2 4 6 8

EXTREME TREE & POST PULLER VS. TERMINATOR TREE PULLER & STUMP REMOVER

A NEW TERRITORY

JACOB DELAY EXPANDS ROLE TO EQUIPMENT SALES

STEPS TO FERTILITY MANAGEMENT

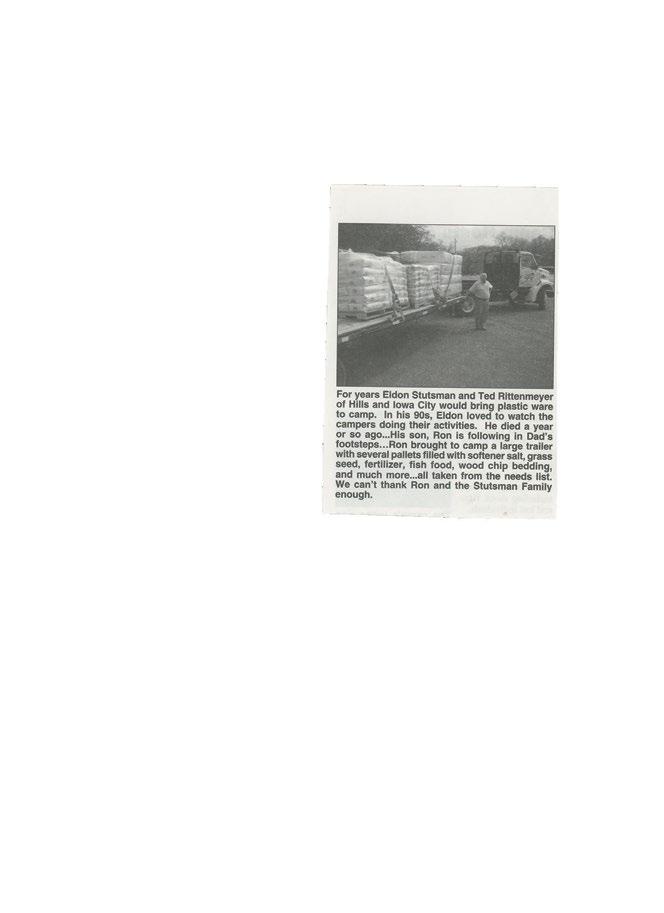

CONTINUING ELDON’S TRADITION

THE 2023 CUSTOMER APPRECIATION RAFFLE

MEET THE TEAM SAM ROTH

FALL HARVEST REMINDERS

PRIORITIZING SAFETY AROUND GRAIN HANDLING EQUIPMENT

BACK TO THE BASICS

THE IMPORTANCE OF P AND K

THE SALFORD INDEPENDENT SERIES

OUR GO-TO FOR VERTICAL TILLAGE EQUIPMENT

MEET THE TEAM KEEGAN MEYER

THE NEW BAZOOKA FARMSTAR PHANTOM 2 INJECTION UNIT

REDUCING DOWNTIME, INCREASING UPTIME

2024 HYBRID PICKS

COVER CROP COMMENTARY: FALL SEEDING

NH COOLERS SAFETY AND MAINTENANCE

Our chairman of the board, Ron Stutsman, was recognized as an Iowan of the Day at the 2023 Iowa State Fair for making a positive di erence in the community.

Find out what jobs you can tackle from the cab of your skid steer. View the attachment catalog online! ecsattachments.com

Manure parts are now on shopstutsmans.com!

Trade in your legacy display and receive credit towards the purchase of a new Raven Viper 4+, CR12 or CR7. Contact our equipment division for more information.

» Agronomy Sales Representative

» Custom Applicators

» General Operations

» Grain Bin Installation Manager

» Parts Specialist

» Wholesale Hose and Valve - Eastern U.S.

Territory Sales Manager

» Wholesale Hose and Valve - Western U.S.

Territory Sales Manager

Apply at stutsmans.com/careers or call HR at 319.679.5268

On the fence (see what we did there) between the Extreme Tree & Post Puller and the Terminator Tree Puller & Stump Remover? The questions I pose are: what are you trying to accomplish now, as well as are there any o -the-wall projects you may have in the future?

If recreational small tree and post plucking (all above ground) is all you’ll ever intend on doing, I’d recommend the Extreme Tree & Post Puller all day long. If above-ground tugging is your primary use but you know you tend to venture into some more serious tree and brush-clearing situations from time to time, I’d encourage you to not limit your future self and lean into the digging power of the Terminator Tree Puller & Stump Remover. Beyond the ability to cut and dig below-ground roots, the bigger, dual hydraulic cylinders o er more squeeze power for larger posts, trees or brush. Given the more aggressive power of the Terminator, the back shield protects your skid steer as you tackle overgrown areas. Here are a few of the key features and di erences of both:

EASILY

TERMINATOR TREE PULLER & STUMP REMOVER

HYDRAULIC CYLINDERS OUT FRONT FOR MORE POWER

PROTECTIVE SLEEVES ON HYDRAULIC HOSES

TWO 1½” PIVOT PINS ALLOWING BOTH SIDES TO OPEN

DUAL 3½” X 4” CYLINDERS WITH 1¼” PINS

48” JAW OPENING AND 29,000LB CLAMPING FORCE TO PULL 12” TREES

⅝” AR400 SERRATED VERTICAL TEETH FOR CUTTING UPWARD THROUGH ROOTS

1” X 8” CUTTING EDGE IS ABLE TO DIG UNDER STUMPS AND ROOTS

STEPS ON BOTH SIDES BACK SHIELD

While this resident TikTok creator extraordinaire, Jacob DeLay, is not new to Stutsmans or the manure equipment division, he is expanding his current role to include sales in the Illinois territory. Jacob grew up on a cow-calf operation in Milo, IA and received a degree from Iowa State University in agricultural studies. His time at the Iowa State University dairy farm and experience as a flow and control electronics technician at Stutsmans makes Jacob a perfect fit for this new role helping customers find the right manure equipment for their operations' needs. He has hit the road and started serving customers in his new position. To connect with Jacob, call 319.325.0913.

I LOOK FORWARD TO WORKING WITH THOSE WITHIN MY SALES TERRITORY AND BEYOND AND HOPE TO EARN THEIR FRIENDSHIP AND TRUST.

HOW WILL YOUR PREVIOUS ROLE IMPACT YOUR NEW ROLE?

My knowledge of equipment and precision will help me o er better service to customers.

WHAT EXCITES YOU THE MOST ABOUT YOUR NEW POSITION?

I am most excited to get out and meet new people, be out on the road, and help expand our sales territory to reach more customers.

WHAT ARE YOU MOST EXCITED TO LEARN IN YOUR NEW ROLE?

Every day I learn something new. I am excited to learn more about the manure and liquid pumping industry. As I take on a sales role, I look forward to learning more about di erent geographical regions and what application types help meet customer needs in these di erent areas.

WHAT DO YOU ENJOY DOING IN YOUR SPARE TIME? TELL US ABOUT YOUR HOBBIES. A few of my hobbies are shotgun sports, fishing and camping. I am also a volunteer firefighter and nationally registered EMT.

WHAT IS YOUR PROUDEST ACCOMPLISHMENT?

My proudest accomplishment was obtaining my National Registry of Emergency Medical Technicians (NREMT) certification.

IF YOU COULD SNAP YOUR FINGERS AND BECOME AN EXPERT AT SOMETHING, WHAT WOULD IT BE?

A professional sporting clay shooter so I could shoot in the circuit.

WHAT IS THE BEST ADVICE YOU HAVE EVER BEEN GIVEN?

Plan your work and work your plan.

WHICH STUTSMAN CORE VALUE BEST REPRESENTS YOU?

Value Collaboration. I like working with others and being able to collaborate on work and projects.

FULL HYDRAULIC FUNCTIONS

TWO NOZZLES WITH INDIVIDUAL SHUTOFFS

DIRECT DRIVE OIL COOLER

LOW NOZZLES

REMOTE CONTROLLED

STRONGER HITCH ATTACHMENT

STORAGE LEGS

Many have heard agricultural companies promoting their products as “increasing yield” or “adding bushels.” This common advertising tactic captures the attention of the farmer and creates an interesting conversation piece, but in reality, input decisions farmers make can only protect yield – not increase it. It is easy to get caught up in the hot topics of biologicals and foliar nutritionals, but if other, more fundamental factors aren’t prioritized then additional crop inputs may not provide a return on investment.

Many have heard agricultural companies promoting their products as “increasing yield” or “adding bushels.” This common advertising tactic captures the attention of the farmer and creates an interesting conversation piece, but in reality, input decisions farmers make can only protect yield – not increase it. It is easy to get caught up in the hot topics of biologicals and foliar nutritionals, but if other, more fundamental factors aren’t

Grain yield is determined by the plant’s most limiting resource as described in Liebig’s Law of the Minimum –o ten illustrated as a barrel with staves representing independent growth factors (Liebig’s law of the minimum, 2019). If one growth factor is limited or deficient, then yield cannot be maximized. Corn and soybeans have the most yield potential when they are seeds in a bag – as soon as planting begins, the seeds and plants become exposed to biotic stresses (e.g., insects, diseases, weeds) and abiotic stresses (e.g., weather, fertility, soil characteristics) that minimize yield potential. Obviously, some factors carry more weight than others, and there are many variables farmers cannot control. As for things farmers can control, soil fertility management is key, and it may help get back the basics with a step-by-step plan.

uptake of all other essential nutrients.

Soil pH a ects a plant’s ability to uptake nutrients. The ideal pH for corn and soybeans is between the range of 6.0 to 7.0. Most of the pH management decisions made in southeast Iowa have to do with correcting acidic soils (pH < 6.0). Grid soil sampling and applying lime to the low testing areas is the most e ective way to properly manage soil pH.

Phosphorus and potassium are two macronutrients that are taken up by corn and soybeans in large quantities. One must consider the removal rates of these nutrients when making fertilizer applications as well as the soil test value. Improper soil sampling and fertilization for P and K will have a negative e ect on the crop and will become most apparent under adverse weather conditions.

The term “micro” in micronutrient does not mean “less important” but rather it means a smaller quantity is required than macronutrients. Soil and plant tissue sampling is a good way to monitor these nutrients. Using these samples to make applications accordingly in low performing fields will help protect yield (Pagani et al., 2013).

There are many more details to talk about and highlight on this topic, but there is value in getting back to the basics in a world full of new, eye-catching products and advertisements. These steps provide a basic overview of fertility management and should help give farmers an order of importance to focus on. Good soil fertility is a proven way to take more control of crop performance and will help maximize yield in both favorable and

https://cloudprod.dekalbasgrowdeltapine.com/en-us/agronomy/corn-nutrition-101.html

https://en.wikipedia.org/wiki/Liebig%27s_law_of_the_minimum

Camp Courageous is an organization near and dear to our hearts here at Stutsmans. Eldon Stutsman admired Camp Courageous and its mission to help local youth with special needs and their families. Throughout the years, Eldon would collect plastic silverware, paper products and whatever else the camp needed to ensure the children could have a successful experience. Eldon and the family would travel to support the annual spring omelet and fall pancake breakfast benefits. On their trip, they would take the collected supplies as well as a monetary donation to give to Camp Courageous. With a big heart, Eldon loved to support the children and the camp each year. We have continued to honor his passion for Camp Courageous with support whenever we get a chance whether that be a semi-load of so tener salt, livestock supplies for their barn or monetary donations.

During our 2023 Customer Appreciation Dinner, we held a ra e for the first time to raise money for Camp Courageous. Attendees could purchase one ticket for $10 or 12 tickets for $100 for the opportunity to win a $1,200 gi t certificate to use at Stutsmans. All proceeds from ticket sales went toward Camp Courageous.

A ter the ra e was all said and done, the big winner was Nancy Waldschmidt. A total of $1,588 was raised for Camp Courageous during this inaugural ra e. From the bottom of our hearts, thank you to everyone who purchased a ra e ticket, helping us continue Eldon’s tradition.

Today, Camp Courageous, based in Monticello, IA, provides year-round recreational, respite and travel opportunities for individuals with special needs and their families. Camp Courageous supports around 10,000 individuals of all ages every year.

2023 Wi er Nancy W midt

Ron Stutsman t king w h mp ura s CEO, arlie Becker

2023 Wi er Nancy W midt

Ron Stutsman t king w h mp ura s CEO, arlie Becker

Fall harvest is a bustling time. It’s the pinnacle of the crop season – the Super Bowl for row crop growers if you will. It can also be one of the most tragic and devastating times. The stories usually go something along the lines of “a corner was cut,” “a deadline needed to be met,” “exhaustion had set in,” or “it has been done this way in the past and nothing bad has happened.” We realize how exciting, exhausting and potentially dangerous this time can be. So, here are a few grain equipment safety tips for when you’re in the thick of it:

Make sure anyone working around grain equipment is properly trained in how to safely use and be around it. This is especially important for keeping younger workers safe. A Purdue University study found in 2022, five U.S. grain entrapment cases were individuals under 21 years old (Cheng et al., 2023).

Double check all guards and shields are placed on belts, augers and PTOs to prevent getting entangled.

Be aware of electrical lines when moving equipment like augers. Before moving, lower your auger so it can safely clear electrical lines.

Place a safety gate (also commonly referred to as a safety door or guard) on grain bin ladders to prevent unauthorized individuals, including children, from climbing grain bins when they shouldn’t be.

Check for leaky gas lines.

Watch out for any auger shaking and whether your auger needs to be reattached.

If grain becomes spoiled and you need to break up clumps or crusts, avoid entering the grain bin and placing yourself at risk of becoming entrapped. Instead, try using a long pole to disrupt the clump or crust.

If you absolutely need to enter a grain bin, LOCK OUT, TAG OUT to avoid an accidental engagement of the grain bin unload auger, have an observer watch that nothing goes wrong, wear a mask or respirator to avoid small dust particles making it di cult for you to breathe, and wear a harness attached to a secure rope to prevent falls or entrapments.

Even though we know more about staying safe on the farm than ever, grain-related entrapments and farm accidents are still rising. We don’t want you or someone you love to become a statistic. Stay safe this season!

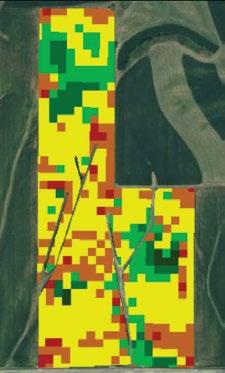

Farming and crop production have always been a balancing act with Mother Nature, and this year was certainly no exception. The dry conditions experienced at the end of the 2022 growing season carried over into the start of 2023. These conditions were compounded by excessive cool temperatures in the last two weeks of April. As the crop emerged and began to develop into the vegetative stage, some drought-induced deficiencies symptoms appeared phosphorus and potassium notably. This was not a rare sighting for some of the historically lower performing parts of a field, but it was abnormal for these deficiencies to also show up in higher-yielding and well-fertilized areas, in both corn and soybeans.

Dry conditions reduce plant uptake of nutrients, including phosphorus and potassium. Additionally, factors such as soil compaction, side-wall smearing during planting and root pruning further limit the plant’s ability to uptake nutrients during a period of abnormally dry soil conditions like we witnessed (Sawyer, 2000). With whole fields and sections of fields already being low in phosphorus and potassium at the start of the growing season, dry conditions only made the nutrient deficiency symptoms worse. Even some of the fields or sections of fields which started the growing season with adequate P and K levels were impacted by the dry conditions, limiting the plant’s uptake ability of these nutrients.

Although we can’t control the rain patterns and in many areas of southeastern Iowa we grow crops without irrigation, we can minimize the factors that reduce nutrient uptake when the weather is favorable so we’re always maximizing our potential. Consider the following:

Know the nutrient value of your soil by soil testing every four years. Use grid sampling to get the best representation of your fields high performing and low performing areas. Consider 2.5 acre grids for sampling.

Consult with an agronomist to determine the amount of nutrient removal from your fields each year from harvest and at what pace you want to build the “lower than optimum” nutrient levels in your soil.

Many factors impact the rate at which you build P and K levels, including your designated budget for dry fertilizer application, application timing, weather, tillage program, etc. An agronomist can help you drill into a potential yield return on your investment in building P and K levels in your soil so you can be profitable while improving your soil.

Consider reading the recently updated, February 2023 publication from Iowa State Extension and Outreach about optimum fertility levels for crop production on their website.

Phosphorus and potassium are foundational nutrients for crop production and can be maintained at

PHOSPHORUS DEFICIENCY

POTASSIUM DEFICIENCY

GRID SOIL SAMPLING

PHOSPHORUS DEFICIENCY

POTASSIUM DEFICIENCY

GRID SOIL SAMPLING

blended dry fertilizer tailored to your fields’ nutrient needs and yield goals. We have any and all dry fertilizer products and can blend them together in di erent proportions based on your crop production goals. We can also deliver products to your farm or field and apply them for you at either a flat rate application or using variable rate technology, taking the work out of getting your fertility management under control.

In recent years, costs for dry P and K fertilizer have trended to all-time highs, pushing some growers to reduce or even eliminate their long-term plans for building P and K nutrient levels. However, markets have begun to swing downward, and costs for dry P and K this fall are less than the highs experienced in recent years. It is the perfect time to re-engage your P and K to more optimum levels in your fields and reduce nutritional deficiencies for the coming year’s crop. VARIABLE

RATE APPLICATION MAP

either 7½” spacing (I-1100) or 5” spacing (I-1200). These machines are typically run in the spring for seedbed prep but can be run in the fall at up to 4” deep.

The I-2100 and I-2200 o er the 1⅝” Coil-Tech Coulter II with 22” diameter blades on either 7½” (I-2100) or 5” (I-2200) spacing. These machines are more for fall fieldwork as they tend to be heavier, but they can also be run in the spring for seedbed prep. Maximum fall depth is around 4½” while spring depth is usually no deeper than what the planter would run.

The I-4100 and I-4200 are o ered as “hybrid vertical tillage” machines. They have two rows of rubber suspension-mounted concave blades in the front of the machine-mounted on a compound angle. These are followed with individually-mounted Coil-Tech II Coulters to assist with mulching and burying residue. These

I-4200 I-2200

Meet Keegan Meyer, our new AR/AP clerk! This rural Lisbon native and FFA member joined our administration team this past March. Prior to joining us, Keegan worked at a local vet clinic. In addition to being an AR/AP clerk and assisting with billing for the agronomy department, Keegan is also currently working toward her Associate of Applied Science degree in business administration through Kirkwood Community College.

WHAT ARE YOU MOST EXCITED ABOUT IN YOUR NEW ROLE?

I am excited to build customer relationships.

WHAT DO YOU ENJOY DOING IN YOUR SPARE TIME?

I enjoy working with and showing livestock, being with family and friends and being outdoors.

WHAT IS SOMETHING RANDOM THAT MOST PEOPLE DON’T KNOW ABOUT YOU? I am an only child.

WHAT IS ON YOUR BUCKET LIST? To travel out west!

WHAT IS THE BEST ADVICE YOU HAVE EVER BEEN GIVEN? Great things come from hard work and perseverance.

WHICH STUTSMAN CORE VALUE MEANS THE MOST TO YOU? Value Collaboration. I believe it takes a team to be successful.

In May, Bazooka Farmstar introduced its newest injection unit, the Phantom 2. The new unit’s predecessor, the Phantom 1 injection unit, set the standard for decreasing erosion, soil disturbance, and manure runo , which can negatively impact the environment. Like the Phantom 1, the Phantom 2 injection unit is compatible with both toolbars and tankbars. The new row unit comes with the hallmark features of the Phantom 1 such as precise injection ability at 4” to 6” below the surface, nickel-plated pins for corrosion resistance, 13-wave closure blades for more nutrients to be absorbed in the soil with less odor, and ease of repair.

The Phantom 2 injection units have a 2,500 to 20,000 GPA capability compared to the 2,500 to 15,000 GPA capability for the Phantom 1 injection unit. They also include a closure blade downforce adjustment, leading to more consistent coverage when field conditions and soil types vary (because no two fields can be the same, right?). If a field has harder ground, the closure blade can be adjusted to place more pressure downwards. As a result, more soil and plant matter will be moved then placed back over the trench the injector creates.

We’ve talked about the Phantom Edge units in the past when they were introduced as an upgrade to the Phantom 1 injection unit. In need of a refresher on the Phantom Edge units? Visit the “Getting an Edge With the Latest in the Phantom Line” and “Phantom Edge Follow-Up” articles on our blog. With a wider trench, the Phantom Edge Upgrade for the Phantom 2 allows for a higher GPA of 25,000. The Phantom Edge Upgrade is also further designed to tackle harder ground conditions.

Our manure experts have vetted the Phantom 2. Here are manure salesman, Mark Rohret’s, thoughts: The Phantom 2 injection units are an especially good fit for custom applicators because of their increased durability and longevity. One example of a longevity upgrade is the main hub now having two seals. They also require less maintenance than other injection units, keeping the manure pumping instead of being stuck in the shop. Replacing parts became a whole lot easier with the Phantom 2 because everything is bolted on, saving time when it matters most – not to mention, it’s one less thing to do when you’re already worried about everything else that needs to be done. The closure blade downforce adjustment is an added perk to the injection unit because of coverage consistency and adaptability to varying fields it provides.

As the Phantom 2 injection units see their first season this fall, we look forward to seeing what customers think about these new units. If we’ve piqued your interest, our manure equipment team is just a phone call or visit away.

SEE THE PHANTOM 2 INJECTION UNITS IN ACTION.

Seed placement can be a challenging task for anyone to accomplish. Fortunately, it doesn’t have to be a daunting task if we have yield goals, field history and yield potential in mind. There are numerous ways to place hybrids, but I like to break a field down into three categories when determining hybrid placement. This method helps simplify the seed placement process.

Our first category focuses on the high productivity acres. This category can have a bigger ROI impact on your operation and is usually where we can find the highest yields. From a hybrid standpoint, we want to try and maximize our yield potential by planting an o ensive or “racehorse” type of hybrid on these acres. A high productivity field can include the following: increased CSR2 ratings (83+), higher fertility levels and well-drained soils.

The second category includes variable or average acres. These acres are still productive but can have some issues like variable terrain and soil type, average fertility, or could have drainage issues. This category could describe most fields in a grower’s operation. For this category, a broad-acre placement hybrid is ideal –something that o ers a mix of defensive and o ensive traits, is adaptable to changing field conditions, and still delivers good yield results.

Finally, the last category describes tougher acres where soil types can vary significantly from light sandy soils to heavy clay sidehills. This could also include fields with rolling terrain, lower CSR2 ratings and lower fertility. Thanks to modern hybrid genetics there are solutions tailored to this environment. For these fields, we are looking for a hybrid with a strong root system to handle tough, root-limiting environments, stalk strength for harvest standability, and a good disease package (especially for areas with limited access to fungicide applications).

HERE ARE SOME OF MY 2024 PICKS FOR THE CATEGORIES BELOW:

HIGH PRODUCTIVITY ACRES

AVERAGE OR VARIABLE ACRES

TOUGH ACRES

AgriGold A641-85TRE

Brevant B09Z08AM

Dekalb DKC62-89TRE

AgriGold A644-19 3220EZ

Brevant B12C01AM

Dekalb DKC65-95RIB

AgriGold A643-52VT2

Brevant B13K20AM

Dekalb DKC63-57RIB

If you frequent any ag forum, chances are you will see discussion on cover crops with opinions ranging from growers that have had success to growers who have given up on them. Cover crops do have the potential to increase organic matter, provide weed control, reduce compaction and erosion, and produce feed for livestock. However, they also come with some potential downfalls and their own set of challenges. Whether you’re on the cover crop train or not is entirely up to you, but if you’re even just a little bit curious, here are a few things to consider as we enter the fall cover crop seeding time in Iowa and across the Midwest.

One of the first steps to integrating cover crops into an agronomy plan is deciding how to seed in the fall. There

While drilling guarantees the best seed distribution and seed-to-soil contact, it is also dependent upon the corn and soybean harvest being completed. Depending on how long that takes, drilling might not be able to take place until a ter the ideal planting date (mid to late October). Less grow time equals less biomass and

Broadcasting with incorporation is the most common seeding method we see our customers using. This method can occur using a single or double pass system. One example would be using an air seeder or applicator like the Valmar 56 Series attached to a piece of equipment. A ter the seed is broadcasted, it should be incorporated into the soil using vertical tillage or another tillage form. Some growers use a rig that allows them to seed and incorporate (i.e., broadcasting seed while applying dry fertilizer and tilling) in a single pass rather than two. We find that growers in our area prefer broadcasting cover crop seed with dry fertilizer and following with tillage. Broadcasting with incorporation should also take place from mid to late

Overseeding is done using high-clearance equipment or aerial broadcasting since it takes place when there is methods used in the Midwest because it can be done while the corn or soybean crop is still in the ground around late August to early September. Overseeding should take place by September 15. Aerial seeding also allows for more acres to be seeded in less time. However, it tends not to be as evenly distributed and has a greater likelihood of the seed being eaten by rodents or birds. To combat this, it is better to plant a heavier

Aerial seeding can also now be done using a drone; however, it is not done this way much in our area yet. Drones can more easily navigate smaller fields, more obstacles or acres near urban areas, all of which make it more di cult to seed using a plane (Swoboda, 2020). Only time will tell how soon this method hits our area. Planes, on the other hand, can be more cost-e ective at times, especially for growers with more acres.

incorporation, the timing challenge is waiting for the fall corn and soybean harvest to be completed, which can

Even though cover crops have been around for many years, we are still learning more about how to best use them. The ever-unpredictable weather does not make that any easier. Nevertheless, without a plan and some practice, you will most likely not see the results you are hoping for. There is no “one size fits all” approach. Fortunately, there are resources out there for getting started with cover crops, and of course, our agronomists are always here to help provide answers on seed and application options.

Sources Anderson, M. (2023). Cover crop termination review for 2023. Iowa State University Extension and Outreach. https://crops.extension.iastate.edu/blog/meaghan-anderson/cover-crop-termination-review-2023 Bader, Z. (2020). Iowa cover crops: Answers to 8 common questions. Iowa Farm Bureau. https://www.iowafarmbureau.com/Article/Iowa-Cover-Crops-Answers-to-Common-Questions

https://crops.extension.iastate.edu/blog/mark-licht/look-cover-crop-seeding-methods

https://crops.extension.iastate.edu/cropnews/2021/07/considerations-when-overseeding-cover-crops

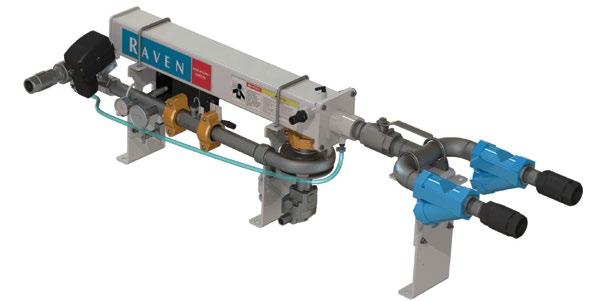

NH3 is one of the most stable and concentrated forms of nitrogen and still probably the most popular form of nitrogen to use across the Corn Belt. We’ve all heard the stories of close calls and disasters. Try not to become one of those stories in the attempt to save a minute or two. Safety, maintenance ahead of time, and a little common sense in-season can go a long way. Let’s look at a couple of ways to make sure we can have a safe fall when using NH3 coolers like the Raven AccuFlow.

If you must work on an NH3 toolbar or do any maintenance in-season, it always takes longer than you think to bleed down a bar before you can work on it. If you have multiple bleeder valves in di erent locations, it can drastically reduce the amount of time it takes before you can do your work. Just don’t forget to shut them all! Another good option is to visit us in Hills and pick up a few pass-through bleed valves. They operate just like normal but have a hose barb on the outlet where you can attach a hose and run it somewhere else on the bar and away from the operator.

Any hose that would be deemed “pressurized” should be dated hose. If it isn’t, that should be changed. If it is a dated hose, check the hose to see if it is out of date. NH3 causes normal hose to become more prone to cracking due to the product and the constant heating and cooling. Any “non-pressurized” hose should also be visually checked for wear and brittleness. The white and clear row hose is especially prone to this. We have black EVA hose that is sun-wear resistant and kink resistant, making it a good, economical replacement hose.

Finally, just use common sense. Try to park upwind when you are changing tanks, always drive defensively when going from farm to farm, and do any tests and procedures you can while the NH3 toolbar is not under pressure. You may not be able to save the extra minute that the guy across the fence can, but that extra minute may save your life.