INDIA IS POWERING A NEW ERA OF CLEAN MOBILITY—WHERE PUBLIC POLICY, PRIVATE INVESTMENT, AND INNOVATION CONVERGE TO BUILD A SUSTAINABLE, NETZERO FUTURE ON WHEELS.”

India Fast-Tracks ₹2,000 Crore PM EDrive to Build EV Charging Grid for Sustainable, Net-Zero Mobility

Union Minister for Heavy Industries chaired an inter-ministerial coordination meeting to review and accelerate the rollout of EV charging infrastructure under the ambitious PM E-Drive scheme The PM E-Drive initiative aims to establish a robust nationwide electric vehicle (EV) charging network to reduce fossil fuel dependence and support India’s clean mobility transition. With a financial allocation of ₹2,000 crore, the scheme targets the installation of nearly 72,000 public EV charging stations across the country These chargers will be strategically located along 50 national highway corridors and in high-density zones such as metro cities, toll plazas, airports, railway stations, fuel stations, and state highways

Scania Commercial Vehicles India has announced strategic service agreements with top financial facilitation firms to support customers across the mining, infrastructure, and transport sectors. This initiative aims to integrate tailored financing solutions directly into the vehicle purchase journey, further strengthening Scania’s customer-first approach and accelerating its Solutions Sales growth across India As part of this strategy, Scania has onboarded key financing partners including True Blue Asset Services Pvt Ltd (Hyderabad), CorpCare Investech Private Limited (Mumbai), and Connect Residuary Private Limited (Mumbai) These firms bring deep expertise and extensive networks within the financial services sector, enabling Scania customers to access a broad spectrum of loan and leasing solutions

Energy Motors to Invest ₹3500 Cr in Maharashtra for EV Truck Manufacturing Facility

Ather Energy Raises $128 Million in Series E Round to Boost EV Expansion

Ather Energy has successfully closed its Series E funding round, securing $128 million in investments The round saw participation from the National Investment and Infrastructure Fund Limited’s (NIIFL) Strategic Opportunities Fund (SOF), along with Hero MotoCorp, a significant stakeholder in Ather, and other investors The funding is set to accelerate Ather’s expansion plans, which include scaling up manufacturing capacity, enhancing R&D, boosting charging infrastructure, and widening its retail network across India The company currently operates 38 Experience Centres in 32 cities and aims to grow this presence to 150 centres across 100 cities by 2023 April 2022 marked a milestone for Ather, as the company recorded its highestever monthly sales, delivering 3,779 units

Blue Energy Motors Ltd , a trailblazer in clean-energy trucking and a key partner in Essar’s green mobility initiative, has signed a MoU with the Government of Maharashtra at the World Economic Forum in Davos The agreement signals the company’s ambitious plan to invest ₹3500 crore in setting up a world-class electric truck manufacturing facility in the state The proposed facility will be equipped with cutting-edge R&D units, battery-pack assembly lines, motor production systems, and a network of EV charging stations With a target to manufacture 30,000 electric trucks, the initiative is expected to generate over 4,000 direct jobs, boosting both industrial development and green employment in Maharashtra

Electric mobility startup Simple Energy plans to go public by FY27, aiming to raise ₹3,000 crore The Bengaluru-based firm will use the funds to expand its retail presence to 500 outlets, double its production, and boost R&D With a revenue target of ₹800 crore for FY26 and plans to achieve EBITDA breakeven, Simple Energy is focusing on vertical integration and tier-II/III markets after securing $20 million and launching two electric scooter models

Maharashtra Electric Vehicle Policy 2025 Targets 30 Percent EV Adoption With Strong Incentives And Charging Infrastructure

Maharashtra's Electric Vehicle Policy 2025 aims to make the state a leader in EV adoption from April 2025 to March 2030. It targets 30% EV registrations, offers subsidies up to ₹2 lakh, and exempts EVs from road tax and tolls The policy supports charging stations every 25 km, mandates EV-ready infrastructure in buildings, and promotes battery recycling ₹15 crore is allocated for R&D in battery and hydrogen tech, with Centres of Excellence in key cities Skill development programs will prepare workers for EV design, battery systems, and energy management sectors

Uttar Pradesh inaugurated its first solar-powered EV charging station in Banthra, launched by BJP MLA Rajeshwar Singh The station marks a major step in green mobility, reducing reliance on fossil fuels and cutting carbon emissions It aligns with India’s 2030 climate goals and targets 30% EV adoption The initiative supports over 3 75 lakh EVs in the state and complements UP’s solar energy expansion plans The Banthra station serves as a model for future installations, aiming to create a cleaner, more sustainable transportation network across the state

Union Minister Dr Jitendra Singh launched the 'Battery Aadhaar' initiative at Battery Summit 2025, introducing unique digital IDs for battery packs to enable traceability and improve safety Integrated with AI and national EV databases, it aims to boost recycling and prevent counterfeiting Highlighting India's innovation growth and clean energy commitment, Dr Singh emphasized key policies like PLI, FAME, and PM-eDrive. He also outlined R&D missions in AI, quantum tech, and supercomputing, backed by increased DST funding and public-private collaboration to drive India’s clean energy and innovation future

The Government of India has notified the SPMEPCI scheme to boost electric passenger car manufacturing and support its 2070 net-zero goal Key features include reduced customs duty (15%) for importing up to 8,000 EVs annually, with a duty foregone cap of ₹6,484 crore or actual investment Applicants must invest ₹4,150 crore within three years and achieve 50% domestic value addition in five years. A bank guarantee equal to the duty or investment is required The scheme supports Make in India, inviting global EV manufacturers into India’s sustainable mobility ecosystem

Ministry of Heavy Industries Unveils New Guidelines To Boost Local Manufacturing Of Electric Passenger Cars

The Ministry of Heavy Industries has issued updated guidelines for the Scheme to Promote Manufacturing of Electric Passenger Cars in India (SPMEPCI), effective June 2, 2025. It aims to attract investments, boost EV production, and support the Make in India initiative Applicants must invest at least ₹4,150 crore, with import duty benefits capped at ₹6,484 crore Guidelines cover eligibility, application process, investment norms, and compliance Imported EVs must meet price and quantity limits, and operations must begin within three years Non-compliance leads to penalties The scheme is closely monitored by an interministerial committee for effective implementation.

Commission for Air Quality Management Mandates Shift To Electric And CNG Vehicles For Aggregators And Delivery Services In Delhi-NCR

The Commission for Air Quality Management (CAQM) has mandated Aggregators, Delivery Providers, and E-Commerce firms in Delhi-NCR with over 25 vehicles to shift to CNG or electric vehicles Effective January 1, 2026, no new diesel or petrol vehicles can be added to their fleets States like Haryana, UP, and Rajasthan must develop similar policies and tracking platforms This directive, under the CAQM Act 2021, aims to curb vehicular emissions and promote cleaner mobility. The move complements earlier measures like the phased diesel auto ban and supports broader efforts to combat air pollution in the NCR region

KSERC Unveils New Tariff And Guidelines To Promote Solar-Powered EV Charging Stations In Kerala

The Kerala State Electricity Regulatory Commission (KSERC) clarified tariff rules for EV charging stations, especially those with Solar PV systems. Under the Time of Day tariff, solar hours (9 AM–4 PM) are charged at 0 70x ART, and non-solar hours at 1 30x ART, with no fixed or demand charges Solar-exported energy can offset imports within billing cycles, with a 7/13 adjustment allowed for cross-time use Banking is allowed till March 31, with charges Battery storage is permitted to store solar energy The goal is to promote solar-based EV charging and reduce grid reliance during non-solar hours.

“INDIA’S JOURNEY TO CLEAN TRANSPORT IS NO LONGER A FUTURE PLAN—IT'S A PRESENT MOMENTUM BACKED BY BOLD FUNDING, PUBLIC-PRIVATE SYNERGY, AND A MISSION TO LEAD IN GREEN INNOVATION.”

Dots.eco Partners with Ayvens to Link Sustainable Mobility with Global Climate Action

Dots eco has partnered with Ayvens, a global leader in sustainable mobility, to launch a new initiative in Portugal that links responsible driving habits to tangible climate benefits The new program, Ayvens Eco-Rewards, encourages drivers to adopt more sustainable behaviors behind the wheel such as reducing mileage, choosing electric vehicles, and practicing fuel-efficient driving

Sicona Partners with Himadri to Launch SiCx® Production in India Accelerating Global EV Supply

Sicona, a pioneer in next-generation battery materials, announced a landmark strategic partnership and technology licensing agreement with Himadri Speciality Chemical Ltd, a leading specialty chemical conglomerate in India The deal includes a AU$15 million cornerstone investment by Himadri and marks a major step toward commercializing Sicona’s flagship Silicon Carbon anode material, SiCx®.

and HPCL Join Forces to Supercharge India’s EV Charging Network

Statiq has announced a landmark partnership with Hindustan Petroleum Corporation Limited (HPCL), one of the nation’s premier oil marketing companies This strategic collaboration aims to onboard HPCL’s entire EV charging network both operational and upcoming onto Statiq’s advanced EVLinq platform via the Statiq mobile app

EV &

The Directorate General of Training (DGT) under the Ministry of Skill Development and Entrepreneurship (MSDE), in collaboration with Shell India, has launched an ambitious training initiative focused on Green Skills and Electric Mobility. The program, implemented by the Edunet Foundation, aims to equip students and trainers across Industrial Training Institutes (ITIs) and National Skill Training Institutes (NSTIs) with cutting-edge skills aligned with India’s net-zero vision

VinFast Partners with Global Assure to Launch Pan-India Customer Service Network Ahead of EV SUV Debut

Global EV pioneer VinFast has announced a strategic partnership with Global Assure, one of India’s most trusted customer service providers, to establish a robust and reliable support infrastructure across the country The collaboration aims to deliver round-the-clock assistance and innovative mobility solutions to enhance the ownership experience for VinFast’s Indian customers.

Tata Motors and Vertelo Join Forces to Accelerate Electric Commercial Vehicle Adoption Across India

Global EV pioneer VinFast has announced a strategic partnership with Global Assure, one of India’s most trusted customer service providers, to establish a robust and reliable support infrastructure across the country The collaboration aims to deliver round-the-clock assistance and innovative mobility solutions to enhance the ownership experience for VinFast’s Indian customers.

EKA Mobility and GreenCell to Deploy 750 Electric Buses Across Andhra Pradesh

EKA Mobility has been awarded the Letter of Award (LOA) for the supply and deployment of 750 state-of-the-art electric buses across 11 major cities in Andhra Pradesh The project will be executed in collaboration with GreenCell Mobility. The large-scale initiative will witness the rollout of both 9-meter and 12-meter fully electric buses in cities including Amravati, Anantapur, Kadapa, Kakinada, Kurnool, Rajahmundry, Nellore, Guntur, Vijayawada, Visakhapatnam, and Tirupati

Global Luxury Car Market Set to Cruise Past $920 Billion by 2029, Driven by EV Boom and Digital Innovations

The global luxury car market is set to grow from $623 9 billion in 2024 to $672 26 billion in 2025, reaching $920 17 billion by 2029 Key growth drivers include electric luxury vehicles, sustainable design, digital showrooms, and subscription-based ownership models. Top automakers like Tesla, BMW, Mercedes-Benz, and Toyota are investing in smart mobility and R&D Market segmentation spans vehicle type, class, and propulsion systems Asia-Pacific leads globally, driven by rising affluence and tech adoption, with Europe and North America also showing strong innovation in premium automotive experiences

Surge in Autonomous Innovation: Automotive AI Market Set to Hit $18.43 Billion by 2029 Amid Rising EV Demand

The global automotive AI market is set to grow from $3.75 billion in 2024 to $5.22 billion in 2025, reaching $18.43 billion by 2029. Driven by autonomous vehicles, connected systems, and predictive maintenance, AI is reshaping mobility Key trends include deep learning, computer vision, and ADAS integration North America currently leads, but Asia-Pacific is the fastest-growing region Major players include NVIDIA, Tesla, Intel, and Waymo With rising demand for smart, safe, and self-reliant vehicles, AI is transforming the automotive landscape into a highly intelligent and techdriven ecosystem.

India’s Electric Vehicle Market Poised for Explosive Growth, Expected to Reach USD 1,64,420 39 Million by 2033

India’s Electric Vehicle (EV) market is projected to grow from USD 2 36 billion in 2024 to USD 164 42 billion by 2033 at a 57 23% CAGR, driven by subsidies, tax incentives, expanding charging infrastructure, and rising demand for 2W and 3W EVs Southern India leads with 38 6% market share, while BEVs dominate sales Mid-range EVs remain most popular due to affordability Key players include Tata Motors, Ather Energy, and Hero Electric Despite rural infrastructure challenges, strong government support, R&D, and industry investment signal a robust future for India’s EV transformation and clean mobility mission

India’s vehicle ownership will more than double by 2050, reaching nearly 500 million, with twowheelers comprising 70%, per CEEW’s district-level study While EVs are already cheaper than petrol in two- and three-wheeler segments, diesel will dominate commercial transport unless electrification accelerates CEEW recommends battery leasing, improved charging, and real-world trials Key urban hubs like Delhi and Bengaluru will host 10% of total vehicles Diesel demand may peak only by 2047 Policy incentives, integrated planning, and R&D are essential for India’s transition to sustainable, low-emission mobility and to mitigate rising transport fuel use and emissions

The global EV Battery Cell and Pack Materials Marke to grow from $16.75 billion in 2024 to $34.10 bil 2029, driven by soaring EV sales, battery innovatio sustainability mandates Key trends include sol batteries, LFP chemistries, and fast-charging breakth like CATL’s 10-minute charge tech Leading players s CATL, LG Chem, and Panasonic are expanding R& manufacturing Asia-Pacific leads the market, follow Western Europe and North America Applications spa HEVs, and energy storage, with greener, high-perfo materials reshaping global battery supply chains

Adani Enterprises flagged off India’s first hydrogen fuel cell truck in Raipur, Chhattisgarh. The initiative aims to gradually phase out diesel vehicles across the company’s logistics operations, promoting a sustainable shift in the mining and cargo transportation sectors The hydrogenpowered truck, developed in collaboration with a major Indian auto manufacturer and a global energy technology firm, is equipped with smart systems and three hydrogen tanks It has the capacity to carry up to 40 tonnes of cargo over a 200-kilometre range The pilot deployment will be used to transport coal from the Gare Pelma III block to the Chhattisgarh State Power Plant

Kinetic Watts and Volts Inaugurates Next-Gen EV Manufacturing Hub in Maharashtra, Marking Strategic Comeback in India’s Electric Mobility Sector

Kinetic Watts and Volts (KWV) officially inaugurated its state-of-the-art electric vehicle manufacturing facility in Ahilya Nagar, Maharashtra Spanning over 87,000 sq ft , the facility is aimed at delivering scalable and sustainable EV production, marking the Group’s significant reentry into the electric mobility sector The launch is seen as a major milestone in the company’s transition from a traditional two-wheeler legacy to a modern, clean mobility brand The new plant will serve both domestic and international markets with Made-in-India electric vehicles

Delhi Accelerates Green Mobility Drive with Launch of 400 New DEVi Electric Buses, 120 by JBM Group

In a landmark move towards cleaner and smarter urban transport, the Hon’ble Chief Minister of Delhi along with Hon’ble Union Minister flagged off 400 new Delhi Electric Vehicle Interconnector (DEVi) electric buses from the Kushak Nallah Depot. Among these, 120 buses have been manufactured by JBM Group, India’s leading electric bus maker, and will be operated from the Ghazipur Depot, serving multiple neighborhoods across the national capital These state-of-the-art buses are equipped with an Intelligent Transport Management System (ITMS) to provide efficient, connected, and sustainable last-mile mobility on key city routes

India is witnessing a major shift in the electric vehicle (EV) space, and at the center of this change are new battery technologies and advanced powertrains. These two components are key to how far, fast, and efficiently an EV can run As more people and businesses choose electric vehicles, companies are focusing on making batteries and powertrains better, cheaper, and more reliable.

In the past, EVs had limited range and higher costs due to battery limitations But next-generation battery technologies like solid-state batteries and lithium iron phosphate (LFP) chemistries are changing that Solid-state batteries offer higher energy density, which means vehicles can travel longer distances on a single charge They also have better safety features and can charge faster than current lithiumion batteries. Meanwhile, LFP batteries are gaining popularity in India for being safer, having longer lifecycles, and using materials that are easier to source locally

and motors within the country to reduce import dependence This not only cuts costs but also supports the government’s Make in India and energy security goals. New battery gigafactories are being announced across states, and EV startups are partnering with global tech providers to bring in modern manufacturing practices

On the policy front, the government is supporting the growth of the EV ecosystem through production-linked incentives (PLI), FAME-II subsidies, and customs duty reductions on key components These steps are helping Indian firms invest more in research and development of better batteries and powertrain systems At the same time, large automakers are joining hands with startups and research labs to explore technologies like battery recycling, battery swapping, and powertrain software upgrades.

Another big change is happening in EV powertrains Unlike traditional engines, electric powertrains rely on motors, inverters, and controllers that work together to convert energy from the battery into motion New innovations are making these systems smaller, lighter, and more efficient Some companies are working on integrated drive units where the motor, gearbox, and power electronics are combined into a single system This helps reduce vehicle weight and improves performance, making EVs smoother and more responsive on the road.

India is also moving toward localized production of EV components Several companies are setting up manufacturing plants for batteries

The combination of technology improvements, local manufacturing, and policy support is creating a strong foundation for EV growth in India As battery range increases and charging times go down, more users are likely to shift from petrol or diesel vehicles to electric ones Advanced powertrains will also ensure that EVs can meet the needs of both personal and commercial users, from city scooters to longhaul trucks

In the coming years, how well India develops its battery and powertrain ecosystem will decide the speed of EV adoption. With the current momentum, it’s clear that next-gen batteries and smart powertrains will power the future of India’s EV revolution

Electric vehicle (EV) manufacturers are rapidly embracing vertical integration to strengthen their control over the most critical components of the EV ecosystem: batteries and powertrains As the global shift toward electrification accelerates, the ability to secure a reliable, cost-effective, and technologically advanced supply chain has become a competitive advantage for Original Equipment Manufacturers (OEMs) Vertical integration where companies internalize stages of production or supply has re-emerged as a strategic model, especially in the EV industry, where battery supply chains are complex and geopolitically sensitive

One of the key motivations behind this shift is the central role that batteries play in EV performance, cost, and range. Traditionally, OEMs relied heavily on third-party suppliers for battery cells, modules, and battery management systems However, this approach exposed them to volatility in raw material prices, supply disruptions, and technology lock-ins To mitigate these risks, OEMs are now investing directly in lithium-ion cell manufacturing, securing longterm contracts with raw material miners, and developing in-house battery packs. Tesla set the precedent with its Gigafactory model, while others like BYD, Volkswagen, and General Motors are following similar paths

In India, vertical integration is gaining momentum as companies aim to reduce dependency on imports and increase value creation within the country Tata Motors and Ola Electric are building integrated ecosystems that include battery assembly, motor production, and powertrain development. This approach not only aligns with the government’s Make in India initiative but also positions these firms to control quality, lower costs, and drive innovation.

Powertrain components including motors, inverters, and transmission systems are also becoming part of this vertically integrated strategy. Companies are either acquiring startups with niche technologies or developing proprietary solutions to optimize energy efficiency and vehicle performance The integration of battery systems with electric drivetrains ensures seamless

communication between hardware and software, enabling better thermal management, regenerative braking, and range optimization.

Another benefit of vertical integration is the ability to customize solutions across different vehicle platforms For instance, EVs designed for mass-market urban use require different battery and motor configurations than commercial or performance vehicles. By developing in-house capabilities, OEMs can rapidly prototype and deploy tailored solutions without waiting on external suppliers

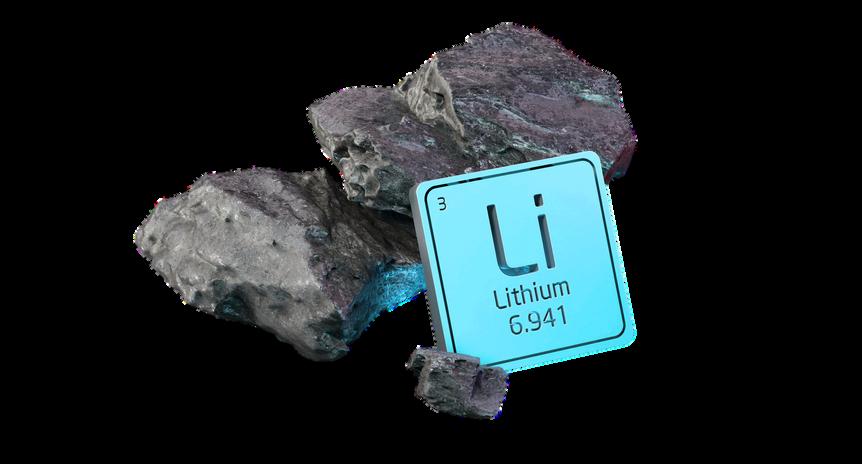

However, vertical integration is not without its challenges Building battery manufacturing facilities, also known as gigafactories, involves massive capital investments, long lead times, and the need for skilled labor Moreover, securing raw materials such as lithium, cobalt, and nickel involves geopolitical risks and environmental considerations OEMs are responding by forming strategic joint ventures, investing in recycling technologies, and exploring alternative chemistries like LFP (lithium iron phosphate) to reduce dependency on critical minerals.

As EV adoption continues to rise, the ability of OEMs to integrate battery and powertrain manufacturing will determine their agility and profitability in the evolving market Vertical integration offers greater control, faster innovation cycles, and stronger supply chain resilience While not all companies will adopt this model to the same extent, those that do are likely to emerge as leaders in the next generation of automotive manufacturing

India’s electric mobility story is rapidly unfolding, and at its core lies a pressing challenge: securing a resilient, self-reliant EV battery supply chain While the country has made admirable strides in EV adoption with over 1 5 million electric vehicles sold in FY 2023–24 our dependence on imported battery components remains a bottleneck Over 70% of India’s lithium-ion cells are sourced from a handful of countries, leaving the industry exposed to global price shocks, geopolitical tensions, and uncertain availability

The stakes are high The International Energy Agency (IEA) estimates that global demand for lithium will increase more than 40-fold by 2040, while demand for cobalt and nickel will rise 20–25 times. As the world races to decarbonize, countries are aggressively investing in domestic battery production capabilities China currently processes over 60% of the world’s lithium, 80% of cobalt, and nearly 90% of rare earth elements The concentration of critical mineral refining and battery manufacturing in one country poses a risk that India cannot afford to ignore especially as it scales both its EV and renewable energy targets

The Indian government’s Production Linked Incentive (PLI) scheme for Advanced Chemistry Cell (ACC) battery storage is a landmark intervention aimed at reversing this trend. The scheme is designed to boost 50 GWh of domestic battery manufacturing capacity with an outlay of ₹18,100 crore It has already drawn commitments from industry leaders to set up giga-factories across states like Gujarat, Tamil Nadu, and Maharashtra However, manufacturing alone won’t ensure resilience To truly localize, India must integrate upstream and downstream capabilities from raw material sourcing to end-of-life recycling

Securing access to critical raw materials is a cornerstone of this effort India holds the fifth-largest reserves of rare earth elements, and recent discoveries of lithium deposits in Jammu & Kashmir and Karnataka offer fresh hope However, exploration and extraction are capital-intensive and time-consuming, often constrained by environmental and regulatory complexities The formation of Khanij Bidesh India Ltd (KABIL) and recent bilateral agreements with resource-rich countries like Argentina and Australia are steps in the right direction But we need more than intent we need speed, scale, and strategic execution.

Battery recycling offers a complementary path to reduce raw material dependency With millions of EVs and portable electronics reaching end-of-life in the coming decade, India’s urban mines are a largely untapped resource. Lithium-ion battery recycling, if implemented at scale, can recover up to 95% of valuable minerals like cobalt, lithium, and nickel At Recyclekaro, we’re aggresively investing in hydrometallurgical recycling and second-life battery applications to ensure that every battery has more than one life The potential here is massive: McKinsey estimates that by 2040, recycled materials could meet up to 15% of the global battery materials demand.

Technology and talent are critical enablers of localization India must invest in battery research and development not just to catch up, but to lead Globally, next-gen batteries like solid-state, sodium-ion, and

lithium-sulfur are fast approaching commercial viability Companies like CATL, QuantumScape, and Toyota are pioneering designs that are safer, lighter, and less reliant on scarce minerals. India must be part of this innovation race Institutes like IIT-Madras, IISc Bangalore, and private R&D hubs are already working on breakthroughs, but stronger industry-academia collaboration is needed to fast-track prototypes to market.

Localization also demands robust logistics and policy alignment From GST incentives for battery swapping to standards for safety, interoperability, and traceability, a supportive regulatory environment is essential The National Critical Minerals Mission (NCMM), launched recently, outlines a strategic roadmap for securing key minerals and promoting recycling and reuse. It is encouraging to see frameworks emerge for Extended Producer Responsibility (EPR) and battery passports, which will ensure transparency and accountability across the value chain

Localized manufacturing hubs can significantly de-risk global supply chains When coupled with circular economy principles, they not only reduce import dependence but also help meet climate goals. The carbon footprint of producing a battery cell can be reduced by up to 50% when raw materials are recycled instead of mined This is an environmental imperative as much as it is an economic one

India’s vision of becoming a global battery hub is not a far-off dream it is a real opportunity According to NITI Aayog, domestic battery manufacturing could contribute $15 billion to India’s economy by 2030, creating over 1 million green jobs But to unlock this potential, India must act decisively with investments in mining, refining, recycling, and innovation

As someone who has spent over 15 years building solutions in the battery waste and metals recovery space, I’ve seen firsthand how challenges eventually evolve into opportunities if we stay the course The battery revolution is not just about mobility it’s about energy security, job creation, and sustainable growth By committing to self-reliance today, we ensure that India not only meets its EV targets but becomes a strategic player in the global clean tech economy of tomorrow

major challenge in this transition is India's heavy import dependency for critical battery minerals These include lithium, cobalt, nickel, and graphite key raw materials needed to manufacture EV batteries and powertrains At present, India imports more than 90% of these minerals, mostly from countries like China, Australia, the Democratic Republic of Congo (DRC), and South American nations This high dependence makes India vulnerable to global price shocks, supply chain disruptions, and geopolitical risks.

As demand for EVs rises, the need for these minerals will also increase India is expected to require hundreds of kilotonnes of lithium-ion battery materials annually by 2030. The growing demand and import dependency highlight the urgent need for strategic planning India must secure a stable, long-term supply of these minerals One key solution is the creation of a Strategic Mineral Reserve similar to what India has for petroleum

A Strategic Mineral Reserve would act as a buffer against global supply chain disruptions It would ensure that Indian manufacturers of batteries and EV powertrains have continued access to critical raw materials. Such reserves could be maintained through a mix of domestic exploration, overseas resource acquisition, recycling of used batteries, and stockpiling of imported minerals.

Domestic exploration is already underway. The Geological Survey of India has identified lithium reserves in Jammu & Kashmir and Karnataka Further efforts are needed to develop these into commercially viable mining operations However, India’s domestic resources are still limited, so the government must also invest in

mineral assets KABIL is exploring lia, and Bolivia to gain access to lithiu

In parallel, India’s policy must enc ery recycling infrastructure. Spent batteries contain reusable amounts of lithium, cobalt, and nickel. A circular economy approach can reduce dependency on virgin materials To support this, India’s Battery Waste Management Rules and Extended Producer Responsibility (EPR) guidelines must be enforced and updated regularly

Policy coordination is key. The Ministry of Mines, Ministry of Heavy Industries, and Ministry of External Affairs must work together under a National Critical Mineral Strategy This strategy should define a list of priority minerals, allocate funding for exploration and overseas acquisitions, and create frameworks for public-private partnerships

Incentives must also be provided for private companies to enter the mining and recycling sectors This includes easier clearances, risksharing mechanisms, and tax benefits India can also look at international partnerships through platforms like the International Energy Agency (IEA) and the Quad Critical Minerals Partnership to ensure a diversified and resilient supply chain.

India's EV revolution depends not only on building battery and powertrain factories but also on securing a steady supply of critical minerals A Strategic Mineral Reserve, backed by strong policy measures and global partnerships, can provide energy security, reduce import risks, and support India’s long-term clean mobility goals Now is the time to act before the mineral race tightens further

India’s agricultural backbone has long relied on diesel-powered tractors, but today this dependency poses serious environmental and economic challenges Diesel tractors consume approximately 7 4% of India’s annual diesel nearly as much as all buses combined Beyond fuel costs, they emit high levels of particulate matter (PM₂₅) and nitrogen oxides, contributing to rural pollution and health risks

Enter electric mobility solutions especially electric tractors which offer zero tailpipe emissions, reduced noise, and fewer moving parts, promising lower maintenance costs Despite these advantages, adoption remains negligible In FY2024–25, not a single e tractor was registered in India. Nationwide, only 16 electric tractors are currently registered out of over 800,000 total tractors

Still, momentum is building Electric tractors powered by lithium-ion or swappable batteries deliver consistent torque, fewer emissions, and quieter operation improving farmer health and livestock welfare Economically, electric tractors offer compelling savings: ICRA estimates show a 39% lower total cost of ownership over six years, translating into substantial long-term savings and faster payback

Yet, obstacles remain Infrastructure gaps in charging especially in remote areas limit uptake High purchase prices, limited battery range, and lack of skilled technicians further hinder progress . Addressing these issues requires investment in solar-powered charging hubs, rural training for EV maintenance, and inclusive tech education in local languages

Government backing is crucial The FAMEIndia scheme and statelevel subsidies (e g , Haryana’s 50%, Andhra Pradesh’s 5%) aim to make electric tractors affordable However, many models exceed subsidy caps, leading to underutilization . Startups like AutoNxt, Moonrider AI, and TI Clean Mobility are launching AIS 168 certified models, while ICCT’s pilot programs using 28–60hp e tractors in Haryana are showcasing viability.

Electric mobility in rural areas also enables shared-use models. Cooperatives and agri-entrepreneurs are piloting “mobility-as-aservice,” allowing farmers to rent electric tractors and access modern tech affordably mirroring urban trends .

The environmental stakes are clear: ICCT’s 2016 study projected that by 2030, emissions from non-road vehicles like tractors will exceed those from on-road vehicles Transitioning to electric mobility is essential for India’s climate goals and the wellbeing of farming communities

To accelerate this shift, coordinated action is needed: clearer policies under FAMEII, streamlined subsidies, private-sector innovation, and rural infrastructure development Integrating EV solutions into cooperative frameworks can democratize access and spread modernization across the farming landscape

Ultimately, opting for electric mobility in agriculture isn’t merely a technological upgrade it’s a path to resilient, cost-effective, and sustainable rural livelihoods By replacing diesel with electric tractors, India takes a significant step toward green farming, rural prosperity, and its net-zero aspirations As electric mobility rolls into fields across the country, rural India stands poised for a cleaner, more efficient, and more vibrant future one charge at a time

India is making big moves to become self-reliant in electric vehicle (EV) battery manufacturing. As the demand for EVs grows rapidly, the country is focusing on building gigafactories and local supply chains to reduce its dependence on imports. This is a major step in supporting the government’s push towards clean mobility and energy security.

At the heart of this effort are gigafactories large-scale facilities that produce battery cells in high volumes These factories are essential for meeting the rising demand for EV batteries in India According to NITI Aayog and various industry reports, India needs at least 100–120 GWh of battery manufacturing capacity by 2030 to support its EV targets Currently, most of the battery cells used in India are imported, especially from China and South Korea To change this, the government has introduced the Production Linked Incentive (PLI) scheme for Advanced Chemistry Cell (ACC) manufacturing Under this scheme, ₹18,100 crore has been allocated to support the development of 50 GWh of domestic battery manufacturing capacity. Companies like Reliance Industries, Ola Electric, Rajesh Exports, and Hyundai-LG Energy have been selected to set up these facilities

Alongside gigafactories, the development of a strong local supply chain is equally important Battery manufacturing needs several raw materials, including lithium, cobalt, nickel, graphite, and manganese India currently lacks local reserves of many of these critical minerals. To tackle this challenge, the government is exploring international partnerships to secure raw materials from countries like Australia, Argentina, and Chile At the same time, India is encouraging local research and innovation to find alternatives and reduce reliance on rare materials

Several Indian companies are also working on developing indigenous battery chemistries Startups and research institutions are exploring sodium-ion and solid-state batteries, which could offer safer and more sustainable options These new technologies may also make it easier to scale up using local materials, helping reduce import dependency in the long run

The battery ecosystem also includes recycling With a large number of EVs expected to be on the roads in the next decade, battery waste will become a concern Recycling used batteries to recover valuable materials is now becoming a key part of India’s battery strategy The draft Battery Waste Management Rules and Extended Producer Responsibility (EPR) guidelines are pushing manufacturers to take responsibility for the end-of-life of batteries

Powertrain innovation is also closely linked to the battery ecosystem

A growing number of Indian companies are now producing electric motors, controllers, and battery management systems locally. Together, these components form the core of an EV's powertrain A self-reliant powertrain and battery setup will lower costs, improve efficiency, and reduce supply chain risks for the Indian EV market

By building gigafactories, developing raw material partnerships, encouraging innovation, and strengthening local manufacturing, India is creating a complete EV battery ecosystem These steps are important not only for cleaner mobility but also for energy independence, job creation, and long-term industrial growth With the right support from government policies and private investments, India is on the path to becoming a global hub for EV battery production and a leader in sustainable transportation

In the bustling industrial hubs of India, the relentless pursuit of operational efficiency and sustainability has transcended from a mere side issue to an absolute necessity In the ever-evolving landscape of the manufacturing industries, companies are actively seeking out innovative solutions to optimize resource utilization and reduce their environmental footprint, given the increasing energy costs and the nation's growing commitment to sustainability

While advancements in battery technology have received significant attention, an often overlooked but effective alternative offers a compelling path to achieve these crucial objectives of lead acid battery refurbishment Industries that heavily rely on these dependable power sources can benefit greatly from implementing efficient refurbishment projects, resulting in substantial financial gains and contributing to a more sustainable circular economy

Despite the emergence of newer battery chemistries, lead-acid batteries remain a vital component across various industrial applications, including material handling equipment, uninterruptible power supplies (UPS), and telecommunications infrastructure Battery refurbishment continues to be highly effective and valuable in sectors such as telecommunications, manufacturing and other industrial operations. The idea of extending the life of an industrial asset is naturally enticing from a financial standpoint Replacing a bank of forklift batteries or a large-scale UPS system requires a significant capital investment. Battery Refurbishment Technologies like EBEP (Electrochemical Battery Enhancement Process), on the other hand, provides a cost-effective alternative, often restoring a battery's performance close to new unit at a minimal cost

Beyond the immediate financial advantages, battery refurbishment aligns powerfully with the growing emphasis on sustainability The lifecycle of a battery involves the extraction of raw materials, energyintensive manufacturing processes, and eventual disposal By opting for refurbishment, manufacturers actively participate in a circular economy model, reducing the demand for new raw materials and minimising the environmental burden associated with battery production and disposal

Furthermore, the energy savings associated with lead acid battery refurbishment are substantial. Manufacturing a new battery from mining and processing raw materials to assembling the final product requires a significant energy input By restoring existing lead-acid battery banks, end users can effectively conserve this embedded energy, therefore reducing the total carbon impact and reduced operational costs. Although exact numbers will vary, it is well known that refurbishing a battery uses far less energy than building a new one, so perhaps lowering the related carbon emissions by a notable margin This fits the rising need for clearly sustainable practices and the growing corporate focus on environmental responsibility

The process of lead acid battery refurbishment involves a comprehensive assessment of the battery's condition, followed by special techniques to restore its performance The procedure can include Screening, Hydration, Restoration Diagnostics, Desulphation, Charging & Final Quality Testing of the lead acid battery and in some cases, the repair or replacement of specific components Advanced diagnostic tools are employed to identify underlying issues and ensure the effectiveness of the refurbishment process A well-executed

refurbishment programme restores capacity and improves the lead acid battery's overall lifespan and reliability compared to a neglected or poorly maintained unit

The economic benefits of lead acid battery refurbishment extend beyond the cost savings associated with direct replacement Another advantage is reduced downtime When batteries fail, they can cause disruptions in critical operations, resulting in production losses and higher labor costs Refurbished batteries that have undergone rigorous testing and restoration are less prone to premature failure, resulting in enhanced stability and reliability during operation

Furthermore, adopting battery refurbishment technologies like EBEP can help manufacturers strengthen their reputation as an ethical, forwardthinking company In an era when stakeholders including customers, investors and regulators are solely concerned with environmental and social governance (ESG) issues, proving a commitment to sustainable practices can provide a substantial economic advantage. By actively participating in the circular economy through battery refurbishment, manufacturers can improve their brand image and attract environmentally concerned customers and partners

To fully realise the benefits of battery restoration, manufacturers must take a proactive and planned approach This includes:

Implementing regular battery maintenance programs, such as timely health check-ups, proper charging, cleaning and inspections to maximize lifespan and improve refurbishment potential

Choosing skilled and technically proficient partners offering highquality refurbishment operations and dependable performance of restored lead acid batteries

Monitoring the lifespan and performance of refurbished lead acid batteries provides valuable data for optimising refurbishment strategies and demonstrating cost savings.

In conclusion, lead acid battery refurbishment is not merely a costcutting measure; it is a strategic imperative for manufacturers seeking to enhance their operational efficiency, embrace sustainability, and contribute to a more circular economy By breathing new life into these essential power sources, manufacturers can significantly reduce replacement costs, minimise their environmental footprints, and strengthen their positions as responsible industry leaders. As the focus on resource conservation and environmental stewardship intensifies, the intelligent and widespread adoption of battery refurbishment will undoubtedly play a crucial role in shaping a more sustainable and economically viable future for manufacturers

As the global automotive industry accelerates toward electrification, the demand for smarter, safer, and more sustainable materials has never been greater like today. At the heart of this transformation lies silicone technology an enabler of performance, protection, and progress across electric vehicles (EVs) and their charging ecosystems

Dow, a global leader in materials science, is pioneering with highperformance silicone solutions that address the evolving challenges of emobility Through its DOWSIL™ and SILASTIC™ product lines, Dow is helping OEMs and their suppliers meet the demands of thermal management, fire protection, electronic reliability, and design flexibility

The shift to electric mobility is driven by a convergence of factors: stringent emissions regulations, government incentives, and growing consumer demand for cleaner transportation. But this shift also brings technical challenges higher power densities, elevated operating temperatures, and the need for lightweight, durable materials

Silicones, with their inherent thermal stability, electrical insulation, and mechanical resilience, are uniquely suited to meet these demands. Our silicone portfolio supports the full lifecycle of EVs from design and production to operation and end-of-life recycling

As EVs become more power-dense, managing heat is critical to ensuring safety and performance Dow offers a range of thermally conductive silicone materials designed to dissipate heat efficiently across battery packs, inverters, converters, onboard chargers, and electronic control units (ECUs)

Our silicone-based thermally conductive gap fillers play a critical role in managing heat in high-performance electronics and battery systems These materials are designed to relieve mechanical stress between components like battery modules and cooling plates while maintaining consistent thermal conductivity over time With features such as low abrasion, rework ability, and controlled bond line thickness, they ensure efficient heat dissipation and long-term reliability in applications ranging from electric vehicles to industrial control units.

Passenger safety is paramount in EV design, particularly in mitigating thermal runaway events We offer a range of silicone-based battery fire protection (BFP) materials which offers flame resistance, thermal insulation, and self-extinguishing properties

Solutions include:

Fire resistant coating: Offers excellent protection

Silicone foams: Offer vibration damping, encapsulation, and thermal shielding

Thermal barrier sheets: Ceramify rather than combust at extreme temperatures, limiting thermal propagation

Battery Sealing: Sealants for superior sealing of battery providing IP protection in tough environments

These materials are tunable in viscosity and cure time, allowing customization for different cell types and pack configurations

Our innovation extends to EMI shielding and electrical grounding with products like Electrically Conductive Adhesive: A high-performance silicone that delivers bonding, grounding, and EMI shielding for power electronics It performs reliably under high temperatures and vibrations, ensuring long-term durability and our RTV sealants covers the long range of applications in Mobility and Industrial segment for reliable bonding between different substrates

We are combining decades of our silicone expertise with patented carbon nanotube (CNT) technology to provide innovative thermal management solutions providing enhanced conductivity, reliability and tunability This simplifies thermal interface management (TIM) selection, offering predictable and affordable consumer, industrial and manufacturing solutions

As EV adoption grows, so does the need for robust and scalable charging infrastructure Our technology empowers our customer to innovate the development of charging stations, connectors, and energy storage systems with materials that withstand harsh environmental conditions and ensure long-term reliability

Our Mobility Science platform’s commitment to sustainability is embedded in its product development From enabling energy-efficient production through dual-cure mechanisms to designing materials for disassembly and recycling, Dow is helping the industry transition to a circular economy

The reworkability of our silicone gap fillers allows for easier removal of battery cells during end-of-life processing supporting reuse and reducing waste

Dow’s MobilityScience™ platform approach brings together crossfunctional expertise to co-develop solutions with customers By working closely with OEMs, Tier suppliers, and equipment manufacturers, Dow ensures that its materials are optimized for real-world applications and future-ready challenges

Looking ahead, Dow is focusing on next-generation silicones with even higher thermal conductivity, improved electrical performance, and greater sustainability As powertrain electrification and vehicle autonomy evolve, we remain committed to solving the industry’s toughest problems.

“With the power of silicone technology, we are not only addressing today’s mobility needs we are also enabling the future of e-mobility With proven expertise and innovation we ’ re delivering solutions right at our customers’ doorsteps”

Electric vehicle (EV) battery technology is advancing rapidly as the world shifts towards cleaner transportation While lithium-ion batteries are currently the dominant choice, researchers and companies are now working on the next generation of battery technologies that promise to make EVs safer, more efficient, and more affordable Solid-state batteries, sodium-ion batteries, and other innovative chemistries are at the center of this next leap in EV battery development.

Solid-state batteries are considered one of the most promising technologies to replace traditional lithium-ion batteries. Unlike lithium-ion batteries that use a liquid electrolyte, solid-state batteries use a solid electrolyte, which reduces the risk of fire and improves battery life. They also have the potential to offer higher energy density, which means a longer driving range for EVs Solidstate batteries can also charge faster and operate better in extreme temperatures. Companies like Toyota, BMW, and QuantumScape are investing heavily in this technology, and while commercial adoption may take a few more years, early prototypes show great promise.

Another alternative gaining attention is sodium-ion battery technology Sodium is much more abundant and cheaper than lithium, making it an attractive option, especially for markets with cost-sensitive applications Although sodium-ion batteries currently offer lower energy density than lithium-ion, they are safer and more sustainable to produce In India, where lithium resources are limited, sodium-ion batteries could play an important role in local manufacturing and energy storage applications Companies like CATL and Faradion are leading the charge in commercializing sodium-ion solutions.

Beyond solid-state and sodium-ion, other battery innovations are being explored to solve the challenges of cost, safety, performance, and material availability Lithium-sulfur batteries, for example, use sulfur as a cathode material, which is both abundant and inexpensive. They can potentially deliver higher energy densities than traditional lithium-ion batteries but currently face problems like shorter cycle life Research is ongoing to improve their stability.

Another emerging technology is silicon-anode batteries, which replace the conventional graphite anode with silicon. Silicon can store more lithium ions, significantly increasing the battery’s capacity However, silicon expands during charging, which can damage the battery over time. Companies are working on engineered materials and protective coatings to overcome this issue

In parallel, EV battery developers are looking into hybrid and semisolid batteries, which aim to combine the best features of existing technologies These approaches may offer a smoother transition path between lithium-ion and solid-state, allowing manufacturers to upgrade performance without completely overhauling their production lines

These battery innovations are not just about improving range and charging speed They also focus on reducing reliance on rare and expensive materials like cobalt and nickel, improving recyclability, and enabling local sourcing This aligns well with national policies promoting sustainable manufacturing and self-reliance in energy storage

As demand for electric vehicles grows, so does the need for smarter, safer, and more affordable battery solutions. Solid-state, sodium-ion, and other advanced chemistries represent the next big leap in EV battery innovation. While challenges remain in scaling these technologies, the progress being made suggests a promising future where EVs can become truly mainstream across different price segments and use cases.

India’s electric vehicle (EV) ecosystem is witnessing a surge in investments, especially in battery manufacturing and drivetrain technologies The government's push for electrification through schemes like FAME II, PLI (Production Linked Incentive) for Advanced Chemistry Cells (ACC), and Make in India has set the stage for large-scale manufacturing in the EV supply chain As India aims to become a global hub for EV production, both domestic and international players are betting big on the battery and powertrain segments, which are critical for cost, performance, and market competitiveness

Battery manufacturing, which accounts for nearly 30%–40% of an EV’s cost, has become a strategic focus area The ACC PLI scheme, with an outlay of ₹18,100 crore, has attracted companies like Reliance New Energy, Ola Electric, Rajesh Exports, and HyundaiAmara Raja consortium, who are setting up gigafactories with a cumulative capacity of 50 GWh. These investments are not only expected to reduce India’s dependence on battery imports but also foster backward integration in raw material sourcing, recycling, and cell-level innovation. Lithium-ion battery technologies, especially LFP and NMC chemistries, continue to dominate investment decisions, but new chemistries like sodiumion and solid-state batteries are also attracting early-stage funding. On the EV drivetrain front, Indian manufacturers are scaling up capabilities to produce motors, controllers, inverters, and gearboxes tailored for local driving conditions With powertrains contributing significantly to the vehicle's overall efficiency and performance, startups and tier-1 suppliers are collaborating with global technology firms to localize advanced drivetrain components The focus is also shifting towards integrated e-axle systems and thermal management solutions, which are more compact and efficient Automotive giants such as Tata Motors, Mahindra Electric, and Ashok Leyland have announced plans to

indigenize powertrain systems, while global players like Dana, Bosch, and Valeo are expanding their manufacturing footprints in India

Private equity and venture capital funds are increasingly viewing the EV supply chain as a long-term investment opportunity Between 2022 and 2024, over $3 billion was invested in Indian EV startups and component makers, with battery and powertrainfocused companies receiving a significant share Investors are encouraged by the high-growth projections of the Indian EV market, expected to reach annual sales of 10 million EVs by 2030 Strategic investments are being directed toward R&D, capacity expansion, and vertical integration States like Tamil Nadu, Gujarat, and Maharashtra are emerging as EV manufacturing hubs due to their proactive EV policies, logistics advantages, and access to ports.

Another trend driving investments is the co-location of battery plants with vehicle assembly lines and gigascale energy storage projects. This helps in reducing logistics costs, enabling just-in-time delivery, and scaling operations rapidly. Several auto OEMs are forming joint ventures with global battery giants to ensure technology transfer and secure long-term supply contracts The localization of raw material refining, cathode and anode production, and battery recycling is also attracting industrial investment as India aims to build a circular battery economy

As global supply chains face disruption and the urgency of energy transition intensifies, India’s EV battery and powertrain manufacturing sector is poised to offer profitable opportunities for investors Policy support, domestic demand, cost advantage, and technology partnerships are aligning to create an attractive investment outlook The next decade will likely see deeper capital inflows, wider R&D efforts, and stronger industrial ecosystems supporting India’s electric mobility ambitions

essential for electric vehicle (EV) batteries As countries move towards clean energy and sustainable transportation, the demand for minerals like lithium, cobalt, nickel, and graphite has surged These minerals are key components in the production of lithium-ion batteries, which power electric vehicles With the global transition to EVs accelerating, securing access to these critical minerals has become a strategic priority

India currently imports most of the raw materials used in battery manufacturing. This dependence makes the country vulnerable to price fluctuations and supply chain disruptions To reduce this reliance and become self-reliant, India has begun exploring international partnerships, local exploration, and investment in mineral processing

One major step has been the formation of Khanij Bidesh India Limited (KABIL), a joint venture between three government-owned companies NALCO, HCL, and MECL KABIL has been tasked with acquiring critical mineral assets abroad, particularly in countries like Argentina, Australia, and Chile, which are rich in lithium and cobalt In early 2024, KABIL signed agreements with Argentina to explore and develop lithium reserves in the Catamarca province This move is seen as an important step toward building a secure supply chain.

India is also focusing on domestic sources The Geological Survey of India (GSI) recently confirmed the presence of lithium reserves in Jammu & Kashmir and Karnataka These reserves are still under assessment, but if proven viable, they could support India’s EV battery manufacturing for years Efforts are also being made to explore other minerals like nickel and graphite within the country, with the goal of reducing import dependence

China, the United States, and European nations, all of which are rapidly locking in mineral supply deals China currently dominates the battery mineral market, particularly in processing and refining To catch up, India is working on developing its own refining capacity Investments in mineral processing facilities are being encouraged under the government’s Production Linked Incentive (PLI) scheme for Advanced Chemistry Cell (ACC) battery manufacturing The scheme aims to promote both domestic battery manufacturing and localization of the supply chain.

Another strategic focus is recycling. India is developing policies to promote battery recycling and the recovery of valuable materials Companies are being encouraged to set up battery recycling plants to extract lithium, cobalt, and other minerals from used batteries This circular economy approach could help reduce the need for raw material imports while also supporting sustainability

India’s efforts are also aligned with its climate goals The country aims to achieve net-zero emissions by 2070 and increase the share of electric vehicles. By securing critical raw materials and developing local processing capabilities, India is preparing to meet the future demand for EVs. Industry players, including government bodies and private companies, are now working together to create a strong EV battery ecosystem.

Although challenges remain such as geopolitical risks, financing issues, and the need for skilled workforce India’s positioning in the global mineral race is becoming clearer With focused strategies and international collaboration, the country is laying the foundation for a competitive EV battery supply chain This will not only strengthen India’s energy security but also make it a key player in the global electric mobility revolution

markets Our Ferrato electric two wheelers are built for urban consumers who demand stylish, high-performance commuting solutions For semi-urban and rural regions, our OTTOOPG electric three-wheelers offer efficient and rugged options for both passenger and cargo transport

To drive accessibility, we’ve established a wide dealer network across Tier 1 to Tier 4 cities, supported by financing partnerships with SBI and over 15 NBFCs, ensuring our EVs are affordable and relevant for customers across geographies

How do changing EV policies like FAME II impact your pricing and strategy?

FAME II ended in March 2024, and the current policy framework is PM e-DRIVE With revised incentives under this scheme, we’ve optimized our pricing through deeper localization and tighter cost structures Strategically, we’re focused on delivering strong value through safety, technology, and performance, ensuring our offerings remain competitive while aligning with evolving government policies

Government policies and incentives such as FAME II have played a pivotal role in building the EV industry in India. They helped generate initial awareness, enabled affordability, and gave the ecosystem much-needed early momentum Now, with the transition to PM e-DRIVE, the market has matured to a point where customers are increasingly aware of the long-term benefits of switching to electric mobility beyond just subsidies

While incentives remain helpful, our strategy is evolving to focus more on value engineering, localization, and operational efficiency Recently, we were able to negotiate better terms with local vendors, which allowed us to reduce input costs across our EV lineup Rather than absorb this

Expanding EV reach with tailored two- and three-wheelers for urban and rural India.

Leveraging localization and in-house battery manufacturing to reduce costs and improve access

Building a full EV ecosystem including charging, servicing, financing, and battery lifecycle solutions

internally, we chose to pass on the benefit directly to consumers by lowering the prices of our products

This aligns with our broader goal to make highquality, performance-driven electric vehicles more accessible across both urban and rural India, regardless of shifting policy landscapes

What’s OPG’s approach to the last-mile and shared mobility segment?

Last-mile and shared mobility are key focus areas for us Our Ferrato two-wheelers, beyond daily personal use, are increasingly adopted for deliveries and shared urban commutes, while OTTOOPG three-wheelers serve both passenger and cargo transport needs in high-usage routes We’ve strengthened our offering with durable design, low TCO, and smart IoT features, supported by financing options to drive adoption across cities and small towns alike

How are you addressing battery cost, range, and charging challenges?

Battery-related challenges are central to the EV ecosystem, and we’ve approached them with a long-term strategy On cost, our in-house battery production through MTEKPOWER gives us better control over pricing and availability This localization helps us reduce dependency on imports and bring down overall vehicle costs

When it comes to range, we use tested chemistries like LFP in most of our models to offer a balance of safety, performance, and longevity. Our focus is on building vehicles that suit realworld usage, not just on paper specifications

For charging, we’re actively working on expanding charging infrastructure with our group capabilities and also optimizing our Battery Management Systems to enable faster charging and better efficiency

These three areas are tightly linked, and we believe solving them together, not in isolation, is key to delivering a reliable EV experience

What sets OPG apart from other EV startups and big players in India?

What truly sets OPG apart is our ability to bring together experience, scale, and speed We come with a decade legacy in batteries and energy solutions, which gives us a strong foundation to build reliable, performancedriven EVs At the same time, we operate with the agility of a young company that’s deeply focused on execution. Most of our core components, including batteries, are manufactured in-house through MTEKPOWER, giving us better control over cost, quality, and supply

Our vehicles are built for real Indian conditions, affordable, rugged, and backed by a service network that reaches metros as well as Tier 3 and 4 towns More than just EVs, we’re building a complete ecosystem around charging, servicing, and financing That endto-end focus is what makes OPG stand out in the EV space.

How is OPG integrating sustainability and battery lifecycle solutions?

At OPG, sustainability is central to how we build and scale We use environmentally safer LFP chemistries, manufacture locally to reduce our carbon footprint and comply with ISO-certified environmental processes across our plants

Beyond vehicle use, we’re actively developing second-life battery applications and working with partners on structured battery recycling programs, ensuring responsible resource recovery and minimal environmental impact

Our goal is to create EVs that are clean not just at the point of use, but throughout their entire lifecycle.

Electric vehicles (EVs) are becoming more popular in India as the country moves towards cleaner transportation However, many people still have doubts about EV batteries These doubts are often based on myths or incomplete information This article explains the truth behind some common myths related to EV battery charging, degradation, and second-life applications, using research-based facts

One of the most common myths is that frequent charging damages an EV battery In reality, EV batteries are designed to handle regular charging. Modern lithium-ion batteries used in EVs have built-in battery management systems (BMS) that protect the battery during charging While it is true that extreme fast charging, if used every day, can slightly increase battery wear over the years, most Indian EV owners use normal or slow chargers, which are safe for long-term battery health Studies show that if EVs are charged up to 80% regularly and only fully charged when needed, the battery lasts longer

Another popular myth is that EV batteries degrade quickly. Many people believe that within a few years, the battery becomes useless But real-world data shows otherwise EV batteries usually retain more than 80% of their original capacity even after 6 to 8 years of use Manufacturers like Tata, MG, and BYD offer warranties of 7 to 8 years or around 1 6 lakh kilometers for their batteries in India. Also, new technologies such as solid-state batteries, thermal management systems, and better cell chemistry are further improving battery life Research also shows that EVs in India, due to moderate average daily driving distances, may face less battery stress compared to countries with longer travel patterns

A third myth is that once an EV battery is no longer suitable for driving, it becomes useless and has to be thrown away In fact, batteries that are no longer fit for vehicles still have a second life Once the battery capacity drops below 70-80%, it can be reused for stationary applications like solar energy storage, powering homes, or backup power systems Several pilot projects in India, supported by agencies like NITI Aayog and international development banks, are exploring second-life battery applications This helps in reducing battery waste and also creates new business models for battery reuse

Concerns about the environmental impact of EV batteries are also linked to these myths Many people worry about battery disposal and pollution But with growing interest in battery recycling, India is building capacity for collecting, testing, repurposing, and recycling used EV batteries Companies like Lohum, Attero, and Gravita India are already active in this space The Ministry of Environment and Forests has also introduced the Battery Waste Management Rules, 2022, which mandate producers to take back used batteries for proper handling.

Many concerns about EV battery charging, degradation, and end-oflife use are not based on facts. Instead, modern battery technology, responsible user behavior, and upcoming second-life solutions make EVs a reliable and sustainable option for India. As more people become aware of the science behind these systems, the acceptance of electric mobility is likely to grow further across the country

India’s EV logistics space has seen rapid growth what major trends do you foresee shaping the sector in 2025 and beyond?

India’s EV logistics sector is entering a phase of accelerated maturity, driven by both macro and micro trends At the macro level, increased corporate focus on sustainability and green logistics mandates by progressive cities like Delhi are setting the tone At the micro level, fleet operators are doubling down on cost optimization through improved Total Cost of Ownership (TCO), Telematics based route planning, real-time vehicle diagnostics, and advanced energy management systems These innovations are boosting efficiency while reducing operational costs The rollout of rapid, interoperable EV charging infrastructure will be a major enabler, alongside evolving state policies and regulatory incentives Additionally, models like Battery-as-a-Service (BaaS) and Vehicle-as-a-Service (VaaS) are helping ease capex challenges for operators With growing consumer demand for green and same-day deliveries, EVs are poised to become a strategic advantage. 2025 and beyond will mark the shift of EV logistics from isolated pilots to a scalable, mainstream logistics solution

Magenta is using AI and IoT to improve fleet efficiency Could you share specific innovations or use cases?

At Magenta, deep tech is central to how we scale our fleet and operations across clients and geographies

Our focus today is on building robust IoT and telematics platforms that deliver measurable operational improvements Our IoT-enabled system tracks vehicle health, driver behavior, and energy consumption in real-time, enabling predictive maintenance and minimizing unplanned downtime This foundation is already driving significant efficiency gains.

EV logistics evolving from pilot projects to mainstream scalable solutions in India

AI, IoT, and telematics boost fleet efficiency and reduce operational costs

Enterprises adopt EVs for cost control and to meet sustainability targets.

While our AI and ML capabilities are still maturing and I will not say we are there yet, we are actively developing tools like an AI-powered route optimization engine that will factor in live traffic, battery levels, weather, and delivery urgency potentially contributing up to 15% efficiency gains.

Magenta committed to reducing 1,500 tons of CO₂ annually. How do you measure impact and future targets?

We use a robust, data-driven carbon accounting system to track our emissions reductions in real time Our proprietary NorMinc platform aggregates data from EV kilometres driven, fuel replaced, battery usage, and energy sources to calculate precise CO₂ avoidance. These figures are benchmarked against ICE (internal combustion engine) baselines using internationally recognized emission factors

Additionally, we integrate third-party audits and carbon tracking standards like the GHG Protocol to validate our results To date, our EV fleet has helped eliminate over 2,300 tons of CO₂ annually, and we’re scaling this impact as we expand into new geographies and customer segments Our target is to double this figure by 2027 through increased fleet electrification, renewable-powered charging stations, and expanded deployment of Technology for operational efficiency Sustainability is not just a metric for us it’s a commitment woven into every layer of our business model and decisionmaking process.

With fuel prices rising and sustainability a priority, are large enterprises changing their logistics strategies?

Absolutely. There is a marked shift in how enterprises approach logistics, with EVs moving from experimental pilots to strategic enablers of cost control and ESG alignment

High and unpredictable fuel prices have accelerated the need for long-term cost

certainty, and EVs offer a compelling solution with lower running and maintenance costs. Meanwhile, sustainability has moved from CSR to the CFO’s dashboard logistics now play a critical role in helping companies meet Scope 3 emissions targets We are seeing a growing demand for green logistics partners who can offer transparent emissions data, real-time tracking, and verifiable impact Several of our enterprise clients are embedding EV logistics into their procurement mandates and incentivizing vendors who align with their climate goals In effect, logistics is no longer just a backend function it’s becoming a visible, strategic pillar of enterprise sustainability, resilience, and brand reputation

What message do you have for traditional logistics firms hesitant about EV adoption?

‘Electricity is the new Oil’ To traditional logistics players still on the fence, this would be my simple position. The transition to electric is no longer a question of “if,” but “when” and those who act early will have a clear competitive edge

EVs are now backed by proven economics, scalable technology, and strong policy support Initial challenges like range anxiety, charging infrastructure, and total cost of ownership have seen significant improvements. Moreover, customers and enterprises are actively seeking greener logistics partners, making EV adoption a business growth lever not just a sustainability checkbox At Magenta, we have helped traditional fleets transition with minimal disruption and tangible ROI, leveraging our Telematics platforms and deep operational expertise

The risk today lies not in adopting EVs, but in delaying the shift and losing relevance Embrace the change it’s not just good for the planet, it’s smart business

“Like the human body, EV batteries need the right temperature to perform. In India’s extreme climate, thermal management isn’t optional it’s essential for safety, performance, and longterm reliability. Without it, even the most advanced EVs can fall short of their potential."

Electric vehicles (EVs) are becoming more common on Indian roads, and one of the most important parts of an EV is its battery These batteries power the vehicle and are responsible for how far it can travel on a single charge But to keep these batteries working well for a long time, one key factor needs attention temperature control

EV batteries work best in a certain temperature range. If the battery gets too hot or too cold, its performance drops, and it can even get damaged In India, where temperatures can be extreme, this is a serious concern. During summer months, especially in cities like Delhi or Nagpur, battery temperatures can rise to unsafe levels Similarly, in colder regions or during winter mornings, the battery can become too cold, which reduces its ability to supply power. Both extremes put stress on the battery and reduce its life

When a battery gets too hot, the chemical reactions inside it speed up While this may sound like a good thing, it actually causes the battery to wear out faster High heat can also lead to swelling, leakage, or in rare cases, even fires. On the other hand, when it gets too cold, the battery loses its ability to hold a charge and deliver power This means the vehicle’s range drops and it may take longer to charge. So, maintaining the right temperature is crucial for safety, performance, and cost

Modern EVs use thermal management systems to keep battery temperatures under control These systems use air or liquid cooling to remove extra heat In more advanced EVs, battery packs

are equipped with sensors and control units that monitor temperature in real time and adjust the cooling or heating accordingly These systems may add cost to the EV, but they help in avoiding bigger problems later like battery failure or costly replacements

Battery manufacturers in India are also working on making batteries that can handle a wider range of temperatures Some use special materials or coatings to protect battery cells from heat Others are testing solid-state batteries, which are believed to be safer and less affected by temperature changes Still, until such technologies become common, temperature control systems will remain essential for today’s EVs.