TWO INDEPENDENT, FAMILY-OWNED COMPANIES. ONE SHARED MISSION.

Progress is impossible without change. Throughout our story, change sometimes came naturally as we found new ways to serve others. Other times, we had to be more proactive to adapt how we were doing business. Both types of change are woven throughout our agronomy story.

We entered the world of agronomy in the late ‘50s to early ‘60s with our first fertilizer dealings (80-lb bags of 3-6-12). However, it wasn’t until the summer of 1964 when Ron Stutsman purchased a Hahn Hi-Boy that our agronomy endeavors started gaining traction. He charged $1.25 per acre, plus the cost of 2-4-D. On a good day, he could spray 100 to 125 acres. The next year, he started spraying Treflan and Amiben pre-emergent for soybeans.

Shortly a ter Ron started custom crop protection application, we were approached by WR Grace to take 41% nitrogen they had overpurchased. This happenstance relationship with WR Grace kick-started our dry and liquid fertilizer business.

In the first year, growers allowed Ron to test the liquid nitrogen in their fields by sidedressing in 40-row increments. Growers were thrilled with the yield bump, so by year two, Ron was sidedressing entire fields with the help of neighborhood friends and borrowed tractors from their fathers.

“Ron, Jim and Eldon had such a gi t of being able to look over the horizon and identify the next product or service that our customers would see value in,” Mark Stutsman, COO, said.

The ‘70s brought about foundational change as well. Ron’s vision was to become a full-service provider that could introduce agronomic innovations to growers. One of these innovations was soil sampling, which allowed us to figure out what was happening in growers’ fields and make fertilizer recommendations accordingly. This went against the standard recommendation of 100 lbs of ammonia, 130 lbs of potash and 133 lbs of DAP. However, soil sampling broke the ceiling for many and proved how important trying something new can be. Liquid suspension products also became more of a focus in this decade and were quite popular with growers thanks to their quality and price-point advantage over traditional fertilizers.

Jim (Eldon’s son), Eldon (founder) & Ron (Eldon’s son)

Jim (Eldon’s son), Eldon (founder) & Ron (Eldon’s son)

The ‘80s and ‘90s would bring substantial facility improvements — increased storage capacity, environmental protections and automation. However, one of the biggest advancements from the ‘90s in our mind was AgLeader’s yield monitor. This uncharted territory was a learning curve for many. For us, it highlighted the importance of being willing to embrace change for the sake of progress — and having people willing to step up to the task.

In this case, Al Kessler was the one to raise his hand and lead the precision ag technology charge. Having a department dedicated to working alongside our agronomists to bring this technology (along with other field and application equipment) to growers also elevated our ability to make agronomic recommendations from yield maps and give growers the power to make more accurate management decisions based on pH, weed control, tile drainage and more.

One new opportunity leads to another. With increased field data, we needed a tool to help process and organize the data e ciently for growers. Insert HighQ, a program designed to help growers evaluate their management choices to make less risky and more profitable decisions. HighQ laid the foundation for our precision ag analysis program of today, ProVantage.

Our goal is to “be a partner on the cutting edge of technology and how [growers] invest in their crop,” Bill Parchert, VP of Fertilizer Services, said.

The agricultural industry has evolved significantly since Ron first purchased his Hahn Hi-Boy in the summer of 1964, and it’s certainly not done yet. As new products and technologies continue to hit the market by the dozens, we want to ensure our recommendations are those with the growers’ best interest in mind. That’s why we continue to put these products and technologies to the test before recommending them for your acres. We never want to be afraid to try something new, especially if it means providing you with new and improved solutions for your operation.

“This industry has changed a lot in the past 10 years, and it’s going to change even more,” Curt Miller, Fairfax Plant Manager, said. “At the end of the day, we’re going to continue providing needed services to growers.”

O ering innovative products and services is important, but in doing so, we don’t want to compromise our mission and what keeps us rooted. As we evaluate new opportunities, we want to ensure they align with our values and, more importantly, benefit you.

Whether it’s been for one growing season or multiple generations, we’re grateful for the opportunity to serve you for success.

Thank you,

The Agr y Team

For 90 years, Eldon C. Stutsman, Inc. has been on a journey to consistently provide the best products and services for the communities we serve. A key component of this journey is seeking out and aligning ourselves with customer service-minded partners. That's why it's with great joy we announce the next step on our journey — adding Beck's to our seed o ering.

Founded in 1937, Beck's is the largest family-owned seed company and the third-largest seed brand in the U.S. With a history rooted in agriculture, it's clear Beck's and their family of employees pride themselves on living out their culture each day. It's stunning how closely their values align with ours; it's almost like looking in a mirror. Just as our mission is to serve others for success, theirs is to help farmers succeed.

"As we've gotten to know Beck's, it has struck me the similarities between the two family-owned companies and the value structure in an era of consolidation," Mark Stutsman, COO, said.

Like Eldon Stutsman, who believed in "emphasizing service, and sales will come naturally," Beck's is committed to o ering solutions that benefit growers — even if they are not directly related to seed.

"We very much admire their customer-first approach and extensive research programs, which is one of our focuses as well," Mark said. "We just saw this as an opportunity for a great collaboration between two companies."

Our Fairfax, Iowa, location has o ered Beck's seed for many years, allowing us to see how Beck's employees treat each other and their customers. The service they have provided our Fairfax employees and customers and the level of integrity they have shown is a breath of fresh air.

"Integrity is a big deal to me," Curt Miller, Fairfax Plant Manager, said. "Beck's handles everything very professionally, and they treat you as an individual. It's clear they're concerned about your needs, not just a broad-stroke, everybody-fits-into-this approach."

Actions speak louder than words. The values they hold and the integrity they've displayed in Fairfax are two reasons Beck's has appealed to us as a business. More importantly, the support they provide to customers and their reliability as a company will benefit our growers. We have seen firsthand their unwavering commitment to helping farmers succeed.

Another reason we're excited to partner with Beck's is their extensive product lineup. One of Beck's strengths is their ability to provide growers with a wide variety of genetic and trait packages from all the major providers. We're confident there is a solution for every grower in Beck's lineup, no matter their diverse operational needs.

As an agronomic advisor, we aim to provide you with localized solutions that will work in your fields. We know that one-size-fits-all recommendation isn't in your vocabulary — and it's not in ours either. Something we appreciate about Beck's is their local hybrid recommendations, leading to better results at harvest. When it comes to seed (and other agronomy products, for that matter), the product is only as good as its placement. Good placement requires experts who can make data-driven recommendations. Our local Beck's team is second to none when it comes to helping place products for each acre.

"The three Beck's employees calling on us in eastern Iowa have been with Beck's for a very long time," Mark said. "They have tenures of 13, 12 and eight years with the company, a tenure that speaks volumes about how Beck's treats its employees. We have not seen that level of loyalty with any other seed company we have represented over the years."

Beck's goes above and beyond in many ways, especially when it comes to standing behind their product. Their 100% Free Replant Policy is unique to the industry, and we hope this added value gives growers the confidence and freedom they need to try Beck's on their operation.

Likely, this isn't the first time you've heard us say this, but we strongly believe in putting products to the test before we make recommendations and o cially bring them on board. A few of the fields at the Stutsman Farm have had Beck's products on them for a few years, and we've seen positive results that have given us the peace of mind to make this move. This spring, we planted a seed plot comparing Beck's with other leading brands. If you're curious about the performance of these products throughout the season, we'd love to have you come check it out.

From their company values rooted in doing what's best for farmers to the exceptional service they provide and their strong product lineup, we're excited to bring Beck's to your farm gate for the 2025 growing season. We look forward to introducing you to the brand, the values we found so appealing and how Beck's can fit in your operation.

OUR KEY BECK’S SEED ADVISOR

Je Junge and his wife Becky live near Atkins, Iowa, just west of Cedar Rapids. With over 36 years of experience in the seed industry, Je has brought an immense wealth of knowledge to area farmers during his eight years as a Beck's seed advisor. Before Beck's, Je worked for 16 years in retail (seed, fertilizer and chemicals), three years as a District Sales Manager for Monsanto (Asgrow Seed), and over nine years of seed production with Pioneer as a production leader.

"I see many similarities in culture between Stutsmans and Beck's, and I look forward to working with the Stutsman sales team to help Iowa farmers succeed." - Je Junge

Beck's Farmers At Heart® revolutionized the customer seed buying experience by remaining true to a foundation built on faith, family and farming. Founded in 1937, Beck's appreciates the farmers who have helped them become the largest family-owned retail seed company and the third-largest seed brand in the United States. The Beck family is now in its fi th generation of family members who work in the business to honor God and help farmers succeed. The Beck family and team of employees help farmers achieve success from generation to generation through authentic customer experiences, product diversity, seed quality and performance. With a home o ce located in Atlanta, Indiana, Beck's serves farmers throughout the Midwest and mid-south. For more information about Beck's, visit http://www.beckshybrids.com/. Follow Beck's on Facebook, Instagram, TikTok, LinkedIn, X and YouTube.

Fungicide applications to corn and soybeans continue to be e ective strategies for profitable crop production by providing important plant health and stress relief benefits while also mitigating disease and preventing late-season, yield-robbing pathogens.

Each growing season, crops face a myriad of disease pressures. In 2023, disease reduced corn yield by an estimated 2.9% and soybean yield by 4.8% across the U.S. Stalk and ear rots in corn and stem and root rots in soybeans were some of the top yield reducers across the Midwest. Northern corn states estimated more than 189 million bushel in yield loss for 2023 from corn disease and pathogens that can be controlled with fungicides (Sikora et al., 2024a; Sikora et al., 2024b).

Disease prevention is commonly the most discussed benefit of fungicides, but plant health promotion should not be overlooked. Fungicides work in the plant to create greener leaf tissue, improving and increasing photosynthesis and the plant's ability to feed itself. Greener leaf tissue and plant strength also lead to more water conservation and e cient energy use to create pods and kernels.

While the 2022 and 2023 growing seasons were considerably drier and saw less disease pressure than prior years, fungicide application to corn and soybeans still improved yield in several of our southeast Iowa fields compared to untreated fields.

In the past 10 years, our ProVantage field data has shown a fungicide treatment around the corn tassel stage has produced a minimum of a 14-bushel and a maximum of a 23-bushel advantage over untreated acres. In the past eight years, a fungicide treatment around the R3 growth stage on soybeans has averaged a 6¼-bushel advantage over untreated acres. Grain markets and fungicide benefits vary from year to year, but in the last eight to 10 years the application of fungicide has generally paid for itself and put more corn and soybean bushels in the bin than fields that didn’t receive treatment.

Application Timing: Application timing is important because fungicide products provide a window of plant-health and disease-fighting benefits that can expire a ter 10 to 21 days, depending on the products used and growing conditions. Application is prescribed at VT though R1 on corn and R3 on soybeans to protect the plant during a crucial developmental period and the stages immediately following. In some instances with strong disease pressure, a second application to finish the growing season is necessary to extend that window.

Application Method: Ground rig and aerial application with an airplane, helicopter or drone are the most practical ways to apply fungicide in southeast Iowa. This season, Stutsmans is supporting customers with ground rig, airplane and drone fungicide application options.

Fungicide Product Selection: There are several di erent fungicide products on the market with unique formulations ranging from one mode, two modes and three modes of action to provide stress relief and fight diseases in di erent ways.

Insecticides and foliar nutrient packages can also be tank mixed with fungicides to control any late-season insects or round out a complete fertility plan. There are also several secondary products to consider mixing with fungicides to improve canopy penetration and reduce o -target movement.

Each growing season brings unique factors to consider with choosing inputs and defending our crops against pests. Fungicide and late-season foliar applications are a proactive way to positively influence your corn and soybeans for what is usually the last time through the field before harvest. Planning ahead is the best way to ensure your product selection, as well as timing and method of application are scheduled to maximize your investment.

In my 38 years working in ag retail and as a grower myself, I have seen many changes in trends and a myriad of potential new opportunities arise. When they do, I naturally have many questions. Is there a real opportunity here, or will the buzz go away just as quickly as it arrived? Is it in our best interest to steer clear, or should we jump on the train while we can? Will the financial return be worth the risk and extra e ort?

Throughout the past decade, we have seen an emergence in initiatives to sequester and reduce the footprint of carbon in our environment. Sometimes these initiatives are e orts developed by companies to reduce the emissions in their supply chain, referred to as inset markets. In this scenario, companies work with segments of their supply chain to implement sustainable practices. The alternative strategy is o set markets, where an organization purchases carbon o sets from those who are reducing emissions or sequestering carbon. By doing so, they can continue complying with industry emission regulations or benefit from voluntary programs (Thompson et al., 2021).

Today, the income opportunity in carbon sequestration that I am watching is the 45Z tax credit going into e ect January 1, 2025. As part of the Inflation Reduction Act (IRA), the 45Z tax credit rewards biofuel plants for lowering their biofuel’s carbon footprint, also referred to as their carbon intensity. The carbon intensity of biofuel is an accumulation of the emissions created when producing, distributing and consuming the biofuel. Contributing to the overall carbon intensity score is the carbon intensity of feedstock, materials such as grains used in biofuel, which is based on the carbon footprint of growing and delivering the grain to the biofuel plant (Kiel, 2023). The national average carbon intensity score for corn is 29.1 (Continuum Ag, n.d.). Like in golf, the lower the carbon intensity score, the better. Biofuel companies are incentivized to purchase grain with a lower carbon intensity score to o set their overall carbon intensity score and help them receive the 45Z tax credit (Kiel, 2023).

On average, gasoline has an average carbon intensity score of 100. Ethanol has an average carbon intensity score of 55 (Continuum Ag, n.d.). The 45Z tax credit awards ethanol plants two cents per gallon for each point they can achieve below a score of 50 (Morgan, 2024). For a plant in Iowa that produces a couple million gallons per year, this could amount to a large amount of money.

To capture these tax credits, biofuel plants are faced with trying to make plant e ciency improvements that don’t move the needle very much or push for carbon pipelines, which are still several years out (Continuum Ag, n.d.). What can move the needle from day one is purchasing corn with a low carbon intensity score. Practices influencing the corn crop’s intensity score could include no-till, cover crops, strip-till, replacing commercial fertilizer with manure, the type and amount of nitrogen used, the amount of LP used to dry the crop, and more (Eckelkamp, 2023). However, there is still uncertainty about which practices the agency overseeing this tax credit will deem applicable. I am confident we work with several farmers who already employ most of these practices in their operations and could qualify for up to a couple hundred dollars in tax credit subsidy per acre.

But here is the big kicker ... how much of the couple hundred dollars per acre tax credit will the ethanol plant share with the grower? How much will the grower have to pay someone to do the detailed record-keeping needed to enable them to become certified and eligible for the tax credits? I am also confident that as more and more farmers participate, less and less of the tax credit will be shared.

Sources

Continuum Ag. (n.d.). Carbon intensity FAQ. https://continuum.ag/carbon-intensity/ci-faq/ Eckelkamp, M. (2023, August 28). What is a carbon intensity score? AgWeb. https://www.agweb.com/news/business/conservation/what-carbon-intensity-score Kiel, J. (2023, November 2). Know your carbon intensity score. Farm Progress. https://www.farmprogress.com/conservation-and-sustainability/know-your-carbon-intensity-score Morgan, T. (2024, March 15). There’s a new way to cash in on your CI score on the farm, thanks to the Inflation Reduction Act. AgWeb. https://www.agweb.com/news/crops/corn/theres-new-way-cash-your-ci-score-farm-thanks-inflation-reduct Thompson, N. M., Hughes, M. N., Nuworsu, E. K.M., Reeling, C. J., Armstrong, S. D., Mintert, J. R., Langemeier, M. R., DeLay, N. D., & Foster, K. A. (2021, June 28). Opportunities and challenges associated with “carbon farming” for U.S. row-crop producers. Purdue University Center for Commercial Agriculture. https://ag.purdue.edu/commercialag/home/resource/2021/06/opportunities-and-challenges-associated-with-carbon-farming-for-u-s-row-crop-producers/

There aren’t too many options for hauling grain. Option one is a wagon, which is a popular choice if where you need to haul to is close by. If it’s not, this method can be both ine cient and dangerous. Option two is to hire someone to haul your grain for you. However, this doesn’t always pencil financially and also puts you at the mercy of someone else’s schedule. Option three is to add a grain trailer to your arsenal. If option three is something you are considering, but traditionally cost or size has held you back, Demco’s steel grain trailers are an economical and reliable hopper bottom option to check out.

» 25” Hopper Clearance

» 98” Overall Width

» 9’ 6” Height from Ground to Top Rail

» 35-Degree Hopper Slope

» Full Center Dividers on Trailers 30’ & Up

» Ladder Rungs on Inside of Trailer

» Hopper Sight Windows

» Rubber-Mounted LED Lighting and Sealed Wiring System, 7 Way Receptacle by Truck-LiteTM

We’ll be the first to admit, hopper bottoms aren’t a traditional equipment line for us. However, when the first Demco grain trailer showed up on our lot last fall, there was more interest in the size and price point than expected. Although not a fit for every operation, the Demco grain trailers seem to be a viable option for growers who have been on the fence to make the switch to hopper bottoms. If you are looking for a quality grain trailer at a reasonable price point, we have a Demco grain trailer on the lot if you want to check it out in person.

There is much to admire about those who work hard in silence. They’re guaranteed to be kind, humble and people you can rely on. What they probably won’t be is someone to jump into the spotlight. This rings true for the Waldschmidts; they exemplify the importance of family and working together toward common goals.

For the Waldschmidts, farming runs in their blood.

“It goes back clear to the beginning,” Ron Waldschmidt said. “We were always farmers. My grandfather, my great grandfather, both sides of the family, they were all farmers.”

The Waldschmidt family has spent several generations farming in their township, four of which have been on the same home farm.

“The farm where we live, my grandfather bought it in 1938,” Ron said.

Ron is the third generation on his family’s row crop operation in Iowa City. Preceding Ron on the family operation were his parents, Harold and Helen Waldschmidt, and his grandparents, Louis and Alice Waldschmidt.

Today, Ron works alongside his son, Mike Waldschmidt, and two of Mike’s children, Alyssa Moran and Clayton Waldschmidt. Both Alyssa and Clayton have brought with them their unique experiences and skills to the operation.

“[Clayton] does the mechanics stu a lot better than I ever could,” Alyssa said, “and I do more of the agronomy.”

While each member of the operation has a little bit of their own ground, the family works together to tackle the growing season.

“It’s really a family a air,” Ron said.

continued on page 12

The Waldschmidts have been and continue to be exceptional people to work alongside in many ways. Multiple generations of the Waldschmidts have placed trust in Stutsmans, something we certainly don’t take lightly.

One such showing of faith dates back to the start of Stutsman's involvement in fertilizer. Around 1964, Ron Stutsman, our Chairman of the Board, held his very first fertilizer meeting and invited five local farmers. One of them was Ron Waldschmidt’s father, Harold. A ter the meeting, Harold trusted Ron Stutsman to apply a little bit of 41% liquid nitrogen that year.

“I didn’t get all of [the five local farmers in attendance’s] business,” Ron Stutsman remarked, “but if I would have gotten all of their business, I couldn’t have done it.”

In addition to the agronomy side of things, the Waldschmidts were one of our early grain bin customers. Special Project Lead, Roger Slaughter, recalls going on service calls to the Waldschmidt bin site in the ’70s.

“You couldn’t ask for a better customer in a lot of ways,” Roger said.

The relationship between the Waldschmidts and Stutsmans grew even more when Alyssa spent some time with our agronomy team as an intern and a sales agronomist before returning to farm with her family.

From the very beginnings of Stutsmans to now, we’re proud of the partnership we have still standing strong with the Waldschmidts.

Ron Waldschmidt has witnessed many changes on the farm from the time he was a young boy until now, especially in equipment. Some of Ron’s earliest farm memories include the team of horses his parents had when he was around three to four years old.

“We hooked them onto the wagon,” Ron said, “and we went around the outside of the field and we’d pick corn to open up the field for the picker.”

This team of horses was also used to seed oats, which served as the fertilizer program of the time.

Then, when Ron was a few years older, they got a little VAC Case tractor to replace some of the jobs the horses performed before. As farming equipment continued to advance, the Waldschmidts were eventually able to get their first combine.

“We started out with our AC (Allis Chalmers) combine my dad had,” Ron said. "It was 5’, and of course, a pull type.”

When Ron got out of high school, he helped pay for his first combine, a self-propelled 45 John Deere.

“It didn’t have a cab on it,” Ron said. “We ran that for 10 years.”

Ron recalls the days of using two- and three-bottom moldboard plows, along with the push to get the ground plowed before it froze. He’s also experienced advancement in chemicals such as the introduction of herbicides.

For Mike, some of the biggest advancements he’s witnessed have been in yield monitors and other electronics as precision ag has taken o .

Alyssa and Clayton will also certainly see many evolutions as they carry on the operation, which they speculate might be more automation, a focus on carbon farming and continued consolidation in the industry.

While the Waldschmidt operation has seen many changes in equipment and practices, what hasn’t changed is how members of the family, no matter their age, work together to get the job done.

“Our long-term goals are to keep farming our farm,” Ron said. “It’s been in the family some time, and I would sure like to keep it that way.”

Mike echoed his father’s sentiment by saying his goal was also to “keep it in the family.”

Ron and Mike’s caretaking mindset has ensured their farm is in a good place to be ready for the next generation when the time arises. Their love for what they do has also instilled a passion for their occupation in Alyssa and Clayton.

“Farming … there’s a good opportunity there, but you gotta have it in your blood,” Ron said. “It’s gotta be your cup of tea, but it’s a heck of a good occupation and a great way to raise a family.”

Both Alyssa and Clayton have fond memories of growing up on the farm, even though a few of those memories include a few mishaps while learning to operate equipment. Alyssa remembers the many heart attacks she gave her dad while learning to drive a semi, and Clayton recalls the time he learned to drive a tractor.

“I didn’t know the di erence between a clutch and a brake,” Clayton said. “I pushed in on the clutch and rolled into a fuel barrel.”

Beyond the many learning experiences, Alyssa and Clayton cherish the time they’ve been able to spend with their grandpa and dad.

“I spent a lot of time in a combine cab with [my grandpa],” Alyssa said.

The opportunity to grow up on the farm surrounded by family is something Alyssa is thankful her daughters get to have today.

“I’ve got my daughters,” Alyssa said, “and I’m pretty excited to see them grow up in and around farming like we did and farming the family farm. [My daughters] get to spend time with great grandpa, which is not something every girl gets to do.”

For the Waldschmidts, farming truly runs in their blood. It is their heritage and what has brought them to where they are today. It is also their future one which is filled with the next generation in place to continue the legacy started by those before them.

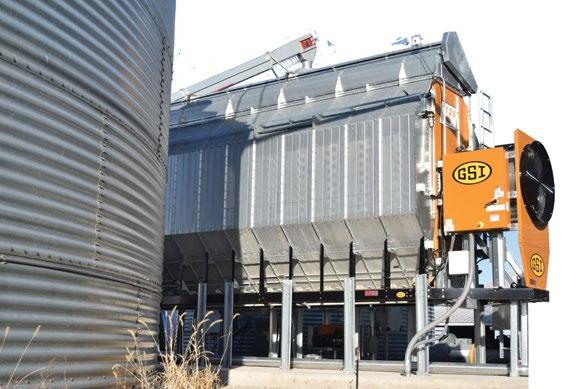

Upgrades. Upgrades. Come get your upgrades. No, you’re not at the ballpark hearing a man call for anyone who wants a hot dog. You are, however, reading about grain handling equipment and upgrades, two things you don’t hear together all that o ten. Even though equipment like dryers can feel stagnant compared to some of the other types of equipment we have, GSI has been chipping away at improvements to make life easier for growers.

The most recent improvement GSI has made is their new dryer remote monitoring platform, GSI Connect, for dryers with Vision controls. The new platform is meant to be more user-friendly than WatchDog, which was challenging to navigate at times and provided limited insight into what was happening with your dryer.

GSI Connect is available in two formats: web-based or cellular-based. The web-based option functions similarly to WatchDog where you will visit a website to view information about your dryer. What you see when you visit GSI Connect will look and feel di erent than WatchDog because there is an updated interface with new capabilities. The cellular-based option is accessible through a mobile app, allowing you to easily adjust temperature set points, fan and load settings, compare grain temperature and moisture stats, and stop the dryer if needed — all from the convenience of your phone.

Another perk to the app format is it can be set to send you text alerts and push notifications, making sure you're alerted to what’s going on with your dryer when you're not actively using the app. You can even customize what notifications you do and don’t receive. Before, growers were at risk of going to bed with a dryer running and waking up the next morning to find that their bin wasn’t empty, and the dryer shut o in the middle of the night. Now, this setback can be avoided with the ability to know what’s happening and address the issue in real time.

With this new system, there is also no longer a need for a static IP address from your internet provider. We can all collectively let out a sigh of relief because having to have internet hardwired to a dryer or finding a way to get it to transmit wirelessly was nothing short of a hassle. What was once a deterrent for some is now obsolete. Instead, all operations are managed via the cloud, an internet-based remote data storage service.

GSI Connect is a yearly subscription-based service with an annual fee of $399. A hardware kit is also required to retrofit current vision dryers. Moving forward, the necessary hardware will be available for customers to have installed in new dryers before they leave the factory.

WatchDog will be turned o in 2027, so for current WatchDog users it’s beneficial to get the switch made to GSI Connect now. By doing so, you will ensure there is no lapse in coverage, and you will be able to experience the improved usability sooner.

Another one of the beneficial upgrades GSI has launched in recent years is the UV flame sensor for dryers with Vision controls. GSI portable dryers have a flame probe designed to detect the energy a flame gives o as it burns. The probe sends that energy to the flame sensing board to show there is a flame present and therefore, the gas valves should remain open. What tends to happen is the flame probe fails or the flame isn’t touching the probe, and the flame will extinguish and not relight until the dryer is physically restarted. Luck always has it that this happens in the middle of the night or at a time when you aren’t nearby, slowing down the drying process and wasting precious time.

This issue can be one of the past with the UV flame sensor, designed to replace the flame probe. The sensor uses ultraviolet light to sense the light the flame produces to keep the dryer running. While the sensor is now a standard o ering on new GSI grain dryers, older dryers with a flame probe can also be retrofitted.

We installed our first UV flame sensor in 2019 and since then, that dryer has not had a lighting issue or a problem staying lit as a result of a flame probe malfunction. The UV flame sensor is a handy upgrade that can save time when it matters most and keeps your dryer doing what it should — drying.

It’s not all the time that we see new options for dryers to help improve the drying experience. Both GSI Connect and the UV flame sensor are designed to keep your dryer operating smoothly, allowing you to spend more time farming and less time babysitting your dryer. Not to mention, you can go to that baseball game without having to worry about what’s happening back at your bin site.

Since their introduction in 2022, Bazooka Farmstar’s Renegade agitation trailers have been popular with manure pumpers of all types. Designed to maximize e ciency, the Renegade line provides agitating, transferring, tank filling or force feeding in an all-in-one package. As a compact trailer-bound agitation solution, Renegades are easy to transport at highway speeds, pull right up to the manure source and quickly maneuver the boom into a manure pit or lagoon. Conveniently, they eliminate the need for additional equipment, like traditional vertical pit pumps, to agitate manure. At the 2024 World Pork Expo, Bazooka Farmstar announced a new addition to their Renegade lineup, the 32’ Renegade 2.

The 32’ Renegade 2 is designed to be a cost-e ective agitation gooseneck or bumper-hitch trailer with its predecessors' convenient and e cient design. It has a 32’ triple-section boom reach with 8” through-the-boom plumbing, a key upgrade the Renegade 2s have from the Renegade 1. This plumbing minimizes the need for external hoses and reduces the time spent setting up. It also has a 13’ below-grade pumping depth, 28’ maximum reach from the side of the trailer at ground level and 15’ 6” maximum slurry height. The 32’ Renegade 2 comes standard with a 125CC hydrostat motor; when paired with the standard 173HP engine and 15” Bazooka Farmstar submersible pump it can reach up to 2,900 GPM. The pump has a heavy-duty bearing housing with no mechanical seal (hello, easy maintenance). This agitation trailer also has many other popular upgrades like the 10” integrated load stand, remote controls (including tank fill remote fobs to switch from agitate to fill mode) and hydraulic rear-mounted hose reel.

Low-Mounted Discharge Plumbing

200-Gallon Steel Fuel Tank with Ba es and Sump

Manual Hydraulic Agitation and Boom Controls

Rear-Mounted Hydraulic and Engine Controls

4 Hydraulic Downriggers, Rear Driver Side Extends Outward

Bazooka Farmstar’s Renegade 1 (the original) has a 29’ triple-section boom with a 15’ below-grade pumping depth. While not initially introduced with the trailer, it now has a hydraulically controlled, 10” integrated load stand option. The trailer comes standard with a 125CC hydrostat motor, 15” Bazooka submersible pump, 173HP engine and 150-gallon steel fuel tank, giving you over 16 hours of run time and a GPM of over 2,900.

The 42’ Renegade 2 upped the game from the Renegade 1 with increased flow, longer boom lengths and even more convenient features. When the Renegade 2 was launched, one of the key di erentiators was its ability to work for manure lagoons, hard-to-reach confinement pits and slurry storage tanks. The high-ground clearance gooseneck or bumper trailer has a 42’ triple-section boom with through-the-boom plumbing, 21’ below-grade pumping depth, 41’ maximum reach from the side of trailer at the ground level and 20’ 6” maximum slurry store height. It also came with increased flow; it has a GPM of up to 4,000 when the standard 180CC hydrostat motor is paired with a 250HP or 310HP engine and 18” Bazooka Farmstar submersible pump.

All Renegades come equipped with two, 3.5” diameter nozzles, manual agitation and boom controls, LED flood lighting, built-in storage baskets and optional remote controls.

TRIPLE-SECTION BOOM LENGTH

BELOW GRADE PUMPING DEPTH 42’ RENEGADE 2

TRAILER TYPE

TANK

LOW MOUNTED DISCHARGE PLUMBING

INTEGRATED REAR TOOLBOX WITH USB CHARGING PORT FOR REMOTE

OUTRIGGERS/DOWNRIGGERS

OPTIONAL HOSE REEL

OPTIONAL LOAD STAND

GPM over 2,900 when paired with a 125CC hydrostat motor, 15” Bazooka submersible pump and 173HP engine

GPM of up to 2,900 when paired with a 125CC hydrostat motor, 15” Bazooka submersible pump and 173HP engine

Bumper Pull or Gooseneck

GPM of up to 4,000 when the standard 180CC hydrostat motor is paired with a 250HP or 310HP engine and 18” Bazooka Farmstar submersible pump

2 Hydraulic Rear Outriggers 4 Hydraulic Downriggers, Rear Driver’s Side Extends Outward

Holds 100’ of 8” Lay Flat Hose

Holds 100’ of 10” Lay Flat Hose

Holds 100’ of 10” Lay Flat Hose

24” Stroke Front Hydraulic Downriggers & 30” Rear Hydraulic Outriggers, Extending 60” 12” diameter

The entire Renegade lineup has been designed with manure pumpers in mind — from its all-in-one design to its ease of use and e ciency. The newest addition to the lineup, the 32’ Renegade 2 brings many of the key features that have made the Renegades so popular at a size that is a good fit for a wide range of manure management situations. To learn more about the newest Renegade, chat with a member of our manure equipment team.

From scouting customers’ fields to serving employees to coordinating the movement of freight, you can find our 2024 interns scattered throughout our organization. We’re excited to gain their fresh perspectives this summer in agronomy, human resources and logistics. Help us in welcoming our intern class by getting to know a little bit about them!

Oliver: I am involved in Agricultural Business Club and Iowa Corn.

Claire: Agronomy Club and Weight Club

Emily: I am involved in the Iowa Corn Growers Association, Agronomy Club, Collegiate Cattlemen's and Agricultural Business Club.

Sam: DMACC Ag Business Club and FFA

IOWA STATE UNIVERSITY | AGRICULTURAL BUSINESS, INTERNATIONAL AGRICULTURE

AGRONOMY INTERN, HILLS LOCATION

AGRONOMY INTERN, HILLS LOCATION

CLAIRE BEITZ | TIFFIN,

IOWA STATE UNIVERSITY | AGRICULTURAL STUDIES WITH A MINOR IN AGRONOMY

Oliver: Some of my hobbies are playing guitar, going to the gym and working on my truck.

Claire: I enjoy hanging out with friends, playing golf and traveling.

Emily: I spend most of my free time working with my dad on our family farm, washing show calves, li ting weights and going on drives with my friends.

Austin: Some clubs and organizations I am involved in are the Supply Chain Management Club and the Ski and Snowboard Club.

Savannah: I am involved in Student Senate (I was elected to be the Central College Student Body President for the '24 to '25 academic year), volunteering as an English teacher for ELL students each week at a nonprofit organization in Des Moines, A Cappella Choir on campus, and Wind Ensemble on campus.

Sam: I play the guitar and sing, so I stay pretty busy playing at bars and other venues during my free time. I also have some cattle I spend time with as well.

Austin: I enjoy various hobbies that allow me to unwind and connect with others. Golfing is a passion of mine; I enjoy the competitive part of the game and being able to hang out with friends. Skiing is another favorite pastime; it is something that I have been doing for a long time and hope to never stop doing.

Savannah: I like to read, be outdoors and spend time with my friends and family.

Oliver: Growing up I have always had a passion for agriculture. I am pursuing a degree in ag business because of the opportunities that arise from this great major at Iowa State.

Claire: I was inspired to get into agriculture by my FFA Advisor, Alyssa Amelon. I was an FFA soil judge, and that is where my curiosity for agriculture grew.

Emily: I grew up on a family farm and had the opportunity to be very involved with it. I realized I had a massive passion for the agriculture industry and knew it was what I wanted to do for the rest of my life.

Sam: Growing up on a farm had a big influence on me wanting to go into agriculture. Along with people I've met through FFA, it made me want to find ways to stay involved in the ag industry.

Austin: One of the things that inspired me the most to pursue a career in logistics was the 2020 COVID-19 pandemic. The pandemic started when I was a junior in high school, but it showed many people significant flaws in their supply chains. Once I got to college, I wanted to be able to be an asset to anyone that I worked for. This degree seemed the best for that.

Savannah: I am very interested in business and knew that is what I wanted to study in college. I was not sure exactly what I wanted to do, but I knew I wanted to study business. Shortly a ter I started college, I realized that I definitely wanted to go into an area of business that allows me to work with people every day. I felt human resources was a perfect career choice for me because it involves business but also allows me to work with people every day.

Oliver: I’m looking forward to learning a lot about crops and what discrepancies or deficiencies may arise in the corn from insects or even fertilizers.

Claire: I am most looking forward to working with local farmers, learning more about the industry and putting my drone skills to use.

AGRONOMY

AGRONOMY INTERN, HILLS LOCATION

AGRONOMY INTERN, FAIRFAX LOCATION

DES MOINES AREA COMMUNITY COLLEGE | AGRICULTURAL BUSINESS

Emily: I look forward to the hands-on aspect and learning more about crops. I am also excited to know more about what to do if a problem arises and how to keep plants healthy.

Sam: Learning more about crops and how di erent companies work.

Austin: The part of the internship I am looking forward to the most is being able to understand all parts of the supply chain. By the end of the internship, I hope to understand which part I was most interested in. I am just learning about what it takes to be able to organize and run a supply chain e ectively.

Savannah: I am looking forward to working with the new Paycor system, learning more about recruiting and getting to know people at Stutsman!

Oliver: I look up to my grandpa Scott Day the most because of how supportive he has been to me along my college journey. Claire: I look up most to my mom. I admire her for her exceptional work ethic and drive. She has an infectious humor, and she approaches her work with passion and dedication. She has set a great example for me growing up, and I hope to emulate that in my life.

Emily: I look up to my dad the most because he is why I am so involved with agriculture. He always let me be a part of the farm; sometimes, it was as small as picking up food for the planting/harvest crew. Other times, I was able to be a part of the crew by doing tillage or running the grain cart. He helped teach me my independence and work ethic from a young age. He always pushed me to be the best me I could be.

Sam: My ag teacher, Mrs. Bridget Mahoney. During high school, she was always someone we could go and talk to whenever we had a problem. She also tried her best to help us out with whatever we were doing, whether it was for a contest or for our Iowa FFA Degree. I never looked forward to going to school, but I always looked forward to going to her classes as there was never a dull moment in her room.

Austin: The person that I look up to the most is my grandpa. He has always been a super hard worker, and when times are tough, he can put a smile on anyone's face.

Savannah: I look up to my grandma because she is the kindest person I know. I aspire to be like her.

Oliver: When I graduate, I would love to pursue a career in grain merchandising and show o my expertise in grain markets.

Emily: I want to become an in-field agronomist and possibly return to school to earn my doctorate.

IOWA STATE UNIVERSITY | SUPPLY CHAIN MANAGEMENT

Sam: I hope to be an ag education teacher and an FFA advisor.

CENTRAL COLLEGE | BUSINESS MANAGEMENT WITH AN EMPHASIS IN SECONDARY EDUCATION AND A MINOR IN SPANISH

Austin: A ter graduation, I am unsure if I would like to find a job right away or continue to get my master's degree. Savannah: I would like to go into human resources. More specifically, I would like to go into recruiting!

Claire: While I’m still exploring my interests, one of the aspects I am most drawn to about the agriculture industry is the diverse range of opportunities. I have a genuine passion for working alongside farmers and engaging with people, which is why roles in sales or research interest me the most.

Oliver: The core value that means most to me is Instill Authenticity, because I believe everyone should take pride in their work. I believe everyone should be honest, and everyone should be proud of what they can bring to the table no matter what their profession is.

Claire: Radiate Enthusiasm is my favorite core value of Stutsmans. I want to bring a good attitude into the workplace, and I am excited to learn and see what I can do in this new position.

Emily: The core value that means the most to me is to Set the Bar Higher. I would choose this one because I always hold myself to a high standard to be the best I can be. I must hold myself to higher standards to ensure that the work I am doing for someone else is as good or better than the way I would do it for myself. It is important because if everyone has that mindset, there are no limits on what can be accomplished.

Sam: Radiate Enthusiasm. I think having a good attitude is very important all the time. Even though it can be di cult to have one sometimes, being with others who have a good attitude can always help yours and others.

Austin: The core value that means the most to me is Take the Lead. By instilling this in everyone in the company, no matter the position, anyone can be a leader. Also, to be able to be a leader, you need to have the ability to be led.

Savannah: I think Radiate Enthusiasm stands out the most to me because it really emphasizes the importance of having a positive attitude. It is true that attitudes are contagious, and I feel it is essential to have a positive attitude in order to make work enjoyable!

Take the guesswork out of disease control in corn and soybeans with Miravis® Neo fungicide. With a power-packed combination of ADEPIDYN® technology, azoxystrobin and propiconazole, Miravis Neo delivers unmistakably superior plant-health benefits and disease control for a greener, healthier plant that you can see.

If you haven’t already, ask how Miravis Neo can help boost yield and ROI potential. Visit SyngentaUS.com/Miravis-Neo

The Ferti-GO’s 409 painted stainless steel, four-ton capacity hopper comes with the same metering system used on Salford’s ST series and other Valmar products. Salford’s metering and air manifold system is known for being highly accurate and easy to use and clean out. The metering is performed by plastic pegged rolls located underneath the hopper driven hydraulically by PWM valves. The metering rolls drop dry fertilizer into Venturi air manifolds where they meet air coming from Salford’s high-volume, hydraulic-driven fan. A single fan can output up to 200 lbs of fertilizer per acre at speeds up to 6 miles per hour on 24 planter rows. The optional dual fan setup allows up to 400 lbs per acre at the same rates.

The fertilizer output on the Ferti-GO can be calibrated per section and per row. The Ferti-GO can be paired with planters in 8-, 12-, 16-, 18-, 20- and 24-row configurations. Optional splitters allow for use in up to 36-row planters. All Ferti-GO units can meter variable rates with four-section control. The Ferti-GO comes standard as rate control ready with sensors for metering, fan speed and bin level. For controllers, the Ferti-GO can be optioned with Salford ISOBUS, or our recommendation, a Raven Rate Control Module. Both ISOBUS controllers plug into the ISOBUS connector on the tractor or can be piggybacked onto the ISOBUS of the planter.

The Ferti-GO comes standard with a manual roll tarp, ladder and platform to allow for easy fertilizer loading. Options include extensions to add two tons of capacity (total six tons), scales that can be tied into the ISOBUS, various sizes of manifolds and hose combinations, air di users to keep air from blowing fertilizer out of the trench, low-rate meters, and the high-output, dual fan option.

The Ferti-GO is a fairly unique piece of equipment because you don’t see too many options for on-planter dry fertilizer applicators. One of the main benefits of the Ferti-GO is the ability to do more in one pass. When you’re operating by yourself or with limited additional help, this can make a big di erence. Compared to applying dry fertilizer at other times, an on-planter option allows you to put the fertilizer in the ground rather than on top, making it more readily available. You can also apply the full fertilizer rate with the Ferti-GO.

If the Ferti-GO sounds like a good fit for you, visit with one of our precision equipment sales team members. The Ferti-GO is a very specialized piece of application equipment, and there will be some questions to answer regarding the planter it is intended to be mounted on. However, for those with the right type of planter, the Ferti-GO has the potential to be a great addition.

One of the biggest things I like about the Nuhn toolbar is you have various options of di erent footages and rows. You can go smaller or very large with 16 rows. I run a ten-row bar. I really like the way it covers and how you can do slight corners with it. So, that works really well because the openers will actually swivel, and I like the double rear cover on it.

I like the row units because they’re simple, lightweight and do a good job to no-till behind. They allow us to run bigger bars on our tanks than what anybody else o ers, increasing our load capacity. If something breaks, they’re easy to fix because there are very few parts to the whole system.

Cedar Family Farms

Cedar Family Farms

Even though our newest team member grew up on a farm, his interest in precision ag wasn’t sparked until his senior year of high school when working with his dad to put precision equipment on their new tractor. In his new role in precision ag sales and service, Jacob Draves helps customers develop a technology game plan for their equipment. He also helps with product installation and assists the technicians in the shop with trailers, sprayers, pumps and more.

Jacob grew up in Muscatine, Iowa, where he is the fourth generation on his family’s farm. He attended Muscatine Community College to get an associate degree in farm management. Before joining our team, Jacob worked on his family’s row crop and cattle operation as well as multiple other farm operations. In his free time, Jacob can be found enjoying spending time with loved ones, walking through his cattle herd, hanging out with friends and playing sports.

WHAT ARE YOU MOST PASSIONATE ABOUT?

I’m most passionate about spending time on the farm and trying to achieve the goals I have had ever since I was a little kid.

WHAT IS THE BEST ADVICE YOU HAVE EVER BEEN GIVEN?

My grandpa once told me, "If you tell the truth, it doesn't matter what the reaction will be."

WHAT IS YOUR PROUDEST ACCOMPLISHMENT?

Having my own cattle herd.

IF YOU WERE A PRODUCT YOU WORK WITH, WHAT WOULD IT BE?

I would be the Ag Leader’s RightSpot product because you would get to see so many di erent places, cover more acres and keep your owner happy by reducing input costs, time and labor while increasing the number of coverage options.

WHO HAS INFLUENCED YOUR CAREER THE MOST?

My parents by far. My mom taught me more about the business side of my career; she taught me how to present myself in front of others and to always hold my head high. She also encouraged me to go o the farm. My dad showed me what hard work truly is and was always willing to let me try my way, whether it failed or succeeded.

WHICH STUTSMAN CORE VALUE MEANS THE MOST TO YOU?

Radiate Enthusiasm. I feel like when people are enthusiastic about what they’re doing, it makes the whole workplace more enjoyable.