Patent Disclosure

Vertical Machine Opening: Product covered by US Pat. 9,126,381, 9,539,785

EZ-Covers: Product covered by US Pat. 11,274,004

HD Die Cutting: Patent Pending

What is the SUN625® HD?

For over a decade, the SUN625® Rotary Die Cutter (RDC) has been a stalwart in the industry, renowned for its reliability and performance.

Throughout this time, SUN has made incremental improvements to the flagship machine, culminating in the most powerful heavy-duty RDC on the market today: The SUN625® HD Rotary Die Cutter.

The SUN625 HD retains the fixed-frame, vertically opening design that made the original a success. Capable of feeding, printing, and converting up to 125”, it’s engineered for 24/7 production of high-quality containers. With structural upgrades, increased load capacity, enhanced speed, and reduced wear, the SUN625 HD redefines productivity and durability in high-volume production environments.

What’s New?

Increased Productivity

Building on the original SUN625's productivity gains, the SUN625 HD delivers even more volume without compromising quality. With a 300% increase in load capacity, it enables longer production runs and higher throughput while maintaining precision. Its optimized design ensures seamless 24/7 operation, making it ideal for high-volume demands.

Enhanced Durability

The SUN625 HD is built to withstand the toughest conditions, offering a 500% improvement in fatigue resistance and a 60% reduction in deflection under load. It can operate longer without the wear and tear that typically slows production. These efficiency enhancements ensure consistent, high-speed output while reducing the need for downtime.

More Flexibility

Designed to handle everything from lightweight single flute to rigid multi-flute mediums, the SUN625 HD supports a wider range of materials and configurations. It processes thicker and more complex corrugated board types, including heavy-weight paper and double-wall configurations, to give your box plant the versatility to meet customer needs.

Higher Container Quality

SUN625 HD upholds the highest standards in container quality, more so now with advanced die-cutting accuracy and improved tooling due to the use of a larger anvil cylinder and improved nip positioning. Moreover, this machine ensures exceptional print-to-print registration for even the most demanding customer jobs.

Smarter Operations

The SUN625 HD comes standard with Helios, SUN Automation Group’s OEM-agnostic IIoT solution that provides real-time machine performance insights, predictive maintenance, and optimized

Maximum Sheet

60.5” x 125” (1537mm x 3175mm)

Maximum Die Cut 125” (3175mm)

What’s Inside?

Larger Journals

The SUN625 HD’s journals are more than double the size of any other offering in the 66” RDC category, significantly boosting load capacity for more demanding production needs.

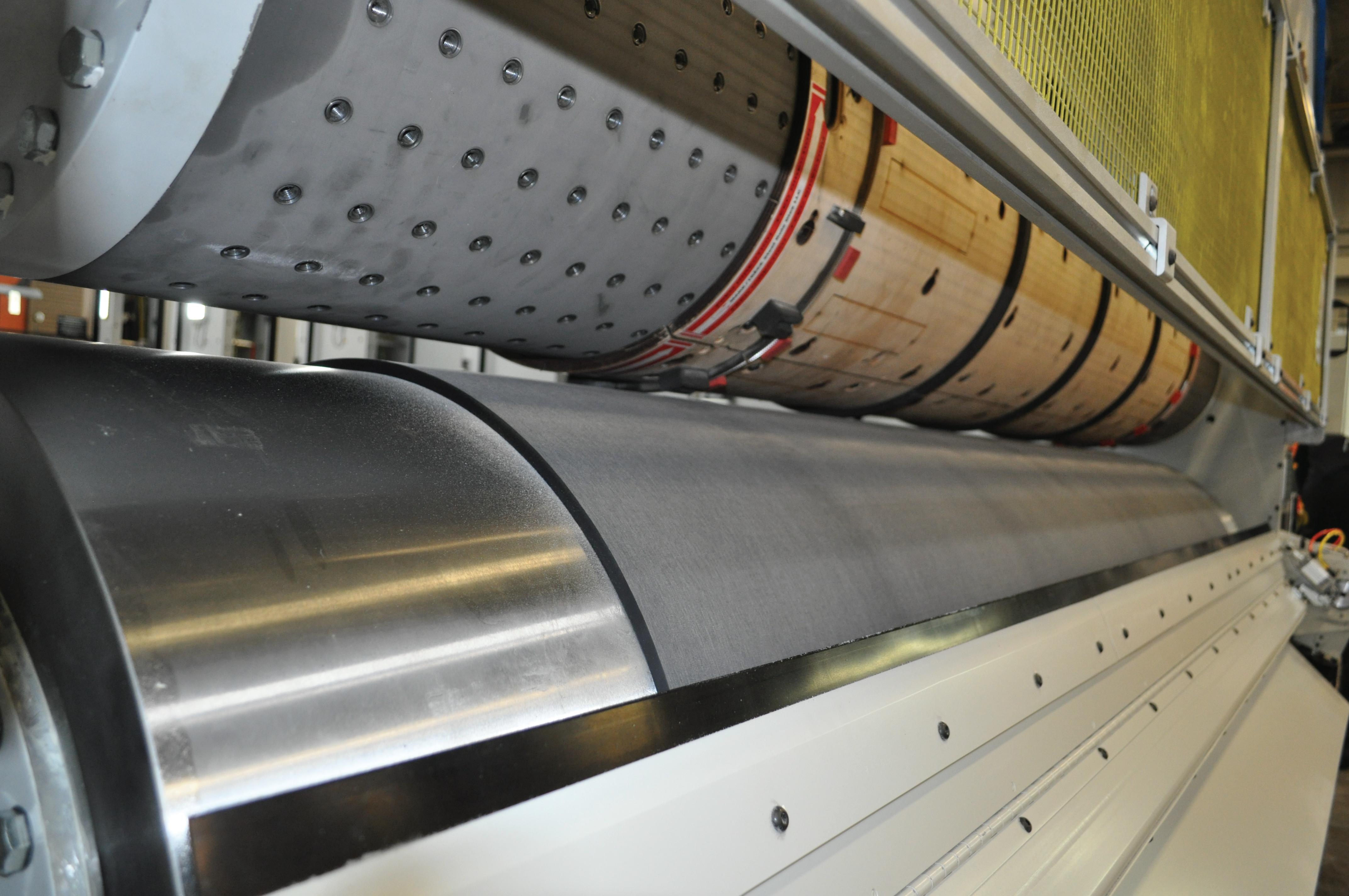

Nip Position & Anvil Cylinder

SUN’s patent-pending nip position and larger-diameter anvil cylinder allow for the smoothest die cutting operations, even in the toughest of conditions.

Extend-O-Feed®

The Extend-O-Feed® Lead Edge Feeder enables superior registration, reduced feed roll crush, and the ability to handle heavier pile heights.

Integral Dwell Sections

The SUN625 HD features dwell units between the feed and first print sections, and between the final print and die-cut sections, ensuring exceptional print quality.

What’s Inside?

Choice of Ink System

Customize your SUN625 HD with either the ColorMaster® single blade system or Absolute Carbon Fiber doctor blade systems for unrivaled ink metering.

MicroGrind®

The MicroGrind® Die Cut Accuracy System enables the rapid and precise conversion of even the most complex die-cut orders.

Digital Harmonic Register

The Digital Harmonic Register offers intuitive touch screen controls for precise adjustments, eliminating backlash by controlling rotational and lateral positioning accurately.

SunTrac® Vacuum Transfer

The SunTrac® Vacuum Transfer System provides complete sheet control and delivers outstanding print-to-print registration.

Advanced Machine Architecture

Compatible with Your Facility

The low board line, fixed-frame design of the SUN625 HD integrates seamlessly into existing facilities and auxiliary equipment, while occupying a similar footprint to conventional-opening machines.

Fixed-Frame, Vertically Opening

Step inside the machine for quick order changes without any of the traditional obstructions, thanks to its innovative vertically opening design.

Superior Print Quality

With enhanced sheet control and precise ink-metering, SUN625 HD ensures precise die positioning and built-in drying time, resulting in exceptional print quality.

Quick and Easy Plate Change

SUN625 HD is ready for set-up within 40 seconds of passing it’s last board, allowing for quick and effortless print plate changes. The walk-in architecture ensures unobstructed access, enabling operators to make adjustments with ease.

24/7 Uptime + Increased Load Capacity = Maximum Productivity

Quality Printing, Cutting, & Scrap Release = Increased Customer Satisfaction & Retention

High Dependability + High Durability = Minimal Maintenance & Downtime

Increased Capabilities & Versatility = More Orders Accepted

Production Capabilities of Two standard RDCs = Only One Production Line & Operator Required SUN625 HD = Maximum Return on Investment

Increased Longevity = 2+ Decades of High Performance