MATERIAL HANDLING

From Roll Stock to Shipping Dock

Machinery and Handling for the Corrugated Board Industry

From Roll Stock to Shipping Dock

Machinery and Handling for the Corrugated Board Industry

The CRAB System is a fully automated roll delivery system designed to eliminate the safety concern of a fork lift racing up and down the side of your corrugator. The CRAB will pick up and transport from a designated Drop-off/Pick-up point and deliver to and from your single facers. The CRAB is seamlessly integrated into your ERP system to deliver and return the rolls, and even stage high use rolls alongside the corrugator. Every time a roll is picked up or moved, the CRAB measures the lineal feet of paper on the roll and updates your roll stock inventory in real time.

High-Speed Palletizer, now with Satellite System for Automated Chimney Stacking

The Eleva Palletizer is a fully automated load former that can form almost any combination of patterns and layers without any operator intervention. This includes inserting bottom sheets, tie sheets and even pallets. With the addition of the patented Sattelite system, it can even form automated chimney stacks without slowing down your high speed FFG. With no pits, foundation work or hydraulics required, the Eleva Palletizer is a quick and easy installation.

The Pallet Inserter offers unique double stacking capabilities, meaning two piles can be stacked vertically on the same pallet. The system is equipped with a side stacking system, a lateral folding system for bottom protection sheet, and muting security photocells at product entrance, exit, and physical security perimeter barriers. The system is optionally available with a top sheet inserter that is capable of inserting many different types of materials. The Pallet Inserter is rated at a maximum speed of 200 pallets per hour.

The PARA Pre-Feeder greatly reduces the need for operator intervention, improving safety and efficiency. With the ability to store presets for future orders and remote monitoring via camera systems, this system fully automates the pre-feeding process.

The PARA Pre-Feeder features a continuous shingling delivery system that delivers sheets to the feed table in a stable manner, vitually eliminating the need for operator intervention. The PARA Pre-Feeder is fully eelectric and uses no hydraulics, reducing the need for maintenance and increasing workplace safety.

Overhead Stacking Solution increases stacking efficiency

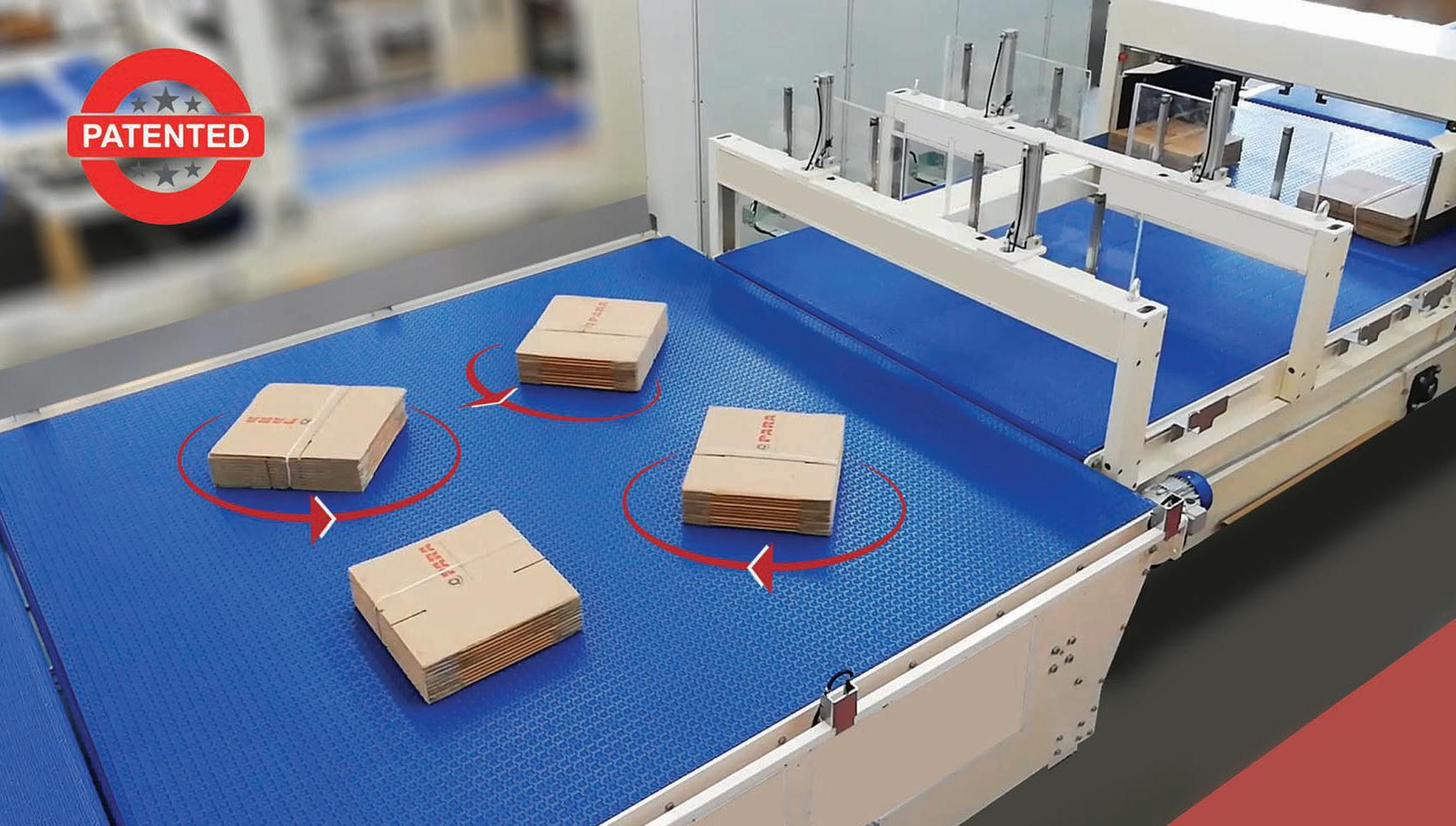

The PARA Vacuum Overhead Stacker is designed to receive all sheets from the die cutter as a single sheet nicked together in both the ups and outs direction. This system, unique in its market segmentation, working in harmony with the 2 PARA breakers and the PARA Palletizer, allowing for cleaner and more precise stacking. The PARA Stacker can be integrated with virtually any camera inspection equipment and automatically eject bad sheets without skipping a beat.

100% Automation with Minimal Moving Parts

The Vertical WIP System is a fullyautomated storage solution that leverages vertical real estate to drastically reduce floor space usage. The system is suitable for any industrial environment, allowing for increased space, efficiency, and storage accuracy.

Designed for effortless integration, PARA’s Material Handling Solutions introduce advanced technology to the reliable performance of your SUN625, LMC Jumbo, PP Series, and PP 66”, or existing OEM equipment.

Being both RDC and FFG friendly is only one of the many benefits of implementing PARA’s Material Handling solutions into your operations. Other benefits include:

• Optimize Roll Delivery, Stack Formation & Palletizing

• Eliminate Manual Operations

• Reduce Labor Costs

• Enhance Workplace Safety

• Maximize Production Capabilities

• Minimize Jam Risk

PARA was established in 1976. Since the beginning, the company has remained steadfast in its industrial ethos: PARA’s aim is to capitalize on the full potential of automated production line methods, constantly monitoring change in an increasingly technical and global market.

Over the years, PARA continuously expanded its range of offerings, demonstrating a strong ability to meet the demands of the global market. Through consistent innovation, PARA successfully staked its claim as a leading player in the international corrugated board industry.

PARA Becomes an Industry

The mind behind the company – and current president – Giovanni Para successfully blends specific technical expertise and know-how with an entrepreneurial approach tailored to the social and economic changes of the era. Later on, second-generation professionals Emanuele and Caterina Para entered the company, each one bringing specific personal experiences and aptitudes.

The company consists of a highly qualified team of over 50 people and over 100 external collaborators and subcontractors to support a worldwide customer base across Europe, Mediterranean Africa, The United States and Australia. PARA’s history is that of a company which, despite having achieved an international presence, has maintained its family character.

PARA seeks to maintain its family-driven values and company culture, empowering customers and employees to become high achievers in their professional and personal lives.