INNOVATORS DAY 10.09.2025

TECH METAL TRANSFORMATION CHALLENGE

DESIGN OFFICES BERLIN HUMBOLDTHAFEN | ALEXANDERUFER 3-7 | 10117 BERLIN

INNOVATORS DAY 10.09.2025

DESIGN OFFICES BERLIN HUMBOLDTHAFEN | ALEXANDERUFER 3-7 | 10117 BERLIN

10:00 – 10:30 Arrival + Coffee

10:30 – 11:15 Tech Metal Transformation Challenge: Intro + Q&A

11:30 – 12:30 Matchmaking – Part 1 Individual SPRIND sessions

12:30 – 13:00 Lunch Break

13:00 – 14:00 Mentor/NSF/jury talks Individual SPRIND sessions

14:00 – 15:00 Matchmaking – Part 2 Individual SPRIND sessions

Closing Final tips and advice from SPRIND Team

✓ Hear first-hand from the SPRIND team about design and vision of the challenge.

✓ Ask us questions about the challenge and get 15 minutes of unfettered access with the team for a private conversation, where you can preview your idea.

✓ Build your network. You might have part of the solution but are looking for others to create A team or join someone else's team.

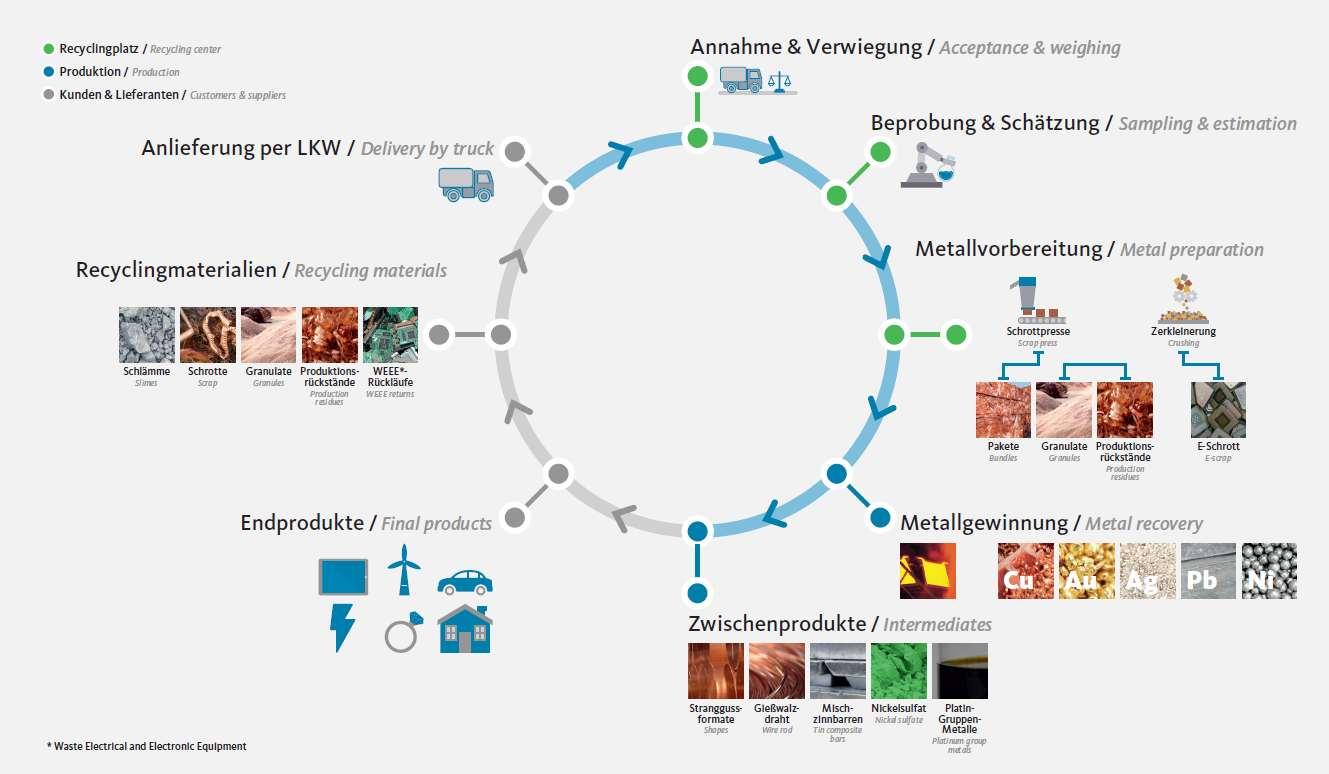

✓ Gain insight into the complex e-waste recycling value chain and learn about today's challenges from senior industry experts.

✓ Meet our partners at the U.S. National Science Foundation, who will be developing the aligned us version of this challenge.

WE EMBRACE UNCONVENTIONAL, CREATIVE, INTERDISCIPLINARY APPROACHES THAT CHALLENGE THE STATUS QUO.

WE EMPOWER RISK TAKERS, CELEBRATE FAILURE, AND SEEK OPENMINDED INDIVIDUALS, WHO ARE MORE PRONE TO SERENDIPITOUS DISCOVERY.

EVERYTHING MENTIONED IN THIS BRIEFING IS OUTLINED IN THE APPLICATION MATERIAL

DEVELOP AN END-TO-END PROCESS IN WHICH RECOVERED METALS CAN BE DIRECTLY REUSED AS FUNCTIONAL MATERIALS WITH A LIFE-AFTER-NEXT IN MIND.

ACHIEVE PILOT PLANTS WITH A TECHNOLOGY READINESS LEVEL OF 6 TO 7 WITHIN THREE YEARS.

ALL METALS ARE UP FOR THE TAKING

SMARTPHONES USE 69 ELEMENTSLESS THAN 25% RECYCLED

CRITICAL METALS ARE OFTEN LOST NO VIABLE BUSINESS CASE FOR LOWVALUE, HIGHLY DISPERSED METALS

UTILIZE AN INTERDISCIPLINARY APPROACH

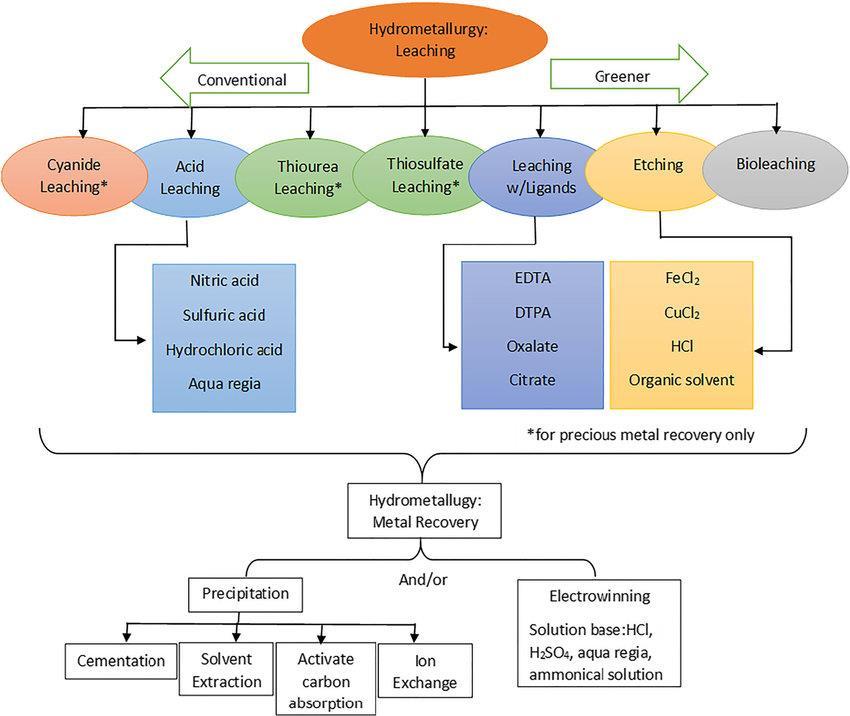

UTILIZE BIOLOGICAL, CHEMICAL AND PHYSICAL-MECHANICAL APPROACHES AND BUILD A MODULAR SYSTEM TO GAIN ACCESS OF THESE CRITICAL METALS.

REDUCE ENERGY

CONSUMPTION, REDUCE WASTE STREAMS, LIMIT THE USE OF TOXIC INDUSTRIAL CHEMICALS, REFINE RESOURCE INTENSE PROCESSES

Produce new, functional materials with targeted industrial applicability

• High-entropy alloys with a better strength-to-weight ratio, a higher degree of breaking and tensile strength, as well as corrosion and oxidation resistance

• Bio-based nanoparticles with tailored shape & size for diverse industries

• The processes are to be optimized in such a way that metal losses through dissipation are avoided, energy consumption is significantly reduced and the resulting products are optimized in terms of their functionality in line with market requirements.

• Projects are developed from the laboratory stage (TRL 2/3) to prototypes in a real operating environment (TRL 7).

• If you have not created or have an existing company in year two, your chances of moving to Stage 3 are limited.

PROOF OF CONCEPT

FUNCTIONAL EXTENSION

DEMONSTRATION OF THE SOLUTION

NUMBER OF TEAMS

FURTHER DEVELOPMENT

STAGE 1 - LAB

Demonstrate high recovery rates on

standard e

Validate the process for at least one market

STAGE 2- PILOT

Integrate biological, chemical & mechanical steps

STAGE 3 – REAL-WORLD

• Identify the key fractions or target metals suitable for recovery and functional transformation from shredded mobile phone circuit boards and displays.

• Demonstrate a process route that produces at least one functional metal product with real application potential.

• Validate important process steps on a laboratory scale: carry out small-scale tests with the process steps and record material balances and energy input per step.

• Use the measured recycling yields as well as the officially provided supply risk and economic importance values to calculate an initial critical raw materials score.

• HAZOP analysis of the process: implement a basic safety concept for the handling of byproducts such as toxic gases and brominated flame retardants.

• LCA preview: indicate values for energy use and main reagents and complete an assessment of how these values can be improved through scaling or optimization.

• Provide analytical proof that the recovered material meets the purity or functionality requirements.

• Reduce metal dissipation and energy requirements to a minimum.

• The metal or mineral products obtained are to be optimized in terms of their functionality.

• At least one end-of-life product is to be completely recycled.

• Complete a comprehensive techno-economic analysis and a life cycle analysis.

• Demonstrate in a real operating environment how the complete metal inventory of at least two significantly different end-of-life products can be processed into functional metal or mineral products.

• The functional metal or mineral products obtained must be suitable for direct use by customers and demonstrated for use in proof-of-concept manufacturing.

• The process must include a complete life cycle.

• This demonstrator must show how it can be integrated into existing industrial recycling processes or disrupt them in terms of material recovery and economic viability.

IMPORTANT DATES

THE APPLICATION PERIOD RUNS UNTIL NOVEMBER 7, 2025 (18:00 CET).

INVITATIONS TO PITCH IN PERSON TO SPRIND WILL BE 4/5 DECEMBER

THE CHALLENGE STARTS ON THE DAY OF THE JURY DECISION (DECEMBER 5)

IT IS PUBLISHED AND AVAILABLE WITH THE APPLICATION DOCUMENTS THE CONTRACT IS NON-NEGOTIABLE

FOR STAGE 1, 8 TEAMS MAY RECEIVE UP TO EUR 1,500,000 (PLUS VAT) EACH.

UP TO SIX TEAMS WILL ADVANCE TO STAGE 2, WITH FUNDING OF UP TO EUR 2,000,000 (PLUS VAT) PER TEAM.

FOR UP TO FOUR TEAMS MOVING INTO STAGE 3, SPRIND WILL PROVIDE UP TO EUR 2,500,000 (PLUS VAT).

WITH FUNDING BASED ON EACH TEAM’S PROJECTED COSTS

- opportunities & challenges for CRM recovery from complex (electronic) products

Dr. Christian Hagelüken

SPRIND Innovators Day

Berlin, 10.9.2025

▪ Biggest challenge in recycling of electronic products?

►Their proper collection at EoL

▪ Challenge No. 2?

► Channelling collected EoL products into best performing processes

▪ Challenge No. 3? (overarching)

► Making it all economically viable without negative side effects

▪ Challenge No. 4?

►High quality recycling technology coping with product complexity

→ Effective recycling technology is key for CRM recovery – but it‘s useless when not properly embedded into the overarching system

Challenges: Low value of single unit,

complex waste mixes & product compositions

• Metal value of 1 smart phone: 2 €*

(at current record prices for Au & Ag)

• Net value of 5 t of phones at gate of Umicore recycling plant: ≤ 90,000 €

• Metal value of ~2 B mobile phones sold globally annually: 4 B €

E-scrap / mobile phones, a complex mix …

▪ Ag, Au, Pd… (precious metals)

▪ Cu, Al, Ni, Sn, Fe, Bi, Sb, In… (base & special metals)

▪ Hg, Be, Pb, Cd, As, …(hazardous substances)

▪ Halogens (Br, F, Cl...)

▪ Plastics & other organic materials

▪ Glass, ceramics, wood, …

Environmental risk in case of landfill/bad recycling

Important source for raw materials (incl. CRM)

How to recycle responsibly?

→ cope with hazards while recovering value

High quality recycling

= economically viable recovery

• of various relevant contained materials,

• with high yields,

• in marketable quality,

• and meeting high environmental**- & social standards.

** incl. energy & CO2-balance

* e.g. electronics

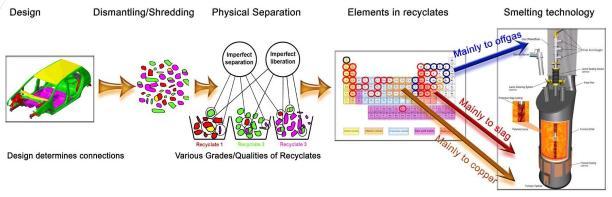

efficiency is decisive factor for overall metal yields

source: Reuter/ Van Schaik, 2010

Co-Ni-Cu-Li recycling from Li-Ion batteries

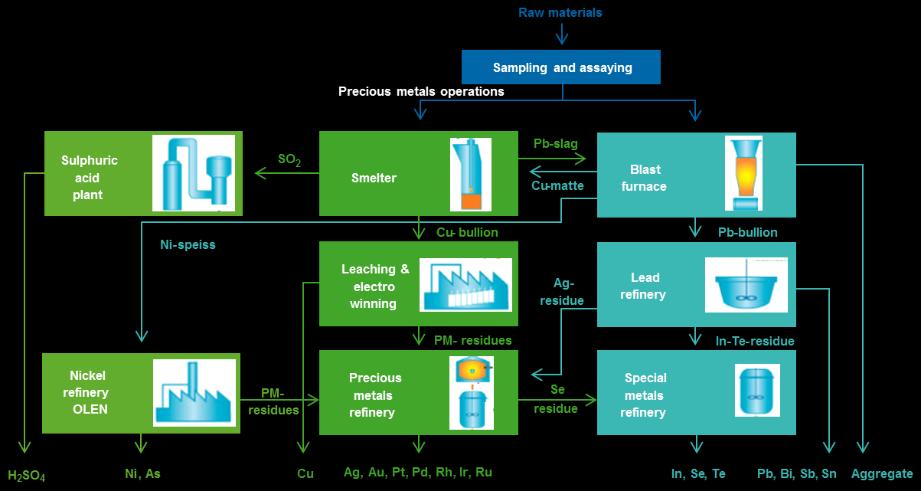

process based on Cu/Pb/Ni metallurgy, input capacity up to 500,000 t/a

Au, Ag, Pt, Pd, Rh, Ru, Ir, Cu, Pb, Ni, Sn, Bi, Se, Te, In, Sb, As

Recyclables: catalysts, circuit boards, …

Industrial by-products: smelter intermediates, slags, dusts, bottom ashes, …

Collector metals

17 different metals

• Highly flexible, energy efficient & robust process

• High performance due to optimised input mix

• In addition, dedicated process for battery recycling, recovering Co, Ni, Li, Cu

Recycling prerequisite: channelling of the relevant material fractions to such plants!

• High recycling yields for (chemically noble) metals that fit metallurgically/thermodynamically – even as trace elements!

• The value of precious metals & Cu enables co-recovery of (many) other metals – if state-of-the-art facilities are used.

• Success factors: Economies of scale, technical infrastructure, metallurgical skills.

• Ignoble metals in input-Mix (Al, Fe, Ga, Ge, Ta, REE, Li, …) are lost as oxides to the slag (→ high dilution)

neither economical nor environmentally beneficial to recover these from the cold final slag.

• To recover these metals, dedicated metallurgical processes are needed (and available)

such target metals need to be separated & concentrated beforehand in pre-processing

→ Li-Ion batteries: Co, Ni, Li, Cu

→ Al; Steel; REE-magnets; Ge-residues...

• Need to mitigate CO2-emissions from fuel, energy & organic input.

• Slag discharge is crucial, need for reliable slag utilisation options.

• Metallurgical sites are the backbone of an EU circular economy.

(technical/organisational)

➢ Optimisation of interfaces for processing/pre-treatment:

• Pre-sorting of products („separate smartphones from electric toothbrushes“)

• Pre-separation of relevant components (batteries, magnets, LCDs, Al-heat sinks/housings, Fe-frames, …)

• not useful: separation of smallest components (e.g. Ta-capacitors) from complex assemblies,

usually leads to losses of other valuable materials (e.g.Ag, Pd), high costs

➢ More selective collection: collection groups more strongly orientated towards recycling requirements

➢ Better transparency of real material flows at EoL

➢ Improved product design: modular structure, accessibility of raw material-relevant components (see above)

➢ New metallurgical processes:

• Separation of „ignoble“ metals via the gas phase upstream/in the smelter (“fuming”)

• Separation from the liquid slag

Product passports, process-digitalisation along recycling chain, AI, optical recognition, new online (analytical) tools, etc. are offering new opportunities to improve CRM recovery

►Make sure: output materials to be suitable as reliable input for new products

Waste price recoverable material value

material content x yield x price product composition & market trends (pollutants can have negative value)

• Technical performance

• Process chain efficiency

• Factor costs (labour, energy, capital)

• Available volumes/economies of scale

• EHS-performance (incl. reporting & hazardous emissions control)

• Shipping costs (incl. taxes, customs)

• Administrative costs (incl. time delays)

Impacted by:

Recycling industry Legislation & enforcement Trade regulations

The lack of level playing field for EHS-compliant high-quality recyclers hampers the circular economy recycling chain costs recycling fee* = - +

*legislation / business model to cover externalised costs

C. Hagelüken, C. Meskers (2023): Economic aspects of metal recycling, in: Handbook of Recycling (2nd ed.), Elsevier, 627-644

2nd law of the recycling economy: All metals can be recycled in principlebut not from every combination of materials (entropy problem)

• Challenge of complex products & multi-material mixtures: requires prioritisation → what can be ‘sacrificed’ to enable the extraction of a target metal?

• Consider thermodynamic limits of metallurgy (e.g. chemically noble vs ignoble metals); compatible and incompatible trace elements.

• Importance of product design and mechanical processing technology. → can incompatible components/material mixes be separated before metallurgy and fed into suitable special processes (e.g. magnets, batteries)?

• Limits of R&D funding: 100% recycling is impossible.

Regulation, incentives and R&D funding are important, but they face thermodynamic/physical limits.

1. Technical recyclability & generation of marketable output as basic requirement

2. Accessibility of relevant components → product design

3. Economic viability intrinsically or externally created

4. Comprehensive collection

5. Transparency on real flows of EoL products

6. Use of best performing recycling infrastructure

7. Optimal technical-organisational set-up of chain

Complex products require a systemic optimisation & interdisciplinary approaches (product development, process engineering, metallurgy, ecology, social & economic sciences)

contact: christian.hagelueken@t-online.de

Publications: www.researchgate.net/profile/Christian_Hagelueken/contributions

C. Hagelüken, D. Goldmann (2022): Recycling and circular economy - towards a closed loop for metals in emerging clean technologies, Mineral Economics, https://rdcu.be/cNsl7

UBA Ressourcenkommission (2023): Opportunities & limits of recycling in the context of the Circular Economy – frame conditions, requirements, and recommendations for action.

C. Hagelüken, C. Meskers (2023): Economic aspects of metal recycling, in: Handbook of Recycling (2nd ed.), Elsevier, 627-644

• CE is more than recycling - also optimise use & service life (incl. repair).

But at some point, high-quality recycling is required to physically close material cycles!

• CE is essential for a sustainable supply of raw materials in Europe.

• ‘Good’ recycling is more expensive than poor recycling Regulation & standards are important!

• Recycling (only) ends with the production of marketable material (for the manufacture of new products).

• The more complex the material composite & the greater the variety of materials, the more difficult it is to recycle many ingredients.. Take priorities: recovery of recyclable materials and avoidance of pollutants.

• High-quality industrial recycling processes already exist for complex products (electrical and electronic products, catalytic converters, EV batteries, etc.). Make sure that they are used!

• No recycling without collection! Create more collection incentives and better transparency about real material flows at the end of a product's life (→ potential key role for product passports).

• Innovative business models for CRM-relevant consumer goods are decisive. New forms of collaboration (‘roundstream’) & product service models/leasing as game changers.

• Focus: CE strategies for ‘green’ products, as they increase demand for (critical) raw materials and must be sustainable by definition. E-mobility is an ideal test case for CE.

“

… where the value of products, materials and resources is maintained in the economy for as long as possible, and the generation of waste minimized… to develop a low carbon, resource efficient and competitive economy”

EC Communication Dec. 2015 “Closing the loop – An EU action plan for the Circular Economy”

Metals are the ideal candidate: “eternally” recyclable, no downcycling, no material quality issues…

CE = much more than recycling (use efficiency, repair, reuse, …) but finally raw material loops need to be closed physically!

➢ Loop is only closed if recyclates are reused for production of new products (replacing primary metals).

➢ Current waste legislation misses this physical aspect. Reported recycling rates cannot be taken as suitable indicators for CE.

* Meaning going beyond the traditional German expression „Kreislaufwirtschaft“

Macro-economic/societal level

• Resource conservation

• Supply security

• Responsible sourcing

• CO2 footprint

• Environmental protection

Micro-economic level

• Product type & composition

• Market prices of metals

• Recycling performance

• Economies of Scale

Addressed in CRM-Act, NKWS & other policy initiatives but so far without a ‚price tag‘

• societal benefits

• externalised costs for society

Indirect impacts:

• Collection infrastructure

• External collection incentives (e.g. leasing, deposits, …)

• Legislation / monitoring / enforcement

• Business model for product (B2C, B2B)

• Stakeholder behaviour & motivation (Consumers, OEMs/EPR culture, distributors, recyclers)

Price development Au, Ag, Pd & Pt 1988-2025/05

SPRINDTech-MetalTransformation

Innovators’Day

TorbenEDENS,Berlin,10September2025

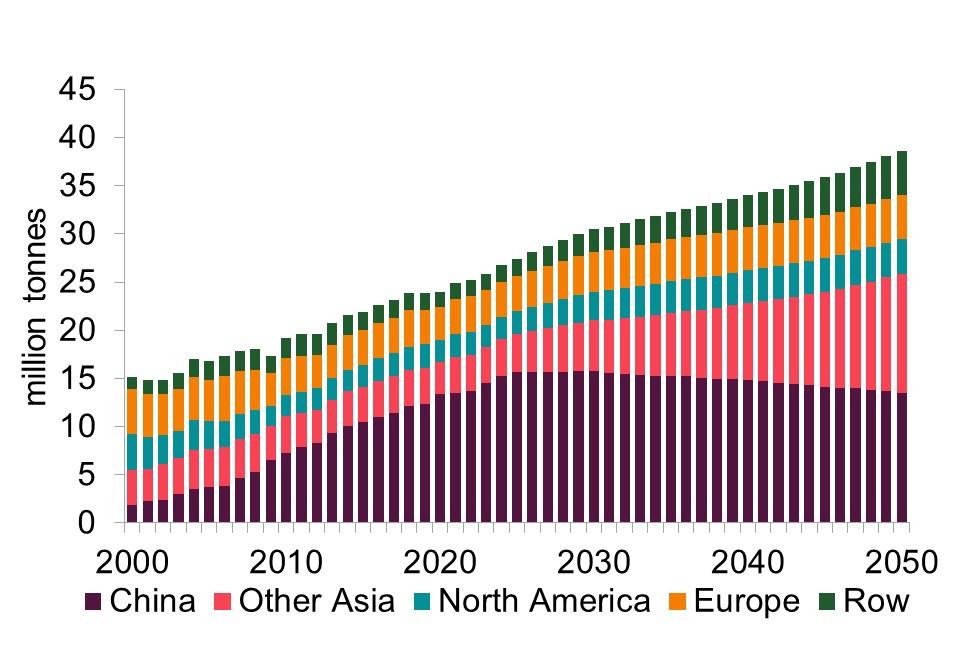

Copper-thematerialformodernlife recyclingisincreasing,butnotenoughtocoverallcopperdemand

Characteristics

»Electricmotors

»Cablesandwires

»Microchips

»Airconditioners

»Heatexchanger

»Kitchenappliances

»Sanitaryinstallation

»Piping

»Roofsandfacades

»Coins Final

»Transformers

»Brakepads

BuildingandConstruction:Copperpipes,roofing,cladding:~50–100years

Theseproductsareoftenembeddedininfrastructureandhavelongservicelives duetocopper’scorrosionresistanceanddurability.

ElectricalApplications:Wiringinbuildings:~30–50years, Consumerelectronics:~5–10years

Electricalcomponentstendtohaveshorterlifespansdueto rapidtechnologicalturnover.

TransportSector:Copperinvehicles(e.g.,wiringharnesses):~10–20years

IndustrialEquipment:Machineryandheavy-dutyapplications:~20–40years

Oftenreusedorrefurbished,extendingeffectivelife.

OtherUses(e.g.,coins,cookware,art):Highlyvariable,oftendecadesoreven centuriesinsomecases.

Therecycledcoppersupplyisdelayed,creatingatimelagbetweenproductionandrecovery.

Recyclingmarkettrends

Strongglobalmacrotrendsdrivegrowthinrecyclingmarkets SPRINDTech-MetalTransformation-Innovators'Day

Multipolarbusiness world

Morecomplex materials

Increasingrecycling efforts

Localhandlingof recyclingmaterials

Growthinemergingcountrieswilloutpace Westerncountries

Risingnumberofelementsanddecreasing metalcontentinprimary&recyclingraw materials

Stricterlegislationandincreasingconsumer awarenessregardingsustainability

Developingcountriesarereducing orbanningimportsofwaste materialsfromtheWesternworld

Source:WoodMackenzie-GlobalcopperstrategicplanningoutlookQ22025

PrimaryvsSecondaryRecycling?

Copperis100%recyclablewithoutlossof properties:

32%ofglobalcopperdemandismetthrough recycling.(Aurubiscathodescontain45% recycledcopper) Two-thirdsofallcoppereverminedisstillin usetoday.

Thishighrecyclabilitymeansthatcopperoften re-enterstheproductioncyclemultipletimes, effectivelyextendingitsfunctional lifetimeacrossgenerationsofproducts.

TheInternationalCopperAssociation

Howiscopperproduced?

SPRINDTech-MetalTransformation-Innovators'Day

Aurubis:weareexpertsformetals.

Successfulin

20countrieson

3continents

>7,000x passionand engagement

159years experienceinthe productionofnonferrousmetals

about1milliont

20 Oneofthe worldwideleading companiesin copperrecycling ofrecyclingmaterials isprocessedbyAurubis onayearlybasis

SPRINDTech-MetalTransformation-Innovators'Day

differentmetals arerecoveredby Aurubis

OurstrategybuildsonthesoundmissionofAurubisandcoversall relevantaspectstodrivesustainablegrowth

Secure CoreBusiness Strengthen CoreBusiness Pursue GrowthOptions

IndustryLeadershipinSustainability

EnablersDigitalization,automation,and “PlantoftheFuture”

Strategicresourcemanagement,talentand personneldevelopment

Itisourmissiontoresponsiblytransformrawmaterials intometalsforaninnovativeandsustainableworld.

SPRINDTech-MetalTransformation-Innovators'Day

HeadquartersPrimaryCopperRecycling/PreciousMetals

CopperProducts

Aurubis

SPRINDTech-MetalTransformation-Innovators'Day

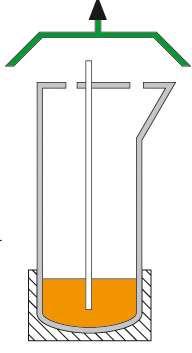

Richmond–SecondaryCopperSmelter

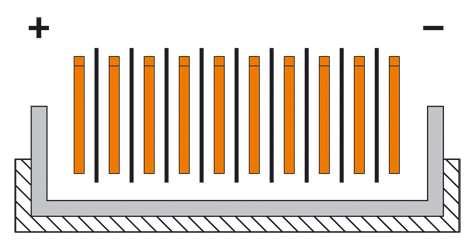

RecyclingdedicatedtoPrintedCardboards

Off-gascleaning

Sampling, Blending

PbSn-alloyfurnace

PbSn-alloyingots

Recyclingdedicatedforcopperscrapswithoutsulphur

Abgasreinigung

Schlämme Rückstände

Probenahme, Materialvorbereitung

KRS

KayserRecyclingSystem

E-Schrott Schwarzkupfer80%

TSL

Eisensilikatsand

Altkupfer

Konverterkupfer95%

Abgasreinigung

Blei-ZinnLegierung

Anodenofen

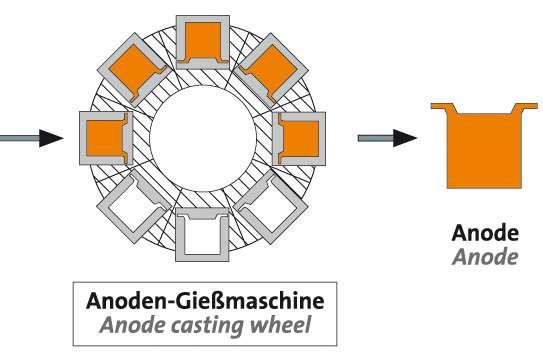

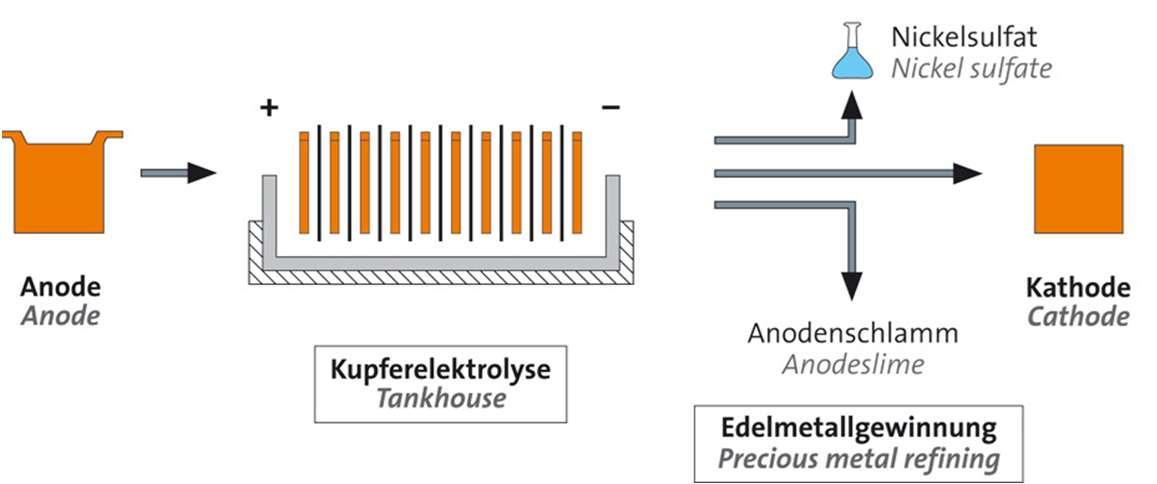

Anodengießanlage Anode KupferelektrolyseEdelmetallgewinnung Kathode Nickelsulfat Kupfersulfat Anodenschlamm

dedicatedtoCu-sulphidesandScraps

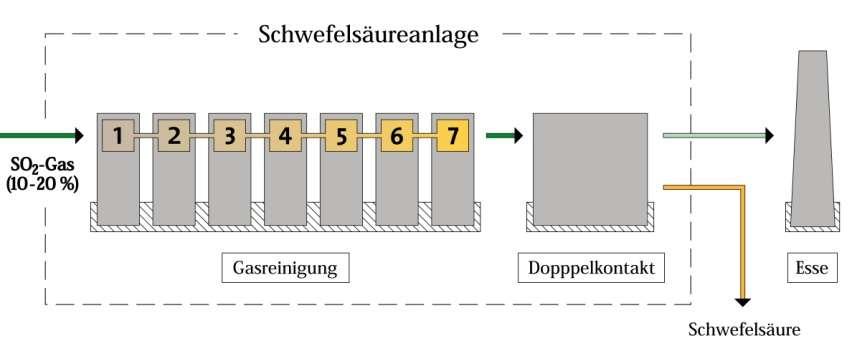

Sulfuricacidplant

Wasch-&Kühlanlage Washing&Coolingsection Kontaktanlage Contactplant

Hamburg–SecondaryLeadandPM-Smelter dedicatedtoCu-Pb-separationandPreciousMetalExtraction

E-wastecontainsover1,000differentchemicals,includingheavymetals(lead,mercury, cadmium),polychlorinatedbiphenyls(PCBs),brominatedflameretardants,andplastics.Improper handlingreleasestoxicsubstances.

•Collection,sortingandsamplingareimportantpartsoftherecyclingprocess:

•Creatingmanyfractionsspreadsvaluablemetalsandreducesrecoveryratesbecauseselectivityisnotunlimited.

•Impropersamplingjeopardizesbusiness.

•Extractivecopperpyrometallurgyoffershighrecoveryratesformanymetals(Ag,Au,Cu,Ni,Pb,Pd,Pt, Se,Te,Sn,Zn)andbromides.

•Theplasticsareburned,producingCO2andheat.

•Thefiberglassisslagged.

•Unfortunately,therareearthelementsarelostintheslag.

•Hydrometallurgyisoftenveryselective,butextractingonlyonemetalandleavingtheresidueforfurther (pyro)processingisnotattractive.

Recyclingisacomplexprocessthatneedsaholisticviewconcerningenvironment(air,water), legistaltion,technologyandeconomics.

SPRINDTech-MetalTransformation-Innovators'Day

SPRINDTech-MetalTransformation

Innovators’Day

TorbenEDENS,Berlin,10September2025