For fall-applied products, we are o ering the flexibility of payment not due until January 5. See your sales agronomist to learn more!

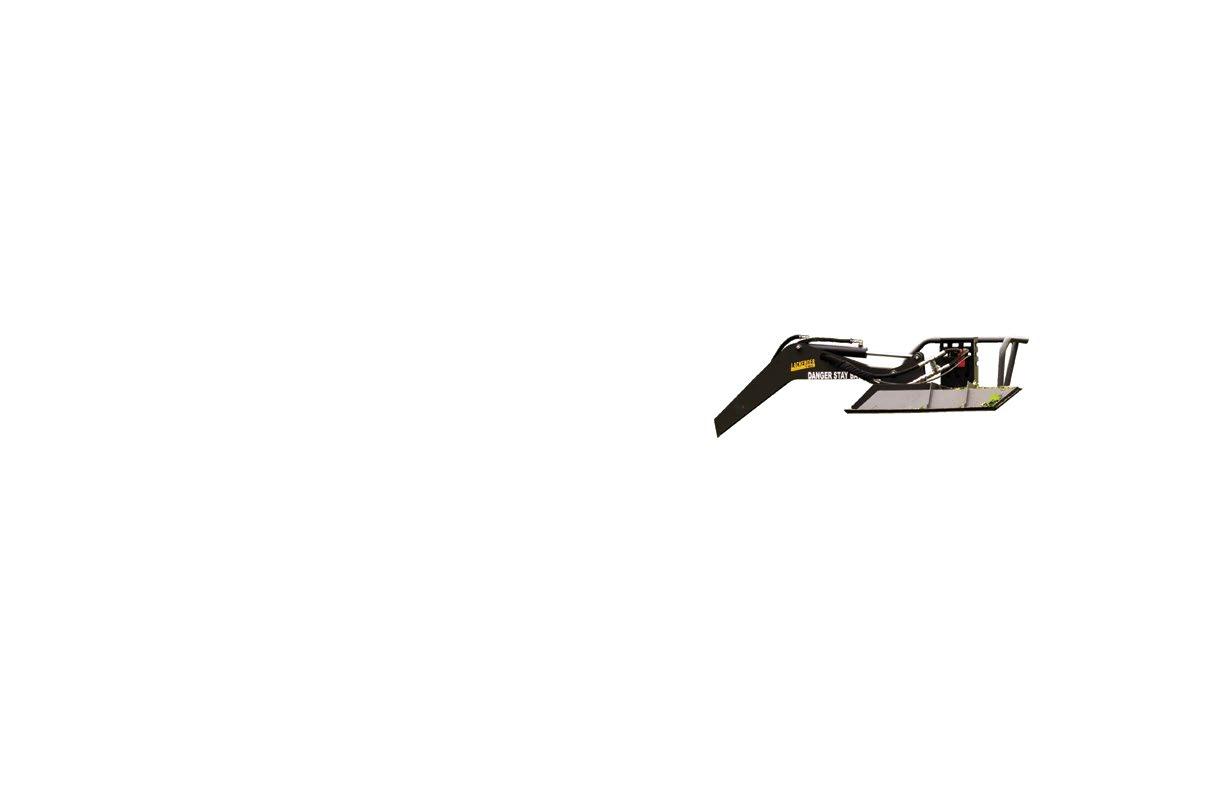

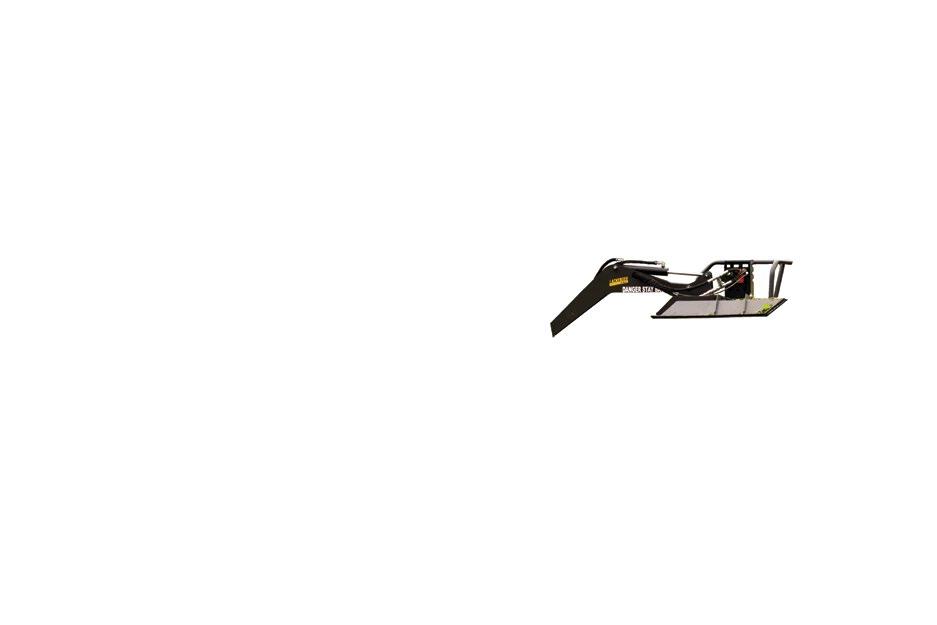

"I love going out a ter a midwest snowstorm to shovel snow by hand!" - said no one ... literally ever. Get ready for the first snowfall by pre-ordering any Lackender by ECS snow attachments you need.

Custom Applicator

Developmental Sales Agronomist

Digital Marketing Specialist

Graphic Design Associate

Logistics Carrier Manager

Logistics Senior Sales Executive

Logistics Intern

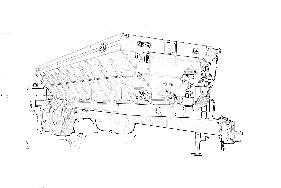

I grew up on a farm near Stutsmans. In 1980, I was 18 years old and looking for a job. Seeing the big applicators Stutsmans had, I knew I wanted to run big equipment. On my first day, a ter Ron Stutsman hired me, I gave a few details about myself to Larry Culver in the o ce and went down to the shop to start working. My first task was sweeping the welding rods out of a new nitrogen tank. A lot of various tasks followed in my early years: torching steel, cutting and loading scrap, running application equipment and building grain bins. Wherever we were needed, that’s what we did. One day I might be driving a straight truck and picking up a few cows to put on the semi, the next I would be helping repair fertilizer spreaders to sell. Salvaging and fixing up equipment was something we did a lot in the ’80s; it was one of the ways we were able to get through those tough times.

I have always been someone who wants to stay busy; that’s how I ended up in the manure equipment division. Even though Stutsmans had been selling hog feed and Star Big Butch feeders already, we entered the hog industry in a new way in the early ’70s when we sold our first Better-Bilt manure spreader. Merlin Geuder would go on to spearhead the new division, but as the division grew, he needed more help. Recognizing this, I began helping Merlin during the o -season when I wasn’t running a dry fertilizer truck or sprayer. I eventually went from serving in a mechanic role for the manure division to sales and now VP.

The manure industry has changed a lot during my time at Stutsmans. Companies that were big when I started are no longer in business or have shrunk in size. I’ve also seen a lot of people and dealerships come and go. We’ve been fortunate to remain in the manure equipment business. Equipment has also evolved from the very first 800-gallon manure spreader we sold to the 16,000-gallon Nuhn Quad-Trains of today. The introduction of dragline systems around the ’90s changed the game for many, especially as hog building size started to increase. The ’90s also brought improved technology and a desire to control manure flow. We have most likely not seen the last of industry changes as advancements like manure processing and gas harvesting have emerged. I think that a ter my time in the industry ends, we’re going to look at it and say, “Wow, this is very di erent.” While it might look di erent, we’ll still be raising livestock and providing quality food.

We appreciate you very much, and we will continue to appreciate you. Thank you for your business and your support.

John Yoder VP of Manure Equipment

At the end of the day, when it’s all said and done, the quality of the people, both coworkers and customers, has been the highlight of my time at Stutsmans. I am extremely proud of our people. What we sell will continue to change and evolve. However, I think how we sell it will remain the same. As long as we continue to use Eldon’s philosophy – taking care of the little things and taking care of our customers – we will continue to reach more milestones.

We spread our service to manure equipment in the early ’70s when we sold our first Better-Bilt manure spreader. The addition of Better-Bilt also thrust us into handling manure equipment parts; Eldon and Ron Stutsman fully believed that if we were going to sell equipment, we would have to have the parts to service it. Our first parts “room” was a retired 20-foot feed truck box.

While the manure handling equipment was gaining momentum, we entered the hog building business in 1980 with AgCra t “hog houses”. While they were primarily used for farrowing and nurseries, some producers used them for calves also. For 15 years, five to six employees built them in Hills and then transported them to producers’ farms.

The ’90s brought significant change and expansion to the hog industry, including larger barns which eliminated the demand for our AgCra t hog houses. Larger barns also brought increased amounts of concentrated manure. While searching for a quality pump for our lime pit, we were approached by a Houle (now known as GEA) salesman. We were thrilled with how it performed, and the rest is history. Our first GEA tank sold was 4,500 gallons … our second and third were a pair of 6,000-gallon tanks; and to think, we thought those were big! Today, we are one of the largest GEA dealers in the country.

In 1993, Bazooka Farmstar moved to Washington, Iowa. During this move, we took a toolbar to demonstrate on a farm. Although the demonstration led to a sale, it wouldn’t be until 1997 or 1998 that drag hose equipment would slowly start taking hold. By 2008, approximately 30% of our business was drag hose. Currently, it’s around 55%.

A key theme for the manure division has always been a relentless desire to make handling manure easier, more e cient and better fit for each pumper’s operation and fields. Around 1998, some manure customers inquired about the ability to control manure flow. Using expertise across our divisions, we adjusted a Krohne flow meter to control manure flow on a used tank. Although it took a few years, we were eventually able to perfect the process.

As drag hose systems started to get further away from pump sites, the need for more reliable engine controls became apparent. Once again, we leaned on our team and the help of irrigation technology company, Murcal, to find a solution. By 2014, we had a sellable product with robust features like pressure throttling to give manure applicators peace of mind and control from miles away.

To serve the growing requests for dry manure spreaders, Artex was added to the manure lineup in 2016. While we still o er many of the same early brands such as GEA and Bazooka Farmstar, other leading manufacturers like Nuhn have also been added. Our equipment o ering today includes spreaders, toolbars, pumps, engine units, load stands, agitation boats, flow control systems and more.

We started with our marketing team creating the graphic. Then, our ProVantage advisor brought it into SMS, overlaid the 'EST. 1934' text in the field, sized it to the appropriate dimensions and turned the text into a boundary file. The population was increased around the text graphic to ensure there was a major contrast with the corn and the unplanted graphic. The prescription was loaded into a Precision Planting 2020 system (Gen 2) and planted with a John Deere 1770 NT 16-row planter with high-speed Precision Planting seed tubes. For the herbicide program, we did a residual application with a post-applied Bellum/Atrazine/Glyphosate combination.

BY: ADAM GUY | AGRONOMY SALES

We have seen some surprising and interesting results in our small plot trials this growing season, especially in the biological/biostimulant studies. With more ideal weather conditions, I was surprised by the results we have collected so far. Usually, most biological products require some form of environmental stress to show positive results; however, several products have shown promising and exciting results without the presence of too many stressors.

Foliar Fertilizer/Starter Fertilizer

Plant Growth Regulator

Foliar Feed

Foliar Fertilizer

Potassium Acetate

Adjuvant (helps increase nutrient uptake)

Stress Mitigator

(Iron, Molybdenum, Copper, Zinc)

Plant Growth Promoter, Seaweed Extract, Humic/Fulvic Acids, Microalgae, Zinc, Molybdenum

Prior to planting, the trial areas were laid out and flagged. Our corn foliar/in-furrow trial is a 20- by 130-foot plot, and our corn biological/biostimulant trial is a 20- by 100-foot plot. Both the foliar/in-furrow and biological/biostimulant trials were planted on May 11. Untreated controls were also planted for each trial.

PRE-EMERGENCE BIOLOGICAL/BIOSTIMULANT TREATMENTS

Hopper Throttle and EndoFight were applied at planting on May 11. Network and Bio 800+ were applied on May 13.

Before planting, the trial areas were laid out and flagged. The soybean sulfur study is a 20- by 110-foot plot, and the soybean foliar/biological/biostimulant study is a 20- by 120-foot plot. Both trials were planted on May 18. Untreated controls were also planted for each trial.

SULFUR TREATMENTS

Rates of 0, 10, 15, 20 and 30 pounds of sulfur were applied on April 13.

PRE-EMERGENCE BIOLOGICAL TREATMENTS

Pre-emergence biological products were applied at planting on May 18.

» Bio 800+ | .5 gallons per acre

» Hopper Throttle | Per Label

» EndoFight | Per Label

FOLIAR TREATMENTS

Foliar products were applied on May 31 at the V3/early

Radiate (2.6 fluid ounces per acre) with Tachline Pro (1

NanoPro (4 fluid ounces per acre) with Tachline Pro (1 quart

POST-EMERGENCE BIOLOGICAL /BIOSTIMULANT TREATMENTS

Corn biologicals/biostimulants were applied on May 31 at the V3/early post-emergence stage.

Network | 1 quart per acre

Katapult | 1 quart per acre

Network (1 quart per acre) with Katapult (1 quart per acre)

The soybean foliar products were applied on June 14 at the V2 to V3 growth stage.

» Radiate | 2.6 fluid ounces per acre

» Tachline Pro | 1 quart per acre

» Zinc 9 | 1 quart per acre

» Radiate (2.6 fluid ounces per acre) with Tachline Pro (1 quart per acre)

» NanoPro (4 fluid ounces per acre) with Tachline Pro (1 quart per acre)

POST-EMERGENCE BIOLOGICAL/BIOSTIMULANT TREATMENTS

Post-emergence products were applied on June 14 at the V2 to V3 growth stage.

» Network | 1 quart per acre

» AF5Plus | 2 quarts per acre

» TERRAMAR | 1 quart per acre

» Network (1 quart per acre) with AF5Plus (2 quarts per acre)

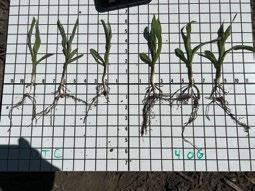

We have collected quite a bit of data since planting, including vigor, emergence, root and shoot weights, and tissue tests. While the verdict is still out on how the products we’ve been studying will perform come harvest time, we have a few early takeaways.

Early in the growing season, we were able to see some solid di erences in the corn biological/biostimulant data. The first thing that comes to mind with these products is an increase in early season vigor and emergence. Network applied as a pre-emergence shined, showing a 33% increase in plant emergence and a full growth stage ahead of the other treatments.

Root and shoot weights were collected at the V1 and V6 growth stages. At the V1 root dig, all treatments applied at planting showed an average of a 40% increase over the untreated control. At V6, both Network and EndoFight showed excellent di erences in development compared to the control. Network (applied pre-emerge) had a 20% increase in shoot and root weight. EndoFight had a 13% increase in shoot weight and 3% increase in root weight.

During the V9 to V10 stage, tissue tests were performed. EndoFight (P = +8%, K = +22%), Bio 800+ (P = +24%, K = +25%) and pre-emerge applied Network (P = +21%, K = +19%) had an increase in P and K in the plant tissue compared to the control.

5.23.24 ROOT DIG

V1 GROWTH STAGE

6.6.24 ROOT DIG

V6 GROWTH STAGE

For the in-furrow portion of the study, we tested the e ect of 10-34-0 and 10-34-0 with Zinc on the emergence and development of the corn crop. Using a starter fertilizer showed an approximately 20% increase in corn crop emergence. At V6, roots and shoots were collected to see di erences in growth and development. The addition of starter fertilizer did not show a significant increase in plant biomass.

As for the foliar products, treatments containing Radiate did show a slight increase of 5% in both root and shoot weights. However, the addition of NanoPro, an adjuvant helping increase the intake of foliar products, to Tachline did show the highest increases in plant biomass with approximately an 8% increase.

SULFUR TREATMENTS

A plant tissue test was taken at the R1 growth stage. Sulfur was applied at rates of 0 (untreated control), 10, 15, 20, and 30 pounds per acre via ATS. All treatments did show an increase in sulfur in the plant tissue compared to the untreated control; however, the rates above 15 pounds did not show a significant increase in sulfur. As of now, it looks like 15 pounds of sulfur is optimum, showing a 10% increase in sulfur uptake.

BIOLOGICAL/BIOSTIMULANT TREATMENTS

Emergence scores were collected but no significant di erences could be observed in the counts. At the V1 growth stage, good di erences could be observed in the seed talc (Hopper Throttle and EndoFight) and Bio 800+ products. Both Hopper Throttle and Bio 800+ showed a 35% increase in root and shoot weight. EndoFight showed a 21% increase in plant biomass.

At V6, another root and shoot weight collection was done. Bio 800+ and TERRAMAR showed around a 30% increase in plant biomass. AF5Plus showed a 17% increase in shoot weight and 21% increase in root weight.

6.6.24 ROOT DIG

FOLIAR TREATMENTS

No significant findings could be observed in the early season evaluations. This could be due to adequate rainfall, normal conditions leading to more uniform growth and cooler July temperatures during pollination.

See any member of our agronomy sales team for additional information and results a ter harvest!

cylinder & hitch designed to flex to adapt to the ground

continued on page 12

Even though there was room in the operation for Mike and Amy, they spent a few years working elsewhere before returning 15 years ago.

“I really valued my experience with living and working o the farm,” Mike said. “I think that gave me a lot of perspective for coming back. So, I think if any of my kids wanted to farm, I’d encourage them to do the same thing; go work somewhere else first and prove that you can make it on your own and then come back on your own terms.”

All of the corn the Paustians grow goes through their feed mill and gets fed to their pigs. Roughly five and a half million gallons of hog manure is then used to fertilize their crops each year.

For a long time, the family used manure tanks as their method of choice for spreading manure. Their past lineup has included Better-Bilt, Balzer and Houle (GEA) spreaders. The Paustians switched to a dragline system around 15 years ago, something that they didn’t think was an option for them before making the transition.

“We had always thought we didn’t have enough manure volume to justify a dragline system,” Mike said.

A ter working with Rob Frank, the Paustian’s Stutsman manure equipment salesperson, what felt impractical turned into a reality. Together, they developed a game plan that included a less expensive pump to make the system more justifiable with the amount of manure they spread.

“Going to the dragline really helped eliminate a lot of the compaction issues we were dealing with and that then allowed us to start doing no-till and eventually getting into cover crops as well,” Mike said. “It’s had a big impact on our operation.”

Not only has a dragline system helped with compaction, but it has allowed the Paustians to be much more e cient during the fall manure season.

“It made our lives a lot easier in the fall,” Mike said. “It seemed like we were always finishing applying manure in the middle of a snowstorm because we’d have to start hauling manure as soon as the first field was harvested basically, and we’d be hauling right up until the ground froze almost. With the dragline now, we’re waiting until harvest is completely done.”

With increased e ciency has come the ability to wait for ideal ground temperatures below 50 degrees and their cover crops to be established before manure application.

Changing how they handled manure paved the way for adjustments in their practices, including implementing no-till and cover crops.

When reflecting on their goals, Mike said they want to “keep doing things every single day that will help us improve or get better” and “be willing to try new things and see if they work better than what we’re doing now. That’s kind of how we ended up where we are with the crop side of things with the no-till and cover crop.”

“We’re still kind of tweaking how we do it and trying di erent things,” Mike said.

In addition to planting cover crops, the Paustians grow their rye seed for the next year’s cover crop by harvesting it over the top of 30 acres of soybeans. A ter the success they had growing their seed last year, they are making changes to this year’s process to get even better results.

E orts to consistently improve their operation’s sustainability extend beyond no-till and cover crops.

“Anymore, if you’re talking about manure management, I think you need to be thinking about nutrient management too,” Mike said, “and how we make sure those manure nutrients are staying in the field and how we make sure that they’re still there when we have our next crop growing.”

One such nutrient management practice they are trying is saturated bu ers, an edge-of-field practice designed to reduce the nitrates reaching a water source.

“Whether it’s building improvements, whether it’s what we’re doing to the ground — preventing soil erosion, keeping nutrients in the field — all those kinds of things from a conservation standpoint to just make the farm better than what it was when we started taking care of it so that future generations will have the opportunity to farm too if they so choose,” Mike said.

Not only are the Paustians working to be stewards of the land, but they also have the responsibility of being stewards of their family’s legacy and ensuring future generations have the same opportunities they did.

“It can be a lot of pressure if you start thinking about the legacy of all the sacrifices that people had to make for me to have the opportunity to be here,” Mike said. “I don’t want to squander that

While the weight of that responsibility is not light, the ability to work with his family toward their goals is something that Mike cherishes.

“The vast majority of people do not get the experience of multiple generations working side by side,” Mike said, “and I think that goes a long way to helping instill work ethic and pride and teamwork within our family.”

The Paustians set a positive example for others in the agriculture industry, but for Mike, setting a good example for his children takes the cake.

“You can tell your kids to work hard and do a good job,” Mike said, “but it’s a whole ‘nother thing when they are actually working with you, and you can show them how to work hard and do

When Frederick Paustian settled in Walcott and became a farmer, he probably didn’t know the tradition he was starting in his family. It’s a tradition of doing something every day to be stewards of the family’s operation and land while accomplishing something even greater — a heritage of working hard while taking pride in what they can accomplish together, as a family.

It’s hard to believe it's time to start thinking about next year's crop decisions. With early order programs on the horizon, seed is likely at the top of many farmers' minds. As we transition our seed o ering to Beck's, we want to ease your mind and answer any questions you have regarding their products and programs.

Whether you've had a lot of exposure with Beck's or just have heard passing comments, chances are you've heard rumblings of them being a "gimmick" company that relies on giving away "freebies" to earn business. We've heard it all before; "Why don't they lower the cost of their seed?" "It's just a toy catalog," or "What a gimmick." It's easy to be skeptical when some things appear too good to be true.

However, as we've become more educated about Beck's Commitment Rewards program and now understand the math (and logic!) behind this innovative program, we can say without a doubt that it is simply a financial tool for growers to add to their arsenal, especially in today's market.

As it turns out... what some call a gimmick isn't so much of a gimmick a ter all. Here's why.

Commitment Rewards is an equipment and financial tool that can provide your operation with a competitive advantage. The program is designed to help farmers leverage Beck's buying power to overcome obstacles like access to working capital and high interest rates. Each year, Beck's works with industry-leading equipment providers, placing bulk orders upfront to get the best possible pricing. By leveraging their significant buying power, equipment discounts are passed directly to growers that would not be attainable for a single operation.

Beyond getting access to better pricing, Commitment Rewards can put more cash back into your pocket.

Patrick Hines, a Missouri grower, has been a customer of Beck's since 2021 and purchased a small amount of seed each year to try out on his farm. For 2024, he committed 100% of his acres to Beck's and worked with his area dealer to sign a multi-year, Level 8 agreement with Commitment Rewards a ter learning more about the value the program o ered.

"Part of my decision to commit 100% of my seed order this year was due to Beck's flexibility in helping me put up a new equipment shed," said Hines. "A ter meeting with my dealer at Beck's Southern Illinois Field Show and seeing the terms of the agreement, I was shocked at how much cash Commitment Rewards would free up for me."

And while Patrick's Level 8 multi-year agreement didn't cover the entire cost, he is now paying back a minimal amount per year for three years (on an already highly discounted equipment shed) with ZERO interest, saving him roughly $23,000. Plus, he can now write o the cost of that shed as an asset on his taxes that same year and boost his savings.

If you're looking for innovative ways to increase your working capital, Commitment Rewards provides an interest-free payback over time. By partnering with First Mid Bank & Trust, Beck's allows growers to use their earned points as a "down payment" on the equipment they need and pay the rest of the cost back to First Mid Bank & Trust completely interest-free.

Let's break it down.

Say you are considering signing a Level 4 multi-year agreement at a $120,000 seed commitment. At this level, you would receive 80 total points to use, valued at $30,000 ($375 per point). Your skid loader has been giving you fits, and it's the next equipment upgrade you had on your list. While this scenario may seem far-fetched, we can assure you that the savings and interest-free payments are not.

It's not just about securing the tools you need for your operation at a heavily discounted, interest-free cost; it's about freeing up cash that wasn't previously available, providing you with the flexibility to purchase additional equipment that would not have been possible without the program.

While a skid loader might not be something you need on your farm, Beck's has options for every operation and every acre size, ranging from large equipment, trucks and trailers, shop essentials, and even home and recreation. Although the examples we've included so far illustrate a three-year commitment, you can take advantage of the program with just a one-year commitment!

Beck's chooses to put more money into farmers' pockets by passing along additional value through Commitment Rewards than they would get through a simple cash discount on seed. By expanding farmer's cash positions and freeing up working capital through Commitment Rewards, growers can secure the tools and equipment they need, create significant tax savings opportunities, and gain more value for their operations.

It's a value-adding, working capital-multiplying, cash-expanding return on your seed investment.

Want to learn more about how the Commitment Rewards program might benefit your operation? Scan the QR code »

$120,000 Per Year Seed Commitment

80 Program Points Valued At $30,000 ($375 Per Point)

New Holland C337 Skid Steer $73,500

Sales Price (196 points x $375)

$73,500 (Skid Steer Cost) - $30,000 (Total Point Value) = $43,500 (Remaining Cost to You)

$43,500 (Remaining Cost to You) / 3 (Multi-Year Commitment) = $14,500 Final Per Year Cost to You at 0% Interest

One-Year $40,000 Seed Commitment

3 Program Points Valued at $1,125 ($375 Per Point)

M18 Fuel 1 in. Milwaukee Impact Wrench $1,125

Beck’s Sales Price (3 Points x $375)

$1,125 (Wrench Cost) - $1,125 (Total Point Value) = $1.00 (Remaining Cost To You)

If you had to pick between going to the doctor for a yearly wellness check-up or visiting the emergency room, which would you choose? Chances are the once-a-year visit to your doctor is a lot less stressful. The same thing can be said when it comes to maintaining a grain bin site. It’s a lot easier and less stressful to perform pre-season maintenance than it is to have an emergency repair in the middle of harvest.

When performing any inspections or maintenance, keep safety at the top of your mind. Turn o and disconnect any mechanical, electrical, hydraulic and pneumatic elements that could cause harm. Lock out, tag out.

Air systems are a commonly overlooked component of a grain bin system when it comes time to perform maintenance.

» Blowers have oil in them, which is o ten forgotten about. Oil should be changed following the manual recommendations.

» Check air system filters to avoid learning they’re plugged when moving grain through the system.

» Watch for wearing and holes in the pipes at the elbows.

A broken-down grain dryer can put a real damper on harvest. A little bit of pre-season maintenance can prevent catastrophe.

» Clean the control box and fan using so t brushes, a vacuum or compressed air. If you have a portable GSI or Sukup dryer, the metering rolls need to be cleaned out as plugged grain columns can overheat and cause a fire. For sites with a Shivvers dryer, the transfer augers should be cleaned out.

» Check the gearbox oil level and lubricate if needed.

» Turn on the electrical power supply, control panel and other electronics to ensure they are working properly.

» Verify the fan turns on and watch for any unusual vibration.

» Ensure the heater runs and burns blue. If the flame is yellow, the heater is not burning e ciently.

» Check for potential gas leaks using soapy water.

» Test the conveying equipment to verify grain moves in and out of the dryer e ectively.

Due to the sheer size of grain bins, there is a lot more area to cover when doing pre-season cleaning and maintenance.

» Top of Grain Bin

» Open the lid and check the grain spreader for bird or mice nests, bare wires and bad bearings.

» Inside the Grain Bin

» Inspect the stirring machine or auger for bird nests, cracked belts, rough sounds in the motor and any divots in the track. Inspect augers for anything sharp or shaped like an hourglass. When turning on the machine, the down augers should run true without a wobble.

» If you have a Shivvers unit in your bin, you need to grease the gearboxes.

» Give each grease zerk a couple of pumps, but do not over grease.

» Check the tapered sweep to make sure the flighting is not sharp and the wheel is not worn out.

» Sweep the floor and remove all foreign material.

» Inspect underfloor flighting for excessive wear (anything from sharp areas to rusted o spots).

» Inspect side wall sheets for cracks, holes and excessive rust.

» Outside the Grain Bin

» Ensure the door is sealing properly with no visible cracks.

» Inspect ladders and steps for loose bolts, broken ladder rungs and clear any obstructions.

» Inspect fan to ensure blades are intact and wires aren’t broken or frayed. Do not turn on your fan until one ring of grain is in the bin.

» Inspect heater for bad wires and replace any bare wires.

» Check the spark plugs and burner ring to ensure the holes are open and not rusted shut.

As always, reference your user manual when performing maintenance for more specific guidance based on the model and brand of your equipment. If you have any questions or see areas of concern, give us a call. We are happy to come out and take a look. This season, we hope more preventative maintenance means less emergency repairs.

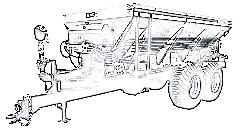

We’ve carried Valmar’s 56 series applicators for several years now; they continue to be our most popular option for seeding cover crops as well as a good choice for small grains, soybeans and low rates of granular herbicide and dry fertilizer because they allow growers to accomplish more in one pass. In the last couple of years especially, we have witnessed more interest in cover crops and consequently these applicators as a result of the available subsidies for cover crops. Due to the Valmar 56 Series’ a ordability, growers who already have a tillage bar can quickly recuperate the cost of adding the applicator with subsidy program money.

Valmar’s granular applicators come in two sizes: 40-cubic-feet (the 4056) and 60-cubic-feet (the 6056) capacities. The 4056 has 16 hose outlets with application widths from 16 feet to 40 feet. The 6056 can come with either 24 or 32 hose outlets with application widths from 24 feet to 60 feet.

With these applicators, you can broadcast products using deflectors or apply in-furrow with air di users. Additionally, airline splitters can be used for doubling lines near the product disbursement point.

The 56 series applicators have three di erent mounting styles: skid mount, three-point hitch or pull-behind chariot, making them a versatile option for many di erent operations. Our most popular option is the skid mount, which is especially adaptable because it can be fixed on the three-point hitch mount, chariot cart or mounted on an implement of your choosing. The three-point hitch mount is available in a 350 horsepower or 600 horsepower size. It allows for pass-through hydraulics and electrical while coming with a draw-bar hitch for pulling an implement behind. The advantage of the chariot mount is its ladder and platform, making it easier to access the hopper.

Both models have hydraulic or ground-driven metering options. We have found the hydraulic drive option through ISOBUS monitors to be the top pick because the 56 series applicators can tie into John Deere, Case, New Holland, AGCO, Ag Leader, Topcon, Trimble or other universal terminals through a single ISOBUS plug. This means the applicator can perform automatic half-width section control and as applied maps (with a task control interface). ISOBUS also controls on-the-go rate control with changes in ground speed. For those who would prefer the ground drive mechanism, the rates can be increased and decreased in 5% increments using a 60-speed gearbox. This allows for an accurate rate to be applied regardless of the ground speed. An in-cab control box allows manual half-width shuto .

Calibration is key to ensuring proper flow rates. This is made easier by the ability to drop out the Venturi and manifold system to insert a funnel tray for collecting product. There is a crank handle to simulate ground travel. Furthermore, this feature makes for a user-friendly clean-out of the hopper. Changing out metering rolls to accommodate various products is also a simple process with the 56 series applicators.

When talking cover crops, the Valmar 56 series applicators are typically a part of the conversation for us. Their versatility, price point and ability to accomplish more in one pass make them an easy choice for growers.

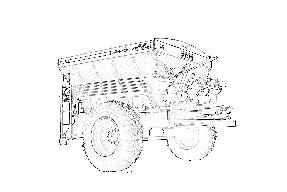

Whether you want to clean drag hoses, blow o combines, clean balers or complete various other tasks around the farm, the Applied VariMount 350 PTO Compressor o ers versatility with a lower price tag than a diesel engine unit. This compressor also has an impressive output of 350 cubic feet per minute, significantly speeding up the time spent clearing a hose. The Applied VariMount 350 PTO Compressor is powered by a tractor PTO rather than a separate diesel engine and can conveniently be moved around and/or mounted with a 3-point hitch. Since it is fully air-driven, it does not have any electronics making the Applied VariMount 350 PTO Compressor more reliable and better able to withstand outdoor conditions. The compressor is also easy to use and maintain, adding to the overall appeal of it over the alternatives.

» Volume Flow | 177 to 360 CFM

» Operating Pressure | 189 PSI

» Compressor Weight | 2,623 lbs

» Filling Capacity | Engine Oil: 5.3 gallons

» Dimensions | Height: 47”, Width: 43”, Depth: 52”, BSP air outlet: 2 x 1.5 in.

» Power Requirements | Rated Speed: 540 to 1000 RFM, Sha t Power: >93 HP

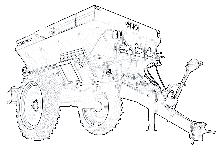

MAGNASPREAD:

Fertilizer / Lime

» Capabilities of spreading lime up to 2 tons per acre at 14 mph with a 60-foot swath and fertilizer up to a 80-foot swath

» 320-cubic-foot stainless hopper

MAGNASPREAD PLUS:

Fertilizer / Lime

» Application widths up to 60 feet with lime and 80 feet with fertilizer

» 440-cubic-foot stainless hopper

LIBERTY:

Fertilizer / Lime

» Application widths up to 60 feet with lime and 80 feet with fertilizer

» 200-cubic-foot stainless hopper

GRASSHOPPER:

Fertilizer / Lime

Application widths up to 60 feet with lime and 80 feet with fertilizer

200-cubic-foot stainless hopper

Pre or post applications spreader

SNIPER:

Fertilizer Only

» Application widths up to a 120-foot swath with built-in section control

» 264-cubic-foot stainless hopper

» Pre or post applications spreader

ENDURANCE: Lime / Manure

» Application widths up to 60 feet with lime and 40 feet with manure

» 456-cubic-foot carbon steel hopper

Salford BBI has a spreader for about any application, meaning there is a good fit for a variety of operations. Most of these spreaders are on our lot if you would like to see a unit up close in person. If you are still curious about which spreader of BBI’s extensive lineup best fits you, please feel free to reach out to a member of our equipment team.

Only a few short months ago, we learned about another tragic manure accident involving a man trying to retrieve equipment that had fallen into a manure tanker. A ter losing consciousness from the manure gas, his coworker tried to help him and also lost consciousness. Neither of the men returned to their families. This is unfortunately a common story. Accidents like this have been around for a while and continue to happen even though the risks of working around manure and the gases it produces are known.

Someday, we hope we never have to write about this topic again, but until then, it is always good to remind ourselves how important it is to stay aware when handling manure and working around manure tanks and storage systems.

Being around manure storage areas, especially during agitation, can present multiple hazards; the greatest of these hazards is manure gas. Manure produces toxic gases as a result of anaerobic digestive fermentation. These gases are methane, hydrogen sulfide, carbon dioxide and ammonia. While some of these gases can have an odor to signal their presence, others can be odorless. This can make their presence even more dangerous. These gases can be flammable and explosive as well as cause su ocation, unconsciousness, nausea, drowsiness, irritation, headaches, respiratory failure and in the worst cases, death (Erickson, 2021).

In 2022, there were eight fatalities in the U.S. related to agricultural waste storage, handling, transport equipment and facilities. The most common cause of these accidents was performing maintenance tasks in or around manure storage, which follows suit with accidents in prior years. Concerningly, accidents like these are on an upward trend (Cheng et al., 2023).

The benefits of making risky decisions when working around manure storage systems are few … and they’re not benefits at all considering what’s at stake. Unfortunately, manure accidents are o ten a result of trying to recover a piece of equipment or tool (like in the case we discussed above) and not taking the time to make safe choices. In some cases, investing in and using a gas monitor could have resulted in a drastically di erent outcome.

Because gases can be colorless and odorless, gas monitors are vital to monitoring conditions when operating near manure. Gas monitors can range in abilities and price, but the most basic and least expensive gas monitors are single-gas H2S personal monitors. These monitors have audible and visual alarms to alert the wearer when conditions become unsafe.

If you already have a gas monitor, don’t forget to check the sensor and alarms to verify they are working properly. One way to do this is through bump testing, the application of gas with a H2S concentration to the monitor to determine if the alarms work and if the sensor identifies the correct gas concentration. Manufacturers of gas monitors have gas canisters and tubing accessories to utilize for bump testing.

MAKE SURE ALL EMPLOYEES, FAMILY AND VISITORS ARE AWARE OF THE DANGER MANURE GASES PRESENT THROUGH EDUCATIONAL TRAINING AND WARNING/HAZARD SIGNS.

HAVE AN EMERGENCY RESPONSE PLAN IN PLACE.

NEVER GET ON TOP OF OR INSIDE A TANK TO INSPECT IT.

WORK WITH A PARTNER AND STAY IN COMMUNICATION.

COVER OR BARRICADE MANURE PIT OPENINGS TO PREVENT FALLS INTO THE PIT.

OPEN UP THE BUILDING TO MAXIMIZE VENTILATION WHEN AGITATING.

PUMP WHEN THERE IS A MINIMUM OF 7 TO 10 MPH CROSSWIND.

KEEP AGITATION NOZZLES BELOW MANURE SURFACE TO PREVENT SHOOTING GASES INTO THE AIR.

IF MANURE IS WITHIN 2 FOOT OF THE SLATS, PUMP BEFORE AGITATING TO LOWER THE MANURE LEVEL TO AT LEAST 2 FOOT BELOW THE SLATS.

The benefits gained from disregarding safety protocols simply do not outweigh the risk — loss of life. As fall pumping starts to ramp up, we wish you a safe manure season.