UNITING MATERIALS, TECHNOLOGY AND DESIGN

• Across the Atlantic: European Influences in the Industry

• The Evolution of Surface Solutions

• Tooling Up for the Future

• @the Show

UNITING MATERIALS, TECHNOLOGY AND DESIGN

• Across the Atlantic: European Influences in the Industry

• The Evolution of Surface Solutions

• Tooling Up for the Future

• @the Show

®

At Rev-A-Shelf ®, we believe that true innovation happens where storage, lighting, and design converge. From intelligently crafted organization systems and artisan-crafted wood range hoods to brilliantly engineered LED solutions, our unified approach transforms everyday spaces into extraordinary environments.

PRESIDENT/PUBLISHER

Patrick Adams

PH: 714-486-2735 padams@526mediagroup.com

VICE PRESIDENT

Shelly Adams

MANAGING EDITOR

Jennifer Williams

PH: 714-486-2735 jwilliams@526mediagroup.com

David Koenig, DIRECTOR OF EDITORIAL Sara Graves, SENIOR EDITOR

GUEST COLUMNISTS & CONTRIBUTORS

Gerri Chmiel, Keith Christman, Eric Marshall, Susan Palé, Tovi Spero, Denise Williams

SALES

Nick Kosan

PH: 714-486-2735 nkosan@526mediagroup.com

Chuck Casey

PH: 714-486-2735 ccasey@526mediagroup.com

John Haugh

PH: 714-486-2735 jhaugh@526mediagroup.com

GRAPHIC DESIGN

Greg Lane

DIGITAL SUPPORT

Katherine Williams kwilliams@526mediagroup.com

CIRCULATION/SUPPORT

PH: 714-486-2735 info@526mediagroup.com

526 MEDIA GROUP 151 Kalmus Drive, Ste. J3 Costa Mesa, CA 92626

PH: 714-486-2735

UNITING MATERIALS, TECHNOLOGY AND DESIGN

FEATURES

12 Beyond the Surface

Experts weigh in on the influence of European design aethetics

14 Across the Atlantic

How European design is shaping North American interiors

18 Euro Influence

Top 5 trends from across the pond

22 Touching the Future

How technology is transforming surfacing solutions into smart, sustainable, and sensory-rich experiences

24 Beyond the Repeat

Today’s evolution in surface design with Andrew Korzen, President and CEO for Wilsonart Engineered Surfaces

26 Gloss, Grain and Glass

A bold resurgence in residential design

28 Riding the Wave of Innovation

How technology is transforming the closet industry

31 Tooling Up for the Future

How evolving technology is reshaping tools & machinery

34 Distribution Matters

Limiting tariff trauma

38 Beautify Homes with Decorative Hardwoods

Enhancing aesthetics and functionality

42 More Than a Workshop:

Creating pathways to careers in wood manufacturing

45 Get Educated at the AWFS Fair

Tovi Spero shares a bit about the education opportunities to be found at this year’s AWFS

46 AWFS 2025 Product Roundup

A look at some products to be seen at AWFS and where to find them at the show

60 @ The Show

A recap and overview of some of the recent and upcoming shows in our industry

DEPARTMENTS

8 From the President

Hope is not a strategy

10 From the Editor

Innovation connects us all

40 Human Resources

Why pay discussions are important

72 Ad Index

74 S&P By Design

Kids Space installation at A Casa Ovunque in Milan using Organoid sensory-rich surfaces

It’s a phrase I’ve used a lot over my life that applies to countless situations. My somewhat detail-obsessive personality finds peace in the over-preparation for, well, just about everything. It started a long time ago with a simple statement I made to a mentor: “I hope we make it.” His response was, “Hope is not a strategy, what is your plan to make it?”

Then came children. As much as I’ve tried to engineer parenting, I find myself often left with hope. I used to think that with enough education, planning, preparation and deliberation that you could control the outcome. I think by the time my daughter was five, I started to give up on that plan.

What I was left with was more simple yet required more hope. Provide unconditional love. Make her feel safe and assure her basic needs were met. Be a good example of both a human being, as well as a partner to my wife. Reinforce good behavior and values. Allow her to fail but try to prevent life-changing failures. And be there… and hope a lot.

She has recently had a very rough month. Aside from being a 14-year-old teenager with me as a parent, she has had a string of challenges lately. So-called “friends” at school have turned into “mean girls” who test the very core of human decency. She is a loyal and sincere person, so this hits hard. It is time to decide what high school to attend, and trying to imagine your high school experience as an 8th grader is stressful. Some outside good friends are no longer good friends. And to top it off, in the middle of a volleyball tournament, the director of her team chose to deliver some exceptionally cruel “feedback” in the middle of a match.

Putting myself in her shoes, I think any one of these things — much less combining them all — would have brought anyone I know to their knees. The tournament situation itself would have tested the strongest people I know. She trains six days a week for a nationally ranked club travel team. She makes sacrifices and, while balancing school, home and friends, is proud of her role on the team. Personally, I would have been very tempted to share a few opinions of my own with this director and then walk off the team if I were in her shoes.

However, that’s not what she did. She still goes to school every day with a smile on her face, even though these “mean girls” led her to decide to not attend her 8th grade trip to Washington, D.C. Instead,

It started a long time ago with a simple statement I made to a mentor: “I hope we make it.” His response was, “Hope is not a strategy, what is your plan to make it?”

she is studying on her own about our nation’s capital. Instead of her social circle at school, she studies or volunteers to help the school staff. She made her high school selection along with us and is excited about her decision. Oh, and volleyball? Her response courtside to the director was simply, “Yes, Coach,” until the attack ended. She went back on the court and finished the tournament, has not missed a practice, and has not shown that it affected her one bit.

I could write a novel at this point just about my feelings about this situation and how she handled it all. The word “proud” would be used no less than a thousand times. But all I can do now is look back and try to figure out what we did right. She’s just a 14-year-old girl, doing the things she loves, and in the midst of that, got attacked by them all. Yet, she didn’t fold, complain or quit. She just kept moving forward, perhaps with the hope that tomorrow would get better.

I wrote a long time ago about how my very young daughter at the time had already taught me more about life and happiness than I had learned in a lifetime. So many years later, the lessons continue and perhaps, that in certain situations, hope is a strategy.

I hope that your year so far has been more positive than not and that, if faced with a challenge, that hope for a better day is a part of your strategy to move forward. As always, I am humbled for the privilege of serving this great industry.

Patrick S. Adams, Publisher/President padams@526mediagroup.com

Send your thoughts and messages on this issue and article to Patrick at padams@526mediagroup.com

In a world more connected than ever, design no longer evolves in isolation. The pace of innovation, collaboration, and inspiration has accelerated dramatically, fueled by technology and driven by global events that bring together the brightest minds and most daring makers in the industry.

I recently had the opportunity to attend both interzum and Ligna, two of the most significant trade fairs for our industry. Held in Cologne and Hanover, Germany, these shows offered a firsthand look at the direction our global industry is headed — and the experience was nothing short of eye-opening.

What stood out most to me was not just the groundbreaking products or polished presentations (or the amazing booths and food to be discovered), but how deeply technology is transforming design on a global scale. Whether it's AI-enhanced manufacturing systems, tactile surface materials with embedded functionality, or sustainable solutions being implemented, innovation today moves at speeds not imagined just a few years ago. Trends once rooted in a specific region now spread across continents within months or even weeks.

At interzum, I was captivated by how material manufacturers are leaning into sensory design. Ultra-matte finishes, realistic textures, and surfaces that smell like flowers or can even heal themselves are no longer novelties — they're becoming commonplace. And sustainability isn't a buzzword anymore, but instead is being woven into the very DNA of products and materials.

At Ligna, the story was equally forward-looking. Machinery is no longer just a tool; it's a system: smart, integrated, and connected. Seeing robotics, cloud-based data platforms, and AI-powered optimization on display made it clear that the future of production is agile, automated, and deeply responsive to design demands.

What I took away from these shows is this: the lines between materials, machinery, and methods are blurring.

Design, manufacturing, and distribution are no longer separate steps, but rather are part of a continuous, digitally enabled process. For our readers in North America and beyond, that means staying globally informed is no longer optional…it’s essential.

As you explore the pages of this issue, you’ll see that thread woven throughout: stories of companies adapting, inventing, and reimagining what’s possible when ideas and craftsmanship meets cutting-edge technology.

Whether you’re a fabricator, designer, supplier, or builder, we hope this issue fuels your curiosity, challenges your assumptions, and connects you more closely to the global design community of which we all are a part.

Jennifer Williams, Managing Editor

Beyond the Surface poses a question to prominent members of the industry, who then share their thoughts with us.

This quarter’s question is:

How is European design influencing the way North American interiors are being designed, specified and built today?

Crystal Morris

“European design, particularly Scandinavian influence, is playing a significant role in shaping the future of North American interiors. Designers across North America are increasingly embracing the minimalist characteristics of European design: clean lines, neutral color palettes and an emphasis on functional, clutter-free living. Inspired by Europe’s tradition of compact and efficient living, especially in

urban areas, there’s a growing trend towards designing smaller footprint homes. This shift is driving demand for smart storage solutions, integrated built-ins and multifunctional furniture that maximizes utility without sacrificing style. Additionally, Europe’s long-standing leadership in sustainability is influencing North American design decisions. There’s heightened interest in eco-friendly materials, energy-efficient systems and circular economy principles, especially in architecture and furniture, reflecting a broader cultural shift toward responsible and future-focused design.”

– Crystal Morris, Product & Decor Manager, EGGER North America

Simon Desrochers

A“Of course, there is an influence from Europe in terms of design (technology, sustainability, aesthetic and trends), and what is crossing to North America gets here more quickly now in general. But the European and North American market are very different markets. Not everything transfers, and the speed at which aesthetic and trends are adopted is still very uneven across North America. So, finding what element could migrate and when is still an important challenge for many North American manufacturers, distributors and designers.”

-Simon Desrochers, Director of Innovation and Product Development, Tafisa

Laurence Keighan

A“European design continues to shape North American interiors through its emphasis on minimalism, functionality, and refined textures — trends we observed firsthand at Interzum and Ligna. These aesthetics are driving increased demand for clean lines, natural tones, and high-performance materials that seamlessly blend beauty and utility."

- Laurence Keighan, Marketing Project Manager, Uniboard

Gerri Chmiel

“The influence of European design on North American design continues to evolve over time. North Americans are exposed to many international design styles with the internet and social media, and the effects of these influences can be quite fluid with a shortened trend cycle. I also feel that the flow of inspiration is a two-way street. It is not only the Europeans that influence us — our design aesthetic influences them as well.

We could see these influences at the Eurocucina show in Milan last year...Most European style kitchens sold in North America are featured in higher echelon showrooms, but we do see more affordable options coming to America like the collaboration between Wren Kitchens and The Home Depot, which will trickle affordable European design to the masses.”

- Gerri Chmiel, Senior Design Manager, Formica Group North America

BY JENNIFER WILLIAMS

In recent years, the influence of European design on North American interiors has evolved from a niche trend to a mainstream movement, affecting everything from cabinetry to surface materials, color palettes, and functionality. What once seemed distinctly “continental” now resonates deeply with North American homeowners, designers, and fabricators, thanks to the global exchange of ideas, the rise of social media, and a growing appetite for clean, modern aesthetics.

Driven by a shared desire for functionality and beauty, today’s interiors on both sides of the Atlantic reflect a dynamic fusion of European minimalism, American practicality, and globally inspired customization.

“The influence of European design on North American design continues to evolve over time,” says Gerri Chmiel, Senior Design Manager, Formica Group North America. “North Americans are exposed to many international design styles with the internet and social media, and the effects of these influences can be quite fluid with a shortened trend cycle.”

Among the most prominent European design elements reshaping North American interiors is the rise of clean-lined, handleless cabinetry. This hallmark of modern European kitchens, long embraced for its minimalist elegance, is quickly gaining

traction in the U.S. and Canada.

“We’re seeing strong and growing demand from North American customers for clean-lined, flat-panel cabinetry with a handleless channel system,” says designer Eva Littlefield with nobilia North America. “This sleek, modern European aesthetic offers a striking contrast to the more traditional, framed cabinetry often found in American homes.”

Beyond appearances, the European emphasis on functionality — such as integrated lighting, concealed storage, and ergonomic layouts — is also making its mark. As Littlefield points out, performance expectations are no longer regional.

Motion Redefined

MOVENTO’s synchronized runners move as one, delivering a smooth, weightless feel—even under heavy loads. It’s a difference that reflects the quality of your craftsmanship, felt in every glide.

“I’ve been fortunate to have clients on both sides of the pond, and I’ve found that performance preferences are the same,” she explains. “Features like anti-fingerprint technology, integrated task lighting, and appliance garage systems are just as valued in North America.”

As surface trends evolve, texture is emerging as a critical driver of design innovation. Whether it’s ultra-matte finishes, woodgrain decors, or stone-inspired laminates, the tactile appeal of European surfaces is transforming how North American spaces feel — literally.

“Textures are growing in popularity; clients love the way they offer a sense of depth and customization that elevates the overall design,” Littlefield notes. “High-gloss lacquers and realistic faux stone decors are trending.”

This movement isn’t lost on major suppliers. Laurence Keighan of Uniboard echoes the shift: “European design continues to shape North American interiors through its emphasis on minimalism, functionality, and refined textures,” shares Laurence Keighan of Uniboard. “[These are] trends we observed firsthand at interzum and Ligna. These aesthetics are driving increased demand for clean lines, natural tones, and high-performance materials that seamlessly blend beauty and utility.”

Historically, American homeowners prioritized resale value, favoring neutral finishes and safe design choices. But that is changing.

“European design has long prioritized personal expression and modern aesthetics,” says Littlefield. “Today, we’re seeing a cultural shift — homeowners and designers alike are embracing more personality-driven surface choices.”

The result? A growing appetite for bold finishes, deeper color palettes, and layered textures; design moves that once felt too risky for conservative North American buyers. In this new climate, Scandinavian-inspired tones like soft white oak, tactile blackened ash, and muted ceramics are making significant headway in both urban lofts and suburban remodels.

While the European aesthetic is gaining ground, there’s still work to be done in bridging the knowledge gap.

“Education is key,” Littlefield admits. “Helping my clients understand the value behind nobilia’s frameless construction, compact layouts, or sleek finishes takes time and often requires a shift in mindset from more traditional (American) preferences.”

Visual storytelling plays a critical role in this process. “Imagery, photographs, and videos not only showcase aesthetics but also

demonstrate the functionality behind the design,” she explains.

Fortunately, the internet has accelerated exposure. Social media, influencer walkthroughs, and visual platforms including Instagram, Pinterest and Lemon8 have made it easier for consumers to discover and desire European design, often before they step into a showroom.

The global design conversation is no longer one-way. While Europe continues to inspire, the flow of influence is becoming increasingly reciprocal.

“It is not only the Europeans that influence us – our design aesthetic influences them as well,” says Chmiel. “We could see these influences at the Eurocucina show in Milan last year, with kitchens featuring Shaker cabinet door styles in white – a distinctively American style”

“At the same time,” she adds, “European-style kitchen styles influence us with clean lines, furniture-like installations, waterfall islands and floor to ceiling walls of cabinetry. Most European style kitchens sold in North America are featured in higher echelon showrooms, but we do see more affordable options coming to America.”

At Salone del Mobile, Chmiel says she observed three key trends gaining traction across the Atlantic:

• Bold statement stones with dramatic veining and saturated colors

• Design nods to the 1970s and 80s, including high-gloss metals, chrome accents, and lacquered surfaces

• Elevated outdoor living, with multifunctional furnishings that blur the line between interior and exterior spaces

Despite these convergences, significant differences remain between the markets.

“Of course, there is an influence from Europe in terms of design, technology, sustainability, and trends,” says Simon Desrochers of Tafisa. “But the European and North American markets are very different. Not everything transfers, and the speed at which aesthetic trends are adopted is still very uneven across North America.”

Desrochers underscores that for manufacturers and designers, understanding when and how to adapt Euro-centric designs remains a critical business challenge. “Finding what element could migrate and when is still an important challenge,” he says.

But he also raises a larger, more complex question: How might the recent evolution of the North American economic and cultural landscape impact the European design industries in the

upcoming years?

He suggests the answer may come down to trade policies and strategic investment.

“While the full impact of these tariffs remains to be seen, they are most likely already influencing many business decisions in Europe,” says Desrochers. “Over time, this could lead to shifts in investment strategies related to innovation and design — affecting not only how European manufacturers develop new and existing business, but also how they approach product development. Will Europeans invest heavily in factories to produce in North America? Will they pivot to other markets? Which companies will seize the opportunities created by this evolving situation? Time will tell.”

So why does European design resonate so strongly across the Atlantic?

“From the world of fashion to the sexiest cars on the planet, Americans love Europe,” says Eric Marshall, cofounder and owner of the Closet Training Institute who currently serves as a GlobalConnect advisor for the NKBA. “We know in home design it’s true, too. Bright and varied color palettes from TFL and quartz slab suppliers beg paint suppliers to follow them.”

And details matter, he says: “What’s going behind doors — pullout organizers and high-end, aesthetic drawer organizers to display kitchen utensils — is purely European. It just feels high end, and it’s catching on in the U.S.”

Ultimately, the European aesthetic, refined, minimal, and deeply functional, has become a design language that transcends borders. In an increasingly globalized world, North American homes are no longer just borrowing from Europe — they’re becoming fluent in the same design dialect. S P

European design elements are transforming how we think about function and style across the industry. Eric Marshall, cofounder and owner of the Closet Training Institute who currently serves as a GlobalConnect advisor for the NKBA, shares his top five Euro-inspired trends gaining momentum in the North American market.

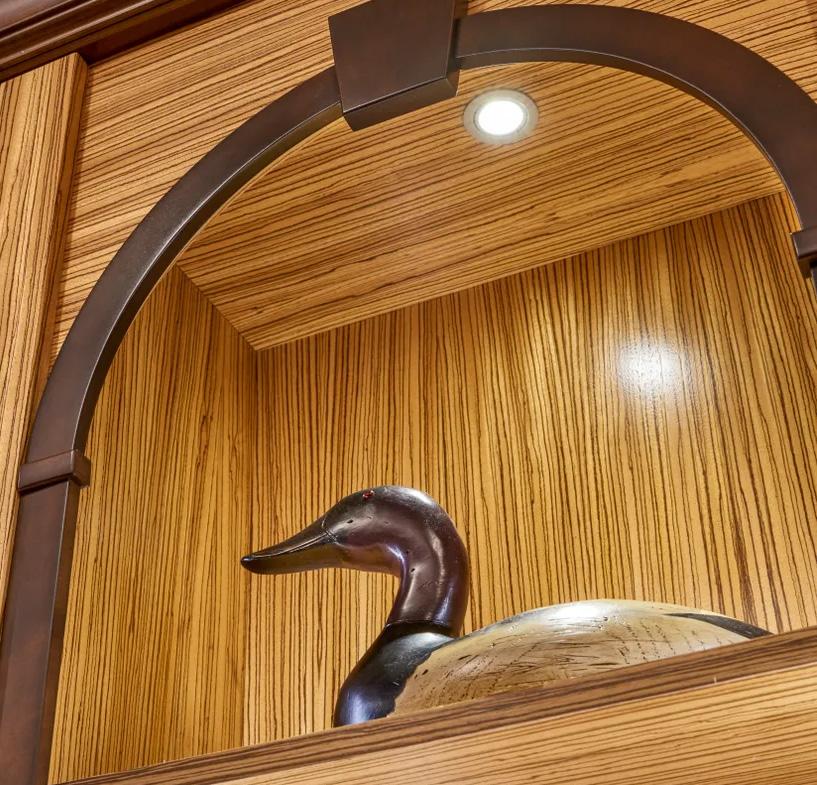

1. Lighting

Closets can’t go without lighting anymore. It’s expected these days that a display unit must be lit!

2. Metal Drawers

It true that Europe and Asia have switched from a finger-jointed or dovetail drawer to a metal drawer side with integrated, soft-close, full-extension runners, that also offer push-to-open capabilities. It’s so fun to use TFL as the bottom and back in a matching color to give your drawers that matching custom-built look.

3. Handleless Fronts

It just looks cleaner and less holes drilled for possible crooked handles.

4. Super Matt and High Gloss

Although colored cabinets are taking the trend today, the solid colors have switched from textured to high-end, high gloss or super matte finishes, which look fresh and clean.

Fronts/Super Matte:

A few trends converge in this kitchen space from ALVIC, featuring their Zenit 3.0 technology, a supermatte lacquer with a silky touch. Also seen are drawer faces without handles or hardware.

5. Anthracite Accessories

It looks as though in Europe, the days of wooden and chrome accessories are fading into the background. The new color replacing it is a very dark gray, also known as anthracite. It looks rich and almost invisible when it comes to organizing the things you’re storing.

This lighting, shown here from L&S Italia Spa, won both an interzum Best of the Best and an iF Design award this year.

(L) Multiple storage solutions from Vauth-Sagel are available in the trending anthracite shade.(R) Thoughtful accessories like these from CAP's Natasha Shtapauk are very on-trend

The Grass Nova Pro Scala Drawer System allows full extension and offers metal drawers

PerfectSense Premium Laminate Gloss from EGGER features an ultra-gloss, durable laquer surface

No matter what kind of lamination you need, Daubond® PUR adhesives are made to fit the mold. We’re committed to finding the best solution for you, offering guidance and support every step of the way. When you work with Daubert®, you get a team dedicated to meeting your needs and helping you achieve success that sticks.

- 3D LAMINATING & THERMOFOIL

- FLAT LAMINATING

- PROFILE WRAPPING

- EDGE BANDING

- AUTOMOTIVE

- ASSEMBLY

- CLEANING & LUBRICATING PRODUCTS

- AND MORE

BY JENNIFER WILLIAMS

Gone are the days when surfacing materials were judged purely by looks. In today’s design landscape, they are expected to do far more — fusing form with function, wellness with sustainability, and tactile beauty with technological performance.

From antimicrobial laminates to fingerprint-resistant finishes and AI-driven production lines, the surfacing industry is undergoing a high-tech evolution that’s reshaping how we interact with our spaces at home, at work — and everywhere in-between.

“Technology continues to transform the surfacing solutions industry, particularly in how we develop textured panels and tactile finishes,” says Meghan Howell, Design & Creative Director, Formica Group North America. “What's fascinating is how manufacturing innovations are enabling us to meet multiple consumer needs simultaneously.”

At the core of this evolution is innovation in surface engineering, where companies are using new methods and technologies to produce materials that are not only visually stunning but soft to the touch, ultra-matte, or even self-healing.

“Over the last few years, we’ve seen a lot of development at

the surface of decorative surfaces,” says Simon Desrochers, Director of Innovation and Product Development with Tafisa. “Antimicrobial laminates, fingerprint-resistant finishes, and thermal healing tech — all these having contributed to making a more sensual, healthier and low-maintenance living spaces.”

Today, more than ever, design is sensory, with texture playing a starring role in creating emotional resonance in a space, bringing warmth, depth, and authenticity. Whether it’s the natural grain of wood or the subtle groove of a matte stone, today’s surfaces are designed to be touched.

“Texture plate technology has been a game-changer,” explains Howell, “allowing us to create more sophisticated textures [and deliver] an authentic stone feel with a matte finish [or a] delicate open-pore ticking in a non-linear pattern that mimics the casual look — and feel — of natural wood.”

The next generation of materials now emerging — surfaces that do more than look pretty — those embedded with lighting, touch-responsive controls, heating elements, and even energy storage capabilities.

“Technology is driving rapid innovation in surfacing, leading to more sustainable, high-performance materials made from recycled content, bio-resins and repurposed sources.,” says Crystal Morris, Product & Decor Manager, EGGER North America.

“[And] there’s growing demand for natural-feeling textures that also offer practical benefits like anti-fingerprint and anti-microbial properties.”

This fusion of design and embedded technology offers exciting applications, from intuitive kitchen counters to workstations that respond to human touch.

The transformation isn’t limited to what we see and feel, but also in how these surfaces are made. At Uniboard, cutting-edge AI is helping to reshape the production process.

“Technology is transforming surfacing with smarter, more intuitive materials, like our Eclipse anti-fingerprint finish and thermal healing capabilities — that support both aesthetics and functionality,” says Laurence Keighan, Marketing Project Manager at Uniboard. “With the AI-driven Renaissance Project at our Vald’Or mill, we’re pushing innovation even further by integrating next-gen manufacturing to meet the rising demand for tactile, durable, and sensory-rich panels.”

These advancements in digital manufacturing allow for unprecedented control, enabling the creation of naturalistic, random textures while reducing waste and increasing efficiency.

“The manufacturing technology behind FENIX Innovative Materials represents one of the most significant contributions to material technology,” says Howell. “By combining multi-layer coating with nanoparticle technology and Electron Beam curing, we created a surface with remarkable properties…fingerprint resistance, ultra matte, soft touch and thermal healing capabilities that allow minor scratches to be repaired with heat.”

“Arpa has pushed textural boundaries with TUET, a deep textured laminate, which draws inspiration from Piedmontese reedbeds,” she adds. “Technology demonstrates how advancements in manufacturing can translate natural inspirations into functional surfaces.”

Experts agree that the evolution of surfacing is just beginning.

“Looking ahead, surfaces are becoming smarter,” says Morris, “with integrated lighting, touch controls and embedded sensors,

blending design with interactive functionality.”

And across the industry, surfacing is becoming smarter, greener, and more emotionally resonant.

“[The] next waves of development that could reach more mainstream applications could very well be ‘underneath the surface,’” says Desrochers. “[From] Smart panels with electric conductivity or energy storing capabilities, heating laminates and ballistic laminates, all of these [are] creating smarter, more efficient and safer spaces.”

With each new advancement, surfacing becomes not just something we see, but something we experience. In the spaces we inhabit every day, these materials are helping us live cleaner, feel more connected, and interact with design on an entirely new level.

“I believe we'll continue to see technology enabling more haptic materials that engage our sense of touch,” says Howell. “After years of sterile, white and gray interiors, consumers and designers are specifically requesting surfaces that create emotional connections through tactile experiences.”

“The challenge for manufacturers will be developing technologies that can deliver these sensory experiences while meeting demands for durability, cleanability, and sustainability,” she continues. “That's where I expect to see the most exciting innovations in the coming years.” S P

How the surfacing industry is evolving:

HYGIENE & CLEANABILITY

SELF-CLEANING, UV-PROTECTIVE

ANTIMICROBIAL, FINGERPRINTRESISTANT

MATTE TEXTURES, LAYERED EMBOSSING

EMBEDDED FUNCTIONALITY

TOUCH-FRIENDLY, LIGHTING

SELF-CLEANING, UV-PROTECTIVE

TEMPERATURESENSITIVE, HAPTIC FEEDBACK

SENSORINTEGRATED, HEATED, CONDUCTIVE

AESTHETICS & SUSTAINABILITY

RECYCLED, LOWVOC MATERIALS

MANUFACTURING INNOVATION

AI-DRIVEN TEXTURE AND FINISH DEVELOPMENT

CARBONNEUTRAL, BIOBASED TECH

FULLY AUTOMATED, MASSCUSTOMIZED

CONCLUSION: The future feels different

BY JENNIFER WILLIAMS

In the world of surfacing, one persistent limitation has long frustrated designers and architects: repeating patterns in large-format laminates.

“Traditionally in a 12-foot pattern you'd actually see the repeat every four feet,” says Andrew Korzen, President and CEO for Wilsonart Engineered Surfaces.

The result? A jarring visual break every few feet — hardly the seamless expanses clients crave. Now, a new wave of technology is setting a higher bar.

“But we have technology that we're coming up with — and this is just one example — where it now mimics a full slab which you would see in natural stone or in wood-grain designs,” says Korzen. “We're really excited about this new technology because it's always been a limitation.”

Wilsonart introduces this year what Korzen calls “a No-Repeat HPL,” an innovation that mimics full slabs of natural stone or wood without the tell-tale breaks. By erasing pattern repetition, these HPLs bring the realism of natural materials to large commercial and residential spaces.

But it’s not just about aesthetics. Fabricators and installers prize durability and cost-efficiency. “That’s a true value proposition,” Korzen asserts. “This beautiful, seamless look, along with the installed cost advantage versus traditional tile and speed of installation.” With shorter setup times and less labor than

traditional stone or tile, these laminates offer practicality — and costsavings — alongside luxury appeal.

“We're using more and more technology for both performance and appearance,” he says. “We continue to innovate and feel we're one of the industry leaders on some of these new innovative large moves.”

Korzen also emphasizes performance credentials, saying you can “drop a bowling ball on it and it’s not going to break or shatter. You can beat the heck out of this.” He spoke of a demo in which one of these surfaces proved to have high resilience and scratch resistance after impacts that would damage natural stone or other composites. The durability of these new laminates makes them wellsuited for busy kitchens, commercial spaces, and active households, he adds.

Until now, fabricators relied on specialized tools to shape surfaces, but Korzen highlights a crucial advantage: “You can cut these materials with saws and woodworking tools,” he says. “You may need a few to have special bits and blades, but we provide that to the customers. There’s a little learning curve, but once you do it once, you got [it].”

And because these laminates work with familiar equipment plus manufacturer-provided tooling, even smaller shops can fabricate high-end surfaces without significant capital investment, he says.

Wilsonart is also working to close the gap in many designs

featuring laminated surfaces, says Korzen, by introducing coordinated lines across the spectrum of laminates offered.

“What we are able to offer is not just HPL, but also the coordinated TFL or low-pressure laminate that coordinates exactly with our high-pressure laminates,” he explains. “We are the only producer in North America that's capable of doing this — not just the design, but the finish. What this means is that you can have your high-pressure laminate on your horizontal surface and then coordinating surfaces to use elsewhere in your design or project.”

“It looks so much more finished,” he says, meaning designers and homeowners can now achieve cohesive looks, from cabinet exteriors to drawer interiors, without extra costs.

Aesthetics continue to evolve, ranging from high-gloss to matte finishes. “We’re working on some new technologies for a higher gloss finish,” says Korzen, “but we’re getting a lot of requests for higher design, quartzite design. We have a whole collection, Ultra Matte Ultra Luxury, but it’s still low [pressure laminate]. It is fingerprint-resistant to greases and anything on your hand, but looks and feels like a luxury, more-expensive material.”

These innovations aren’t just for offices or hospitality; they’re penetrating the residential market, as well. “So we've introduced this coordinated linens interior offering so that is a little bit of an upgrade,” he explains. “But if you're spending money on a kitchen remodel, it won’t break the bank — and it looks so much more finished. Whether it's in your drawers or cabinets or — you know what? We're also seeing it in a lot of master bedroom closets remodels.”

As these non-repeat laminates scale across residential and commercial segments, offering coordinated interior finishes and ultra-matte textures, they may well redefine expectations across the industry.

And Korzen recognizes that this is a turning point in surfacing innovation: high-pressure laminates are no longer limited in pattern size, visual realism, or fabrication ease. These materials are merging design beauty with rugged endurance and installation efficiency, making stylish, seamless surfaces accessible to more people. “This isn’t just a minor tweak,” he says. “It’s a paradigm shift in how we think about surfaces — from how they look, to how they’re made, installed, used, and experienced. It’s a super-exciting time.” S P

BY GERRI CHMIEL

The surfacing industry has undergone an evolution in residential design, with a notable resurgence of bold textures, glossy finishes and natural materials. As we cycle through various design eras, one trend stands out — an unmistakable return to the 1980s aesthetic, infused with modern sensibilities. This trend, which can be seen across a variety of materials from wood to glass, is quickly becoming a hallmark of contemporary residential interiors.

In recent years, there has been a noticeable shift toward glossy and shiny finishes reminiscent of the slick surfaces that defined the 1980s. While the ‘80s embraced high gloss, often with a sleek, polished appearance, today’s designs are bringing a more refined version of this trend. The juxtaposition of highgloss surfaces, whether on stone, wood or furniture, adds a sense of luxury and dynamism to living spaces.

A significant component of this revival is the use of statement stones. Rich, dramatic surfaces, like those seen in marble, are once again commanding attention. Burgundy and deep red

stones, along with intricate veining, create striking focal points in the home. The '80s saw the rise of bold color palettes and current homes are following suit with the addition of statement stones in hues of deep green, red and violet. The glossy finishes on these stones paired with modern, high-lacquer wood finishes offer an elegant blend of craftsmanship and contemporary flair.

While the 1980s focused heavily on sharp lines and glossy finishes, today’s trends are more about softness. Organic asymmetry has made a comeback, with furniture and decor pieces embracing more curvaceous, flowing lines that create a sense of harmony in the home. Gone are the days of harsh, angular edges, instead, rounded and soft forms dominate both furniture and architectural elements.

This desire for organic and soothing design is further reflected in the resurgence of natural materials. Bamboo, once a staple of the wellness trend, is now being used in both furniture and accessories to evoke a sense of nature inside the home. Woods, both light and dark, are used in low contrast, often

in harmony with organic stone surfaces, creating an overall calming aesthetic.

Glass also plays a significant role in these evolving design trends. However, it’s no longer just about simple, transparent glass. Glass surfaces are becoming more textured and artisanally crafted and feature intricate patterns that add an element of tactile interest to the space. Wavy, grooved and bubbly glass surfaces are being embraced for their unique aesthetic qualities. This trend is especially prominent in furniture in which glass is often encased in tubular metal frames, creating a playful juxtaposition of transparency and solidity.

Additionally, back-printed glass is being used to preserve intricate designs while offering durability. These glass surfaces not only protect delicate patterns but also provide a striking visual element to spaces. The trend toward more innovative glass surfaces represents the fusion of craftmanship and modern technology, as designers experiment with new techniques to push the boundaries of what glass can achieve in design.

The 1980s were known for their maximalist approach to design: bold colors, luxurious materials and statement-making furniture were the defining characteristics. Today’s iteration of ‘80s-inspired design retains some of these maximalist elements but introduces a more minimalist approach when it comes to overall spatial planning. Furniture is low-profile and cloud-like, featuring plush, comfortable textures that are neither furry nor velvet, but somewhere in between.

As we continue to see a revival of 80s design, particularly in the surfacing industry, it’s clear that these trends have staying power. The movement toward organic shapes and the reintegration of bold, statement-making surfaces all point to a growing desire for balance in our living environments. Designers are embracing these trends for their ability to create spaces that feel both timeless and modern.

The surfacing industry is responding in kind, with products that blend natural stone, glass and wood in innovative ways. As materials evolve, so does our approach to living spaces — spaces that are luxurious, serene and deeply connected to our sense of well-being. The return to ‘80s maximalism coupled with a focus on organic design is setting the stage for a new era in residential design. S P

Gerri Chmiel joined Formica Corporation in 2001 and is the Senior Design Manager. Chmiel is responsible for creating and managing the trend and design portfolio of surfacing materials for the North American residential market including Formica brand laminate, 180fx laminate, Everform Solid Surfacing and Homapal Metals brand. She leads the effort for design research and residentially focused design development, and acts as one of Formica Corporation’s voices of design through targeted customer presentations and speaking engagements. 800-457-746 8 • peak

Explore our beautifully redesigned website, featuring a new e-commerce platform. We keep you operating at PEAK performance.

• Advanced manufacturing and inventory capabilities boost operational efficiency.

• Industry-leading quality from tool manufacturing to sharpening.

BY JENNIFER WILLIAMS

From custom walk-ins to sleek reach-ins, the modern closet is no longer just about storage — it’s about smart design, seamless experiences, and cutting-edge tools behind the scenes.

As digital solutions become central to how closet professionals design, sell, and deliver, technology is transforming every step of the process.

At the forefront of this evolution is ClosetPro Software, whose cloud-based platform and forward-thinking approach are helping shape the future of the industry with their software being used by many closet design and installation companies across the country.

“One of the primary benefits of our software is the 3D and the high-res renders that you can generate right through the system,” says Joe Bergamo, Director of Sales and Marketing

for ClosetPro Software. “And that really opens up what you can do and makes things a lot easier for everyone involved.”

That reliability is vital, he adds, since the closet industry — particularly on the design side — depends on speed and accessibility. Software that used to require bulky downloads or dedicated systems now lives entirely online. “You just need access to the Internet,” says Bergamo. “And if you are out at a new build with no Internet, you could hotspot off your phone, start a design, and then go home and finish it later.”

And because renderings and processing happen on powerful remote servers, users no longer need high-end machines to run complex visuals. “All that information takes the onus off of user PC requirements,” explains Bergamo. “You just submit a render and it gets shot off to our server. When it’s complete, you get an email, and it’s automatically attached to the job.”

This improved experience is thanks not only to ClosetPro’s custom software but also to the ever-evolving performance of cloud infrastructure giants like Google and Amazon, he adds. “We’re kind of just sitting on top of the wave,” says Bergamo. “As [technology] moves forward, we can access all these things and continue to improve how our business functions.”

Few tools are more persuasive in the sales process than a clear, immersive visualization. In today’s closet industry, highresolution 3D renderings are becoming the expectation — not the exception.

And it’s not just about pictures — it’s about experience. Thanks to native smartphone and tablet capabilities, ClosetPro’s platform supports 360-degree VR renderings. “When you’re on

a smartphone or tablet, that basically becomes your viewing window, and you rotate the device to look around the room,” explains Bergamo. “We don’t have to do anything special to make that happen — it’s built into the tech people already have.”

This accessibility and quality serves a dual purpose: streamlining workflow for the designers and fabricators who use ClosetPro’s software, while also enhancing the client-facing experience. “It’s all a way to improve upon the sales process,” he says. “The end customer expects to see what they’re going to get. Things have become more visual. In every facet of life, that’s the norm now.”

In contrast to older, key-based design software that required physical dongles and specific system setups, ClosetPro’s tool reduces friction. “A lot of the other tools that we would compete with are key-based,” says Bergamo. “We get questions like Do I have to download a key? or Do I need specific system requirements? ”

His answer is usually a pleasant surprise for users familiar with more cumbersome systems: “No, you just need Internet access.”

This open accessibility also supports collaboration and flexibility. A user can start a design in the field, pause, then resume from the office or at home. “Everything is saved in real-time on our servers,” says Bergamo. “You’re not tied to a single machine.”

While cloud computing and rendering technology have matured, the industry is just beginning to tap into the next

frontier: artificial intelligence. And while AI isn’t fully integrated into ClosetPro’s design platform yet, Bergamo says they have their eye on it.

“AI is the big unknown right now,” he admits. “But it’s not just for fun anymore — there’s real utility.”

In fact, the team already uses tools like ChatGPT for some business and marketing tasks. “It gets you quite a bit of the way there, but you still have to add your own experience and business context,” says Bergamo.

Others in the industry are beginning to use AI creatively for mood boards and concept generation — tools that help clients visualize their dream closets even before a design is finalized. And while ClosetPro has not yet built AI into the software side of the company, Bergamo says he sees its integration as inevitable. “Everyone is curious, and we’re no different,” he says. “It’s going to be the next step.”

Bergamo’s approach to AI echoes a broader philosophy about technology: Don’t rush — adapt wisely. “AI has been a slow burn,” he says. “At first, it was a novelty, but now it’s actually useful. And people are starting to say, I don’t want to be stuck behind the 8 ball.”

That cautious optimism sets the tone for where he sees the industry heading. Rather than adopting new tools just to check a box, Bergamo emphasizes the importance of thoughtful implementation. “It’s about figuring out the best way to use it as a tool — not just saying, Hey, we use AI,” he explains. “You have to figure out how to actually make it helpful, how to make it work FOR you.”

For the ClosetPro team, technological advancement isn’t an isolated benefit — it’s a ripple effect. Improvements in global infrastructure, whether in Wi-Fi speed, server power, or mobile capability, automatically enhance their product.

“We’ve kind of attached ourselves to these bigger advances,” says Bergamo. “And then our customers benefit. And then the homeowner benefits. Everybody gets a better experience.”

That approach allows ClosetPro to scale smartly while staying lean. As servers get faster and design tools more intuitive, their software naturally becomes more powerful without needing massive overhauls. “The customer experience gets better, 3D gets better, rendering gets better,” he adds. “That just comes with the advances we’re fortunate enough to have access to — without having to build them ourselves.”

In a world where homeowners increasingly expect instant visual confirmation and businesses seek greater efficiency, the role of technology in the closet and organization industry is no longer a bonus — it’s essential. For innovators like ClosetPro Software, the secret to success isn’t simply using the latest tech — it’s understanding how to harness it to create a better experience from design to delivery.

“We’re riding that wave,” says Bergamo. “And it’s carrying the whole industry forward.” S P

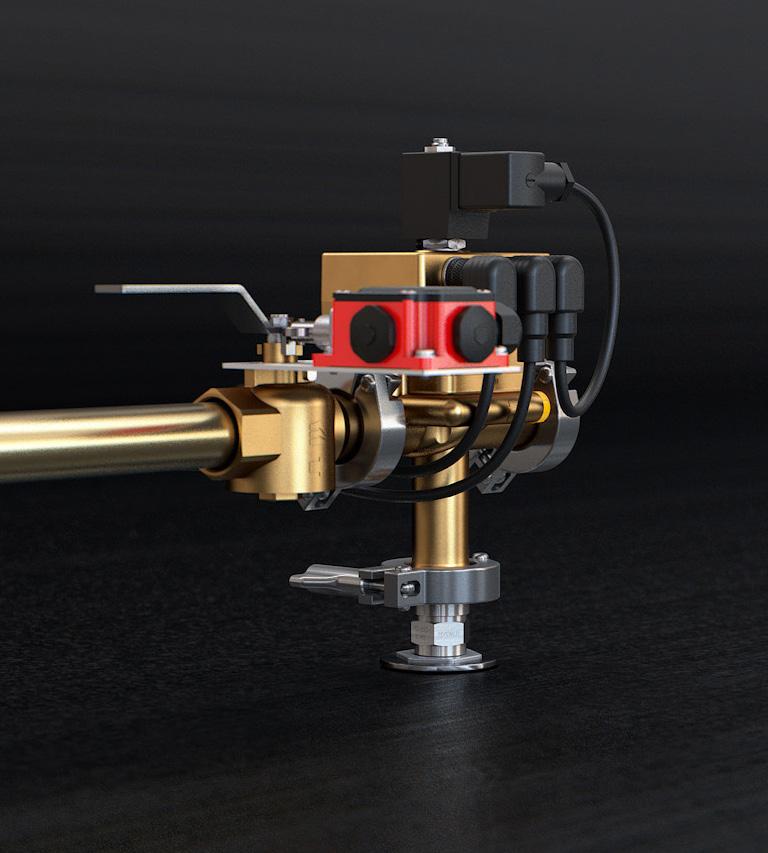

BY JENNIFER WILLIAMS

From refined panel surfaces to AI-driven production lines, our industry is undergoing a technological revolution — especially in the tools and machinery that bring custom millwork, cabinetry, and furniture to life.

As consumer tastes shift toward high-end, highly customized finishes, manufacturers and fabricators are investing in smarter, more precise, and increasingly automated systems to keep pace. At the heart of this transformation are new generations of cutting tools, CNC routers, and intelligent systems that are helping shops of all sizes streamline their workflows and elevate craftsmanship.

The days of basic melamine are long gone. Today’s panels come with complex surface treatments, ranging from ultramatte and high-gloss to deeply textured, fingerprint-resistant laminates. These materials are not only more visually striking but also more demanding to machine.

“Panel finishes have evolved significantly, with more customers demanding high-gloss, textured, or ultra-matte surfaces,” said Duane Marrett, Vice President of Marketing at Thermwood

Corporation. “These finishes are less forgiving and require more precise machining to avoid chipping, tear-out, or surface imperfections.”

This trend has driven a surge in demand for advanced cutting tools — especially compression spiral bits and diamond tooling that reduce edge fraying and surface damage. Coupled with next-generation CNC routers, these tools provide the delicate balance between aggression and control.

“Thermwood’s high-performance CNC routers, including the CabinetShop 43 and Cut Ready Cut Center, are engineered to meet these needs by providing the accuracy and tool control necessary to handle delicate, high-end finishes,” added Marrett. “These systems reduce the need for excessive sanding and rework, streamlining the overall production process.”

Perhaps the most impactful changes are being seen in the custom residential millwork sector. Custom cabinetry, trim, and built-ins often involve one-off parts, traditionally requiring manual measuring, programming, and cutting. Today’s tech changes that equation entirely.

“Custom residential millwork often involves highly detailed, made-to-order components, traditionally requiring extensive labor, manual programming, and long lead times,” Marrett explains. “Thermwood’s CabinetShop 43 Work Cell integrates intelligent nested-based CNC routing, automatic part labeling, and material handling to create an efficient, production-ready workflow ideal for custom cabinetry and millwork.”

That efficiency has massive implications, not only in reducing lead times, but also in simplifying labor. Shops that once relied on experienced programmers can now deploy intuitive systems that require minimal training.

“For shops looking to eliminate programming altogether,” Marrett continues, “Our AI-powered Cut Ready Cut Center allows users to produce custom cabinets through a simple touchscreen interface — no CNC experience required. Paired with modern 3D

rendering tools, these technologies enable a seamless transition from digital design to [the] finished product.”

The effects can be widespread: designers can visualize in 3D, clients can approve with confidence, and fabricators can go directly from concept to creation, faster and with fewer errors.

While CNC routing has long dominated panel processing, robotic automation is opening new doors, particularly when paired with 3D scanning.

“The affordability of 3D scanning has allowed for the introduction of new types of routing, i.e. routing with a robotic-mounted spindle,” says Joey Koenig, President of 7Robotics. “By being able to have accurate 3D models, automated programs can be more easily written to produce the part.”

This pairing allows for advanced contouring, shaping, and nonlinear routing that traditional flat-bed CNC machines struggle with. It’s a solution especially useful for architectural millwork, curved panels, stair components, and other non-standard geometries.

As machines grow more intelligent, so too does the information they can provide. Manufacturers are now moving into a new era where machine learning and real-time data acquisition play an increasingly vital role in operational efficiency.

25_004297_Surface_and_Panel_Q3 Mod: May 13, 2025 4:29 PM Print: 05/20/25 2:24:25 PM page 1 v7

Protect your precious cargo! From peanuts to padding, Uline has hundreds of cushioning items to fill your void. Order by 6 PM for same day shipping. Best service and selection – experience the difference. Call 1-800-295-5510 or visit uline.com

“We foresee that manufacturers will be able to get accurate and timely data around product defects, throughput bottlenecks and preventative maintenance,” says Koenig. “Robotic systems with sensors, cameras, 3D scanners and other sensing devices will help capture this data. Artificial intelligence can then interpret and make decisions as datasets expand.”

These insights allow manufacturers to anticipate problems before they become costly delays, optimize scheduling, and refine production parameters in real time. This creates a more agile, responsive factory floor — one capable of adapting to market demands with far greater precision.

So what does the future hold for tools and machinery in our industry?

“In the woodworking, cabinetmaking, and millwork industries, we’re seeing a clear trend toward smarter, more automated production,” says Marrett, who adds that systems like the Cut Ready Cut Center are only the beginning of what’s possible when machine intelligence and user-friendly interfaces converge.

“The machine’s built-in intelligence handles design, optimization, and machining, allowing even small operations to achieve high-end results with dramatically less labor,” he explains.

On the more industrial end of the spectrum, Thermwood’s CabinetShop 43 Work Cell continues to evolve as a fully integrated

solution, combining material handling, part tracking, and optimization within one seamless flow.

“Looking ahead, we anticipate even greater integration between design software, production data, and machine control,” says Marrett, “creating a more connected, responsive manufacturing environment that boosts productivity and flexibility.”

And it’s not just about speed or scale — it’s about empowering shops of all sizes to offer fully customized, made-to-order products with minimal waste and maximum quality.

Whether it’s ultra-matte panels that require delicate tooling or oneoff architectural features made possible through robotic routing, the surface & panel industry is embracing innovation at every level. Tools and machinery are no longer just equipment — they are intelligent collaborators in a fast-moving production chain. S P

Outstanding anti‑fingerprinting (Perfect Matt)

Remarkable colour depth

maintenance

Smooth, velvety touch

Highly scratch resistant

Heat resistant

UV light resistant

Manufactured in North America

BY DENISE WILLIAMS

We knew they were coming…and now they’re here. Boy, oh boy, are they ever here. The U.S. supply chain, including wholesale distributors, must now figure out how to navigate a challenging tariff landscape that is at once confusing, highly fluid, and starkly different from what the country has grown accustomed to over the last quarter of a century.

Crowe LLP Principal Dan Swartz, who specializes in global customs and duties, says that, to their credit, many companies recognized the writing on the wall and tried to prepare for the onslaught by beefing up capacity. “Among the companies that were reading the tea leaves during the summer of last year, when it became increasingly more likely that [Donald] Trump was going to win the election, there was a big push to bring inventory forward into the United States,” he observes.

Given the President’s longstanding and vocal pro-tariff

stance, Swartz gently scolds, this year’s swift policy action shouldn’t have caught anyone off guard. The same can’t be said, he concedes, for what has unfolded since.

While Trump’s campaign rhetoric laid the foundation for a potential 50-60 percent additional tariff on China, Swartz agrees no one could have predicted what he frames as a “gamechanging” escalation. Before a temporary suspension took effect on May 12, the levy had reached upwards of 145 percent — more than double what had previously been viewed as the worst-case scenario. The spike delivered a stinging blow against the backdrop of a “staggeringly low” effective duty rate for goods coming into the United States since the late 1990s/early 2000s. The culture shock from watching the needle accelerate from about 4 percent during that time to approach 15 percent only deepened the cut. Although the 90-day freeze extends some relief, what happens once that time runs out is anyone’s guess.

In the meantime, Swartz suspects, the temporary protection afforded by boosting capacity is slipping away from distributors that tried to get out in front of the chaos. “The challenge now

is that as inventory is being sold off in the market, it must be replenished — but at a much higher tariff rate,” he explains. “I think a lot of companies weren’t really prepared for that second step of dual-sourcing or near-shoring, and now they’re scrambling.”

From a supply chain perspective, pivoting to dual-sourcing and near-shoring is one of the first, natural, and most obvious responses to the new tariff climate. But Swartz assures there are additional levers that can be pulled for relief, depending on a company’s profile and circumstances. He explains a few here:

Lowering your effective duty rate. There may not be any way around paying a particular tariff that’s been imposed, but Swartz and other experts know there are ways to at least bring the cost down. For example:

• Duty Drawbacks. Companies that both bring in and send out goods may be eligible for refunds from the United States each time they export.

• First Sale for Export. Under the right circumstances, this provision can benefit a company with multi-tier transactions, Swartz says. Specifically, he elaborates, “you utilize the transaction between the manufacturer and the intermediary as the declared value for customs purposes, as opposed to using the transaction between the intermediary and the U.S. import buyer,” which has a higher value. Although companies will have to jump through some hoops to make this strategy work for them, Swartz says many are giving the option a hard look.

Exploring Foreign Trade Zone (FTZ) status. Numerous distributors have retained Crowe LLP to conduct cost vs. benefit analyses to support a decision to convert their business into a FTZ…or not. Once labeled as such, a space designated as an FTZ — whether a warehouse, factory, or other area — is treated as though it’s outside of the customs territory. Therefore, the company can bring in both domestic and foreign goods, with no duty liability to speak of until that merchandise exits the zone.

“We’re definitely finding monetary benefit for clients” as Crowe LLP performs these audits of import data, Swartz reports, although he acknowledges that the uncertainty of the situation in the future complicates the decision to move in this direction. Getting an FTZ up and running requires a lead-in time of 6-9 months and a financial investment of anywhere from $95,000-$185,000, he estimates; so while it may be on the table for some, it won’t be an ideal solution for every distributor.

Examining tariff classification. This next option is, however, applicable across the board. Building materials distributors are

particularly vulnerable to Section 232 tariffs, notes Swartz. He urges any firm that deals in steel, aluminum, or derivatives of steel or aluminum (but that hasn’t yet reviewed this information) to run — not walk — to ensure their classifications are accurate. If they aren’t, he warns that the correction could be costly for them by subjecting their products to tariffs.

These various tactics are hardly groundbreaking, Swartz points out — they’ve been available all along but the comfortable trade environment in recent decades effectively muted the need for them.

Nor is this list of recommendations exhaustive. In a National Association of Wholesale-Distributors (NAW) webinar on tariff policy that took place in April, some of the same strategies to reduce import value, embrace FTZs, and diversify supplier sources were mentioned; and additional potential solutions were highlighted as well.

The No. 1 move for distributors in the current tariff climate, according to NAW guest expert Edward “Eddy” Hayes, who leads the international trade and customs practice at Leake & Andersson, entails poring over contractual agreements with a magnifying glass. Whether they are basic terms and conditions or detailed supply and distribution agreements, he impressed that companies must proactively check contract language

and insist on clauses that protect their business. Specifics they should be looking at, he suggested, include:

• Material price escalation. Long favored by construction companies, Hayes noted that this clause is drawing a great deal of attention from the distributor community. It allows for a tariff adjustment in the event that the price of a key material moves above or below set thresholds.

• Country of origin Delving into customs classifications is key, Hayes underscored, and not just for importers. For example, he said, “If shipping components between multiple countries…it might be that you could get origination in a country that has a lower base tariff rate.” But companies must perform the due diligence to discover this information.

• Force majeure. Typically used during wartime or in the aftermath of natural disasters, Hayes suggested it might be worthwhile to test the boundaries of this clause, which provides an escape route from contractual obligations following an extraordinary event. Force majeure was in heavy rotation during the COVID-19 pandemic but, Hayes proposed, now might be a good time to investigate government action as a qualifying trigger for this clause.

Material price escalation and tariff adjustments have been largely underutilized among distributors but, according to Hayes, they’re part of the conversation now.

While consultants like Crowe LLP and industry groups like NAW are eager to educate the distributor community on what steps to take to minimize tariff-related pain, they also advise companies on what they definitely should not do.

In the NAW briefing, Hayes cautioned against continuing to rely on China for supply chain needs. Take a hard look at alternative sources, he recommended. Keep in mind, he reasoned, that although other countries may also be subject to reciprocal tariffs, they won’t be as high as they are for China.

Meanwhile, Swartz warns that, as they explore the different avenues to blunt the impact of tariffs, distributors and other companies must take care not to step over the line. Noncompliance, whether intentional or not, comes with steep penalties; and, from what he’s seen thus far, there’s likely to be focused attention on enforcement in the days ahead — particularly with respect to the USMCA (United States-Mexico-Canada Agreement). Customs and Border Protection is keenly aware of this trade pact increasingly doubling as an opportunity for fraud, Swartz says, and will be paying close attention to whether or not

goods qualify. And, he explains, eligibility typically hinges primarily on — you guessed it — tariff classification. More about trade compliance, as well as additional insights on valuation stripping, transfer pricing, and more, can be found in an article Swartz recently penned for Industry Today.

There’s no doubt that the tariffs unleashed by the Trump administration are causing growing pains for U.S. commerce. But, Swartz emphasizes, the experience should make American companies stronger going forward. The takeaway, particularly for distributors, he suggests, is that “we have lost our sense of how to navigate around a lot of these trade issues because we’ve been in a virtual free-trade environment for so long. Now companies are having to pay attention to things like classifying goods under the tariff, investigating what sort of valuation opportunities there are to try to reduce import value, contemplating becoming FTZs, and utilizing duty drawback for recovery.”

Experts agree, today’s turmoil is a reminder for distributors to keep U.S. tariff structure on their radar regardless of the policy climate at any given time. “Good practice says to pay attention to these things year-round.”

The current struggles, he continues, should raise a red flag for companies that now is the time “to reinvest in duty management, by having either consultants or staff who are knowledgeable on tariffs and duty issues and by looking holistically at the supply chain and seeking opportunities to recover duty, mitigate duty, or even defer duty.”

Indeed, experts agree, today’s turmoil is a reminder for distributors to keep U.S. tariff structure on their radar regardless of the policy climate at any given time. “Good practice says to pay attention to these things year-round,” Hayes said during last month’s NAW webinar.

Adapting to the new reality is critical for those who want to remain competitive, according to Swartz. He’s confident that tariff rates will eventually come down but insists the “laissezfaire” days of trade with America are in the past. “We’ve gone from being your local bar where anybody can walk in to now we’re a club and we’re charging a cover to get in,” he offers as a colorful analogy. “We’re not going back to being a local bar again.” S P

Denise Williams is the Editorial Senior Manager at the North American Building Material Distribution Association. Visit www.nbmda.org for more information.

Designed and assembled in Austria, Dynapro undermount slides set the standard for superior running performance, silent operation, and effortless motion. Its internal, synchronized rack and pinion system and multiple front-locking device options make it the smoothest and most versatile slide on the market.

Give your cabinetry the best with Dynapro. www.grassusa.com

BY KEITH CHRISTMAN

Homeowners and interior designers have long valued the aesthetic appeal and versatility of hardwood products. Among the preferred choices are hardwood plywood, hardwood veneer, and engineered wood flooring. Each of these materials offers distinct advantages, making them suitable for various applications within home interiors. Let’s examine the characteristics, benefits, and optimal uses of these three hardwood products.

Hardwood plywood is a type of plywood in which the surface and back veneers are made from hardwood species such as oak, maple, cherry, and walnut. The inner layers may

consist of softer wood species or engineered wood. Hardwood plywood is noted for its strength, stability, and natural beauty. Hardwood plywood made in the United States is generally manufactured to meet the American National Standard for Hardwood and Decorative Plywood (ANSI/HPVA HP-1-2024).

ANSI/HPVA HP-1-2024 is the North American consensus standard for hardwood plywood and decorative plywood. It details the specific requirements for all face, back, and inner ply grades as well as formaldehyde emissions, moisture content, tolerances, sanding, and grade marking. HP-1-2024 establishes marketing classifications and includes veneer grading tables. Hardwood plywood in the U.S. is also made from abundant wood sources. The volume of U.S. hardwood growing stock increased by more than 130 percent from 5.2 billion in 1953 to 12 billion cubic meters in 2012.

Characteristics and Advantages

• Durability: Hardwood plywood exhibits high durability due to the quality of the woods used and the meticulous manufacturing process. The cross-grain construction of the core layers enhances its strength and minimizes the risk of warping.

• Aesthetics: The surface veneers of hardwood plywood display the natural beauty of hardwood, providing a rich and sophisticated appearance.

• Versatility: Hardwood plywood can be utilized in a broad range of applications, including cabinetry, furniture, wall paneling, and architectural millwork.

• Environmental Benefits: The use of hardwood plywood can be more environmentally sustainable than alternative materials. Wood products through photosynthesis of growing trees absorb carbon dioxide from the atmosphere and store it in the wood structure for decades while in use.

Optimal Uses in Homes

• Cabinetry: Hardwood plywood is an excellent choice for kitchen and bathroom cabinets due to its strength and beautiful finish that can be stained with lighter or darker finishes or even painted if desired.

• Furniture: Many high-quality furniture pieces are crafted from hardwood plywood, offering both durability and an appealing appearance.

• Wall Paneling: Hardwood plywood can add warmth and sophistication to living spaces when employed as wall paneling.

Hardwood veneer is composed of thin slices of hardwoods. Hardwood veneer is an economical way to use a smaller amount of beautiful hardwoods to cover a surface. There are a wide range of veneer species available from the United States and around the world. Species include oak, walnut, hickory, cherry, alder and many more. Different visuals can be accomplished by selecting different cuts including rotary cut, plain sliced, quarter sliced and others. The Decorative Hardwoods Association Veneer Guide is an excellent source of information and inspiration and is available on DHA’s website.

Optimal Uses in Homes

• Furniture: Veneered furniture pieces are popular for their elegance and affordability.

• Doors: Interior doors with hardwood veneer can enhance the aesthetic appeal of any room.

• Wall Panels: Veneered wall panels are a stylish option for both modern and traditional interiors.

Engineered wood flooring is constructed from several layers of wood, with a hardwood veneer on top and a core of

high-density fiberboard or plywood. This construction method offers stability and resistance to environmental changes. Engineered Wood Floor is typically manufactured in the U.S. to the American National Standard for Engineered Wood Flooring (ANSI/HPVA EF 2020). ANSI/HPVA EF 2020 is the North American consensus standard for engineered wood flooring. The standard includes grade descriptions, test procedures, and requirements for veneer thickness, machining, moisture content, and finishing.

• Stability: Engineered wood flooring is less likely to expand, contract, or warp due to temperature and humidity changes, making it suitable for various climates.

• Ease of Installation: Many engineered wood floors feature click-lock systems that simplify installation, even for do-ityourself enthusiasts.

• Aesthetic Appeal: The top layer of hardwood veneer provides the natural beauty of solid hardwood flooring.

• Sustainability: Engineered wood flooring is a climate responsible choice. In fact, the USDA recently completed a Life Cycle Assessment of engineered wood flooring and reached the following conclusion “This study showed that engineered wood flooring can be considered a carbon-negative material that stores carbon (22.85 kg CO2eq/m2 flooring) for decades and thus can help to mitigate climate change.”

• Living Areas: Engineered wood flooring is ideal for living rooms, dining rooms, and bedrooms due to its aesthetic appeal and durability.

• Basements: Its resistance to moisture makes engineered wood flooring a suitable choice for below-grade installations.

• Kitchens: The stability and ease of maintenance of engineered wood flooring make it a practical option for kitchens.

In conclusion, hardwood plywood, hardwood veneer, and engineered wood flooring each offer distinct advantages for home interiors. Whether aiming for durability, cost-effectiveness, or environmental sustainability, homeowners can select the appropriate hardwood product to enhance the beauty and functionality of their living spaces. Suppliers of these products can be found in DHA’s 2025 Where to Buy guide. Thousands of designers, specifiers, end-users, architects, and woodworkers use the Where to Buy Membership Directory to find hardwood plywood, engineered wood flooring, and veneer. S P

Keith Christman is president of the Decorative Hardwoods Association, formerly known as Hardwood Plywood and Veneer Association. He welcomes your thoughts and questions at kchristman@decorativehardwoods.org. www.decorativehardwoods.org

BY SUSAN PALÉ

For many managers and supervisors, talking with employees about their pay ranks right up there with a root canal on the misery scale. Those conversations have never been easy, but as wage growth slows and prices for just about everything increase regularly, pay becomes increasingly important to your employees.

For some context, Pew Research Center conducted a survey of over 5,000 employees in late 2024 to gather their input about their pay. The key findings include:

• 50 percent of surveyed employees were extremely/very satisfied with their pay

• 38 percent were somewhat satisfied

• 12 percent were not satisfied

On the surface, that looks like good news for employers. But scratching below the surface finds this:

• 76 percent of surveyed employees believe they regularly go “above and beyond” in performing their jobs

• Two-thirds of those who were somewhat satisfied with or not satisfied with their pay feel that their pay does not reflect the work performed

• And 69 percent of the above group report that they struggle to pay bills. Employees at all levels — not just those in entry or low-pay positions — participated in the survey

There are many similar surveys and information available, but a key takeaway is that employees care about their pay and want to be paid fairly. That means communicating regularly and effectively about compensation.

Unfortunately, there isn’t a 10-step guide to make this easy. But there are things you can do to improve the process.

Your compensation policies and procedures should always be documented and communicated. This doesn’t have to be complicated — you may not need salary grades and ranges — but you should have written information about how pay and pay raises are determined. When are employees eligible for increases? How are these increases determined (e.g., pay for performance, cost of living, profit sharing)? Is market information used to determine the increase amount? Are there additional increases employees may be eligible for?

Collecting and updating market information is important to remaining externally competitive. This can be a relatively straightforward task if all your employees work in a single location, but as you expand to multiple locations and hire remote employees, collecting relevant market data becomes increasingly critical. For example, average pay for corporate accounting positions in the New York City metro area is 36.5 percent higher than the national average; average pay in Mobile, Alabama, is 14 percent lower than the national average.

It’s common for new hires to demand — and get — salaries that are higher than those of current employees doing similar work. Often, employees who have been in the same role for a long time are paid at or above market rates and aren’t eligible for the same increases as newer employees. These situations create what is known as salary compression and make pay discussions about internal equity even more difficult.

You may also be subject to legal requirements when talking to your employees about pay. Twelve states and the District of Columbia now have some type of pay transparency law, and another 13 states are considering this legislation in 2025. The laws vary and are complex, but the common requirement that employers list salary ranges on job postings often results in employees finding out about pay ranges for their positions by seeing a job posting on ZipRecruiter or Indeed.

All of the above information serves as the foundation for a discussion about pay. If you are a manager or supervisor, be sure you understand this context before you sit down to talk with your employees. And when it’s time for the discussion, keep these four things in mind.

1. Clearly communicate the pay decision and the rationale behind it.

This is absolutely critical. If an employee isn’t getting an increase because of poor performance, say so. Then discuss what needs to be done to improve performance and when the employee will be eligible for an increase.

The most difficult discussions are often with employees who feel they go “above and beyond” (the 76 percent in the Pew survey mentioned above), but are paid at or above market. In these discussions, it’s important to acknowledge the employee’s contribution, but explaining why no increase or a small increase will be given is just as important.

2. Don’t negotiate — ever.

If you’ve made a pay decision based on employee performance within the company’s policies and procedures framework, that’s it. As pay transparency increases, employees may know the salaries of others and want to discuss them. They may also have salary information from online sources and want to use those numbers to discuss and negotiate.

Don’t get involved in these discussions. Your job is to clearly communicate the pay decision and that the decision is final.

3. Listen.

It’s hard to listen when you’re in the middle of a difficult discussion, but listening is important. Listening helps you understand the employee’s perspective of their performance and pay, and can also provide additional information helpful to both of you. Employees may need additional training or experience to improve their performance. They may not have the equipment or information needed to fulfill their job requirements. They may want to know what is needed to be considered for promotion. As a manager or supervisor, these are issues that you can sometimes — not always — resolve.