DripTech Irrigation has opened a new facility in Pomona, Borrowdale, adding to their steadily expanding branches across Zimbabwe. Originally focused on micro-irrigation, it has broadened its offerings to include a comprehensive array of water-related products, including borehole pumps, tanks, pressure tanks, booster pumps, and an extensive range

Let’s zoom in on the concrete realities, the projects breathing new life into communities and driving localized growth.

The mining town of Mazowe is poised for a

Our lead story brings us to Shurugwi, a town with a rich mining history now looking towards a revitalized future. The grand opening of the MIPF Shopping Mall, a long-awaited project brought to fruition by the Mining Industry Pension Fund, marks a pivotal moment. This three-story complex, meticulously constructed by Mak Bokano, now stands as a testament to resilience and forward-thinking urban planning. It’s more than just shops; it’s a symbol of Shurugwi’s renewed hope.

The Hive 25 is a vibrant business hub where professionals can work, connect and grow in an environment infused with natural beauty and community spirit. The place is not only a sanctuary for productivity, creativity and collaboration, but one aimed at building a community.

of a state-of-the-art shopping mall, known as Mazowe Walk Shopping Mall. This ambitious project is being spear headed by Gateway Construction.

The iconic Harare Showgrounds is set to undergo a dramatic transformation following Terrace

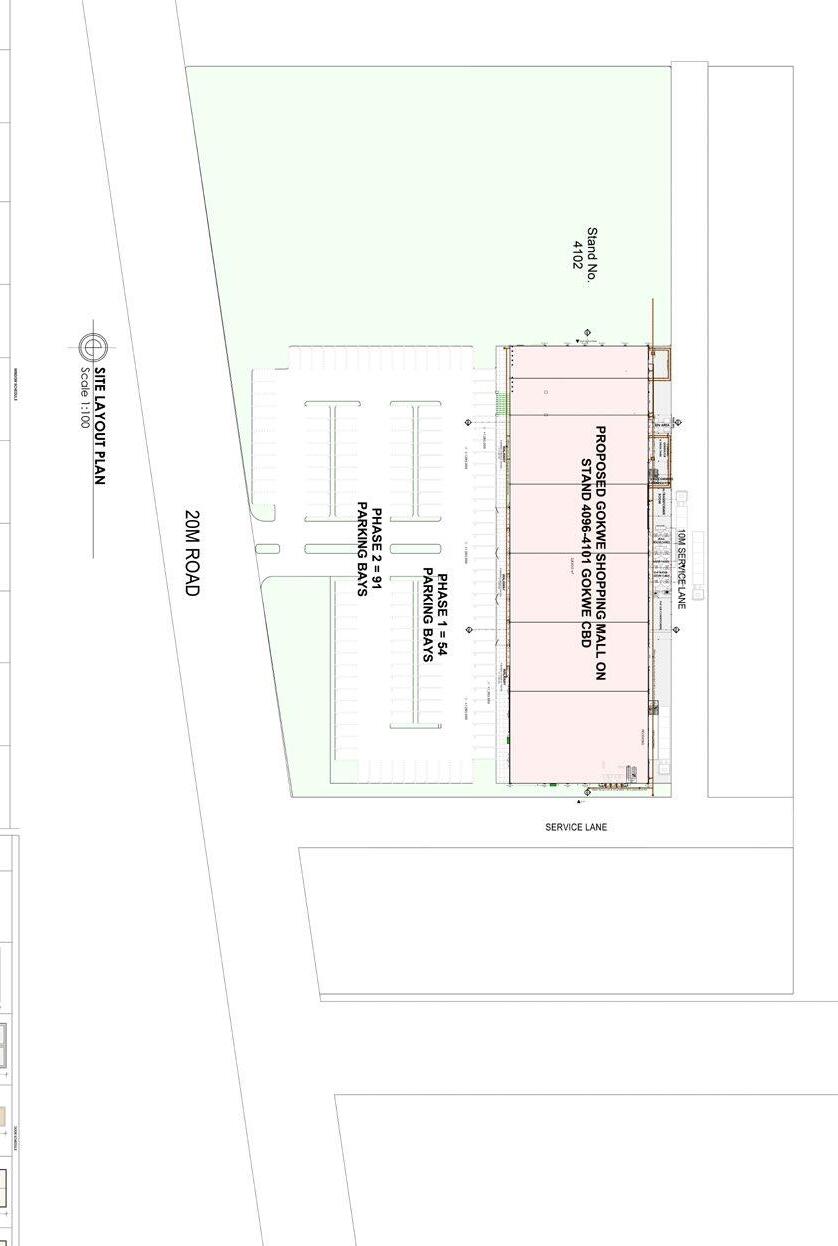

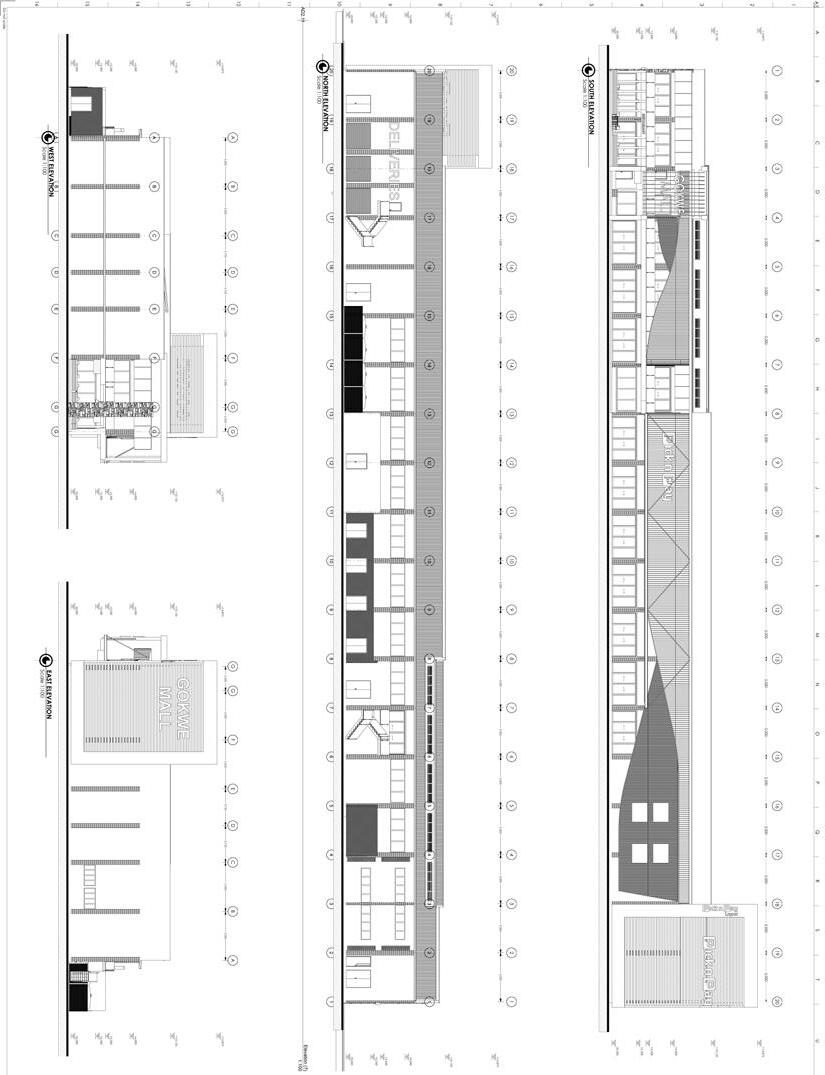

Delomic Construction Company’s commencement of earthworks for the MIPF Gokwe Mall marks a significant step in redefining the image of Gokwe-Nembudziya, bringing modern commercial infrastructure to a town poised for growth.

Several leading construction companies have been roped in to spearhead the project and among them is steel infrastructural experts Brown Engineering Group.

Finally, we acknowledge Mutate Enterprises (Jenita Engineering), a significant player in Zimbabwe’s construction industry since 1996, providing comprehensive structural steel products and services from their Harare and Norton bases.

KW Construction’s Thames Road Development showcases significant progress, with roofing nearing completion and finishing touches underway. This project exemplifies the synergy of their expertise as both contractor and developer, delivering an upmarket offering that seamlessly blends architectural sophistication with practical everyday living.

Coastal Construction, a leading and trusted name in construction, offers a comprehensive range of services to bring your vision to life. Based in Harare, they specialize in all aspects of brickwork, substructure foundations, and related works.

Our piece on 258 Hotel, looks at a hospitality player positioned on the fringes of Harare’s Central Business District, and offering a contemporary retreat that successfully blends modern luxury with rich cultural heritage. An in-

its unassuming elegance, providing a tranquil haven for both business and leisure travellers alike.

The striking extension of a technology company’s double-story structure in Eastlea, Harare, with its modern facade expertly framed by Brown Engineering’s structural steel work, adds a contemporary edge to the city’s commercial landscape, reflecting growth and innovation.

touches, they are committed to delivering excellence in every project.

German Construction’s diverse expertise across the entire construction lifecycle – from planning to management – underscores their significant contributions to the nation’s infrastructure and property development.

Founded in 2016, Bellington Riggers (Pvt) Ltd is one of the foremost construc-

This issue celebrates the tangible progress being made across Zimbabwe, driven by dedicated individuals and companies committed to building a stronger, more prosperous nation, one project at a time.

expertise in steel fabrication, electrical engineering and of course, rigging, the

tractor of choice in the rapidly advancing construction sector.

Enjoy the read.

In our attempt to support women in construction we feature several women doing wonders in the in the broader building construction space. These are Padsor Scaffolding and Construction, a company at the forefront of providing innovative scaffolding solutions and construction services; MajorCon, a leading civil engineering company specializing in precast concrete products and services and Elegance Ivy Construction and Interior Design, renowned for crafting luxurious, functional, and elegant spaces.

While every effort has been made to ensure the accuracy of its content, neither editor nor publisher can be held responsible for any omissions or errors: or for any misfortune, injury, or damages which may arise there-of.

All rights reserved. Copyright 2025

All rights reserved. Copyright 2024

No Part of this magazine may be reproduced or transmitted in any form or by any means electric or mechanical, including photocopying or recording.

For more surprise insights in this editing, keep reading!

While every effor t has be en made to the accuracy of its content, neither edi publisher can be held responsible fo omissions or errors: or for any misfo injury, or damages which may arise the

No Par t of this magazine may be repro or transmitted in any form or by any m electric or mechanical, including photoc or recording

KHAYA CEMENT

SIMBISA BRANDS

BATA HEAD OFFICE

KOALA MEATS

TM PICK N PAY

OVEN ART

Mautric Electrical Pvt LTD set its foot as an electrical supply and equipment trading and services company. Over the years, the company has earned a reputation for excellence and professionalism for continuously striving to meet - and even exceed - standards which set the climate for a sustainable business relationship with its clients.

As an electrical solution specialist, we offer electrical power products ranging from transformers, switch gears, breakers, XLPE cables, panel boards, power meters, and switches. The company also offers control products such as variable frequency drive, soft starters, UPS, AVR, batteries, motors and even lighting fixtures.

Our team is composed of technically skilled and highly dedicated personnel working cohesively to promote value-added solutions with a competitive pricing structure to suit your needs.

We also engage in electrical product installations, testing and commissioning, preventive maintenance, automation, and energy saving solutions. Our commitment is to deliver outstanding results that will exceed your expectations.

NGEZI ZETDC PROJECT

CROCO MOTORS VICTORIA FALLS

GARFUNKELS RESTAURANT BIG POPPAS

ATTICUS INVESTMENT

REVO SERVICE STATION REVO GAS

BALMAIN/NORICH (N RICHARD STORES)

Caast Media Group

MARKETING

Tinashe Mafiko Newton Musara

+263 781 421 866

+263 781 512 568

+263 78 953 2918

DESIGN, LAYOUT & VIDEOGRAPHY

Saul Chidakwa

WEBSITE & SOCIAL MEDIA

Saul Chidakwa

JOURNALISTS

Martin Chemhere Farai Chaka

DISTRIBUTION

Gift Sepi

PHOTOGRAPHY

CAAST MEDIA GROUP

marketing1@caastmedia.org markerting@structureanddesign.co.zw

FIND US AT 31 Alexander Rd, Highlands, Harare

Italian Products Which Are Functional, Durable And Elegant. WE SUPPLY A RANGE OF:

As we celebrate 14 successful years in business, we reflect with gratitude on the journey that has brought us here.

As we celebrate 14 successful years in business, we reflect with gratitude on the journey that has brought us here.

We wish you and your loved ones a joyful holiday season and look forward to continuing our journey together in the new year

We wish you and your loved ones a joyful

season and look forward to continuing our journey together in the new year

• WeatherTough Protection

• 2x Thicker Paint Coating

• Prevents Damp on Walls

Property Developer - Mining Industry Pension Fund(MIPF)

Architect - Hbn Simela Architects

Main Contractor - Mak Bokano

C.N. Cube Consulting Engineers

• Main Works: Jan 2023–Dec 2024

• Site Establishment: 2 months (offices, sheds, staff accommodation)

• Foundations: Strip and pad

• Framework: Reinforced concrete, structural steel, timber trusses

• Finishes: Porcelain tiling, granolithic paving, plasterboard and vinyl ceilings

• Final finishes (early 2025): Interior fitting, electrical systems, air‑conditioning and landscaping were completed from January to March 2025.

By April 2025,the anchor supermarket Pick n Pay was ready for opening.

The shopping complex was developed by the Mining Industry Pension Fund (MIPF) in Shurugwi which is historically a mining town. The project (approximately US$7–8 million in value) was conceived to revitalise Shurugwi’s economy, which had been set back from the collapse of mining companies and the subsequent infrastructure neglect.

This long-promised shopping mall began as a bold idea in 2013, when the town council entrusted Inductoserve Holdings with a plan for a three-storey complex complete with a supermarket, bank halls, retail shops and even a council-run “mayor’s bar.” Contracts were signed; ground was broken late that year.

However, a string of funding shortfalls and logistical setbacks stalled work twice, leaving half-finished foundations and idle equipment. By 2017, the council’s patience had run thin and it was going to reclaim the site unless progress resumed.

Nothing changed, till five years later in August 2022, when the Mining Industry Pension Fund (MIPF) stepped in. The pension fund, which manages retirement assets for mine workers, had been diversifying into real estate, and it took up Shurugwi Mall as a strategic investment.

Tasked with diversifying its assets and stimulating local growth, MIPF relaunched the project under its own banner, treating the mall as part of Zimbabwe’s broader Vision 2030 push for urban renewal and smart-city development.

With nearly 8 million U.S. dollars drawn from pension reserves and designated as a prescribed asset under regulatory guidelines, the fund cleared legal hurdles and licenses, hired architects and contractors and set an ambitious deadline: to open by the first quarter of 2025.

The architects HBN Simela Architects, drew up plans for a sleek, open-air centre built to blend durability with daylight. Exposed brick and concrete facades give way to wide glass fronts and a steel-framed canopy of skylights drapes the central courtyard in soft, natural illumination.

Shops line broad, tiled corridors, while designated kiosks outside offer space for local artisans. The anchor tenant, Pick n Pay, has its spot on the ground floor, flanked by banking halls and smaller retail units. Behind the scenes, designers specified low-maintenance finishes and energy efficient lighting, signalling an eye toward long-term sustainability even as they met pressing community needs.

Mak Bokano’s role as the main contractor on the Shurugwi MIPF Shopping Mall was defined by precision planning and strong execution from the outset. Site establishment began in November 2022 and lasted two months, during which time Mak Bokano ensured the seamless mobilisation of equipment, materials and skilled labour.

Temporary structures, including site offices, work sheds, and accommodation for staff, were constructed efficiently to support the full duration of the build. With the groundwork laid and all support systems in place, the project officially commenced in January 2023.

The bulk earthworks phase presented one of the most complex challenges due to the steeply sloped terrain and the presence of a natural stream dissecting the site. Mak Bokano’s team expertly cleared the land, removed vegetation and undertook extensive cutting and filling operations to sculpt a level platform suitable for large-scale commercial development. Retaining walls were constructed to hold back earth along the steeper inclines, and canalisation of the stream was carried out with care to ensure proper water flow without compromising the design or structural integrity of the mall.

Structural work unfolded next, with a solid combination of strip and pad foundations anchoring the buildings. The mall’s framing system brought together reinforced concrete frames with brick infill panels and a hybrid roofing system using structural steel and timber, clad in durable Chromadek sheets.

High-spec materials, including steel beams, aluminium,and various grades of brick, were carefully integrated throughout the build. This phase also included the installation of plumbing and electrical containment, along with windows and door systems that combined glazed aluminium shopfronts with pressed steel frames and timber doors, all finished with high-quality ironmongery. Finishes and final touches brought the project to life.

Externally, a blend of face brick cladding, plaster, paint, and Chromadek finishes offered both durability and visual appeal.

Our Clearview Fence offers superior security without compromising on visibility. Constructed from high-quality galvanized wire, it features an anti-climb design that ensures robust protection for commercial, industrial, and residential properties. Its sleek, modern look provides an aesthetically pleasing boundary solution, while its durability ensures long-lasting performance.

Landline: 0242 883 753/4 I Email: sales@pomonasteel.co.zw

Harare Branch: 966 Pomona Industrial Park, Pomona, Harare Call: +263 773 091 567

Bulawayo Branch: 16471 BT Cnr Fort & 15th Avenue Bulawayo Call: +263 714 193 488

Kwekwe Branch: 2782 Cober Street Kwekwe Call: +263 776 226 975

Internally, porcelain floor tiles were laid across all retail spaces and walkways, while toilets and back areas were fitted with plasterboard ceilings or vinyl-clad ceiling tiles in a suspended grid.

Mechanical and electrical installations included solar geysers and mechanical ventilation in restrooms, plus standby generators or uninterrupted operation. Notably, Mak Bokano accommodated specific tenant requirements, such as double-sealed factory lite roofing for Pick n Pay and plinths for their HVAC and refrigeration systems.

The challenging topography, proximity to the highway and railway line and integration of natural water features make this project a standout example of thoughtful engineering and refined execution.

MIPF SHURUGWI PROJECT SUPPLIERS

Plascon

Lesop Plumbers

Jenita Engineering

Marsden Consulting

Onel Electricals

The Garden Guru

Chubb

Pomona Steel & Fencing

Homestyle Bricks

V Peretti

Tregers Products/Monarch Steel Division

Electrosales

Liquid Telecoms

Nakiso Borehole Drilling

Shower

Geyser Installations

+263 24 2709615

+263 8644243257

+263 773 097 019

+263 773781877 lesopplumbers@gmail.com

The MIPF has reported that roughly 120 local residents found jobs during construction and councils expect that number to swell now that the shops have officially opened their doors. Tenancies are already under negotiation: the anchor tenant Pick n Pay’s branch opened in late April 2025, drawing its first customers.

Three commercial banks have committed to hall space, while a cluster of smaller outlets will occupy the corridors.

Outside, the mayor’s bar which has been rebranded as a community café, will channel proceeds back into town projects, just as planners first envisioned. The pension fund expects to recoup the outlay through rental income and asset appreciation.

Lease revenues from the tenants and numerous shops should provide steady yields over time. For Shurugwi residents, the mall is a promise that they will no longer need to travel 50 kilometres to Gweru for basic goods or banking services.

MIPF now has its eye on Gokwe next, hoping to replicate Shurugwi’s model in another growth centre.

Established in 1996, Mutate Enterprises, trading as Jenita Engineering, has firmly positioned itself as a significant player in Zimbabwe's construction industry. From its head office in Avondale, Harare, and workshop in Norton, the company offers a comprehensive suite of structural steel products and services, catering to a diverse clientele across the nation.

With a commitment to quality, efficiency, and a safe working environment, Jenita Engineering has contributed to numerous landmark projects, shaping the country's infrastructure landscape. Jenita Engineering's expertise spans a wide spectrum of structural steelwork, encompassing the design, fabrication, and erection of roof trusses, factory shells, and communication tower masts.

Their capabilities also extend to fencing solutions, architectural steelcraft, and the supply and installation of roof sheeting. The company's versatility allows them to undertake general engineering projects for the construction industry, making them a valuable partner for both large-scale developments and smaller, specialized requirements. Their dedication to getting things right the first time and a zero-tolerance policy for defects underscores their commitment to delivering superior quality on every project.

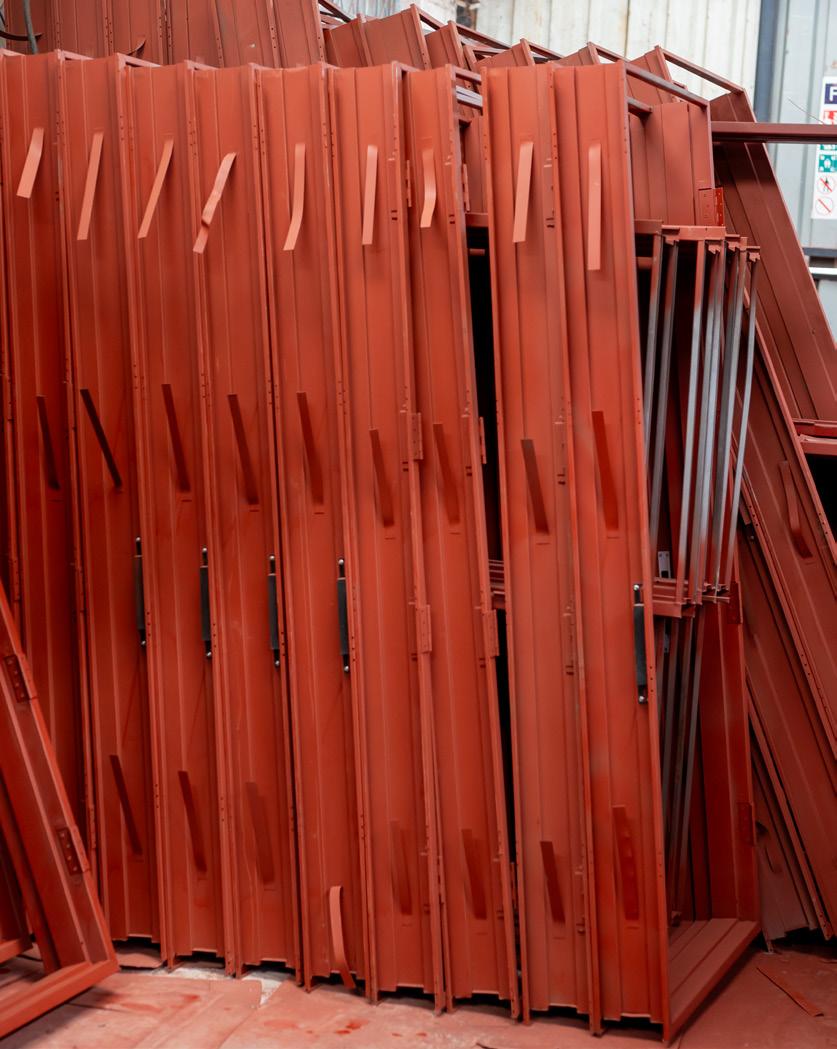

Among their recent projects, Jenita Engineering was entrusted with a significant undertaking in Shurugwi, where they were mandated to handle the entire structural steelwork for the proposed commercial complex. This comprehensive project involved the fabrication and erection of the Pick n Pay structural roof and its supporting staircases, ensuring a robust and safe structure for the retail space.

The intricate design of the Pick n Pay feature, a prominent architectural element of the building, was also executed by Jenita Engineering, showcasing their ability to handle complex and aesthetically important aspects of construction. Furthermore, Jenita Engineering's scope of work for the Pick n Pay in Shurugwi extended to the main entrance feature, creating a welcoming and structurally sound access point for shoppers.

They also undertook the structural steelwork for the hardware at the complex - the roof, partitions, and staircases- demonstrating their capacity to manage diverse structural elements within a single project.

The construction of the walkway connecting the Pick n Pay store to the adjacent hardware section, as well as the structural framework for the proposed shops and banks within the development, were all integral parts of Jenita Engineering's contribution to this significant commercial project in Shurugwi.

Over the years, Jenita Engineering has built a strong portfolio of successful projects. In the realm of structural steel roofs, sheds, and warehouses, they were responsible for the massive multipurpose hall at Midlands State University, the ZIMSEC Printing Press in Norton, as well as the OK Malven Shop in Waterfalls and the OK Karoi Complex. Their expertise also extended to the industrial sector, with the steelwork for Delta Lager Beer Lines Three and Four

being a testament to their capabilities. These projects, completed to the satisfaction of their clients, highlight Jenita Engineering's ability to handle large and complex structural steel assignments.

Jenita Engineering has also been actively involved in the refurbishment and rehabilitation of factories and buildings. Notable projects include work for TM Pick and Pay stores across various locations, the Pearl Properties Factory in Ardbennie, and Stenhop Factory.

Their understanding of the intricacies involved in upgrading existing structures has made them a preferred partner for companies looking to enhance their facilities. In the specialized area of communication tower masts, Jenita Engineering has established a strong reputation as a supplier to major telecommunications companies such as Econet, Telecel, and NetOne. For over a decade, they have been involved in the fabrication and erection, including civil works, of

numerous tower masts and associated steelwork, playing a crucial role in expanding Zimbabwe's telecommunications infrastructure. Their capabilities further extend to balustrading, handrails, and staircases, where they have successfully completed supply and installation for clients like NSSA at the Beitbridge Hotel, ZIMRA at the Chirundu Border Post Main Building, and ARIPO Headquarters in Natal Road.

These projects demonstrate their attention to detail and ability to deliver high-quality architectural steelwork. With a clear philosophy centered on quality, integrity, and safety, and driven by the objective of consolidating their market share through client satisfaction, Jenita Engineering continues to be a vital contributor to Zimbabwe's infrastructural development. Their commitment to these core values, coupled with their extensive experience and diverse capabilities, positions them as a reliable and trusted partner in the construction industry.

Anothen Architecture and Design

Text

By

Martin Chemhere

Images By

Caast Media Group

In a testament to their growing capabilities, Harare-based Delomic Construction Company, recently commenced earthworks for the landmark MIPF Gokwe Mall in Gokwe-Nembudziya. Delomic was entrusted as the main contractor for this state-of-the-art commercial building, a project that promises to redefine the image of a town long considered lagging behind modern urban centres like Harare and Bulawayo.

Established in 1997, Delomic Construction has rapidly built a reputation for its comprehensive suite of services, spanning painting (interior and exterior), renovations, and full-scale construction of residential and commercial properties. The company's unwavering commitment to quality, coupled with a strong focus on client satisfaction, has positioned them as a reliable partner for diverse projects across Zimbabwe.

The Gokwe Mall will be a significant double-storey structure, marking a pivotal moment for Gokwe North. This ambitious project aligns with the government's vision to uplift rural areas and bridge the development gap with urban centres. Upon its completion, the mall will signify a tangible step towards bringing urban amenities and opportunities to the local community.

A key highlight of the mall is the anticipated increase in access to banking services. While Nembudziya already hosts a CBZ Bank branch, the new mall will introduce the town's second financial institution. Reports indicate strong interest from AFC and ZB Banks, with a final decision on occupancy expected soon. This development is poised to significantly ease financial transactions for residents, reducing the need for long journeys to access banking facilities.

Beyond banking, the fully inclusive mall is designed to offer a diverse range of goods and services typically found in urban centres. This enhanced access aims to improve the quality of life for local residents by providing convenient access to essential products and services within their community. The construction of the mall is widely viewed as a transformative project, poised to shed Gokwe-Nembudziya's previous image and align it with national development aspirations.

Delomic Construction did not undertake this significant project in isolation. Key partners played crucial roles in bringing the vision to reality. Anothen Architecture and Design served as the project Manager, while Arkhi Studio Architects provided the architectural design. Infra Design Associates were responsible for the civil and structural engineering aspects, and QED Consulting Engineers handled the electrical and mechanical engineering components.

The successful completion of the MIPF Gokwe Mall demonstrates Delomic Construction's capabilities and commitment to delivering impactful projects. This modern commercial hub is expected to inject much-needed economic growth and create employment opportunities within the Gokwe region, marking a substantial leap forward in rural development. For Delomic Construction, this landmark achievement underscores their potential to handle large-scale projects and solidifies their position as a force in Zimbabwe's construction industry.

MIPF GOKWE PROJECT SUPPLIERS

MCDONALD BRICKS

M&S METAL FABRICATORS

DAVIS GRANITE

HALSTEDS

GOKWE RDC

Great strides are being made at KW Construction’s Thames Road Development! Roofing work is nearly complete, window and door installations are well underway and the painting phase is now in full swing.

Promoted as an ultra-modern, upmarket offering, the project brings together the KW Construction ’s dual expertise as both contractor and property developer to deliver a product that balances architectural sophistication with everyday practicality.

Occupying a generous 5,052 square metre site at the corner of Thames and Alpes Roads, the development replaces a former single-residence property with a thoughtfully designed gated complex comprising approximately 36 two-bedroom apartments.

These apartments are carefully planned homes that reflect a deep understanding of what today’s buyers want: privacy, security, aesthetic and location.

KW Construction has maintained complete control over the project, overseeing everything from site planning and infrastructure to the building’s premium finishes, save for the roofing, which was expertly executed by Brown Engineering.

For the structural framework, Brown Engineering employed robust UB203x133x25 Universal Beams and cold-formed lipped channels, further reinforced with angled bracing.

Designed by Bruce Rowlands of Architexture Spatial Design, the architectural language of 25 Thames Road is sleek and contemporary. Steel, aluminum, concrete, and glass define the building envelope giving it a refined urban edge, while the interiors are clean and light-filled, favouring large windows, open-plan layouts, and seamless indoor-outdoor connections via private balconies.

Each unit spans a single floor and includes two bedrooms and two bathrooms, an open-plan lounge, a modern fitted kitchen, and built-in cupboards. The bedrooms are generously sized, and the finishes throughout are geared toward luxury.

These details make the apartments especially appealing to young professionals, couples, and investors looking for stylish, low-maintenance living just minutes from Pomona, Arundel Village, Groombridge, and Sam Levy’s Village and Highland Park.The developer has also prioritised infrastructure and amenities. The complex is fully serviced, with dual boreholes supplementing municipal water, rooftop tanks for each unit, and a solar power system backing up ZESA electricity. Residents benefit from high-speed internet wiring, pre-installed appliances, and enhanced security, including 24-hour guarded access, CCTV, boom barriers and a fenced perimeter.

Parking is ample too with two covered carports per unit and additional space for visitors. Communal amenities include a landscaped garden and a shared entertainment area, elements that encourage both relaxation and that neighbourly connection. Few units are still available so get in touch with them if you want to be a part of this community.

Text By Martin Chemhere

The skyline of Eastlea, Harare has been further enhanced by the striking extension of a technology companies’ double-storey structure in Eastlea. The building boasts a contemporary facade of tinted glass and high-end Hulabond aluminium composite cladding in a sophisticated charcoal and white. This architectural statement not only exudes an appealing presence but also reflects the dynamic commercial landscape of its surroundings.

Brown Engineering played a pivotal role in realizing this vision, undertaking the crucial task of installing the entire structural steel framework that underpins this impressive expansion. The design philosophy of the original head office, conceived by Architect Nyatsanza, drew inspiration from the logical and interconnected world of computer science. Just as computer components work in synergy to create a unified machine, the building's form and function emphasized a cohesive and integrated design.

The extended office structure, with its newly installed steel framework by Brown Engineering, was meticulously planned to connect seamlessly with this foundational concept, ensuring a harmonious architectural language and a unified sense of functionality across the entire expanded facility. This careful consideration of the existing architectural context underscores the collaborative approach adopted throughout the project.

Brown Engineering's contribution to the head office extension was comprehensive, encompassing the complete structural steel framework. This involved a multi-stage process, beginning with the precise erection and alignment of robust steel columns.

These columns serve as the primary vertical load-bearing elements, providing the essential stability for the new structure. Following this critical stage, Brown Engineering's skilled team expertly installed the intricate network of steel rafters. These rafters were meticulously engineered to provide optimal support for the roof and efficiently distribute its weight across the underlying structure.

The final phase of Brown Engineering's work involved the secure fixing of the roof sheeting, ensuring a durable and weather-resistant covering for the newly extended office space. This holistic approach to the steel installation formed the fundamental skeleton upon which the entire extension was built.

"The core rationale behind the steel installation project at the head office extension centred on the strategic creation of vital warehousing facilities and supplementary office areas," explained Shepherd Tshalibe, the experienced Site Manager from Brown Engineering overseeing the project.

This expansion was a direct response to the burgeonin needs of a company experiencing significant growth. The provision of additional warehousing space addresses the increasing demands of their operations, while the new office areas offer the necessary infrastructure to accommodate a growing workforce.

The specific steel structures expertly installed by Brown Engineering formed a fundamental structural framework. This involved the precise placement and secure connection of robust vertical columns, which provide the primary vertical support for the entire structure. Interconnecting these columns was a network of carefully engineered horizontal rafters, designed to support the roof and distribute its load effectively.

"Furthermore, the project incorporated the installation of a mezzanine level, effectively introducing an intermediate floor that maximizes the usable space within the expanded structure, thereby further enhancing operational efficiency," added Tshalibe.

This mezzanine level provides valuable additional space without increasing the overall footprint of the building, demonstrating efficient space utilization in line with modern commercial design principles. To effectively address any logistical or technical challenges that arose on site, Brown Engineering adopted a proactive and collaborative approach, working in close partnership with the civils contractor involved in the broader construction project.

This close coordination proved invaluable in ensuring the efficient flow of materials to the site, optimizing site access for machinery and personnel, and guaranteeing that the steel erection process seamlessly integrated with the ongoing civil works.

This spirit of collaboration was crucial in proactively identifying and resolving any unforeseen issues, thereby maintaining the project's momentum and ensuring adherence to the demanding schedule. For the intricate steel installation process, Brown Engineering utilized a range of specialized equipment and techniques.

A crane played a vital role in the safe and efficient lifting and precise placement of the heavy structural steel components, ensuring accuracy and speed in the erection process. To guarantee the structural integrity and precise alignment of the steel framework, the team employed highly specialized laser measurement devices.

These advanced tools were used to meticulously verify the plumbness of the vertical columns, ensuring they were perfectly upright and capable of bearing the intended loads. Additionally, laser technology was employed to check the linearity of the horizontal beams and rafters, ensuring they were perfectly straight and aligned as per the design specifications.

This commitment to accuracy and the use of advanced technology underscores Brown Engineering's dedication to delivering high-quality and structurally sound installations. The actual steel installation work on the head office extension commenced on the 3rd of March and was successfully completed by the 4th of April.

This relatively short timeframe highlights the efficiency and expertise of the Brown Engineering team. Currently, the project is in the snagging phase, which involves a detailed inspection to identify and rectify any minor imperfections or outstanding items before the final handover to the client.

"Brown Engineering fostered strong collaboration through bi-weekly site meetings. These regular gatherings facilitated effective communication and coordination among the client, consultants, and other contractors involved in the head office extension project," stated the site manager.

These regular meetings served as crucial platforms for open dialogue, allowing all stakeholders to stay informed of progress, address any concerns promptly, and ensure that all aspects of the project were aligned and moving forward smoothly. This commitment to clear and consistent communication was instrumental in the successful execution of the steel installation phase.

The steel installations utilized a carefully selected range of structural steel sections, each chosen for its specific load-bearing capabilities and suitability for its intended application within the framework. These included various types of Universal Columns (UC), such as the UC203x203, which are commonly used for vertical load-bearing members.

Additionally, different sizes of Universal Beams (UB) were employed, including UB457x191 and UB406x140, which are typically used for horizontal structural elements like rafters and floor beams. All the steel materials and specifications adhered to relevant Zimbabwean and international standards for structural steel, ensuring the safety, durability, and longevity of the installed framework.

This project holds significant importance for Brown Engineering's portfolio and its ongoing contribution to industrial development in Harare and Zimbabwe as a whole. "This project signifies excellence in all aspects of industrial development, as we have been involved in industrial, commercial, educational, recreational structures," affirmed the site manager. Brown Engineering's extensive track record encompasses a diverse range of successful projects across various sectors, including industrial facilities that drive economic growth,

commercial buildings that facilitate business activities, educational institutions that support learning and development, and recreational structures that enhance the quality of life. This latest undertaking at the Eastlea project further solidifies the company’s reputation as a reliable, capable, and committed partner in the nation's infrastructural advancement. The company is consistently delivering high-quality steel installations, thereby actively contributing to the development of robust, functional, and aesthetically pleasing spaces

that underpin economic progress and enhance the built environment throughout Zimbabwe.While the steel installation phase of the head office extension is now complete and the project is currently in the snagging phase, the formal handover to the client has not yet taken place. The anticipated handover of the completed steel structure is targeted for the first week of May 2025. This marks the culmination of Brown Engineering's significant contribution to this important development.

Text

German Construction is a dynamic and award-winning construction company based in Harare, Zimbabwe, making significant contributions to the country's infrastructure and property development.

With a proven track record, the company has established itself as a reliable partner for both property owners and tenants, consistently delivering projects that add tangible value to their portfolios.

At the heart of the company's success is its unwavering commitment to a collaborative approach. The company strongly believes in engaging all stakeholders throughout the project lifecycle, from initial concept to final execution.

This inclusive strategy ensures that the client's business objectives are thoroughly understood and that the resulting projects are precisely tailored to meet their specific needs. Open communication and transparent processes are prioritized, thereby fostering strong, lasting relationships with its clients.

German Construction prides itself on its innovative thinking and its ability to see beyond conventional limitations. The company embraces a global perspective, recognizing that fresh ideas and best practices can originate from anywhere in the world.

This philosophy fuels their drive to stay at the forefront of the construction

industry, constantly seeking new and improved ways to deliver exceptional results. Offered by the company are a comprehensive suite of professional services, catering to diverse needs across the construction spectrum.

Their expertise spans the entire project lifecycle, encompassing planning, design, engineering, consultancy, and program and construction management.

This holistic approach allows them to provide seamless and integrated solutions, ensuring efficiency and consistency throughout every stage of a project. The company's core service offerings include steel structures, building construction and repairs,

paving services, plumbing services, carpentry services, water proofing and more. German Construction is dedicated to upholding the highest standards of quality in every project they undertake. The company also places a strong emphasis on occupational health and safety, prioritizing the well-being of its workforce by providing safety equipment, implementing rigorous safety protocols, and fostering a culture of safety awareness.

Furthermore, the company is committed to environmental responsibility. The company adopts sustainable practices, striving to minimize its environmental impact by preserving natural flora and fauna during construction and, where feasible, reinstating them upon project completion. The company values the relationships it forges with its clients and partners. It is dedicated to creating mutually beneficial partnerships characterized by open communication, transparency, and a shared commitment to achieving common objectives.

This dedication is evidenced by its diverse portfolio of partners, which includes prominent organizations across various sectors. Germany Construction’s strong commitment to excellence has earned the company numerous accolades and a strong reputation in the Zimbabwean construction industry. The company consitently delivers quality projects, prioritizing client satisfaction, and adhering to ethical business practices, simultaneously continuing to play a vital role in shaping Zimbabwe's built environment.