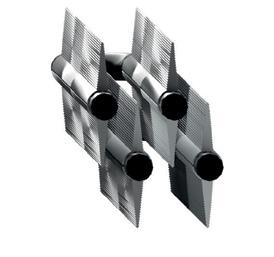

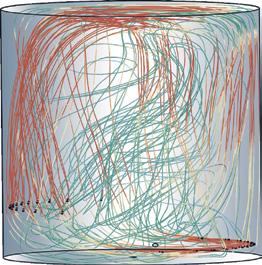

• optimisation with (CFD)

Computational Fluid Dynamics

+49 511 2129-221 | sales@koerting.de | koerting.de

China

WINNERS 2023 FInd out more > tankstorageawards.com EMERGING TECHNOLOGY GOLD iSensPro BRONZE CLIIN Robotics SILVER Voliro ENVIRONMENTAL PERFORMANCE GOLD CIRCOR BRONZE Aquacycl SILVER TECAM INNOVATIVE TECHNOLOGY GOLD Nordweld BRONZE Imbibitive Technologies SILVER TWTG PORT OF THE FUTURE GOLD North Sea Port BRONZE Port of Amsterdam SILVER Port of Antwerp-Bruges TERMINAL OPTIMISATION GOLD Diamond Key International BRONZE Insights Global SILVER Smartflow

SAFETY TECHNOLOGY

GOLD

Real Safety

SILVER

ScoutDI

OUTSTANDING ACHIEVEMENT AWARD

GOLD

Nicholas Gohl, CFO, Aquarius Energy

SILVER

Helena Hjortberg, Manager

Solutions for Rosemount Tank Gauging, Emerson

SAFETY EXCELLENCE

GOLD Odfjell Terminals Korea

SILVER

ITC Rubis Terminal Antwerp

RISING STAR AWARD

GOLD Guy Curtis, EWFM

SILVER

Martyn Bazem, Exolum

TERMINAL INNOVATION

GOLD

ORLEN Unipetrol RPA

SILVER

Rubis Terminal Tepsa

Bilbao

TERMINAL OF THE FUTURE

GOLD Advario

SILVER

Euro Tank Terminal

EXCELLENCE THROUGH DIVERSITY

GOLD

Emerson

SILVER

Pallavi Kanhere, CCO, Assai Software Services

BRONZE

CLIIN Robotics

BRONZE

Patrick Kulsen, Managing Director, Insights Global

BRONZE

GPS Chemoil

BRONZE

Amy McKeown, Re-Gen Robotics

BRONZE

Koole Tankstorage

Botlek

BRONZE

ACE Terminal

BRONZE

Vopak WeConnect

MATEC® GROUP is a leading company specialized in the production of flexible hoses of different type, in its factories throughout ITAY:

• COMPOTEC® flexible composite hoses,

• ENCO® flexible metal hoses,

• DACAFLEX® flexible PTFE hoses,

• ROITER® flexible rubber hoses

THE PRODUCT

For over 40 years the name of MATEC® Group has been synonymous with special hoses for the Petroleum and Chemical industry, for Fuel transportation with Tank trcks or Marine loading/unloading purposes.

COMPOTEC® hose is light, strong, highly flexible, anti-static and kink-proof. Yet it is extremely durable thanks to the tensioned internal and external steel wire spirals, which give great strength.

COMPOTEC® offers the most extensive and varied composite hose range for an extremely wide range of applica-tions. Precisionengineered end fittings complete the range.

Boasting a temperature range of -200°C (Cryogenic hose), to +200°C (Hitemp hose), and pressure ratings of 10, 15 and up to 40 Bar W.P. for special types, COMPOTEC® hoses are lined with either Polypropylene or PTFE, giving the hose excellent resistance to solvents, chemicals, acids, resins and all petroleum based products. So, if you are in the petroleum or chemical business, call the people who specialize in making hoses for your applications.

THE COMPANY

Founded in 1980, we have constructed in the course of the years an advanced product structure, which is equal or superior to the Quality, Environmental and Safety demands of the market.

Day-in day-out our 12000 sq/mt Italian plants produces flexible hoses for customers worldwide, using te-chnologically advanced manufacturing systems.

Our manufacturing capabilities and expertise ensure that we are able to respond positively to customer needs, no matter how unusual or difficult.

We have an excellent reputation as a specialist company providing a highly technical and efficient service to custo-mers in the wide range of industries served.

We pride ourselves on our ability to adapt existing products or develop new ones to solve specific problems, and ho-pe you will call on our expertise to meet your special needs.

aca lex

THE BEST CONNECTION YOU CAN MAKE IN THE PETRO-CHEMICAL INDUSTRY. CONNECT WITH COMPOTEC®

MATEC GROUP SRL Via Primo Maggio, 7 • 20068 • Peschiera Borromeo (MILANO) • ITALY Tel. +39 02 5530 1788 • Fax. +39.02 5472 158 e-mail: matec@matecgroup.com • web: www.matecgroup.com

Proud to say that we really are the “FLEXIBLE SOLUTION”

TANK TERMINAL UPDATE

OKEA

Products: Oil

Cost: $220 million (€200.36 million)

Capacity: 40,000 boed

Construction/expansion/acquisition: Norwegian independent oil and gas producer Okea has agreed to buy a 28% stake in Norway’s Statfjord production licence from Equinor. The deal increases Okea’s total production by between 13,000 and 15,000 barrels of oil equivalent per day (boed) in 2023 and by between 16,000 and 20,000 boed in 2024.

Comment: Okea says: ‘In addition, the agreement contains contingent payment terms applicable for 2023-25 for certain thresholds of realised oil and gas prices.’

SAUDI ARMACO

Products: Oil, ethylene and paraxylene

Cost: $12.2 billion (€11.3 million)

Capacity: 300,000 (bpd)

Construction/expansion/acquisition: Saudi Aramco has signed an agreement with Chinese partners for an oil refinery and petrochemical project in northeast China expected to start in 2026 to meet the country’s growing demand for fuel and chemicals.

Comment: Construction at the complex will start in the second quarter after the project secures the required administrative approvals. The plant is expected to be fully operational by 2026.

EXXONMOBIL

Products: Petrochemical

Capacity: 630,000 bpd

Construction/expansion/acquisition: ExxonMobil has announced the successful startup of its Beaumont refinery, USA, expansion project, which adds 250,000 barrels per day of capacity to one of the largest refining and petrochemical complexes along the USA. Gulf Coast.

Comment: Karen McKee, president of ExxonMobil product solutions says: ‘ExxonMobil maintained its commitment to the Beaumont expansion even through the lows of the pandemic, knowing consumer demand would return and new capacity would be critical in the post-pandemic economic recovery.’

SEMPRA

Products: Liquefied natural gas (LNG)

Cost: $13 billion (€12.5 billion)

Construction/expansion/acquisition: US power and gas utility Sempra Energy has announced that the first phase of its proposed Port Arthur liquefied natural gas (LNG) export terminal will move ahead with investment firm KKR & Co agreeing to a minority stake in the project. Sempra Infrastructure Partners, the 70%-owned unit of Sempra, would target 20% to 30% of indirect ownership interest in the project, subject to the closing of the KKR sale.

Comment: Sempra estimates the total capital expenditure for the 13.5-million tonnes per annum (MTPA) plant’s Phase 1 at $13 billion (€12.5 billion).

BP AND ADNOC

Products: Offshore natural gas

Cost: $2 billion (€1.8 billion)

Construction/expansion/acquisition: BP and Abu Dhabi’s state oil giant have made an offer to acquire 50% of Israeli offshore natural gas producer NewMed Energy for around $2 billion (€1.8 billion).

Comment: The offer involves acquiring NewMed’s free-floating shares and taking the company private and would mark Abu Dhabi National Oil Co (ADNOC) and BP’s entry into Israel’s growing energy sector.

ONYX POWER

Products: Hydrogen

Capacity: 1,200 MW

Construction/expansion/acquisition: Electric utility company, Onyx Power plans to make a significant contribution to emission reduction in the Netherlands by building a hydrogen production plant at its existing site in the Port of Rotterdam.

Comment: With a capacity of 1,200 MW the plant could produce some 300 kiloton per annum blue hydrogen, to aid in decarbonising the industry and meet national targets.

PAGE 27 TANK TERMINAL UPDATE

USA

Netherlands

Norway United Arab Emirates

USA China

HARBOUR ENERGY AND BP

Products: Carbon capture and storage

Capacity: 30 million tonnes of per year

Construction/expansion/acquisition: Independent oil and gas company, Harbour Energy and energy giant, BP have announced that they have entered into an agreement to develop the Viking CCS transportation and storage project, the Humber, UK. Under the terms of the agreement, Harbour will continue as operator of Viking CCS with a 60 per cent interest and Bp will acquire a 40 per cent non-operated share.

Comment: The announcement follows the UK Government’s recent decision to launch Track 2 of its CCS cluster sequencing process.

it has signed a sales and purchase agreement with anode producer, Aluchemie. The new site in Rotterdam provides Advario with the opportunity to develop, build, innovate and operate the storage infrastructure its customers and partners need to successfully transition to cleaner energy.

Comment: The target date for completion is 31 December 2025, after which Advario can start construction.

TOTAL ENERGIES

Products: Oil, gas and renewables

Cost: $27 billion (€24.6 billion)

LINDE AND HEIDELBERG MATERIALS

Products: Carbon capture and storage

Capacity: 70,000 tons (63,500 tonnes)

Construction/expansion/acquisition: Industrial gases and engineering company, Linde has announced it has signed an agreement with building materials company, Heidelberg Materials to jointly build, own and operate a largescale carbon capture and liquefaction facility. Through the use of carbon capture, Linde and Heidelberg Materials will aim to reduce carbon emissions at Heidelberg’s Lengfurt plant in Germany.

Comment: ‘Our innovative project with Heidelberg Materials is one of the first large-scale plants of its kind for the cement industry,’ says Sean Durbin, executive vice president EMEA at Linde.

EVOS

Products: Green hydrogen and hydrogen fuels

Construction/expansion/acquisition: Evos Hamburg, the Lother Group and E-Fuel GmbH have announced that they will be cooperating with the intention of establishing the Hamburg Blue Hub. This is a core initiative within a chain of other projects to get ready for the import of green hydrogen and hydrogen-based fuels in Hamburg. The aim is to establish Hamburg as key distribution centre for green fuels in Europe.

Comment: Managing director of Evos Group, Harry Deans, says: ‘Evos is determined to put our extensive experience to great use and ensure that we handle future fuels with the same care and expertise.’

Construction/expansion/acquisition: French oil major TotalEnergies has confirmed it has reached an agreement with the Iraqi government on a longdelayed $27 billion (€24.6 billion) energy project, reviving a deal that aims to bring back foreign investment into the country.

Comment: The deal was signed in 2021 for TotalEnergies to build four oil, gas, and renewables projects with an initial investment of $10 billion (€9.1 billion) in southern Iraq over 25 years.

INEOS PHENOL

Products: Chemicals

Cost: $330 million (€302 million)

Capacity: 1 million tonnes of product each year

Construction/expansion/acquisition: Producer of phenol and acetone, INEOS Phenol has announced the acquisition of the Japanese chemicals manufacturer, Mitsui Phenols Singapore from Mitsui Chemicals is complete.

ADVARIO

Products: Energy products

Construction/expansion/acquisition: Liquid energy storage and logistics provider, Advario B.V, has announced

Comment: Gordon Adams, business director of INEOS Phenol says: ‘Entering the Asian market via this acquisition gives INEOS Phenol a unique capability to support our global customers’ plans for future growth.’

PAGE 28 TANK TERMINAL UPDATE

United Kingdom

Iraq

Germany

Germany

Netherlands

Singapore

12 - 14 March 2024 Save the date. Scan the QR code to be kept up to date with the latest news, exclusive editorials, interviews and more. > Stocexpo

SPEARHEADING THE DIGITAL REVOLUTION

A HOLISTIC STRATEGY

Odfjell Terminals is a global provider of independent tank storage solutions for the chemical industry, with a track record in developing, owning, and operating tank terminals for more than five decades. With four tank terminals across the world, two in the USA in Houston and Charleston, the company has positioned itself in a strategic position, offering a total of 1.32 million m3 of storage capacity across 450 storage tanks.

‘It’s undeniable that the world continues shift and transform. We’re continually thinking of new ways to approach old problems by becoming more effective and efficient. Automation is part of how any company has to operate to stay competitive in current markets,’ says Varilla. OTUS’s digital transformation includes implementing terminal management systems, assets management, data warehouse and business analytics, and more.

IN 2021 , Odfjell Terminals US (OTUS) launched a multi-year digital transformation programme at its US terminals. The ambitious programme aims to harness the latest technologies to help maintain the highest safety standards, boost efficiency, and provide a future-proof foundation for business scalability and growth.

Two years on, Aldrich Varilla, IT director, received the Corporate ORBIE for organisations with up to $300 million (€273 million) annual revenue. The ORBIE Awards is the leading technology executive recognition program in the United States. ‘Just making it through the preliminary rounds of the ORBIE awards is a huge accomplishment,’ says Varilla. The finalists are chosen through an independent peer review process, led by previous ORBIE winners, which adds to the awards’ credibility and integrity. The nominees are then subjected to a rigorous evaluation process and their efforts must be documented and confirmed by coworkers and employers, leaving nothing to chance.

This year, the jury received over 180 nominations from a range of business

areas and industries. ‘The calibre of the nominated CIOs and CISOs demonstrates the high level of digital expertise in Houston,’ says Varilla. Of the 180, 36 finalists were elected, and by that recognised by their peers as the best in their field. Varilla was announced as the winner of the HoustonCIO ORBIE for 2023 in April.

‘Automation is more than just new equipment and systems. When thinking about holistic solutions, the operational philosophy, organisational change management, people, and processes are all important. We have to view the entire journey map and elevate every stakeholder involved, to work in concert. Unlocking that gives us real automation,’ says Varilla.

With this in mind, the digitalisation strategy cannot be left to just the IT department. ‘It takes a unified approach with all departments and parties,’ says Varilla. ‘Realising that early and attacking it from a holistic mindset unlocks boundless benefits.’

DIGITAL TRANSFORMATION

‘Digital transformation never really ends. It’s a philosophy and woven into the fabric of an organisation’s culturescape,’ says Varilla. ‘We’re constantly looking at new ways to execute and innovate.’

Before beginning the implementation of the digitalisation project, the majority of operational and administrative processes at OTUS were highly manual. Data capture was limited, and most documentation was done through excel

PAGE 30

Fresh from his ORBIE award win, Aldrich Varilla, IT director for Odfjell Terminals US tells Tank Storage Magazine about the company’s digital initiatives 01 02 PROFILE ODFJELL TERMINALS US

spreadsheets and paper forms. Now, workflows will become streamlined, safer and with fewer manual errors. Tasks will be carried out more efficiently, leading to reduced costs, and data collection will be highly automated.

‘I can say our digital transformation stage is essentially set in perpetuity but understanding we’re bound by economic means, we’ll approach it through our project governance prioritised by risk and benefits,’ says Varilla. ‘Even then, we’ve still unlocked tremendous benefits so far that have helped feed our continued transformation journey.’

OTUS also recognises that the digitalisation strategy has led to improved safety performance and increased customer and employee satisfaction. Varilla says: ‘Our mission is to provide value to our customers through safe, reliable and efficient operations.’

MEETING STRATEGIC OBJECTIVES

OTUS focuses on meeting its set strategic objectives through sustainable means:

• Safety

• Cost control

• Commercial growth and;

• Service excellence

Varilla refers to these as the pillars of the business, and therefore the key priorities when it comes to decision-making. This allows the team to draw ‘a prioritised business capability-driven map of our company’s gaps and challenges aligned to their functional areas, with hard benefits tied,’ he says.

‘In the short term, we always think with a ‘small wins, big gains’ strategy,’ continues Varilla. ‘Target the low-hanging fruit within the strategic objectives: easy wins, drastic gains.’ In terms of a digitalisation strategy, it starts with small applications that can still make a big difference to the way people work.

‘We start with things like low code applications, digitalising process workflows, electronic signatures, electronic visitor check in, modern workplace, stable communications, modernising our physical badging and security system, upgrading our data centres, rationalising costs and catching up overall on our lowhanging technical debt items,’ says Varilla. ‘This all leads to building momentum for the greater changes.’

Tackling these short-term challenges paves the way to approach larger projects. ‘In other words, there’s no shortcuts or short-term thinking. Transformation isn’t easy; it takes extreme perseverance if you want to realise recurring benefits.’

LOOKING TO THE FUTURE

Growth, excellence and expansion are on the agenda for OTUS’s future, according to Varilla. ‘We must think in terms of longevity and ability to maintain this for the long haul. Our strategic roadmap and solutioning is shaped by this. Long-term, I can only imagine having our terminal operations as best in class,’ he says. ‘I think the fact that we’re already undergoing a tremendous transformation journey and putting hard investments into it show case our commitment to customers, ourselves and securing our future.’

Varilla gives more concrete example of how the digital transformation will likely impact terminal operations long-term: ‘Tactically, this is an emulsification of processautomation, data democratisation, heavy internal and external system integrations, high cybersecurity posture, Mobility Field Services, led by proper governance and organisation maturity to play at it professionally.’

However, Varilla recognises that OTUS is not the only terminal looking to digitalise. ‘While the act of transformation isn’t going to stand out in a competitive market, the yield results of what we are expecting and delivering will,’ he says. ‘These include a better customer experience with integration and customer

portal capabilities, stable and effective operations to ensure we facilitate a crucial part of our customers supply chain, and knowing that by focusing on our safety and effective operations, our customers product quality retain best quality due to the consistent services we provide.’

Odfjell is an award winning activist in ESG and already seen as leaders in sustainability. ‘We’re constantly thinking of these areas and our digital transformation initiative removal of paper is just one example of helping our environment,’ Varilla says.

He stresses the importance of crosscompany collaboration and a holistic approach to digitalisation. ‘I can speak for our terminals in that the IT and OT space are drastically converging. I’m fortunate that our IT and engineering departments are heavy partners and work closely together in unison. There’s been many areas that traditionally, in our industry, may have been a strictly engineering function, but with more focus on cybersecurity, data and automation through systems, networking, infrastructure and mobility, we see IT really coming in to help elevate it all.’

For more information:

www.odfjell.com 01

PAGE 31

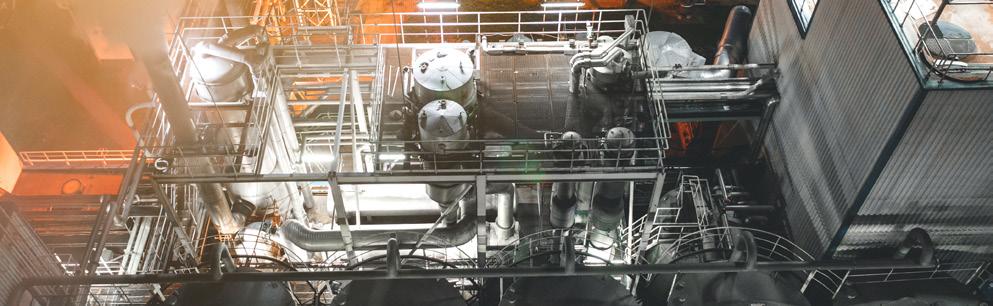

Odfjell Terminals Houston

Aldrich Varilla, IT director for Odfjell Terminals US

Odfjell Terminals Houston 03

02

03

PROFILE ODFJELL TERMINALS US

‘There’s no shortcuts or short-term thinking. Transformation isn’t easy; it takes extreme perseverance if you want to realise recurring benefits.’

OFF-GRID ENERGY AND MEETING TARGETS

Flogas Britain’s business development director, James Rudman tells Tank Storage

with the ever-changing energy market

FLOGAS BRITAIN has completed a tripartite deal with North Sea Midstream Partners Limited (NSMP) and Exolum Seal Sands (Exolum) at the Teesside gas processing plant, UK. The deal is set to boost the resilience of offgrid energy across the north of England and Scotland and provide security of supply to homes and businesses in the region. At present, the Teesside plant handles much of the gas extracted from the North Sea, including a significant tonnage of propane. However, James Rudman, business development director at Flogas Britain, explains: ‘To date, this gas has not been turned inland for UK use and is instead exported to global markets. We wanted to change this.’

Over the years, the UK off-grid gas market has become a net importer of propane. However, there’s a definite requirement for a more stable supply. Demand is growing, especially as off-grid homes and businesses are set to move away from oil to a lower carbon alternative. According to a report by WLPGA on LPG and bioLPG, propane has a 20% lower carbon intensity than oil and emits far fewer pollutants, so Flogas believes it is set to play a key role in the energy transition for off-grid Britain.

‘This is why we were so keen to find a way to bring in propane from the North Sea. Teesside is an excellent opportunity to boost the resilience of off-grid energy across the north of England and Scotland, and our new tripartite deal means we’ll see up to 120,000 tonnes of propane turned inland later this year,’ says Rudman.

LOCATION AND COLLABORATION

For more than two decades, Flogas has been investigating ways of getting propane extracted from the North Sea to be turned inland. Two years ago, it was decided that the caverns storing the propane, were going to be decommissioned. Flogas contacted NSMP and Exolum to find a way to load the propane on to road tankers for inland distribution to its customers. ‘We were able to form an agreement with NSMP and Exolum Seal Sands, whereby NSMP will transport propane to existing

infrastructure owned by Exolum, and then we act as the off-take partner, distributing the supply across the region,’ explains Rudman.

The current Teesside site is dormant and hasn’t been used in over a decade. However, works for the collaboration are underway, and propane is planned to be brought in from October 2023. In addition to storing propane, Flogas has the opportunity to consider infrastructure for other products handled at the processing plant, including butane. The facility also has capacity to be a gateway for renewable gases in the future, with space for additional storage vessels. NSMP will bring in large volumes of gas via the 404 km-long CATS gas pipeline

that’s connected to various gas fields in the North Sea, as well as having an existing pipeline connection to Exolum’s nearby storage facility. ‘This site was the perfect location, as there were five unused tanks there, which were capable of being converted to handle propane,’ says Rudman.

Flogas expects that all off-grid homes and businesses in Scotland and the north of England will see the benefit of an increased and more resilient supply of gas. ‘The collaboration will also be beneficial to future customers moving away from fuels like oil, and looking for a cleaner, more efficient alternative,’ says Rudman.

OFF-GRID ENERGY

‘Flogas is leading the industry in improving the security of the UK’s off-grid energy supply, reducing the reliance on imports, and providing clear options for renewable energy in the future, in support of net zero targets,’ says Rudman. The company’s new supply at Teesside will represent about 10% of the current market size and offers a significant increase of product to improve security and resilience of supply.

PAGE 32

Magazine

it’s

01

how

keeping up

PROFILE FLOGAS BRITAIN

‘The collaboration will also be beneficial to future customers moving away from fuels like oil, and looking for a cleaner, more efficient alternative.’

In addition to the development in the north at Teesside, Flogas also has a solution in the south of England. It is developing the UK’s largest above ground propane storage facility in Avonmouth, Bristol, which will have the capacity to store 34,564 tonnes. Planning permission for a pipeline into Avonmouth was recently granted, linking the UK to a diverse, global supply of offgrid gas, and enabling it to import ship cargos of up to 20,000 tonnes.

ADAPTING FOR THE TRANSITION

Flogas is dedicated to helping off-grid customers navigate their pathway to net zero emissions. ‘Propane is one of the cleanest, most efficient conventional off-grid fuels available at scale, and customers switching from other fuels,

such as oil, benefit from significant carbon savings and better air quality with fewer pollutant emissions,’ explains Rudman. ‘Propane has an important role in the off-grid energy transition.’

Thinking to the future, Flogas is serious about meeting its 2040 ambition. ‘We want to provide 100% renewable energy solutions to customers and have a solid plan in place that involves a phased introduction of renewable products, building on our existing portfolio,’ says Rudman.

As well as helping customers on the road to net zero, Flogas is also focused on making its own business fit for the future. Rudman says: ‘We have pledged to reduce our direct carbon emissions by 20% by 2025, and we aim to become completely carbon neutral by 2050.’

FUTURE OF FUELS

At the moment, Flogas’ priority is to get the propane infrastructure delivered, but it is also looking at the possibility of butane and other products in the future. ‘One exciting opportunity is to look at rDME (renewable Dimethyl Ether). This renewable fuel can be produced from municipal solid waste and has very similar properties to propane. In fact, it can be blended with propane up to a maximum of 20%, reducing the carbon intensity of the blended fuel as a result,’ says Rudman. Flogas plans to install an rDME storage tank in the next two years to enable these propane/rDME blends to be loaded on to road tankers, which will only increase its capacity for off-grid energy.

On top of this, Flogas also acquired Protech Group last year, adding a full suite of low carbon and renewable technologies to its portfolio, including air-source and ground-source heat pumps, solar PV, and hybrid systems.‘This means we’re now fully equipped to help customers meet legally binding carbon reduction targets,’ says Rudman.

Flogas is making progress to provide a stable supply of off-grid energy in the UK. The collaboration at Teesside will strengthen the use of off-grid energy and will turn up to 120,000 tonnes of LPG inland from October 2023.

For more information:

www.flogas.co.uk

www.wlpga.org

James Rudman,

PAGE 33

02

01

business development director, Flogas Britain

02 Teesside gas processing plant, Seal Sands

PROFILE FLOGAS BRITAIN

‘We want to provide 100% renewable energy solutions to customers and have a solid plan in place that involves a phased introduction of renewable products.’

WORLD-CLASS FACILITY

Leading regional player for processing industry chemicals in the GCC region, AquaChemie, inaugurates its new petrochemical terminal at Jebel Ali Port

AQUACHEMIE Middle East has officially inaugurated its world-class petrochemical terminal in DP World’s Jebel Ali Port in Dubai. The advanced $50 million (€46.1 million) terminal will be one of the most functional and versatile bulk liquid terminals in the GCC region. It will serve as a vital gateway to facilitate and boost the growing petrochemical trade between manufacturers and endusers across the Middle East and globally. The new terminal, which is essentially a break-bulk facility, fills a supply chain void by serving as a strategic hub for the liquid petrochemical trade and distribution.

THE DEVELOPMENT

AquaChemie commissioned Mott MacDonald for the new facility’s design, detailed engineering and project management. The region’s leading mechanical, electrical, instrumentation, and civil contractors are also credited for the project’s completion in record time.

‘It took us over four years to bring the AquaChemie terminal from concept to reality,’ says Subrato Saha, AquaChemie’s MD. ‘We are thankful to have met such capable collaborators along the way who assisted us in shaping it.’

The foundation of the petrochemical terminal was laid in November 2020, with the new facility being awarded its OFC (Operation Fitness Certificate), along with all of the required regulatory certifications from Dubai Civil Defense and DP World in January 2023. Since, the facility has been fully CDI-T assessed and is ISO 9001,

ISO 14001, and ISO 45001 certified. The terminal has already serviced the first vessel carrying chemicals.

ACCOMPLISHMENTS

The chemical terminal covers an area of 20,000 m² and is located some 500 m from Chemical Berth 4 in Jebel Ali Port. The new facility is linked by five SS pig-gable jetty pipelines, making it one of the most functional and versatile bulk liquid terminals in the GCC region.

With a total storage volume of over 34,000 m³, the 26 large tanks in tankfarms A, B, C, and D are well equipped to handle over 100 UN Class 3 and 8 chemicals. The terminal has three tanker truck loading bays for top and bottom loading, five semi-automatic drumming lines, a warehousing facility with over 6,300 drums, a dedicated ISO tank storage area, and a weigh bridge at the truck entry point.

‘Our new state-of-the-art terminal is a step towards integration of our current oil and gas offering for the upstream and downstream petrochemical sectors,’ says Anand Kumar, managing director of AquaChemie. ‘The supply reliability and lower supply chain cost will benefit our existing customers, as chemicals will be delivered on time so that the customers’ operations are not disrupted.’

‘The new terminal will also assist in the formation of strategic alliances with regional and global manufacturers of petrochemicals, in order to distribute bulk products to customers in smaller

packaging. To maximise capacity and partially offset operation costs, a few tanks in the new facility will be leased for third-party storage. Chemicals hold enormous promise for the region. We hope, humbly, to contribute to this value chain,’ Kumar adds.

STAND OUT POINTS

The terminal is fully monitored and controlled from a central control room. AquaChemie’s corporate headquarters are located on the same site to allow the leadership team to stay in close proximity. This houses the terminal’s operation control room, support and sales staff offices, dining and recreation areas, management office and board room.

LOOKING TO THE FUTURE

The regional petrochemical industry also stands to benefit from the new terminal, located in Jebel Ali Port. This is part of a trade network connecting one-third of the world’s locations, while also offering streamlined customs clearance and other trade-related processes.

Snehal Karia, VP business development of AquaChemie, says: ‘I am especially excited about our combined offering of a centrally located storage terminal supplemented by local setup in each Middle Eastern country. We will become a dependable chemical product supplier all year round, and serving on all days. Our new facility now enables the storage of several new products with improved pricing and availability for end-users.’

China, the United States, Russia, Saudi Arabia, and South Korea are amongst the top six countries, by volume, producing bulk petrochemicals worldwide. The global petrochemical market is expected to reach $5.4 trillion (€4.9 trillion) by 2027, growing at a CAGR of 4.1% during the forecast period.

For more information:

www.aquachemie.com

PAGE 34

01

PROFILE AQUACHEMIE

01 Inauguration of the new AquaChemie Petrochemical Terminal

Featuring: Exclusive interviews with leading terminal operators Thoughtful analysis into the latest tank storage and future fuels CHEMICAL STORAGE SUPPLEMENT Distributed at: BOOK YOUR ADVERT NOW IN THE AUG/SEPT EDITION. BOOK NOW anamika.talwaria@easyfairs.com GASTECH, SINGAPORE TANK STORAGE ASSOCIATION CONFERENCE, UK ADIPEC, ABU DHABI WORLD HYDROGEN CONGRESS, NETHERLANDS POSTED TO 3,500 & EMAILED TO 30,000 TERMINAL PROFESSIONALS WORLDWIDE Established 2005. Trusted. Valued. Influential. Established 2005. Trusted. Valued. Influential.

‘DO NOT CALL ME A DIVERSITY HIRE’

Embracing and encouraging diversity in the industry leads to endless possibilities, says Smartflow’s Stefana Sopco

SMARTFLOW’S head of content marketing, Stefana Sopco, journeyed into the tank storage industry following a passion for technology and digitalisation. During her first two years of living in the Netherlands, before Smartflow, Sopco worked at another tech company that built a gamified learning app. Following this position, she landed the role of head of content marketing at Smartflow – a SaaS company with a solution used to digitalise inspections and checks within the energy, maritime and TIC industries. Sopco aims to inspire women and girls across the world, but in particular those from Romania, to explore opportunities in historically masculine industries. ‘I have always been drawn to technology,’ says Sopco. ‘My journey into the world of tank storage was never planned, but technology and digitalisation were always an interest of mine.’

Having previously worked in IT, Sopco knew the significance of digitalisation in the modern world. In her current role, Sopco helps to spotlight future ideas, workers, and generations of the tank storage industry. Whilst her start in the industry incorporated a mixture of learning and tackling obstacles, three

years on, she has established a platform as a woman in the industry, lifting up others. Sopco says: ‘I am being put at the table in the industry. And even if it is extremely scary, I must be there. I am never going to say no to opportunities to talk about my experience in the industry.’

‘One day I hope young Romanian girls who dream of building a career and leaving difficult environments, will come across my LinkedIn profile and see that Stefana Sopco from Romania has managed to achieve what she wanted. I do not want them to fear a potentially ‘mannish’ industry,’ says Sopco.

IMMERSION IN THE INDUSTRY

Sopco is responsible for everything that falls under Smartflow’s marketing division, allowing her to be close to customers and end users. She enjoys being immersed in the industry and getting to be at events, learning and developing her understanding of the industry, as it too evolves. This is key, as it’s important to understand how an industry works before trying to implement a product or solution. Sopco is interested in the development of others and the challenges they face. And therefore, how