Delivering Reliable Power Protection and Backup Power Efficiently

Delivering Reliable Power Protection and Backup Power Efficiently

Could AI be the key to supercharging our energy efficiency efforts? Tim Ballard from Finning UK & Ireland explores more.

The private sector should lead the way when it comes to rolling out the UK’s EV charging infrastructure, argues Asif Ghafoor, CEO of Be.EV. 16

Tania Saxby, Head of Sustainability at Connected Energy, explores how we can make EV batteries even more sustainable by giving them a new lease of life.

Data centres are often criticised for their burden on the power grid, but Billy Durie from Aggreko has practical guidance on how data centres can bridge the growing energy gap.

Phil Thompson, CEO of Balance Power, explores how behind-the-meter generation can help businesses decarbonise quickly and efficiently.

Welcome to the 2024 Sustainability Issue from Electrical Review. This is our third and final issue of the year, but it’s one full of insightful discussions into the sustainable world that could be in our future.

Before you dive in, let’s be honest – many of us are eager to live in a more sustainable world right now, especially as the impacts of climate change become increasingly evident, but change takes time. That’s why it’s important to highlight the positives and celebrate the progress we’ve made.

The first milestone worth celebrating is the imminent closure of the UK’s final coal power plant. The Ratcliffe-on-Soar Power Station, operational since January 1968, is set to cease operations by October 2024. This marks the end of an era and the rise of cleaner energy sources – be it renewables, nuclear, or even natural gas – as the sole contributors to the UK’s electricity generation.

Considering the UK was the first country to build a coal-fired power station for electricity, this transition underscores a significant shift. Natural gas, which initially helped us move away from coal, is also seeing a decline. Gas generation has returned to 2012 levels after peaking in 2015 and 2016, signalling a continued commitment to reducing carbon emissions.

Progress isn’t limited to how we generate energy, however – it’s also about how efficiently we use it. While I have previously criticised the often nonsensical policies of the UK Government, I must praise its recent initiatives, which have led to energy efficiency upgrades in millions of homes. Up to the end of July 2024, around four million energy efficiency measures have been installed in approximately 2.5 million homes under the Energy Company Obligation. Additionally, the Green Deal has facilitated 13,867 financial packages for home energy improvements.

This is a significant step forward, especially since, in 2023, our housing stock was among the most energy-inefficient in Europe. Using energy more efficiently is key to our sustainable future, and so it’s encouraging to see real progress towards addressing this.

But these milestones are just glimpses of the broader efforts underway to create a sustainable future. In this issue, you’ll discover many more exciting developments and innovations driving us toward that goal. Let’s continue to build on this momentum and embrace the sustainable changes shaping our world.

Jordan O’Brien, Editor

EDITOR

Jordan O’Brien

jordano@sjpbusinessmedia.com

CONTRIBUTING EDITOR

Kayleigh Hutchins

kayleigh@datacentrereview.com

DESIGN & PRODUCTION

Rob Castles

robc@sjpbusinessmedia.com

GROUP ACCOUNT DIRECTOR

+44 (0) 207 062 2539 sunnyn@sjpbusinessmedia.com

BUSINESS DEVELOPMENT MANAGER

Tom Packham

+44 (0)7741 911 317 tomp@sjpbusinessmedia.com

GROUP COMMERCIAL DIRECTOR

Fidi Neophytou

+44 (0) 7741 911302 fidin@sjpbusinessmedia.com

PUBLISHER

Paid subscription enquiries: subscriptions@sjpbusinessmedia.com

SJP Business Media

Room 2.13, 27 Clements Lane London, EC4N 7AE

Electrical Review is a controlled circulation monthly magazine available free to selected personnel at the publisher’s discretion. If you wish to apply for regular free copies then please visit: www.electricalreview.co.uk/register

Electrical Review is published by

Industry-leading b2b technology brands

Room 4.13, 27 Clements Lane London, EC4N 7AE

Any article in this journal represents the opinions of the author. This does not necessarily reflect the views of Electrical Review or its publisher – SJP Business Media

ISSN 0013-4384 – All editorial contents © SJP Business Media

POWERSAFE® SBS XL 320-3900 BATTERIES

At EnerSys we recognize that increasing battery replacement intervals is a key step toward improving Total Cost of Ownership! Across Industrial and Utility segments, the need for longer life and greater energy density is driving the natural battery selection process. Discover how our Thin Plate Pure Lead technology for stable grid float applications has evolved to render the conventional extinct.

We’re Powering the Connected World.

In this case study, Simmtronic explores how it integrated smart technology into its manufacturing site and boosted its energy efficiency.

In recent years, companies are increasingly looking at retrofitting their existing facilities to enhance energy efficiency and integrate smart building technologies. Simmtronic, a leader in lighting control systems and smart building infrastructure, recently undertook a major refurbishment of its manufacturing site in Hoddesdon. This project has proven to be a resounding success, transforming the building into a modern, energy-efficient smart facility while maintaining day-to-day operations.

The primary goal behind the refurbishment

was to modernise Simmtronic’s headquarters and manufacturing site by creating a smart building that would not only improve the work environment but also significantly reduce energy consumption.

By implementing a comprehensive smart infrastructure, the company aimed to achieve long-term savings and contribute to sustainability efforts. Simmtronic sought to create a space that optimised energy use, reduced operational costs, and improved workplace conditions – all while showcasing the possibilities of the very technology it develops and supplies.

This project demonstrates that retrofitting

existing buildings can be a cost-effective solution for companies looking to modernise while reducing their environmental footprint.

The centrepiece of the retrofit was the creation of a digital twin – a real-time, virtual representation of the physical building, powered by a web of sensors and automated systems.

By installing Simmtronic’s SPQ.7 environmental sensors, the building now continuously monitors key factors including CO2 levels, humidity, temperature, and even volatile organic compounds (VOCs).

These sensors feed real-time data into the Building Management System (BMS), enabling automatic adjustments to optimise air quality, lighting, and energy consumption based on occupancy and environmental conditions.

One of the most exciting integrations was the Mechanical Ventilation with Heat Recovery (MVHR) system, which responds dynamically to indoor air quality metrics. When CO2 levels rise in an area, the system increases fresh air intake, ensuring optimal air quality without excessive energy use. This precision-driven approach ensures that energy is only used when and where it’s needed, dramatically reducing waste and wear on equipment.

The building’s smart lighting system further enhances its energy efficiency. Simmtronic’s occupancy sensors automatically switch off lights in unused areas, and daylight linking technology adjusts artificial lighting based on natural sunlight. This integration significantly cuts energy consumption while maintaining a bright, comfortable environment.

Perhaps one of the most impressive features is the integration of smart access control using HID readers, which allows employees to enter the building with a tap of their mobile phone via Apple Wallet. This system not only enhances security but also reduces the need for plastic ID cards, aligning with the project’s sustainability goals. The building’s smart infrastructure even controls corridor lighting based on entry points, adding another layer of energy efficiency.

Like any ambitious project, the Simmtronic retrofit faced its share of challenges. One of the most significant was the inevitable scope creep – the expansion of the project’s objectives as new ideas and opportunities emerged.

Initially, the plan was to reuse much of the existing equipment. However, as the team saw the potential of modernising more deeply, they chose to upgrade and replace more systems than originally planned. This allowed for even greater efficiency and better integration, but it also required careful management to maintain the project’s momentum while the building remained operational.

Retrofitting a facility while keeping it operational is a significant challenge, but it was made possible through a collaborative effort. From the start, Simmtronic’s team of engineers, consultants, and contractors worked together

to address the technical issues that arose.

One major challenge was integrating systems from different manufacturers, especially since the HVAC units were installed at different times and operated on various protocols. Fortunately, modern units reduce these inconsistencies.

The advantage of having isolated systems means that if one outdoor condenser fails, only a specific area is affected, allowing the rest of the building to stay fully functional. This is a crucial benefit. Despite these challenges, the team embraced the opportunity to streamline systems and ensure seamless communication between the different technologies.

As one engineer put it, “We were building the plane while flying it.” Even with the complexities, this adaptive, forward-thinking approach allowed the team to innovate as they went, ultimately creating a smarter and more efficient building than originally planned.

The results from the refurbishment have been impressive. The real-time data generated from the various sensors and control systems have already led to an approximate 15-20% reduction in energy consumption, a figure that could increase further during the winter months. This reduction has been achieved primarily by optimising plant and lighting systems, including the use of daylight linking to minimise artificial lighting in areas that receive natural sunlight.

Additionally, Simmtronic has noticed a significant improvement in workplace conditions for both office and manufacturing staff. Improved air quality, personalised lighting, and optimised workflows have resulted in a more comfortable and productive environment. This demonstrates that smart building retrofits can deliver tangible benefits beyond just energy savings.

In retrospect, there are several areas where Simmtronic acknowledges that the project could have been more efficient. One of the key lessons learned is the potential benefits of gutting the entire building from the start rather than opting for a phased retrofit. This would have allowed for a more streamlined integration of systems and could have reduced

the overall cost and complexity of the project, though it would have prevented or at least disturbed day-to-day operations.

Furthermore, the company realised that integrating fewer but more efficient systems would have been beneficial. Instead of having 20 different condensers scattered across the building, the entire facility could likely have run off just four condensers, simplifying the system and reducing maintenance costs.

This project showcases the advantages of retrofitting older buildings with modern smart technologies. Not only does it lead to substantial energy savings, but it also creates a more efficient, comfortable, and future-proof environment for occupants.

By implementing smart sensors, lighting controls, and building management systems, companies can drastically reduce their energy consumption and carbon footprint while improving the quality of the workspace.

The lessons learned from Simmtronic’s retrofit demonstrate the importance of flexibility and collaboration in large-scale projects. While scope creep and technical challenges can complicate matters, the results clearly show that the benefits far outweigh the difficulties. Retrofitting is not just a technological upgrade but a sound financial decision, offering long-term savings and a more sustainable way to operate buildings.

As Simmtronic continues to monitor the performance of its refurbished site, they are already looking at future innovations such as energy storage systems and solar panels to drive energy costs even lower. With a commitment to sustainability and smart technology, Simmtronic is leading the way in showing how retrofitting can turn older facilities into high-performing, energy-efficient buildings of the future.

The latest addition to the technologically advanced 30 0 0 Series, the Ei3030 combines individual Optical, Heat and CO sensors for the ultimate fire and CO response, while maintaining the simplicity that Installers love.

Smart, connected and future-proof.

Scan here to learn more about the Ei3030

Add the Ei3000MRF for wireless interconnection and data extraction via the Ei1000G Gateway

The UK is harnessing the power of artificial intelligence (AI) to supercharge clean energy. With rapid advancements in AI technology, the potential to scale up clean energy solutions has never been more promising. The UK government is leading the charge with its ambitious £1.73 million Artificial Intelligence for Decarbonisation Innovation Programme.

The role of AI in energy

AI is poised to bring enormous value to the energy sector, particularly through its ability to provide sophisticated real-time analysis far beyond human capabilities.

By creating the right algorithms and supplying them to AI, we can analyse vast amounts of energy consumption data in real-time, identifying system and operational inefficiencies that might otherwise go unnoticed. This data can help reduce waste across sectors, from industrial design to home appliances, promoting energy efficiency.

On a domestic level, AI-powered energy management systems can automatically adjust heating, ventilation, and air conditioning, delivering significant energy savings without sacrificing comfort at home.

On a larger scale, AI’s role in the clean energy transition includes facilitating the integration of renewable energy sources into the grid.

The intermittent nature of solar and wind power has traditionally posed challenges for grid operators, but AI can help overcome these hurdles. By analysing weather patterns, historical renewable energy generation data, and other relevant variables, AI algorithms can accurately forecast renewable energy production.

This predictive capability allows grid operators to better plan for and

manage the integration of clean energy sources into the overall energy mix. With AI’s assistance, the world can more effectively utilise the power of renewables.

Given the growing mix of renewable energy sources and decentralised generation, maintaining grid stability is more crucial than ever. AI has the potential to enhance grid management by predicting demand fluctuations, identifying potential failures, and optimising the distribution of energy resources.

By analysing real-time data from smart meters, sensors, and other IoT devices, AI can help grid operators make informed decisions to balance supply and demand, prevent outages, and ensure a reliable energy supply. AI can also optimise the charging and discharging cycles of energy storage systems, such as batteries, to maximise their efficiency and further stabilise the grid.

While the potential benefits of AI in the clean energy transition are clear, several barriers need to be addressed to enable widespread adoption. High-quality data is key; without it, algorithms cannot be trained correctly, rendering them unreliable and unusable.

Data privacy and security concerns must also be addressed to facilitate secure data sharing among stakeholders. Transparency and accountability are crucial here.

Additionally, operability and compatibility between different components and systems can be complex, requiring significant upfront investments in infrastructure upgrades and software development. However, with the right approach and strategic investments, these challenges can be overcome, paving the way for AI to play a pivotal role in the journey to net zero.

AI, while still being understood and developed further, offers transformative potential in accelerating the transition to a cleaner, smarter energy future. By leveraging AI’s capabilities, we can enhance energy efficiency, integrate renewable energy sources more effectively, and ensure a stable and reliable energy supply.

The UK’s commitment to AI-driven decarbonisation is a promising step towards a sustainable future. The future is bright, green, and powered by AI.

Recolight is the leading UK WEEE compliance scheme for lighting, taking on responsibility for its members’ WEEE compliance. O ering free integrated Lamp and Luminaire collection and recycling and the biggest UK-wide network of collection points for all WEEE lighting.

Recolight go beyond recycling, by o ering circular economy services, facilitating the reuse of lighting equipment, and helping to avoid unnecessary recycling of surplus new lighting.

Working with the lighting industry, Recolight o er support and services to help their Producer Members transition to a Circular Economy.

Charlotte Enright, Head of Renewables at Anglo Scottish Finance, explores how AI is being used – and could continue to be used –in helping us achieve our climate ambitions.

Recent reports suggest that, though public support for the UK’s net zero targets has recently seen a huge uptick, the country remains off-track for its 2030 target of reducing carbon emissions by 68% compared to 1990 levels.

Professor Piers Forster, Interim Chair of the Climate Change committee, has noted that Keir Starmer’s new government “has the opportunity to course-correct, but it will need to be done as a matter of urgency to make up for lost time.”

Investment in new, more efficient technology is one of the most important ways that the Labour Government can continue accelerating the renewables revolution and AI has found itself at the forefront of that quest.

Predicting energy demand peaks and troughs

If you’re anything like me, you’ll often pop the kettle on for a cuppa during an ad break when watching terrestrial TV – and even while streaming, thanks to the introduction of ads on popular streaming services.

It’s well-known that this has placed strain on the power grid in the past, but now thanks to AI, we can predict more than just a quick cuppa break when we’re waiting for Coronation Street to come back on.

By analysing vast swathes of power usage data, AI can help the power grid manage demand better by understanding when we’re using energy the most. That same principle applies to renewable energy too: these AIpowered systems can understand when renewable energy is available and when it’s required.

This also makes integrating renewable energy into the grid easier. Predicting wind power can help us to understand how much energy can be collected by turbines, which can in turn forecast how much of it will be available to the grid.

Karen Panetta, an Institute of Electrical and Electronics Engineers’ fellow, recently told me, “[AI is used to] correlate trends and do better forecasting. AI can allow us to explore relationships and look at ways to mitigate failures in the grid and understand how to re-distribute energy in the most efficient ways.”

Keeping energy generators up and running

Renewable energy generators, like wind turbines and solar panels, are not immune from wear and tear and the need for maintenance. But rather than waiting for a fault to occur to fix generators, businesses are using AI for predictive maintenance.

This involves using sensors placed on the generators, which will analyse data and predict when it’ll need maintenance performed. Considering how many of these generators – particularly wind turbines –are placed in remote locations, this allows for the strategic scheduling of maintenance to minimise downtime.

As well as predicting the maintenance of generators like wind turbines, AI can also be harnessed to monitor temperature and identify hot spots on large-scale solar panels, which can indicate malfunctioning cells. Maintenance can be performed on the panels, but in the meantime, they can be re-angled to optimise the power captured.

Another of AI’s many renewable applications lies in its ability to predict –and then simulate – future weather conditions.

Renewable energy will always be available in the sense that there will always be sun, wind, organic material and rain. The unpredictability comes in that it’s not always sunny, rainy or windy – and too much or a lack of these conditions can then affect organic materials like the growth of grass and plants.

Intelligent weather simulators are being used to predict future weather conditions, giving us insight into our future energy capture potential. But these tools are used in a way that far outstrips simple weather reports; one simulator shows how the layout of a city can impact airflow.

This means that architects can support the future of renewable energy by using this insight to design buildings and cities that work with the weather and renewable energy sources, not against them.

The production of renewable energy supports the fight against climate change, so it must be fully sustainable, right? Well, not necessarily.

Many renewable energy generators are made from rare earth metals, using valuable and limited resources. As well as the materials themselves, the process of manufacturing these generators can be highly energy-intensive.

AI is being used to speed up trials of new materials and their performance, meaning thousands of manual tests can be condensed into a more manageable number. What’s more, AI can support in making sure that these generators are recyclable once they reach their end of life, a key tenet of sustainability.

The renewable energy sector is one of many that is benefitting from the transformative effects of AI. From ensuring generator uptime is maximised to predicting energy demand and adapting accordingly, we’re seeing this smart technology improve our generation and usage of renewable energy. And considering the importance of the fight against climate change, this may be one of its most important uses to date.

Asif Ghafoor, CEO of Be.EV, argues that the Government should let the private sector lead the way in rolling out the UK’s EV charging infrastructure.

It’s an exciting time to be in the EV charging business. There are over 1.1 million EVs on the road, and with the ban on sales of new ICE vehicles set to be brought back to 2030, this number is set to grow at an increasing pace.

While building the EV charging infrastructure for the UK’s EV community is an exciting venture, it does come with its challenges. One of the main hurdles is ensuring we have the power needed to make it happen.

We’re all familiar with the difficulties of the National Grid. It will form the backbone of our net zero transition, yet was built in the 1930s. It’s not an endless well from which we can draw electricity – we need to be clever about how we’re going to give each green sector the power it needs.

Unfortunately, the previous Government’s roll-out of the public EV charging infrastructure hadn’t been clever. Its policies have led to an inefficient and uneven charging network.

Fortunately, even with these challenges, there are still many of us in the industry who know how to navigate these boundaries and provide the infrastructure our EV community truly deserves. It’s really quite simple –if the new government can just listen and take a step back, we can make great things happen together.

Think about where you’re putting chargers

There’s enough power to reach the target of 300,000 EV chargers by 2030, but that doesn’t mean we can put chargers anywhere. If I had a pound for

every time someone made plans to install chargers in an area that didn’t have enough power, I’d probably have enough money to build 300,000 EV chargers myself.

Installing chargers in places with enough power is essential, and providers need to make sure they’re using reputable charging networks who will make sure this is the case before installing anything.

In more rural areas where there are EV drivers, but not enough power, there should be Government subsidies to help charging networks install the necessary power to give clusters of villages charging hubs.

This doesn’t mean Labour should be the ones delivering these chargers though, because as we will see, the previous government’s strategy of leading the roll-out hasn’t gone to plan so far.

Scrap lamppost chargers

The Conservative Government’s main policy to install EV charging infrastructure was through Local Electric Vehicle Investment (LEVI) funding, which gives local authorities grants to install chargers.

It’s a good idea in theory, but the policy doesn’t give them any guidance on what to do with the money. What inevitably happens is that councils take the quick and easy option of installing ‘fast’ lamppost chargers, given they’re cheaper to install.

Installing lots of these chargers generates headlines, but it’s shortsighted. Despite what the name suggests, these chargers are very slow, resulting in one person taking up the charger for hours at a time.

More importantly, as vehicle batteries evolve, these chargers will need to be replaced as EVs will become too advanced for them. We need to be far more judicious with our precious power supply than using it up on street clutter.

Instead, we need to build community hubs of rapid and ultra-rapid chargers where drivers can get up to 80% charge in as little as half an hour. This not only gives us chargers that will last for decades, but also allows EV drivers to conveniently incorporate a quick charge into their daily routine.

Another misguided policy from the last Government comes in the form of the Rapid Charging Fund (RCF). This contains a commitment of £70 million to install ultra-rapid EV charge points at motorways.

It’s good to see the Conservatives recognised the need for ultra-rapid charging, but as with lots of other policies it has failed to take power supply into account.

The National Grid is not well-connected enough to give all motorways the power they need for the nation’s EV drivers. And even if there was, there isn’t even enough physical space at motorway service stations to match current or future demand for EV chargers.

Labour needs to be less rigid than the Conservatives were and realise that motorways aren’t the answer – this sort of logic dates back to the 1950s and the world is very different to how it was then.

We should turn our attention to the convenient en-route and easy stop-off areas surrounding our motorway junctions. There is plenty of unused land here that is well-connected enough to the National Grid to have EV charging.

Landowners can take advantage of the need for EV charging by leasing this land for chargers and taking a share of the charging revenue. This way, we can get more ultra-rapid hubs that serve local communities while avoiding National Grid headaches.

“ The National Grid is not well-connected enough to give all motorways the power they need for the nation’s EV drivers

The National Grid does make EV charging a bit trickier than we would like, but it’s nowhere near as difficult as you might think. Charging networks are typically well-acquainted with the challenges of getting power to chargers and we know how to get around the problem.

The problem is that the roll-out is being led by a Government that has a million other problems to deal with. EV charging might not be top of the agenda, but that doesn’t mean we can’t make progress. All the Government needs to do is get out of the way and let the private sector get on with it.

At the end of the day, we all want the same thing, and we have more than enough knowledge and capital to get it done – let’s make everyone’s lives easier and let the experts lead the way.

Maintaining that competitive edge in today’s cutthroat environment has never been more critical. We live in a world that wants things faster, whilst at the same time wanting improved economics, which essentially translates to cheaper. These pressures filter down from the boardroom to all employees working in the production industry but perhaps the people who feel it most are the guys in facilities management.

When production plants and factories are working flat out any potential weakness in plant and machinery is suddenly exposed. Pieces of equipment that have been working perfectly for years are suddenly stressed to breaking point as more and more demands are placed on them.

Anyone working in facilities management will know that it is a multifaceted job that ensures the functionality, safety and efficiency of the environment. Engineers need to have a wide range of knowledge from understanding ventilation and heating all the way through to repairing electrical systems, all aimed at maintaining and improving the physical infrastructure and services of an organisation.

Take an electric motor, for example. They are often taken for granted, with an out of sight, out of mind mentality. However, dust and debris can build up on motors blocking air flow holes that are designed to help cool the motor. The motor may not be old or have any obvious issues – in fact, it may appear to be working perfectly well

until it suddenly fails.

Failures on key production lines can be extremely costly with the cost of breakdown extending way beyond the price of a new motor. Unscheduled downtime costs European businesses billions of Euros per year in lost production and sometimes lost orders and company reputation.

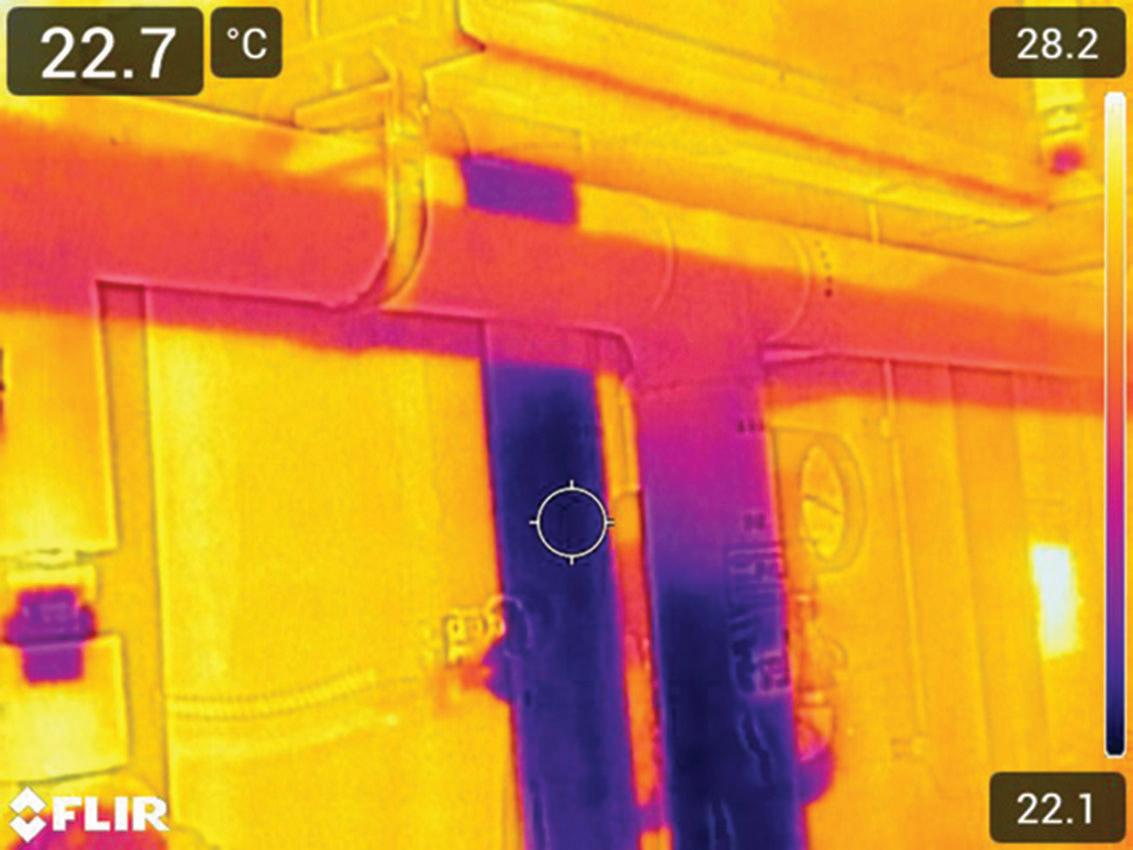

Other examples might be electrical connections, fuse boxes, contactor plates, or other components found in electrical cabinets. Over time, tiny vibrations and heat cycles can cause crimped connections to loosen, along with nuts and bolts on connective wiring which give rise to elevated temperature as the electrical resistance increases.

Problems are also caused by a breakdown in ageing insulation material as it oxidises and degrades over time. This type of common fault has no visual clues and can happen at any time during the production process, yet in most cases can be prevented using predictive condition monitoring techniques.

Regular thermal inspections can provide thermal signatures for each piece of electrical equipment on a production line. Whilst equipment operates as intended, temperatures will remain reasonably consistent, and the insights gained will be no more than regular reassurance. However, if a spike in temperature is recorded during routine inspection, then this

may be indicative of a developing fault.

As mentioned earlier in this article, correcting faults may be as simple as tightening a connection or cleaning cooling fins or air-ways – but faults may be more severe and require more detailed maintenance or component replacement.

In the example of an electric motor exhibiting higher temperatures due to a build-up of dust and dirt, the fix may take 5 minutes when the motor has been turned off to clean it thoroughly. If the issue isn’t identified early, the motor may suddenly fail without warning and require a replacement motor to be installed – potentially resulting in a shut down over several days whilst waiting for a new motor to be delivered and installed.

FLIR Teledyne thermal cameras are easy to use and require little training in the hands of an operator. Often, the investment in a camera, operator training, and associated reporting software may cost less than people think. The one certainty is that the overall cost will be less than an unplanned plant shutdown with the associated cost of lost production and delayed orders.

FLIR produces a range of thermal cameras, with products such as the FLIR E8 Pro having seamless cloud-based backup and file transfer through to FLIR Thermal Studio reporting software.

Thermal imaging is a powerful, non-invasive tool used by Facilities Managers during building inspections to detect issues not visible to the naked eye. Infrared cameras capture temperature variations in a variety of electrical equipment and circuits including motors, switchgear, connectors and transformers.

Early detection of electrical problems such as overheating and overloaded components using a handheld thermal imaging camera allows for preventive measures to be carried out, reducing the risk of costly repairs and enhancing safety.

Teledyne FLIR offers a range of versatile and advanced thermal imaging cameras, designed for professional building inspections and maintenance managers.

These cameras, the FLIR E5 Pro, E6 Pro, and E8 Pro models, feature highresolution thermal sensors that capture detailed infrared images, allowing users to detect temperature variations with precision. With up to 320 x 240 pixel resolution, these cameras provide clear images, making it easier to identify a variety of potential issues and faults in electrical equipment.

One standout feature of the FLIR Ex-Pro series is the MSX (Multi-Spectral Dynamic Imaging) technology, which overlays thermal images with visual details from the built-in digital camera. This enhances clarity, providing more context and making it easier to pinpoint issues.

The camera is designed with user-friendliness in mind, equipped with a large touchscreen display, an intuitive interface, and Wi-Fi connectivity for quick sharing of images and reports. Overall, the FLIR thermal imaging cameras are reliable tools that help professionals improve their diagnostic capabilities.

The advanced Ex-Pro cameras are now more accessible than ever before, with a limited time promotion from FLIR

The features and benefits of the Ex-Pro cameras speak for themselves, but add in an extended warranty, professional software and training, all at no extra cost, and the offer becomes even more appealing to those looking for a comprehensive thermal imaging solution:

FLIR Protect provides an extended warranty, reflecting FLIR’s confidence in the quality of its products. This ensures that users receive the care, service, and support they need long-term.

FLIR Ignite Pro is a cloud-based solution designed to streamline the workflow for thermal imaging professionals. It allows users to automatically upload, organise, and share thermal images and videos directly from their cameras. With Ignite Pro, users can access their files from anywhere, ensuring seamless collaboration and efficient data management. Advanced features such as secure storage, report generation, and thermal image analysis further enhance productivity.

FLIR Academy offers comprehensive thermography courses that cover essential topics like infrared theory, camera operation, and practical applications in various industries.

The ‘Infrared Essentials, Ex-Pro Camera Operation’ course helps Facilities Managers maximise the benefits of their thermal imaging cameras. With these courses, professionals

gain a deeper understanding of how to interpret thermal images and diagnose issues such as insulation defects, moisture intrusion, and electrical faults.

With these three product offerings, completely free of charge with this promotion, customers are always ‘Connected, Protected and Trained’.

Finally, this promotion also includes a reduced purchase price on the E5 Pro, E6 Pro, and E8 Pro thermal imaging cameras, offering savings of up to 49% on the total bundle.

With environmental sustainability remaining high on the agenda, Facilities Managers should take advantage of this limited-time promotion. With their userfriendly interface and Wi-Fi connectivity, the FLIR thermal imaging cameras streamline data sharing and reporting, making them a smart investment for long-term operational benefits.

are key to a more sustainable future

Bringing electric vehicle batteries into the circular economy can have a huge impact on the sustainability of both EVs and energy storage. Tania Saxby, Head of Sustainability at second life battery expert Connected Energy, explains why.

The transition to electric vehicles presents a significant opportunity towards a cleaner and more sustainable future for transportation, moving away from fossil fuels and decarbonising the transport sector. However, it also presents a significant challenge. The production and disposal of the lithium-ion batteries that power these EVs come at an environmental cost.

As demand for EVs grows, mineral extraction increases. At the same time, early electric vehicle models are coming to the end of their life, with the next five years set to see a significant increase in the volume of batteries retiring from a vehicle. While the lithium battery recycling industry is growing, it does not yet have the capacity to process these volumes at the scale that we will see in future years.

At the same time, the drive to decarbonise energy is moving fast, leading to an increased deployment of renewable energy. Energy storage is being increasingly relied upon to support this transition to renewables, ensuring we capture and optimise the benefits of cleaner power.

By applying circular economy principles, we can take batteries from end-of-life EVs and repurpose them in energy storage applications. This has the potential to not only significantly improve the sustainability of EVs and energy storage, but also to create economic value.

The growing demand for batteries to power the energy transition places a contradictory strain on the principles of sustainable supply chains, as it requires the mining and refining of large volumes of critical minerals.

Analysis by Statista estimates that global sales of EVs are anticipated to reach 17 million units by 2028. Batteries will grow exponentially, as uptake of electric buses and trucks increases – these vehicles require much larger battery packs than cars and vans.

In conjunction, demand for critical minerals is rising. Lithium-ion batteries use several critical minerals including lithium, graphite, cobalt and nickel, some of which are subject to dubious mineral extraction practices.

Since 2015, EVs and battery storage have surpassed consumer electronics to become the largest consumers of lithium, together accounting for 30% of total current demand.

Experts at the International Energy Agency (IEA) forecast that mineral demand from EVs and battery storage will increase between 10 and 30 times by 2040, from a baseline of 2021. By weight, mineral demand in 2040 is dominated by graphite, copper and nickel. Lithium sees the fastest growth rate, with demand potentially growing by over 40 times.

Energy storage is also growing at a rapid rate, as it is rolled out to support the transition to renewables. According to research by Deloitte for the IEA, in 2023, the battery energy storage sector was the fastest growing energy technology, with deployment more than doubling yearon-year. BloombergNEF predicts that the global market will grow by 21% annually up to 2030.

Against this backdrop, the benefits that second life systems can deliver are hugely exciting. Firstly, they have much smaller carbon footprints than first life energy storage. Research commissioned by Connected Energy from the University of Lancaster concluded that second life storage units provide a positive carbon benefit of 450 tonnes of CO2 emissions for every 1MWh installed.

Repurposing batteries in this way also provides some much-needed breathing room for the burgeoning lithium recycling industry. A recent IEA report estimates that total global capacity for recycling EV batteries stands at just 180,000t per year. It warns that, by 2040, there could be 1,300 GWh worth of batteries no longer suitable for EV use, far exceeding the recycling industry’s current capabilities.

Batteries in EVs face demanding operating cycles, resulting in a useful life of eight – 15 years. After this, the battery can still hold around 80% of its original capacity. This results in a reduction in vehicle range, but means the batteries still have a lot to give. A lighter duty application such as stationary energy storage is ideal for these batteries. And with the right management, they can work in these applications for another decade or more.

The numbers certainly stack up. For example, 800 million tonnes of batteries amounts to circa 90 million MWh of second life battery capacity. Assuming even 25% of these batteries are reusable, that would deliver estimated CO2 savings of 10,1250 million tonnes compared to using first life batteries.

Ultimately, a battery will reach the end of its useful life within an energy storage system. At this point, recycling is the best conclusion. And the industry is already working on ways to better understand and develop sustainable and environmentally responsible business models for the repurposing and recycling of EV batteries.

“ The global market [for energy storage] will grow by 21% annually up to 2030

Along with helping to conserve critical minerals and reduce the carbon costs of stationary energy storage, second life offers other benefits.

Firstly, it can help us to build more resilient economies that are less reliant on mineral extraction from regions with geopolitical risk. It can also help create a new sustainability industry, bringing with it jobs and prosperity.

Secondly, it is cost-effective. Giving a battery a second life value can improve the economics of EVs as well as enabling lower cost energy storage. A recent study by Deloitte estimated that adopting a multi-life cycle model for EV batteries has the potential to reduce car battery costs by up to €3,000, making EVs more affordable.

If we want the UK to reap these benefits by becoming a global leader in second life energy storage, then we have to act now. Government and industry must collaborate to incentivise and standardise the repurposing of batteries to extend their life before recycling. We need regulation, stronger supply chain development, and better battery traceability.

As increasing numbers of EV batteries come to the end of their life in a vehicle, this is even more pressing. Second-life batteries offer a truly transformative opportunity to create a more sustainable and circular economy for the battery industry. By promoting “Second Life First” practices, governments, businesses, and consumers can work together to maximise battery lifespan, minimise environmental impact, and pave the way for a clean energy future.

Charles Deacon, Managing Director at Eclipse Power Solutions, explores how to get more battery energy storage connected to the grid.

Despite predictions, 2023/24 saw a shortfall in battery storage projects connecting to the grid. What can be done to boost these connections? Are market reforms or extensive policy changes the answer, or perhaps a combination of the two?

We are going through what seems like a perfect storm of reasons as to why there might be fewer lithium battery storage projects coming online. Connection constraints, supply chain problems, and a lack of skilled resources all have the potential to hold back the much-needed transition to a carbon-free economy.

The issue that most people point to is the grid connection queue.

Estimates suggest that the queue is now approaching the terawatt range. In fact, the amount of battery energy storage system connections in the queue is forecast to outstrip even the most optimistic future battery requirements needed to meet net zero.

However, while it’s one of the most popular issues cited, it’s not alone. There are also significant constraints on the supply chain. Some of the largest switchgear suppliers are discontinuing popular models because of

the phasing out of SF6 gases that have been used as an insulator across the electricity sector for decades.

This presents an issue because when you are connecting to the DNO or transmission system, you are also limited to the types of kit that the DNO or transmission operator approves for use on their systems. By contrast, IDNOs offer more flexibility in the choice of kit, which means it’s possible to avoid some of those supply chain issues.

Planning is also an obstacle, where the biggest limitation is resources. We don’t need planning policy changes, but we do need to put more resources into local planning. Delays mean the 16-week determination doesn’t happen anymore and projects can take six to 12 months to be reviewed.

All of these problems are compounding to create a bit of a gold rush among developers, and some projects are possibly heading towards where they can get a connection rather than where a battery energy storage system could provide the most benefit to the grid.

That’s why changes are needed to ensure priority is given to those mechanisms that ensure that energy storage is located in the right place to help the grid.

In the past, battery energy storage was being skipped in the balancing mechanism because the way that dispatch occurred was quite manual. It was easier to dispatch a large 300 MW CCGT (Combined Cycle Gas Turbine) than it is to dispatch maybe five or six smaller battery sites run

by different companies. Thankfully, National Grid ESO has started to introduce reforms to level the playing field.

Tradable volumes can also affect how the asset can be traded in balancing markets. The way Eclipse is set up is that we have projects totalling 100s of MWs that are split into smaller metered connections.

A good example is a project that is 150 MW and is split into three connections of 50 MW each. When these projects were developed there was not much of a market to trade over 50 MW. But now people are looking to trade 100 and 200 MW projects, which has increased the appetite for larger connections.

This raised the appetite for battery energy storage system schemes from individual 50 MW schemes (or 50 MW parcels of bigger schemes) to projects in the 100s of MWs. So, there are now projects or sites with big connections for 400 or 500 MW. They might want to sit on that amount and wait until they either decide to split it up or so just trade that whole amount at once.

It’s not just the reforms happening in the balancing market that are having an impact on battery energy storage, but National Grid ESO is also changing the connections process, with the first major reform being the two-step process.

As part of this, National Grid ESO has changed the background planning assumptions which will hopefully bring some connections forward. Initial feedback was suggesting that at least 40% of connections

in that queue would see an improvement in their date – which leaves 60% who won’t. This process has now concluded, so we should start to see the final impact soon.

This change has been in conjunction with the Transmission Works Review, the first results of which we hope to see this summer.

There is also a proposal to offer ‘non-firm’ or flexible transmission connections to batteries, whereby they can be constrained or curtailed if they were going to cause an issue on the grid.

The current modelling assumes import or export all the time, which as we know doesn’t happen. A reform to extend the active network management principles of distribution up to transmission might mean getting a connection sooner, similar to the non-firm proposals mentioned above. So, if you try to export your full amount between 12 and two in the afternoon in June, you may see a curtailment if there is solar PV in the area, because that is when the PV is producing energy.

This is pretty logical as you wouldn’t wish to sell your power from a battery then anyway, because the market is loaded with cheap solar energy.

“ Increasing competition is a sure-fire way to introduce more innovative problem solving

If things go as planned, Connections Reform should be in by January next year, this will prioritise ‘first-ready first-connected’. This relies on land rights and a planning submission. As battery energy storage is often inherently quicker to get planning consent, it is more likely to be connected.

National Grid ESO is also bringing forward a ‘Technical Limits Initiative’ where you can be connected, with a constrained connection until the transmission system is reinforced. That has seen 30 GW come forward according to UK Power Networks. The average curtailment nationally is given at around 20%. It essentially means that connections can be fast-tracked ahead of transmission work, which can be really beneficial. However, the works will still go ahead and customers will be required to pay or securitise towards these.

There is no doubt that the energy industry is looking for innovative ways to address the many challenges that the sector is going through at present and will do for several more years. Market and connection reforms will go some way to unblock the biggest challenge – the connections queue. But it is likely to take a more radical change than those suggested. Increasing competition is a sure-fire way to introduce more innovative problem solving.

We would like to see more competition in the transmission space, especially at a very localised level around the last-mile connections. If you’re installing a point-to-point connection for a single customer, why not use this to extend the licensed network and make it drive more value? Applying an IDNO-style model could tip the IRR (Internal Rate of Return) into a more attractive proposition for battery storage projects getting approval and being built.

Michael Akinla, Business Manager Central Europe North at Panduit EMEA, explores the role UPS plays in sustaining the expansion of the data centre sector amid increasing worldwide energy demands and evolving power grid infrastructures

The pressure on energy networks to sustain the expansion of the data centre sector and IT-dependent enterprise has intensified due to the growing worldwide demand for energy and the lack of investment in power generation and transmission grid infrastructure.

This is made worse by our increasing reliance on renewable energy sources. While energy matching is a typical solution today, using renewable energy necessitates procuring power from many providers, including solar and wind, which are not currently guaranteed to be available continuously.

Power outages can have disastrous effects on companies, and according to the Uptime Institute, this includes between 10 and 20 high-profile IT outages per year that cause serious financial loss. Although there has been a reduction in outages, still 55% of operators that responded to the 2023 Uptime Institute data centre survey, reported an outage in the last three-year period. As the demands on ageing

infrastructure increase major grid failures will occur even in nations with secure electrical infrastructures, such as the UK.

One of the most important parts of any setup where maintaining constant and consistent electrical power to IT equipment is essential is the UPS. MarketWatch projects that the uninterruptible power supply industry will reach $13 billion by 2025, growing at a compound annual growth rate of 3.98%.

Key components for the successful operation of IT systems are battery UPSs, diesel generators, and backup electrical generation or storage systems. When an outage occurs the backup generator power is not immediately available, and it is usually the UPS that provides the facility with the bridging power needed to run critical systems to maintain data or processes, or allow a structured shutdown of essential systems.

There is a vital window of time which is

measured in milliseconds between the loss of utility power and the IT load switching to the UPS. Any power outage lasting longer than 20 milliseconds is likely to cause an IT system crash. If the outage lasts up to 60 seconds, it can also cause a protracted ITE restart procedure, which might have a major impact on data centre operations and customer applications. Long-term outages may also result in financial penalties from clients and harm to one’s reputation.

UPS components and technology are improving, which is changing the range of capabilities available. The necessity for backup energy is also changing due to the rapid development of faster processors and server storage. The UPS’s capabilities will be determined by the IT applications it supports, the customers’ risk tolerance, and the resilience of the applications. Therefore, before choosing the UPS to support this, the data centre engineering/operational team or customer must precisely identify their needs. For many hyperscale data centres, the UPS chosen is required to maintain the energy supply to the supported system for as little as one to two minutes, while colocation sites normally need five minutes of power. However, the UPS runtime is usually between 10 and 15 minutes in the financial industry, where data is mission-critical and even a small number of dropped trades could cost many hundreds of thousands of pounds. The longer the duration of power needed, the higher the initial and ongoing expenditure in

the number of available UPS to any specific customer.

On the other hand, over-purchasing UPS with long runtimes in situations when backup generators are easily accessible may result in extra ongoing costs and needless capital expenditures that can impact profitability.

Choosing UPSs that are appropriate for the IT load is crucial. ITE is the obvious target for UPS with its essential workloads, and taking a wider view, as faster processors increase server heat output, UPS for the cooling systems that supply those servers is also becoming a crucial load. Keeping that in mind, the UPS unity power factor is another crucial component of the procurement cycle. The unity power factor of the latest UPS is 1, therefore today, a customer’s 100kW IT load could be covered by 5x 20kVA UPSs or a single 100kVA UPS, depending on the preferred configuration.

However, if installing older model UPS this could have a bearing on its unity power factor, which could be less than 1, and that would impact the UPS configuration needed to sustain the critical load. Panduit uses a three-stage charging process that matches the best power curve and incorporates algorithms for temperature adjustment and battery life extension.

Bringing together the old and the new

When merging older UPS systems in an environment that is moving to higher power-

rated ITE racks, modular UPS components are a solution. The design and components of the latest systems can lower costs and increase energy efficiency by matching the rack kW with improved UPS kVA, which is crucial to optimise battery life.

As the technology is incorporated into more applications, lithium-ion batteries, which are now firmly established in the market, will provide consumers with increased capacities. Li-ion battery UPSs are gaining market share in edge data centres and off-site locations due to their longer lifecycles, lighter weight, smaller footprint, and lower cooling requirements, compared to lead-acid batteries. Li-ion batteries’ ability to provide twice as much energy in smaller devices at a factor of two to three, along with cooler operation that eliminates the need for specialised cooling systems, raises the possibility of doing away with the need for separate battery rooms and increasing space utilisation.

Many new device management and safety features are being incorporated as technology advances providing detailed data on battery health and connectivity. Increased connectivity options, as well as the ability to disseminate that data across the power and data centre network, are also available.

The Li-ion UPS can be integrated into preconfigured data centres, enabling customers to order using a single SKU to include the entire UPS system, have it shipped to any location, install it easily, connect it to power,

and start using it. These expanded capabilities are supported by the intelligent power distribution units (iPDUs) in the racks, which offer additional communication and data management capabilities.

The key to the data centre’s future UPSs offer higher efficiency, dependable power protection, and backup power for IT systems and other vital equipment. When necessary, modular systems enable hot swapping, which paves the way for quicker maintenance, and the replacement of outdated or malfunctioning individual units to guarantee maximum capacity and instantaneous power availability.

The latest systems offer superior electrical performance, intelligent battery management, enhanced intelligent monitoring, secure networking services, and a long lifespan for lithium batteries to satisfy the expanding power demands of data centre, enterprise, and edge IT equipment. Support for administration, monitoring, control, and alerting throughout the wider environment, including power chain, environmental, cooling, security, IT assets (Physical & Logical), and connectivity infrastructure, is provided by integration with cloud-based DCIM solutions.

The clear objective is to keep vital assets from going offline. The constant evolution of technology makes it more difficult to minimise disruptions, and that’s why UPSs continue to be an essential component of data centre best practices.

ABilly Durie, Global Sector Head for Data Centres at Aggreko, shares practical guidance

s Europe faces energy challenges, data centre operators must adapt. Uncertainty around grid connections makes forward planning essential to address facility cost, resilience, and operational concerns.

According to CBRE, demand for colocation space in European data centres now exceeds supply, with significant growth in 2023. Driven by increasing demand for digital services, the data centre construction boom is quite rightly seen as a good news story that transcends the continent’s borders. However, this rapid expansion pressures Europe’s power infrastructure, especially as grid connection delays grow.

Just look at German data centres which face connection dates as far off as 2031, while UK counterparts may wait up to 13 years for grid power. Elsewhere, the Dutch implemented strict new rules governing data centre operations in Amsterdam, and Dublin has paused facility construction until 2028.

These issues have been long-standing in Tier 1 markets but now those pressures are beginning to affect Tier 2 markets like Madrid, Milan, and Warsaw. Many projects in these countries face power delays, with over 200 GW of projects awaiting grid connections in Italy and Spain alone.

Data centres use about 1.5% of the world’s electricity; tackling these power issues is urgent and will limit constructors’ and operators’ exposure to fines and reputational damage. The need to address such concerns will grow at a commensurate rate to the size of the market.

Ireland, where data centres now consume more power than all the urban homes combined, can provide a preview over how pressing this matter could become.

Beyond power supply concerns, data centres are navigating stricter sustainability rules and low-emissions regulations. New EU legislation will soon require European data centres to report on energy use, as part of efforts to cut energy consumption across member states by 11.7% between 2020 and 2030. These changes will likely impact how the industry operates, and their progress should be monitored by facility stakeholders.

Initiatives like the European Commission’s RePowerEU and various national government actions are accelerating the shift to green energy sources and aiming to reduce grid connection delays. However, the benefits of these efforts may not be immediately apparent, and action is required in the short to medium term to alleviate current concerns.

These actions include sourcing decentralised energy equipment. However, finding the right solutions can be challenging. Many

stakeholders face obstacles when procuring power equipment, with internal hesitance over purchasing decisions. Focused on profitability, there remains scepticism over acquiring permanent solutions for immediate, temporary issues.

Yet these issues persist, lowering site efficiency and causing logistical headaches, making generator equipment potentially unavoidable – even with the risk of stranded or improperly sized assets. Regardless of the selected solution, incorporating and maintaining new on-site generator equipment in this capacity adds further complexity for stakeholders awaiting grid connections, especially in areas facing long delays.

The situation is compounded by the unpredictable nature of Europe’s energy pricing markets. Fluctuations have forced energy management to the forefront for data centre stakeholders.

In recent research, it’s been shown that inefficient energy solutions can increase operational costs, emphasising the importance of strategic planning to preserve profit margins. It also underscored the necessity to manage noise levels and adhere to various national regulations when selecting generator equipment, particularly in urban areas.

Data centre operators should reconsider the supply chain for shortterm energy solutions to navigate this challenging situation. Adopting a holistic approach to third parties can unlock greater expertise. Stakeholders involved in facility construction or operations should evaluate potential suppliers based on several criteria.

Firstly, suppliers must provide the latest, most energy-efficient generator technologies and services. The ability to scale these solutions up or down modularly depending on site needs is crucial, and attention should be paid to how quickly this equipment can be deployed across Europe.

Finally, it’s key that suppliers offer remote monitoring services informed by deep expertise in data centre operations. Engaging knowledgeable stakeholders and comprehensive services is crucial for ongoing efficiency and adherence to legislation in a fast-moving regulatory landscape.

The continued expansion of the data centre sector in Tier 1 and Tier 2 markets is welcome news. But as demand escalates, power availability and sustainability considerations will become more pressing. Decentralised energy solutions may hold the key to maintaining this upward trajectory, allowing data centre stakeholders to bypass grid connection delays and supplement or replace grid power if required.

By implementing these technologies and services at every stage of data centre development – from initial design to full operation – potential disruption can be mitigated or even averted. To recognise the true potential of these solutions, they must be easily accessible to construction and facility management professionals.

Moving energy equipment procurement from a one-time investment to a scalable, ongoing expense can assist in this effort. By partnering with experienced suppliers, data centre stakeholders can ensure access to reliable power and bolster operational resilience throughout their facility’s lifetime.

As a product manager, I keep a close eye on trends in the field and have regular contact with our users. One thing is clear: As the grid continues to grow, the number of systems to be tested is constantly increasing.

Our CPOL3 polarity and wiring checker is the perfect addition to the COMPANO 100, CPC 100, CT Analyzer, or one of our CMC test sets Together, they enable you to combine several aspects of a wiring test during commissioning of protection, automation, and control systems. The benefits start with the test signal, which is easily transmitted in the system and does not cause magnetization of transformers. It goes on with a polarity detection and additional information such as voltage and signal view. As a result, you will reduce your test time while increasing the safety of your systems.

How optimising solar is an easy win for utilities and end-users

Daniel Cross,

Load

at

discusses the advancements made in solar technology that can make it more efficient than ever.

Arecent study found that the sunniest place on earth is a large plain near the Andes Mountains in Chile which sees as much sun as Venus. Even on average, the solar irradiance on the plateau is around 308 watts per square metre, meaning that the solar energy potential in the region is roughly twice as high than in Europe.

However, whether someone lives in Chile or Chichester, they are likely increasingly looking to the skies as a source of power as traditional fossil fuels continue to be phased out. Whilst solar has been a viable power source since Bell Labs first produced practical photovoltaic cells in the 1950s, it has only gathered momentum as a key household power source in the past decade.

Like many other Western countries, the UK residential solar market continues to expand rapidly. The growth in solar panel ownership has been buoyed by the decreasing cost of solar installations, government grants, and increased awareness of the environmental and economic benefits of solar energy. Plus, there have been significant advancements in battery technology.

Battery technology improvements have been driven by advancements in materials science, manufacturing processes, and the growing demand for efficient energy storage solutions.

One of the key areas where battery technology has evolved is in energy density. Modern lithium-ion batteries have far better energy density than in the past, allowing for longer-lasting batteries in smaller, lighter packages. Then there is the emergence of solid-state batteries that use a solid electrolyte instead of a liquid one, offering higher energy densities, improved safety, and longer lifespans.

That’s not to mention the gains that have been made in reference to their relative charging speed. Some new technologies allow batteries to reach 80% charge in as little as 15 minutes. And it shows no signs of slowing down. Current research into alternative materials and designs promises even faster charging rates in the future.

“ Whether someone lives in Chile or Chichester, they are likely increasingly looking to the skies as a source of power

In addition to the above, modern solar batteries have a longer lifespan, are more resistant to degradation, are safer than ever before and often have in-built smart battery management systems (BMS) that can monitor battery health, optimise charging and discharging cycles, and predict potential failures.

Enhancements in battery technology are timely. Increasingly volatile extreme weather patterns, data centres required to power the new era of artificial intelligence, population increases in urban areas, and the popularity of electric vehicles are all putting more load on the power grid than ever before.

Batteries will play a crucial role in a future grid stabilisation. Not only are enhanced battery technologies being integrated into the grid to store energy from renewable sources to smooth out supply fluctuations. But those being used in end-user residential and commercial solar power systems allow users to store solar energy for use at night or other times when the sun is no longer reaching the panels.

Plus, such efficient battery storage has made it easier for end-users to push excess energy back to the grid at opportune times. This is helping to level off the grid and mitigate the threat of outages.

Whether an end-user gets 12 hours of sunlight a day or 12 minutes, maximising the effectiveness of the solar energy system is imperative.

The first key aspect of solar optimisation is to ensure that the angle and direction of the solar panels are adjusted to capture the most sunlight. Typically, panels are oriented towards the equator and tilted at an angle that maximises exposure. Using tracking systems so that the panels follow the sun’s path from east to west during the day can make them even more effective. Of course, make sure that panels are placed where they will not be shaded by trees, buildings, or other obstructions throughout the day.

Using advanced photovoltaic technology to increase the conversion rate of sunlight to electricity can also help. As can regular cleaning of the panels to remove dirt and debris that would otherwise reduce their efficiency.

In addition to ensuring optimal placement and physically maintaining any solar array, there are several ways that technology can also help optimise solar energy systems.

Software and Internet of Things (IoT) devices can be used to monitor and track the performance of solar systems in real time. In addition, artificial intelligence (AI) and machine learning (ML) can be used to analyse huge data sets on weather conditions and average cloud coverage to ensure that an end-user gets the most out of their system. Also, data analytics can be used to predict and prevent potential issues before they impact system performance.

Then there is the aforementioned BMS that can store excess energy generated during peak sunlight hours so it can be used during cloudy periods or at night. Or devices that convert DC electricity from solar panels to AC electricity, optimising energy flow and storage.

Another important consideration with the design of any solar array is to make sure that the energy produced by the system balances with the energy consumption patterns of the end-user. Plus, to ensure the system is flexible enough that it can be expanded upon in the future if energy needs change.

The increased proliferation of smart meters is also helping to enhance the effectiveness and management of solar power systems. By utilising the real-time data on both the energy produced and energy consumed, the user can better understand usage patterns and adjust accordingly to optimise their solar systems.

Plus, by monitoring the performance of the solar power system, any drop in expected production can be quickly identified, prompting troubleshooting to ensure the system operates efficiently.

“ The more end-users can help with energy production, the more consistent energy supply will be

Maybe the most important component to ensure effective solar optimisation, though, is the energy industry itself. Whilst Government incentives are welcome, it is important that suppliers reward customers who embark upon a journey towards a renewable future. Energy suppliers need to do all they can to encourage end-users to use their batteries effectively so that any excess energy produced can find its way back to the grid.

After all, it is a win, win. In addition to the obvious environmental benefits, the more end-users can help with energy production, the more consistent energy supply will be. This means suppliers – and in turn the end-users themselves – will not be as exposed to higher prices.

Solar power is instrumental to building a greener future for us all. Wind is far more volatile. Plus, the setup costs are far higher. Thankfully, the advancements of solar panel and battery technology, has massively enhanced the overall efficiency, reliability, and costeffectiveness of solar energy systems. This has made such systems a much more viable option. This, in turn, is helping to reduce the strain on an ageing power grid, lower bills, reduce the chance of black outs and reduce the need for the industry to build additional power plants.

Not just any rad. Stelrad.

Phil Thompson, CEO of Balance Power, highlights behind-the-meter (BTM) generation as a promising solution for businesses to quickly and efficiently decarbonise their operations.

Renewable uptake in the UK is gaining momentum once again. The new Government has injected a much-needed surge of energy back into the marketplace with its ambitious plans and policies for net zero.

Within just a few weeks of coming into power, we’ve seen Labour lift the historic ban on onshore wind, approve three large-scale solar PV projects totalling 1.35 GW of clean capacity, announce plans for a stateowned energy company, and the largest budget yet for renewable energy via the Contracts for Difference (CfD) scheme, which yielded a record 131 projects.

This swift and frankly bold action has reignited hope in the sector. However, there is still a lot to overcome before we can turn the Government’s vision into reality.

Increasing renewable energy capacity is vital, yet it is just one piece of the net zero puzzle, and it ultimately hinges on a reformed planning process. The industry grappling with grid delays is somewhat old news for those close to the sector, but it has only recently entered public consciousness as reports of developers receiving grid connection dates decades into the future have surfaced in the past year.

There are only so many connections to hand out before we need to expand the grid network, and the sheer number of renewable energy projects joining the queue has created a ‘clogging’ of the pipeline. This problem is still tangible and real.

Whilst work is underway to address our congested grid, the scale of the problem has incentivised some developers to pursue different avenues to get projects up and running.

One such avenue is behind-the-meter (BTM) generation. This typically involves a partnership between a business and a clean energy developer, who will identify the most effective method for generating renewable energy on their premises or on land nearby. The energy generated is supplied directly to the business via a private wire.

As this method bypasses the grid, projects can be up and running in just a year or two, compared to an average of five years with more traditional methods. This also helps businesses avoid third-party costs and other charges that are added to their normal energy bill, slashing operational costs at a time when many are being crippled by the soaring price of energy.

According to POWWR’s Quarterly Energy Barometer Report in July, UK businesses are spending 12.6% more each year on energy compared to the previous quarter. That’s a significant increase and is representative of a general upward trend in prices that shows no signs of stopping.

It’s also worth noting that this model reduces strain on the grid. By generating electricity locally, especially during times of high demand, BTM systems reduce the amount of power needed from the grid, effectively ‘shaving’ peak loads and lessening stress on existing grid infrastructure. This not only helps prevent grid overloads during peak times but also reduces congestion on the network, making the grid more efficient and bolstering energy resilience.

The beauty of BTM generation is that it is well-suited to energy-intensive businesses, from those involved in manufacturing foundation materials like chemicals and glass to large retailers and those in the food and packaging sectors. These businesses consume vast amounts of power and produce tonnes of emissions through their operations – we simply can’t wait for grid infrastructure to be expanded or optimised before connecting them to a clean alternative to fossil-fuelled power.

Some of the biggest and most influential players across a range of industries are waking up to its potential. Vodafone, for example, which holds 20.5% of the mobile market share in the UK, is set to derive 44% of its annual energy requirements from five solar farms in Norfolk, Nottinghamshire, Staffordshire, Buckinghamshire and Dorset through a power-purchase agreement (PPA) with supplier Centrica and generator MYTILINEOS.

Similarly, Iceland, one of the UK’s major food retailers, is planning to power 14% of its annual electricity needs through a PPA with Octopus Energy via a solar farm in Cambridgeshire.

Samsung Semiconductor, which is responsible for manufacturing electrical components (a highly energy-intensive process) is leading in the silicon semiconductor industry – since 2020, its US and Chinese business sites have been powered by clean energy through installing large-scale renewable facilities.

The cost savings that businesses are able to derive through BTM generation are not only beneficial to the businesses themselves but can also have a ripple effect throughout the community. For example, businesses can reinvest the money saved on energy bills into expanding operations, creating new jobs and improving local infrastructure, contributing to a more robust local economy.

BTM projects can therefore help address one of the primary concerns that drives NIMBYism – communities feeling that they bear the burden of hosting energy projects without reaping the rewards. With BTM setups, the energy produced is used locally and residents and businesses see tangible benefits such as lower energy costs, local job creation, and improved economic conditions, helping enhance community support for projects.

“ [Behind-the-meter] not only helps prevent grid overloads during peak times but also reduces congestion on the network

The potential of behind-the-meter generation extends beyond positive environmental impacts – it provides a compelling incentive for businesses to decarbonise. As pressure mounts from governments and investors, businesses are being forced to reevaluate their supply chains and procurement processes to meet decarbonisation goals.

Simultaneously, they are under increased scrutiny from eco-conscious consumers who are more aware than ever of the climate crisis. Surveys consistently show that consumers prefer eco-friendly brands, with millennials and Gen Z leading the charge. In the UK, for instance, 66% of 18-24-year-olds are more likely to buy from retailers or brands with strong ethical and sustainable credentials.

As sustainability becomes a key differentiator, businesses have an opportunity to enhance their bottom lines and gain a competitive edge by transitioning to renewable energy to power their operations.

A viable and quick pathway to decarbonisation