ARE YOU READY FOR

ARE YOU READY FOR

Welcome to the November edition of From the Field! In this issue, we’re shining the spotlight on Winter Maintenance – it’s time for greasing! Plus, we take a look at drainage with the TF-10 and give you a sneak peek inside the factory, where our new dynamic balancer machine has just been installed!

Are you ready for Agritechnica?

Location: Hanover, Germnay

Date: 9th-15th November 2025

The bags are packed, the lorry loaded and we're show ready! Join us at Agritechnica from 9-15th November to see SpreadPoint Machinery and talk to our team about our entire product range.

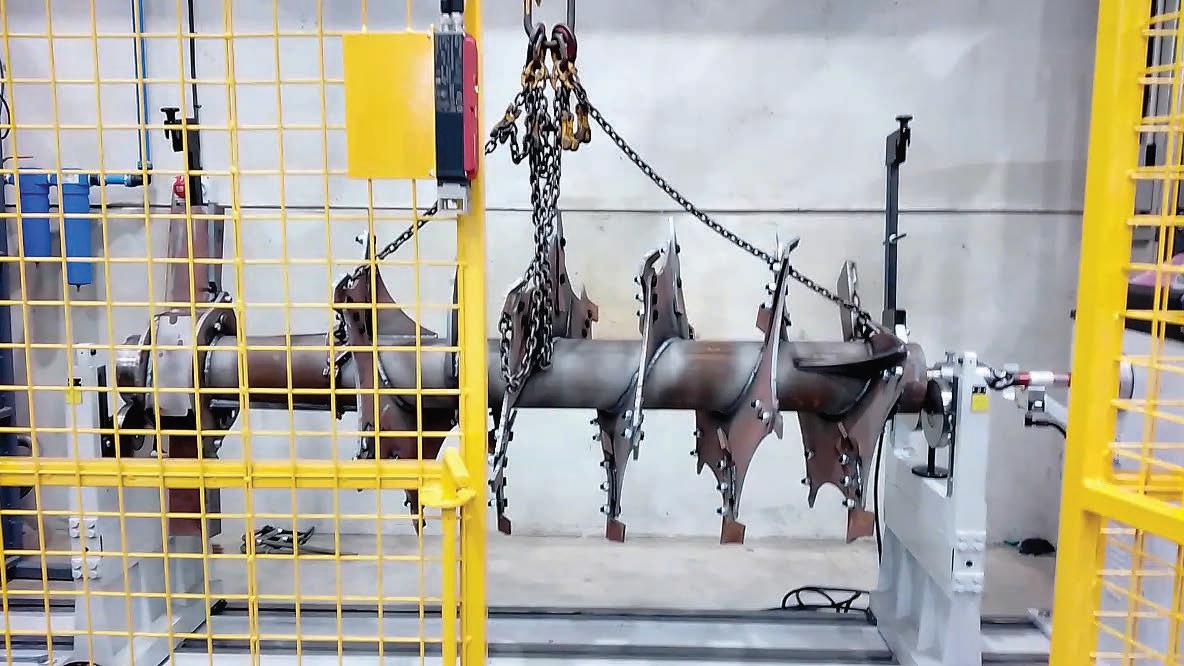

At SpreadPoint, we have always prided ourselves on our ability to produce world-class machinery. We also strive to do as much as possible in-house, from our laser cutting & folding of steel sheets, to our state-ofthe-art shot blasting & paint units. Recently we have expanded our in-house ability with the introduction of a new dynamic balancer machine which will ensure perfectly balanced rotors for our rear discharge muck spreaders. Richard Kane, Managing Director says: ‘While our cutting edge design and manufacturing process reduced manufacturing tolerances greatly, variation is always present in welded and fabricated assemblies. As our rotors are made with some of the most robust materials on the market with a large diameter, the inertia and any dynamic unbalance can cause machine vibration and premature gearbox and bearing failures.’ He adds, ‘ We would never manufacture the machine without dynamically balancing such rotational parts, but up until now we have sub-contacted this out of our everyday assembly.’ 'The benefits of incorporating in-house dynamic balancing enables us to save time, improve quality and gives us total control over our products which will ultimately increase customer satisfaction'.

The gritting and salting of roads, private car parks, amenity sites and even your own laneways is essential for keeping things moving in the Winter months.

Winter maintenance just got easier with the SpreadPoint Gritty, the tractor-operated salt and grit spreader designed for efficiency, safety and simplicity.

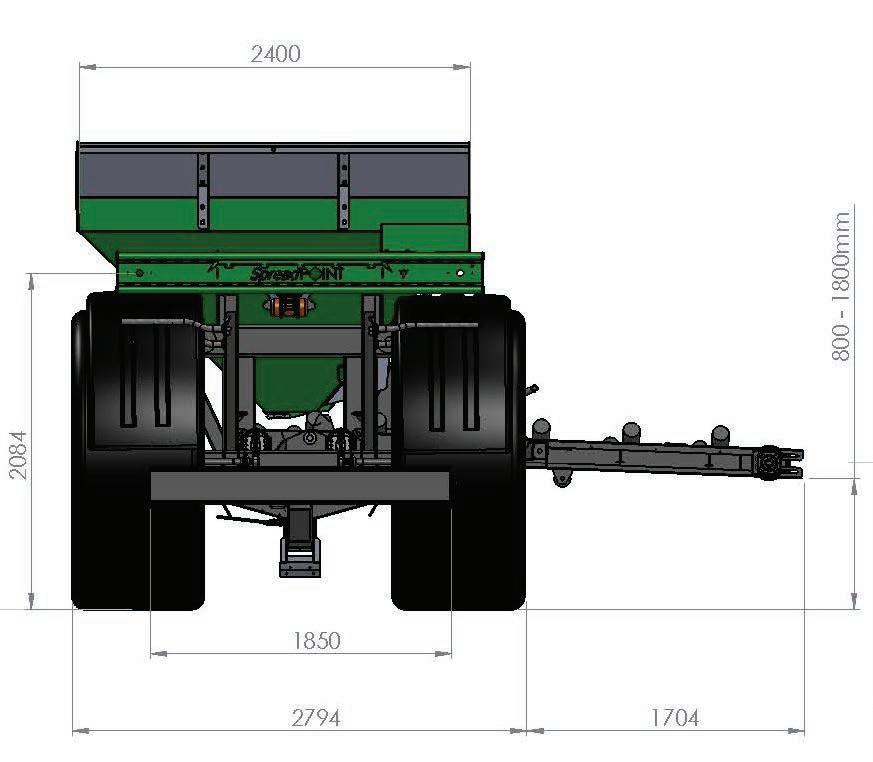

With capacities ranging from 4m³ to 14m³, the Gritty can handle jobs of any size, all without the need for HGV licenses, tachographs or extra fuel and tax duties. Built to last, it features a stainless-steel rear door, heavy-duty flange bearings and durable mudguards, all finished in oven-baked SpreadPoint yellow.

The spreader operates via hydraulic controls, eliminating PTO shafts for safer, low-maintenance operation while the adjustable SD-A salt module allows you to fine-tune height, width and pattern to suit your site. In-cab monitors and LED lights make winter work safer and more precise, whether you’re a private business, contractor or local authority.

The Gritty can also be customised with options like stainless steel mesh grids, hopper extensions, rollover covers, tandem or single axles and adjustable K80 spoon hitches, making it adaptable to any

Stone drainage which is often used alongside perforated pipes, is the use of clean, course stone to create or enhance drainage channels across a field. This operation helps to improve soil drainage, helps water to move laterally to collector drains & ditches and assists with removing surface water quickly after heavy rainfall. The SpreadPoint TFRange is the most advanced machine on the market for the job!

• Capacity: 7 - 20T (50mm clean) Including the extensions

• Extensions galvanised

• Galvanised Conveyor

• Widest Belt On The Market at 630mm

• HD chassis RHS construction

• Push bar

• Folding hydraulic conveyor with road safety locks

• Reach 1700mm from face of tyre

• Load Compensated Hydraulic belt control

• Adjustable swivel hitch

• Mudguards

• LED lights on SpreadPoint Lightbar

• High speed brakes

• Square beam axle (TF-7 & TF10), Round Axle (TF-20)

• Range of tyre options including turf tyres

TF-Range of Gravel Carts. For drainage jobs big or small! Niall

• Shot blasted & 2K oven baked paint and Galvanised finish.

Vibrator Option (Essential For Sand)

Tiernan

+44 (0) 284433 0447

As the days shorten and evenings grow longer, winter is fast approaching. Here in Northern Ireland, we may not experience the harsh snowfalls seen in Norway or across the United States, but keeping your SpreadPoint machinery well maintained remains a priority, no matter the location.

1. Greasing Prevents Rust

Moisture & cold temperatures can cause metal components to rust, especially if your MK-1200 is stored outside. Greasing creates a protective barrier.

2. Greasing protects moving parts

Bearings, linkages and joints in your TF-7 can seize or wear if not properly greased. Greasing allows for smooth movement on metal-on-metal parts. Grease it or cease it!

3. Freeze Damage is real

Any water or dirt which has made its way into joints on your SP-900 can freeze, expand and cause cracks or stiffness. Properly cleaning your machines before storage will help prevent this.

4. Be Ready for Spring

With the working season coming to an end, why not get your SP-600 or MK-900 ready to roll come Spring? By servicing and greasing your machine, you can avoid breakdowns, downtime and emergency repairs when it's time to go again.

5. Keep your performance standards up

A well maintained TF-10 will ensure the SpreadPoint top-quality performance is maintained for next season.

6. Extend your machine lifespan

SpreadPoint machines are built to last. But regular maintenance will ensure its longevity. It will help reduce downtime, wear and will keep your Gritty in good working order.

7. General Maintenance

As well as winter maintenance, you should aim to carry our regular checks on all your SpreadPoint equpment. Check out our maintenace Interval to help get started.

Need to order maintenance parts? Contact our parts team for more details!