UNITING MATERIALS, TECHNOLOGY AND DESIGN

• The Trends Issue

• Smart Surfaces

Evolution

• AI and Robotics in the Industry

UNITING MATERIALS, TECHNOLOGY AND DESIGN

• The Trends Issue

• Smart Surfaces

Evolution

• AI and Robotics in the Industry

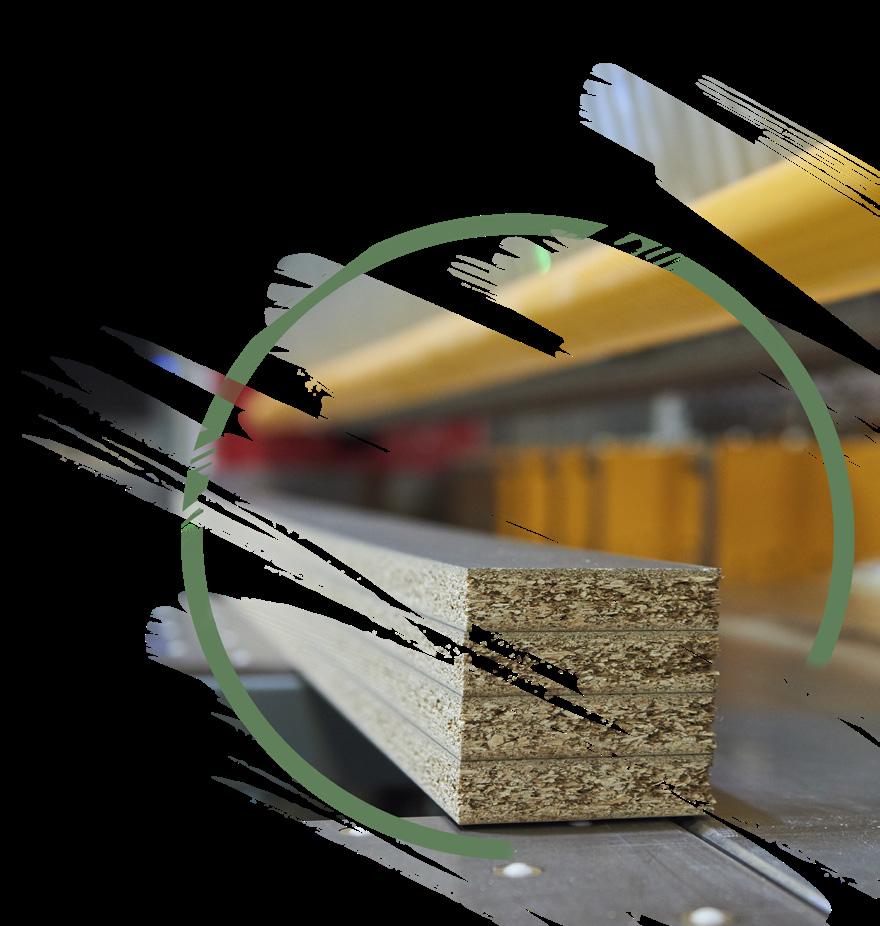

The award-winning Smartshop® 2 Elite has been the workhorse of the Laguna line of CNC machines. Designed to cut everything from wood to non-ferrous metals, the Smartshop® 2 Elite is dependable and built to last. Constructed with an all-steel frame featuring helical rack and pinion, the Smartshop® 2 Elite excels at giving the precision you need with a cut quality rivaling any machine on the market.

Learn more — Scan the QR

UNITING MATERIALS, TECHNOLOGY AND DESIGN

FEATURES

6 ASID'S 2026 Trends Outlook And what it means for the Surface & Panel Industry

10 2026 Kitchen & Bath Trends

Insights from the latest NKBA | KBIS Kitchen and Bath Trends reports

14 Hardware in Focus Defining the trends shaping 2026

16 Trade Policies for the Decorative Hardwood Industry

18 Designing for More

How commercial surfacing is evolving for flexibility, sustainability and impact

20 The Top Five Closet Trends for 2026 From Closet Guru Eric Marshall

24 Tom Lenderink

Still innovating after six decades in the industry

28 Smart Surfaces, Quiet Tech

How responsive materials are reshaping design

32 The Future is Automated — and it's Already Here A quiet revolution is taking place on factory floors across the world

36 The Promise of the PIM

Distribution gateway to an AI-driven Future

40 Distribution Matters Distributiors as early adaptors

50 A Look at the 2026 Colors of the Year

42 Human Resources: What you need to know moving into the new year

46 @ The Show KBIS 2026

48 Ad Index

PRESIDENT/PUBLISHER

Patrick Adams

PH: 714-486-2735 padams@526mediagroup.com

VICE PRESIDENT

Shelly Adams

MANAGING EDITOR

Jennifer Williams

PH: 714-486-2735 jwilliams@526mediagroup.com

David Koenig, DIRECTOR OF EDITORIAL

Sara Graves, SENIOR EDITOR

GUEST COLUMNISTS & CONTRIBUTORS

Keith Christman

Meghan Howell

Eric Marshall

Michael Wilbur

Denise Williams

SALES

Nick Kosan

PH: 714-486-2735 nkosan@526mediagroup.com

Chuck Casey

PH: 714-486-2735 ccasey@526mediagroup.com

John Haugh

PH: 714-486-2735 jhaugh@526mediagroup.com

GRAPHIC DESIGN

Greg Lane

DIGITAL SUPPORT

Katherine Williams kwilliams@526mediagroup.com

CIRCULATION/SUPPORT

PH: 714-486-2735 info@526mediagroup.com

526 MEDIA GROUP 151 Kalmus Drive, Ste. J3 Costa Mesa, CA 92626

PH: 714-486-2735

BY S&P STAFF

As the built environment enters 2026, design is no longer reacting to disruption — it is actively reorganizing around it. The 2026 Trends Outlook from the American Society of Interior Designers (ASID) frames the year ahead as one defined by recalibration: between technology and tactility, efficiency and emotion, innovation and restraint.

For the surface and panel industry, these shifts signal more than aesthetic change. They point to evolving expectations around materials, performance, sourcing, and storytelling — areas where manufacturers and suppliers will play a decisive role.

One of the strongest undercurrents in ASID’s 2026 outlook is the return of nostalgia, though not in a literal or ornamental sense. Consumers, particularly Gen Z, are embracing antiques, patina, and visible aging as markers of authenticity and sustainability. For surface and panel producers, this creates demand for finishes and textures that tell a story: matte over gloss, layered visuals over flat uniformity, and materials that feel “earned” rather than manufactured.

At the same time, design is becoming more openly narrative-

driven. As America enters the year of its semiquincentennial, ASID notes a renewed interest in storytelling tied to place, culture, and personal history. Panels, laminates, and composite surfaces are increasingly expected to act as backdrops for these narratives through regional wood looks, historically inspired patterns, or materials that reference craftsmanship while meeting modern performance standards.

Another major lifestyle shift is the elevation of outdoor space from an optional amenity to essential living area. This redefinition is already reshaping product development, driving demand for exterior-rated panels, moisture-resistant substrates, UV-stable finishes, and surfaces that bridge indoor and outdoor applications seamlessly.

ASID’s outlook underscores the growing influence of an aging population alongside a workforce grappling with burnout, hybrid models, and shifting expectations of the workplace. For designers, adaptability has become a core requirement. For manufacturers, this translates into surfaces and panels that support modularity, durability, and long-term use across multiple life stages.

In residential settings, adaptive living is becoming a baseline

rather than a specialty, creating opportunities for panelized systems that support accessibility without sacrificing aesthetics. In commercial environments, declining employee engagement is pushing employers to rethink interiors as tools for well-being and retention. Materials that contribute to acoustic comfort, visual warmth, and psychological safety are gaining renewed relevance, particularly in office, healthcare, and education projects.

Rather than positioning technology as a disruptive force, ASID frames 2026 as a moment when digital tools mature into design partners. Artificial intelligence is increasingly being used to refine, curate, and personalize rather than automate creativity outright.

For our industry, this has implications across product development, visualization, and customization, especially as clients expect faster iteration, more options, and clearer performance data.

However, ASID also highlights growing concern around cybersecurity as smart environments proliferate. While this may seem peripheral to materials at first glance, it reinforces a broader theme: accountability. As surfaces integrate sensors, lighting, or connectivity, manufacturers will be expected to understand how materials interact with technology ecosystems, energy use, and long-term resilience.

Notably, the report acknowledges tension between technological advancement and conservation. As smart systems and datadriven design expand, so does energy demand, placing greater pressure on materials that support efficiency, carbon reduction, and responsible sourcing.

Economic uncertainty continues to shape design decisionmaking. ASID notes that while tariffs and supply chain disruptions have not hit as severely as anticipated, pricing volatility remains a

reality. Designers are responding by seeking flexibility — diversifying suppliers, exploring alternative materials, and favoring systems that can adapt to changing availability.

Multifamily residential development stands out as a growth sector, driven by both younger renters and aging populations seeking community-focused living. This creates sustained demand for high-performance panels and surfaces that balance cost, durability, and design consistency across large-scale projects.

For manufacturers, the message is clear: agility is now a competitive advantage. The ability to pivot between markets, finishes, and performance tiers will be critical as designers look for partners who can keep pace with evolving project demands.

Wellness emerges as one of the most material-driven themes in ASID’s 2026 outlook. Color is positioned as a tool for emotional regulation, with designers using palettes to soothe, energize, or ground occupants. This places renewed emphasis on surface coloration, finish depth, and consistency — particularly as bold hues re-enter the conversation.

Health-driven design is also accelerating demand for low-VOC

materials, healthy substrates, and finishes that support indoor air quality. Importantly, ASID notes a shift away from abstract sustainability claims toward measurable impact. Designers want data and clear metrics around sourcing, emissions, and lifecycle performance.

Layering is another defining concept for 2026, with ASID highlighting multisensory design that combines visual texture, tactility, lighting, and acoustics. This reinforces the value of integrated solutions, where panels contribute not just visually, but functionally, to comfort and experience.

Perhaps the most important takeaway from ASID’s 2026 Trends Outlook is convergence. Sustainability, wellness, technology, and economics are no longer separate conversations. They intersect at the material level, where decisions directly influence performance, cost, and experience.

This year will be less about chasing trends and more about refining fundamentals: material honesty, adaptability, transparency, and partnership with designers who are navigating a more complex built environment. As ASID’s outlook makes clear, the future of design will be shaped not just by what spaces look like, but by how intentionally they are built — and the materials behind them will matter more than ever.

The full ASID report, sponsored by Sherwin Williams, will be released January 27, 2026, at asid.org/resources/research S P

The AVENTOS top range combines sleek design and everyday convenience — transforming upper cabinets into a smarter, more refined solution. See how easy it is to elevate your cabinets at KBIS in Booth W1442.

BY JENNIFER WILLIAMS

The kitchen and bath have always reflected how we live, but heading into 2026, these spaces also are beginning to anticipate how we want to feel.

According to the recently released 2026 Kitchen and Bath Trends reports from National Kitchen & Bath Association (NKBA | KBIS), both spaces are undergoing a fundamental transformation driven by rapid advances in technology, a renewed emphasis on wellness, and a growing demand for deeply personalized environments.

“Bath design is becoming deeply personal,” said Bill Darcy, Global President & CEO of NKBA | KBIS. “Beyond considerations like resale value, designers are focusing on how spaces support a homeowner’s individual rituals, preferences, and self-care routines. This perspective encourages creativity, niche trends, and designs that truly reflect how people live today.”

Based on survey data from nearly 700 designers, manufacturers, remodelers, architects, and industry professionals, the reports paint a clear picture: kitchens and baths are no longer static, utilitarian rooms. They are intelligent, lifestyle-centric spaces that inte -

grate seamlessly with the rest of the home while still serving highly individual needs.

Below is a closer look at how these parallel evolutions are shaping surface, material, and product decisions across the industry.

Technology is moving away from novelty and toward integration in both kitchen and bath spaces going into 2026. Rather than being showcased as a standalone feature, smart functionality is increasingly embedded into surfaces, fixtures, lighting, and storage, enhancing daily routines without disrupting aesthetics.

In today's bathrooms, technology is influencing design in three distinct ways: as a source of inspiration, as a functional upgrade, and as a wellness tool.

Younger homeowners, in particular, are turning to AI-driven platforms for design inspiration, blending smart features with sustainability and style. Intelligent showers, lighting systems, and energy-efficient fixtures are rapidly expanding, while wellnessfocused technologies — including stress-reduction tools and aging-

in-place innovations — are becoming mainstream rather than niche. In the kitchen, smart technology adoption is selective but growing. WiFi-enabled appliances, app-controlled lighting, embedded wireless charging, and intelligent refrigeration systems continue to gain traction. These advancements are being paired with healthoriented features such as steam cooking, powerful ventilation, and enhanced food storage, positioning the kitchen as a hub for both nourishment and well-being.

• AI-driven design inspiration tools

• Smart showers, lighting, and energy systems

• WiFi-enabled and app-controlled appliances

• Embedded wireless charging in kitchens

• Technology supporting wellness and aging in place

While technology is evolving quickly, color and material preferences are moving in the opposite direction — toward calm and timeless appeal.

In both kitchens and baths, neutrals dominate. Nearly all respondents identified neutral palettes as the most popular choice in both kitchen and bath design, with off-whites, light browns, tans, and whites leading the way. Greens, particularly brown-based shades like sage and olive, are emerging as favored accent colors, while bold hues remain firmly on the fringe.

Design styles are also converging across both spaces. Transitional and timeless aesthetics top the list, followed closely by organic/natural and contemporary minimalism. The emphasis is on longevity rather than trend-chasing, with materials and finishes selected for durability, ease of maintenance, and visual cohesion. Surface decisions reflect this mindset. Large-format flooring

• Neutral palettes dominate kitchens and baths

• Brown-based greens (sage, olive) rise as accents

• Transitional and organic design styles lead

• Large-format flooring and slab surfaces preferred

• Wood grain surpasses painted cabinetry

• Matte, brushed, and satin finishes over polished

with minimal grout lines is preferred in baths, driven by a desire for cleaner visuals and lower upkeep. In kitchens, slab cabinet doors, panel-faced appliances, and solid-surface backsplashes support a streamlined, architectural look.

Natural materials continue to gain ground. Wood-faced vanities have surpassed painted options in the bath, while wood grain cabinetry — especially white oak — leads kitchen design. Quartz remains dominant, but natural quartzite is closing the gap for both countertops and backsplashes.

Despite shrinking overall home sizes, both kitchens and baths are expected to grow in footprint over the next three years. This expansion reflects a shift in how homeowners prioritize space — not just for function, but for experience.

In the bath, larger footprints allow for spa-inspired features,

wellness zones, and universal design elements. More than half of respondents indicated that a larger shower is more important than having a bathtub, opening the door to steam functions, aromatherapy, chromotherapy, integrated seating, and built-in shelving. Primary baths, in particular, are becoming sanctuaries rather than secondary spaces.

Kitchens are similarly expanding, with 76 percent of respondents expecting growth over the next three years. And kitchens are increasingly influencing whole-home design. The traditional dining table is being replaced with multifunctional islands, integrated storage, and flexible layouts that support entertaining, working, and gathering, maximizing space usage in a home.

One of the most striking parallels between kitchen and bath trends is the growing influence of hospitality design. Homeowners are looking to hotels, resorts, and wellness retreats for inspiration, seeking spaces that feel indulgent, restorative, and intuitive.

In baths, this translates into environments that prioritize physical and mental well-being. Smart toilets and bidets, patterned and textured tiles, layered lighting, and spa-like showers contribute

• Spa-inspired primary bathrooms

• Steam showers, chromotherapy, and aromatherapy

• Health-focused kitchen appliances and ventilation

• Design inspired by hotels and resorts

• Spaces that support mental and physical well-being

to a holistic experience rather than a collection of individual features. The bath is evolving from a purely functional room into a daily retreat that supports self-care.

In kitchens, wellness shows up through healthier cooking methods, better air quality, connections to outdoor spaces, and layouts that reduce stress and clutter. Powerful ventilation, steam cooking, and thoughtful storage all support healthier living while maintaining a clean, minimal aesthetic.

Lighting has become one of the most critical — and nuanced — design elements in both kitchens and baths. Rather than relying on a single solution, designers are layering light options to support function, mood, and aesthetics.

In baths, task lighting is considered essential, particularly around vanities, while mood lighting in showers and nighttime-specific lighting are gaining popularity. Natural light remains a top priority, complemented by integrated mirror lighting that reduces visual clutter.

Kitchens, meanwhile, are embracing lighting as a statement feature. Decorative fixtures coexist with highly functional solutions such as under-cabinet, interior cabinet, and pendant lighting. The result is a space that can transition effortlessly from task-oriented to social, day to night.

Personalization is no longer an upgrade — it’s an expectation.

In baths, custom storage solutions are increasingly designed around daily rituals. Vanities and cabinetry now incorporate built-in storage for hair tools, makeup, medications, and electronics, along with integrated power and charging stations. These tailored solutions simplify routines while reinforcing a sense of bespoke luxury.

Kitchens are following suit, with 100 percent of respondents agreeing that lifestyle enhancements will drive kitchen layouts over the next three years. Dedicated beverage stations, pet feeding areas, eat-in kitchens, walk-in pantries, and islands packed with storage reflect the kitchen’s role as a multifunctional hub.

“ 100 percent of respondents agree that lifestyle enhancements will drive kitchen layouts over the next three years. “

• Configurable vanity and cabinet storage

• Built-in charging and electrical integration

• Dedicated beverage and pet stations

• Walk-in and butler pantries

• Islands designed for maximum storage

Perhaps one of the most telling indicators of where the industry is headed is the normalization of universal design. Agingin-place features are no longer perceived as clinical or purely functional; they are being seamlessly integrated into high-end design.

In the bath, curbless showers, grab bars, benches, wider doors, and barrier-free entries enhance safety while elevating the overall aesthetic. These features are increasingly viewed as luxurious rather than limiting — proof that accessibility and beauty can coexist.

In kitchens, accessibility shows up in smarter storage, reduced clutter, and layouts that support multi-generational living. As demographics shift, these considerations are becoming essential components of thoughtful design rather than optional add-ons.

The kitchen trends report also highlights how generational priorities are shaping design decisions. Gen X and Boomers currently lead kitchen remodel activity and spending, but motivations differ across age groups.

Millennials without children prioritize entertaining and high-

end convenience, while families seek multifunctional layouts that support daily life. Boomers favor accessible kitchens and classic styles with premium materials, while Gen X focuses on value, storage, and flexibility for multi-generational households. Gen Z, looking ahead, is expected to drive demand for fully connected, smart homes.

Taken together, the 2026 NKBA KBIS Kitchen and Bath Trends reports reveal a powerful throughline: the most successful spaces will be those that balance innovation with restraint, and personalization with cohesion.

“The integration between the kitchen and whole home is a really exciting opportunity for the kitchen and bath industry,” added NKBA’s Darcy. “[The 2026 Trends reports] further confirm this evolution, as homeowners desire connection and cohesive design between spaces for entertainment, functionality and wellness. [These reports] help provide an inside look at what the market demands so that designers can be empowered to offer clients beautiful spaces tailored to their individual needs.”

For our industry, these trends underscore the importance of materials, finishes, and systems that support technology, wellness, durability, and timeless design. Kitchens and baths are no longer isolated rooms; they are central players in a connected, experience-driven home.

As we kick off the new year and prepare to see the latest and greatest at KBIS in Orlando next month, we look to not just follow trends, but to create spaces that adapt, endure, and genuinely enhance how people live every day. S P

BY S&P STAFF

This year’s hardware trends are defined less by sweeping reinvention and more by purposeful refinement. Across the industry, manufacturers are honing in on specific innovations that address performance, integration, sustainability, and user experience.

Highlighted here are some of the top hardware trends for the new year, offering a glimpse of the ideas and technologies shaping hardware design and specifications heading into 2026.

A timeless favorite among designers, linear bar pulls like these Erika Pulls from Atlas Homewares, continue to redefine kitchens with their understated charm. With clean lines and a sleek silhouette, these decorative hardware fixtures create a modern yet enduring style. In addition to easy grip and comfortable use, its style elevates both traditional and contemporary cabinetry and are available in 3-18-inch lengths.

Consumers continue to look at ways to make spaces their own, and that now extends into custom hardware. The U-Design Decorative Pulls from Richelieu give designers the freedom to turn a simple pull into a living story: its clear acrylic tube becomes a canvas for whatever sparks the imagination — from confetti from a celebratory moment to stones collected on travels or a special keepsake, and can be updated whenever the mood strikes. The

posts, offered in matte black, brushed nickel, or Lima gold, are built to last and made to evolve.

Modern kitchen designs are celebrating effortless minimalism and quiet luxury, focusing on clean lines, uninterrupted surfaces and a contemporary look that emphasizes calm and cohesive spaces. With innovative functions like Häcker Kitchens’ Push-toOpen mechanisms, homeowners can easily access cabinets with one simple touch, elevating both convenience and sophistication. By removing visible hardware on cabinetry, the focus shifts from ornamentation to materiality and craftsmanship, reflecting the essence of elegant simplicity.

One dominant design trend for 2026 is the personalization of spaces with subtle details. In response, the decorative hardware product design team at Hardware Resources’ Jeffrey Alexander brand is focused on creating collections that provide maximum flexibility to make spaces feel intentional and highly functional. Weser is one of four new collections for 2026 that feature six pull lengths, two appliance handle lengths, and coordinating knobs in six finish options. These new collections allow designers to select pull lengths relative to the size of the door or drawer, creating a harmonious, intentional feel in any space.

AVENTOS lift systems from Blum were created to make moving through the home a seamless experience, providing unlimited functionality with a modern style. Whether you choose fold up, up and over, lift up, or pivot up, you can retrieve items from your cabinets quickly and easily as the door moves up and out of the way. The newest generation of these systems — AVENTOS HF top, HS top and HL top — features a sleek lift mechanism that is intuitive to install. Two lift mechanism strengths, three telescopic levers and front fixing brackets that can all be used symmetrically. Additionally, the sleek and slim form of the lifts and levers leave a small footprint in the cabinet, providing more room for storage within. S P

BY KEITH CHRISTMAN

The decorative hardwoods industry, encompassing hardwood plywood, engineered wood flooring, and hardwood veneer, is at a critical juncture as it approaches 2026. Trade policy brought many changes for the industry in 2025. But more policy changes and a critical trade case will bring bigger changes in 2026.

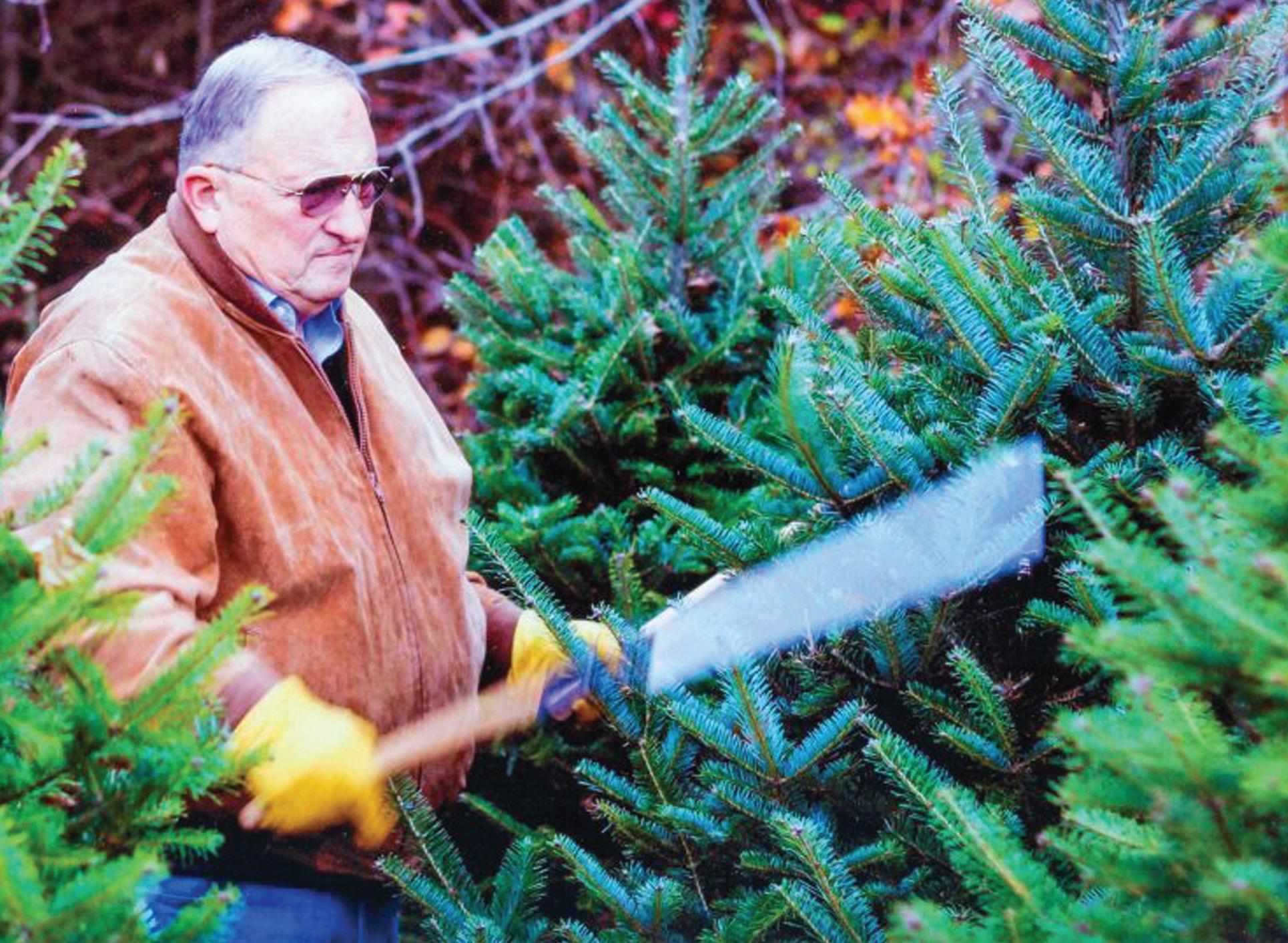

In 2024 and 2025, the decorative hardwoods sector continued to be challenged by high levels of imports of dumped and subsidized products particularly from Asia most notably Vietnam, Indonesia and China. These countries provide significant subsidies to their wood products industry and in many cases benefit from state-owned forests and/or imports of birch from Russia harvested by oligarchs on state-owned land with no regard for the environment or sustainability. These subsidies result in imports priced at levels less than raw material cost in the U.S. By contrast, in the U.S. hardwoods are produced mostly on private lands by family own -

ers who must receive fair value for their trees. These families also responsibly manage their lands for generations to come.

Higher tariffs on wood products are needed to ensure fair trade in wood products and prevent the destruction of rural mills which are closing at high rates throughout the U.S., eliminating jobs and leading to forest overgrowth and destructive fires. In September Roseburg Forest Product closed its last hardwood plywood plant noting the market is dominated by ultralow priced Asian imports.

Early in 2025, President Trump proposed reciprocal tariffs on key countries that are sources of very high levels of low-cost imports to the U.S. including China and its allies Vietnam and Indonesia. In addition, the administration proposed Section 232 national security-based tariffs on wood products. Reciprocal tariffs did not apply to many decorative hardwood products as the Section 232 tariffs were being considered. In late September, the Administration imposed Section 232 tariffs on cabinets and uphol -

stered wood products at 25 percent. Cabinets are an important domestic end market for hardwood plywood, so this policy is important to turn around this struggling end market. Unfortunately, hardwood plywood and other decorative hardwoods were not included in the Section 232 announcement. This exclusion from Section 232 tariffs, together with the current challenge to reciprocal tariffs at the Supreme Court leaves trade policy on decorative hardwoods uncertain as we start 2026.

In addition to Trump Administration trade actions, the Coalition for Fair Trade of Hardwood Plywood launched antidumping (AD) and countervailing duty (CVD) challenges against hardwood plywood imports China, Vietnam, and Indonesia in May 2025. These cases, while overshadowed in 2025 by Administration policies, are taking center stage for decorative hardwoods in 2026.

On June 12, 2025, the U.S. Department of Commerce announced the initiation of the antidumping duty and countervailing duty investigations of hardwood and decorative plywood from China, Indonesia, and Vietnam. Commerce initiated at dumping margins of over 500 percent for China, between 138 and 150 percent for Vietnam and nearly 85 percent for Indonesia.

On July 3, 2025, the U.S. International Trade Commission unanimously voted for a preliminary determination. The Commission

determined that there is a reasonable indication that a U.S. industry is materially injured by imports of hardwood and decorative plywood from China, Indonesia, and Vietnam that are sold in the United States at less than fair value and subsidized by the governments of China, Indonesia, and Vietnam.

As we begin 2026, the Commerce Department is scheduled to issue preliminary CVD rates in January, triggering the collection of duties on hardwood plywood imports from these countries. The Coalition has also pointed to surging imports after the cases were launched this could lead to retroactive duties going back 90 days. Preliminary AD determinations are due in late February. These trade cases will be decided in 2026 and should result in fairer trade in these products in 2026.

Unfortunately, we expect China and other allies will quickly move production and transship through allied countries limiting the benefit to these cases. Policies that prevent transshipment and vigorous enforcement will be needed to see a longer-term recovery. S P

Keith Christman is president of the Decorative Hardwoods Association, formerly known as Hardwood Plywood and Veneer Association. He welcomes your thoughts and questions at kchristman@decorativehardwoods.org. Visit the DHA at decorativehardwoods.org

BY MEGHAN HOWELL

Commercial surfacing has always played a critical role in shaping how spaces function and feel. Today, that role is more dynamic and innovative than ever. At the heart of this transformation is a growing demand for more. From hybrid corporate offices to bustling hospitality spaces, the surfacing industry is entering a new era shaped by flexibility, performance and meaningful sustainability.

With so many demands on modern surfaces, designers are walking a tightrope as performance alone doesn’t satisfy. This intersection of needs is driving innovation across substrates, core materials, finishes and even manufacturing processes. From scratch-resistant laminates to high-pressure decorative surfaces that mimic stone or metal, materials are being asked to do more, last longer and tell better stories.

Modularity dominated at design shows like NeoCon this year, not just as a furniture trend, but as a mindset influencing surfacing and material selection. Spaces are no longer static but

are fluid environments that must respond to shifting workflows, hybrid schedules and multipurpose demands.

Surfacing materials are now expected to support this movement whether through lightweight construction, mobile applications or multi-functional finishes. The show saw this functionality in the form of nesting tables, modular seating systems and surfaces integrated with writable, high-gloss layers designed for teamwork.

While function reigns, form isn’t falling behind. Gloss finishes, once retired for their fingerprint woes, are making a purposeful return. This time they’re more intentional, often appearing as accent materials to deliver visual impact, highlight key areas or add a multifunctional element such as a writable surface in collaborative zones. There's a clear desire to create focal points to bring some contrast into commercial spaces.

At NeoCon, gloss reappeared in small but powerful ways: highshine accent walls, chrome-like side tables and glossy panels used as message centers with writable surfaces. Often achieved with

glossy surfaces like glass, these finishes focus less on tradition and more on creating visual energy and defining anchors in spaces designed for greater usability.

Sustainability is non-negotiable in today’s surfacing industry. Designers and specifiers are seeking not just materials that reduce harm, but those that actively contribute to circular economies and regenerative design. There is added emphasis not just on how products are made, but on how they can be “unmade” at the end of their lifecycle.

From biodegradable vinyl that decomposes in landfill conditions to terrazzo-like surfaces made from post-consumer plastics that can be recycled, the future of commercial surfacing lies in sustainable material stories. Some of the most exciting innovations are happening where science, art and design converge. This trend is especially relevant in sectors like education, healthcare and corporate environments where environmental, social and governance goals are influencing procurement and material selection. Brands that can quantify their impact, whether through water savings, carbon offsets or material reclamation will increasingly have the competitive edge.

Another shift shaping commercial surfacing is the growing influence of hospitality and residential aesthetics. Workplaces, healthcare and education venues are borrowing cozy, comforting cues such as warm wood tones, plush textiles and more tactile surfaces to create spaces that feel welcoming and lived in.

That doesn’t mean sacrificing performance. Instead, it’s about selecting materials that balance emotional resonance with technical requirements. Expect to see warm woodgrains, rounded edges and surfaces that feel as good as they look. This hybrid aesthetic bridges the gap between utility and comfort.

Looking ahead, the next three to five years promise more disruption and innovation. As artificial intelligence, immersive platforms and digital integration become embedded in our everyday lives, the materials that define those environments will need to evolve in tandem. It’s no longer just about surface performance but also connection. Whether it’s embedded technology, responsive finishes, design or materials that interact with both people and digital systems, design will need to support the merging of physical and virtual experience.

The future of commercial surfacing isn’t about a single material or aesthetic. It’s about materials that fuse form and function — those that adapt, respond and offer more than just a surface solution. As the industry navigates new expectations, from climate challenges to redesigned workspaces, the most impactful solutions will be those that evolve and deliver more resilience, intentionality and more design-forward thinking. S P

Meghan Howell is the North American Design & Creative Director at Formica Corporation, where she leads the company’s visual identity, product development, and storytelling across its decorative surfacing brands. With over a decade at Formica, she has spearheaded initiatives like the Beyond Boomerang book— celebrating the cultural impact of Formica Group’s iconic patterns—and most recently launched the award-winning InDepth Surfacing line, which showcases layered, tactile design rooted in material innovation. A graduate of the University of Cincinnati’s College of Design, Architecture, Art, and Planning (DAAP), Meghan is passionate about connecting design legacy with forward-looking, research-driven strategies that keep Formica Groups product portfolio at the forefront of the industry

Eric Marshall, the “Closet Guru,” shares his top five Closet Trends for 2026 — noting that some are widely available already, and some are just making their way to North America. Most will be on full display at KBIS in February, where Marshall once again will host his popular Closet presentation as part of KBIS’ Voices From the Industry at 9 a.m. Thursday, February 19.

“It’s funny that most of the colors of the year we are seeing are light or neutral, but I’m seeing closets going dark — dark, mysterious and sexy. Allanna Bell with Optimization Dolls and Domenic Marcolongo with Las Vegas Closet Design have both recently shown black closets and I am there for it! I’ve even seen an anthracite closet that was simply stunning. Another side trend seen in this OPM Dolls closet is the use of wallpaper to accent a wall or even highlight the ceiling!”

Dark Closets are becoming more popular with their high-end finishes and moody look. optimizationdolls.com lvclosetdesign.com

“OK, so everybody's doing it…they're putting lighting everywhere, but I would definitely put my this one on the top of the list for trends. Lighting on shelves, inside drawers, on mirrors—even lighting on and under knobs on cabinets. It’s almost more of an expected thing to have more than just overhead lighting in closets and pantries these days, but there always seems to be new places to put lights and ways to do it. Dolmus Line recently featured these chasing lights diodes that were just cool, and they have a lot of other unique lighting options, as well.”

Dolmus Line’s is a micro profile with symmetrical light projection for surface or flush panel recessed installation on a 6mm wide and 6mm deep milled groove, recommended for use on any furnishing element. The device, with a high-strength 3M adhesive base, hooks and screws for mechanical surface fixing, is configurable with power cable, back-to-back connector, and end cap (sold separately), with Plug&Play connection system. domusline.com

“A lot of companies have pullout options for closets, but new styles of pullouts are emerging to help make closets more functional. From pull-down hang bars to access higher clothes rods and shelves to pullout racks for pants and shoes — even rotating shoe racks. I know pants racks have been around now for a while, but there are so many other specific pullout racks—for purses and other accessories — that are being incorporated into closet design. I really like ones I’ve seen from TAG Hardware and June Wei Bai [JWB Closet Hardware]. Vauth-Sagel also has this cool, tall pull-out to store various cleaning supplies in a laundry room or closet. These have mostly been around a while but are kinda showing their faces right now and becoming increasingly popular.”

Pullouts, including this Pull-Out Pant Rack from TAG Hardware and the Wardrobe Lift Closet Rod from JWB Closet Hardware, are becoming increasingly popular in the closets and organization world. Vauth Sagel also offers this pull-out VS TAL Pantry Flex Broom, on which you can store more than just a broom or vacuum. taghardware.com jwbhardware.com vauth-sagel.com

“I’ve noticed more safes, both large and small, being incorporated into closet designs, whether to safeguard jewelry, documents or larger items. Safes in closets are nothing new, but you used to see these gun safes that were bulky and deep and industrial. Now, there are companies like Mycube making safes that are different than the old style — they've got these nice 14-inch deep safes that are super tall in Tiffany blue and other colors so it doesn't look like a gun safe anymore. They have cleaner lines and smooth powder coated paint so it's glossy and customizable, instead of just the standard, rugged grey gun safe finish. I think they are really cool and think they will become increasingly popular once people see that they are available.”

More decorative small and tall safes like these from Mycube are becoming increasingly popular additions to closet designs. mycubesafe.com

25_000541_Surface_Panel_Q2 Mod: February 21, 2025 10:01 AM Print: 02/24/25 3:18:56 PM page 1 v7

All box sizes always in stock! And with thousands of other products also in stock, you’ll love our variety. Order by 6 PM for same day shipping. The best service, products and selection –that’s how we do business. Please call 1-800-295-5510 or visit uline.com

“Everyone wants to customize their spaces — particularly in closets, where customers are wanting to make their space work best specifically for them. I’ve been impressed with accessories I’ve seen from Like a Bossanova, including their integrated watch winders. I think details like these are only going to get more popular and we will see more specialty accessories like these coming to market.”

Specialty accessories including this built-in watch winder from Like A Bossanova Home, are becoming more popular as companies and consumers continue to take customization to the next level. likeabossanovahome.com

Eric Marshall owns the Closet Training Institute and has worked in the closet industry for more than 40 years. He served as the president of the Association of Closet and Storage Professionals (ACSP) from 2020-2022. He is a Master Storage Designer and proudly holds a Doctorate in Closetology.

BY JENNIFER WILLIAMS

By any measure, Tom Lenderink’s career spans eras.

He entered the wood products industry when particleboard was still “coming in stronger,” as he recalls, and he has spent the decades since helping redefine what panels, surfaces, and composites can be.

More than 60 years after graduating college, Lenderink remains deeply engaged in the industry — not by repeating what has worked before, but by continuously asking what could work better.

“I studied engineering primarily related to wood, which has to do with chemistry and physics,” Lenderink says. His academic path took him through North Carolina State College and Michigan State University, where he focused on wood technology, engineering, and business. That interdisciplinary foundation, equal parts material science and practical application, would become a throughline in his career.

Graduating in 1964, Lenderink didn’t jump straight into owner-

ship. Instead, he went looking for experience. He took a role in a particleboard plant, working in quality control, the lab, and sales, “just to get experience,” he says.

That experience soon brought him back to his roots. His family-owned wood veneer factories, where he had worked summers during college. Returning to the family business, Lenderink gravitated toward sales, but also toward something more exploratory. “I always had a desire for new products and product development,” he says.

That curiosity sparked one of his earliest and most enduring innovations: micro-thin wood veneer. While working in the veneer business, Lenderink encountered thin wood business cards made from two plies of veneer, produced by a small operation in New York run by a professor and a county agent.

“I kind of liked them,” he says. So much so that he and a friend bought the company, moved it to Michigan, and began improving the process.

That business eventually became Cards of Wood Incorporated, now run by Lenderink’s son. Today, the company produces ultrathin wood veneers — cut to just 0.005 to 0.010 inches thick — for applications ranging from business cards and wedding invitations to display materials and point-of-purchase graphics.

“It’s pretty much the only company like it in the world,” Lenderink says. Achieving that thinness required not just precise veneer processing, but new bonding solutions. “You could not use wet glue,” he explains, “you had to use a dry film glue.”

To solve that problem, Lenderink worked with Eastman Chemical to develop specialized dry film adhesives. That effort didn’t just solve a single challenge — it launched an entirely new direction for his business. “Now we’ve got a large portfolio of dry film adhesives that work across many applications,” he says.

Over time, Lenderink Technologies evolved from a manufacturing-focused operation into something more flexible — and more experimental. Lenderink Technologies added its own lab to its Grand Rapids facilities, allowing the company to prototype, test, and refine ideas for customers across industries.

“We do a lot of research and development,” he says, “along with prototyp -

ing and R&D for different companies. As we do these different things, we get more requests and more ideas, and when we find a product we like, we expand that and resell it if possible — or change it and develop it into a product that will work.”

Eventually, Lenderink made a deliberate shift away from owning manufacturing facilities. “When you manufacture, you get trapped because you’ve got to sell what you make,” he says. “If we have the option of many things, we can be a full service to our customers.”

That flexibility allows the company to focus on solutions rather than inventory. “We try to give the very best answers and best solutions for our clients, wherever we have to go.”

Ask Lenderink about the most significant developments of recent years, and one theme surfaces again and again: lightweight performance.

The development of more sophisticated dry film adhesives tops his list. These adhesives help keep panels flat by eliminating water, while enabling strong bonds between dissimilar materials. “They can be rigid or flexible,” he says, opening the door to new design and construction possibilities.

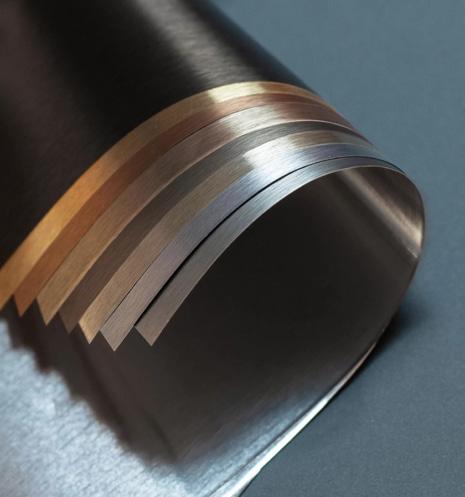

Those adhesive innovations helped support another standout product: micro-thin aluminum decorative surfaces. At just 0.004 inches thick, the aluminum is flexible, lightweight, fire-retardant, and available with coatings that resist fingerprints.

“You can literally get a piece of brushed aluminum that looks

exactly like stainless steel,” Lenderink says, “but it will not show fingerprints.”

This micro-thin aluminum can be folded around edges, laseretched for decorative detail, and used in applications where weight and fire performance matter — everything from interiors to displays.

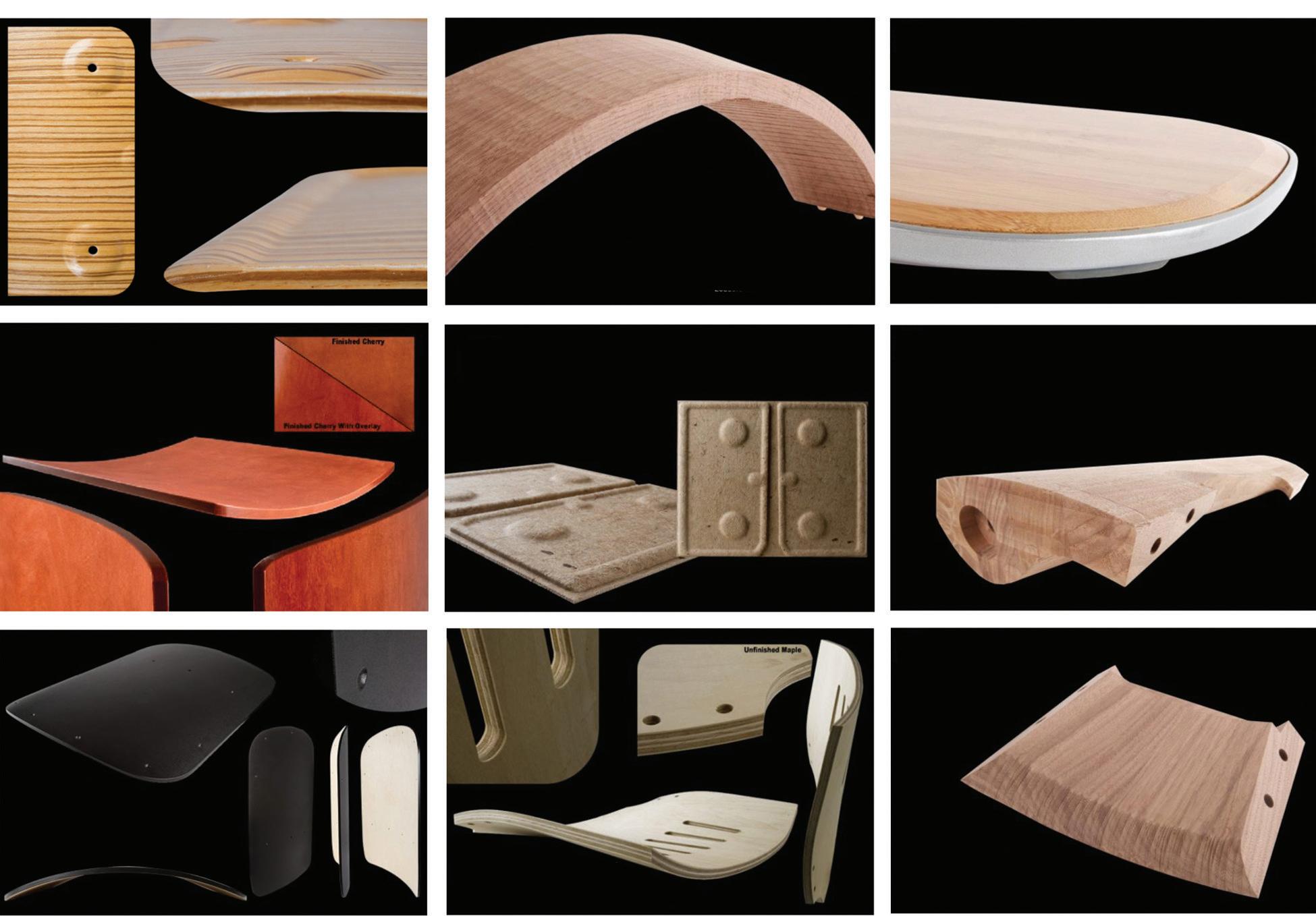

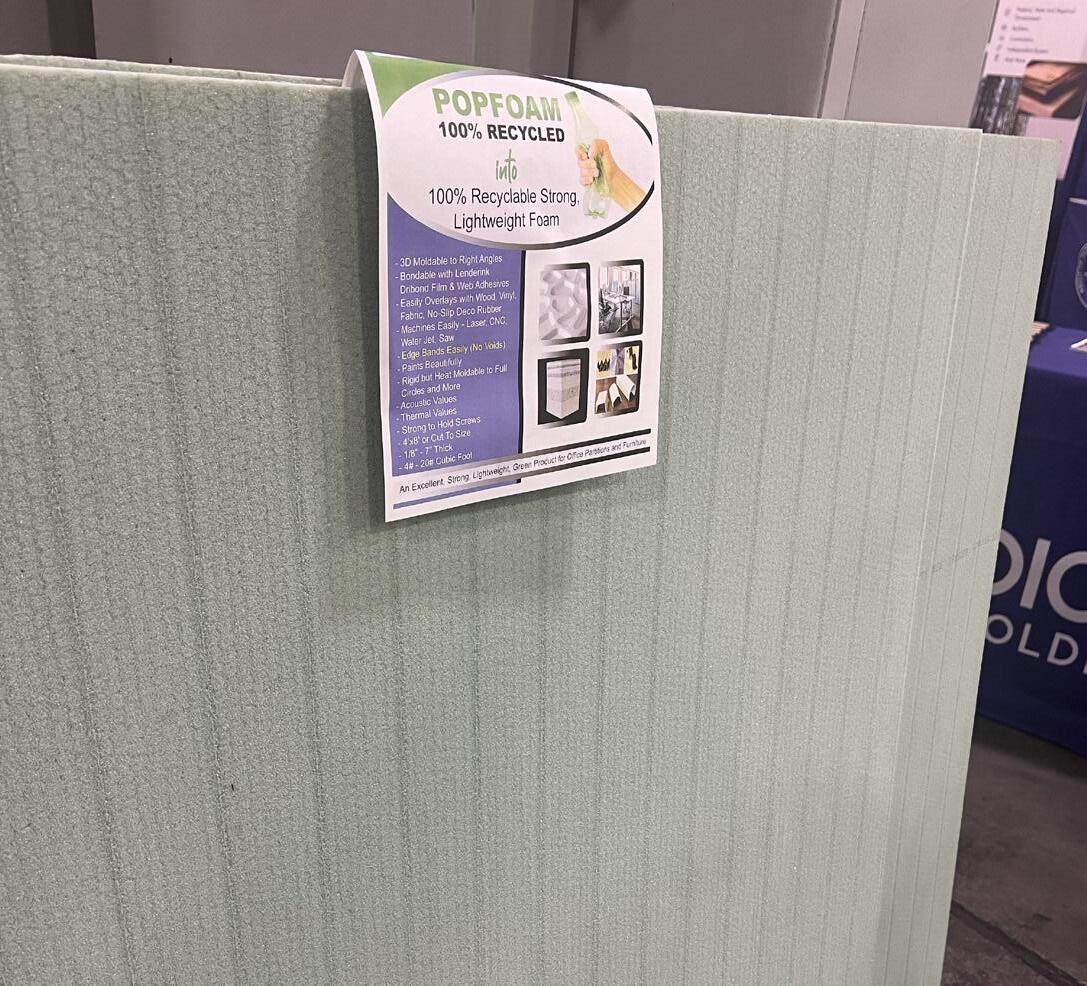

Beyond surface layers, Lenderink has been deeply involved in developing alternative core materials. One example is a lightweight wall panel made from nearly 100 percent polyethylene, used in mobile homes, exhibits, and displays.

“It’s about half the weight of wood,” he says, “much stronger than wood,” and resistant to rot and mold. “The material, known as Elkboard, can be formed into three-dimensional shapes without expensive tooling and can be painted, printed, or laminated thanks to its specialized surface treatment.”

Another major focus is recycled PET foam made from post-consumer plastic bottles, says Lenderink. Available in densities from four to 12 pounds per cubic foot, the foam is dramatically lighter than wood, offers acoustic benefits, and can hold fasteners at

higher densities.

“It can also be molded into 3D shapes quite easily,” Lenderink says, especially when paired with the company’s dry film adhesives. Heating the foam, applying veneer, aluminum, or paper, and shaping it by hand or with simple tooling allows manufacturers — and even small shops — to create complex forms without large presses, often on the job site, he explains.

One major furniture manufacturer is currently exploring the material for lightweight components. “They’re bringing all their engineers up here,” Lenderink says, to experiment in the lab and test the possibilities.

What really sets Lenderink Technologies apart, he believes, is the ability to take ideas beyond the lab. The Grand Rapids facility houses flat hot presses, vacuum forming machines, double belt laminators, heated nip roll systems, and more.

“We can take it from the lab and walk 100 feet to the other building and run it on full size production machines,” Lenderink says. “There’s very few places that can do all that at one place at one time.”

That capability attracts partners across industries — from furniture to aerospace to automotive. “If somebody asks us to check something out, we can quickly take whatever components they have…and test them on all different kinds of equipment.”

Even now, Lenderink is focused on what’s next. One emerging development is a heat-activated adhesive that can be pre-applied and later bonded in the field using nothing more than a hair dryer or heat gun.

“You don’t need big machinery,” he says. “Just warming it up…and putting the two pieces together will bond permanently.”

Other projects include new fire-retardant coatings, lower-temperature thermoset plywood adhesives, and hollow wood veneer tubes designed to soften sharp edges and corners in healthcare and senior living environments. “So many injuries come from people falling or hitting square 90-degree corners,” Lenderink says.

Throughout it all, the driving principles remain consistent. “Ultimately, all of it leans to lighter weight, better bonds and better quality,” he says.

After decades in the industry, Lenderink still finds and excitement in experimentation. “If somebody gets an idea…they either work on it themselves or they call us,” he says. “That’s fun for us, plus it teaches us.”

For an industry balancing performance, sustainability, labor constraints, and design ambition, that mindset continues to push surfaces — and the people who make them — forward. S P

BY JENNIFER WILLIAMS

IMAGES COURTESY DESIGNS OF DISTINCTION

In today’s built environments, intelligence doesn’t always announce itself. The newest wave of responsive surfaces isn’t defined by blinking lights or voice commands, but by subtle accommodations: ventilation-ready panels, seamlessly integrated lighting, and fixtures that anticipate human needs before we even touch them.

“The common thread is beautiful millwork that quietly does more, with technology that’s serviceable, safe, and practically invisible,” says Michael Wilkerson, Vice President and General Manager at Comtrad Strategic Sourcing.

This shift reflects a deeper evolution in how the surface industry approaches technology — not as a layer added after the fact, but as a foundational design element embedded from the start.

For many fabricators, designers, and specifiers, smart surfaces are less about novelty and more about capability without compromise.

“We’re seeing responsiveness show up less as overt technology and more as intentional accommodation,” says Jenny Rhead,

Marketing Director at Designs of Distinction. “Clients aren’t always asking for ‘smart panels,’ but they are asking for materials that allow for airflow, lighting integration, wireless signals, or access to hidden systems.”

In other words, responsive surfaces are becoming architectural enablers; supporting HVAC systems, hiding LED channels, or offering modular access to power without calling attention to themselves.

This can particularly be seen in the explosion of lighting used in designs, says Wilkerson. “Across kitchens, closets, and retail fixtures, the fastest adoption is integrated low-voltage lighting: tunable white task lights, motion-lit drawers, edge-lit glass and discreet sensors that trigger scenes,” he says. In both residential and commercial settings, what was once a high-end differentiator is now becoming part of the baseline expectation in projects at every level.

One of the key challenges of this evolution lies in material selection. Traditional panel construction was never intended to accommodate motion sensors, wiring, or embedded lighting. But that is changing.

“Thickness, density, and construction methods matter more than ever,” explains Rhead. “[So now] the biggest opportunity is designing surfaces that anticipate technology rather than react to it.”

A poorly selected core material might block a wireless signal. A poorly planned surface spec might lead to overheating or warping when lighting is added. Designers must now ask new questions from the outset: Will this surface transmit signal? Can it accommodate cooling airflow? Will it accept integrated lighting without shadow lines?

“Embedded tech must survive heat, moisture, vibration, and daily abuse. It has to be field-replaceable without tearing apart cabinetry,” explains Wilkerson.

That kind of performance requires intentional planning from layout to lamination to the final install.

To meet these demands, forward-looking companies are overhauling their design and production workflows. “We’re placing greater emphasis on material behavior and construction logic early in the design process,” says Rhead. “Instead of asking, ‘How do we add tech later?’ the question has become, ‘How do we design this panel or component so technology can live inside it naturally?’”

From a manufacturing standpoint, that includes wiring channels, sensor tolerances, and seamless panel joins — all before the first toolpath is programmed.

“Many companies now design ‘tech-friendly’ panels with engineered wireways, keyed quick-connects, and standard 24V DC buses so installers aren’t fishing cables on site,” Wilkerson adds. Some manufacturers are even incorporating end-of-line electrical testing, thermal diagnostics, and lot traceability to ensure performance standards are met before the panel leaves the floor.

Cross-team collaboration has become essential. Finish teams now coordinate directly with engineering to ensure that apertures, shadow reveals, and heat-sink placement align with both aesthetic and technical requirements.

Despite the sophisticated back-end work, most clients aren’t chasing high-tech features for their own sake. They simply want invisible function and assurance.

Today’s clients are requesting tech-enabled surfaces, says Rhead, “but rarely in flashy terms. They want surfaces that don’t interfere with technology, don’t overheat, don’t block signals, and don’t require visible compromises.”

Wilkerson agrees, noting four consistent client priorities:

1. Invisible integration (no wires or plastic boxes)

2. Reliability & safety (certified components, cool operation)

3. Easy install/service (plug-and-play harnesses, clear labeling)

4. Aesthetic control (tunable white, low-glare optics, consistent color)

From motion-activated lighting in closets to soft-close drawers that illuminate on contact, success lies in delivering intuitive experiences without adding friction or complexity.

Looking to design or fabricate smarter? Here are five essential tips from responsive surface experts Jenny Rhead (Designs of Distinction) and Michael Wilkerson (Comtrad Strategic Sourcing):

1. Design for Technology First — Not Last

Begin your design process with airflow, lighting, signal transmission, and service access in mind. Avoid treating tech as an afterthought.

2. Keep It Quiet, Keep It Clean

Today’s “smart” means subtle. Focus on invisible integration, clean millwork, and minimal hardware disruption.

3. Make Serviceability Elegant

Use plug-and-play harnesses, modular drivers, and clear labeling. Installers — and clients — will thank you.

4. Choose Materials That Support Responsiveness

Verify material compatibility with lighting heat, signal transparency, and embedded wiring before fabrication begins.

5. Think Beyond the “Wow” Factor

Interactivity should enhance—not distract. Prioritize comfort, usability, and seamless design over tech gimmicks.

Looking 3–5 years into the future, experts agree: responsive surface functionality will quietly become the new normal.

“Passive responsiveness will become standard,” says Rhead. “Materials that allow airflow, accommodate lighting, support modular access, or work seamlessly alongside wireless systems will be expected — not special.”

Wilkerson points to a shift in baseline expectations across sectors. “Expect power-ready casework out of the box,” he says, “along with presence- and ambient-aware lighting that self-calibrates, and modular sensor tiles that feed maintenance alerts.”

He compares it to the soft-close hinge: once a premium upgrade, it is now a feature few consumers would want to live without. “The winners will make tech disappear behind craftsmanship,” predicts Wilkerson, “and make serviceability as elegant as the first install.”

The rise of smart surfaces in 2026 isn’t about turning walls into touchscreens, but rather about designing spaces that quietly understand and support the people inside them, through airflow, lighting, connectivity, and adaptability. For fabricators and specifiers, that means choosing materials and workflows that don’t just look beautiful, but that make everything else work better, too.

“Smart surfaces aren’t about showing off technology,” says Wilkerson. “They’re about making sure the technology stays invisible… and indispensable.” S P

Strength, reliability, and a clean finish are non-negotiable elements of panel adhesion. That’s why Daubond® PUR adhesives from Daubert Chemical are the premier option for panel production and manufacturing. Our high-performance bonding solutions are engineered to elevate panel fabrication for a wide range of industries and materials.

Whether you’re producing decorative wall panels, engineered wood products, architectural composites, or specialty cladding, Daubond® PUR adhesives deliver the reliable strength and visual quality that modern panel production demands, without compromising on sustainability or process efficiency.

Traditional panel construction methods, like mechanical fasteners or contact adhesives, often require extra finishing or create aesthetic challenges. Daubond® PUR changes that. Its precise, clean application results in smoother, more visually appealing panels. It can even be used in place of nails for stair tread panels, reducing post-assembly touch-ups like patching and sanding.

From MDF and laminates to composites, metals, and high-pressure surfaces, Daubond® PUR adhesives bond reliably across a wide range of substrates and skins. The moisture-cure formulation develops a permanent, durable bond that stands up to thermal cycling, mechanical stress, and long-term use, perfect for high-demand architectural, industrial, and OEM panel applications.

Switching panel materials? Rethinking your lamination line? We don’t just formulate. We support your full production process. Daubert’s technical team works directly with panel producers to test new materials, evaluate process improvements, and find ways to optimize efficiency while reducing waste and labor.

Regulatory pressure and customer expectations are always evolving. Daubond® PUR adhesives are formulated to support low-VOC, environmentally responsible production, helping panel manufacturers meet sustainability goals without sacrificing speed, strength, or finish quality.

With Daubond®, we go beyond bonding. Our focus is advancing panel performance. From simplifying production to improving aesthetics and long-term durability, Daubond® PUR adhesives give panel manufacturers a smarter, more capable alternative to traditional bonding methods.

BY S&P STAFF

As pressure mounts for faster production, tighter tolerances, and more customization, the surface manufacturing industry is rapidly adopting automation — and not just on the shop floor. From machine learning-driven dashboards to robot-ready equipment and predictive maintenance protocols, artificial intelligence (AI) and robotics are transforming how fabricators think, build, and grow.

And yet, this transformation isn’t just about machines replacing humans. For leaders like Matt Thackray, Chief Commercial Officer at Laguna Tools, and Lon Riley, Founder and CEO of DPI Laboratory, the goal is clear: automation should enhance the work of people—not eliminate it.

“Our philosophy with AI and automation is not to eliminate jobs,” says Riley, “but to provide the functions that make operational teams more effective — making production more efficient and reducing error rates so the same number of operators can produce a better product, faster.”

For many companies, robotics have moved well beyond basic pick-and-place tasks. CNC systems now operate with multi-axis precision, auto tool changers, and integrated motion control that allow for fully automated panel machining and complex surface treatments.

At Laguna Tools, machines like the SmartShop 5-Axis and CF-20 Composite Fabricator are already transforming workflows. These systems reduce the need for manual repositioning or refixturing and allow fabricators to tackle intricate jobs that would traditionally require multiple setups and extensive hand-finishing.

“What once required constant operator oversight can now be handled with minimal disruption,” says Thackray. “It’s about improving consistency, speeding up cycles, and enabling high-throughput operations.”

For DPI Laboratory, robotics are part of a longer vision. “We’ve designed the mechanics and the electronics of our printers for future integration with robotic systems,” Riley explains, noting the company’s open architecture approach.

The most advanced automation in Laguna’s lineup comes from machines such as the SmartShop 5-Axis and the Composite Fabricator CF-20. The SmartShop 5-Axis offers full multi-axis motion combined with a 12-position tool changer, which allows precise machining on complex geometries and three-dimensional surfaces. The CF-20 is built for large-scale surface work and features a large table footprint, multiple spindles, and automated tool changing for efficient architectural panel fabrication. Together, these machines reduce the need for manual repositioning or re-fixturing, speed up production cycles, and support high-throughput workflows, helping fabricators complete jobs that would otherwise require multiple setups or extensive manual finishing.

SMART SHOP AXIS 5

“We’re building in the flexibility for automated material loading and customizable workflows to be added seamlessly over time.”

AI’s most immediate impact is behind the scenes, in dashboards, diagnostics, and decision-making.

Riley emphasizes the importance of visibility: “We mine the actual printer performance data and consolidate the key metrics into management dashboards. That gives managers full visibility into runtime, ink consumption, and job performance.”

This kind of real-time data makes it easier to route jobs to underutilized lines, predict maintenance needs, and plan for future expansion. “Over time,” he adds, “this helps companies budget better and maximize system utilization.”

At Laguna Tools, smart controls monitor everything from spindle health to tool wear, using automated height sensing, thermal track-

ing, and motion feedback to ensure consistent output. “Automation is capable of reducing manual error while also minimizing operator fatigue,” says Thackray. “It’s about getting more from the same equipment — safely.”

No matter how smart the equipment gets, it’s still only as good as the team using it. That’s why both Riley and Thackray emphasize training and integration as critical to success.

Thackray notes that Laguna Tools prioritizes clear documentation, familiar industrial controllers, and hands-on support to help customers scale with confidence. “We want operators to feel comfortable running, maintaining, and even troubleshooting their systems,” he says.

At DPI Laboratory, the shift is more software-driven. “These types of printers have traditionally been standalone, physical systems,” Riley explains. “We’re now investing in the backend software and MES integration that allows our machines to function as part of a larger ecosystem.”

That means designing systems that speak the same language as others on the line—so order data, surface application, and raw material flow can all be synchronized.

So where is AI and robotics headed next?

According to Riley, the biggest breakthroughs will come not from futuristic concepts but from connecting real-world data with real-time decisions. “If we can automate the marriage of raw materials, surface prep, surface application, and order data,” he says, “we can get from order to shipment with full visibility—even when multiple runs and shipments are part of the same job.”

Thackray agrees that automation will simplify complexity. “The opportunity lies in smarter motion control, more integrated tooling systems, and automated material handling,” he says. “Fabricators need solutions that reduce setup, keep quality consistent, and allow smaller teams to do more.”

Both leaders stress that the goal isn’t bells and whistles — it’s repeatable, scalable, and serviceable production.

As Riley puts it, “The winners will be the companies that make the right information flow through the right machines — without friction.” And if current trends are any indication, the surface industry is ready to rise to that challenge. S P

• Automation is expanding accessibility beyond enterprise-scale shops, enabling small and midsize operations to stay competitive.

• AI is quietly enhancing production by optimizing tool usage, reducing downtime, and improving consistency.

• Human operators remain essential, but they’re increasingly acting as tech-savvy supervisors of intelligent systems.

• The future of fabrication will rely on hybrid intelligence: the collaboration of people, machines, and data.

MBY DENISE WILLIAMS

ake no mistake: “artificial” intelligence is real.

It’s real, and it’s the future. While the years leading up to now have introduced software after software capable of managing data in amazing ways, the result is a patchwork of technology solutions that accomplish the same task while using their own unique “language.”

In distribution, it shows up as one company using an ERP or design software even as another business leans into e-commerce, for example. However, the true power of AI will be realized only when all those myriad applications are empowered to “talk” to one another through a universal communication mechanism.

Companies that fail to adapt to that eventual landscape will find themselves on the wrong end of an industry shakeout, unable to compete. That is also real, but it doesn’t have to be the reality for distributors and suppliers in the building materials niche, according to experts.

The technology is already here to start laying the foundation for the transition to a fully AI-enabled future, they say, adding that the

interim benefits are considerable, too. The “change agent” in question, a product information management (PIM) platform, is a novel approach to an existing tool that has been deployed throughout the distribution sector but, despite the advantages, never in the building materials corner of the market.

That is no longer the case, thanks to Cienapps, which has developed a PIM platform designed with this workforce in mind and is working with NBMDA to roll it out. Freya Hannah, Head of Business Development North America for the company’s Cieblink platform, breaks down what outcomes a PIM can deliver; what needs to happen for it to succeed; and why industry participants won’t want to miss out on a low-risk opportunity to get in front of the next round of technology evolution affecting how they do business.

In other industries, a typical PIM scenario involves all manner of suppliers supporting a single distributor, which then spends a pretty penny for the data to be incorporated into their system of choice. It’s costly and, Cienapps observes, it does nothing to better the entire supply chain.

The PIM now available to North American building material dis -

tributors turns the model on its head, offering a central location where many suppliers can share out their catalog information to many distributors. The purpose is to create a clearinghouse for product data: SKUs, descriptions, pictures, technical forms, safety data sheets, etc. Those details are then at the fingertips of distributors, no matter what part of the world the information is sourced. Uploaded material, excluding price and inventory, is populated into a standardized format, so that it is consistently presented to every PIM user and with every access. “The current challenge,” Hannah notes, “is that everybody has a different format, which forces companies to manually input all data unless they can bear the high costs of a custom PIM solution.” But when a common language is established, she continues, “now you have the ability to keep the software that you have and integrate it with other software so that they are seamlessly communicating together.” With the PIM, she points out, data is all in one place; it’s accurate; and it’s available to large, mid-size, and small distributors alike. It also saves countless hours of manpower wasted on data entry, which is a considerable advantage for users.

• PIM allows users to remove data entry from the equation, which in turn:

o Reduces errors and missed deadlines

o Streamlines processes and saves time

o Accelerates product launches, by facilitating the seamless addition of related information

o Permits reallocation of labor, freeing up staff for other tasks that could contribute to profit, such as cold calls to prospective clients or follow-ups with existing customers

• The above outcomes independently generate profit for companies

To be sure, Hannah concedes, effective integration of AI does not rely on implementation of a PIM. But it sure does help. “The incorporation of a PIM system significantly enhances our industry's capability to establish a competitive edge. This is primarily because it eliminates the necessity for human intervention to manage translations and communications between various software platforms,” she explains. “Essentially, the PIM serves as the foundational infrastructure upon which future advantages are built, rather than being the advantage itself.”

Another key benefit of the PIM lies in the ability of different technologies to connect and communicate with one another, which preconditions the industry for the next phase of AI. Hannah describes a future of advanced machine thinking. “The next era, the AI era, is

Some businesses, smaller operations, in particular, are content to keep using Excel sheets for inventory purposes, for example; but Hannah warns that ignoring technological innovation is risky, keeping some distributors small and less competitive.

not about making another software,” she explains. “It’s about connecting them so that we can develop AI tools.” For example, AI might question an order of a particular item based on the buyer’s past preference for a different product. An elevated level of customer service is produced through this kind of experience, with stellar customer service then translating to brand loyalty.

However, Hannah cautions, “If someone doesn’t come along and create a common language that everybody can share, which is what the PIM would be doing, then we don’t have the tools to even step the first step into the next era and a new way of doing things.”

The PIM addresses that need; but the challenge, as it often is in this industry, is the cultural resistance to change. “Guess what wood people like to talk about?” Hannah asks facetiously before answering the question herself. “Wood!”

“What do wood people not want to talk about?” she continues. “Software topics!” Some businesses, smaller operations, in particular, are content to keep using Excel sheets for inventory purposes, for example; but Hannah warns that ignoring technological innovation is risky, keeping some distributors small and less competitive. The PIM levels the playing field for them, providing access to the same information available to large and medium-sized companies. These bigger competitors might not be thrilled at the prospect of losing some of their edge in that respect. Hannah’s response to that is to underscore NBMDA’s mission, which includes ‘developing and promoting the effectiveness of distribution processes to improve member profitability and growth.’

The PIM, Hannah asserts, will put all product information in one place and allow all participants across the supply chain, not only distributors and suppliers but even designers and architects, to be empowered to communicate efficiently, for the advancement of the entire channel.

What does that look like? Hannah offers her vision, assuming the PIM is fully embraced. “In five years on a regional level,” she begins, “each one of these individual distributors is going to improve supply chain collaboration, which is going to reduce errors. It’s going to increase profits for the ones that adapt their strategies to use the industry PIM system for connecting their clients to their own software.”

“On a national level,” she continues, “what I’m more excited about is that it will start to standardize material and methods so that sustainability discussions, which are really difficult right now,

‹ CONTINUED FROM PAGE 37 can be streamlined and quickly answered.”

“Finally, on a global level,” Hannah concludes, “we’ll have the ability to have much better cross-border relationships.”

To get there, though, she says someone must be the first to raise their hand. The platform will only reach its potential if all players get on board, but right now all the players appear to be waiting for someone else to take the plunge. “Distributors don’t want it unless the suppliers are there already,” she remarks. “But then mill workers don’t want to use it if they don’t have the suppliers and the distributors on there.”

To make it easier for everyone to participate, Cienapps/Cieblink worked with NBMDA to craft a limited-time offer that sounds almost too good to be true: a free one-year subscription to the PIM. Cienapps saw a need in its own backyard, to connect the company’s many software apps and internal systems and also recognized the broader potential. There’s no ‘catch,” Hannah assures, explaining that Cieblink simply has that much confidence in the product that it’s willing to essentially give it away (at a significant cost to itself, considering the usual $299/month price tag) to registered members of NBMDA. That way, companies can see for themselves, without risk, just what the PIM can achieve. “The intention was to create the PIM to help everybody,” Hannah emphasizes. Visit cieblink.com/pim/nbmda for more information about the PIM. S P

Denise Williams is the Editorial Senior Manager at the North American Building Material Distribution Association. Visit www.nbmda.org for more information.

La Pacifica , from our wood grain collection, brings the essence of natural oak into a refined, modern space. With its soft, linear grain and balanced warmth, this finish exudes an organic sophistication that pairs effortlessly with both contemporary and classic designs. The subtle texture enhances its natural depth, offering a tactile experience that complements its visual appeal.

Timberline captures the raw beauty of natural wood with an elevated, modern sensibility. Its bold grain patterns and textured surface add dimension and authenticity, creating a finish that feels both grounded and sophisticated. The interplay of linear and organic grain details brings a dynamic yet balanced aesthetic, making it a versatile choice for spaces that embrace warmth and character.

Mid-Century Walnut brings the perfect balance of warmth and refinement, offering a smooth wood grain with an understated elegance. Its clean, linear pattern enhances the depth of the finish, creating a sophisticated look that seamlessly integrates into both modern and timeless interiors. With a nod to mid-century design, this finish pairs beautifully with sleek hardware, minimalist forms, and bold contrasts.

BY MICHAEL WILBUR

In the world of consumer electronics, those who jump on board with brand-new products are known as “early adopters.” They were the people who bought crank-start automobiles when all their neighbors were riding horses. They bought CDs and adapters when every car in the country came equipped with a standard cassette deck. And they waited in line for the first iPhone while the rest of us clung to our Nokias and BlackBerries.

While these voluntary guinea pigs are resigned to the growing pains of the first-generation of a new technology, they also reap the earliest benefits that technology has to offer; and their feedback shapes subsequent iterations of that tech for years to come.

As market conditions and business models continue to evolve, there is a new demographic of forward-looking and action-oriented companies that I'll call "early adapters." These are the companies

that see the writing on the wall within their industry and — rather than digging in their heels and relying on 'the way we've always done it' — lean into the turn and accelerate. They are harder to spot in real time; but after a few years, you can easily pick them out of a line-up.

Netflix, for example, came into a market saturated by national chains and local video rental stores, creating a more convenient — if less immediate — experience: select your movies at home and have them shipped straight to you. But Blockbuster, Hollywood Video, Family Video, and others had large selections and shelves of inventory ready to grab on the way home from work without waiting for the mail. Cue Netflix’s shift to streaming, which landed the knockout punch to the legacy players.

IBM, meanwhile, was the long-time leader in computer hard -

ware until competition put it on the ropes in the 1990s. Recognizing that the company’s legacy expertise uniquely positioned it to support the newly computer-centric business world, officials pivoted to specialty software and IT consulting. Decades later, IBM is one of the largest tech companies in the world and an innovation leader within the sector.

Naturally, there are a staggering number of companies that gravitated in the other direction. And while some would include distributors in that ‘innovation-averse’ camp, I am bullish on the channel’s ability to adapt and thrive.

Coming out of our 2025 NBMDA Annual Convention last fall, I can recall countless conversations with executives and front-line managers at small, mid-size, and large building material distributors.

Let me tell you, they are not asleep at the wheel.

They are leaning in hard to the trends that they see impacting the distribution channel and the broader market. They are improving their e-commerce. They are getting smart on AI. They are staying informed and adapting to trade policies. And most of all, they are keeping in close communication with their peers and their supplier partners.

While they fight on the front lines, we at NBMDA are busy providing them with the resources and intelligence they need to keep pushing forward. A few of those efforts are worth pointing out as we dive into 2026:

After exposing the challenges and inefficiencies of manually typing data at a convention session in Chicago, Cieblink has been supporting our members with the creation of an open-source repository of product data. This approach has worked for dozens of other sectors — electrical supplies, HVAC, plumbing, etc. — and allows suppliers, distributors, and end customers to have confidence that the SKUs and product specs in their catalogs are truly up to date. It also frees time for existing staff to move from manual data entry to providing value-add contributions for customers and internal operations. In an era where everyone is asked to do more with less, giving your team the right tools can make all the difference.