PAGE 5

EDITOR’S WELCOME

Introduction to our SSEAMS Special guests, Courtney & Co Button Makers

PAGE 6

THE PERFECT FINISH

Meet the Courtney & Co team

PAGE 9

Q&A

With Andrea Courtney

PAGE 11 to 25

STYLE GUIDE - Corozo collection

Up close detail from the brand community

PAGE 27 to 31

STYLE GUIDE - Codelite® collection

Up close detail from the brand community

PAGE 33 to 39

STYLE GUIDE - Horn collection

Special feature with SEH Kelly

PAGE 40 - 41

A COMMUNITY OF EQUALS

The Courtney & Co community

PAGE 42 - 43

TREND REPORT

Emotional Durability by Andrew Dudgeon

PAGE 44

BEST FOOT FORWARD FOR ‘24

Words by David Courtney

PAGE 46 - 47

THE LAUNCH OF THE ARCHIVE ROOM

PAGE 49

SSEAMS EDITORIAL TEAM

PAGE 51

ISSUE DIRECTORY

Image credits:

Front cover - Thank you Sirplus

Inside front cover and this pageThank you Genevieve Sweeney

I met the buttons before being introduced to the owners of UK leading button makers Courtney & Co some years ago! Exquisite Corozo, Horn and Codelite milk casein, carefully curated into a button book collection that deserves to sit front and centre of any raw materials library The buttons are by far the best I have seen in 30 years working in the textile industry Quality exudes every aspect and the creation of their 3 product collections is not by chance, rather it’s created by people who care deeply about the future of British button making After all this is a craft we really should never fear will leave our shores

The team at SSEAMS met Andrea and David Courtney earlier this year and anyone who has been lucky enough to call them a supply chain partner knows they are working with people who firstly love what they do, and secondly know this true craftsmanship legacy is in their hands - a fate they take very seriously

That is why Andrea and David have invested in their facility over the course of the last 10 years and intend to build a strong community around what they like to say to their brand partners, “As we see it our role is small in the product sense but we know our trims can certainly make the product sing ”

Enjoy this special issue. They really are part of a beautiful community! Diane

Hello, and welcome to Courtney & Co For the last decade, w immersed ourselves in the rich heritage of UK button making today we proudly consider Courtney & Co as a ‘go to’ maker o quality natural material buttons. In this time we have positione ourselves among progressive and emerging brands in the UK around the world who are seeking buttons which reflect their v and enhance their collections desirability

We started our journey back in 2012, after acquiring many ma and the heritage of the 155 year old button maker James Gro Sons Ltd upon its sad demise It was the last maker of horn b the UK and our intention was to keep the memories, skills and alive Fast forward, and with investment in more machines and people, we continue the innovation drive and skills to turn, dye and finish our buttons to the highest standards.

Innovation is integral to the business and further investment in machinery continues firstly with 2 state-of-the-art turning machines and a horn grinder. New and reconditioned polishing barrels for a superior finish and a further investment in a purpose built dye shop. Every single button is crafted in-house through each process and quality controlled within our facility We champion and support our raw materials contemporaries within the industry supply chain and encourage cross-collaboration and two way introductions to new customers.

Additionally, we pride ourselves on providing excellent customer experience for many well known apparel, fashion and home interior brands

It is our ambition to build upon these modest beginnings and to build our partnership with discerning brands who appreciate the essence of the finest quality buttons And through their support, we are able to invest and innovate to future-proof our efforts in support of their goals. In this way we aim to partner with our customers – helping them maximise their potential and ambitions – rather than act as another trim supplier

Read on to discover how and why we aim to do so

“There should be no substitute for nature. Nature sustains us if we sustain it and buttons

made from the most alluring natural materials are part of that ethos. There should be no substitute for them either.”

When you pick up the phone to place your order you may be lucky enough to hear Andrea’s voice at the end of the line. Andrea makes it her business to ensure customer experience is paramount, and along with the quality of buttons Courtney & Co. has a reputation in the industry for efficiency and customer care We took time out with Andrea to ask her some questions about the business...

Q1: Andrea, it is the 10 year anniversary since starting the button making business, can you share a few highlights with us?

10 years of ups and downs, learning the art of button making, of making mistakes, finding new solutions and improving year by year to finally being confident enough to promote that we have mastered the skill of turning the highest quality natural buttons. During that time, the most memorable highlights were the arrival of our state of the art turning machines from Italy, which are placed alongside our characterful heritage wooden barrels (which are still polishing the most stunning horn buttons and have done so for nearly 100 years). The other highlight was the day that Steve and also, Lise, after years of training, turned and finished the most beautiful horn button It was the day we could finally say that we are ready to offer the highest quality horn, Corozo and casein buttons, made proudly in the UK

Q2: How many customers do you now have and what are they using the buttons for?

We have around 450 customers at present, mostly fabulous smaller brands promoting sustainability above everything else, but also some bigger names who have made it their goal to support British manufacturers where possible

They are using our buttons for tailored garments, shirts, dresses, jackets, suits, sports and outdoor clothing, bed linen, even in soft toys, uniforms and the list goes on

Q3: David is also a driving force involved in future proofing the business and your innovation work around natural raw materials is excellent. What’s next for Courtney & Co as you kick off 2024?

We believe in natural materials and have made it our ethos to stick with this concept In 2024, we will still keep our main focus on corozo, casein and real horn buttons as these are the materials we have mastered and can confidently support our customers with the best quality possible. Other natural options exist as well, for example wood, coconut and mother of pearl buttons, but these come with various new (eco) challenges. We are still relatively new in the industry and there are hopefully lots of options to still expand our customer network, concentrating on the three materials we do best, and hoping that we will become the go to button maker in this country for natural buttons

Corozo is derived from the nut of the Tagua Palm which grows in the equatorial rainforests of central America Reputedly, the best comes from Ecuador – which is where we get ours Otherwise known as ‘vegetable ivory’, Corozo is no ordinary material

Each year, a tagua palm tree produces 15 large, spiny balls called ‘mococha’ which each contain around 20 small compartments in which some 6 nuts can be found That’s 1,800 nuts per year in total. Given that these, in turn, vary in size, each tree, therefore, yields sufficient nuts for thousands of Corozo buttons each and every year!

The Corozo collection by Courtney & Co is available to view We invited some of their brand customers to feature in the highlights over the page...

Charlbury 4011

featured by Mid Moor and Mountain

The Corozo tailoring buttons are available from stock in all 8 patterns in sizes 24L, 28L, 32L, 36L, 40L and 44L and are available in natural, black, navy, grey and brown. They are satin polished and 4-hole, as standard. We also make 18L Corozo backing buttons in each of the standard colours.

Cornbury 965

featured by Nicholas Daley

The Corozo tailoring buttons are available from stock in all 8 patterns in sizes 24L, 28L, 32L, 36L, 40L and 44L and are available in natural, black, navy, grey and brown. They are satin polished and 4-hole, as standard. We also make 18L Corozo backing buttons in each of the standard colours.

Tewkesbury 310

featured by 6876.

The Corozo tailoring buttons are available from stock in all 8 patterns in sizes 24L, 28L, 32L, 36L, 40L and 44L and are available in natural, black, navy, grey and brown. They are satin polished and 4-hole, as standard We also make 18L Corozo backing buttons in each of the standard colours

For bespoke colours, we offer a colour matching service at a cost of £40.00 + VAT per colour. This applies to orders of all sizes. Bespoke orders normally take around 7-10 days from receipt of a fabric colour swatch and confirmation of order.

Tewkesbury 310

featured by Bamford

The Corozo tailoring buttons are available from stock in all 8 patterns in sizes 24L, 28L, 32L, 36L, 40L and 44L and are available in natural, black, navy, grey and brown. They are satin polished and 4-hole, as standard. We also make 18L Corozo backing buttons in each of the standard colours.

Tewkesbury 310

featured by FRAHM

The Corozo tailoring buttons are available from stock in all 8 patterns in sizes 24L, 28L, 32L, 36L, 40L and 44L and are available in natural, black, navy, grey and brown. They are satin polished and 4-hole, as standard. We also make 18L Corozo backing buttons in each of the standard colours.

Tewkesbury 310

featured by Navygrey

Corozo shirting buttons are available in 5 patterns in sizes 16L and 18L and are available in natural, black, navy grey and brown. They are satin polished as standard.

For bespoke colours, we offer a colour matching service at a cost of £40.00 + VAT per colour This applies to orders of all sizes Bespoke orders normally take around 7-10 days from receipt of a fabric colour swatch and confirmation of order

Adderbury 2250

featured by Sirplus

Corozo shirting buttons are available in 5 patterns in sizes 16L and 18L and are available in natural, black, navy grey and brown. They are satin polished as standard.

For bespoke colours, we offer a colour matching service at a cost of £40.00 + VAT per colour This applies to orders of all sizes Bespoke orders normally take around 7-10 days from receipt of a fabric colour swatch and confirmation of order

Featuring the Courtney & Co colour dye service

Codelite® is made from casein which is the protein element naturally occurring in milk Cured and hardened in sheets or rods, milk casein became a staple for button making It was first produced in the UK as far back as 1910 at a factory in Stroud, Gloucestershire

Courtney & Co. has not only restarted production of buttons in the UK made from Codelite®, the state-of-the-art version of milk casein, but we have expanded our range to include solid, pearlescent (an alternative to motherof-pearl) and cornu (an alternative to real horn) buttons. When you see them, you’ll understand why!

Processed with different effects, Codelite® is a highly attractive and versatile substance which can be dyed and polished with amazing diversity and clarity of colour

And once finished, the buttons perform like the conventional polyester buttons which replaced them – robust and hardwearing and washable even in conventional machines time and time again But, unlike polyester, Codelite® buttons are bio-degradable, sustainable and traceable, too

The Codelite® collection by Courtney & Co. is available to order. We invited their brand customers to feature in the highlights over the page...

Cornbury965 using the bespoke colour service featured by Genevieve Sweeney

Codelite® buttons are also available from stock, but given the variety of types (solid, pearlescent and cornu) this stock changes constantly That said, we maintain blank stocks (pearlescent only) for 18L shirting buttons, plus blanks in 24L, 28L, 32L, 36L and 40L in all types of Codelite®, meaning that where finished buttons are not available from stock in any one of our 5 shirting patterns or 8 tailoring patterns, these can be scheduled into our production runs and supplied on an agreed timeframe

Grove 564 in Cornu

037 featured by Blackhorse Lane Ateliers

Codelite® buttons are also available from stock, but given the variety of types (solid, pearlescent and cornu) this stock changes constantly That said, we maintain blank stocks (pearlescent only) for 18L shirting buttons, plus blanks in 24L, 28L, 32L, 36L and 40L in all types of Codelite®, meaning that where finished buttons are not available from stock in any one of our 5 shirting patterns or 8 tailoring patterns, these can be scheduled into our production runs and supplied on an agreed timeframe

Featuring the Courtney & Co.

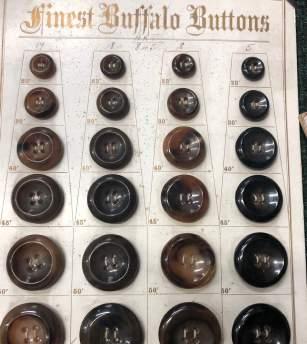

Horn has been used in button-making since the end of the 19th Century when a consignment of cattle hooves sent to James Grove & Sons Ltd in Halesowen also contained water buffalo horns

Real horn (typically from either water buffalo or ox) is a by-product of the farming industry, particularly in India and livestock is not reared specifically for their horn Moreover, the cattle are raised by numerous small, subsistence farmers and the money they receive for their horn is a vital and additional source of income Without it, many poor rural farmers could simply abandon their vocation.

Horn, itself, is made from keratin which is the same substance as human hair and nails. And as keratin is a type of fibrous protein, horn is fully biodegradable.

Given the structure of the grain (imagine thousands of hairs all stuck together) which runs along the length of the horn, the appearance of the blanks and finished buttons varies markedly according to its type As a result, the natural colour variation is extensive and each button is unique in its appearance

The Horn collection by Courtney & Co. is available to order. See highlights from the range featured by S.E.H Kelly over the page...

Grove 564 featured by S.E.H Kelly

Our newly released real horn buttons are available in 24L, 28L, 32L, 36L and 40L in our Grove 564 and Bibury 425 patterns in nero, nero vena blanca and vena mancha blanca appearances They are all 4-hole and have a matt finish However, we can also make horn buttons in other colour variations, patterns, sizes, 2 hole configurations and polished as special orders. Please let us know what you require and we’ll do our best to accommodate your needs

Grove 564 featured by S.E.H KELLY

Our newly released real horn buttons are available in 24L, 28L, 32L, 36L and 40L in our Grove 564 and Bibury 425 patterns in nero, nero vena blanca and vena mancha blanca appearances They are all 4-hole and have a matt finish However, we can also make horn buttons in other colour variations, patterns, sizes, 2 hole configurations and polished as special orders. Please let us know what you require and we’ll do our best to accommodate your needs

Grove 564 featured by S.E.H Kelly

Our newly released real horn buttons are available in 24L, 28L, 32L, 36L and 40L in our Grove 564 and Bibury 425 patterns in nero, nero vena blanca and vena mancha blanca appearances They are all 4-hole and have a matt finish However, we can also make horn buttons in other colour variations, patterns, sizes, 2 hole configurations and polished as special orders. Please let us know what you require and we’ll do our best to accommodate your needs

By David Courtney

One of the most satisfying rewards of our work is seeing our buttons adorn a diverse range of finished articles Clothes are the most obvious, diverse and ever-changing as they are But our customer base has grown over the years to include umbrella makers, makers of fine bedding and a few even more exotic purposes

We have gained a following among many smaller brands who need to find a reliable, responsive and competitive source of trim and have watched as their first collections give way to their second, third and beyond We have seen their orders for buttons rise from our minimum order quantity of 300 to thousands and ever more frequent returns. It has been great for us to form part of their stories. To support them at this crucial time in their existence.

Amazingly, we count around 450 customers in our ‘community’ who have worked with us and entrusted us over the past few years. It is really humbling and satisfying all round.

But we are also growing – growing in size, stature, ability and capability And as we grow, we are able to respond to our customers’ growing and expanding needs so that we can continue to support them in their future developments

We are also now able to partner more established brands – brands who share our vision and purpose; those who are recognise and demand fine quality; those who wish to embrace us and adopt us as partners into their supply chains Those who wish to become a part of our growing community

“Amazingly, we count around 450 customers in our ‘community’ who have worked with us and entrusted us over the past few years. It is really humbling and satisfying all round.”

“Reduce, reuse, recycle” , the frequently used mantra at the centre of the sustainability movement has led to the emergence of a new savvy and conscious consumer searching for validation and meaning behind the items that they invest in and the brands and retailers that they buy from The result is an expectation of ever increasing brand transparency

Provenance is now only part of the equation Ethics are being challenged with all components that make up the brand ecosystem being scrutinised From principled business practices to the importance of trusted partner mills, makers, retailers, ambassadors and the expectation that they all share the same values

Brands are taking note with a shift towards progressive and considered working methods These vary from a focus on renewable resources and maintaining a "local" mindset where possible, to factoring surplus stock into seasonal offerings and the emergence of product rental services that target to offset consumer culture Alongside this is understanding that a product's lifecycle should ideally be cyclical and that “repair and mend” should be a straightforward, cost effective and viable option for any owner and any item.

Credit: SSEAMSSSEAMS SPECIAL

The starting point for many is designing functional and emotional durability into a product On a basic level the focus is on creating an item that has inherent usefulness, versatility and strength at its core Just as important is the need to create objects that won’t date (and aren’t beholden to trends), are aesthetically beautiful and that owners will want to care for, keep and hold on to Closely linked is the emotional value that clothing holds for many Whether it is nostalgic associations and past memories they represent or ideological associations they promote. It’s this connection that will increase the likelihood an item is cared for long into the future.

Product second life extends beyond caring for items we already own and is why the vintage and second hand markets continue to be successful, remaining a key part of the sustainability landscape. Repurposing has increased in popularity and the emergence of businesses specialising in reworked and up-cycled vintage clothing is saving products from landfill and creating entirely unique, often “one-

off” pieces in the process This has coincided with a shift and redefining of what “Luxury” represents to many Label, price point and availability are no longer the sole indicators of whether an item is regarded as exclusive Authenticity, obscurity, individuality and personality are proving to be increasingly desirable

Whether it's valuing what we already have, buying investment purchases for the long term or giving vintage and pre-loved items a second lease of life, repair and mend remains a simple and effective way of extending a product's life and/or elevating an item's identity. It’s also a principle that has stood the test of time and is exemplified by the beauty of the button. A simple mechanism for garment or product closure they are an intuitive, visually engaging and wonderfully tactile component. A key ingredient in the right products life cycle, with the capability to elevate an item at the creation stage through revitalising and adding personality to a pre-loved product with plenty life left

Image credit: FRAHM

SSEAMS SPECIAL

Image credit: FRAHM

SSEAMS SPECIAL

2024 is shaping up to be an exciting new year in many ways.

Building on the efforts of the past few years we are now able to expand and enhance our craft We have already hugely increased our range and stocks of corozo, Codelite® (milk casein) and, most recently, horn buttons. This allows us to turn around almost all our customer orders immediately Where shortfalls for larger orders exist, we are able to plug gaps against given deadlines

Our new, purpose-built dye shop has also been a breakthrough, meaning that we offer an impressive bespoke, colour matching service And our turn-around times are short and reliable. As we progress into 2024 our attention turns to our new ‘Button Lab’. We have recently launched an etching service for small runs

This opens a door for smaller and emerging labels to use their buttons for branding purposes

and aim to expand this service to larger customers as demand dictates But our ambitions extend further Using the archive of historic button dies and patterns we acquired from James Grove & Sons, we aim to combine relics of the past with technology of the future – to re-interpret and relaunch buttons with a pedigree all of their own Our new ‘Button Lab’ is both progressive and retrospective, open source and keen to explore new ideas.

It is available to customers who share our vision and ambition It reinforces our commitment to our customers and it perpetuates our mission to revive and produce the finest quality natural buttons imaginable

Head to courtneyandco.uk to view the button collection

“Horn has been used in buttonmaking since the end of the 19th Century when a consignment of cattle hooves sent to James Grove & Sons Ltd in Halesowen also contained water buffalo horns.

Real horn (typically from either water buffalo or ox) is a by-product of the farming industry, particularly in India and livestock is not reared specifically for their horn. Moreover, the cattle are raised by numerous small, subsistence farmers and the money they receive for their horn is a vital and additional source of income. Without it, many poor rural farmers could simply abandon their vocation

Horn, itself, is made from keratin which is the same substance as human hair and nails And as keratin is a type of fibrous protein, horn is fully biodegradable

Given the structure of the grain (imagine thousands of hairs all stuck together) which runs along the length of the horn, the appearance of the blanks and finished buttons varies markedly according to its type As a result, the natural colour variation is extensive and each button is unique in its appearance

“Wewouldbe delightedtoinvite youintothisheritage treasuretroveof inspiration.”

When we acquired various machines from the estate of James Grove & Sons, we simply could not abandon the heritage of this venerable company. Whilst few people saw use or value in the numerous sample books containing hundreds of button patterns and thousands of historic dies, their loss would have been permanent and immeasurable

Safely stored, we were contacted some years later by Peter Grove, the last of this great button-making dynasty, who offered to supplement what we managed to acquire with some of the Grove family’s own archives. These contained letters, photographs, memorabilia, books, ledgers and a vast array of press cuttings, marketing literature and documents

When we took stock of all that was assembled we took the decision to create the ‘James Grove Heritage Centre’ (JGHC) at our Cotswold factory We have already had a number of passionate visitors who were eager to explore the exhibits and are happy to welcome more ‘buttonista’ in future.

But, the archives don’t merely serve as a reference centre, a place to come to view relics of the past. Quite the contrary. We have already brought a decades-old pattern back to life for a customer and are looking at ways to bring the collection of patterns and designs back to life

Using state-of-the-art technology, we are able to 3D scan and print facsimiles of buttons and dies; we can reproduce designs which can be etched onto our buttons; and we can even bring old button patterns back to life, too!

Like the month of January, the archives act as a way-marker. They are anchored in the past, but offer countless possibilities for the future also They serve as an inspiration for what can be as much as how they were used to be all of those many years ago.

Please contact us to arrange a viewing at our facility in the Cotswolds. We look forward to welcoming you through the doors in '24!”

HOMEWARE - APPAREL - ACCESSORIES

MANUFACTURED IN SCOTLAND SINCE 2012

HOMEWARE - APPAREL - ACCESSORIES

MANUFACTURED IN SCOTLAND SINCE 2012

DIANE RICHARDSON

Diane is Editor at SSEAMS. A veteran of the apparel industry. Now based back in Scotland, managing Studio SSEAMS and independently publishing SSEAMS Magazine.

EMMA VARSANYI

Emma is a Features contributor at SSEAMS Magazine whilst taking her distinguished career in international brand merchandising into private consulting.

ANDREW DUDGEON

Award winning Illustrator and Creative Director at SSEAMS. Andrew helps steer the SSEAMS ship in the right direction.

RUTH KELLY

Vancouver based, Ruth is a leading Materials & Textile Innovation expert managing mill relationships at SSEAMS with a passion for guiding the industry on environmental impact work.

ANDREA AND DAVID

COURTNEY

Founders and owners of Courtney & Co. - the UK premium Button Maker. Located in the Cotswolds, England.

Click to Linkedin

SSEAMS STUDIO

SSEAMS magazine shines a spotlight on UK progressive apparel and lifestyle brands, makers and mills that are reshaping our future. Our studio is based in Stirlingshire, Scotland. Contact Press@sseams.co

DISCLAIMER

SSEAMS Magazine has taken care to make sure that content is accurate on the date of publication. The views expressed in the articles reflect the author(s) opinions and are not necessarily the views of the publisher and editor. The published material, adverts, editorials and all other content is published in good faith. SSEAMS Magazine cannot guarantee and accepts no liability for any loss or damage of any kind caused by this publication and for the accuracy of claims made by the advertisers. Materials contained in this publication are subject to copyright and other proprietary rights. The contributors' articles and copyrights for the text and photographs remain with them at all times, unless indicated at the bottom of the articles.

SSEAMS SPECIAL

ISSUE DIRECTORY & THANK YOU TO COURTNEY & CO. AND CONTRIBUTIONS FROM THEIR BRAND COMMUNITY

S.E.H KELLY BAMFORD

NAVYGREY PETER REED

THE WORKERS CLUB

YARMOUTH OILSKINS

NICHOLAS DALEY

GENEVIEVE SWEENEY

SIRPLUS

6876

MID MOOR AND MOUNTAIN

BLACKHORSE LANE ATELIER

FRAHM

WHITEHILL MERCANTILE

SSEAMS+LAB ISSUE TWELVE

ASQUITH GROUP

AND TO OUR READERS, WE HOPE YOU ENJOY

LEARNING A LITTLE MORE ABOUT THE WORLD OF BUTTONS

SSEAMS SPECIAL