It’s out and ready to be devoured - the Widthwise 2023 Report that is. If you didn’t get a copy alongside your Image Reports you can download it for free from our website at https://www.imagereportsmag.co.uk/ widthwise

A huge thank you to all of those print chiefs who gave up their time to provide their info and insights so that we could compile this independent, wide-format print sector report. Hopefully you’ll find it useful in your strategising. I am certainly finding it so. For instance, this issue there’s a spotlight on software, where the Widthwise survey flagged up something of an anomaly. While half of respondents said improving workflow was on the cards, a much smaller percentage said they’d be investing in software (eg. workflow, MIS, W2P) in the next couple of years. Is that surprising? The heady benefits software integration can bring are well known, but so are the headaches. We therefore asked the industry’s key suppliers: Where do you think the ‘pain points’ remain in software development and integration - and how are you/the market addressing those? Turn to the technology section to see how they responded.

Another anomaly worth pointing out is in environmental attitudes and actions - the report goes into the detail but know that it continues to be a confused picture. Two features in this issue sort of highlight that - one is on a PSP launching a new eco-print service, the other on how a lack of buy-in to a face-to-face EcoPrint has prompted the organisers to ditch that concept and switch it to a virtual event.

Talking Point this time around is with The Printing Charity CEO Neil Lovell on how it sees the UK economy and cost of living crisis impacting those working in this sector - a key concern for so many as the survey flagged up. Yet, the overriding message is one of optimism and opportunity in a still growing sector and given that a large number of PSPs are looking to continue their business transformation journey the Top Tips this issue is on helping you do just that.

Hoping all this helps you in running a successful business.

Editor: Lesley Simpson lesley.simpson@imagereportsmag.co.uk

Production / Design: Rob Castles

Publisher: Wayne Darroch wayned@sjpbusinessmedia.com

Advertising Manager: Carl Archer carl.archer@imagereportsmag.co.uk

Tel: 07723 079928

SJP Business Media, 27 Clements Lane, London, EC4N 7AE www.imagereportsmag.co.uk

For circulation enquiries contact: SJP Business Media

Email: subscriptions@sjpbusinessmedia.com

Image Reports is available free to printers based in the UK. Register at www.imagereportsmag.co.uk/register.

To purchase a subscription please visit www.imagereportsmag.co.uk/subscribe –UK £54, overseas £84

Printed in Great Britain.

No part of this publication may be reproduced, stored in a retrieval system or transmitted by any means without the Publisher’s permission. The editorial content does not necessarily reflect the views of the Publisher. The Publisher accepts no responsibility for any errors contained within the publication.

Editor LESLEY SIMPSON LESLEY.SIMPSON@IMAGEREPORTSMAG.CO.UKTEL:

01932 707173REGULARS:

4 NEWS

Keeping you abreast of all the latest news in relation to digital wide-format print.

6 COVER STORY ADVERTORIAL

Vivid: helping you add value beyond print

24 FORUM

Digging below the surface with Industry Mole; Out and About events diary; Vital stats.

26 ZEITGEIST

Stylographics MD Simon Wheeler extols the benefits of trade bodies.

NEWS AND VIEWS ONLINE

Go to www.imagereportsmag.co.uk for all the wideformat sector’s industry news, updated regularly online. Image Reports can also send a twice weekly enews bulletin straight to your inbox – register at: www.imagereportsmag.co.uk/ newsletter

10 What to Watch: Software

Where do the pain points remain and what’s being done to alleviate them? And what’s middleware?

15 Making software investment pay

First had account from Jack Murphy at The Big Display company.

BUSINESS

16 Talking Point

…with The Printing Charity CEO Neil Lovell on how the UK economy is impacting the call on its services.

18 Top Tips

Advice on handling business transformation.

ENVIRONMENT

21 EcoPrint

Why the 2023 physical event will instead run as a virtual one in October.

23 Thinking inside the box

A look at ImageCo’s new exhibition-stand-in-a-box offering.

z Case studies from Agfa, CMYUK, Drytac, HP, Mimaki, Roland, swissQprint, YPS,

z Government heeds IPIA’s call for engagement

z EcoPrint to run as virtual event in October

z Print4All 2025 dates confirmed

z Akihisa Ogawa appointed as chairman of Mutoh Europe

z Stylographics MD joins Fespa UK board

z Nettle Chippenham goes PVC free

z New UK/Ireland MD for Antalis

z Fespa Global and sister shows hailed a success

z Stibo Complete takes first Vanguard VK3220T-HS

z Fujifilm opens Print Experience Centre

z Jim Fox confirmed sales director of Ultraflex Europe

z PrintFactory now integrates with Graphtec cutting tables

z WOO president warns OOH sector needs more momentum

z Oliver Luedtke takes over as ColorGate CEO

z Innotech to distribute Heytex Bramsche Side Curtains

z Xaar and Quantica forge inkjet partnership

z Vanguard investment central to Horizon’s sustainability drive

z Demo Kudu arrives at swissQprint UK

z Onyx 22.5 now out

z Antalis adds repositionable wallcovering to Coala range

z Contex brings out HD Apeiron/4 scanner

z Roland DG Connect subscription service introduced

z Mimaki shows off coloured textile reuse process

z Innotech Digital made UK distributor for Continental

Grafix media

z Siegwerk reopens Annemasse ink making site

z Artistri P1600 DTF inks launch at ITMA

z Vanguard sets sights on European expansion

z Kavalan signs new partnership with Polyedra in Italy

z New head of commercial development at Solopress

z Color-Logic extends its metallic software availability

z Ecoveritas calls on UK Government to ‘stay the course’ on waste reforms

z Drytac appoints Kieran Blacknall as academy manager

z UPM cuts graphic paper capacity in Europe

z Printing Charity names Rising Stars 2023

z MacroArt undertakes Blenheim Palace wrap

z New marketing lead at Canon digital printing

z Nazdar awarded Silver EcoVadis Medal for sustainability

z SAi expands its operations in India

z EFI sells 100th Vutek Qr Series printer

z Screen Europe appoints new marketing director

z BCF calls for greater urgency on Reach impasse

The BPIF has welcomed the Government’s twoyear extension to the current Climate Change Agreement (CCA) scheme, due to end in July 2025 and not now ending before July 2027. Crucially, it has also reopened the joining window for the scheme to the end of September 2023 and the federation is urging PSPs to sign up.

The BPIF - which has long been the sole provider of the Umbrella Agreement on behalf of the whole print sector and currently administers the scheme for around 330 of the larger energy users within the industry - is flagging up that the September deadline is likely to be the final chance for PSPs to take advantage of savings via the programme.

The federation points out that typically, a company using 500,000kWh’s of electricity in a year would have an annual saving of £3,650 a year before scheme costs. And with the scheme being extended to April 2027 that would mean a saving of around £14,600 over the period. The savings on gas would be in addition to the figures quoted, but are usually smaller as gas is mainly used for heating.

printIQ has developed a Carbon Connect feature operating within v47 of its MIS that empowers users to generate a carbon footprint figure directly from the system for every quote.

The feature seamlessly works in conjunction with CarbonQuota and equips end customers with the information to assess the environmental impact of the materials used in each print campaign.

Dominic Harris, director and co-founder of CarbonQuota, said: “Carbon Connect enables printers to be able to talk about carbon with confidence - providing all the tools needed to increase their offering to clients, increase revenue and reduce their own carbon footprint. Sustainability is a topic that is increasing in relevance daily and carbon footprinting remains at the core of good sustainability programmes.”

MacroArt has launched a banner rental service for the events sector as part of its sustainability drive.

Sales director Matt Guise said of the move: “Our new rental banner service maximises exhibition budgets for clients whilst minimising the environmental impact. Contemporary, modular build banners which are user-friendly, innovative, quick to assemble and fully flexible are ideal for rental and deliver significant costs and sustainability benefits when compared with purchased systems.”

MacroArt flags up that independent analysis by

Green Circle Solutions shows that rental offers significant sustainability benefits. Taking the total embodied carbon for a 10m x 4m x 1.5m hanging box frame banner, those who opt for the rental scheme can reduce their overall carbon footprint by approximately 33% compared to a traditional purchased system that gets used twice.

The new rental option forms a key element of MacroArt’s sustainability strategy based on five pillars - measure, activate, change, recycle, and a commitment to net zero.

The scheme is site specific and by sending the BPIF the site’s annual consumption of electricity in kWhs, it can let the business know how much the site would save. Even by just sending over a representative monthly bill, the site can get an estimate of the savings on offer.

The BPIF will take the site through the requirements of the application process providing it with sample templates and explaining the work involved. Once the application is complete it will be submitted to the government on the site’s behalf by the BPIF.

BPIF CEO Charles Jarrold said: “The CCA rebate scheme has been highly effective in motivating companies to examine and reduce their emissions and energy use, while also offsetting the otherwise considerable costs of the levy. It’s been a great success story for the sector, so, we were pleased after extensive representations that government recognised the need for the incentives to stay in place. We are now working with Government to look at what happens after 2027, to ensure that if a different scheme is adopted it supports UK print competitiveness.”

SDUK will run alongside Printwear and Promotion Live! next year following its recent acquisition by Datateam Business Media from longstanding owner Faversham House. The co-located shows will run side by side in Halls 1 and 2 of the NEC, Birmingham, on 25-27 February 2024.

“Consequently, there will a slight alteration of dates for Sign and Digital, from the original 27-29 February. This will see Sign and Digital open on a Sunday for the first time,” said event director, Tony Gardner.

He added: “The co-location will be a first for the UK’s sign, display and garment decoration markets. There is a real synergy between the two shows with around 1,000 of the 5,000 visitors to Printwear also attending Sign and Digital.”

SA International (SAi) has a new president and COO, Mikki Webb, who has been senior vice president for the last two years. Lloyd Cundiff has now been appointed to that role as well as becoming chief technology officer.

The moves are part of organisational changes at SAi, which sees Dan Purjes stepping down as chairman, though he will remain the majority owner and participate in strategic initiatives. CEO Don Feagan takes on the mantle of chairman too.

“This reflects the importance SAi places on succession planning to ensure we have individuals of the highest calibre in senior positions,”said Feagan.

Fespa UK and ISA UK have joined forces to create an event that will look at ways visual communications firms can push the materials, machines and technology they use to the limits. The event will be held at Hogarths in Sollihul on Wednesday 6 September.

The evening will start with drinks reception held in a gallery of design and concepts, where the printers and sign makers who created the projects will be on hand to discuss how the pieces were created. Each space will be supported by a key supplier, who will also be there to answer questions about the machine, substrate or other technology that went into making the project possible. There will be dinner followed by a keynote speaker.

Epson has unveiled new Monna Lisa printers - the ML-16000/HY and ML-24000, a new configuration ML-8000 and a 340cm ML-32000.

The 180cm wide ML-16000/HY has been developed to reproduce glossy lacquer, metallic gold and silver, and opaque white on printed fabrics. Printing at up to 1200dpi, it runs an 8-colour Genesta water-based inkset and pastes developed and produced by Epson Como Printing Technologies to create the special effects.

The 12-colour Monna Lisa ML-24000, with 24 printheads, offers the widest colour range.

The new Monna Lisa ML-8000 Reacid configuration meanwhile adds a wide selection of other materials and fibres to the list of fabrics already supported by Monna Lisa printers, including non-traditional fibres.

Brother Industries has launched itself into the wide-format digital inkjet market with its WF1-L640 Latex printer.

Brother has made expanding the industrial print area one of its goals as part of its ‘At your side 2030’ vision. In order to achieve this vision, the medium-term business strategy is to create an inkjet portfolio. The WF1-L640, developed for the sign and display market, marks a new business area for Brother, which will aim to leverage the ink and piezo-electric printhead technology it has cultivated through its garment/ fabric print history.

The WF1-L640 is based on the Roland DG TrueVis AP-640 chassis, and through collaboration with Roland DG uses its VersaWorks Rip. The machine has a printable width of 1615mm, a 1200x1200dpi print resolution, and top speed of 15m2/hr. It uses Brother’s in-house developed water-based ink with Greenguard Gold certification. The printer holds six cartridges - CMYK plus two optimisers.

Online print company Solopress has introduced a service that allows customers to order carbonneutral print. This new scheme comes on the back of the Solopress Green range and makes carbon offsetting accessible at checkout.

Customers can opt to ‘Make this order Carbon Neutral’, pledging their support for projects such as Woodland protection and tree planting in the UK, facilitating clean drinking water in Eritrea, or contributing to projects that address the problem of Ocean plastic. The contribution quoted with each eligible order from Solopress is calculated to

balance the amount of carbon dioxide put into the atmosphere during production.

Solopress has already offset 150,000 kilograms of carbon dioxide through the Solopress Green range. With offsetting now extending across a greater spread of products, Solopress aims to increase this figure dramatically.

Meanwhile, Solopress has added an Agfa Oberon RTR3300 roll-to-roll large-format digital inkjet printer to its production arsenal. It has also bought a second Fotoba XLD 320HS cutter to trim products printed on the Oberon.

The anti-pollution system called Clean Air - that is being used by the likes of Hollywood Monster, Octink and RMC Digital Print - has been confirmed as complying with ISO standards 22197-1 after six months of simulated weather impact following testing at the International Photocatalyst Standards testing centre at Queen’s University in Belfast.

Clean Air can absorb up to 222mg a day of NOx (shorthand for the nitrogen oxides most relevant for air pollution and particularly problematic in hightraffic urban areas) from just 1m2 of an exterior coated surface, including outdoor print.

(see feature in Image Reports for details: https://bit.ly/3Nx9Kkd)

UK-based print tech firm Artworker has started a free file-sharing service designed with the specific needs of the printing industry in mind.

The service includes: the creation of a uniquely branded portal, complete with a custom URL for linking from websites and emails; embeddable widgets, allowing customers to share files without leaving the company’s website; artwork preview; structured file storage; and the ability to display studio hours and support information on the portal. For users seeking more functionality, Artworker offers a Pro tier which streamlines approval process, including sending proofs for customer sign-off.

Nate Duckworth, co-founder of Artworker, said: “In a rapidly evolving digital world, it’s crucial that the print industry doesn’t get left behind.

“With Artworker, we’re not just improving file-sharing - we’re transforming the way printers interact with their clients and manage their prepress workflows. Our goal is to make the process as seamless as possible, from artwork submission to final approval.”

Shajjad Rizvi, CEO at developer Resysten, said: “We believe this is a game changer in the fight against air pollution, which costs up to 4,000 lives a year in London alone. The Clean Air coating can be applied easily and safely and is highly cost-effective. This, combined with continually improved and increasingly more sustainable public transport networks that reduce the need for cars for personal use, will help bring about a massive change for the better in our cities. We are looking forward to starting this new adventure by bringing Clean Air by Resysten to the UK market before expanding worldwide.“

Resysten has created a joint venture in the UK with Clean Air Global to sell the product.

Roland DG has created a ‘50 Shades of Ginger’ colour index to celebrate redheads, using its TrueVis colour technology. The company is also teaming up with the Redhead Days Festival 2023 as an official sponsor at the event in the Netherlands in August, where attendees can use the colour index to find their perfect hair match, with branded merchandise then printed on-site. The campaign aims to highlight the colour print possibilities using Roland DG’s TrueVis technology and expertise. Redhead TV quizmaster Jenny Ryan has been recruited as the campaign ambassador and has been interviewed on ITV’s Good Morning Britain to talk about it.

Lauren Swinnerton, head of marketing communications and brand EMEA at Roland DG, said: “Being a redhead goes far beyond hair colour - it’s a visual representation of individualism and we strongly believe no one term can define the vast and beautiful shades of redheads, which is why we’ve created our celebratory colour index. This rings true to the ethos of Roland DG as a global print company that celebrates colour and expressiveness, and thrives on standing out from the crowd.”

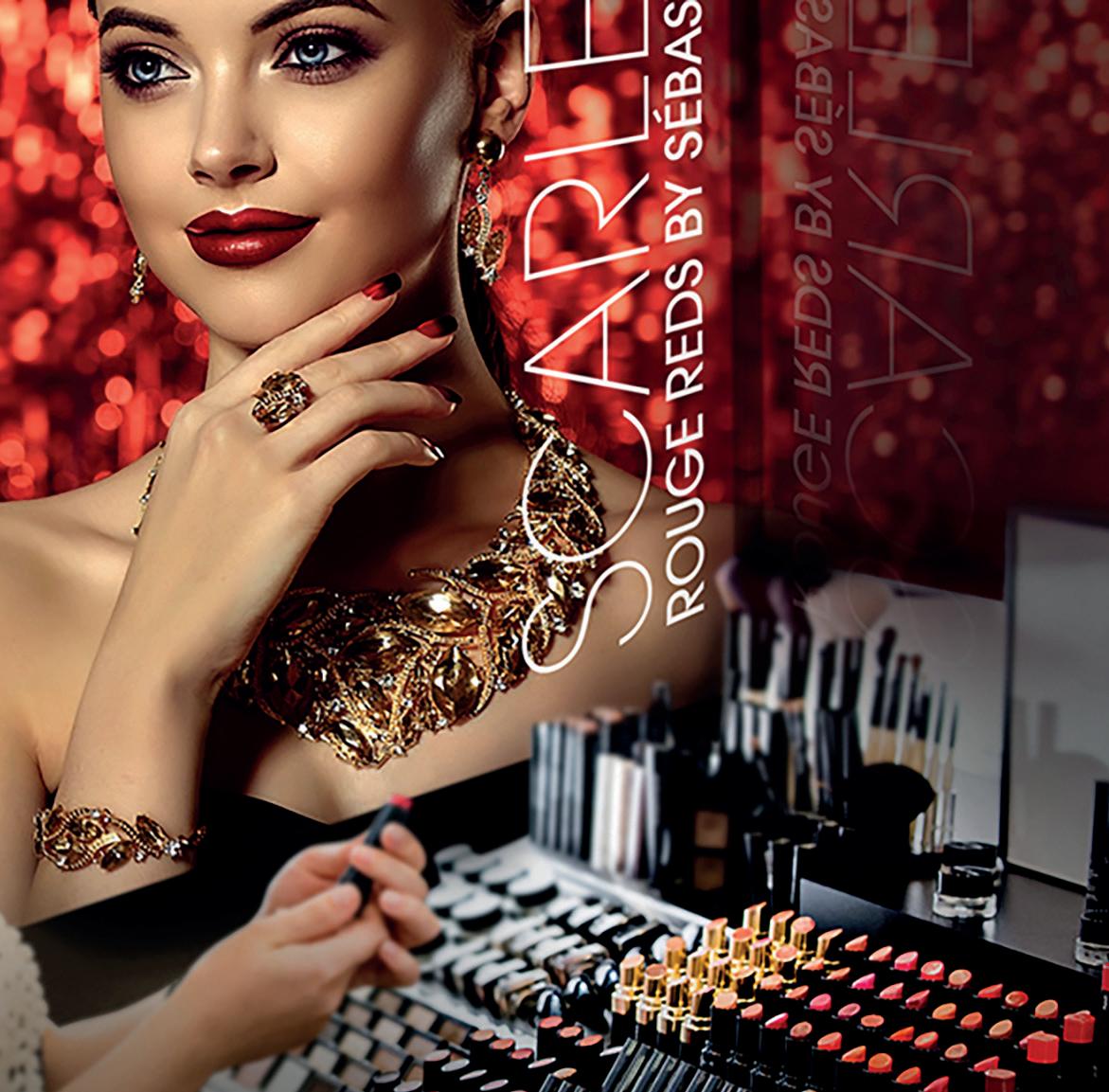

Vivid is Europe’s leading designer and British manufacturer of award-winning print-finishing equipment for over 30 years. Manufacturing a wide range of print finishing equipment from Digital diecutting systems, laminating and

Since 1986, Vivid’s aim has always been the same, to add value beyond print. They do this by thinking outside the box to create cutting-edge laminating and print finishing equipment of the highest quality, robust and reliable. Their work empowers their customers to produce enviable print finishes and deliver bespoke projects, at a fraction of the price of outsourcing.

Vivid believes that unique and eye-catching packaging, products and signage, sets a business apart and makes a lasting impression. To keep pace with the rapidly changing marketplace, their highly experienced team work closely with their customers and partners. Ensuring everything they develop advances on what they’re already doing as well as making their customer’s lives easier and businesses more profitable.

“Our customers and partners are at the heart of everything we do, working closely with end users, industry experts and leading manufacturers in other areas of print gives us a unique ability to continually develop systems that add value beyond print, we see ourselves as a partner to anyone we do business with and will support them every step of the way “ - Martin Evans – Managing Director.

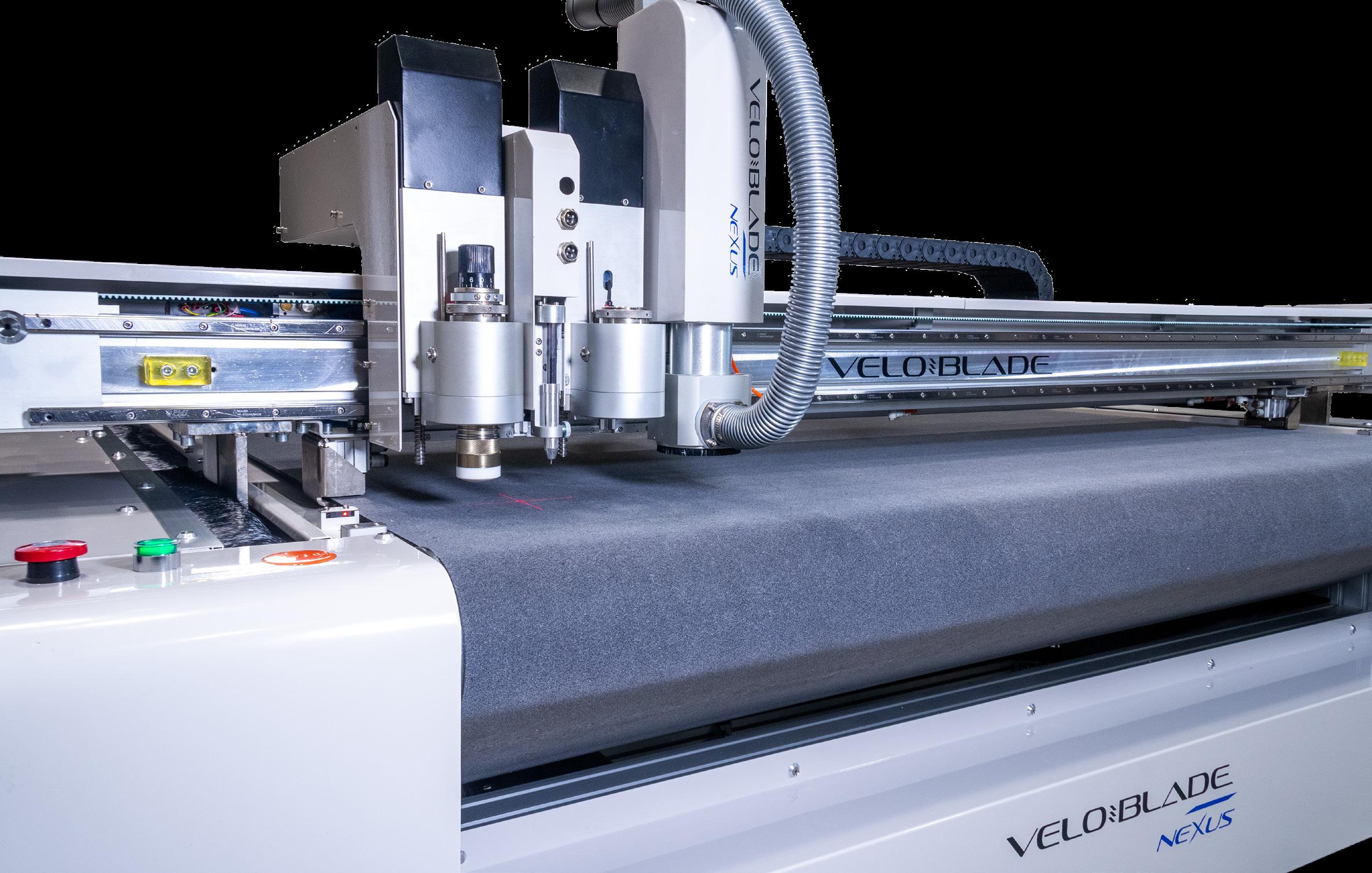

Established in 1987 as the Digiprint group, Nettl now have 2 high street branches - “Nettl Print and Design Studios” located in Bath and “Nettl Signs & Graphics” located in Chippenham, a production factory for signs and displays.

In December 2022 Nettl moved to a brand-new larger production facility to continue to grow their sign manufacturing range and have since invested over half a million pounds in infrastructure and equipment.

Their main goal with investment was to focus on their eco ranges of signs and print, and invest in the latest technologies to fulfil the growing sector of sustainable print and signs. Having previously outsourced most of their CNC and cutting work, they found that delays in production and varying quality issues stopped their workflow. They needed to improve both the quality and keep control of production with their own in-house services.

Having been a customer of Vivid for many years, Nettl

felt confident in the quality, service and support from the team. They had investigated other big brand manufacturers for flat bed cutting and CNC. After having tested and seen the Veloblade Nexus in action, they were far more impressed with the build quality, range of functions and value for money that the Nexus had to offer.

“The Veloblade Nexus is a robust, versatile and affordable piece of kit. We have only scratched the surface of what it can do so far, and we are discovering new solutions for our customers daily. The option to keep all production in-house has drastically sped up production times, kept quality high and exceeded customer expectations. We are yet to find a substrate the Nexus cannot handle and have even thrown it a few curveballs with various woods, plastics and roll media. It has rapidly sped up production for sign boards, banners and posters which are an everyday staple product. But we have also been able to produce short-run packaging, prototypes, and direct print and cut products that were previously unavailable.

The Veloblade Nexus has been a game-changer for our business and if anyone is in the market to install flatbed cutting and finishing, I cannot recommend this enough. From the offset, Duncan in sales was great and really helped with options and information. The install team of Jason and Matt were professional but really friendly and explained everything clearly with great tips and tricks to get the best out of the Nexus and its range of tools and blades.”

- Ben Gregory - Director at Digiprint Nettl

THE 16TH ANNUAL IMAGE REPORTS WIDTHWISE REPORT IS BEING PUBLISHED ALONGSIDE THIS ISSUE AND CAN BE DOWNLOADED FOR FREE AT: WWW.IMAGEREPORTSMAG.CO.UK/WIDTHWISE. IN THE MEANTIME, YOU MAY WANT TO DIGEST THE KEY FINDINGS.

Energy bills and the state of the UK economy continue to worry so many of you running large-format print businesses according to the 2023 Widthwise survey. A massive 91.48% of the 176 print chiefs who provided their insider sector knowledge said energy costs were one of their biggest concerns looking ahead, and 80.68% cited the general state of the economy. The cost of supplies was also flagged up by a significant 63.07%, with 65.34% having experienced supply chain disruption over last year too. None of that is good, but this is - 91.48% of respondents said they were optimistic about their business over the next two years. Over half (52.84%) said they were ‘very’ optimistic. Indeed, only one company said they were ‘mildly’ pessimistic - and none were very pessimistic.

There’s good reason for the optimism. Almost twothirds (63.64%) have seen turnover grow since the start of last year, and for 44.89% turnover was up by more than 10%, though we have to recognise that 11.93% saw a fall. Crucially, profit margins were also up for a large number - 47.16% had seen an increase since the start of 2022, with another 34.66% reporting theirs had remained stable. What’s more, 61.93% said they expected the UK wide-format market to grow over next two years, with only 2.27% expecting it to shrink.

Nearly half of the print bosses interviewed said growing turnover was their top ‘must-do’, with almost a quarter of the sample (23.30%) putting ‘entering new markets’ as their key priority. Although 44.32% said they’d not made any strategic changes across their business in 2022, a very significant 23.30% said they had restructured. And, looking ahead to the next two years, while 27.27% said they had no plans to make strategic change, the majority do. Of those, 22.73% said they would be restructuring. Part of that plan for many is to offer new services to new markets. Of the total research base, 34.66% said they had researched new markets over the last year and 28.41% aim to over the next two years. 10.23% said they’d offered new print applications during 2022 and 22.73% are working towards doing so.

Looking at things from a production capability standpoint, many appear confident that they have what they need to deliver the

91.48%

in what print chiefs understand as the Internet of Things (eg. automation, AI, remote diagnostics), with only 6.82% having said they would be investing in such areas. Yet, half (50.00%) of all those polled said improving workflow is on the cards.

The environment also continues to be a confused picture. Focussing on sustainable practices came out bottom of the list of priorities for next year - 1.14% put it top - perhaps because they believe they’ve already taken the low-hanging fruit and don’t know how to reach any higher, but it seems odd when 77.27% said it is now more important to be seen as environmentally friendly than it was two years ago. Then again, asked about their clients’ main priorities, print quality came top, followed by price, then speed of turnaround - environmental issues came way down the list - only 0.57% said that was their clients’ top priority. Over half (59.09%) said ‘few’ clients ask to see environmental accreditations/policies - though about the same proportion (57.39%) said they are using more recycled/recyclable print materials than

Asked ‘what are your three top environmental priorities over the next two years?’ over half (52.87%) put reducing energy consumption top - but is this about being green or due to the cost of energy, a worry for so many?

It appears that cost cutting while business building is the name of the game as we head into what respondents consider to be a bright future.

said they were optimistic for their business over the next two years

63.64% have seen turnover grow since the start of last year 47.16% have seen margins improve

SOFTWARE INTEGRATION IS WHERE WE’RE TOLD IT’S ALL HAPPENING, BUT MANY PSPS ARE YET TO BE CONVINCED THAT THE BENEFITS OF INVESTING IN TODAY’S SOLUTIONS OUTWEIGH THE HEADACHES. SHOULD WE EXPECT THAT TO CHANGE ANYTIME SOON?

So, you want to improve your workflows and increase efficiencies - but not via software investment. Many of you will be screaming ‘what?’ at this point, but plenty will be nodding in agreement - at least that’s what the Widthwise 2023 poll of UK-based large-format PSPs suggested (the full data set is analysed in the Widthwise Report, free to download from the Image Reports website). The heady benefits software integration can bring are well known, but so are the headaches. We therefore asked the industry’s key suppliers: Where do you think the ‘pain points’ remain in software development and integration for the wide-format digital inkjet print sector - and how are you/the market addressing those?

It’s impossible to cover the whole realm of wide-format digital inkjet print related software here, but the main points flagged up by those that responded are hereinexpect to see the word ‘integration’ appear frequently - as a pain, and as a painkiller. As Serge Clauss, product

manager, Durst software and solutions, reiterates:

“Integrating software systems with various production processes, such as prepress, finishing, and shipping, can present challenges. Ensuring smooth data flow, real-time tracking, and synchronization between different software tools and hardware components is crucial but may require customization and integration efforts.”

He adds: “Durst has been addressing these challenges by growing its software suite, providing 360-degree solutions that provide all the necessary tools to increase customers’ productivity without the need for software integration concerns.”

At Vism, Roksoliana Sydorska stresses the need for better systems integration, saying: “There’s a growing expectation from the printers we speak to that systems talk to each other out of the box. One of the first questions on most demos we do is ‘can it integrate with X, Y or Z?’ Generally, we’re seeing most of the print ERP/

MIS providers are also aware of and responding to this. What’s really important is that you work with system providers that are open and ready to collaborate with others. We just recently launched our API and saw our first partner go live with their integration - Lift ERP from Durst. One of the key reasons we like working with the Lift team is because they share our approach to solving customers’ problems by understanding what they need and getting systems talking to each other to help them achieve that.

Dr Jonathan Rogers, senior manager global marketing and communications, Onyx Graphics, airs a complaint heard frequently within print companies: “The industry has a disconnected approach to connectivity for automation and integration needs, and this won’t do.

“The print industry has seen an influx of software solution providers and from the print production perspective, many are able to take a design file through to production and finishing in a seamless workflow using the same technology or print engine. An example would be a Rip using the Adobe PDF Print Engine that can seamlessly integrate with Adobe PDF print files. Workflow, however, means different things to different people. Workflow to some PSPs means to connect different systems such as Web-to-print ecommerce front end to Rip and simultaneously to MIS, most of which are not adequately done or still rely on manual input which impacts overhead costs and is prone to manual error.

“PSPs need to feel confident that their Web-to-print order is passed to both business management and print production software without the loss of information. Where the industry can improve, then, is in API connectivity or native integration that gives PSPs the ability to seamlessly carry job, customer, and business data from quote to production to shipping without the fear of data loss or reliance on manual data entry.”

He continues: “Data loss - between connected systems, between file type conversions, the design file itself, and in the translation of design file data to printed product - continues to be an issue. An example might be a design file viewed in RGB but designed in CMYK with an expectation to match named brand colours to the RGB view. Minimizing this potential issue comes down to effective colour management to create a colour recipe to map the input profile to the output profile. One way to do this is by removing the colour-space middleman - which happens when translating the CMYK design to LAB then again to RGB to match the RGB expectation. A more direct translation between input and output colour profiles reduces the likelihood of data loss and therefore colour shift between what is expected by the print buyer and what is produced by the PSP. PSPs wishing to limit data loss such as with this colour management example may want to seek solutions that provide what the industry calls ‘device link’ profiles for a direct translation of colour spaces between input and output colour profiles.

Rogers also points to a need for speedier software to market times, and for easier to use solutions: “Software release cycles are increasing in frequency as are hardware devices for new feature functionality to meet market demand. An overlooked aspect of hardware and software compatibility is driver development. For natively integrated solutions, this is not a market issue, but for mixed print environments where PSPs have different machines with a single software solution for their entire site, the speed at which solution providers can

effectively support devices is an area which helps PSPs know vendors have their business interests at heart. PSPs would benefit from seeking solution providers who efficiently and quickly develop device support ahead of making new purchase decisions.”

Mike Horsten, global press and PR manager DPS, Agfa, says that nowadays “software is an essential part in the offering of any hardware manufacturer”. He expands:

“The biggest pain point is that development of software is sometimes slower than the changes in the hardware areas and the extreme testing that is needed for the health and safety that goes with those tests. Integrating is a time-consuming business and the possibilities are enormous. We therefore work on a modular basis offering the modules needed for the jobs on hand in combination with the hardware offered.”

At SAi, Eyal Friedman, VP of product management, and Wenhong Zhu, chief engineer, say one of the biggest challenges with Rip software supporting this market is to speedily meet the demands of hardware development.

“SAi has devoted significant time improving our screening technologies and drivers to handle such state-of-theart printers and advanced applications. We embrace practices that enable us to deliver software faster and safer. Our licensing system and software deployment is done through the SAi Cloud, so we release new drivers or software features as they are developed.”

They also point out that the company has developed a new user interface, called SAi Connect, launched together with Flexi 22. SAi Connect is the next evolution of the SAi Cloud and is available as a desktop application or a Web application that allow access from every device with internet connection, making it easier for Flexi software users to see their production data, manage their licenses, download updates and new drivers.

Raphael Gruber, marketing manager at OneVision Software also notes the oft asked question: How can the software be connected to my existing system landscape?

“Our main goal is to create a smoothly automated endto-end ecosystem that significantly increases production efficiency,” he says (turn to p13 to read more about the company’s approach to middleware development).”

Carlotta Maria Basile, production portfolio marketing manager, Canon UK/Ireland, flags up the company’s partnership with OneVision. “In addition to our own software solutions, we have developed strong partnership with other software integrators and vendors, such as OneVision, in our bid to make life easier for our customers while optimising and automating their workflows.

She adds: “We are actively introducing software that can monitor and control the ink consumption of equipment as a cost saving measure to businesses. Our Accounting Manager tool is an example of our software that can help efficient cost management of print and is easier to define RRP for end customers.”

Alexandra Schalk, team manager marketing, ColorGate, understands that finding the right software can be a challenge for large-format PSPs, saying a lack of knowledge and resources to implement automation hinders companies in this sector. She points to ColorGate’s Productionserver and REST API Module as possible solutions. “The REST API Module empowers printers to connect the Productionserver with any other REST API capable components within their production

THE INDUSTRY HAS A DISCONNECTED APPROACH TO CONNECTIVITY FOR AUTOMATION AND INTEGRATION NEEDS, AND THIS WON’T DO

COMPLEX SOFTWARE INTERFACES MAY HINDER PRODUCTIVITY AND LEAD TO ERRORS

Dr Jonathan Rogers, Onyx Graphics

Mustafa Okanovic, Mimaki

chain. This seamless integration facilitates enhanced collaboration and streamlines the entire workflow. By leveraging the flexibility and connectivity of the REST API Module, printers can create a highly customized and adaptable system that aligns with their specific requirements.

Debra Hobden, sales and marketing manager, PrintFactory, agrees that software compatibility remains a concern in the wide-format print sector, saying the company works closely with partners to ensure compatibility and smooth integration with a wide range of hardware and software tools. “Print service providers often use a combination of software applications from different vendors and ensuring seamless integration and compatibility between these tools can be a challenge. PrintFactory addresses this by providing a centralized cloud-based software platform that integrates all the essential applications.”

At Mimaki Europe senior product specialist Mustafa Okanovic identified three continuing pain points in software development and integration for the wide-format digital inkjet print sector - complex software interfaces, workflow optimization and compatibility challenges.

“Complex software interfaces may hinder productivity and lead to errors. To address this pain point, we keep improving our software and products, focusing on simplicity and ease of use. One example of this is our latest Rip software, RasterLink7, which features increased processing speed, usability and productivity,” he says. “Another example is our Mimaki Printer Controller (MPC) software which is available on our printers, such as the JFX600. This combines machine setup, printer operation and job control via a large user-friendly touch panel.

“Workflow optimization can be a concern too. To address this, we develop software solutions that can streamline or automate these workflows. For example, with the release of our RasterLink6 Plus, we simplified the process of 2D multilayer printing by enabling the Rip software to automatically create up to 17 layers based on just one grayscale image.

“Because printers, software applications and other components of digital print workflows may come from different manufacturers, which can lead to compatibility challenges, in addition to making our software more compatible across various devices and platforms, we also simplify the integration process of our printers into print production workflows - through features like MDL commands and Mimaki Job Controller for example. We also ensure that our software is compatible with a range of popular technologies and devices from other companies commonly used in the market. For instance, our RasterLink Rip software allows the creation of cutting crop marks from popular third-party companies like Fotoba. This enables customers to directly process the printed media on third-party cutters.”

Another production pain point according to Phil McMullin, head of sales for commercial and industrial, Epson UK, is how to quickly and efficiently manage a wide range of short runs and customised applications. “One way this can be improved is with nesting software. In fact the Keypoint Intelligence 2022 Wide Format Applications and Utilization Report found the use of nesting software has been on the rise. It reported 92% of wide format PSPs are utilising nesting and ganging

software for capacity optimisation. Epson Edge Print Pro is a Rip software with intuitive interface that also helps with custom spot colour libraries, pattern repeats, and more. It enables features such as step and repeat, tiling, copy, and trimming too, and works alongside other Epson software such as Control Dashboard, which allows users to set up custom print settings.”

From a print production management perspective, Jane Rixon, business development manager for signage and decoration at HP, acknowledges a problem area for PSPs can be having to tussle with several different Rip solutions driving various printers. She highlights HP PrintOS, a workflow solution that enables PSPs to get the most out of their printing hardware. The latest functionality in HP PrintOS allows customers to increase their management control, allowing them to better monitor and optimise printing workflows.

“One of the most significant developments with HP PrintOS that has helped HP customers all around the world is HP PrintOS Mobile, which enables users to remotely monitor printer status and jobs. HP PrintOS users can also benefit from Print Beat, another remote tool for monitoring production and data analytics while on the go,” says Rixon. “Within this there are two new core applications in the form of HP Live Production and HP Jobs API. HP Live Production allows users to remotely control printer jobs queues. This can be made available to a number of staff to enhance coordination across the business, reduce dependencies on certain team members and improve accuracy on job queue estimations. HP Jobs API transfers a printer’s data to an ERP or MIS system, streamlining production setup. Printer data is transferred automatically with no limit on the number of API recalls.”

The last word - for now - goes to Chris Schowalter, global sales director, Fiery, who says: “What we are seeing is that our customers and, more importantly, our customer’s customers, continue to be very critical on colour accuracy and overall print quality, which obviously is a strong suit of Fiery digital front ends. But our customers are also seeing a lot of price pressure and the ask is not ‘only’ to provide the best possible results but do so in a highly automated manner. This forces the industry to invest in higher productivity equipment. Investment in higher productivity equipment means that process steps need to be automated and touch points either need to be removed completely or moved further upstream in the workflow to allow the print operator to focus on ‘feeding the beast’ so to speak.

“We at Fiery have been preaching a high grade of automation for years and are heavily invested in integration in sophisticated workflows through JDF or other means. As we see the industry mature, the need for automation is expanding to the smaller print providers. We identified this need early on and focus on a solution approach where we can provide entry-level workflow tools like Fiery JobFlow (PDF to PDF workflow) or Fiery Prepit (True shape nesting layouts) without forcing the user into our own ecosystem. All solutions are completely independent and play well with any other Rip vendor for example.

“In a nutshell, we are bridging the gap between entry-level automation solutions and highly sophisticated custom integration without PSPs losing the flexibility to be able to pick and choose what tools fits their needs best.”

WE ARE BRIDGING THE GAP BETWEEN ENTRY-LEVEL AUTOMATION SOLUTIONS AND HIGHLY SOPHISTICATED CUSTOM INTEGRATION

Chris Schowalter, Fiery

What is ‘middleware’, and why should large-format PSPs care? Well, as OneVision Software marketing manager Raphael Gruber, reiterates, everyone is talking about end-to-end digitisation of production processes, but what about the bit in the middle? We know that integration and connectivity are important, but so often systems do not properly ‘talk’ to each other. Middleware is intended to smooth out that problem.

As Gruber points out, if a digitisation and automation project is designed holistically, the focus is on middleware - software solutions that enable vendor-independent integration into existing system landscapes, thus enabling comprehensive connectivity.

Basically, middleware creates an ecosystem, integrating systems from file input to shipping - and it does so independently of machines and software systems already in use. The middleware flexibly integrates with all existing systems and links the individual components with each other. This allows each component to focus on the task in the production process for which it was created. The Rip is not loaded by oversized files, and the utilisation of the printing and finishing machines is optimised. The middleware prepares the files accordingly, making production smoother and more efficient.

New markets or distribution channels, such as Webshops, can also easily be handled, as the middleware controls and prioritises them accordingly.

The middleware first connects to the file input. This can be Webshops, ERPs, MIS, but also hotfolders, email inboxes or any other system that outputs structured data. The middleware retrieves order information and production files from these systems. Each file is checked individually, corrected if necessary and optimised for production. The prepress process is thus fully automated.

The middleware then transfers the prepared print file to the appropriate press/printer, and optimised cutting files to the cutting systems. Order sheets or shipping labels can be generated for logistics and shipping too.

Wide-format printers in particular - where applications and jobs can be so varied - can obviously benefit from such systems. It is often mistakenly assumed that individual jobs cannot be automated, but it is possible.

When selecting middleware, it is important to ensure that the software is as flexible and dynamic as possible as that’s when the strengths of middleware solutions truly pay off.

Digital job tickets are the key to dynamic and highly flexible processing. They contain all the relevant job

details, allowing print files to be routed accordingly in the middleware workflow. For example, a flag is routed to automatic hemstitching, whereas a mega poster is automatically tiled into individual panels, or small-format stickers are nested to save substrate.

Practical examples from various areas of wide-format printing show that the use of reliable middleware is the key to the future sustainability of printing companies.

Aura Brand Solutions is a UK-based wide-format visual communications company that specialises in train and vehicle fleet wrapping. In this area, the company works with huge file sizes. By using middleware, the company says print files could be prepared up to 80% faster than they could before.

The situation is similar at wide-format printer Kleinhempel, whose core business is signage, building banners and large-format prints. Before the implementation of the middleware, 90% of the staff´s time was spent on repetitive, routine tasks, especially in prepress. With the software, much more could be automated - checking, optimising and preparing oversized files, transferring them to the production kit and creating shipping labels are now fully automated.

An impressive growth has been achieved by the digital printing company Siepro. In 2017, the company was using two large-format roll-to-roll presses for label production. Since then, the machine park has grown to 18 printing systems and 11 cutting systems. Middleware has made a significant contribution to this growth. Siepro uses it to automate the entire production process, starting from file input, to file preparation, nesting, printing and finishing of the labels.

By using middleware, these printing companies have been able to automate their production according to their needs, increase their efficiency, and prepare themselves for the future.

WHEN SELECTING MIDDLEWARE, IT IS IMPORTANT TO ENSURE THAT THE SOFTWARE IS AS FLEXIBLE AND DYNAMIC AS POSSIBLE AS THAT’S WHEN THE STRENGTHS TRULY PAY OFF

Up to 1449 m²/h

Inca Onset X range

Extremely high-speed flatbed printers

Up to 905 m²/h

Jeti Tauro range

High-speed hybrid printers

Up to 250 m²/h

Avinci

Dye-sub textile printing – direct or on transfer paper

Up to 248 m²/h

Jeti Mira

High-end flatbed printer with dockable RTR

Up to 224 m²/h

Oberon

High-speed roll printer

Up to 129 m²/h

Anapurna range

Medium-speed flatbed, roll and hybrid printers

When building inkjet printing solutions, we tune all elements to each other: printer, inks, media, applications, and worklow processes. That’s why you can count on outstanding and consistent print quality, 24/7 reliability, and sustainable operations. On top of that, we deliver impeccable service & support across the globe.

Asanti software

• Workflow & color management

• Prepress automation

• Intuitive operation & overview

• Powered by Adobe PDF print engine

Inks

• UV & dye-sub

• Rigid & flexible applications

• Thin Ink L ayer limits ink use

• GREENGUARD Gold certified

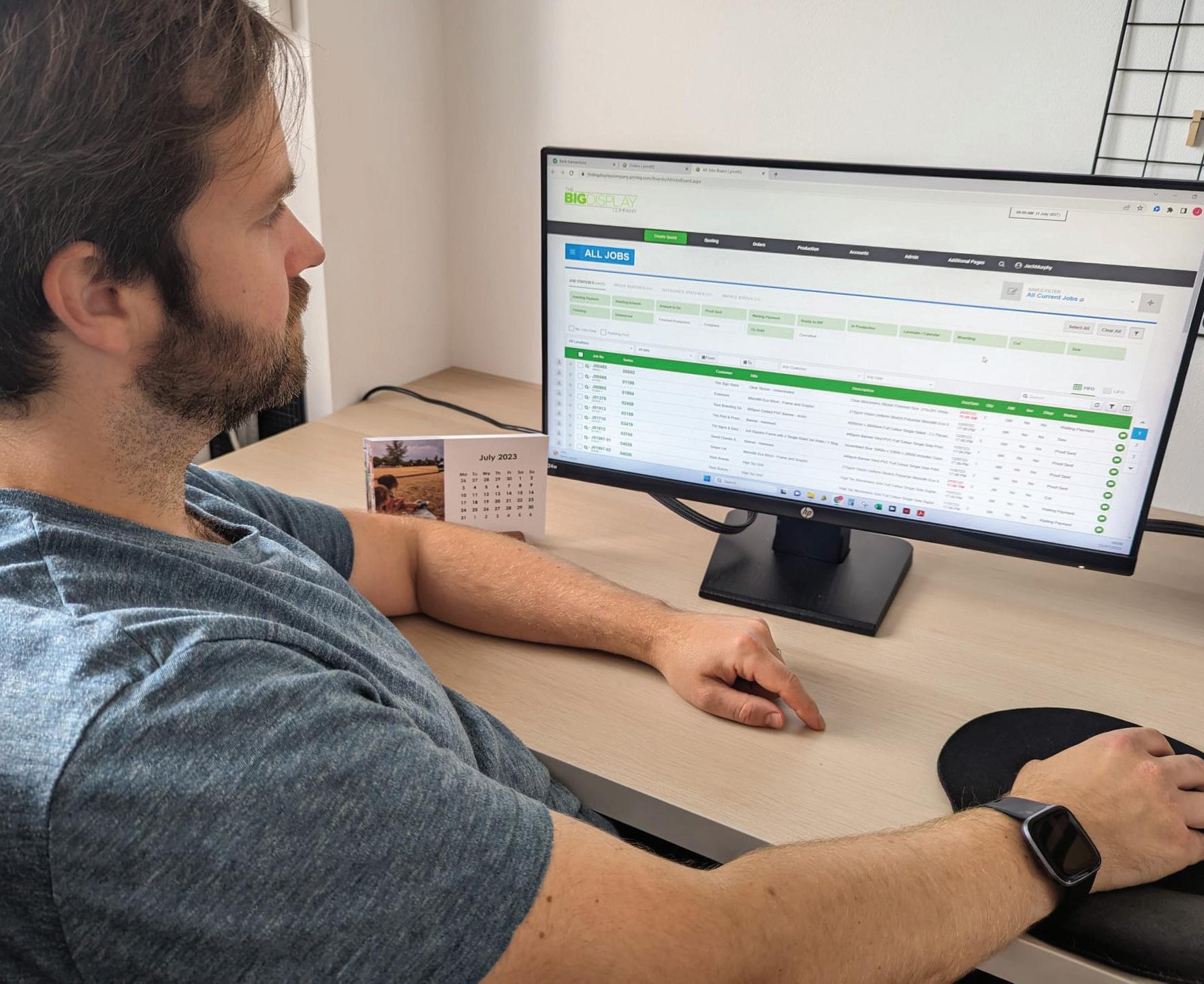

THE BIG DISPLAY COMPANY HAS SWAPPED ITS SHOPVOX ESTIMATING AND PRODUCTION SYSTEM FOR A PRINTIQ SOLUTION. SO HAS THE MOVE BEEN WORTH THE TIME AND MONEY? I ASKED ITS MARKETING DIRECTOR JACK MURPHY…

Want a first-hand account of a wide-format print PSP buying into a new software package to improve workflow and efficiencies? Thought so, which is why The Big Display Company marketing director Jack Murphy’s here tells his story in his own words.

He starts by explaining: “We are a large format printing company based in Slough. Our equipment is predominantly HP latex, with a 2.5m hybrid, two of the 3.2 HP 3600 and two of the 1.6 HP 800, but we also specialise in textile with an Agfa Avinci 3.2m and a Kleverik calendar.

“We used Shopvox.com for four years for our estimating and production board. When each job was approved we would print off the work order for each material and staple the artwork to the back. Some jobs would end up having 10 - 20 pieces of paper due to the complexity of the order/number of artworks/notes etc.

“Although Shopvox is a good platform, it hadn’t developed much over the time we’d been using it and they weren’t very receptive to feedback, so we knew it was time for a change. It was also clear that it wasn’t the right software for us to go paperless, a long-term goal of ours. So, over the next year, we researched different options, including all the usual suspects, but we couldn’t

find anything that directly catered for wide-format. All of the long-standing software packages on the market were too focused on small-format, with a workaround for wideformat. That wasn’t good enough for us.

“We came across PrintIQ and it looked like the best option for our set-up. Its core was set in small-format, but they had put a lot of consideration into the working practices for wide-format and the ways that jobs are estimated (ink per square metre costs/material per square or linear metres/combining multiple hardware components/labour costs etc). After seeing a demo it was pretty clear to us that it was the right software to go for.

“From the initial meetings to go-live was about 12 months. It was a long haul because we had to rethink how we look at our costing and our production processes. Every nut and bolt needed to be accounted for, the timings for each process needed to be factored in, and every product needed to be built from the ground up. It also required every order to split into individual jobs, which wasn’t something we were used to from an estimating or production point of view.

“It wasn’t easy getting the software ready because the level of detail required was so much higher than we had readily available, and the product set-up was very complex to achieve what we needed the system to do. There were plenty of occasions where it just didn’t seem like the benefits would be worthwhile because we had to make so many compromises from the easier processes we had in place. But we kept the faith because we needed to make that move to being paperless, and we needed better accuracy with our estimating. So, although we knew we would lose out on the shortcuts we were used to with Shopvox, this was something we needed to do.

“I had gone into the ‘go live’ date worrying that production would struggle with going completely paperless - there wasn’t a midpoint between running paperwork as we had always done, and being completely digital, we just had to take the dive. After a few days of niggles the production department took to it better than I could have ever hoped for and they have completely embraced an entirely paperless process, from artworking through to dispatch.

“Sales has been much harder to implement because although there are some elements which are much quicker - particularly complicated products that have a lot of finishing requirements, or quotes with multiple quantities - there are some parts of the system which are a lot slower than what we’re used to - like changing an order once it’s been booked in, or quotes with a lot of different sizes in the same material. The team have now got their heads in the right place and are doing a great job with processing even the most complicated orders. More importantly they are able to see the benefits that the system brings to the whole company.

“Now we’re several weeks into it there are still a lot of workflows we’re finalising and we know it’ll always be a work-in-progress, but it has bedded-in really well and I couldn’t imagine going back to how we were running the company previously. Realistically, we couldn’t have gotten to this stage without the continued help and support of PrintIQ, and I’m excited to see how the platform will develop over the coming years.

“The biggest cost for us in the whole project was timeit took much longer than we expected - but it was worth it given the result.”

IT’LL ALWAYS BE A WORK-INPROGRESS, BUT IT HAS BEDDED-IN REALLY WELL AND I COULDN’T IMAGINE GOING BACK TO HOW WE WERE RUNNING THE COMPANY PREVIOUSLY

The Printing Charity has been around for almost 200 years, having been founded in 1827 as The Printers’ Pension Society. Today it provides practical and emotional support for those in need in the printing, paper, publishing, packaging and graphics sectors. Given the current economic climate, I spoke with its CEO Neil Lovell to find out how its services are being called upon.

In our 2023 annual Widthwise survey print chiefs said their biggest concerns for their businesses going forward were energy bills and the state of the UK economy - and we know the cost of living crisis in general is hitting many households. Given this state of affairs, is the charity noticing an increase in calls for support?

We are certainly living in uncertain times. The pandemic created conditions none of us were really prepared for and as you say, we face the realities of a cost of living crisis. With the Joseph Rowntree Foundation finding that one-in-five people in the UK are living in poverty, and 7.9m of those are working age adults, it’s a challenging picture right now, compounded by the most recent interest rate hike.

Against this background, it’s no surprise that we are seeing a steady rise in calls to our free, confidential employee helpline, particularly from people seeking in-the-moment telephone counselling. Of these, by far the greatest number of calls are to do with overall emotional health. We have also seen a rise in the number of people accessing the helpline to speak to our information specialists, most frequently to discuss benefits, finances, housing and a range of legal issues.

Overall, however, the increase in calls hasn’t perhaps been as steep as you might expect, and I think there are two reasons for this.

Firstly, people assume that their problem or worry isn’t significant enough to warrant a call to the helpline. What I would say to those people is the helpline is there for everyone and every problem, no matter what that might be.

Secondly, because the industry we support is so broad, diverse and fragmented, we know that there are people working in print who simply don’t know that our helpline is there for them, or don’t realise that they are eligible. We’re working hard to build our network and, through a range of channels, reach those who don’t yet know that our help is out there, for them.

I’d expect the charity to be hearing from those having lost their jobs and needing financial assistance, but in-work poverty is something we hear more about nowadays. This sector provides good salaries all told, but is the charity hearing from more employed people struggling? Our overall feeling here is that we are still not hearing enough from those who are in work and struggling. Despite increasingly challenging circumstances, we don’t feel this has changed.

If we do hear from somebody who’s employed, one of the first things they tend to say to us is that they’re never reached out for any kind of help in this way before. They find it a very uncomfortable position to be in. Many people may not even realise that they can apply to us for support if they’re in workthose people that will pick up the phone and talk to us about how we may be able to help when they’re working are few and far between.

But simply looking at the practicalities, many families are likely to be struggling, and may well be eligible for help from us, particularly in cases where there is only one income, but we are simply not seeing people in this group enquiring.

I would encourage anyone who thinks that they need support, whether practical, emotional or financial, whatever their personal circumstances, to get in touch with our team and talk it through. As well as the support we ourselves can provide, our team are also able to signpost to other organisations who can provide specialist help, whether that’s expert advice for particular problems, or other avenues for potential financial support.

Can you provide some kind of overview as to what kind of financial support packages the charity can provide?

The financial support we offer falls under two broad areashelp with something specific which is simply unaffordable, and also help for people struggling to afford essential living costs.

Joseph Rowntree Foundation data shows that around 60% of low-income households are not able to afford an unexpected expense, while around a quarter are using credit to pay essential bills, too.

Against this backdrop, the trigger we often see for someone contacting us to discuss financial support is the shock of an unexpected expense. Then, in conversation, our team learn more about other areas of need which the person may not have made contact with us about, because they didn’t feel it was sufficient to warrant making that contact. What we want to encourage people to do is to talk to us whenever they feel they are struggling, not just when they can attribute these problems to something specific.

You offer a wide-range of services in-house, and act as a conduit to other professional bodies. Where are you currently seeing most demand, and is there any discernible pattern?

What we see at the charity is reflected across the UK as a whole at the moment. People are being squeezed from every

side. Since Covid, we’ve seen a rise in people contacting us to discuss debt, and this situation continues. We have certainly seen an increase in people using credit cards for day-to-day spending.

We’ve also seen a rise in financial problems caused by gambling. This isn’t the reason people initially contact us, but something we identify during our financial assessment process.

As well as providing support ourselves, we signpost to the spectrum of excellent specialist support resources out there. There is a page on our website dedicated to this signposting, and when people contact us our team will take the time to find out exactly what is needed, and signpost to these organisations accordingly.

The charity recently flagged-up vacancies within its almshouses for those retired from a career in print and the allied trades. I would have thought they would be snapped up, but perhaps those on the cusp of retiring need to be reminded of the applications criteria...

During Covid we paused promotion of our retirement schemes, so awareness inevitably dropped. We’re now rebuilding our pipeline of eligible people considering moving into our apartments, either at the present time or in the near future. To be eligible, people must be of retirement age; retired from the print, packaging, paper, publishing or graphics sectors; of reduced financial means; and able to live independently.

The friendly, community-focused almshouse developments are located in Basildon and Bletchley, and we have vacancies at both. The one-bedroom apartments are on either the ground or first floor, with a terrace or a Juliet balcony respectively. They’re in great locations for public transport and local amenities, and while they are for independent living, support is on hand when needed through our small, friendly onsite team and an out-of-hours community alarm service. Our on-site teams run plenty of activities for residents to join in with if and when they choose, and the community focus helps anyone moving in to make new friends.

We know there is a need for our homes, not least because the Joseph Rowntree Foundation found that 15% of pensioners are living in poverty, and because in 2017 the Local Government Association predicted that the scale of elderly homelessness is set to double by 2025.

Recent research shows that almshouse housing can help to resolve this crisis, as it is specifically available for people

who are of retirement age and reduced financial means. Not only do almshouses provide secure, quality accommodation, they also help boost residents’ life expectancy due to their unique spirit of friendship and community. Researchers at Bayes Business School found that living in an almshouse can boost residents’ longevity by as much as two and a half years compared to that of their counterparts in the general population.

Affordable rental properties in both our homes’ locations are few and far between, and we are keen for anyone who could be eligible to know about the opportunity to move into one of our developments.

What would you say to someone struggling to manage but reticent about calling the charity for help?

We know it can be really hard at times to talk about issues, whether practical, emotional or financial, but it does help to share what’s on your mind with someone who is there to listen. That’s where our helpline, and the charity’s own welfare team, come into their own. Taking that first step to make a call or look online at how you can get help, is such a positive move, and there can be a real sense of relief that comes as a result of that decision.

Our helpline is available to everyone working in the print, paper, packaging, publishing or graphics sectors. It provides in-the-moment practical, emotional and financial support from BACP-accredited counsellors 24 hours a day, seven days a week; and Citizens Advice-trained information and advice specialists Monday-Friday, 8am- 8pm.

Our strategy for rolling out the helpline is to work with businesses to help them share information about it directly with their employees. We provide all the required information for launch, and on an ongoing basis.

Our goal is to build close, long-term partnerships with businesses using the helpline, so we can make sure the helpline is having the impact that each particular business needs it to.

By working in this way, we can be there when people need support, and we can also share details of the charity’s other initiatives with them so that more people working in our sectors can more easily benefit from everything we have to offer.

We say that we may not always know when people need our help, but we want to be there when they do, and by proactively sharing information about our helpline and other services, we can do our best to achieve this.

OUR STRATEGY FOR ROLLING OUT THE HELPLINE IS TO WORK WITH BUSINESSES TO HELP THEM SHARE INFORMATION ABOUT IT DIRECTLY WITH THEIR EMPLOYEES

Scott Anthony - an influential management theorist who points out that the rate at which industry leaders are toppled from their perch has doubled in a generation - expects threequarters of the 500 largest publicly quoted companies in America to be replaced by new businesses between now and 2040. The old aphorism that if Uncle Sam sneezes, the rest of the world gets a cold isn’t quite as true as it used to be, but the scale of disruption is likely to affect the larger companies that buy wide-format print, so get ready.

MANY A PRINT COMPANY HAS CHANGED THEIR BUSINESS OVER THE LAST COUPLE OF YEARS. DO YOU WANT TO TRANSFORM YOURS? IF YOU DON’T, YOU PROBABLY SHOULD, GIVEN A WARNING OF LARGE SCALE DISRUPTION OF YOUR CUSTOMER-BASE. HERE’S SOME ADVICE YOU MAY WANT TO CONSIDER…

Not all business transformations are the same. When managers use the term, it can mean one of three things: doing what you already do - but better; doing what you do now in a completely different way (the classic example being Netflix moving from DVD rental to streaming); or being transformational - the most risky but if you get it right (like Apple, pivoting from computers to consumer electronics) also the most rewarding.

Relatively few wide-format PSPs will want to strategically transform their business. Many, after all, retain a sentimental attachment to the print process. And yet Apple still sells computers although it makes most of its profit from iPhones. Maybe industry leaders should ask themselves whether they could broaden their base by offering different services. The obvious difficulty here is that buyers are hardwired to pigeonhole their suppliers and printers may find it hard to move up the food chain. That said, the effort may be worthwhile in the long run.

Let’s be brutally honest, a large-scale, Apple-type, transformation will not happen overnight. Depending on your particular circumstances, you may feel that it makes more sense to be less ambitious. And, if you are contemplating selling the business in the next five years, you’re probably right.

There is a knee-jerk drive to do as much as possible as quickly as possible which, however appealing, all but incentivises people to cut corners. At the other extreme, don’t dilly dally. A three-to-five year transformation plan is likely to lose momentum. As one consultant put it: “The trouble with five-yeartransformations is that, probably around halfway through the process, your managers will be sitting around saying: ‘I can’t believe we have two more years of this to go through.’”

One of the biggest causes of unsuccessful change management projects is a disconnect between what the board thinks needs fixing, and what staff think. (Let alone what customers and suppliers might think.) Every employee will have the same three questions about any transformation: what does it mean to me?, what do I need to stop doing? and what do I need to start doing? If you can answer those concerns, you are better placed to prosper.

Change is seldom easy but that doesn’t mean it’s not worthwhile. As the great American management thinker Rosabeth Moss Kanter said once: “Everything looks like failure in the middle.” And remember, there really is no such thing as a ‘seamless transition’. As you press on, it’s worth remembering that, as JFK’s younger brother Bobby said once, “One fifth of the people are against everything all of the time.”

Yup, it is a cliche, but one frequent mistake managing directors make is to focus entirely on their own sector. There may well be lessons you can learn from companies in other industries - for example about cashflows - that could enhance your bottom line. And, if we are honest, who of us is so brilliant that we couldn’t learn something from, for example, reading Walter Isaacson’s absorbing biography of Steve Jobs? Less fashionable, but just as useful, is David Halberstam’s The Reckoning, a definitive account of how America lost the car industry to the Japanese through short-termism, arrogance and a salami-slicing budgeting process.

One of the cardinal vices of British management is to overestimate how much impact a modest spend can have. A common mistake is to invest in improving a product, service, or even a corporate rebrand and not invest adequately to communicate this change. The world is not as interested in your company as you may think. Given we live in a time of ever-diminishing attention span - a trend accelerated by the rise of Tiktok - what is the point of transforming your business if nobody notices?

Nothing stifles transformations quite as frequently as the shop floor perception that nothing is changing. Don’t forget to share - and publicisesuccesses, even in an oblique way (e.g. putting the spotlight on someone who has done something exceptional). At the end of the day, people want to be on a winning team - and to know their efforts have been noticed.

Many experts warn that seven out of ten business transformation programmes fail. That’s not as stark a statistic as it sounds because, as with the T word itself, there are many different definitions of failure. It can be as minor as starting out with seven goals and only achieving five of them or as major as realising that your entire programme is fundamentally flawed. Often, programmes land somewhere between those extremes. Often, the real failure is not about outcomes but inflated expectations at the very start. It’s not so much as being careful about what you wish for, it’s a matter of knowing what you wish, why, and whether those wishes are commensurate with the resources you’re investing.

The first question you need to ask, before you begin the whole process, is: what does success look like? It could be as straightforward as growing turnover or something a bit more ambiguous, like repositioning the business. Your definition of success will, almost inevitably, evolve along the way - which is fine as long as you don’t forget what you were trying to achieve in the first place.

Your transformation programme should be periodically reviewed, reappraised and, if necessary, redefined. And at some point, you need to claim victory. That doesn’t mean falling back into complacency but giving people the space to regroup and yourself time to judge whether the changes you have made are creating value for the business.

Acuity Prime printers feature a multi-award winning design that delivers a unique combination of quality, productivity and ease of use. With industrial build quality and up to seven ink channels plus primer, you can produce a wide range of superb, saleable print at higher speeds than machines costing much more. And now, the new larger bed Acuity Prime L boosts productivity and profits even further, offering even more value.

Discover the new blueprint for wide format.

THERE

A KNEE-JERK DRIVE TO DO AS MUCH AS POSSIBLE AS QUICKLY AS POSSIBLE WHICH, HOWEVER APPEALING, ALL BUT INCENTIVISES PEOPLE TO CUT CORNERS

The high-performance, cost-effective wide format printers with a sustainable edge.

The high-performance, cost-effective wide format printers with a sustainable edge.

…BUT WHERE WILL IT LEAVE YOUR COMPANY WHEN IT DOES? THAT’S THE QUESTION BEING ASKED BY ECOPRINT FOUNDER MARCUS TIMSON FOLLOWING THE DECISION TO SCRUB THE PHYSICAL EVENT THIS SUMMER AND TURN IT INTO A VIRTUAL ONE ON 11-12 OCTOBER.

“The print and sign industry is slow to adopt sustainability. We are behind other industries because the culture of the sector is conservative, we operate in short time cycles, we are risk averse, and not futurefocused.” So says FM Future’s Marcus Timson, adding: “These may seem like harsh words, but that is my opinion. It could be that change will only take place on a large scale with the environment when we are forced by law or by customer demand. With economic uncertainty, rising energy prices, inflation and interest rates, this is further compounding a lack of action concerning the environment. While it is understandable that business owners are prioritising short term survival, neglecting sustainability is ignoring a significant megatrend that will eventually impact everything.

“The current economic crisis will not last forever. When talking to a friend recently he made the point that ‘this storm will pass’, because all storms do. Wars end, energy prices will reduce, inflation and interest rates will stabilise and positivity will return. Sure, we may be in a period of permacrisis, but we cannot control this. So instead of over-worrying, try something counterintuitive for a change. Adopting a sustainable strategy is a great way of taking back control and preparing for the future. Merely offering an FSC paper is not enough - a strategic investment in sustainability is necessary. Scope 3 is a looming reality. Brands must ensure that their supply chains align, failure to do so can result in loss of business. The need to be sustainable is undeniable. Playing catch-up will be incredibly stressful. Yet still, intransigence is what I see.

“In the past few months, I have spoken to some pioneering leaders in sustainability, who are sadly in the minority. What unites these people is that they are committed to sustainability emotionally. They believe it is the right thing to do, believe it is essential and consider it a journey. Rick Bellamy at DScoop said that often, we over-focus on the destination (e.g. which could be Net Zero by 2030) when this may be too distant to encourage action. Just starting the journey is the main thing.

“Once committed, these pioneers are open to learning, and are humble. They have created a plan with goals, done their research and have just begun. They say it is essential to be transparent as opposed to secretive and

that there is always room for improvement. And there is nothing more disarming than honesty, vulnerability and openness.

“Unfortunately, feedback from the industry about sustainability has been ‘we will do something when we have to’, which points to a resistance to change and, because they cannot see an immediate benefit, they do not change. This underlines the herd mentality of the print sector.

“New ideas, innovations and trends will take time to gain acceptance in the ‘traditional’ print community. Even though we had run EcoPrint in 2012, in 2023, we discovered sustainability in print - despite it gaining traction among brands and retailers - had not moved on that much at all. While there are some notable exceptions, namely the people I mentioned earlier in this piece, these are the sustainable pioneers, the outliers. Doing great things on their own but doing so while existing well outside the mainstream.

“Geoffrey Moore’s book ‘Crossing the Chasm’ emphasises the need for guaranteed positive impact to drive mainstream change. Apart from Imageco in Leeds there are few other businesses playing a leading role in helping the industry by openly sharing their success, their honest journeys, including both the wins and the losses.

“I know that the motivation for change for Nathan [Swinson Bullough] at Imageco was watching David Attenborough’s Blue Planet and seeing how so much plastic ended up in our oceans, damaging the precious ecosystems and wildlife habitation. It is a philosophy in which he and his people are emotionally, and commercially invested. Blue Planet triggered a change in him, and consequently, he embarked on a sustainable journey, and this has paid off for the business.

“To be sustainable is to be efficient and modern. And as any expert will tell you, reducing the use of resources is the most effective way to impact the planet, people and your profit.

“It is frustrating to concede that the print and sign industries are still lagging well behind the curve when it comes to sustainability. It could be that the introduction of legislation and regulation is what it will take to make a big impact. But those who make the change now will be futureproofing their business.

THE NEED TO BE SUSTAINABLE IS UNDENIABLE. PLAYING CATCH-UP WILL BE INCREDIBLY STRESSFUL.

YET STILL, INTRANSIGENCE IS WHAT I SEE

A REVOLUTION IN FABRIC DISPLAYS WITHOUT STITCHED FINISHING COMPATIBLE WITH ALL PRINTING TECHNOLOGIES

OCTANORM SYSTEM

EXHIBITION STANDS

A TRIED AND TESTED SOLUTION FOR STRETCHING AND TENSIONING ALL TYPES OF BANNER AND FLEXFACE

MUSEUM INSTALLATIONS

RETAIL DISPLAYS

IMAGECO VISUAL IMAGING MD NATHAN SWINSON BULLOUGH TALKS US THROUGH THE ECO THINKING BEHIND THE COMPANY’S NEW EXHIBITIONSTAND-IN-A-BOX OFFERING.

Exhibitions are pretty up there when it comes to wideformat print markets - but they’re pretty way down there when it comes to their eco credientials. So Imageco Visual Imaging is doing something about it as MD Nathan Swinson Bullough explains.

“Last year while lugging our latest cardboard creation through the halls of a trade show, the Imageco team and I started to think about all the waste that goes into exhibition stands. After a quick Google with my right hand while my left balanced a human-sized cardboard detergent bottle, I learnt that tradeshows are estimated to generate a whopping 600,000 tons of waste each year. Even if a venue has good compost and waste facilities, a mid-size trade show will still send an average of 41% of its rubbish straight to landfill. As someone who cares about the environment and has centred their business around sustainability, these figures didn’t sit right with me. Hence, the newest innovation at Imageco, ExhiBox, was born.

“ExhiBox is, essentially, an exhibition-stand-in-a-box. Importantly, it is 100% recyclable, made from Xanita Board, an ultra-lightweight sustainable fibre board with a repulpable inner core. We also use no adhesive in any of the designs, instead opting for magnets, meaning that ExhiBox is designed so that each wall can be reskinned with a new graphic whenever the client needs it and then recycled when it’s no longer being used.

“Flexibility was incredibly important to us while creating the ExhiBox design, as we had noticed a distinct change in our smaller-scale client’s budget over the past few years since the pandemic. After speaking to our customers, we knew we needed to provide a budgetfriendly solution that would also produce less waste than traditional bespoke event stands.

“Featuring foldable walls that collapse to fit into a carry case, ExhiBox can easily fit into a medium-sized van and be assembled by one person. Once at the destination,

that one person can use our easy-to-follow video tutorials to install the stand, giving smaller businesses the opportunity to attend trade shows at a time when getting their brand out in front of others is essential.