Master 2026

UNITING MATERIALS, TECHNOLOGY AND DESIGN

•

•

•

•

(LDF)

• High Pressure Laminates

• Low Pressure Laminates

• Specialty Laminates (2D & 3D Laminates &

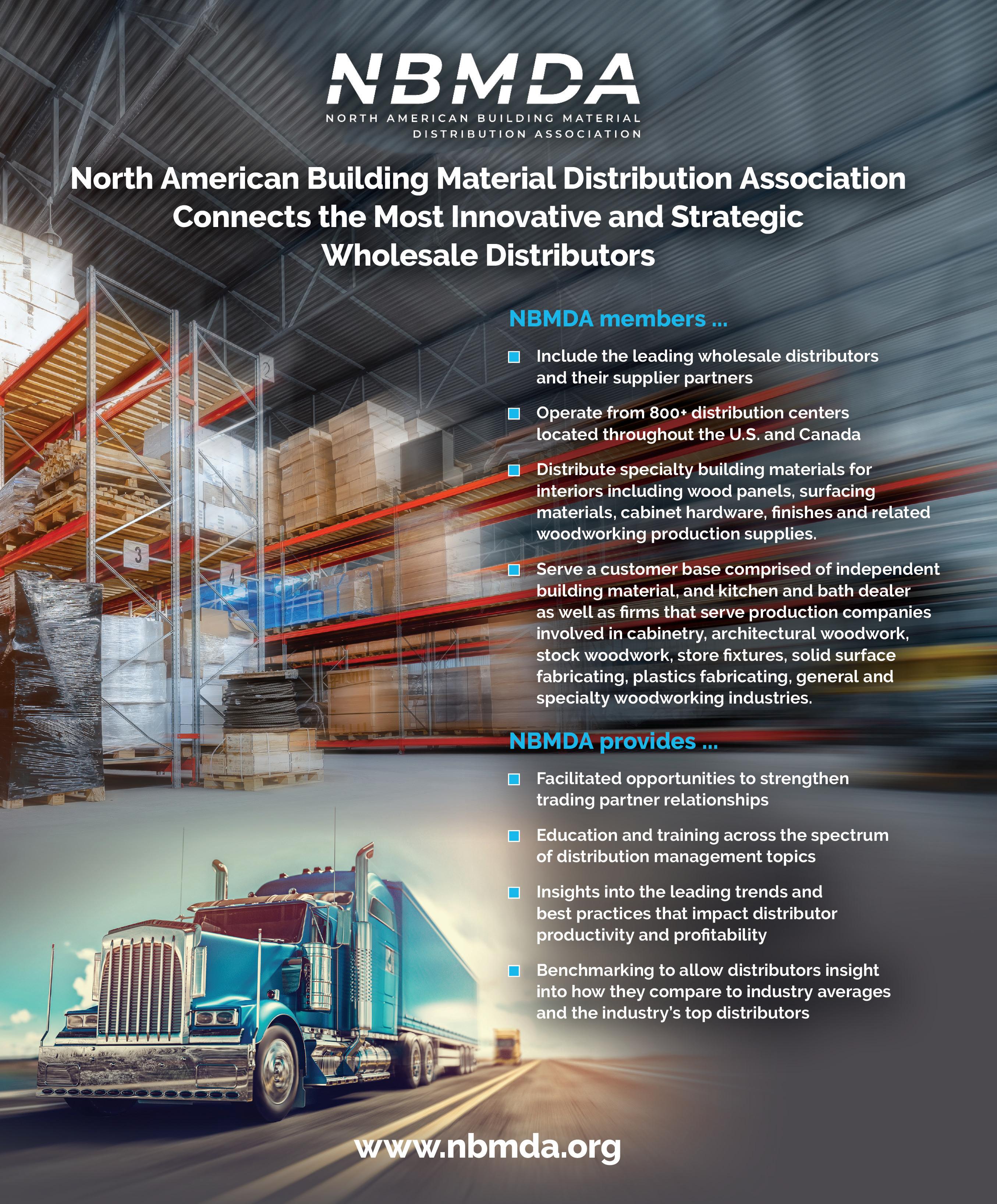

143 DISTRIBUTION MATTERS

Highlighting the North American Building Material Distribution Association (NBMDA)

NBMDA Convention Recap

Navigating change, strengthening the channel

Tariffs are no longer a temporary disruption or a political bargaining chip

150 Community: A Commodity You Can Count On NA message from Michael Wilbur, NBMDA EVP 152 Eyeing the Future

Q&A session with new NBMDA President John Geraghty

154 Recent EDL Graduate Finds Focus and Fraternity in Program

Jonathan Carroll shares his experience with the Emerging Distribution Leaders Program

156 FOMO Fuels Distribution AI Frenzy

How Artificial Intelligence can benbefit the distribution channel

•

•

158 Setting Things in "Emotion"

Tips for selling your distribution business (and how to know it's the right time)

160 2026 NBMDA Member Directory

DEPARTMENTS

6 FROM THE PUBLISHER

OUR APPRECIATION: 526 Media and Surface & Panel Magazine thanks the following organizations who contributed images for the publication of this issue: AkzoNobel, Ambtra, Arauco, Arclin, BASF, Buffalo Veneer and Plywood, Burkle, Columbia Forest Products, Dackor, DVUV, EGGER, Fenix, Formica, Frama-Tech, Funder, GL Veneer, IFS Coatings, Jowat, KCD Software, Leuco Tools, MachMotion, NAPLY, NBMDA, Northern Contours, Onyx Specialty Papers, Panel Processing, Rev-A-Shelf, Richelieu, Riken, Roseburg, Salice, Shelter Forest International, Tafisa, Tece, Thermwood, MASTERS OF THE INDUSTRY 2026

54 A comprehensive listing and directory of the providers of materials and services in the panel processing industry.

Why an annual industry benchmark matters more than ever Timber Products, Titus Group, Uniboard, and Wilsonart.

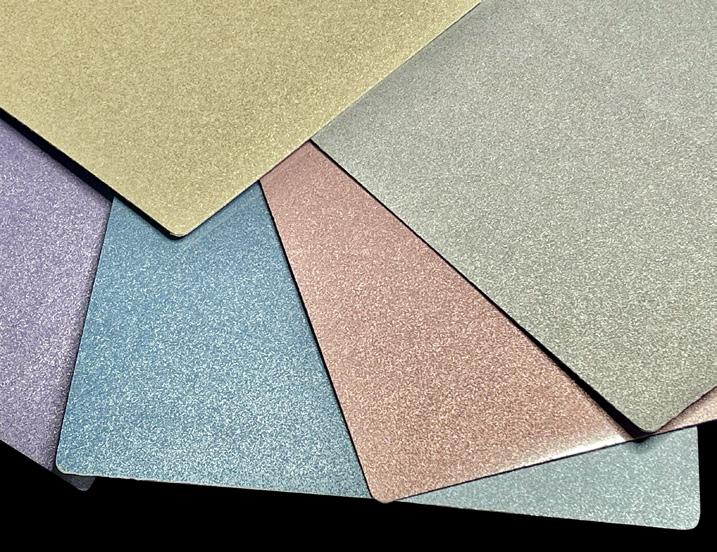

ON THE COVER: Decorative metal laminates and solid metals offer elevated options for designers. This industrial look was created using Nero Ingo FENIX Innovative Materials on the tabletop paired with Black Brushed Aluminum Homapal Metal Laminate sides. Photo courtesy of Formica

PRESIDENT/PUBLISHER

Patrick Adams

PH: 714-486-2735 padams@526mediagroup.com

VICE PRESIDENT

Shelly Adams

MANAGING EDITOR

Jennifer Williams

PH: 714-486-2735 jwilliams@526mediagroup.com

David Koenig, DIRECTOR OF EDITORIAL

Sara Graves, SENIOR EDITOR

GUEST COLUMNISTS & CONTRIBUTORS

Alisha Hystop

Michael Wilbur

Denise Williams

SALES

Nick Kosan

PH: 714-486-2735 nkosan@526mediagroup.com

Chuck Casey

PH: 714-486-2735 ccasey@526mediagroup.com

John Haugh

PH: 714-486-2735 jhaugh@526mediagroup.com

GRAPHIC DESIGN

Greg Lane

DIGITAL SUPPORT

Katherine Williams kwilliams@526mediagroup.com

CIRCULATION/SUPPORT

PH: 714-486-2735 info@526mediagroup.com

526 MEDIA GROUP 151 Kalmus Drive, Ste. J3 Costa Mesa, CA 92626

PH: 714-486-2735

KBIS Gears up for Final Orlando Event

Why an Annual Industry Benchmark Matters

More Than Ever

Every industry needs a point of reference — a place where insight and perspective come together to define both where the market stands today and where it is heading next. The Surface & Panel Master Guide was created to serve that role.

This annual guide is not simply a collection of articles or company profiles. It is a benchmark: an editorially grounded snapshot of an industry in motion, shaped by manufacturing, design, technology, sustainability, and workforce forces. In an environment defined by constant change, the Master Guide provides focus.

As Publisher of Surface & Panel Magazine, I view the Master Guide as one of the most important projects we produce each year. Its purpose is not to capture everything, but to capture what matters — distilling the state of the industry into a single, reliable reference.

The pace of information today is relentless. Product launches, regulatory changes, and technology updates arrive daily. While speed has value, it often leaves little room for context or reflection. The Master Guide is intentionally different.

Published annually, it creates space to step back from the daily news cycle and assess the broader landscape. It looks beyond headlines to examine where momentum is building, where challenges remain, and which developments are likely to have lasting impact. It focuses not just on what is new, but on what is meaningful.

For an industry defined by long investment cycles, complex supply chains, and evolving customer expectations, this perspective is essential. Decisions made today often carry consequences for years to come, and the Master Guide exists to support those decisions with clarity and continuity.

The Master Guide is also designed to be used, not read once and set aside. In print, it offers permanence and focus — meant to live on desks and shelves, shared among teams, and revisited throughout

the year. In digital form, it extends accessibility and reach. Together, they reflect how industry professionals work today.

The surface and panel industry continues to expand in both scope and complexity, spanning materials, equipment, automation, software, and related technologies that serve diverse end markets. The Master Guide reflects this interconnected reality, recognizing that innovation increasingly happens at the intersection of disciplines.

As we look toward 2026, the industry faces both opportunity and complexity. Technology continues to advance. Sustainability expectations continue to rise. Workforce and supply-chain pressures remain.

For me, the Master Guide represents more than an annual publication. It reflects our responsibility as an industry media partner — to listen, to understand, and to serve. At 526 Media Group, and across the entire Surface & Panel team, our commitment to this industry is longterm. The Master Guide is one way we honor that commitment and help the industry move forward with confidence.

Patrick Adams, Publisher, Surface & Panel, 526 Media Group

Send your thoughts and messages on this issue and article to Patrick at padams@526mediagroup.com

2026 MASTER

Plywood Products

Fiberboard Products

Laminates

Veneers

EdgeBandings &

Edge Treatments

Surface Coatings

Lightweight Papers & Décor Foils

Adhesives

Technology & Software

Hardware & Fasteners

Tools & Machinery

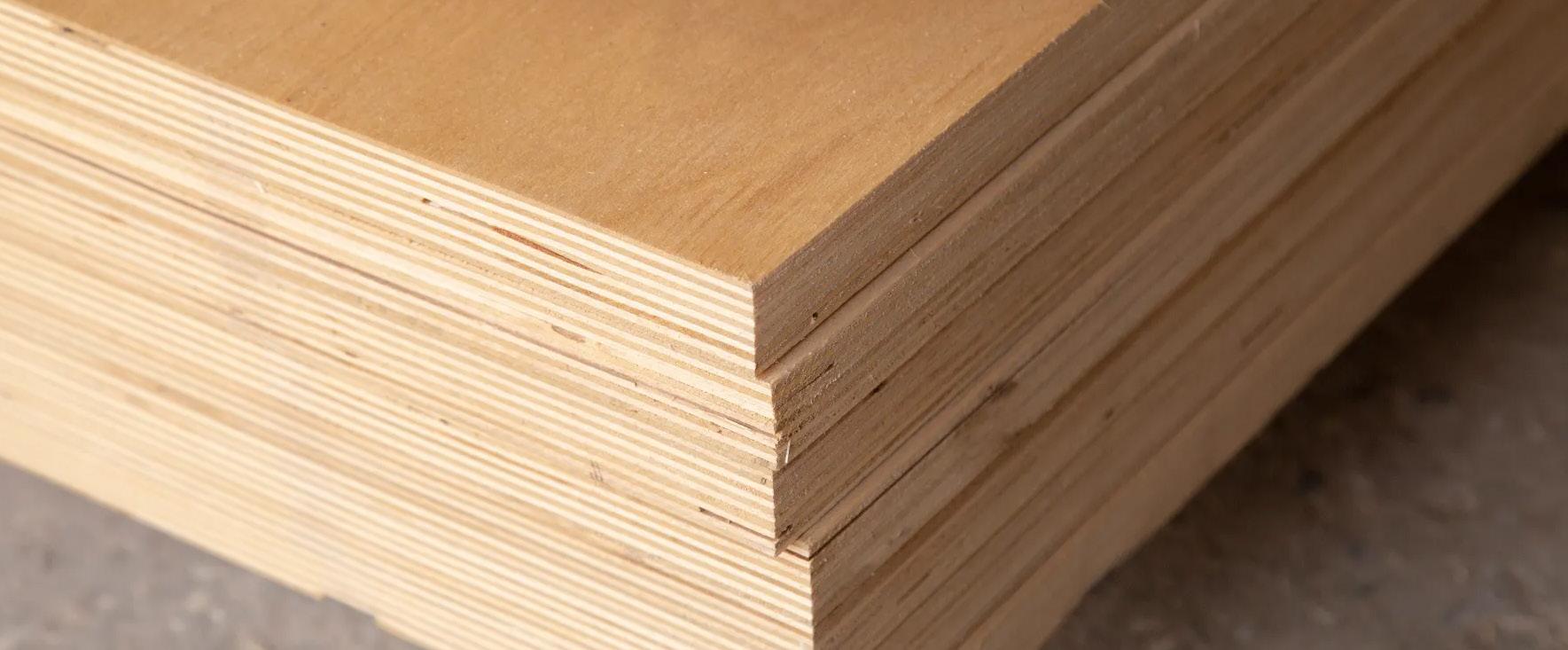

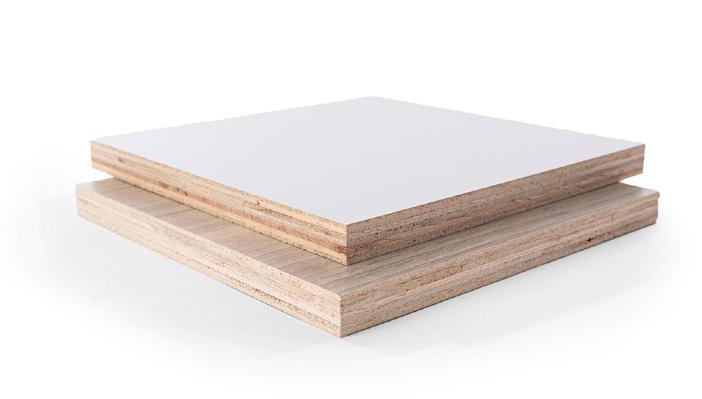

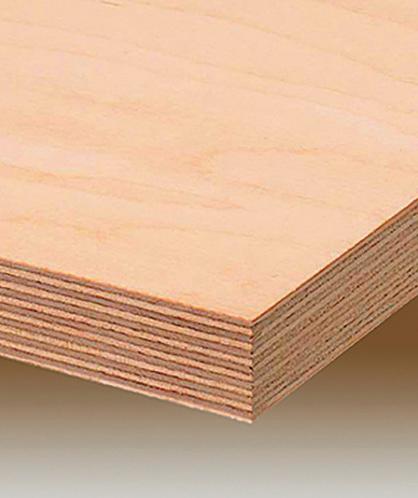

Plywood in 2026

What’s Changing and What’s

Plywood has always been the industry’s “quiet workhorse:” dependable, scalable, and everywhere — often taken for granted until a disruption hits. Heading into 2026, the plywood sector sits at an interesting intersection of steady baseline demand and fast-evolving expectations around performance, sourcing, and downstream compatibility with modern manufacturing.

For fabricators, OEMs, distributors, and specifiers alike, plywood is no longer just a item on a commodity sheet. It’s increasingly a platform — one expected to deliver consistency, cleaner chemistry, and smoother integration with overlays, laminates, and automated production.

Demand is steady, but the mix is shifting

Plywood demand remains anchored by construction and remodeling, but the growth story is increasingly about where

■ SOFTWOOD PLYWOOD

■ HARDWOOD PLYWOOD ■ SPECIALTY PLYWOOD

Holding Strong

plywood ends up — and what it has to do once it gets there. Cabinetry, closets/organization, RV/marine, and light commercial interiors are increasingly demanding panels that are flatter, more uniform, and easier to finish.

At the same time, customers are pressing for better face quality and fewer downstream “surprises” (telegraphing, core voids, thickness variance, or inconsistent sanding). The takeaway: overall volume may not be the only headline in 2026. The segmentation of plywood grades, face expectations, and performance specs is becoming more meaningful than ever.

Quality and consistency are the new competitive battleground

In a world where shops are leaning into CNC routing, nestedbased manufacturing, automated edgebanding, and increasingly

ROSEBURG

tight tolerance requirements, the value of consistent plywood cannot be overstated. Mill-to-mill variability that might have been tolerated a decade ago becomes expensive when it triggers tool wear, rejects, rework, or line stoppages.

Expect manufacturers to keep investing in:

• Tighter thickness control and flatter panels for precision processing

• Cleaner, more consistent core construction to reduce voidrelated defects

• Improved sanding uniformity to support premium finishing and lamination

For buyers, the trend is toward building vendor relationships around repeatable quality rather than chasing the lowest spot price, because “cheap” becomes expensive quickly when downstream yields suffer.

Low-emission and cleaner chemistry are now baseline expectations

The market’s move toward low-emission panels is no longer a niche trend; it’s embedded into how many customers qualify products. Whether driven by regulatory requirements, green building programs, or end-user expectations, plywood producers are under pressure to demonstrate cleaner chemistry and transparent compliance.

In practical terms, that means:

• Stronger documentation and clearer claims around emissions standards

• Continued reformulation and optimization of adhesive systems where needed

• More buyer scrutiny on what “compliant” means across regions and applications

For 2026, the winners will be those who make it easy with clear paperwork, consistent performance, and fewer question marks.

Supply chain resilience remains a strategy, not a reaction

Even as markets stabilize compared to the whiplash years, risk hasn’t disappeared — it has simply changed shape. Freight volatility, labor constraints, and regional supply disruptions still influence lead times and pricing. Many buyers now treat sourcing as a risk-management decision, balancing:

• domestic versus imported plywood availability

• multi-sourcing to avoid single points of failure

• stocking strategies for critical thicknesses/specs

A notable shift is that procurement conversations increasingly include manufacturing realities: “Can we build this reliably, at scale, with predictable quality?” not just “Can we buy it cheaper this month?”

Plywood as a substrate system

One of the biggest under-the-radar developments is how plywood increasingly is being evaluated as part of a broader surface system. More buyers are selecting plywood based on how well it accepts:

• HPL and TFL overlays

• thermofoil and membrane pressing

• veneers, paints, stains, and UV-cured coatings

As surfaces and decorative expectations rise, plywood must support cleaner bonding, improved face stability, and more reliable finishing outcomes. In short, the substrate can’t be the weak link in a premium surface story.

DIRECTORY

These companies are recognized for their production and distribution of plywood products. Please note that this list might not be exhaustive and the availability of plywood manufacturers can vary based on geographical locations and specific market demands.

SOFTWOOD PLYWOOD

Aspen Planers www.aspenplaners.ca

Boise Cascade www.bc.com

Canoe Forest Products www.canoefp.com

Eagle Plywood Specialties www.eagleplywood.com

Freres Lumber www.frereswood.com

GP Wood Products www.buildgp.com

Hardel Mutual Plywood www.hardel.com

Hood Industries www.hoodindustries.com

Hunt Forest Products www.huntforpro.com

LP Building Solutions www.lpcorp.com

Murphy www.murphyplywood.com

Pacific Wood Laminates www.socomi.com

Sustainability is moving from “marketing” to “measurable”

The plywood sector is increasingly expected to show its work. Responsible forestry, chain-of-custody certifications, and traceability are becoming more important — especially as larger organizations formalize ESG reporting and product transparency requirements. Sustainability conversations in 2026 will focus less on slogans and more on measurable proof points:

• fiber sourcing transparency

• certification alignment for targeted markets

• durability and lifecycle value (panels that last longer naturally reduce waste. ■

PotlatchDeltic www.potlatchdeltic.com

Richmond Plywood Corp. www.richply.com

Roseburg www.roseburg.com

RoyOMartin www.royomartin.com

Scotch Plywood www.scotchplywood.com

SDS Lumber www.sdslumber.com

Southern Veneer Products www.southernveneerproducts.com

Swanson Group www.swansongroup.biz

Timber Products Co. www.timberproducts.com

Tolko www.tolko.com

Westlam Industries www.westlam.com

Weyerhaeuser www.weyerhaeuser.com

HARDWOOD PLYWOOD

Besse Forest Products Group www.bessegroup.com

Buffalo Veneer & Plywood www.buffaloveneerandplywood.com

Columbia Forest Products www.columbiaforestproducts.com

Commonwealth Plywood Inc. www.cpiwhitehall.com

Darlington Veneer www.dvcplywood.com

Eastern Panel Manufacturing www.easternpanel.com

Formwood Industries www.formwood.com

Genesis Products www.genesisproductsinc.com

Husky Plywood www.huskyplywood.com

Manthei Wood Products www.mantheiwoodproducts.com

Murphy www.murphyplywood.com

Paged Plywood www.pagedplywood.com

Premwood www.premwoodllc.com

S.J. Morse Co. www.sjmorse.com

States Industries www.statesind.com

Swanson Group www.swansongroup.biz

TigerPly www.tigerply.com

Timber Products Co. www.timberproducts.com

West Frasier www.westfraser.com

The Wood Gallery Inc. www.woodgallery.biz

SPECIALTY PLYWOOD

Aircraft Plywood Manufacturing www.aircraftplywood.com

Aircraft Spruce & Specialty Company www.aircraftspruce.com

Chesapeake Plywood, LLC www.chesapeakeplywood.com

Homestead Hardwoods www.marine-plywood.us

J. Gibson McIlvain www.mcilvain.com

Paged Plywood www.pagedplywood.com

Plywood Logistics www.plywoodlogistics.com

Seacoast Hardwood www.seacoasthardwood.com

Sierra Forest Products www.sierrafp.com

Thomas Canada LTD www.thomescanada.com

Toledo Plywood www.toledoplywood.com

Wicks Aircraft www.wicksaircraft.com

What to watch in 2026

2026 Trends in the Plywood Market

If you’re in the plywood value chain, keep an eye on three practical signals:

1. Tolerance and flatness becoming “must-have” specs, especially for automated shops

2. Documentation and chemistry transparency accelerating in purchasing decisions

3. Growth in plywood-based systems engineered for overlays, finishing, and premium interiors

Plywood isn’t losing relevance — it’s being asked to do more. In 2026, the plywood sector’s advantage will belong to those who can

deliver consistent performance at scale, reduce downstream risk for customers, and prove that “panel reliability” is part of the value rather than an afterthought. ■

Fiberboard in 2026

Precision, Performance, and the Backbone of Modern Surfaces

Often operating behind the scenes, fiberboard products — particularly MDF and HDF — have become foundational to how modern surfaces are designed, manufactured, and finished.

As the surface and panel industry moves into 2026, fiberboard is no longer viewed simply as a cost-effective core material. Instead, it is increasingly treated as a performance substrate, expected to deliver uniformity, stability, and compatibility with increasingly sophisticated surface treatments and automated manufacturing environments.

Consistency is the defining value proposition

Few materials are judged as critically on consistency as fiberboard. MDF and HDF have long been valued for their smooth faces and uniform density, but expectations continue to rise. In 2026, consistency is not just about meeting specifications, it’s more about repeatability at scale.

Manufacturers and fabricators are prioritizing:

• Tight thickness tolerances to support CNC machining and precision joinery

• Uniform density profiles for predictable routing and edge finishing

• Improved panel flatness to reduce rejects and downstream adjustments

As production lines run faster and labor becomes more expensive, the cost of variability grows. Fiberboard suppliers that can deliver dependable, line-ready panels gain a clear competitive edge.

Fiberboard as a premium finishing platform

One of fiberboard’s greatest strengths, its ability to accept finishes cleanly, continues to drive demand across cabinetry, furniture, doors, millwork, and decorative components. In 2026, fiberboard is increasingly specified based on how well it supports high-end finishes, not just its price point.

Key finishing trends include:

• Paint-grade perfection, especially for matte and

high-gloss coatings

• Improved performance under membranes and foils

• Reliable bonding with veneers and laminates

As surface expectations rise, fiberboard is often chosen specifically because it eliminates visual and tactile inconsistencies that can undermine premium design intent.

Low-emission performance is now a baseline requirement

Environmental and indoor air quality considerations are firmly embedded in fiberboard purchasing decisions. Lowemission formulations have moved from differentiators to default expectations in many markets, particularly in residential,

BUFFALO VENEER AND PLYWOOD

ROSEBURG

MDF PANELS

commercial interiors, and institutional settings.

In practice, this means:

• Clear, consistent compliance documentation

• Formulations that balance emissions performance with machining quality

• Confidence that panels will perform consistently across different environments

For 2026, transparency matters as much as performance. Buyers want assurance that panels meet standards today—and won’t raise questions later.

Automation is reshaping how fiberboard is evaluated

As manufacturing environments continue to adopt automation, fiberboard’s role becomes even more central. CNC routing, robotic sanding, automated painting lines, and high-speed edgebanding all place unique demands on panel substrates.

Fiberboard is increasingly selected based on:

• Tool-friendly machining behavior that reduces wear and tear

• Predictable edge quality for consistent finishing and edging

• Dimensional stability under varying temperature and humidity conditions

In automated environments, fiberboard must behave the same way every time. Even small inconsistencies can disrupt throughput and erode efficiency gains.

Sustainability through efficiency and lifecycle value

Sustainability in the fiberboard sector is evolving beyond raw

material sourcing to include resource efficiency and lifecycle performance. The use of wood residuals and recycled fibers continues to support fiberboard’s sustainability narrative, but customers are also looking at how panels contribute to waste reduction and longer product life.

Key considerations include:

• yield optimization during machining

• reduced reject rates due to consistent quality

• durability that supports long-term use and refinishing

In many cases, the most sustainable panel is the one that performs reliably from the first cut to the final finish.

Fiberboard as part of an integrated surface system

Like other sectors of the industry, fiberboard is increasingly evaluated as part of a coordinated surface system. Compatibility with laminates, foils, coatings, and edge materials is no longer assumed — it’s specified.

Manufacturers are looking for:

• Panels optimized for specific surface applications

• Technical support that bridges substrate and surface performance

• Long-term consistency to support décor programs and product lines

This systems-based thinking reduces risk and supports faster development cycles, especially in design-driven categories. ■

DIRECTORY

These companies are recognized for their production and distribution of Fiberboard products. Please note that this list might not be exhaustive and the availability of fiberboard manufacturers can vary based on geographical locations and specific market demands.

HDF

D&M Lumber Products www.dmlumber.com

Kronospan LLC www.kronospan.com

Premwood www.premwoodllc.com

Uniboard www.uniboard.com

West Wood Products www.west-wood.net

MDF

Arauco North America www.na.arauco.com

Buffalo Veneer & Plywood www.buffaloveneerandplywood.com

D&M Lumber Products www.dmlumber.com

Duraplay de Parral SAPI www.duraplay.com.mx

Egger Wood Products www.egger.com

Genesis Products www.genesisproductsinc.com

GP Wood Products www.buildgp.com

Great Plains MDF www.greatplainsmdf.com

Kronospan LLC www.kronospan.com

Langboard www.langboard.com

Maderas Conglomeradas SA www.macosa.com.mx

Pan Pacific Products www.panpacificproducts.com

Premwood www.premwoodllc.com

Roseburg www.roseburg.com

Swiss Krono USA www.swisskronousa.com

Timber Products Co. www.timberproducts.com

Ultrapan www.ultrapan.net

Uniboard www.uniboard.com

Unilin MDF www.unilin.com

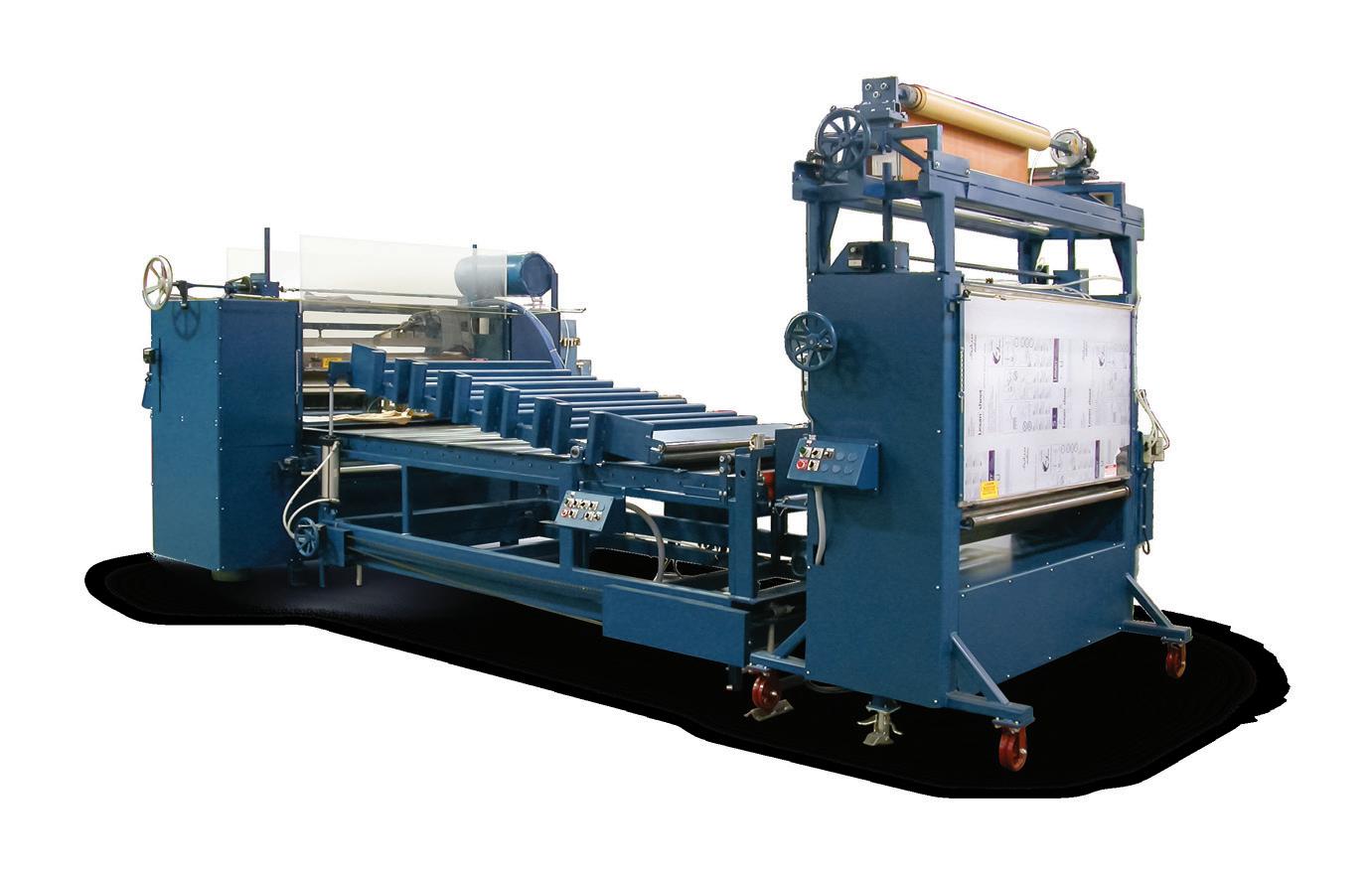

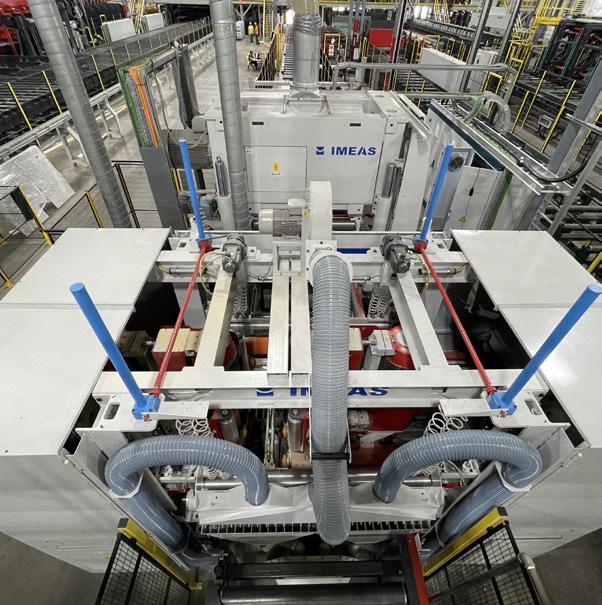

Lamination equipment designed to maximize production output while maintaining precision quality control. The system shown above includes a Union Hot Melt Roller Coater, Union Powered Lay-up Conveyor, and a Union Rotary laminator.

Our high-speed lamination systems are used in a variety of industries for a variety of different applications.

PRODUCTS PRODUCED BY OUR LAMINATION EQUIPMENT INCLUDE:

Acoustic panels, cabinets, decorative wall paneling, doors, flooring, store fixtures and displays, windows, work space dividers, and work tops.

APPLICATIONS INCLUDE: Both sheet to sheet and roll to sheet laminations.

CORE SUBSTRATE PANELS INCLUDE: Plywood, MDF, particle board, and composites.

LAMINATE MATERIALS INCLUDE: Veneers, HPL, vinyl, paper, film, and pre-applied adhesive backed materials.

West Fraser www.westfraser.com

West Wood Products www.west-wood.net

Weyerhaeuser MDF www.weyerhaeuser.com

Particleboard

Arauco North America www.na.arauco.com

BestBoard Impulsora SA www.bestboard1.com

Buffalo Veneer & Plywood www.buffaloveneerandplywood.com

Collins Products www.collinswood.com

D&M Lumber Products www.dmlumber.com

Duraplay de Parral SAPI www.duraplay.com.mx

Egger Wood Products www.egger.com

Florida Plywoods www.fply.com

Forestal Terranova Mexico SA www.masisa.com

Genesis Products www.genesisproductsinc.com

GP Wood Products www.buildgp.com

Kronospan LLC www.kronospan.com

Maderas Conglomeradas SA www.macosa.com.mx

Panel Processing, Inc. www.panel.com

Panolam Industries www.panolam.com

Plummer Forest Products www.plummerforest.com

Several themes will shape the fiberboard sector in the year ahead:

1. Precision and repeatability as non-negotiables

2. Increased focus on finishing performance and surface readiness

3. Sustainability measured through efficiency, not just inputs

Premwood www.premwoodllc.com

Roseburg www.roseburg.com

Tafisa Canada www.tafisa.ca

Timber Products Co. www.timberproducts.com

Uniboard www.uniboard.com

West Fraser www.westfraser.com

West Wood Products www.west-wood.net

Woodgrain Composites www.woodgraincomposites.com

watch

In 2026, fiberboard remains the backbone of countless surface applications, but its role is becoming ever more strategic. As manufacturers push for greater efficiency, better finishes, and tighter integration across materials, fiberboard’s value lies in its ability to quietly deliver reliability, precision, and performance at every stage of production. ■

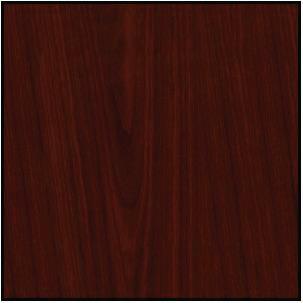

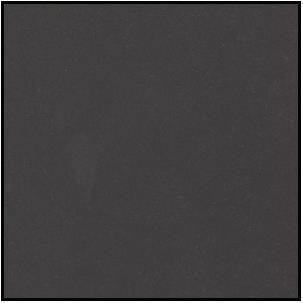

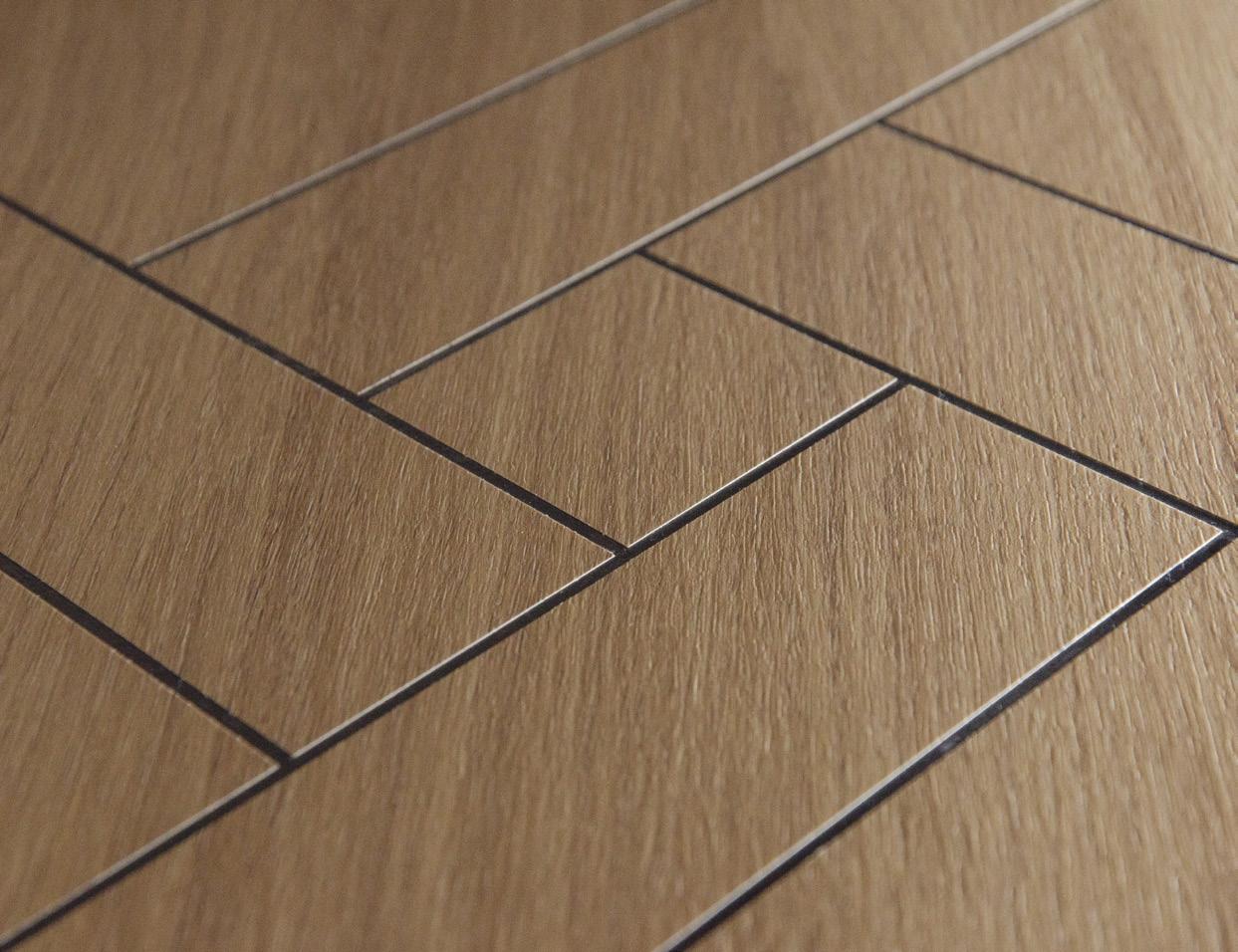

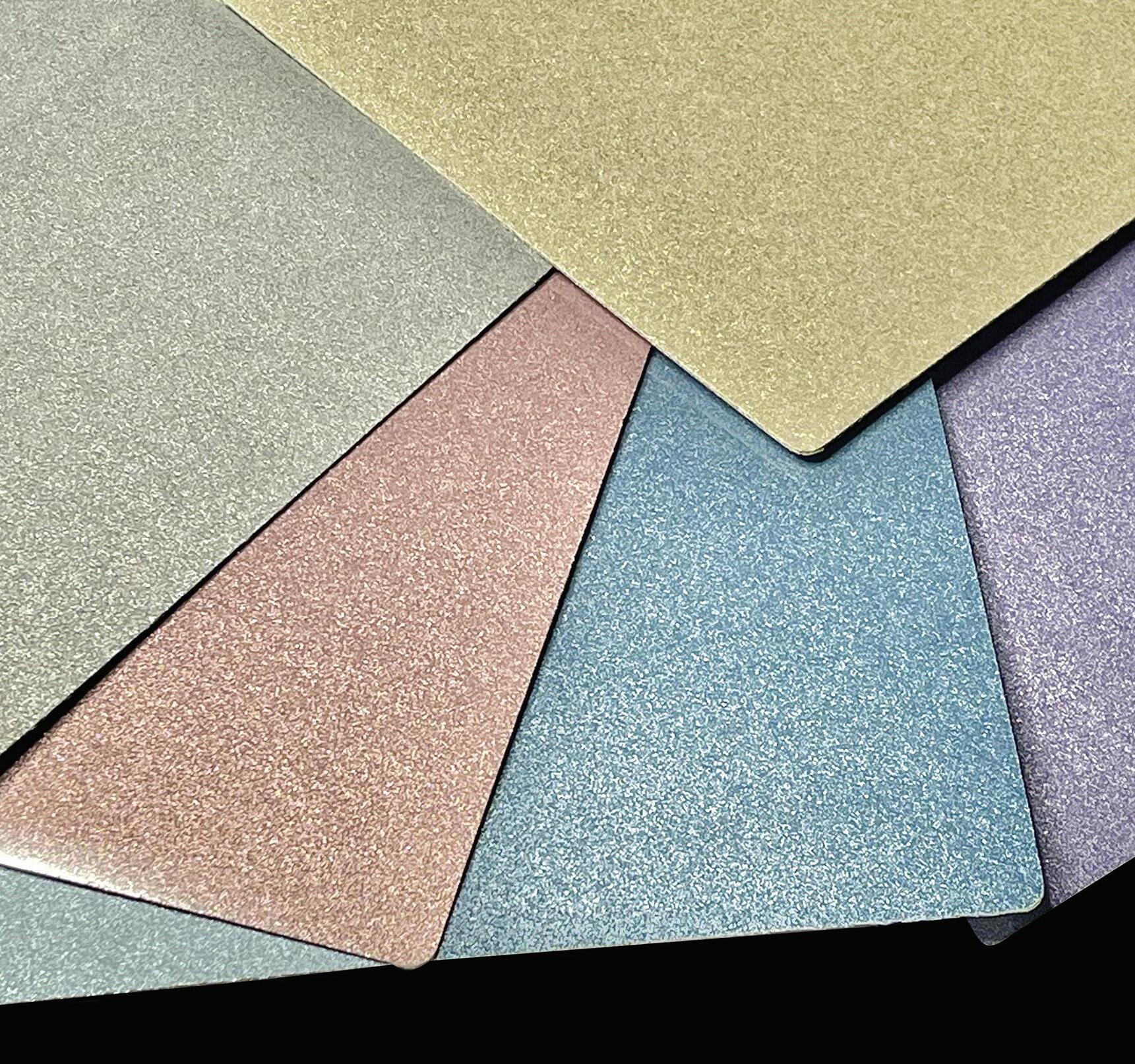

Laminates in 2026

■ HIGH PRESSURE LAMINATES

■ LOW PRESSURE LAMINATES

■ SPECIALTY LAMINATES (2D & 3D LAMINATES & FILMS)

Design Freedom, Performance Demands, and the Next Phase of Surface Innovation

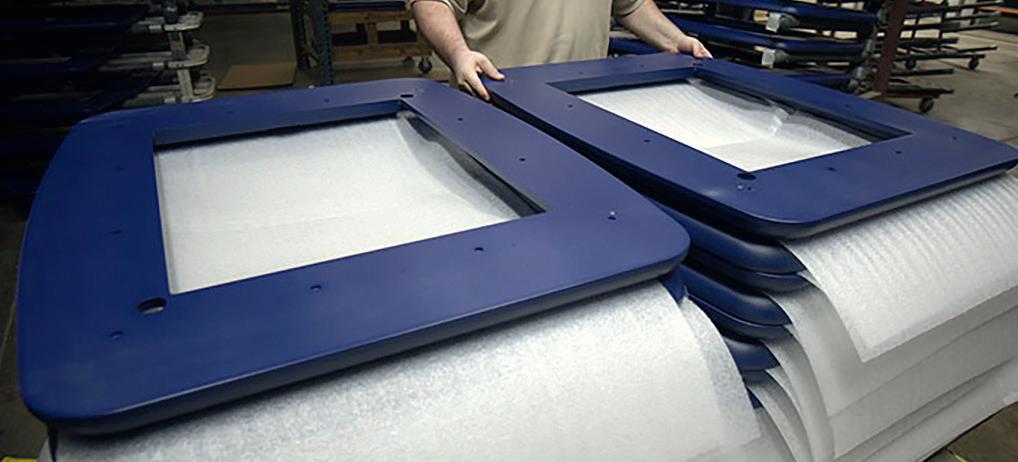

Few categories in the surface and panel industry sit as squarely at the intersection of design, performance, and manufacturing reality as laminates.

Long valued for their durability and versatility, laminates in 2026 are being asked to do more than ever — deliver elevated aesthetics, integrate seamlessly with automated production, and meet rising expectations around sustainability and consistency. As a result, the laminates sector is evolving from a “decorative layer” into a strategic component of the overall surface system.

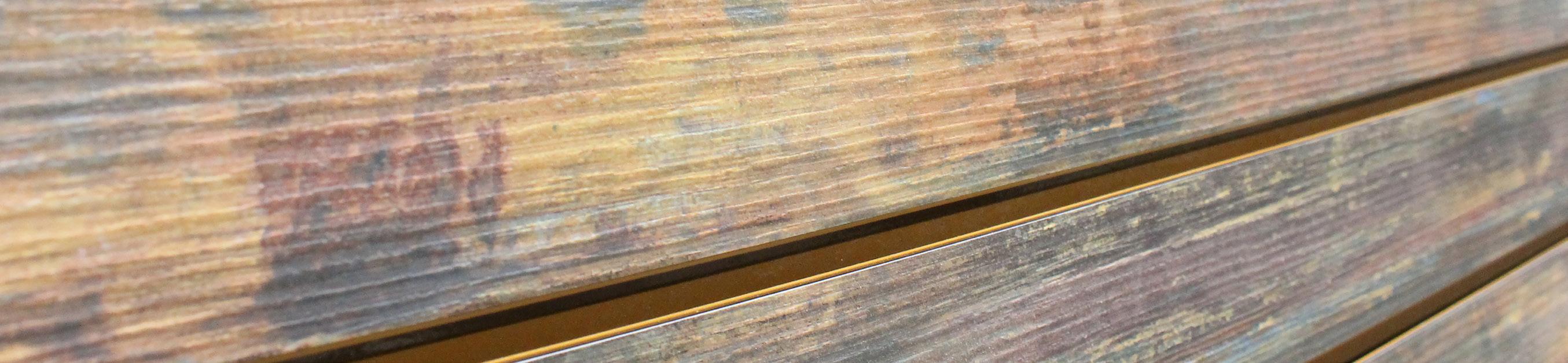

Design is still the driver, but authenticity matters more

Design has always been a core strength of laminates, and that remains true heading into 2026. What’s changing is the level of sophistication customers expect. Visual realism — wood, stone, textile, or abstract — is no longer about simply matching a look. It’s about authenticity across scale, color, and texture, and about how that surface performs in real-world environments.

Advances in printing and embossing continue to narrow the visual and textural gap between natural materials and engineered surfaces. Deeper textures, synchronized embossing, and refined matte and soft-touch finishes are becoming standard expectations rather than premium exceptions. For specifiers and manufacturers alike, laminates that look good and hold up over time are increasingly non-negotiable.

Performance expectations are expanding beyond durability

Durability remains a core value proposition, but performance in 2026 extends well beyond scratch and wear resistance. Customers are paying closer attention to how laminates behave throughout the entire manufacturing and lifecycle process.

Key performance considerations now include:

• Consistent thickness and surface stability to support precision processing

• Predictable bonding and pressing behavior across substrates

• Resistance to fingerprints, chemicals, and light wear in high-use environments

In short, laminates are expected to be both productionfriendly and end-user resilient.

Manufacturing compatibility is shaping product development

As fabrication environments become more automated, laminate suppliers are increasingly designing products with manufacturing reality in mind. CNC routing, high-speed edgebanding, and short-run customization all place new

FORMICA

demands on surface materials.

For many buyers, laminate selection now involves questions like:

• Will this surface run cleanly on our line without excessive tool wear?

• Does it behave consistently across large production batches?

• Can it support fast changeovers and flexible production schedules?

The laminates that gain traction in 2026 will be those engineered not just for beauty and durability, but for process reliability.

Sustainability is now built into the conversation

Sustainability has shifted from a “nice-to-have” talking point to a baseline expectation across much of the laminates market. While aesthetics still open the door, environmental considerations increasingly influence final decisions, especially in commercial and institutional applications.

This shift is reflected in:

• Low-emission and transparent material formulations

• Longer-lasting surfaces that reduce replacement cycles

• Clear documentation supporting green building programs and internal ESG goals

Importantly, sustainability in laminates is no longer judged solely by raw materials, but by how products perform over time and how easily they integrate into responsible

manufacturing systems.

Laminates as part of a coordinated surface system

One of the most significant trends shaping the laminates sector is the move toward system-based thinking. Laminates are being evaluated not in isolation, but in combination with substrates, edge solutions, adhesives, and finishing processes.

Buyers increasingly expect:

• Color and texture coordination across panels, edges, and components

• Reliable availability and long-term décor continuity

What to watch in 2026

2026 Trends in the Laminates Market

For those navigating the laminates market, several signals will define success:

1. Design authenticity paired with functional performance

2. Products engineered for automated, high-efficiency manufacturing

3. Clear sustainability credentials backed by documentation, not claims

In 2026, laminates remain a cornerstone of the surface and panel industry, but their role continues to expand. The most successful laminate solutions will be those that balance visual impact with production efficiency and long-term performance, reinforcing their place not just as a surface, but as a critical component of modern manufacturing systems. ■

• Technical support that spans the full surface stack

This systems approach reduces risk, simplifies sourcing, and supports faster time-to-market — critical advantages in a competitive environment.

Shorter cycles, faster response

Market cycles continue to compress. Customers want access to on-trend designs quickly, without committing to long lead times or excessive inventory. In response, laminate producers are refining their portfolios to balance core, high-volume designs with flexible, responsive offerings that can adapt to changing tastes.

Digital tools, faster décor development, and closer collaboration across the supply chain are all enabling quicker pivots — an important capability as design trends accelerate. ■ RIKEN

DIRECTORY

These companies are recognized for their production and distribution of laminate products. Please note that this list might not be exhaustive and the availability of laminate manufacturers can vary based on geographical locations and specific market demands.

HIGH PRESSURE LAMINATES

AICA Group www.aica-al.com/aica_group

CEI Materials www.ceimaterials.com

Cleaf www.cleaf.it

Dackor www.dackor.com

Formatop www.formatop.com

Formica Corp. www.formica.com

Jiangsu TRSK New Material Co., Ltd. www.js-trsk.com

Lamitech www.lamitech.co

Melaplast www.melaplast.de/en

Merino Laminates www.merinolaminates.com

Panolam Industries International, Inc. www.panolam.com

Stevens Advantage www.stevensadvantage.com

Tafisa Canada, Inc. www.tafisa.ca

Uniboard www.uniboard.com

Virgo Laminates www.virgohplworld.com

Wilsonart www.wilsonart.com

LOW-PRESSURE LAMINATES

AICA Kogyo www.aica.co.jp/english

American Laminates, Inc. www.americanlaminates.com

Arauco North America www.na.arauco.com

Arclin www.arclin.com

Dalbac Manufacturing Co., Inc. www.dalbac.com

Dongwha Malaysia www.dongwha.com/myen/main/main.asp

Egger Wood Products LLC. www.egger.com

Fiberesin Industries www.fiberesin.com

Formatop www.formatop.com

Funder by Genesis Products www.funderamerica.com

KML Corp. www.kmldesignerfinishes.com

Kronospan, LLC. www.kronospan.com

MJB Wood Group www.mjbwood.com

Panel Processing, Inc. www.panel.com

Panolam Industries International, Inc. www.panolam.com

Premier Eurocase www.premiereurocase.com

Purbanchal Laminates Pvt. Ltd. www.purbanchallaminates.com

Roseburg www.roseburg.com

Specialty Laminates www.specialtylaminates.com

Stevens Industries, Inc. www.stevens-wood.com

Swiss Krono Group www.swisskrono.com

Tafisa Canada, Inc. www.tafisa.ca

Texas Wooden Solutions, Corp. www.melaminetex.com

Timber Products Co. (Value -Added Division) www.timberproducts.com

Uniboard www.uniboard.com

Wilsonart www.wilsonart.com

Specialty Laminates & Films

Dackor www.dackor.com

Decotone Surfaces www.decotonesurfaces.com

DNP America, LLC www.dnpamerica.com

Interprint, Inc. www.interprint.com

Klockner Pentaplast www.kpfilms.com/en

Omnova www.omnova.com/laminates

Paladin Ind., Inc. www.paladinind.com

Premier Eurocase www.premiereurocase.com

Profol www.profol.com

Renolit Corp. www.renolit.com

Riken U.S.A. Corp. www.riken-usa.com

Sekisui Kydex LLC www.kydex.com

SSI North America www.ssinorthamerica.com

Synergy Thermal Foils www.synergythermofoils.com

Tafisa Canada, Inc. www.tafisa.ca

Taghleef Industries www.syndecor.com

Toppan Interamerica, Inc. www.toppaninteramerica.com

UFP Packaging www.ufppackaging.com

Vekaplan www.vekaplan.co.uk

UV CURED POWDER COATING ON WOOD

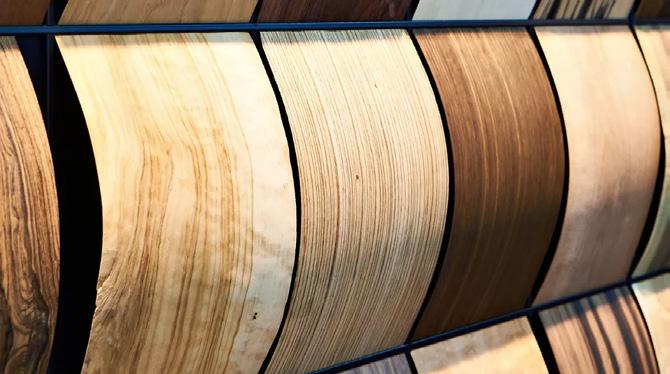

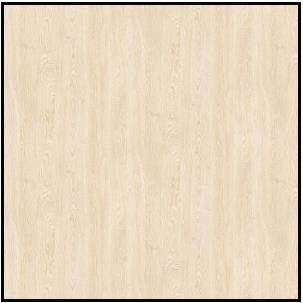

Veneers in 2026

Authenticity, Precision, and the Art of Engineered Natural Surfaces

Veneers occupy a unique space in the surface and panel industry, bridging natural material authenticity with engineered performance.

As the industry moves into 2026, veneers are being asked to deliver more than visual warmth and character. They must align with modern manufacturing realities, support sustainability goals, and offer repeatable beauty at scale. The result is a veneer sector that is evolving rapidly, balancing craftsmanship with precision and natural variation with controlled performance.

Authenticity remains the core value, but predictability is rising

The appeal of veneer has always been its connection to real wood — grain variation, natural depth, and tactile warmth that engineered surfaces still strive to replicate. That hasn’t changed. What has changed is how much predictability customers now expect alongside that authenticity.

Manufacturers and specifiers increasingly want:

• Controlled color ranges and grain matching

• Consistent slicing and layup quality

• Repeatable appearance across production runs

In 2026, successful veneer programs embrace natural variation without letting it become a liability. The challenge is delivering organic beauty with enough control to support modern production schedules and large-scale projects.

Engineered and recon veneers gain strategic importance

While natural veneers remain central to the category, engineered and reconstructed veneers continue to gain traction, particularly in applications where consistency, availability, and sustainability are critical.

Key advantages driving adoption include:

• Uniform appearance and color stability

• Long-term décor continuity across projects and product lines

• Efficient use of raw materials, reducing waste

For many manufacturers, engineered veneers are not a replacement for natural options, but a complementary solution — one that enables broader design freedom while managing

risk and supply constraints.

Precision substrates and bonding matter more than ever

Veneer performance is only as strong as the substrate beneath it and the bonding system that holds it together. As veneers are increasingly used in premium cabinetry, architectural panels, doors, and furniture, expectations around adhesion, flatness, and long-term stability continue to rise.

In practice, buyers are focused on:

• Reliable bonding performance across MDF, plywood, and composite cores

• Minimized telegraphing and surface distortion

• Panels that remain stable through finishing and environmental changes

The veneer sector’s evolution is tightly linked to advances in substrates and adhesives, reinforcing the industry’s shift toward more integrated surface systems.

Finishing performance defines success

Veneers are often chosen for their ability to deliver high-end finishes, but achieving consistent results requires more control than ever. As finish trends move toward lighter stains, matte

BUFFALO VENEER AND PLYWOOD

sheens, and open-pore looks, veneer quality and preparation become critical.

Key finishing considerations include:

• Uniform sanding and thickness control

• Predictable stain absorption and color response

• Compatibility with modern UV, waterborne, and low-VOC coatings

In 2026, veneer suppliers who support finishing success through material consistency and technical guidance will be valued partners, not just material providers.

Sustainability and responsible sourcing take center stage

Sustainability has long been part of the veneer conversation, but expectations are becoming more formalized and data-driven. Responsible forestry practices, chain-ofcustody documentation, and transparent sourcing are increasingly important, particularly for architectural and commercial projects.

At the same time, veneers offer a compelling sustainability story by:

• Maximizing yield from high-value logs

• Extending the reach of natural materials across more surface area

• Supporting long product lifecycles through refinishing and repair

In 2026, sustainability claims must be supported by documentation and traceability, not just tradition.

Veneers as part of a coordinated surface strategy

Like other surface categories, veneers are increasingly evaluated within a broader material ecosystem. Color coordination, long-term availability, and compatibility with edges, substrates, and finishes all factor into purchasing decisions.

Manufacturers are looking for:

• Veneer programs aligned with panel and edge offerings

• Reliable supply for multi-year product lines

• Technical support that spans design through production

This integrated approach reduces risk and ensures that natural beauty can scale without compromising efficiency. ■

DIRECTORY

These companies are recognized for their production and distribution of veneers. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

VENEERS

Atlantic Veneer Corp. www.atlanticveneer.com

Buffalo Veneer & Plywood www.buffaloveneerandplywood.com

Cahaba Veneer www.cahabaveneer.com

Columbia Forest Products www.columbiaforestproducts.com

Commonwealth Plywood www.commonwealthplywood.com

Danzer www.danzer.com

DVC www.dvcplywood.com

Formwood Industries www.formwood.com

Freeman Corp. www.freemancorp.com

GL Veneer www.glveneer.com

Great Lakes Veneer www.greatlakesveneer.com

Manthei Veneer www.mantheiveneer.com

Oakwood Veneer www.oakwoodveneer.com

Timber Products Co. www.timberproducts.com

Treefrog www.treefrogveneer.com

Veneer Technologies www.veneertech.com

What to watch in 2026

2026 Trends in the Veneers Market

Several signals will shape the veneer sector in the year ahead:

1. Growing demand for controlled natural aesthetics

2. Expanded use of engineered veneers to manage consistency and supply

3. Greater emphasis on finishing performance and surface systems

In 2026, veneers continue to define premium surface applications, but their success depends on balance.

The veneer products that stand out will be those that preserve the authenticity designers value while delivering the precision, reliability, and sustainability modern manufacturers demand. ■

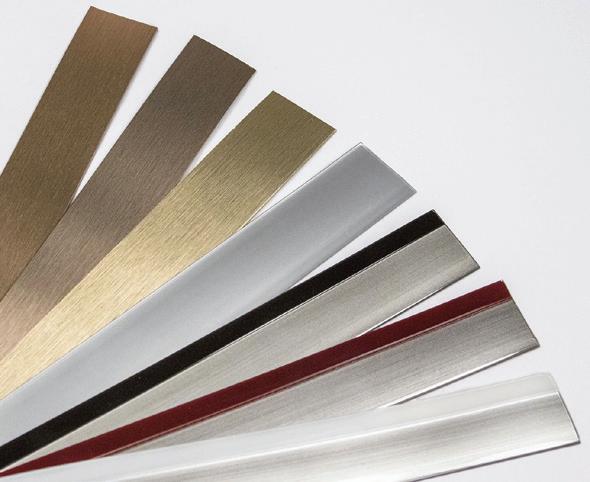

Edgebanding & Edge Treatments in 2026

Where Finish Quality Meets Manufacturing Reality

Edgebanding and edge treatments have moved from functional afterthoughts to defining elements of finished products. In many applications, the edge is the most visible, most handled, and most scrutinized part of a panel, and in 2026, expectations for edge performance and aesthetics continue to rise.

As manufacturing becomes faster and more automated, edge solutions are being asked to deliver flawless appearance, reliable processing, and long-term durability, all while integrating seamlessly into increasingly complex surface systems.

The edge is now a design feature, not just a finish

In modern cabinetry, furniture, closets, and commercial interiors, edges are no longer hidden. Minimalist designs, thinner profiles, and contrasting or color-matched edges place the edge squarely in the visual spotlight.

Design-driven trends shaping the sector include:

• Perfect color and texture coordination with panels and surfaces

• Matte, soft-touch, and anti-fingerprint finishes

• Slim and zero-joint aesthetics that create monolithic appearances

As surfaces become more refined, even minor edge inconsistencies can undermine an otherwise premium product.

Zero-joint and near-invisible edges continue to gain traction

Demand for zero-joint and near-invisible edge solutions continues to grow in 2026, driven by both aesthetics and perceived quality. Technologies that minimize glue lines and improve edge-panel transitions are increasingly viewed as table stakes in higher-end applications.

However, adoption is shaped by practical realities:

• Equipment compatibility and investment considerations

• Material behavior under heat and pressure

• Repeatability across long production runs

For many manufacturers, the challenge is balancing cutting-edge edge aesthetics with production efficiency and uptime.

Manufacturing reliability is a primary decision driver

As edgebanding lines run faster and with less manual intervention, reliability becomes critical. Edge materials must feed cleanly, bond consistently, and trim predictably — every time.

Key performance priorities include:

• Consistent thickness and dimensional stability

• Clean trimming and minimal post-processing

• Reduced tool wear and maintenance requirements

In 2026, edge products are increasingly evaluated not just by how they look, but by how smoothly they run through automated lines.

TREEFROG VENEER EDGEBANDING

Material innovation expands application flexibility

Edgebanding materials continue to evolve, offering a wider range of performance characteristics and aesthetics. From traditional PVC and ABS to PP, PMMA, acrylics, aluminum, and wood veneers, the material mix reflects the diversity of modern surface applications. Manufacturers are selecting edge solutions based on:

• Durability and impact resistance

• Environmental performance and recyclability

• Compatibility with high-gloss, matte, and textured surfaces

This diversity allows designers and fabricators to tailor edge solutions more precisely, but it also raises the bar for coordination across the surface stack.

Sustainability and emissions are part of the edge conversation

Sustainability considerations increasingly extend to edge treatments, especially as customers look holistically at material systems. Low-emission materials, reduced waste, and recyclability are gaining attention — particularly in markets with strict environmental requirements.

Trends influencing purchasing decisions include:

• Material choices with improved environmental profiles

• Efficient processing that minimizes scrap and rework

• Alignment with broader sustainability goals across panels and surfaces

In 2026, edge solutions are expected to support — not undermine — the sustainability claims of the finished product.

Edgebanding as part of a coordinated surface system

Edge products are no longer sourced independently. Color accuracy, long-term availability, and technical compatibility with panels, laminates, and finishes are now essential considerations.

Buyers increasingly look for:

• System-based offerings that simplify sourcing

• Long-term décor continuity across product lines

• Technical support that spans edgebanding equipment and materials

This integrated approach reduces risk, speeds development cycles, and improves overall quality outcomes. ■

PHOTOS FROM TECE

DIRECTORY

These companies are recognized for their production and distribution of edge treatments. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

EDGE TREATMENT PRODUCTS

■ ABS

■ ACRYLIC/PMMA

■ HIGH PRESSURE LAMINATE (HPL)

■ CPL

■ MELAMINE

■ PP

■ PVC

■ WOOD VENEER (EDGEBANDING)

Arborite ■ www.arborite.com

Cefla North America ■ www.ceflafinishing.com

Crown Laminates ■ www.crownlam.com

Edgeband USA ■ www.edgebandusa.com

Edgemate ■ www.edgemate.com

Egger Wood Product ■ ■ ■ ■ www.egger.com

Emco Industrial Plastics ■ www.emcoplastics.com

Finixia ■ ■ www.finixia.com

What to watch

Several key signals will define the edgebanding and edge treatments sector in the year ahead:

1. Continued demand for nearinvisible, premium edge aesthetics

2. Greater emphasis on processing reliability in automated environments

3. Expanded material choices aligned with sustainability goals

In 2026, the edge is where design intent and manufacturing reality meet. The most successful edgebanding and edge treatment solutions will be those that deliver flawless appearance without compromising efficiency — proving that in modern surface manufacturing, the edge truly matters. ■

Formica Corp. ■ www.formica.com

Formwood Industries ■ www.formwood.com

Hopewell ■ www.hopewellplastics.com

Olon Industries ■ www.olon.ca

Panolam Industries ■ www.panolam.com

PRI Edgebanding ■ ■ ■ www.priedgebanding.com

Rehau ■ ■ ■ www.rehau.com

Sonae Industria ■ ■ www.surforma.com

Surteco North America ■

www.surteco.com

Tafisa Canada ■ www.tafisa.ca

Tece ■ ■ ■ ■ ■ ■ www.tece.com.tr

Toppan ■ ■ www.toppan.com

Treefrog ■ www.treefrogveneer.com

Ultrapan ■ ■ ■ www.ultrapan.net

Uniboard ■ www.uniboard.com

Veneer Technologies ■ www.veneertech.com

West Wood Products ■ ■ ■ www.west-wood.net

Wilsonart ■ ■ ■ ■ www.wilsonartengineeredsurfaces.com 222

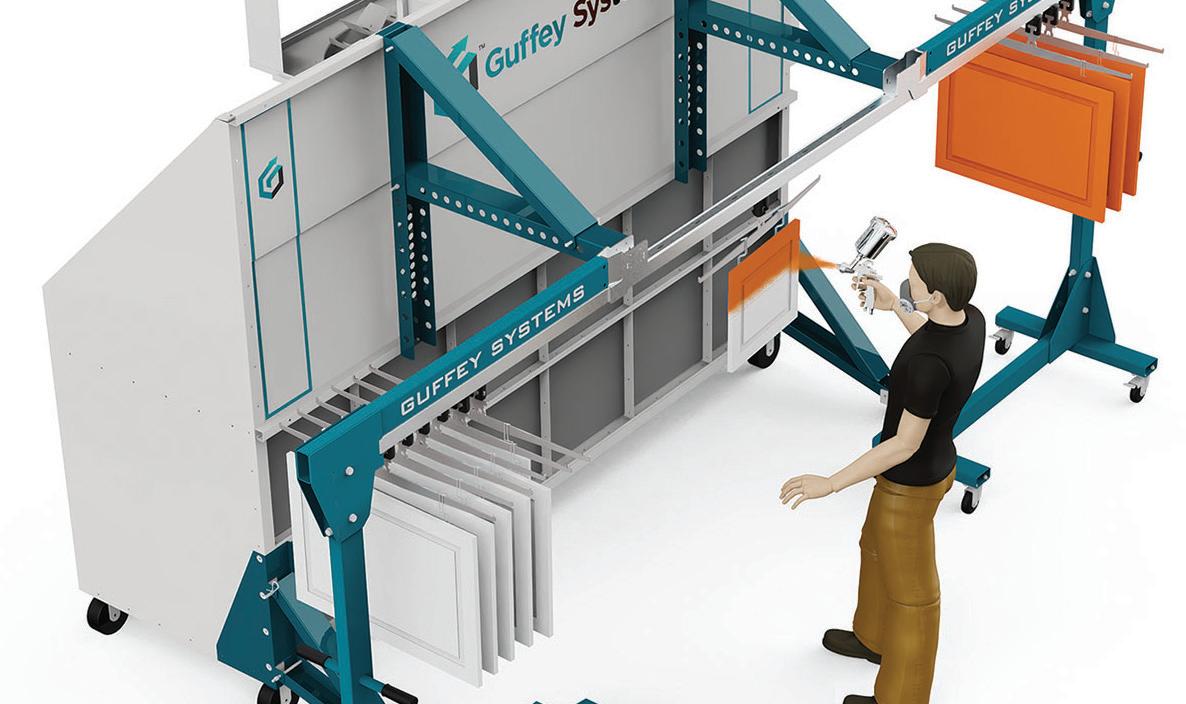

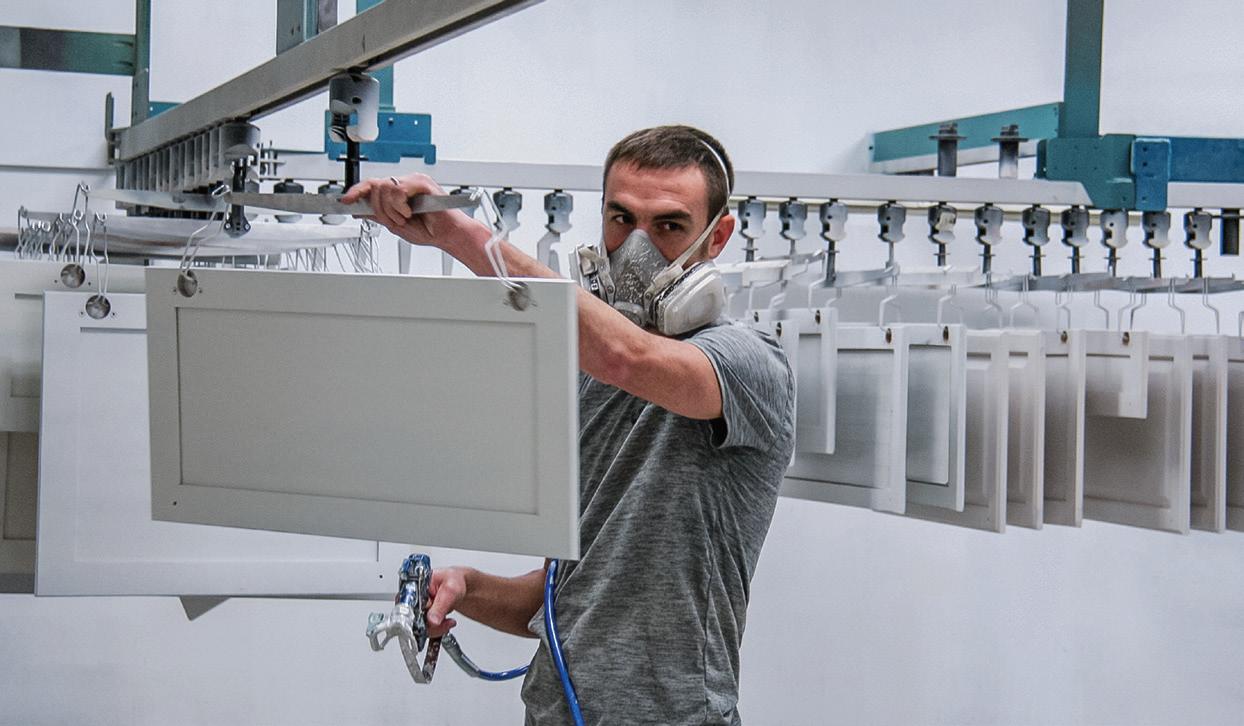

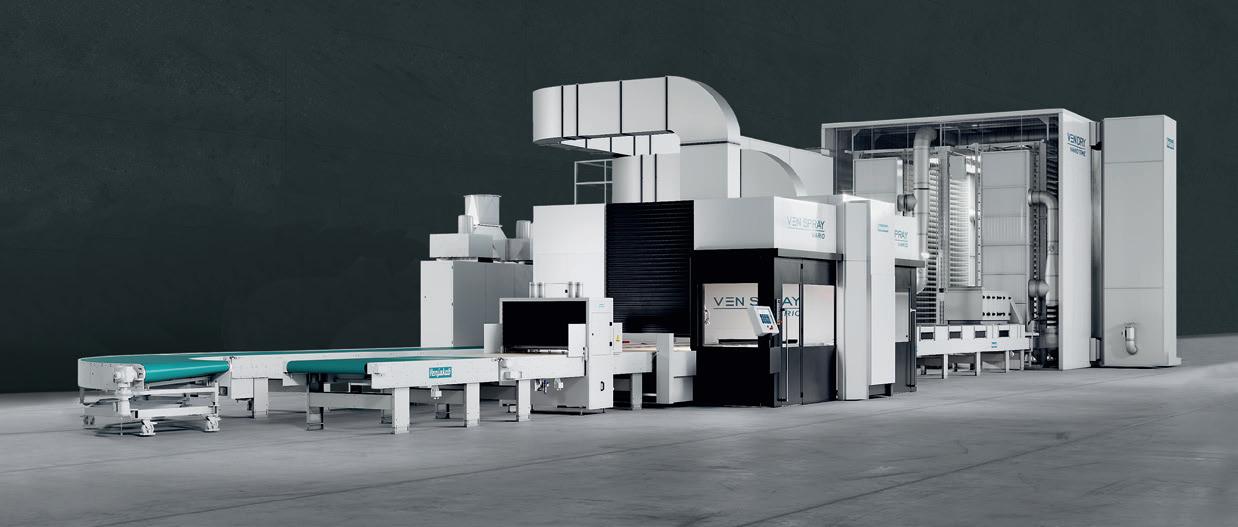

Surface Coatings in 2026

Where Finish Quality Meets Manufacturing Reality

Surface coatings play a pivotal role in how surfaces are protected, perceived, and ultimately valued.

In 2026, powder and liquid coatings are no longer evaluated solely on appearance or basic durability. They are expected to deliver repeatable performance, production efficiency, and environmental responsibility, all while supporting evolving design trends. As surface expectations rise across cabinetry, furniture, architectural panels, and components, the coatings sector is increasingly central to the success of the entire surface system.

Finish quality is rising

The bar for finish quality continues to climb. Matte and ultra-matte finishes, soft-touch surfaces, and refined sheens demand a level of consistency that leaves little room for error. At the same time, customers are less forgiving of defects such as orange peel, inconsistency, or visible touch-ups.

In response, coatings are being selected for:

• Uniform film build and appearance

• Predictable flow and leveling characteristics

• Consistent color and sheen across batches

In 2026, coatings must deliver showroom-level finishes at production scale without slowing throughput.

Beyond scratch resistance

Durability remains essential, but coatings are increasingly judged on how they perform throughout the product lifecycle. Surfaces must resist wear while maintaining their appearance under real-world use.

Key performance attributes gaining importance include:

• Chemical and stain resistance

• Resistance to fingerprints, abrasion, and microscratching

• Color stability under light exposure

Whether liquid or powder, coatings are expected to

maintain their integrity and appearance long after installation, reinforcing the value of the finished product.

Automation is reshaping coating selection

As manufacturers invest in automated finishing lines, the compatibility of coatings with high-efficiency application systems becomes a primary consideration. Robotics, conveyorized lines, and high-speed curing demand coatings that behave consistently under tightly controlled conditions. In practice, buyers are prioritizing coatings that offer:

• Stable viscosity and application windows

• Fast, reliable curing profiles

• Reduced rework and line stoppages

In 2026, the most successful coatings are those that integrate seamlessly into automated environments

— supporting productivity as much as aesthetics.

Powder coatings continue to expand their footprint

Powder coatings are gaining traction in applications where durability, efficiency, and environmental performance intersect. Advances in formulation and application are enabling powders to move beyond traditional metal substrates and into more complex components and assemblies.

Drivers behind powder growth include:

• High transfer efficiency and reduced waste

• Durable finishes with minimal VOC emissions

• Improved appearance options, including matte and textured effects

While not suitable for every application, powder coatings are

DIRECTORY

These companies are recognized for their production and distribution of coatings. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

COATINGS

AKZO Nobel Coatings, Inc. www.akzonobel.com

Arauco North America www.na.arauco.com

Arkema www.arkema.com

Asian Paints PPG PVt. Ltd. www.asianpaintsppg.com

increasingly part of the conversation for manufacturers seeking efficiency and long-term performance.

Sustainability and compliance are embedded expectations

Environmental considerations are now inseparable from coating selection. Low-VOC and low-emission formulations are widely expected, and documentation supporting compliance is often required as part of the purchasing process.

Key sustainability-related trends include:

• Waterborne and low-VOC liquid coatings

• Energy-efficient curing technologies

• Reduced material waste through optimized application

In 2026, coatings that support environmental goals without compromising performance will continue to gain preference.

Coatings as part of an integrated surface system

Coatings are increasingly evaluated in the context of the entire surface stack — substrates, primers, sealers, and topcoats must work together predictably. Compatibility with MDF, plywood, fiberboard, and veneered panels is critical to achieving consistent results.

Manufacturers are looking for:

• Coating systems tailored to specific substrates

• Technical support that bridges chemistry and production

• Long-term consistency to support product lines and color programs

This systems-based approach reduces risk and accelerates development, especially for design-driven applications. ■

Axalta Coating Systems www.axaltawoodcoatings.com

BASF (North America) www.basf.com

Benjamin Moore & Co. Inc. www.benjaminmoore.com

DVUV, LLC www.dvuv.com

Eastman Chemical Co. www.eastman.com

Funder by Genesis Products www.funderamerica.com

Hempel, Inc. (North America) www.hempel.com

Indigo Paints www.indigopaints.com

IVM Chemicals/Milesi Wood Coatings www.milesi.us

Jotun www.jotun.com

Kwality Paints and Coatings Pvt. Ltd. www.kwalitypaints.co.in

Novalk USA www.novalkusa.com

PPG Industries, Inc. www.ppg.com

RPM International Inc. www.rpminc.com

DVUV

Sherwin-Williams www.sherwin-williams.com

Stahl www.wendelgroup.com

Tafisa Canada, Inc. www.tafisa.ca

Teknos www.teknos.com

Tiger Drylac U.S.A., Inc. www.tiger-coatings.com

Toppan www.toppan.com

Worthen Industries www.worthenind.com/adhesives

What to watch in 2026

2.

In 2026, surface coatings are more than finishing materials — they are performance technologies. The coatings that stand out will be those that deliver consistent beauty, longterm durability, and manufacturing efficiency, reinforcing their role as a critical link between surface design and production success. ■

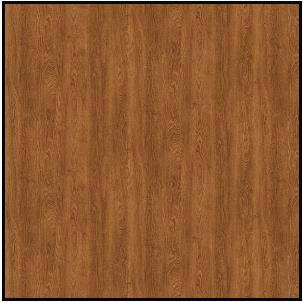

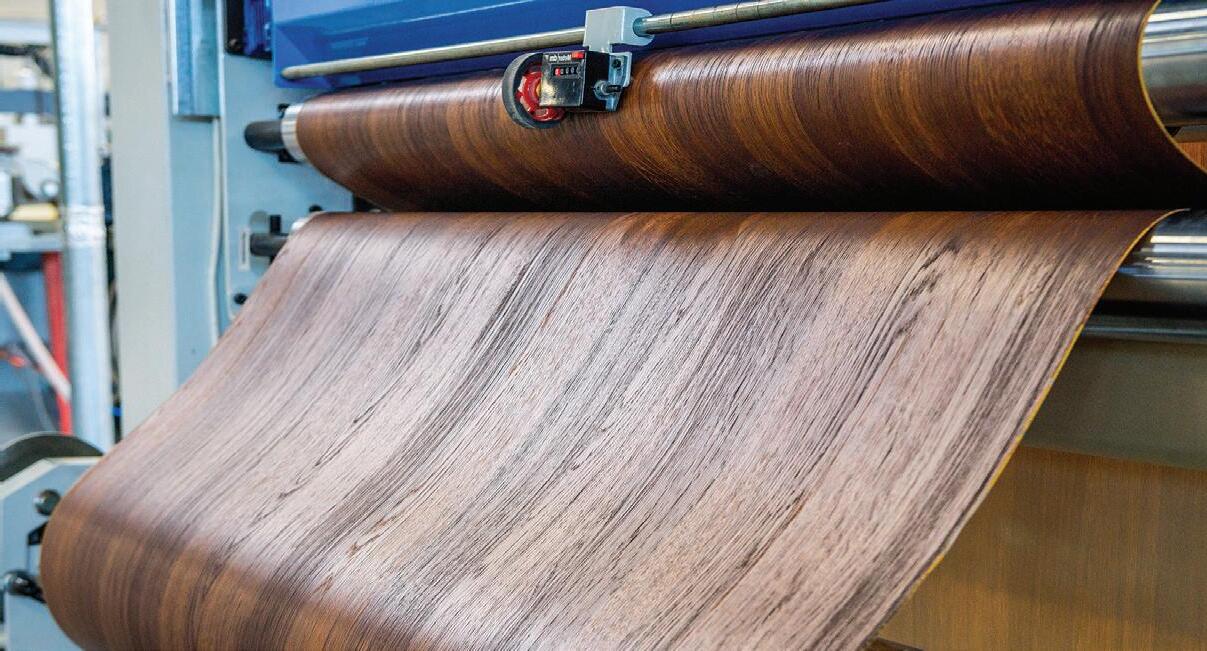

Lightweight Papers and Décor Foils in 2026

Design Agility, Efficiency, and Surface Versatility

Lightweight papers and décor foils have become essential enablers of modern surface design, offering a balance of aesthetic flexibility, manufacturing efficiency, and cost control.

As the surface and panel industry moves into 2026, these materials are no longer viewed simply as economical decorative layers. Instead, they are increasingly strategic — supporting fast-changing design cycles, scalable production, and coordinated surface systems across furniture, cabinetry, closets, and interior components.

Speed to market is a defining advantage

One of the greatest strengths of lightweight papers and décor foils is their ability to respond quickly to design trends. In an environment where color, pattern, and texture cycles continue to accelerate, these materials enable manufacturers to refresh offerings without the long development timelines associated with heavier or more complex surfaces.

In 2026, demand is driven by:

• Rapid décor development and shorter lead times

• Lower tooling and setup costs for new designs

• Flexibility for short runs and frequent updates

For many manufacturers, lightweight papers and foils

serve as the fastest path from concept to production.

Visual sophistication continues to rise

Advances in printing technology have dramatically expanded what lightweight papers and décor foils can achieve visually. Woodgrains, stones, textiles, and abstract patterns are becoming increasingly refined, with better depth, clarity, and color accuracy.

Key aesthetic trends include:

• Improved realism and tonal nuance

• Broader color palettes, from warm naturals to bold accents

• Better coordination across surface families

As these materials improve, the line between entry-level and premium aesthetics continues to blur — especially when paired with effective overlays and coatings.

Performance expectations are increasing

While lightweight papers and foils are valued for efficiency, performance requirements are also evolving. Customers expect these surfaces to hold up under everyday use and throughout the manufacturing process.

Performance considerations now include:

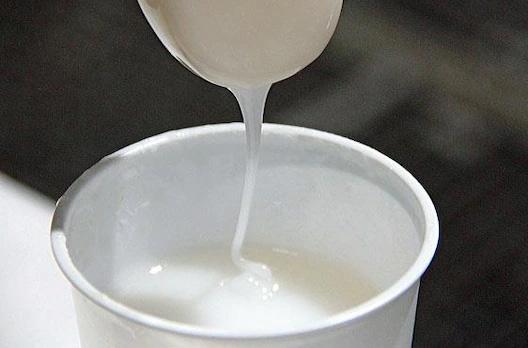

• Consistent impregnation and saturation behavior

• Reliable bonding and pressing performance

• Compatibility with protective overlays and coatings

In 2026, the emphasis is on predictable results: materials that run cleanly on the line and deliver consistent surface quality once finished.

Integration with automated manufacturing

As production environments become more automated, lightweight papers and décor foils must meet tighter process tolerances. Pressing consistency, material stability, and repeatability across batches are critical to maintaining throughput.

Manufacturers increasingly prioritize:

• Uniform weight and thickness

• Controlled roll quality and handling characteristics

• Predictable behavior under heat and pressure

These factors reduce downtime and support efficient,

high-volume production — key advantages for competitive manufacturers.

Sustainability through efficiency and smart material use

Sustainability conversations around lightweight papers and foils focus heavily on efficiency. Using less material while achieving the desired aesthetic aligns well with broader industry goals to reduce waste and resource consumption.

Key sustainability drivers include:

• Lower material usage per finished surface

• Responsible paper sourcing and traceability

• Efficient production processes with minimal scrap

In many cases, lightweight decorative layers enable manufacturers to deliver attractive surfaces with a smaller material footprint.

Part of a coordinated surface system

As with other surface categories, lightweight papers and décor foils are increasingly selected as part of an integrated system. Coordination with substrates, overlays, edge solutions, and finishes is essential to achieving cohesive results.

Buyers are looking for:

• Décor continuity across panels, edges, and components

• Long-term availability for repeat programs

• Technical support that bridges décor and production performance

This system-based approach reduces complexity and supports faster product development cycles. ■

DIRECTORY

These companies are recognized for their production and distribution of coatings and decorative foils and lightweight papers. Please note that this list might not be exhaustive and the availability of these product manufacturers can vary based on geographical locations and specific market demands.

DECORATIVE FOILS & LIGHTWEIGHT PAPERS

Ahlstrom-Munksjö www.munksjo.com

American Adhesive Coatings LLC. www.aacchotmelts.com

Dawei Decorative www.dawei-decor.com

Decorative Panels Group www.decorativepanels.co.uk

Interprint, Inc. www.interprint.com

LamiGraf www.lamigraf.com

Olon Industries www.olon.ca

Omnova www.omnova.com/laminates

Organoid www.organoids.com

Panel Processing Inc. www.panel.com

Schattdecor, Inc. www.schattdecor.com

Surteco North America www.surteco.com

Toppan Interamerica Inc. www.toppaninteramericainc.com

Yodean Décor www.yodean-decor.com/product

What to watch in 2026

2026 Trends in the Decorative Foils & Lightweight Papers Market

Several themes will define the lightweight papers and décor foils sector in the year ahead:

1. Continued emphasis on speed, flexibility, and design agility

2. Rising expectations for visual quality and consistency

3. Efficiency-driven sustainability as a competitive advantage

In 2026, lightweight papers and décor foils remain powerful tools for surface innovation. Their ability to combine design freedom with manufacturing efficiency ensures they will continue to play a vital role in helping manufacturers respond quickly to changing markets — without sacrificing quality or coordination. ■

Adhesives

■ HOT MELT

■ SOLVENT-BASED

■ WATER-BASED

■ HEAT SEAL COATINGS

■ PRIMERS

The Invisible Technology Holding Modern Surfaces Together

Adhesives rarely take center stage, yet they are among the most critical components in the surface and panel industry. From laminates and veneers to edgebanding and composite panels, adhesives determine whether materials perform as intended — or fail under pressure.

As the industry moves into 2026, adhesives are increasingly viewed not as commodities, but as enabling technologies that support precision manufacturing, surface integrity, and long-term durability.

Reliability and consistency are non-negotiable

In high-speed, automated production environments, adhesives must perform the same way every time. Variability in open time, viscosity, or cure behavior can quickly disrupt throughput and compromise quality.

Manufacturers are prioritizing adhesives that offer:

• Predictable bonding windows and cure profiles

• Stable viscosity under changing temperatures and conditions

• Consistent performance across production runs

In 2026, adhesive selection is as much about reducing production risk as it is about bond strength.

Adhesives are being engineered for specific surface systems

The growing complexity of surface stacks — substrates, decorative layers, coatings, and edge materials — has driven a shift away from one-size-fits-all solutions. Adhesives are increasingly formulated for specific combinations of materials and processes.

Key trends include:

• Application-specific chemistries for laminates, veneers, foils, and edges

• Improved compatibility with low-emission panels and advanced coatings

• Tailored performance for hot melt, PUR, waterborne, and reactive systems

This specialization enables stronger bonds, cleaner finishes, and more predictable outcomes.

Speed and efficiency drive adhesive innovation

As manufacturers push for shorter cycle times and higher line speeds, adhesives must support, not limit, efficiency gains. Fastsetting systems, reduced press times, and lower application weights all contribute to productivity improvements.

In practice, buyers are looking for:

• Faster curing without sacrificing bond integrity

• Lower application volumes with equal or better performance

• Reduced cleanup, maintenance, and downtime

In 2026, the most valuable adhesives are those that help manufacturers do more with less time, material, and labor.

Sustainability and emissions are shaping formulation choices

Environmental considerations continue to reshape the adhesives market. Low-VOC and low-emission requirements are increasingly standard, and customers expect transparency around chemical composition and compliance.

Key sustainability-driven trends include:

• Waterborne and solvent-free formulations

• Reduced formaldehyde and isocyanate exposure

• Improved efficiency that lowers overall material use

Importantly, sustainability in adhesives is now evaluated alongside performance. Products must meet environmental expectations without introducing new risks or compromises.

Adhesives play a critical role in surface quality

Beyond structural bonding, adhesives directly influence surface appearance. Telegraphing, read-through, edge failures, or finish defects often trace back to adhesive selection or application.

In 2026, adhesives are increasingly expected to:

• Minimize telegraphing and surface distortion

• Support clean edges and seamless transitions

• Maintain bond integrity through finishing and environmental changes

As surface aesthetics become more refined, the margin for adhesive-related defects continues to shrink.

Technical support and partnership matter more than ever

As adhesive systems become more specialized, suppliers are expected to provide more than products — they must deliver expertise. Process optimization, equipment compatibility, and troubleshooting support are increasingly part of the value equation.

Manufacturers are looking for partners who can:

• Align adhesive performance with production goals

• Support equipment setup and optimization

• Help adapt to new materials and surface trends

This collaborative approach reduces risk and accelerates innovation across the surface stack. ■

DIRECTORY

These companies are recognized for their production and distribution of adhesive products. Please note that this list might not be exhaustive and the availability of manufacturers can vary based on geographical locations and specific market demands.

3M Co. www.3m.com

Akzo Nobel www.akzonobel.com

American Adhesive Coatings LLC www.aacchotmelts.com

Chemique Adhesives www.chemiqueadhesives.com

Covestro www.solutions.covestro.com

Daubert Chemical Co. www.daubertchemical.com

What to watch in 2026

2026 Trends in the Adhesives Market

Several signals will shape the adhesives sector in the year ahead:

1. Greater emphasis on applicationspecific, system-based solutions

2. Continued innovation driven by speed, efficiency, and automation

3. Sustainability defined by performance and transparency, not tradeoffs

In 2026, adhesives remain the invisible backbone of the surface and panel industry. The products and partners

Dow/ChemPoint www.laminatingadhesiveproducts.com

Dupont www.dupont.com

Fielco Adhesives www.fielco.com

Franklin Adhesives & Polymers www.franklinadhesivesandpolymers.com

H.B. Fuller www.hbfuller.com

Henkel www.henkel-adhesives.com

Jowat www.jowat.de

Kleiberit www.kleiberit.com

Mitsubishi Chemical Group www.us.mitsubishi-chemical.com

Panacol-USA www.panacol-usa.com

that stand out will be those that combine consistent performance, environmental responsibility, and technical expertise — ensuring that modern surfaces hold together under the demands of design, production, and everyday use. ■

Sika AG www.usa.sika.com

Solvay www.solvay.com

Surteco North America www.surteco.com

Toppan Interamerica Inc. www.toppaninteramericainc.com

Transcendia www.transcendia.com/industrial

Weiss www.usa-weiss.com

Willamette Valley Company www.wilvaco.com

Wilsonart www.wilsonart.com

Worthen Industries www.worthenind.com/adhesives

JOWAT

JOWAT

Technology & Software in 2026

Digital Infrastructure for a Smarter Surface Industry

Technology and software are no longer peripheral tools in the surface and panel industry — they are becoming core infrastructure. As manufacturers face tighter margins, labor constraints, and rising customer expectations, digital solutions are increasingly relied upon to drive efficiency, consistency, and insight.

Heading into 2026, technology is less about experimentation and more about practical integration: tools that connect design, production, and business systems into a cohesive, data-driven operation.

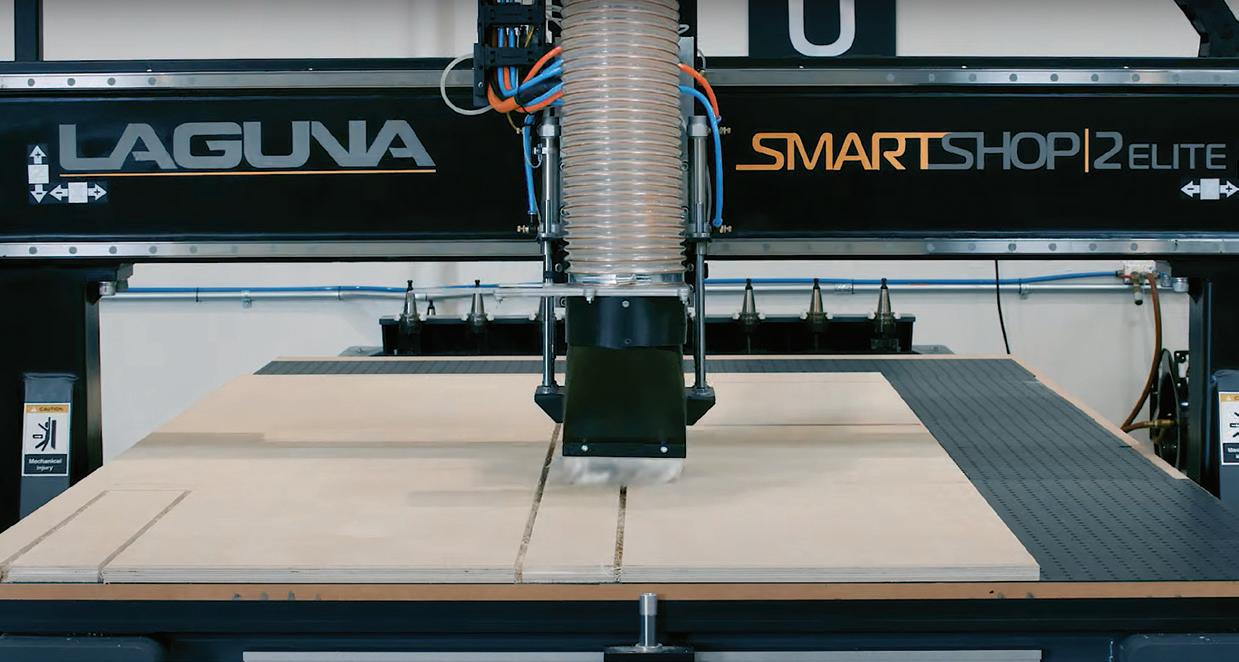

Automation moves from advantage to expectation

Automation has been steadily reshaping manufacturing, but in 2026 it is no longer a differentiator, it is an expectation. CNC equipment, robotic handling, automated finishing lines, and smart edgebanding systems are becoming standard investments across many segments of the industry.

What’s changing is how software supports these systems:

• Smarter machine control and optimization

• Real-time monitoring of production performance

• Reduced reliance on manual adjustments and tribal knowledge

Technology is increasingly expected to make automation more accessible, flexible, and resilient.

Data visibility becomes a competitive necessity

Manufacturers are collecting more data than ever, but the real value lies in turning that data into actionable insight. In 2026, software that improves visibility across operations — from order entry to finished goods — plays a critical role in decision-making.

Key areas of focus include:

• Production tracking and throughput analysis

• Downtime identification and root-cause analysis

• Material usage, yield, and waste reduction

The ability to see problems early and respond quickly can have a direct impact on profitability and customer satisfaction.

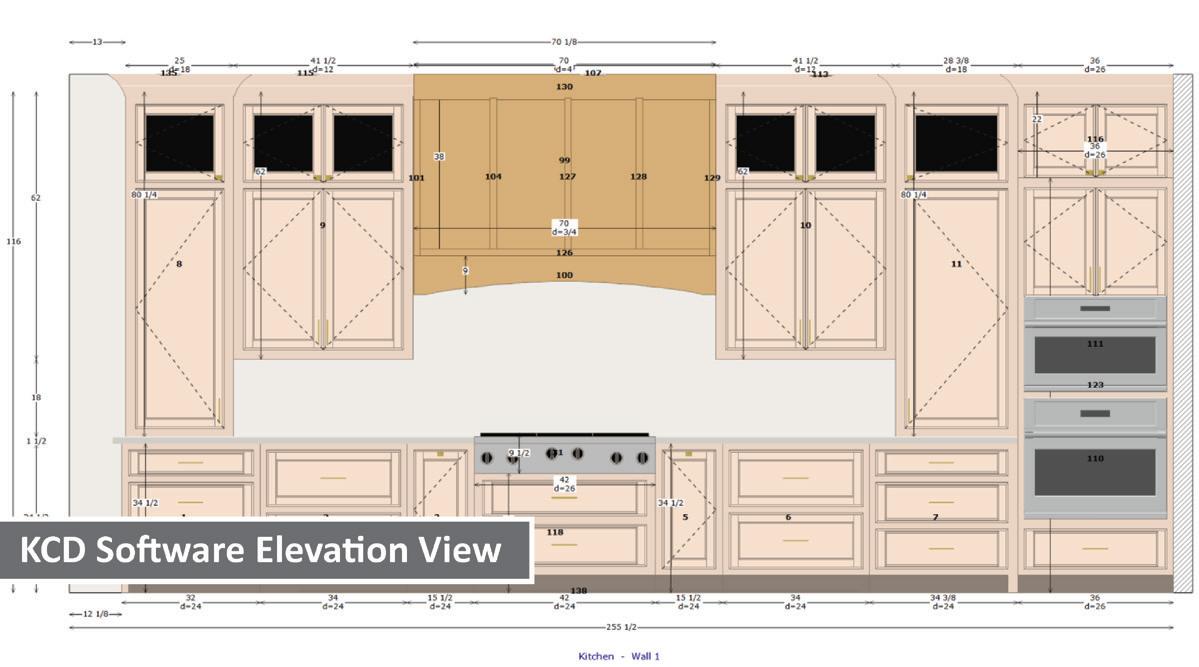

Design-to-production integration tightens

One of the most significant shifts in recent years is the closer alignment between design intent and manufacturing execution. Software platforms are increasingly bridging the gap between CAD, CAM, and shop-floor systems.

Benefits driving adoption include:

• Fewer errors from design translation

• Faster setup and changeovers

• Improved customization without sacrificing efficiency

In 2026, technology that connects design data directly to machines helps manufacturers deliver more complex, customized products at scale.

Scheduling, labor, and resource optimization take center stage

With labor availability remaining a challenge, software tools that optimize scheduling and resource allocation are becoming essential. Advanced planning systems help manufacturers make the

most of available people, machines, and materials.

Manufacturers are looking for solutions that support:

• Dynamic scheduling based on realtime conditions

• Improved labor utilization and training support

• Predictive maintenance to reduce unplanned downtime

Technology is increasingly used to stabilize operations in an unpredictable environment.

Connectivity and interoperability matter more than features

As digital ecosystems grow, the ability for systems to communicate effectively becomes just as important as individual software capabilities. In 2026, buyers are prioritizing platforms that integrate smoothly with existing equipment and enterprise systems.

Key considerations include:

• Open architectures and standardized interfaces

• Scalable solutions that grow with the business

• Reduced reliance on custom workarounds

Interoperability lowers barriers to adoption and enables incremental digital transformation.

Practical AI and analytics begin to show real value

Artificial intelligence and advanced analytics are moving beyond buzzwords into targeted, practical applications. In the surface and panel industry, AI is being used to support specific outcomes rather than wholesale transformation.

Emerging use cases include:

• Quality inspection and defect detection

• Predictive maintenance and performance forecasting

• Process optimization based on historical data

In 2026, the most effective AI solutions are those that are transparent, explainable, and easy to integrate into existing workflows.

DIRECTORY

These companies are recognized for their production and distribution of technology. Please note that this list might not be exhaustive and the availability of technology can vary based on geographical locations and specific market demands.

SOFTWARE

Autodesk www.autodesk.com

Cabmaster Software www.cabmastersoftware.com

Cim-Tech.com www.cim-tech.com

ClosetPro Software www.closetprosoftware.com

Cyncly www.cyncly.com

DAK Engineering www.dakeng.com

DDK Cad Technology Systems www.acadautomation.com

Hexagon www.alphacam.com

Inventables www.inventables.com

KCD Software www.kcdsoftware.com

MachMotion www.machmotion.com

Microvellum www.microvellum.com

Smartech www.smartech.com

DIGITAL PRINTING & SCANNING

Canon www.csa.canon.com

CGS-Oris www.cgs-oris.com/en

Interprint www.interprint.com

SwissQPrint America www.swissqprint.com

What to watch in 2026

Technology Trends to Watch in 2026: AI, IoT, and Beyond

Several themes will shape the technology and software sector in the year ahead:

1. Increased focus on integration across design, production, and business systems 2. Greater reliance on data-driven decision-making at every level 3. Technology adoption driven by

practicality and ROI, not hype

In 2026, technology and software are foundational to how the surface and panel industry operates. The solutions that succeed will be those that simplify complexity, improve visibility, and empower manufacturers to adapt — turning digital infrastructure into a true competitive advantage. ■

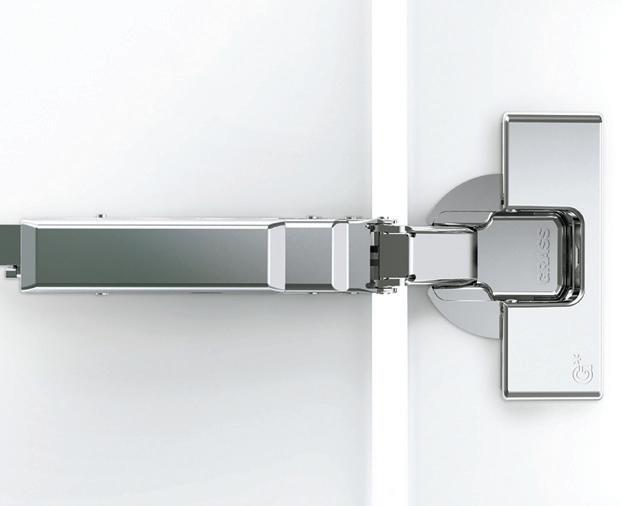

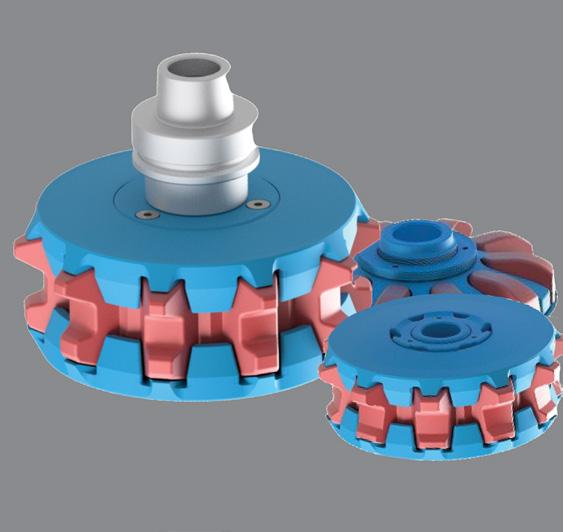

Hardware & Fasteners in 2026

Precision Components in a Design-Driven, Automated World

Hardware and fasteners may be among the smallest components in the surface and panel value chain, but their impact on product performance, user experience, and manufacturing efficiency is outsized.

As the industry moves into 2026, hardware is no longer judged solely on strength or function. It is increasingly expected to support refined aesthetics, smooth operation, and compatibility with automated production while remaining reliable over the life of the product.

Hardware is integral to design, not an afterthought

In contemporary cabinetry, furniture, closets, and architectural interiors, hardware is part of the design language. Minimalist forms, concealed solutions, and coordinated finishes have elevated expectations for how hardware looks and feels.

Design-driven trends shaping the sector include:

• Clean, low-profile, and concealed hardware solutions

• Expanded finish options to coordinate with modern surfaces

• Soft-close, touch-latch, and integrated motion features

In 2026, hardware must enhance the visual and tactile experience without drawing unwanted attention to itself.

Precision and consistency are critical in automated environments

As manufacturers rely more heavily on CNC machining and automated assembly, tolerances around hardware placement and performance become increasingly tight. Even small inconsistencies can disrupt assembly or compromise fit and finish.

Manufacturers are prioritizing hardware that offers:

• Consistent dimensions and predictable performance

• Compatibility with CNC drilling and insertion systems

• Reduced adjustment requirements during installation

Precision hardware supports faster assembly, fewer errors, and more consistent finished products.

Installation efficiency influences purchasing decisions

Speed and simplicity of installation are becoming key differentiators, particularly as labor availability remains a challenge. Hardware that reduces installation time or eliminates secondary steps delivers measurable value on the shop floor.

Trends influencing adoption include:

• Tool-free or simplified mounting systems

• Pre-mounted or pre-assembled hardware options

• Designs that tolerate minor variability without compromising performance

In 2026, ease of installation is as important as durability.

Performance expectations extend beyond basic function

End users expect hardware to perform smoothly and quietly over years of use. As product quality standards rise, so do expectations for long-term reliability.

Key performance considerations include:

• Smooth motion and consistent closing forces

• Durability under repeated use

• Resistance to wear, corrosion, and environmental factors

Hardware failures are highly visible and costly, making reliability a top priority for manufacturers.

Sustainability and material choices gain visibility

Sustainability conversations increasingly include hardware and fasteners as part of the overall product system. Material selection, durability, and lifecycle performance all influence environmental impact.

Key sustainability-related trends include:

• Longer-lasting components that reduce replacement cycles

• Material efficiency and recyclability

• Responsible sourcing and transparent documentation

In 2026, sustainability in hardware is often measured by how well components perform over time — not just what they’re made from.

Hardware as part of a coordinated system

Hardware is increasingly specified as part of a broader solution rather than selected in isolation. Compatibility with panels, substrates, and edge treatments plays a growing role in purchasing decisions.

Manufacturers are looking for:

• Hardware families designed to work together

• Long-term availability for repeat programs

• Technical support that spans design, machining, and installation

This systems-based approach simplifies sourcing and supports consistent quality across product lines. ■

DIRECTORY

These companies are recognized for their production and distribution of hardware & fasteners. Please note that this list might not be exhaustive and the availability of manufacturers can vary based on geographical locations and specific market demands.

HARDWARE & FASTENERS

AFT Fasteners & Industrial Supply www.aftfasteners.com

Comtrad www.comtradsourcing.com

FGV America

www.fgvamerica.com

Grainger www.grainger.com

Grass America www.grassusa.com

Hafele www.hafele.com

Hettich www.hettich.com

Keeler Brass Company

www.keelerbrasscompany.com

Kesseboehmer www.kesseboehmer.com

Leola www.leolafasteners.com

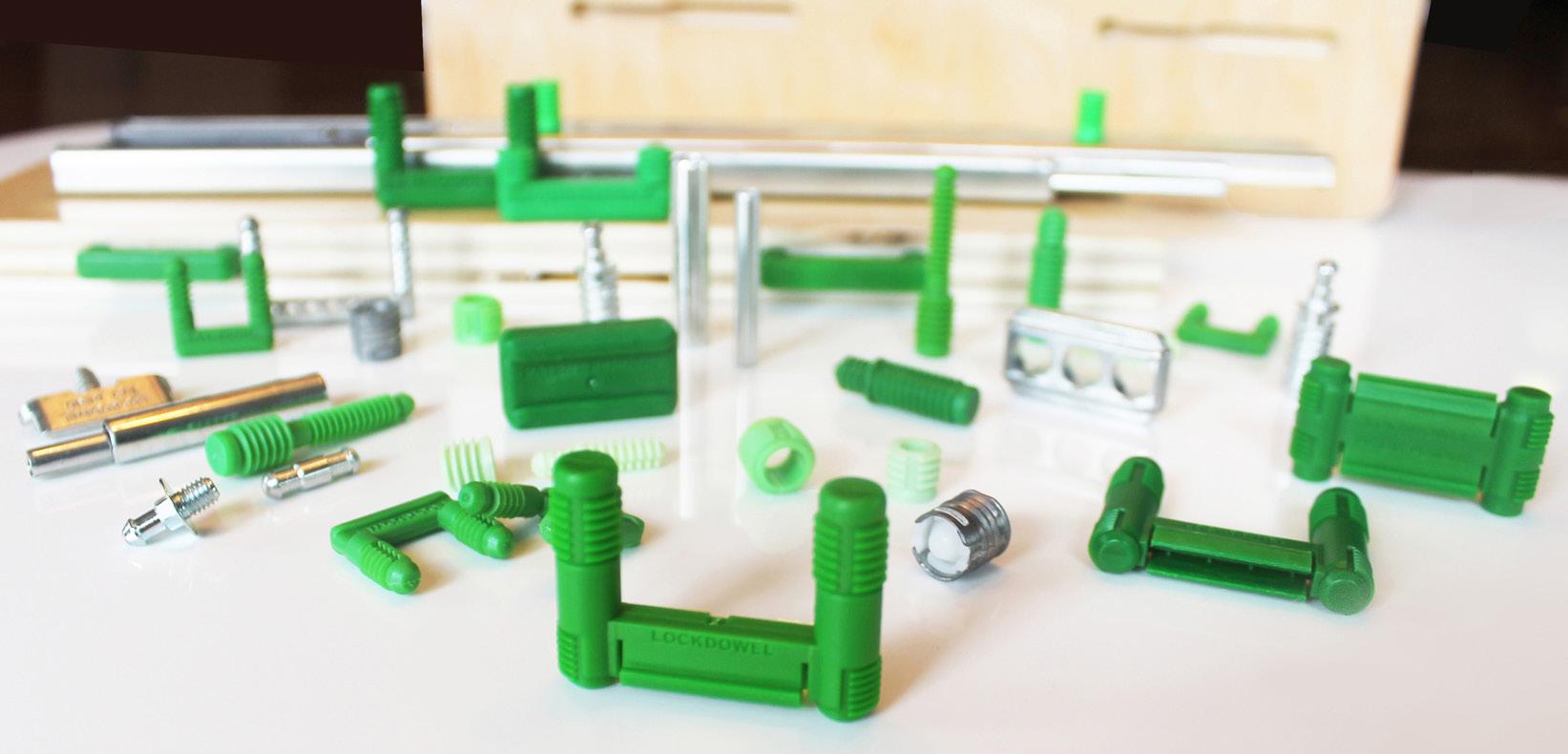

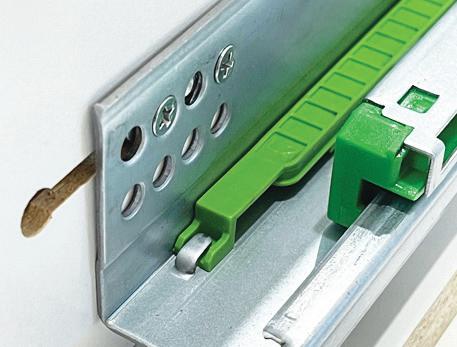

Lockdowel www.lockdowel.com

Richelieu www.richelieu.com

Salice www.salice.com

Sugatsune www.sugatsune.com

Titus Group www.titusplus.com

U.S. Futaba www.usfutaba.com

Vauth Sagel www.vauth-sagel.com

What to watch in 2026

2026 Trends in the Hardware and Fasteners Market

Several signals will shape the hardware and fasteners sector in the year ahead:

1. Continued emphasis on precision and ease of installation

2. Design-forward hardware that integrates seamlessly with modern surfaces

3. Durability and sustainability defined by long-term performance

In 2026, hardware and fasteners remain essential to the success

of surface-based products. The components that stand out will be those that quietly deliver reliability, efficiency, and design alignment — proving that even the smallest details can define the quality of the finished product. ■

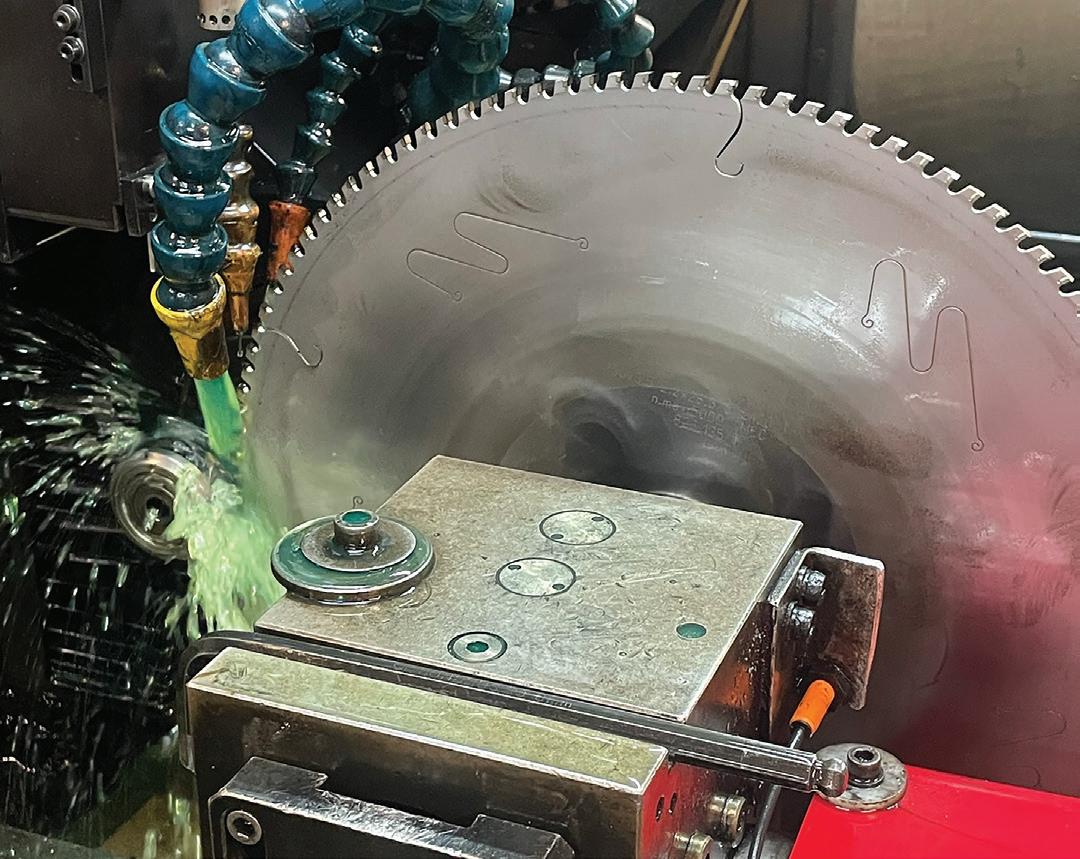

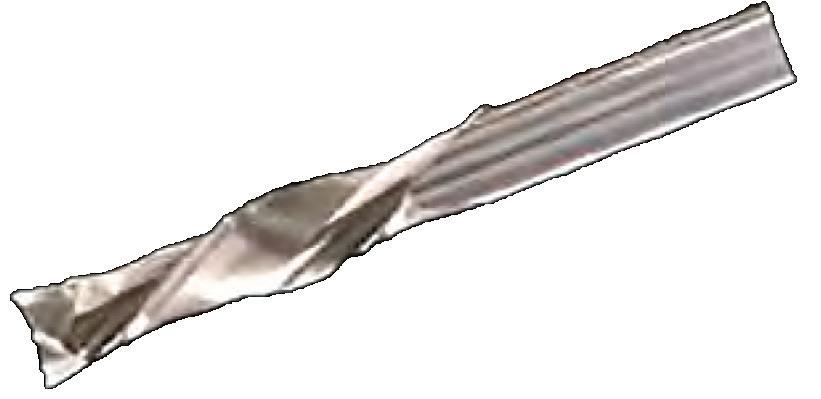

Tools & Machinery in 2026

Enabling Precision, Productivity, and Resilient Manufacturing

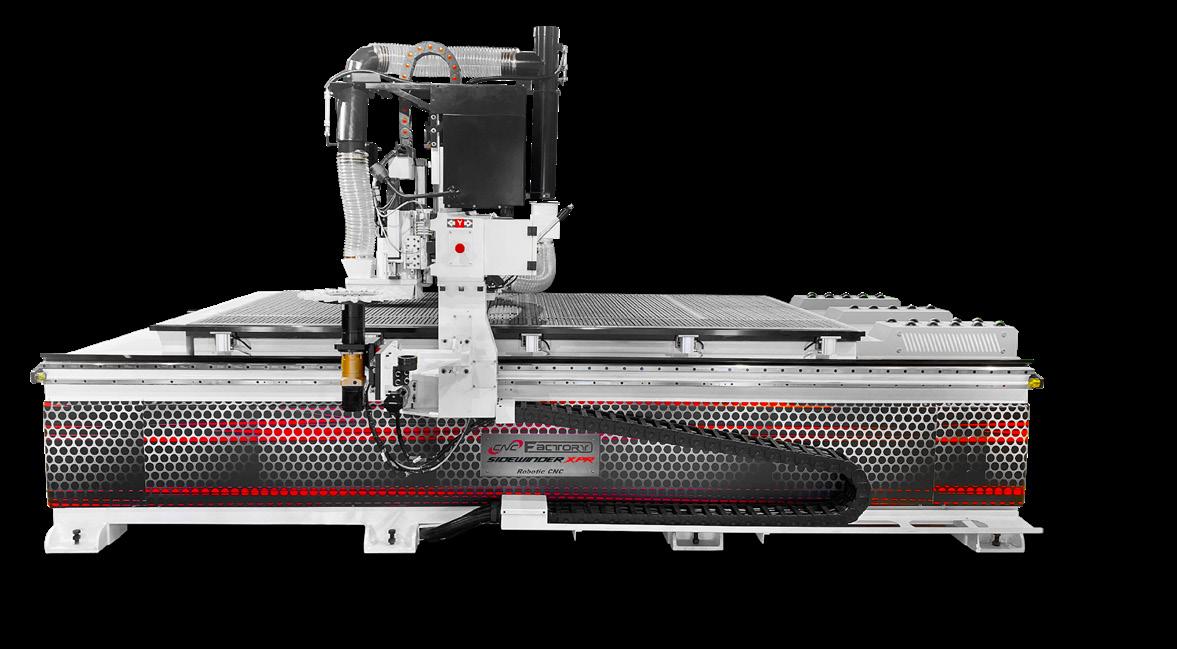

Tools and machinery sit at the heart of the surface and panel industry, translating material potential into finished products.

As the industry enters 2026, expectations for equipment extend well beyond raw power or speed. Manufacturers are looking for solutions that deliver precision, flexibility, and uptime, while integrating seamlessly with digital systems and evolving production demands. In an environment defined by labor constraints and tighter margins, tools and machinery are increasingly viewed as long-term strategic investments.

Precision and repeatability define equipment value

As surface designs become more refined and tolerances tighter, the demand for precision continues to rise. Whether cutting, routing, sanding, finishing, or edgebanding, machines must produce consistent results — shift after shift, operator after operator.

Key priorities shaping purchasing decisions include:

• Repeatable accuracy across long production runs

• Stable performance at higher speeds

• Reduced variability tied to operator input

In 2026, precision is not a premium feature, it’s a baseline expectation.

Automation is about resilience, not just speed

Automation has matured from a productivity booster into a resilience strategy. With skilled labor harder to find and retain, automated machinery helps stabilize output and maintain quality.

Manufacturers are increasingly investing in:

• Robotic handling and material movement

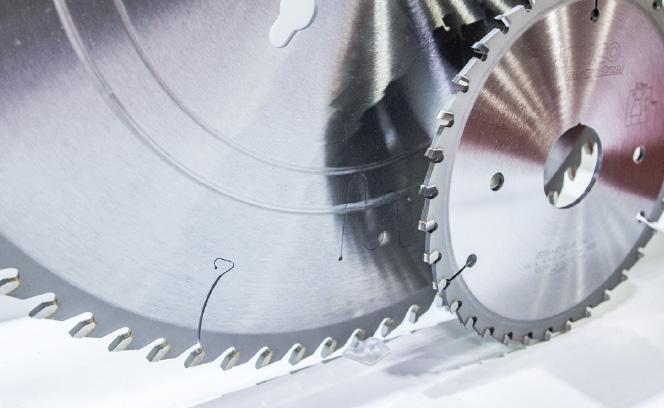

• Automated tool changing and setup