17 minute read

Emerging packaging trends

from SPN April 2021

by spnews.com

More Transparent Packaging

Emerging packaging trends of the future

Advertisement

By analysing emerging technology, global packaging trends, and market projections, we can get a pretty good glimpse into what the packaging industry will potentially look like by 2028 and beyond. In this article, we’ll go over everything from sustainability, design (smart packaging) to machine automation to manufacture, to operations including AI and block-chain technology and more.

Convenience driving innovation

In the future consumers will be able to enjoy an all-inclusive shopping experience. Instead of, for example, a few branded hair & beauty items, it will be customary to offer full-spectrum personal care experiences that go beyond the brand and appeal to customers mentally, emotionally, and sensually. With new technological advances, there will be a shift away from mass production and more towards innovative and specialized brand packaging to serve specified products and services. While we all recognise our classic cardboard boxes, bags and bottles, the future may be reshaping these classics we’ve all grown up with.

With growing consumer demands comes a growing need for convenience. Convenience calls for innovative upgrades and technological advancements that unlock new doors of opportunities for businesses. Let’s explore some changes that we may expect to see in the packaging industry.

Dissolvable Packaging

Edible packaging is an interesting and innovative alternative that alleviates the reliance on fossil fuels and has the potential to significantly decrease our carbon footprint, which is exactly what consumers are already looking for. Using raw materials extracted from algae, natural sweeteners and natural dyes using the skins of fruits and vegetables shows a lot of potential for offering the food industry a variety of options with regards to colours, designs and more. Furthermore, it offers an exciting experience for customers that goes beyond the packaging, seeing as they will be consuming the packaging too!

Edible packaging has been explored and continues to establish credibility and functionality with edible water bubbles entering the market in 2013. According to Design Boom the London-based sustainable packaging start-up wants to transfer from simply selling their water bubbles from pop-ups to challenging plastic waste on a global scale, piloting their water bubbles at major sporting events in 2018. It is estimated that the edible packaging industry is growing at a CAGR of 6.81% from 2017 to 2023. This innovative way to combat plastics may be becoming a norm sooner than we think!

Reducing waste

Reducing waste is not limited to the food and drink industry, but also to household items. We have seen a huge emergence of water dissolvable packaging for dishwashing and laundry detergents, and this is becoming more normalized and part of the mainstream as time goes on. Moreover, corn starch based packaging seems to be gaining more popularity in the retail industry as well as the food and beverage industry

Items such as bags, take away containers and cutlery made from corn starch are gaining more attention in many industries, especially in fast food.From a customer perspective, this will seem like an attractive option due to the growth of the eco-conscious consumer.

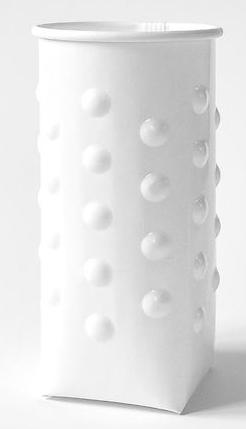

Space Saving Packaging

Storing and transporting mass amounts of packaging is also seen as less eco-friendly as planes, boats and trucks transport packages to mass warehouses to be stored and ultimately end up in a landfill if stock isn’t sold or customers get their hands on product packaging they don’t see a use for. Especially in the food and beverage packaging industry, a lot goes to waste.

Seeing an increase in space-saving packaging to reduce mass transport, storage and waste. So, what does space saving packaging mean for the packaging design industry? We are looking at more square or rectangular packaging for stacking and storage purposes. This doesn’t seem like the most exciting design change considering we have had square or rectangular shaped beverage packaging for a while. However, this concept is already gaining a fair amount of attention. Boxed Water became very trendy amongst social media platforms since its release in 2009. This concept is already starting to become a norm in the drinks and beverage industries. Boxed beverages also ties into sustainability because the use of plastic for the production of boxed drinks is significantly reduced, leaving it to paper and aluminium to do the job.

Smarter, More Intelligent Packaging

Also known as intelligent and active packaging, smart packaging is seeing enormous growth in the packaging industry today. According to Grand View Research, smart packaging revenues came in at $10.8 billion in 2015 and are expected to reach $26.7 billion by 2024. From a consumer perspective, smart packaging offers many value-added benefits, including enhanced unboxing experiences, eye-catching visuals, product preservation and protection, authentication, security, and connectivity.

For brands and companies, a new world of communication is opening up. With the opportunity to track consumer behaviours with more convenience, this type of packaging offers a more tailored experience to your target market, thus allowing companies to meet their consumer demands more effectively. Whilst smart packaging doesn’t offer new shapes to our classics, it does reshape the purpose and capabilities of packaging, allowing the packaging industry to explore the unknown. We may see the implementation of two primary technologies: printed electronics and nano-technology.

Printed Electronics

Printed electronics are seen in the form of near-field communication (NFC); radio-frequency identification (RFID); ambient intelligence; smart LEDs/OLEDs; and compact power sources, screens, sensors, and data storage offering consumers a level of interaction never seen before. Advanced materials and printed electronics with smart LEDs/OLEDs will bring a new level of product interaction, infotainment, digital sales aids, and online connection.

In simple terms – sensor activated screens that are part of the packaging design and huge part of the customer experience. Recently, Karl Knauer and INURU GmbH partnered to create an illuminated Coca-Cola label using printed OLEDs, receiving the German Design Award for their innovative work.

Box clever… and stay cool

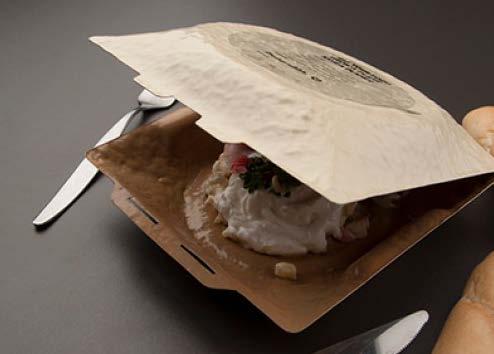

Mondi expands its sustainable e-commerce portfolio with its new BCoolBox, designed to transport fresh food with 100% recyclable packaging that keeps food fresh all the way to the consumer. The innovative packaging maintains a consistent temperature, mitigates food waste and removes the need to use cooling trucks. This is in addition to catering for the needs of the expanding online shopping market.

Mondi, a leading global packaging and paper manufacturer, introduces its latest e-commerce innovation. The BCoolBox is a 100% recyclable and offers a reliable packaging solution to keep perishable food cool whilst in transit. With this new product innovation, food stays fresh from the store to the consumer or a pick-up station and offers online retailers the opportunity to expand their geographical reach for deliveries.

The benefits of Mondi’s BCoolBox include a corrugated packaging solution with thermo-insulation that keeps food chilled below 7°C for up to 24 hours. Its inner corrugated panels enclose the shipment from all sides, providing enhanced insulation. In addition it has the ability to use different cooling agents and is made entirely from recycled material and is thus 100% recyclable. The Covid-19 pandemic has boosted the e-grocery business. During the 2020 European lockdown, 28% of people in urban areas used online shopping as their main channel for buying groceries – a 10% increase compared to before the pandemic. Furthermore, 80% of European consumers who started buying groceries online plan to continue doing so.

Mondi said it is proud to introduce a reliable solution that is proven to handle all the challenges that online food retailers face. After having tested various scenarios, the company came up with a formula for the perfect packaging composition. “Our approach is to listen to our customers and evaluate their needs along the entire supply chain. Our aspiration is to create packaging for the e-commerce sector that is sustainable by design.

This corrugated packaging solution expands our wide offer for the online food shopping market.” said Tarik Aniba, Sales & Marketing Director Corrugated Solutions at Mondi.

P&G Meeting its goals on sustainability

P&G unveils refillable paper packaging

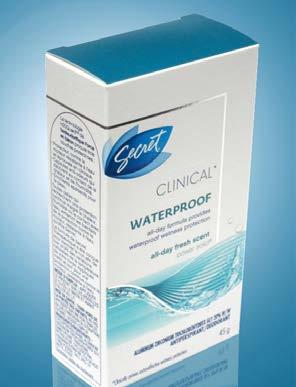

Kirstin Linnenkoper reported recently that in an effort to help reduce plastic waste, Procter & Gamble has created a line of refillable packaging for its deodorants Secret and Old Spice. The 100% aluminium-free, recyclable paper tube cases are available across the US as of this month.

The easy-to-use, refillable packaging is made of 90% recycled paperboard, certified by the Forest Stewardship Council (FSC). Both types were manufactured without any single-use plastic. The refills have a retail price of EUR 6.50, ‘making this one of the most affordable refill options on the market today’, the producer said.

We know the most sustainable choices for consumers are not always the most affordable – and that limits the impact we can have on our environment,’ comments Freddy Bharucha, senior vice president, P&G Personal Care. ‘By providing sustainable solutions for both antiperspirants and aluminium free deodorants at some of the most affordable prices on the market, we’re able to make sustainable choices a reality for more consumers.’

Featuring a signature push-pop design, ‘much like lipstick’, the packaging releases the product ‘with a simple twist’, adds Anitra Marsh, vice president, sustainability, citizenship and communications, P&G Beauty. Once consumers have used up the deodorant, they can easily crush the empty paperboard case and drop the package right into their recycling bin. She is confident this no-hassle packaging will convince people to use the product long-term, and make it easy to recycle.

ASDA’s new paper trail

In another sustainability ‘coup’, the packaging manufacturing giant, DS Smith announced in February this year that it is supporting ASDA in order to help it to replace over one million pieces of unnecessary plastic from its POS displays.

The breakthrough comes after a re-evaluation of an in-store feature that many often take for granted: price ticket holders on the edge of shelves known as ‘shelfedge-labels’. or “SEL’s”.

ASDA recognised that these were adopted by the temporary point-of-sale industry from permanent shop fixtures as a quick and easy solution to display price labels. The challenge with SEL holders is that these have been widely accepted as a standard and easy application for displaying price tickets on temporary cardboard displays. However, the nature of the type of plastic used in these fixtures (PVC) means that when they reach the end of their life, they cannot be disposed of in a sustainable way.

By undertaking rigorous trials a solution to use a special adhesive was reached which could eliminate plastic altogether. The move has been shown to be beneficial to both ASDA and to the environment – it means that less than 5% of point-of-sale displays now contain plastic, as such recovering fibres in the recycling process is more efficient and store operation workload is reduced when separating materials at the back of stores. As a result, ASDA is looking to adapt these point-ofsale guidelines more widely - a simple but effective reassessment that will have savings of approximately 8 tonnes of plastic waste and 21 tonnes of CO2 each year. The move is the latest in a strong partnership between ASDA and DS Smith which began over seven years ago. Concurrently, ASDA is targeting a 15% reduction on own brand plastic by the end of 2021 while DS Smith, which is known for its sustainable business model, has its own sustainability target to remove 1 billion pieces of plastic from supermarket shelves by 2025. Last year both parties began this journey with an initiative which reduced plastic on point-of-sale displays by 15%; with the latest SEL initiative rolling out it will mean displays in ASDA will get close to being entirely plastic free.

Stretching the point

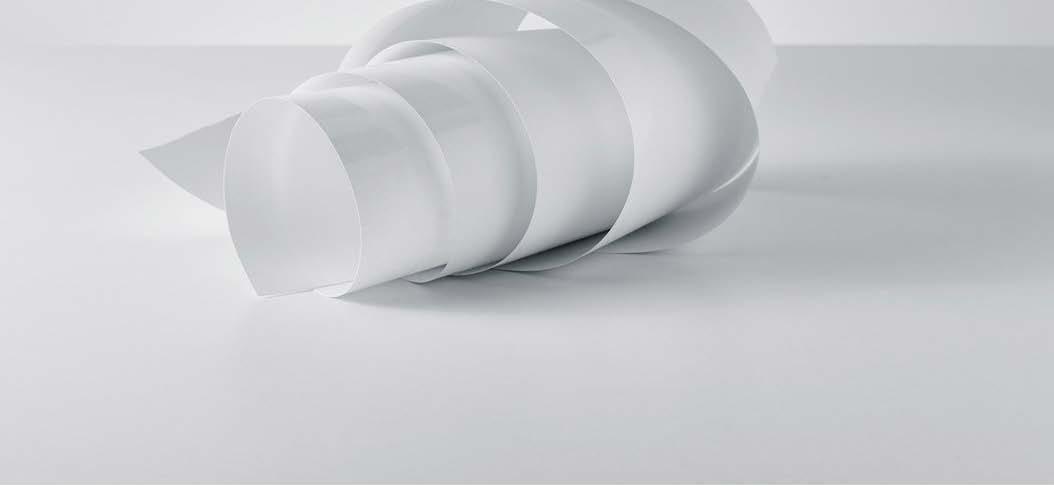

Innovation is alive and well at FreeForm packaging in Sweden where they are launching a one-sided stretchable laminate based on 85 percent paper called ‘Standard Paper Out’. This all-new laminate swaps the traditional polythene (PE) layer on the outside with paper with a paper based one. It provides an appealing tactile touch, whilst reducing plastic use and substantially improving recyclability.

Interestingly, the task of creating a stretchable laminate with durable sealing qualities proved to be a considerable R&D headache for FreeForm. “If you blow up a balloon, you stress that balloon quite a lot. And that’s what we have to do. It has been very tricky to make a definitive packaging shape that can handle that kind of constant stress,” FreeForm CEO Danevert Åsbrink said.

‘Standard Paper Out’ is suitable for various dry food and non-food packaging, ranging from candy to soap and powders. The paper laminate, which consists of 85 percent paper, 13 percent PE and 2 percent adhesive, has been several years in development and in the making.

Up until now, FreeForm had only been able to offer laminates with PE on both sides to ensure excellent sealing properties. Its stretchable quality is “not normal” to the packaging market, and thus allows for bespoke shapes and sizes, far outside of the standard can or bottle constraints. In addition to the infinitely customisable shapes, the company’s paper’s natural look and feel have also proved to be very attractive to consumers.

The new laminate creates formable paper packaging that is very pleasing to the touch. A feature that consumers have been looking for, for a very long time. It is well understood that the increased use of paper can significantly improve recyclability rates. “One-sided” paper laminates have been in constant demand by brand owners who have two-sided laminates on their “red lists”.

FreeForm told SPN that paper fibres embedded into a double-sided laminate can still be recycled, but one-sided laminates enable the total amount of packaging fibres to be retrieved. Using such mono-materials can elevate brand owners to the “green list,” and there still remains a huge market for multi-materials and companies active in this field who are looking to improve their environmental packaging credentials. FreeForm’s next step will be to reduce the PE inside layer, with a view to 100% elimination of plastic in the future.

FreeForm Packaging is a Swedish company owned by Italybased Curti and the Sweden-based company BillerudKorsnäs.

Increasing versatility

Globally the race is on to achieve 100% recycling rates throughout the packaging industry. The movement towards greater use of paper for packaging is gaining momentum thanks to its increasing versatility.

Currently in Europe, paper packaging is recycled around four times a year. However, paper cannot be recycled indefinitely as the fibres become too short and can no longer be used to create new paper products. This is where virgin wood fibres play an important role, as Philip Yorke reports.

Paper packaging is fundamental to helping us achieve a truly circular economy and has the benefit of being based on wood fibres which are renewable, recyclable and sustainable. Paper is recycled on average four times a year in Europe, however, it cannot be recycled indefinitely as fibres become too short and therefore can no longer be used to manufacture new paper commercially. Hence, virgin wood fibres from trees are needed to continue the cycle. These new fibres come from renewable, sustainably-managed forests and continue the circular loop. In order to maintain quality, it’s important that paper is collected separately from other materials. It can then be sorted and graded to determine its end uses. Then the recovered paper can be mixed with water so that the fibres can be recovered. During this process, contaminants are removed, the fibres cleaned and if necessary, ink is removed. The resulting pulp may then be used to produce 100% recycled paper. Responsibly harvested virgin fibres make a major contribution to maintaining the quality characteristics required across a broad range of innovative packaging products.

Elopak Pure Sustainability

Elopak is leading the global drive for greater sustainability and one clear expression of its mission can be found in the company’s latest Pure-Pak cartons. Elopak is fully committed to moving forward as sustainably as possible, whether it is with its high-quality beverage cartons or across the entire breadth of its diverse company operations.

Interestingly, Elopak was the first carbon-neutral company in the industry to offer carbon-neutral cartons and was also the first to produce 100% renewable cartons made entirely from wood. When it comes to beverages, cartons have unrivalled environmental credentials when compared with alternatives such as plastic bottles.

A recent Lifecycle Assessment Study showed that in comparison to PET bottles, sustainably produced UHT milk cartons resulted in 70.7% less CO2 emissions and in the case of fresh milk it was a massive 83.6% less. In its on-going drive for sustainability Elopak has been pushing this advantage still further and recently reduced the carbon footprint of its cartons by a further 20%.

Sustainability in partnership

With its focus on innovation, Elopak works in close partnership with its customers to help them achieve their sustainability goals by reducing the overall environmental footprint of their finished products. Elopak’s special cartons also help to keep the product safe and fresh, thus minimising waste whilst supporting the effective communication of the brand’s commitment to sustainability.

Innovation and collaboration are central to Elopak’s innovative approach to a greener planet. Since 2017 Elopak has increased its research and development spending by more than 25%, thus allowing it to explore new ways to make the company’s iconic Pure-Pak® cartons more sustainable and recyclable than ever. Recent innovative developments include Elopak’s Natural Brown Board cartons, which are 100% renewable, recyclable and offer a much lower CO2 footprint than conventional cartons.

This is due to their significantly reduced wood consumption and the important elimination of the bleaching process. Their rustic, natural look effectively communicates this commitment to sustainability and in turn enhances the products unique shelf appeal.

Forest-based future

Since its launch, Elopak’s Natural Brown Board cartons has served as a platform for further sustainabilityfocused innovations, these include the latest ‘Pure-Pak® Imagine carton’ which was launched in 2020 and is 100% forest-based. The carton is an futuristic version of the company’s original Pure-Pak® carton, containing 46% less plastic and now designed with a new easy-open feature. In addition, it has no plastic screw cap, thus making it Elopak’s most environmentally friendly carton to date.

Among those to have adopted the ‘Pure-Pak® Imagine’ carton is the multinational European dairy cooperative: FrieslandCampina. Campina Organic is now available in its advanced environment-friendly packaging in line with the dairy’s ‘Nourishing a better planet’ sustainability programme. The new packaging saves 38% CO2 emissions compared to the earlier packaging, with any remaining emissions fully compensated to ensure that it remains completely ‘climate neutral’.

While Elopak’s Pure-Pak® cartons are already renewable and recyclable, the company continues to push itself to become ever more sustainable. Having reduced emissions by 70% between 2008 and 2018, Elopak is now working towards a 55 per cent reduction of internal emissions by 2030, and a 16 per cent reduction across the value chain by 2030 from a 2017 baseline. This is in line with its status as one of the first companies to have signed up to the Science Based Targets initiative, which is a commitment to keep the rise in global average temperature below 1.5°C.

It is no surprise therefore that Elopak’s Natural Brown Board cartons have quickly become a firm favourite with its customers and in February 2021 the volume produced of these cartons surpassed one billion units. Their lower CO2 footprint means an estimated 3,000 tons of greenhouse gas emissions have been eliminated as a result. This is equivalent to approximately 1,400 roundtrip flights for one person between London and New York. SPN congratulates Elopak on its dedicated drive for global sustainability and sees this result as an iconic achievement in itself!