YARDSTICK

The Dollar Divide: What USD/CAD Movements Mean for Canadian Industry

135 Years in the Making. Forging the Future in One Night 73

Find New Ideas and Valuable Insights at the 2025 Hardlines Conference 76

From Legacy to Leadership: The Rise of Home Hardware’s Next Generation

Liz Kovach

Supply-Build Canada President

Jordan Bouchard

Data Entry Administrator

Brenda Bourns

Events and Community Engagement Manager

Amanda Camara Vice President of Business Development and Marketing

Rebekah Doerksen

Executive Assistant

Camilla Josef Online Marketing Coordinator

Matthew Lucek Workforce Development Coordinator

Alisa Luo Design and Social Media Coordinator

Travis Waite Director, Finance and Administration

Amanda Wright Workforce Development Manager

Published June 2025

The Supply-Build Canada Yardstick is the official publication of the Supply-Build Canada and is published four times per year. It is mailed to all retail and associate members of the Supply-Build Canada, to retail lumber dealers and others in the building supply industry in Northwestern Ontario, Manitoba, Saskatchewan, Alberta and British Columbia, and to selected dealers in the Yukon, Northwest Territories and Nunavut. Views expressed in the Yardstick are not necessarily official Supply-Build Canada policy, nor does the publication of product information or any advertisement imply recommendation by the Supply-Build Canada. No part of this publication may be reproduced in any form without the written consent of the Supply-Build Canada.

Subscription rates in Canada: $12 per year, plus applicable taxes. Outside Canada: $15 per year, no tax. Rates quoted are for non-members only.

Canadian publication mail agreement #43754013. Postmaster send change of Canadian address to:

102-226 Osborne Street North Winnipeg, Manitoba R3C 1V4 Phone: 204-560-8235 Toll Free: 1-800-661-0253 Fax: 204-947-5195 supplybuild.ca

To our members, partners, and friends,

Resilience has always been part of our DNA—as Canadians, as business owners, and as an industry that never stops moving, even when the road gets rough. This issue of Supply-Build Canada’s Magazine is dedicated to that very spirit: Canadian resiliency. It’s the spirit that shows up no matter what: record snowfalls, tight margins, shifting policies, and a market that doesn’t come with guarantees. This is the spirit that keeps our industry building.

Over the past year, we’ve seen resilience in action across the country. From independent retailers navigating labour shortages and supply chain bottlenecks, to manufacturers innovating under pressure, to the day-to-day grit of teams showing up and getting the job done—it’s clear our industry doesn’t just adapt; we lead.

But leadership requires more than hard work. It demands a voice. That’s why advocacy continues to be at the heart of our mission at Supply-Build Canada. Whether we’re meeting with policymakers about housing affordability, skilled workers, or supporting small business, our message is clear: our members are essential to Canada’s economy.

We’re telling your stories across the border, in provincial capitals, and on every platform we can find. We’re investing in stronger research, clearer messaging, and more unified action to make sure your stories affect policy change.

“Success is not final, failure is not fatal: it is the courage to continue that counts.”

—Winston Churchill

This issue also marks a milestone for our organization. As you’ve seen, we’ve officially rebranded from the Western Retail Lumber Association to Supply-Build Canada. It’s a name that better reflects the scope, scale, and future of who we are. It honours our roots in the West but recognizes that our work, influence, and community stretch far beyond.

This isn’t just a new name. It’s a recommitment to serving our members with even greater focus, across every region, every segment, and every challenge we face together.

As we look ahead, we’re building on the foundation you’ve helped us lay: a stronger, smarter, more connected industry from coast to coast to coast.

We’re proud to be in your corner.

We’re proud to represent you.

Liz Kovach PRESIDENT, SUPPLY-BUILD CANADA

Amanda Camara, VP of Business Development & Marketing

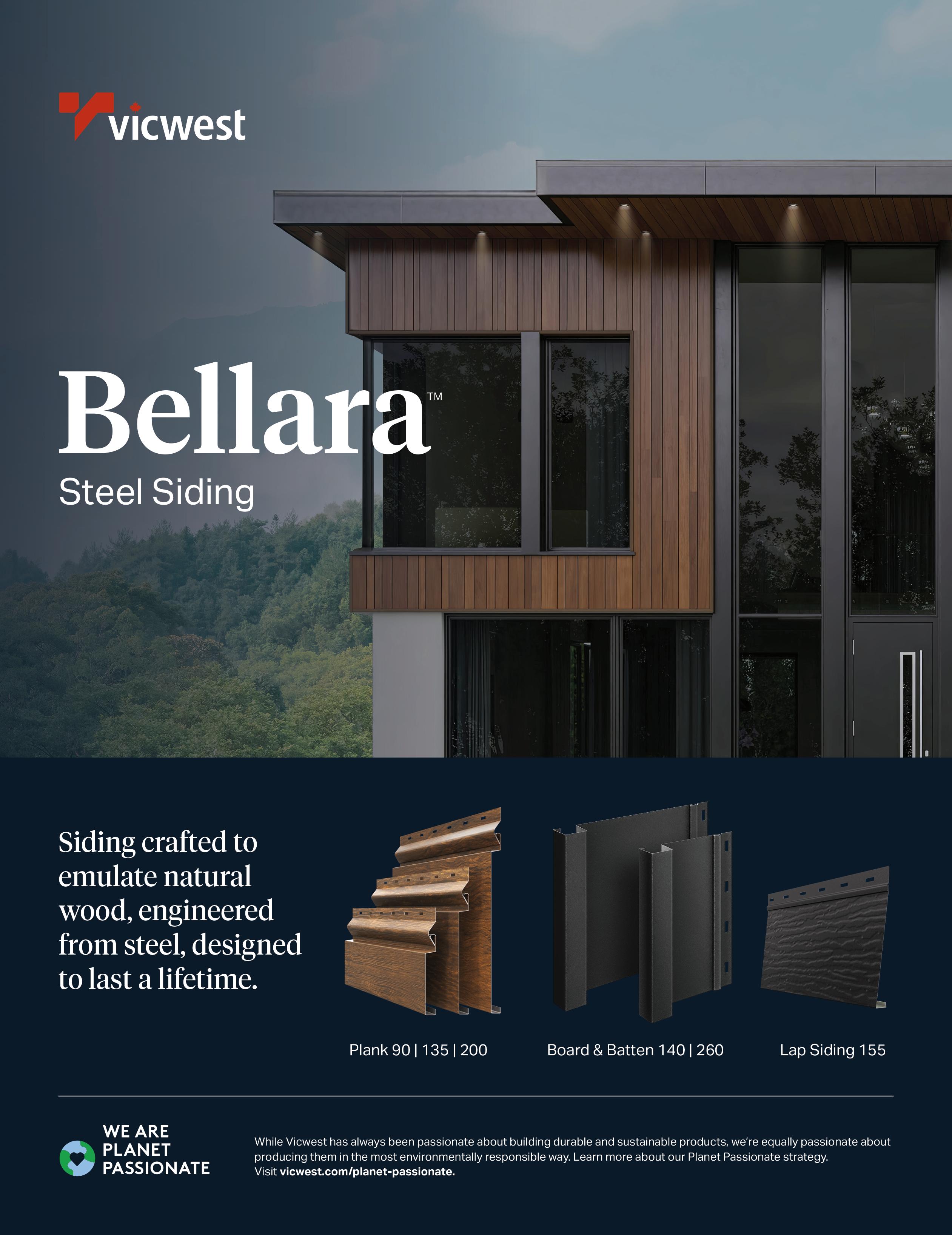

As Canadians face rising costs, inflation, and the impacts of foreign tariffs and duties, one thing is clear: investing in our own economy has never been more important. For the construction and home improvement sectors, that begins with who we choose to support.

Independent building supply retailers are not just a practical choice— they are a strategic investment in Canada’s economic health. These Canadian-owned businesses are deeply rooted in their communities. They offer personalized service, quality products, and the kind of local commitment that can’t be matched by big box or foreign-owned corporations.

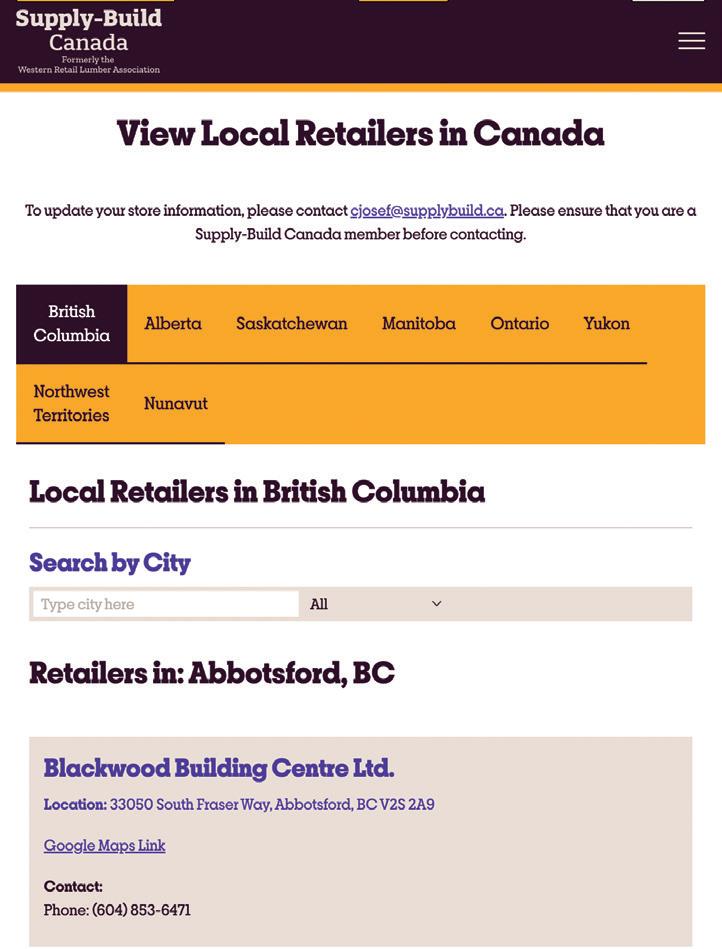

Through its Buy Local, Build Local campaign, Supply-Build Canada is calling on contractors, homeowners, and developers to think differently about where they shop. Backed by fresh data, strong partnerships, and national momentum, the campaign is helping Canadians understand the powerful economic ripple effects of buying local.

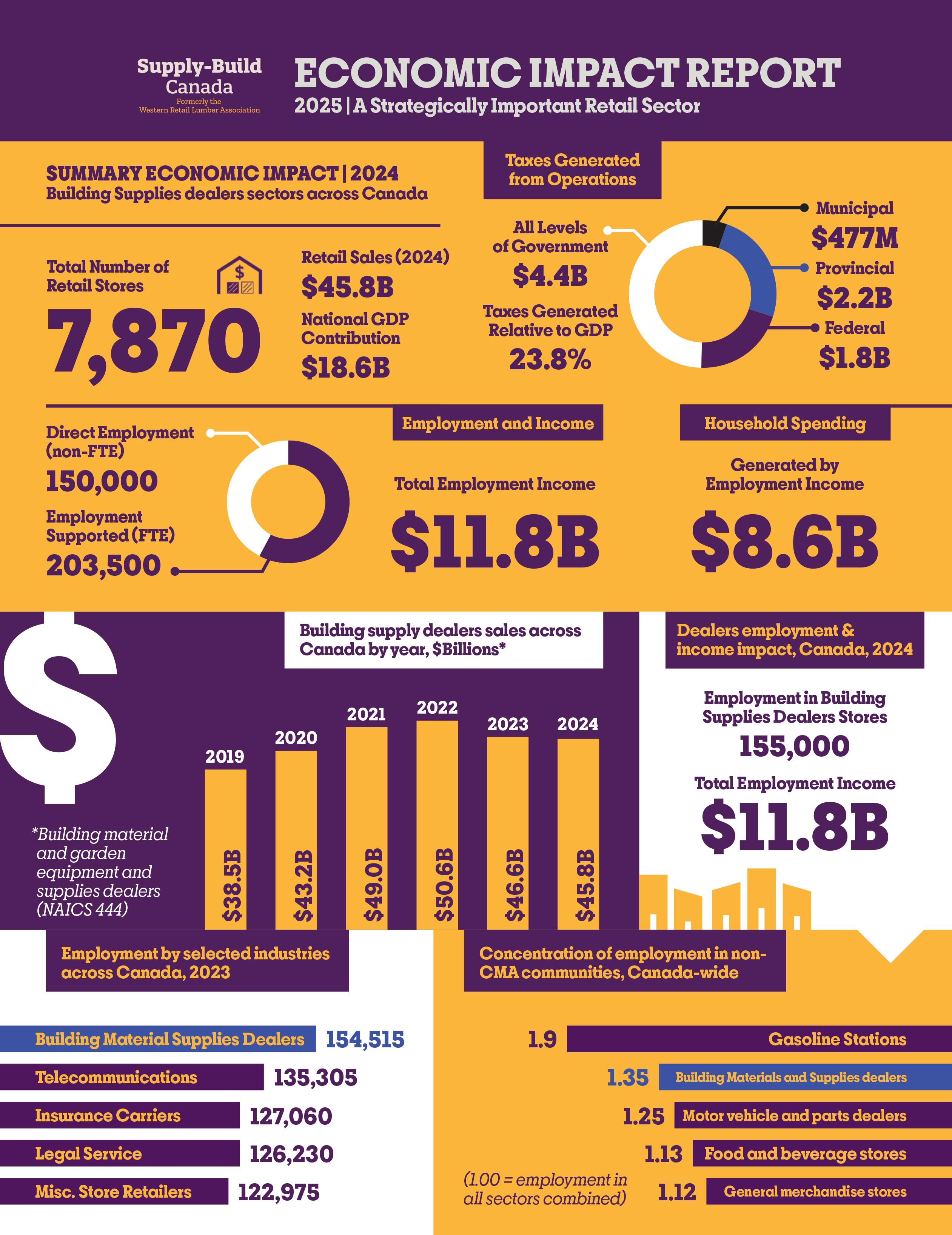

In 2024, Canada’s building supply dealer sector included nearly 7,900 stores employing 155,000 Canadians and generating $45.8 billion in sales. But that’s only part of the story.

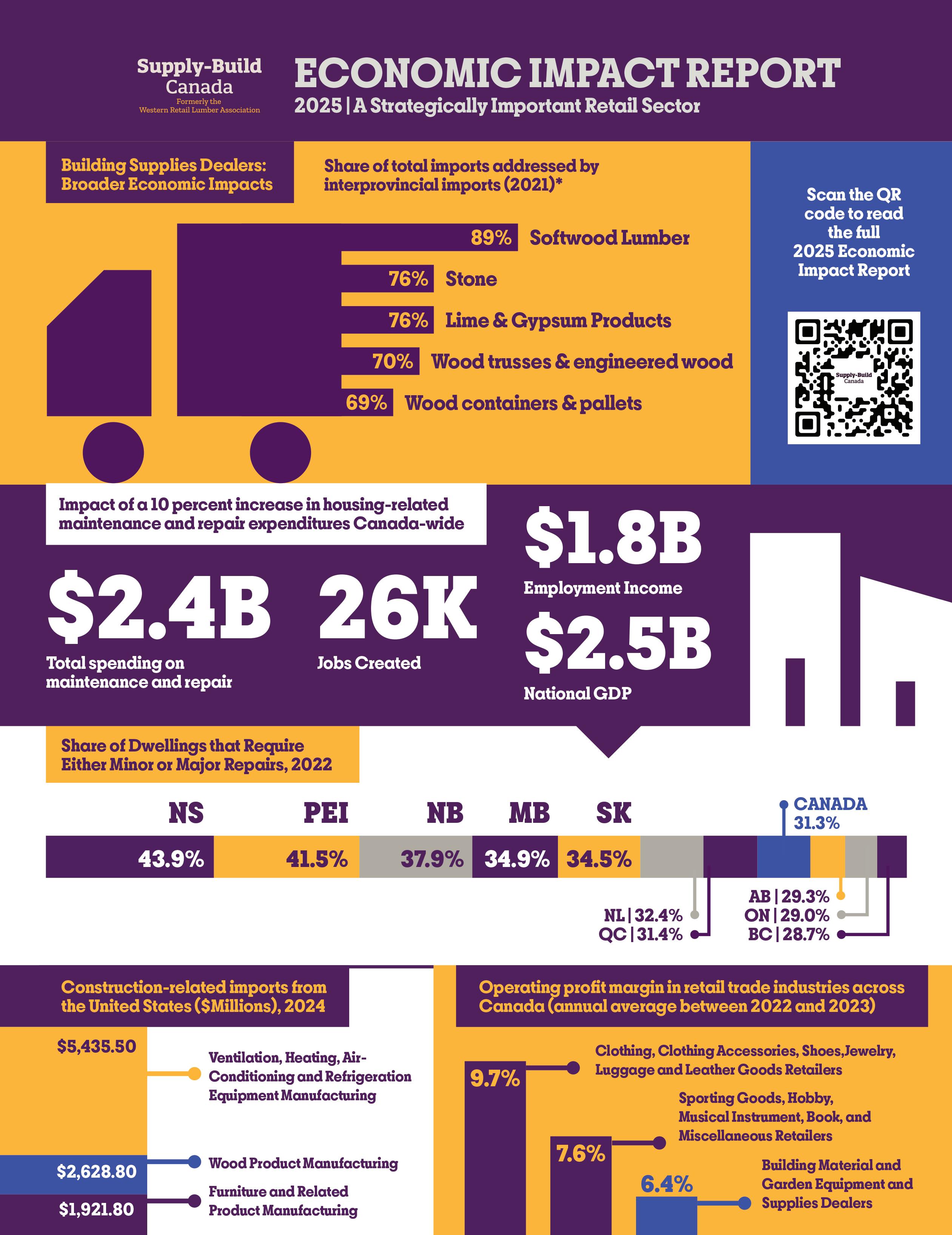

According to Supply-Build Canada’s 2025 Economic Impact Study, the operational expenditures of the sector contributed:

• $18.6 billion to Canada’s GDP

• $11.8 billion in labour income

• $4.4 billion in tax revenue

When indirect and induced effects are factored in, this sector supported 203,500 full-time equivalent jobs. The income generated by the sector also drove $8.6 billion in household spending, strengthening businesses across countless other industries. More than most retail sectors, building supply dealers source a higher volume of Canadian-made products— supporting thousands of jobs throughout domestic manufacturing and supply chains. This also has a greater impact on our GDP having a greater impact on our economy.

This is a sector that punches far above its weight. It’s a cornerstone of economic resilience.

The impact of buying local goes beyond economics—it reflects values. According to BMO’s Special Report on Buy Canadian: Measure the Benefits & Costs, behavioural changes in spending habits can have a measurable macroeconomic impact:

you support local, you support jobs.

“The ‘Buy Canadian’ movement is deepening, and recent years have taught us that behavioural forces matter in the economy. We judge that this shift in attitudes could add roughly $10 billion to the Canadian economy annually, lifting growth by 0.3 ppts (+/- 0.2 ppts).” —Robert Kavcic, Senior Economist and Director of Economics, BMO

This insight reinforces the reality that small decisions—like where to buy building materials—can have large-scale consequences. When Canadians choose to support independent dealers, they’re not just investing in quality—they’re investing in Canada.

To push this message further, Supply-Build Canada has launched a cross-country campaign to encourage buying local. The campaign includes:

• A retailer locator tool at supplybuild.ca/shop-local.html

• Partnerships with Home Builder Associations across Canada

• A national digital and LinkedIn advertising campaign

• A press release and a series of media interviews with President Liz Kovach

“These aren’t just businesses,” says Kovach. “They’re employers, community leaders, and industry innovators. Supporting Canadian-owned building supply dealers is one of the most tangible and impactful ways to fuel our economy and our communities.”

Independent retailers like Home Hardware, RONA independents (non Rona+ stores), and TIMBER MART dealers are woven into the fabric of communities. Many are multi-generational family businesses. They sponsor youth sports teams, support local causes, and help rebuild after storms and fires. These stores also provide thousands of first jobs—and long-term careers—to Canadians in towns and cities across the country.

The Buy Local, Build Local message is simple: when you support local, you support jobs. You support Canadian manufacturers. You invest in your community. And you contribute to national prosperity.

As the economic landscape continues to shift, it’s up to all of us—homeowners, contractors, and businesses—to choose where our dollars go. With every purchase, we have the power to build a stronger, more self-reliant Canada.

Start now at supplybuild.ca/shop-local.html

Email us at marketing@supplybuild.ca or reach out via social media.

AD reports that member sales in the first three months of 2025 increased 23 per cent to a record $24 billion across the group’s 14 divisions and three countries.

AD welcomed over 550 new members in the first quarter through both organic growth and the IMARK Electrical merger. AD members also acquired another 10 companies outside of AD.

Same-store sales increased by 2 per cent in the U.S., 2 per cent in Canada, and 3 per cent in Mexico, in their respective currencies. Within AD’s nine industries, same store growth in Plumbing, PVF and HVAC were the most robust. Member purchases from AD suppliers grew 19 per cent.

Affiliated dealers, vendors, store managers, professional services and company leaders will gather in October for the first edition of this new event

RONA is proud to announce the launch of RONA Momentum, a large-scale event that will merge its four key annual meetings: RONA Connexia, the Vendor Forum, the annual Store Manager Meeting, and the Pro services team meeting. From October 14 to 16, 2025, the first edition of RONA Momentum will bring together over 1,400 participants at the Québec City Convention Centre

Participants will come together for three days of conferences, exhibition, workshops and celebrations that will provide them with an opportunity to network, to align themselves with the RONA network’s priorities, and, more importantly, to discover and learn about products offered by hundreds of vendors.

Manugypse, a TIMBER MART member with three locations in the province of Quebec, has been named one of Canada’s Best Managed Companies. The program awards excellence in private Canadian-owned companies with revenues of $50 million or greater.

“We are honoured to receive this recognition for our team’s hard work, passion and dedication towards our customers’ satisfaction and innovation in interior systems,” says Steve Rancourt, CEO of Manugypse. “Our business has grown exponentially since our inception in 1983 from one facility to three that serve contractors and builders across the Greater Montreal, Quebec City, and Chaudière-Appalaches markets.” Manugypse is a commercial dealer specializing in interior systems.

Home Hardware is proud to recognize a remarkable milestone at Coutts Home Hardware in Forestburg, AB, where longtime employee Jim Anderson has been awarded with their most prestigious honour: the Golden Hammer Award.

The Golden Hammer Award is reserved for team members who have dedicated 50 years of service to Home Hardware. It is a rare and meaningful achievement that celebrates loyalty, commitment to community, and an unmatched level of product knowledge.

Jim’s dedication has helped build not just a strong business, but a trusted community hub in Forestburg.

We are incredibly proud to celebrate this milestone with Jim and the team at Coutts Home Hardware

AD is pleased to announce that effective May 12, 2025, EPCOR Building Supply Inc. joined AD as a new Building Supplies—Canada member

Retail sales increased 0.8 percent to $69.8 billion in March, StatCan reports. Sales were up in six of nine subsectors and were led by increases at motor vehicle and parts dealers. Core retail sales rose by 0.2 percent, a second consecutive monthly gain, led by a 2.6 percent sales increase in LBM and garden categories.

• Q1 2025 operating loss of $29 million; shareholder net loss of $31 million, or $0.26 per share.

• Increase in North American lumber prices through Q1 2025 driven largely by supply constraints amid rising global economic and trade uncertainty; improved results from Western Canada following rationalization in 2024, combined with another quarter of solid earnings from Europe.

• Improved results for Canfor Pulp as global softwood pulp market fundamentals saw modest improvement early in the quarter.

Scan the QR Code to learn more.

On the heels of the landmark announcement granting VISTA exclusive distribution rights across Canada for Outdure’s innovative deck framing solutions, we are pleased to announce the addition of Joe Jacklin, in the newly created position of National Sales Development Manager for our OUTDURE product line.

Vista is also pleased to announce the promotion of James Scott to National Sales Manager, Dwayne Walser to Sales Manager, Ontario and Carol Mussi to Marketing Manager.

The formerly named Building Products of Canada will now be known as BP Canada (see new logo, pictured), as the Montreal-based company celebrates its 120th anniversary. The company has passed through various owners in its existence—and in the 1960s and 1970s was owned by oil company Esso. In September 2023 it was acquired by Saint-Gobain, the international conglomerate that designs, manufactures, and distributes building materials. BP is now part of a large group, in this country, that includes CertainTeed, Kaycan, and Bailey Metal Products.

Econo Lumber has always prided ourselves on being a customer centred business. If you want it, we’ll probably have it in stock. We started as an 850 sqft store in 1970. Today, we’re sitting on almost 100,000 sqft of showroom and warehouse space. We have always been working to better our customer experience, and we knew the next step forward would be revolutionizing the way we display our product. That’s why, in the spring of 2022, the three owners of Econo Lumber, Curtis Lemieux, Cody Lemieux (his son), and Angelo Minier began to plan a new addition to our store.

Planning and designing of the prints took about 8 months until we were happy with the design. We broke ground in May of 2023 on our 14,000 sqft display room expansion, now known as the Design District. After a year of work, the structure was up and finished on the outside.

Then the fun part began—designing and planning our little village and bringing our dream into reality. This part took about 14 months to complete. We wanted to design a center that took the hard parts out of picking the finishing aspects of a project. No more standing in an office looking at a desk full of 5" wide samples, trying to pick the right flavour. Instead, the walls of our Design District are covered in large scale displays—4 brands of siding, with all stocked colours, 90 different stone samples, as well as all of our current and stocked shingles.

This room feels welcoming as soon as you walk in. We have 6 fully finished miniature houses (offices for our salespeople) with all of the most commonly chosen finishes in our area. We have put down turf, flowerbeds, and even full sized trees, address plates for the offices, and even a “man cave” garage. When you’re in the Design District, you get the full effect of walking down a street—there’s even a small sea can diner that serves breakfast and lunch for 4 hours a day. The room is even equipped with a kid’s zone to help make mom and dad’s job just a little bit easier while they make their decisions with the salespeople.

Manugypse, a TIMBER MART member with three locations in the province of Quebec, has been named one of Canada’s Best Managed Companies. The program awards excellence in private Canadian-owned companies with revenues of $50 million or greater.

“We are honoured to receive this recognition for our team’s hard work, passion and dedication towards our customers’ satisfaction and innovation in interior systems,” says Steve Rancourt, CEO of Manugypse. “Our business has grown exponentially since our inception in 1983 from one facility to three that serve contractors and builders across the Greater Montreal, Quebec City, and Chaudière-Appalaches markets.” Manugypse is a commercial dealer specializing in interior systems.

(Article sourced from hardlines.ca)

Home Hardware is proud to announce that Dauphin Home Hardware has been recognized as Best Home Hardware—Western Region at the 2024 Proud of My Home Achievement Awards!

Owned and operated by Mark and Whitney Odut, this family business has been a cornerstone of the Dauphin community for over two decades. Through multiple expansions and renovations, Mark and Whitney have transformed their store, while remaining focused on serving the community and improving the lives of the people of Dauphin.

Congratulations to Countryside Home Building Centre—Fisher Branch on their selection as the Best Home Building Centre—Western Region at the 2024 Proud of My Home Achievement Awards!

This award celebrates the store’s commitment to providing exceptional customer service, meeting the needs of the customers, and being an active part of the community. Thank you to Dealer-Owners Clinton Plett, Evan Plett, and Matt Steiner - and their dedicated team—for their hard work and commitment to excellence.

Congratulations Dustin Chalus, Dealer-Owner of Richardson’s Home Hardware in Nipawin, SK, for being recognized as the Best Young Retailer—Western Region at the Proud of My Home Achievement Awards!

Dustin’s dedication to excellent customer service, community engagement, and innovation within his business exemplifies the values that set Home Hardware apart.

We are proud to see the next generation of independent retailers like Dustin leading the charge in delivering exceptional service and making a real impact in their communities.

• Memorial Home Hardware Building Centre

• Whitehorse Home Hardware Building Centre

• Kaslo Building Supplies

• Avo Solutions

• Wipeco Industries

• Sparks Golf Star

• Westview Co-operative Association - Olds

• North Pole Trim and Supply Ltd

• Moneris

• Acuity Marketing - Custom Branded Merch

• Cochrane Home Hardware Building Centre

• Monaghan Lumber Specialties

One of the major challenges in advocating for our industry is that local, national, and global forces can all have big impacts on our members. So where do we focus?

For us, it all starts with member consultation: you tell us where your pain points are, and we work on connecting with the legislators that can make a key difference.

One such consultation point recently was our AMEX Industry Insights Dinner in Winnipeg, where our members shared about the many things that impact business: from trade with the US to local planning and permitting boards.

As a result of what we’ve heard from members, Supply-Build Canada is focusing on a few key priorities:

• Asking the Federal Government to include Softwood Lumber in the upcoming CUSMA negotiations.

• Combatting misinformation from US lumber lobby groups regarding Canadian softwood lumber.

• Asking Provincial Governments to break down interprovincial trade barriers.

• Working with Provincial and municipal bodies on reducing zoning red tape.

The softwood lumber file is large and complex, and very much on our radar as we met with the Western provincial governments in May. Though this is an issue negotiated at the federal level, provincial governments each have a representative on the Canadian Council of Forest Ministers.

We raised the issue with all four Western provinces as one that will affect building supply and lumber pricing across the country, both this summer and into the future. The more provincial voices calling on the Prime Minister to take up the softwood lumber dispute directly, the more likely it will be to get a deal in place. B.C. Minister of Forestry Ravi Parmar affirmed that the last time a Softwood Lumber Agreement was in place was a result of it being a high priority on the Prime Minister’s desk.

With preliminary review of Canada-United States-Mexico Agreement (CUSMA) beginning this summer ahead of the renewal in 2026, SupplyBuild Canada headed to Washington, D.C. in June with the Canadian Chamber of Commerce’s North American Security Mission. Thanks to many conversations with members, provincial officials, and Global Affairs Canada, our goal was clear: secure a stronger position for Canadian lumber and wood products in the next iteration of the agreement. The current duty structure is unsustainable, and a unified voice is needed to shape fair trade outcomes for our members.

Ahead of our trip to the US, we commissioned an economic impact study of Canadian softwood lumber and created an info sheet to leave

with officials and begin combatting the misinformation spread by the US Lumber Coalition. We have further work to do on this front, with an awareness campaign currently in the works.

In the meantime, while we wait for a renewed CUSMA or softwood lumber agreement, Canadian mills and remanufacturers who sell on both sides of the border are under extreme pressure from current duties, and we will likely many businesses shutter and feel the impacts on both the stability and pricing of our lumber and manufactured wood product supply.

In addition to looming threats to a major building commodity, our members face challenges at the local and provincial level. That’s why we also spoke to all four provincial governments about challenges with local planning boards and how building codes are applied.

We also spoke to zoning issues and barriers to home construction, interprovincial trade barriers, our supply chain, trucking and rail service to member locations, and developing the workforce for the industry. Our Economic Impact Report (see page 20) helped us state the importance of our industry to the Canadian economy and underline the fact that an investment into the industry is an investment that brings high quality jobs and stable building supply for all Canadians.

Different provincial governments had different approaches to the issues we raised. Alberta, for example, has a ‘Minister of Red Tape’, who was interested in hearing from our members about regulations or planning boards that are getting in the way of moving building forward. And, as Alberta is currently one of the most restrictive provinces with respect to zoning and building codes, this is a much-needed position.

To address the gaps in building code alignment municipally, we have formed a Technical Committee to advise government on issues of building codes and zoning. The committee includes architects, retail members, and manufacturers.

While we were visiting each province, we strengthened our relationships with Alberta and Saskatchewan, who each have invested into workforce development with grants to Supply-Build Canada’s recruitment, onboarding, and educational programs in the past year. We also gave B.C. and Manitoba the opportunity to step up and invest in the industry. Both were interested in our work with Let’s Go Build, and we will be submitting a funding proposal to Manitoba in the coming months.

The work continues on all fronts, and your needs remain at the centre. We continue to ask members to keep us informed on the issues that affect you. Please send your comments to advocacy@supplybuild.ca.

What a start to the year. We’ve come through the “COVID years,” followed by a period of high inflation and rising interest rates. This has exacerbated our housing shortage as we failed to keep pace with our growing population. As a result, Canada is poised for what could be a golden era in residential construction, as we work to meet the pent-up demand and restore housing affordability to historical norms.

Unfortunately, as I write this in mid May, this demand remains largely unreleased due to several factors—chief among them being a major shift in U.S. policy toward international relations and trade.

This change in U.S. policy is arguably one of the most significant in generations. Its outcome and even its intended goal—remains unclear. However, it is unlikely, perhaps even impossible, that we will return to our previous level of economic integration. The United States has taken a turn away from globalization, moving toward a more isolationist stance. Given the depth of economic ties between Canada and the U.S., this shift presents a major challenge for our economy.

Canada will need to adapt. The extent of that adjustment depends on how long this period of uncertainty lasts and what the U.S. ultimately aims to achieve. In any trade war, all sides experience short-term losses. Yet when a new economic structure eventually emerges, it will create both winners and losers.

For Canadian lumber and building supply producers—many of whom rely heavily on U.S. trade—it’s difficult to see a positive outcome in the current environment. U.S. tariffs and duties are designed to reduce demand for Canadian exports and promote domestic American production. While there are limits to how quickly and how much the U.S. can onshore its supply, any shift will reduce demand from Canada and negatively impact our producers.

Canadian lumber producers are already facing average duties of 14.54 per cent and this rate is expected to more than double again within a few weeks. This increase alone will continue the recent trend of mill curtailments and closures in Canada. US tariffs including possible industry specific tariffs would further heighten the issue and directly impact producers of other products as well.

Price for wood commodities are also being affected by the impacts on demand. The uncertainty around the Canada—US relationship and the trade war are constraining home purchases, improvements and repairs. This will continue until a better sense of the long term is available. Production cuts will help support prices but until demand rebounds, prices will likely stay depressed.

As for who the long-term winners and losers will be in the face of these shifts? Time will tell. But there is good reason to believe that residential construction will be among the winners. Given housing’s central role in our economy, the government’s renewed focus, and the persistent housing shortfall, construction has the potential to drive our growth once we emerge from this period of uncertainty.

To position yourself for success, stay close to your customers, collaborate with your suppliers, align with a buying group that advocates for you, and continue to work with Supply-Build Canada to hold governments accountable for their promises. These actions will increase your odds of emerging stronger in the new economic landscape.

If you haven’t listened to the Across the Yard podcast yet, we’ve got two great episodes featuring Don Humphry on tariffs.

Scan the QR code to listen to “The Looming Uncertainty of Tariffs Continue” (S03E09), where Don and Liz discuss the current state of trade, what may lie ahead, and where Canadian businesses might find opportunity amid the uncertainty.

Lee Waltham, Brandish Agency

We’re living in a time when the border may be open, but the playing field isn’t level.

Tension between Canada and the U.S. is nothing new, but today’s economic climate is sharpening it. From supply chain friction and subsidy showdowns to diverging energy strategies and trade policy scuffles, it’s increasingly clear that Canadian industries can’t rely on old assumptions. In the brand and marketing world, we know exactly what happens when you let someone else define your story: you become a commodity.

If Canadian businesses want to stand strong, we need more than resilience. We need visibility. We need differentiation. And we need strategy.

In marketing, we talk a lot about positioning. That means defining and owning a unique place in the minds of our audience. Canada has long punched above its weight globally when it comes to quality, ingenuity, and grit. But if we want to compete in a world where perception is as powerful as performance, we can’t afford to be modest anymore. It’s time we started branding Canada with the same energy that other nations pour into global dominance.

Canadian humility is admirable, but it’s also held us back. American firms build hype. We build quality. But quality doesn’t matter if no one hears about it. The reality is that consumers don’t buy the best product. They buy the product they know about. The one they feel something about.

That’s where Canadian companies, and the organizations that support them, have an opportunity. We need to stop treating “Made in Canada” like a quiet disclaimer and start turning it into a loud, proud differentiator. Because it is different. Canadian-made products often come with higher environmental standards, better labour practices, and a mindset of stewardship over-exploitation. That’s not just a policy. It’s a value proposition. But we have to tell that story, and tell it well.

What makes Canada different isn’t just geography. It’s a worldview. As the U.S. doubles down on internal division and short-term gain, Canada has the chance to model a different approach rooted in collaboration, community, and long-term resilience.

That’s a narrative the world is hungry for. But great stories don’t spread on their own. They need intentional marketing. They need brand strategy. They need design, messaging, and channel planning. In short, they need the same tools we bring to every commercial campaign, but pointed inward, at ourselves.

At Brandish, we work with organizations across Canada that are ready to lead. And what we’ve learned is simple. When Canadian companies lean into their identity instead of minimizing it, they grow. Not just in revenue, but in confidence, cohesion, and cultural impact. Whether you’re in forestry, food processing, retail, manufacturing, or software, owning your Canadian story is a brand strength, not a limitation.

This is about more than just waving the flag. It’s about reshaping the mental real estate we occupy in the minds of our customers and trading partners.

Want to command a premium price? Be known for trust. Want to win a competitive bid? Show what sets you apart. Want to build loyalty? Stand for something that matters. In every case, it comes down to brand. And brand isn’t a logo or tagline. It’s what people believe about you.

What they expect when they see your name. And how they feel when they engage with your product or service.

It’s time to invest in those expectations.

“Canadian Resilience” isn’t just about enduring tough times. It’s about evolving through them. It’s about building a country where industries not only survive but thrive by embracing what makes them distinctly Canadian.

Let’s make room at the table. But let’s also show up like we deserve to be there. With brands that are built to last. With campaigns that tell our story. With strategies that don’t wait for permission or applause.

The future of Canada’s economic independence will be shaped as much by how we market ourselves as by what we produce.

Because the world doesn’t just need another supplier.

It needs a Canada that shows up, speaks out, and leads with purpose. And we’ve got the story. Now we just need to tell it.

Phuong Trinh and Jie Zhu, PACE, The University of Winnipeg

Economic downturns can be challenging not only for companies but also for the employees who work within them. In the building materials industry, where projects are often tied to economic conditions, downturns can lead to delays, budget cuts, and restructuring that impact team morale. However, there are actionable strategies that leadership can take to keep spirits high, maintain productivity, and continue fostering growth and development even in tough times. Here are some ways to support your team during economic uncertainty:

One of the most critical aspects of maintaining employee morale during economic uncertainty is transparent communication. In the building materials sector, project timelines and budgets can shift unexpectedly, making it even more important to keep your team informed. Employees want to understand what is happening, why decisions are being made, and how changes may affect them. Regularly communicating updates—whether good or bad—helps reduce anxiety and fosters trust.

Effective communication is a two-way street. Leadership should not only share information but also be open to receiving feedback. Encouraging employees to voice their concerns and ask questions creates a sense of inclusion and respect. Addressing these questions honestly, even when the answers are not ideal, builds credibility and strengthens the relationship between employees and leadership which enhances both morale and employee retention.

When budgets are tight, it may be tempting to cut back on recognition and rewards. However, promoting an appreciation culture becomes even more vital during tough times. A simple “thank you” or public acknowledgment of hard work can go a long way, especially in an industry where teamwork and persistence are critical.

Celebrating individual milestones and successes—like project completions, skill certifications, or personal achievements—boosts morale and reminds employees that their contributions matter. While large bonuses or commissions might not be feasible, small tokens of appreciation, like gift cards, an extra day off, or branded company gear, can still make employees feel valued.

Economic downturns often require employees to adapt to changing workloads and responsibilities. Offering flexible working hours, a hybrid working model for administrative roles, or adjusted shifts for on-site workers can help ease this transition.

Additionally, organizing team-building activities and providing mentorship opportunities can strengthen team bonds and encourage personal growth. This could include training sessions, safety workshops, or leadership development programs. Supporting employees through challenges not only improves morale but also promotes loyalty and commitment to the company. Mentorship allows both an opportunity to build a succession plan for the future of the business as well as a way to assure employees about their future with the organization.

Leadership sets the tone for workplace culture, especially in challenging times. By modelling positivity, resilience, and empathy, leaders can inspire their teams to stay optimistic and engaged. A simple smile or a joyful attitude from leadership can be contagious, spreading positivity across the team.

It’s also important to celebrate small wins, even when larger goals seem distant. These moments of success remind employees that progress is still being made. Additionally, encouraging sharing and learning sessions where team members can discuss their experiences and solutions to challenges fosters a sense of community and collective growth.

This might look like project debriefs, knowledge-sharing on safety best practices, or discussions on innovative building techniques. By investing in development, even during downturns, companies signal their commitment to growth and learning.

Supporting employee morale during economic downturns requires intentional effort from leadership. Transparent communication, recognition, flexibility, and inclusivity are powerful tools that can keep spirits high even in uncertain times. For the building materials industry, where safety, teamwork, and skill development are crucial, maintaining morale is not just beneficial—it’s essential. When employees feel valued, heard, and supported, they are more likely to remain committed and motivated, driving projects forward and setting the stage for recovery and growth.

In today’s unpredictable world, uncertainty touches every part of life, from economic fluctuations and market shifts to personal and family challenges. For business owners, helping employees feel supported during these times is a smart way to strengthen your team and protect your business. One of the most effective ways to do this is by offering a well-designed group benefits plan.

When employees face rising costs or unexpected expenses, a group benefits plan offers a critical financial cushion. Health and dental coverage reduce the burden of medical bills, while life, disability and critical illness insurance provides employees peace of mind that they and their families are protected if something serious happens. Extended health benefits, like prescription drugs and paramedical services (chiropractors, massage therapists, psychologists), help employees take care of their health without sacrificing financial stability.

Periods of economic uncertainty create heightened stress for both employees and business owners. Employees may worry about job security, rising living costs, shrinking household budgets, or the financial health of the company. This stress often translates into increased anxiety, distraction at work, difficulty sleeping, and strained relationships, all of which can negatively affect mental and emotional well-being. Employee and Family Assistance Programs (EFAPs) offer confidential access to professional counselling, mental health resources, and practical support like financial counselling and budgeting advice. By offering a safe and trusted space for employees and their families to address these challenges, EFAPs help mitigate stress before it leads to burnout, absenteeism, or turnover.

EFAPs also provide essential support to managers and leaders, who often find themselves under pressure during tough economic times. Managers may face tough conversations around budgets, team changes, or shifting business priorities, all while trying to keep their teams motivated and focused. EFAPs offer leadership support services including coaching, consultation on handling sensitive or difficult employee situations, and advice on spotting early signs of employee distress. These services ensure managers are equipped with the tools they need to lead effectively without feeling they must carry the emotional or mental health load on their own shoulders.

In today’s uncertain environment, investing in your benefits plan isn’t just about today’s needs it’s about building a resilient, future-ready workforce that can adapt and thrive no matter what comes next. A strong group benefits plan sends a clear message that you value and care for your employees and is an investment in your people and ultimately, in the long-term strength of your business.

If you have any questions or would like to discuss how PIB can help strengthen and support your plan for your employees, please reach out to a PIB Group Benefits Consultant.

Preferred Pricing for Supply-Build Canada Members!

Get customized insurance solutions to safeguard businesses and employees across industries. From group benefits to commercial coverage, PIB ensures you’re protected at every stage.

Trusted by Supply-Build Canada. Plus, enjoy exclusive member pricing! Scan the QR code to view the offers.

With a rich history dating back to 1938, Haney Builders’ Supplies is a true cornerstone of the community it serves in Maple Ridge, British Columbia. Established as the area’s first lumber and building supply store, it began as a humble 10' x 10' corner shop. Over the decades, Haney has steadily grown into the largest lumber yard and home building centre in Maple Ridge, serving the Lower Mainland area.

The business was acquired in 1964 by entrepreneur Bob Stinson, who expanded its footprint by purchasing adjacent properties to create a five-acre site. Around the same time, Bob joined a regional buying group which eventually merged with TIM-BR MARTS Ltd. (TIMBER MART, today). His son, Tom Stinson, took over the business in 1981 and grew the staff from a team of 15 to more than 60 today and laid the foundation for a company that could scale to meet the growing needs of contractors, builders, and homeowners in the area.

“Our job is to help builders’ and contractors’ team deliver on time, within budget, and with confidence that they have the right materials and support to finish the job well.”

“Haney Builders’ Supplies has not only been a loyal member of our group for decades but also a great reflection of what it means to do business right, not only right by your customers, but also right by your community and the people you serve,” says Bernie Owens, president and CEO of TIMBER MART. “They are a true Canadian success story, and we look forward to supporting their continued growth for many more decades to come.”

While Haney has expanded its operations and capabilities, it has remained deeply connected to its community values. The company offers a wide range of products and services, including divisions specializing in dimensional lumber, engineered wood, finishing, landscaping, siding, paint, and more, while maintaining a customer-first, relationship-driven approach to doing business.

Haney Builders’ Supplies also embraces innovation to better serve its growing customer base. It offers a fully functional online store and a 24/7 customer portal which allows clients to browse products, place orders, and access their accounts at their convenience—anytime, anywhere.

Beyond commercial success, Haney Builders’ Supplies is committed to giving back. From supporting local charities like the Christmas Hamper Society and Pink Shirt Day to hosting an annual charity golf tournament that raises over $160,000 for the Ridge Meadows Hospital Foundation, the business continues to invest in the well-being of its community.

“We strive to continuously build a business and a team that exemplifies our core values of legacy, authenticity, and partnership,” says Alex Yakovyshenko, CEO and general manager of Haney Builders’ Supplies. “We view all of our stakeholders as long-term partners and therefore look for employees, clients, and community organizations that share our values.”

Today, Haney Builders’ Supplies remains a family-owned and operated Canadian business that has grown to meet the needs of large-scale projects while staying grounded in the values and relationships that have guided it since day one.

“We see ourselves as an extension of our builders’ and contractors’ teams,” adds Yakovyshenko. “Our job is to help them deliver on time, within budget, and with confidence that they have the right materials and support to finish the job well. That’s what partnership means to us.”

“We’re not just here to generate profit; we exist to support and sustain rural communities and the

FRED THUN, PRESIDENT & CEO OF UFA

Amanda Camara, Supply-Build Canada

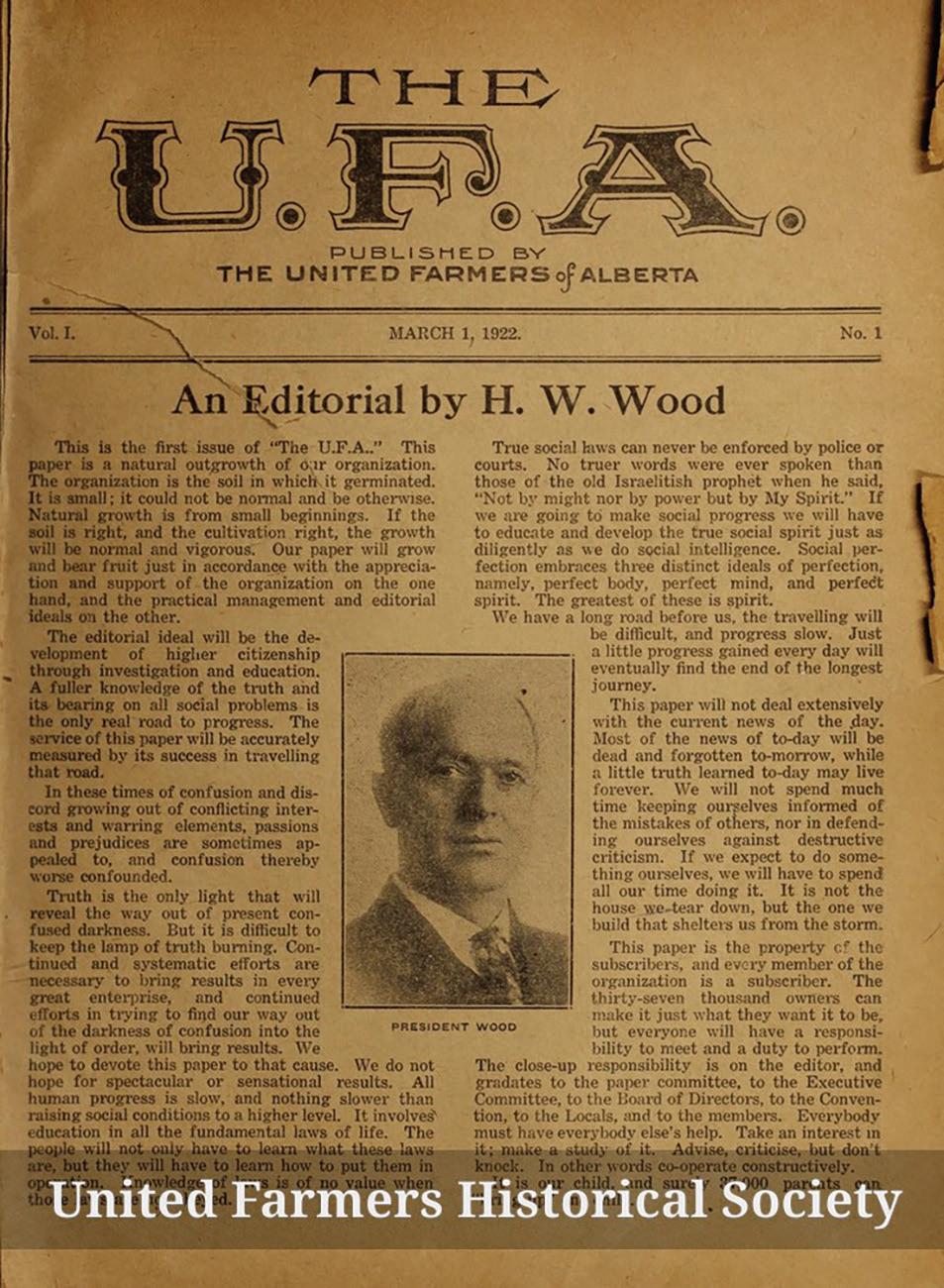

In a rapidly evolving world where rural communities often feel the squeeze of economic and political uncertainty, the United Farmers of Alberta Co-operative Ltd. (UFA) stands tall—116 years strong. Founded in 1909, UFA has grown from a grassroots political movement into a multi-million-dollar co-operative with more than 125,000 members. It remains a proud cornerstone of Western Canada’s agricultural community.

At the helm today is Fred Thun, a Saskatchewan farm kid turned CPA, who assumed the role of President and CEO in January 2025. A seasoned leader in agriculture with previous executive roles at Nutrien and Agrium, Thun brings a blend of financial acumen, grassroots understanding, and vision for UFA’s future.

“UFA isn’t just a business—it’s a way of life,” says Thun. “We’re not just here to generate profit; we exist to support and sustain rural communities and the agricultural lifestyle.”

UFA’s operations are as diverse as the farmers and ranchers they serve, spanning six key sectors: petroleum, lubricants, electrical contracting, farm and ranch stores, crop inputs, and livestock services. With over 34 farm and ranch supply stores and 117 petroleum cardlocks and bulk fuel locations, UFA is woven into the very fabric of the Prairies.

In 2025, UFA will open three new locations in Saskatchewan, with plans to “dip its toes” into Manitoba, expanding its regional footprint while remaining deeply rooted in its co-operative values.

Above: The Amalgamation Committee of the Alberta Farmers’ Association and the Canadian Society of Equity that came to form the UFA in 1909. The name of “United Farmers and Equity Association of Alberta” was shortened to “United Farmers of Alberta” after this photo was distributed.

Thun emphasizes that UFA’s commitment to rural communities extends far beyond business. “We’re not just giving back—we’re investing generationally,” he says.

In 2023, UFA launched the United Farmers of Alberta Agricultural Community Foundation, endowing it with $25 million to support capital programs, food banks, mental health services, and rural law enforcement. The foundation contributes at least $1 million annually to initiatives that directly uplift rural life. A $100,000 capital grant program is just one example, with details and applications available on the foundation’s website.

“This isn’t just about charity,” Thun says. “It’s about building sustainable, resilient communities for generations to come.”

Thun’s leadership style is grounded in authenticity, collaboration, and results. “My door is always open. I don’t have just one mentor—I have 1,200,” he says, referring to UFA’s employees. “They challenge me, they teach me, and they hold me accountable.”

Under Thun’s leadership, UFA has adopted a unified, matrix-style organizational model to better align customer-facing teams and expertise across its six business lines. “Our customers think holistically about their operations—so should we,” he says.

Open town halls, boots-on-the-ground visits, and recurring, simplified communications help manage change and maintain morale. “You can’t build a culture or develop a strategy through a screen,” Thun adds, referencing lessons learned during the pandemic.

Economic pressures, shifting political landscapes, and the unpredictability of global trade are not new challenges for UFA. But 2024 was particularly tumultuous, with rural communities facing increasing costs, crime rates, and mental health issues. Thun is candid about the realities but remains hopeful.

“The unpredictability is paralyzing at times,” he admits. “But farmers are resilient. Our job is to ensure they’re supported—with financing, with advocacy, with reliable service.”

In response to these challenges, UFA introduced innovative financing programs and strengthened collaboration with vendor partners—proving once again that adversity can drive ingenuity.

UFA’s legacy includes not only economic milestones but also political ones—from forming Alberta’s provincial government in 1921 to pioneering women’s rights to vote. More recently, UFA elected its first female board chair, Jennifer Wood, marking another milestone in its evolution.

Thun acknowledges the pivotal leadership of predecessors like Scott Bolton and Carol Kitchen, who helped steer UFA from the brink of bankruptcy to eight consecutive years of growth. In 2024 alone, UFA distributed a record $32.5 million dividend—the largest cash payout in its history.

But for Thun, success is measured in more than dollars. “Our purpose is to sustain communities and preserve the rural way of life,” he says. “When competitors like Peavey Mart exit the market, it’s a stark reminder that we can’t rest on our laurels. Our resilience must be intentional and community-driven.”

As UFA celebrates 116 years, its future looks every bit as promising as its past is proud. With strategic expansion, a renewed focus on customer-centric service, and a mission deeply embedded in the community, Thun and his team are not just leading a co-operative—they’re sustaining a movement.

“Leadership in a historical agricultural co-operative means navigating the unpredictable, embracing innovation, and honouring century-old values,” says Thun. “We’re not just ready for the next 100 years—we’re building for them.”

ON UFA’S MISSION AND IDENTITY:

“We’re not just a co-operative. We exist to support agricultural communities and perpetuate a rural lifestyle. That’s our purpose—and it drives everything we do.”

ON LEADERSHIP AND CULTURE:

“As a leader, I don’t have one mentor—I have 1,200. Every UFA team member has a voice, and I want to hear their ideas. That’s how we grow.”

ON RESILIENCE AND LEGACY:

“UFA has been here for 116 years. Through political movements, economic downturns, and market disruptions, we’ve had the discipline to adapt, grow, and stay rooted in community.”

ON INNOVATION AND COLLABORATION:

“We’ve built a model that brings the right expert to the table—because our customers don’t operate in silos, and neither should we.”

ON FACING UNCERTAINTY:

“The most pressing challenge isn’t a bad year—it’s unpredictability. Our job is to give farmers the confidence and tools to make the best decisions, even in the unknown.”

ON COMMUNITY INVESTMENT:

“We don’t just give back—we invest forward. Through our foundation, we’re making generational contributions to help rural communities not just survive, but thrive.”

Awell-designed retail space does more than make a good first impression. It drives real results. That was the goal when Star Building Materials partnered with BMF to design their new store in Winnipeg. The result is a smarter, more functional space that helps them better serve customers, streamline operations, and support ongoing growth.

As a full-service renovation provider for LBM retailers, BMF offers turnkey solutions covering the design, supply, and installation. Their process is built on understanding each client’s unique business and goals, ensuring the design is both visually appealing and strategically effective.

BMF starts every project by learning the client’s operations and merchandising needs. For Star Building Materials, that meant designing a layout that could effectively serve both contractors and retail customers, while also improving product visibility and support staff-customer interactions.

“BMF helped us from start to finish in designing our new store,” said Mark Kennedy, Vice President at Star Building Materials. “From helping us with store layout, signage, and aisle spacing, down to display ends and proper hooks to maximize space and product merchandising.”

A key feature of the new design was the overhead storage in their core fixture system, which increased floor carrying capacity by 30 per cent. This allows Star to keep more inventory accessible without crowding the customer space. It also improves downstocking efficiency, helping staff stay on the floor to support shoppers. Branded banners conceal the overhead storage and add to a cleaner, more cohesive look throughout the store.

In addition to layout improvements, BMF also introduced educational tools to offer more customer education. New how-to plumbing and electrical feature ends were added, using clearly labelled parts to help guide buyers through complex categories.

These displays give customers the information to make confident product choices. They also make it easier for staff to explain product use and ensure shoppers leave with exactly what they need.

Another key element of the store design is the product displays. Contractors and their clients now have a space where they can review products together. Instead of navigating aisles intended for bulk storage, customers can explore curated displays that showcase available options, creating a more engaging shopping experience.

“We’re experiencing our contractors using our showroom for their customers to showcase the products available for their jobs,” Kennedy explained. “It creates a partnership with our customers that we never expected.”

This collaborative setting not only improves the customer experience but also helps drive additional sales by highlighting full-scope solutions and higher-margin products.

Since opening their new store, Star Building Materials has experienced steady growth in retail traffic and increased engagement from its core contractor audience. The improved store layout, better access to product information, and more educational displays have created a better shopping experience.

“Thanks to the improved product displays and expanded selection, we’re capturing more sales for the whole job,” Kennedy said. “The benefit is immeasurable.”

Across most projects, BMF’s clients see a 30 per cent average increase in sales and a 2 to 3 per cent average increase in gross margin after a renovation project is complete.

BMF’s approach to store design goes beyond fixtures and floor plans. Their work helps retailers create spaces that are efficient, educational, and engaging for both customers and staff. For Star Building Materials, the store resulted in a retail environment that reflects their brand, supports daily operations, and positions them for continued long-term success.

Interested in learning more about the benefits of investing in your store with BMF’s full range of retail design and renovation services? Visit bmfonline.com or contact info@bmfonline.com

Two young Dealers are redefining what it means to run a successful home improvement business in small-town Canada. At just 36 and 32 years old, Dustin Chalus of Richardson’s Home Hardware in Nipawin, Saskatchewan, and Ryan Leger of Richibucto Home Hardware Building Centre in Beaurivage, New Brunswick, are bringing fresh vision, modern strategies, and community commitment to the locally owned, genuinely Canadian retail model.

For Dustin Chalus, retail leadership was always in the cards—but not the initial plan. After years in the mining industry, he returned home in search of a new path. That opportunity came in 2020, when he and his mother, Theresa, purchased the Home Hardware store his grandparents had once run. Now a fourth-generation retailer, Dustin has transformed the family business into a thriving, modern operation.

What began as a modest local hardware store in a small town 70 years ago has increased annual sales by 500 per cent in just five years under Dustin’s leadership. Through aggressive modernization—such as upgrading inventory systems, introducing new product lines, and improving customer experience—he has positioned Richardson’s Home Hardware as a retail destination in northeastern Saskatchewan.

Dustin’s changes go beyond business mechanics. From upgrading store lighting and security to expanding employee benefits and launching a new HR strategy, his approach is holistic. His attention to operations is matched by his dedication to his team members and community. “It takes a village,” Dustin says. “This is about more than business—it’s about building something that supports our customers, our team and our town.”

Notable improvements include a category management overhaul tailored to seasonal trends, expanded power aisles to encourage buying, and full integration with Home Hardware’s national flyer program. Dustin has also introduced top-tier product lines such as Milwaukee Tools, Yeti, Tough Duck, and M&M Express, increasing the store’s appeal to both DIYers and contractors.

On the east coast, Ryan Leger’s entrepreneurial story began at age 14, assembling lawn mowers and barbecues at his family’s store, Richibucto Home Hardware Building Centre. He became a shareholder alongside his father in 2019 and took over full ownership of the business in 2023. Continuing his momentum, Ryan expanded his footprint in December 2024 with the acquisition of a second location—St. Louis Home Building Centre in St. Louis-de-Kent, New Brunswick.

Richibucto Home Hardware has been family-run since 1982, and Ryan represents the third generation to take the helm. His approach to leadership balances deep respect for tradition with a forward-thinking mindset. From day one, Ryan has been hands-on, learning every aspect of the business from the ground up. That practical experience has fueled his leadership style— collaborative, adaptable, and rooted in relationships.

Ryan attributes his success to the strong support system around him—his parents, his wife, his dedicated team, and the store’s loyal customers. “It’s a team effort,” he says. “I’ve grown up with this business, and I want to see it continue to grow alongside me—and hopefully one day, with my son Hudson as well.”

Like Dustin, Ryan is part of a broader movement within the Home Hardware network—a new generation of Dealers who are revitalizing the brand with fresh ideas and a strong entrepreneurial drive. Both Dealers were recognized in 2024 with Home Hardware Store Limited’s annual “Proud of My Home Achievement Award” for Best Young Retailer in their respective regions, honouring outstanding job performance, innovation, and commitment to their communities.

What unites Dustin and Ryan is not just their age or ambition—it’s their shared belief that local ownership matters. They are building on legacies while carving their own paths, combining the strength of the Home Hardware brand with deeply personal leadership styles.

In small towns like Nipawin and Beaurivage, retail success is about more than numbers. It’s about being trusted, being present, and continuously evolving to meet the needs of the community. Dustin and Ryan have embraced that responsibility—and their results speak volumes.

As Home Hardware’s next generation steps forward, the future of independent retail looks bright in their hands—guided by a deep sense of community, innovation, and the values of a truly Canadian-owned and operated company.

Rob Mitchell, President & CEO, Vista Railing Systems Inc.

At Vista, we know strength isn’t inherited—it’s built. As the industry faces one of the most challenging economic climates in recent memory, we’re not retreating. We’re advancing. With sleeves rolled up and a clear sense of purpose, we’re doubling down on innovation, quality, and Canadian market leadership.

This year marks a major step forward: the exclusive Canadian launch of Outdure, a groundbreaking aluminum deck framing system. More than a product, Outdure is a strategic move—a direct response to the shifting dynamics of our industry and economy.

Builders across North America are feeling the strain. The 25 per cent U.S. tariffs on aluminum and steel have squeezed margins, disrupted supply chains, and forced tough decisions across the sector. In Canada, those impacts are magnified by seasonality and regional logistics—influencing everything from purchasing cycles to contractor confidence.

But Vista isn’t in the business of waiting things out. We saw disruption as a catalyst—a moment to ask: How can we lead? How can we equip our partners with better tools, better systems, and better outcomes—not just today, but for the long haul?

Outdure is more than a modern deck substructure—it’s a next-generation platform. Constructed from durable, lightweight aluminum, its modular design is precision-engineered to resist moisture, warping, and the wear-and-tear that shortens the lifespan of traditional timber systems.

Outdure supports virtually any surface—from composite decking and hardwood to porcelain tile and artificial turf. Whether it’s a ground-level patio or a high-rise rooftop, it offers unparalleled design flexibility and speed of installation, while reducing callbacks and maintenance.

Even better? It integrates seamlessly with current building practices. No reinvention required—just smarter, more durable performance.

The introduction of Outdure isn’t just about broadening our product offering. It’s about unlocking new markets.

With Outdure, Vista now enters new verticals—including landscape and tile dealers, rooftop and architectural projects, and even complementary segments within our competitors’ dealer networks. It’s a strategic leap that aligns with our long-term vision: to be the most trusted name in aluminum solutions across Canada.

Initially developed in Australia and proven in global markets, Outdure arrives in Canada at the perfect time. Our climate demands materials that can handle it all—freeze-thaw cycles, rain, snow, and long stretches of sun. Outdure delivers. And with Vista’s decades of experience in the Canadian market, it comes with the support, service, and peace of mind our partners have come to expect.

Launching a new system during a turbulent time may seem risky. For Vista, it’s the logical next step. Canadian builders are resilient by nature—and they deserve products and partners that are just as tough.

Outdure isn’t just a new chapter. It’s a signal of where we’re headed: smarter systems, longer-lasting structures, and a stronger, more connected future for our industry.

This is more than a product launch. It’s a commitment—to Canadian innovation, to growth, and to the people building what’s next.

Above: The entire Cloverdale staff in 1955 at the opening of the second paint store in Newton when there were two corporate branches, Newton and the old Langley factory [L–R]: office clerk, Sam the wax maker, warehouseman, factory worker, factory worker, store clerk, Don Stafford, Sales Manager: Wally Pidgeion, President: Hunter Vogel, Technical director: Frank Giltrow, paint maker: Helmut Much, Langley Manager: Gordy McDonald, Newton Manager: Wink Vogel and a store clerk.

Trevor Maximuk, Cloverdale Paint

In a time of growing uncertainty within the Canadian building supply industry, the threat of tariffs looms larger than ever. Understanding how these economic measures affect our industry—and more importantly, our customers—is not only complex but critical. Navigating the maze of tariff-impacted product categories, tracing their origins, and discerning ownership of suppliers supported by organizations like Supply-Build Canada is no small task. It requires time, insight, and above all, a strong commitment to supporting homegrown industries.

That’s why the theme of this edition of Yardstick—“Canadian Resilience”—could not be more appropriate. There has never been a more important moment to back Canadian-made products and the companies that produce them. In this context, Cloverdale Paint’s enduring legacy as a proudly Canadian-owned and operated business stands out as both timely and essential.

Since the early 2000s, when Cloverdale Paint first began partnering with Canadian building supply dealers, the company has consistently differentiated itself from an industry increasingly dominated by foreign-owned multinationals. While the global paint market has consolidated under a handful of powerful international brands, Cloverdale Paint has remained a Canadian constant. Our commitment to quality, community, and Canadian values has not wavered.

At the heart of this story is a company built on tradition, innovation, and a deep sense of responsibility to its people and its country. Founded in 1933 on a small farm near Cloverdale, British Columbia, by Rudy Henke and Hunter Vogel, the company was born of an entrepreneurial spirit and a dedication to superior customer service. From day one, the goal was simple: produce exceptional paint and sell it directly to customers through a philosophy of “factory direct to you.”

Hunter Vogel often said, “No one ever listened themselves out of a customer.” That commitment to listening and relationship-building laid the foundation for a business based on trust and integrity. His son, Wink Vogel, carried the torch into the next generation, emphasizing values-driven leadership and the importance of family tradition. One of Wink’s guiding principles was to “recruit the sons and daughters of current and past employees,” ensuring that each generation brought fresh ideas while preserving a strong legacy of craftsmanship.

The company’s growth accelerated in the late 1960s with the acquisition of Alberta-based Monarch and Tower Paint. The 1970s brought technical innovation, with Cloverdale becoming the first company in Western Canada to use computer-based colour matching and formulation. By the early 2000s, the company had emerged as a leading supplier of both industrial and architectural

coatings, bolstered by key acquisitions: Northern Paint in 2001, Rodda Paint in 2004, Guertin Coatings in 2008, and both Serif and Spectrum Coatings in 2012. All along, strategic partnerships with building supply dealers across Western Canada has helped strengthen the company’s presence in rural and independent markets—areas often overlooked by larger corporations.

Now, under the leadership of Tim Vogel, third-generation CEO and Chairman of the Board, Cloverdale Paint has grown into the largest Canadian-owned paint manufacturer in the country and the largest family-owned coatings manufacturer in North America. Its corporate head office and primary manufacturing facility in Surrey, BC, remain just a few kilometres from where it all began.

Recent acquisitions of Ontario-based manufacturers All Colour and Kel Coatings have further expanded the company’s reach, reinforcing Cloverdale’s commitment to Canadian ownership and production. With seven manufacturing facilities proudly located in Canada, the company continues to support local workers, families, and communities.

Cloverdale Paint’s growth has never been driven by scale alone. At its core lies a deep commitment to research, innovation, and continuous improvement. The company’s R&D teams have developed a broad range of high-performance architectural, commercial, and industrial coatings—many of which lead the market in durability, environmental safety, and application ease. From arid interior landscapes to humid coastal zones and frigid northern winters, Canadian conditions are anything but ordinary. Cloverdale’s locally produced coatings are engineered to endure them all—providing lasting protection and vibrant finishes from coast to coast to coast.

Left: Our company and Cloverdale Paint and its employees have been active members of their communities across Canada for years. Neighbourhoods surrounding Cloverdale stores and next to where we live have benefited from donations and discount programs that help enhance their quality of life. As a local manufacturer with strong family ties, Cloverdale Paint understands the need for charity and we are happy to support our local communities. In 2017, a treatment unit for children and adolescents with urgent mental health issues was opened at Surrey Memorial Hospital. CAPSU is home to a multi-sensory environment used to help reduce agitation and anxiety and stimulate and encourage communication, the first of its kind for children and youth in a hospital psychiatric unit in Canada. CAPSU serves young people from across the Fraser Health region, aged 6 to 17, who need a 5- to 7-day stay in hospital for stabilization. Cloverdale Paint and the Vogel Family have contributed $1 million to the new unit through the Surrey Hospital & Outpatient Centre Foundation.

Unlike many multinational competitors, Cloverdale Paint’s assets are not siphoned off to foreign shareholders. The company is Canadian-owned, its profits remain in Canada, and its investments fuel Canadian innovation. That matters. When consumers choose Canadian-made products like those from Cloverdale Paint, they’re not just buying a can of paint— they’re investing in a shared future.

Community engagement also plays a key role in Cloverdale’s identity. From sponsoring local sports teams to supporting charitable initiatives and beautification projects, the company gives back in meaningful, visible ways.

Supporting Canadian businesses keeps jobs in our communities, strengthens our economy, and fosters the spirit of ingenuity that defines our national identity. Our roots, our values, and our brands are proudly homegrown—and that pride carries through in every product we make.

So, as we face new challenges and uncertainties, let’s do what Canadians do best: stand together, push forward, and keep our elbows up.

At All Weather at Home, we’ve always believed that resilience isn’t a reaction—it’s a mindset. It shows up in how we support our partners, advocate for our industry, and plan for whatever comes next. As tensions between U.S. and Canadian trade policies continue to evolve, we’ve taken time to reflect on what resilience really looks like—not just for us, but for the broader Canadian building materials sector.

The ongoing tension around tariffs—particularly between the U.S., Canada, and China—has created wide-ranging challenges for Canadian businesses. For some, U.S.-imposed measures have led to increased costs, market disruption, or reduced access to materials. For others, including All Weather at Home, it’s been the Canadian response that has had a more direct operational impact. Regardless of where the pressure originates, the outcome is the same: uncertainty for businesses working to build and supply within Canada.

In our case, tariffs on steel, aluminum, and wood have affected

material costs and have made long-term planning more complex. These trade policies influence how we approach everything from procurement to forecasting to pricing and project priorities.

While today’s supply networks are more stable than they were in the days of the pandemic, they’re now less predictable. And in this kind of uncertainty, the ability to stay informed and stay engaged becomes more critical than ever.

From the outset, we committed to understanding how tariffs and trade policies would affect our business and the partners we work with. We moved quickly to evaluate potential impacts, working alongside our supply partners to access the insight we needed to respond thoughtfully, not reactively.

That early work laid the foundation for how we continue to operate—grounded, responsive, and focused on maintaining consistency through ongoing change.

As a Canadian company, we see advocacy as part of our responsibility. We’ve engaged with municipal, provincial, and federal representatives to ensure the realities of our sector are being heard—not just from us, but on behalf of the broader building materials industry.

We’ve also offered our support to organizations like CHBA, Fenestration Canada, and Supply-Build Canada, each of which plays a critical role in ensuring our industry’s voice is present in trade, regulatory, and policy conversations.

We’re not trying to lead every discussion, but we do believe in standing behind the work being done to protect and strengthen Canadian-based manufacturing and supply.

Above: Window To Canada display we took to many events that gave the community a fun way to show their pride.

In a constantly evolving landscape, we’ve made it a priority to be transparent and accessible in how we communicate with our partners. Whether it’s sharing what we’re seeing in the market, providing updates on how we’re responding, or helping partners understand the potential implications, we have focused on offering clear, timely information.

We believe that transparency builds trust—and being open about what we know, what we’re watching, and how we’re responding helps everyone plan with greater confidence.

At a time when global pressures are growing, supporting Canadian business isn’t just symbolic—it has real, tangible impacts. We know many international companies contribute significantly to our economy and communities, and that contribution is valuable. But we also know that businesses that are founded, owned, and operated in Canada have a unique role to play in driving reinvestment, job growth, and long-term economic resilience.

When you choose Canadian-owned manufacturers and suppliers, more of the value stays here. More of the decisions are made here. And more of the growth happens here.

We’re not anti-anyone—we’re proudly pro-Canadian. And we believe that prioritizing companies built here helps create a more stable, self-reliant economy for everyone.

As we look ahead, we also recognize the importance of broadening Canada’s trade relationships, both globally and across provinces. Relying too heavily on a single trading partner introduces risk. By supporting interprovincial trade and encouraging global partnerships, we create more opportunities—and more stability—for Canadian businesses across the board.

This is about more than economics. It’s about job security, supply predictability, and reducing the strain on businesses and communities during times of political uncertainty.

At All Weather at Home, we believe that the road to success is always under construction. We’re committed to continuing to advocate, communicate, and collaborate in ways that support our partners and our industry as a whole.

Because we know this isn’t just about our future—it’s about building one that we all share.

Let’s keep building what matters—together.

ABI Team

ABI Mouldings is a proudly owned and operated Canadian company supplying quality MDF (medium density fiberboard) mouldings and doors to suppliers across Canada. In 2020 new owners would face uncertainty taking over a business during a global pandemic. Many small businesses had to adjust to economic and product supply disruptions during this time. ABI Mouldings had to pivot and reorganize when pandemic related restrictions were in place. New owner, Dean Petrillo, found himself learning a new industry while trying to keep afloat during uncertain times. The focus for Petrillo and his team was to keep doors open, supply a high-quality product and maintain employment of current staff.

Mr. Petrillo brought with him expertise in customer and employee relationships, and a wealth of knowledge in the building and manufacturing industry. His team had extensive experience and knowledge in window and door manufacturing that they were able to apply to the production of MDF interior mouldings. With the experience of current ABI Mouldings employees and the new team in place, the initial focus was to continue operations during the pandemic and ensure that current customers were receiving a high-quality product in a timely manner. Product being produced by ABI Mouldings was considered an essential service at that time which enabled operations to stay as normal as possible.

Taking over an existing business, especially during a global pandemic, can come with many challenges. At the time, the previous owner had no agreements with direct suppliers. It was a priority to get agreements in place and forge new relationships with suppliers and customers. Without face-to-face contact, it was not an easy task to develop close relationships. Fortunately, suppliers were interested in what the new owners at ABI Mouldings had to offer and they were looking forward to a better product delivered with exceptional customer service. ABI also faced the challenge many companies try to overcome and that is changing corporate culture. “We always did it this way” just didn’t go over well with the new regime and the culture started to change towards a positive atmosphere for everyone to feel important and part of something big.

With the inherited 19 employees, the company began to figure out how to make things better. Profits were hard to come by as shipments were delayed and material costs escalated at an alarming rate. Repairing outdated equipment that would continually break down was suddenly a priority. With equipment working and running smoothly, orders were able to make it out in a timely manner and waste was reduced. The team made the decision to hire a Millwright within the first six months of taking over the business and downtime substantially decreased. We are excited to surround ourselves with reliable and value-aligned individuals that make us stronger.

Being a local Canadian company, it was crucial to start to establish relationships with local suppliers. Previous owners purchased materials from brokers adding 15 to 20 per cent to the cost of MDF. Primer to coat mouldings and doors were also supplied from brokers which added 30per cent. Things had to change if the company was going to succeed. After doing more research, we were able to secure purchases of MDF directly from a mill in Montana. Although this was not ideal with the terrible exchange rate, we were now able to buy our MDF direct and not through a broker. These changes to our operations made a huge difference in the success of our company. Under our new ownership, supply chain increased, bills were getting paid on time, suppliers were being prepaid for material and therefore our credit and reputation changed for the better. We are pleased to partner with true Canadian companies to acquire ou MDF currently.

As the business started to improve and we had survived the COVID 19 pandemic, we were able to implement an ERP system for production and inventory control. The days of excel spreadsheets and hand drawing work orders was over! Our ERP system is now online, and we can easily track the progress of a customer’s order. We are currently introducing a new customer portal for clients to place their own purchase orders and have the status of those orders at their fingertips. In business we need to adapt quickly and be flexible on products we manufacture and distribute.

We continue to look for new and innovative ways to keep costs down to pass on savings to our loyal customers. With 34 employees we are now able to manufacture solid MDF interior doors in all sizes and configurations with customized styles and CNC designs. We have added two vehicles to our fleet for optimal delivery times to our clients.

In March of 2024 we were honoured to become a member of Supply-Build Canada. This membership will allow ABI Mouldings to be a leader in the industry and assist in developing further relationships across Canada. We are grateful for the opportunity to be a part of this established association.

All business at times must brace for the unknown, but very little could have prepared us for what came over the border at the beginning of this year. With little warning and even less justification, Canada was thrown into a trade storm. And, while the policy may have come from Washington, the impact hit us squarely at home.

PinkWood Ltd. has enjoyed long-standing relationships with our customers on both sides of the border. During COVID, almost fifty percent of our production was exported to the United States and that market continues to be a large part of our sales today.

When the current U.S. administration campaigned, there were discussions of tariffs; however, we anticipated Chinese products to be the focus. There was no imminent concern that Canadian manufacturing could be in jeopardy.