The sargassum crisis

Every year, it comes earlier: a massive brown ribbon of seaweed stretching from West Africa to the Caribbean.

By the time it reaches shore, postcard-perfect beaches disappear beneath mountains of rotting algae. The smell triggers headaches and breathing problems. Tourists flee. Fishermen can’t reach the water. This is the annual sargassum crisis, and it’s getting worse.

In 2011, something unprecedented appeared in satellite imagery: the Great Atlantic Sargassum Belt (GASB), an 8,850-kilometre band extending from West Africa to the Gulf of Mexico. By June 2018, it contained over 20 million metric tonnes of seaweed. That same year, more than 1.1 million tonnes invaded Mexico’s Caribbean coast. What had been occasional became catastrophic, affecting 13 countries across the Caribbean, Gulf of Mexico, and Florida.

Source: Origin by Ocean

Source: National Ocean Service

For small island nations where tourism represents 60-90% of GDP, the sargassum season has become a major crisis Caribbean economies, for example, face over $300 million in annual losses from tourism decline, cleanup costs, and fishing industry damage. On the worst days, beaches in Barbados see 1,600 dump trucks’ worth of seaweed pile up in a single day.

Dense mats block sunlight underwater, smothering coral reefs and seagrass beds. As sargassum decomposes, it creates dead zones and releases hydrogen sulphide — causing respiratory problems — and methane, a greenhouse gas 28 times more potent than CO₂.

The seaweed that once captured carbon as it grew now releases greenhouse gases as it dies.

What’s driving the blooms?

Several factors are fuelling the crisis: rising ocean temperatures; nutrient runoff from agriculture and the Amazon river; changing wind and current patterns; and climate change intensifying all of the above.

Current efforts to manage the crisis rely on mechanical beach cleaning, with tractors hauling wet seaweed to overflowing landfills. It’s expensive, never-ending, and treats sargassum as worthless waste.

Source: Lautaro Isern/Dialogue Earth

The hidden opportunity

But what if this plague was an opportunity instead? What if Sargassum could fuel aircraft, fight climate change, and turn cleanup into profit?

The technology already exists — pioneered by a marine researcher who spent years in the Arctic searching for ways to capture carbon from the ocean at scale.

Dr Mar Fernández-Méndez, co-founder of the Canary Islands-based startup

MacroCarbon, believes sargassum could solve two crises at once.

Why algae-to-fuel has failed before

For years, algae biofuels were called “the holy grail” of sustainable energy. The logic seemed unassailable: algae grow fast, capture CO₂, produce oil, and don’t compete with food crops.

Billions were invested. Most of it vanished.

Understanding the algae family

“Algae” covers thousands of species in two main categories:

• Microalgae are microscopic, singlecelled organisms that float in water. These were the focus of most biofuel ventures because some species produce high amounts of lipids (oils). Companies spent billions trying to cultivate them in massive tanks and extract their oils.

• Macroalgae are large, multicellular seaweeds you can see and touch— like kelp, sea lettuce, and sargassum. They’re fundamentally different organisms with different potential uses.

Source: AlgaeBarn

While most failed algae ventures focused on microalgae, MacroCarbon is betting macroalgae, and that changes everything.

Why microalgae struggled

Viridos, the poster child of the algae-to-fuels movement, received $600 million from ExxonMobil in 2009. At the time one of cleantech’s biggest bets. The approach: genetically engineer microalgae to produce oil, then extract it.

After years of work, Viridos achieved impressive growth rates, but the economics proved much too challenging. Despite new investment from Chevron, United Airlines and Breakthrough Energy, the company went bankrupt in April 2025.

Since most algae contain less than 7% oil, extracting it consumed more energy than the fuel was worth.

Moreover, land-based cultivation required massive facilities, freshwater, and competed with food production. One virus could destroy entire crops. Genetic engineering created organisms that worked in labs but failed in real-world conditions.

However, not all algae approaches are failing. A few companies have learned from past failures and found different paths.

HutanBio, a Cambridge startup, utilises naturally robust microalgae strains rather than genetic modification. By targeting coastal deserts with no agricultural value, they achieve high-density cultivation (300 photosynthetic layers versus 6-8 in previous strains) at $1,200-1,500 per tonne.

Chief Commercial Officer Brittany Hook explains: “A lot of people take a lab strain, modify it, then try to take it outside. We took something already hardy and brought it into the lab.”

Currently scaling from lab to pilot near Kuala Lumpur, HutanBio shows the sector is maturing.

Source: Mewburn Ellis

Source: HutanBio

Source: Rafael Microfauna Marina

The macroalgae advantage

Sargassum is a brown macroalgae that spends its entire life floating in the ocean. It makes for a promising source of biofuel, but causes significant damage when it washes ashore.

Rather than extracting oils like the microalgae companies, MacroCarbon uses thermal conversion to break down the entire biomass to extract multiple products including fuel. Their approach sidesteps every problem that plagued microalgae:

• No lipid extraction. No need to squeeze oil from cells; the entire biomass becomes feedstock

• No genetic modification. They use wild sargassum as nature provides it. The process is species-agnostic, working with any brown or green seaweed.

• No cultivation costs where blooms exist. The feedstock grows wild in massive quantities, and communities will pay to have it removed.

• No freshwater or land requirements. Sargassum grows in saltwater in the open ocean. It doesn't compete with agriculture.

• Species flexibility. In locations without wild blooms, they can cultivate sargassum in distributed ocean farms or supplement with other organic waste.

The question that plagued microalgae ventures was: "Can we make this economically viable?"

For MacroCarbon, the question is: "How fast can we scale a solution to a problem people are already paying millions to solve?"

The sargassum difference

Dr. Mar Fernández-Méndez didn't start her career thinking about seaweed. She started by studying ice.

As a marine microbiologist, FernándezMéndez spent years in the Arctic Ocean, studying how tiny algae in sea ice could sequester CO₂.

"I would go every year to the Arctic and even from year to year, you could see how it was rapidly declining," she says. Witnessing the ice disappear strengthened her resolve to find carbon capture solutions.

But it also revealed a problem. "The productivity — the amount of carbon sequestered there — is relatively small compared to other areas."

The Arctic wasn't the answer. So she followed simple logic: If tiny algae in cold water weren't productive enough, what about larger algae in warmer water?

That journey took her from microalgae to macroalgae, from polar regions to subtropical waters, and eventually to pelagic (open sea) sargassum.

What makes sargassum special

Sargassum is remarkably efficient at carbon sequestration and can double its biomass in 10 to 30 days, far quicker than other plants and algae. Floating for its entire life, it can grow almost anywhere in the ocean, which covers 70% of our planet. It is also hardy and adaptable, enabling it to thrive in challenging conditions with minimal nutrients.

The economic reversal

Sargassum causes significant economic losses across the Caribbean, where nations pay to have it removed before it reaches their beaches. The feedstock potentially has a negative cost.

MacroCarbon's technology works with any brown or green seaweed, even rotting beach seaweed.

"Quality doesn't matter because we're converting, not extracting," FernándezMéndez explains.

MacroCarbon avoids the massive bioreactors, arable land, freshwater, fertilisers, and genetic modification that drove up costs and doomed earlier ventures.

"The limit is the ocean and how much funding we can raise," Fernández-Méndez says. "You can get to gigaton scale in 10 years."

Source: Aquaculture UK

Step 3: Methane pyrolysis

The gas flows into an electric methane pyrolysis unit that separates carbon from hydrogen, producing carbon black, 99% pure carbon used in car tyres, inks, and batteries. Like biochar, carbon black represents a permanent carbon storage solution.

Third revenue stream: Carbon black

But the breakthrough is what happens to the liberated hydrogen.

Step 4: Fischer-Tropsch Synthesis

The hydrogen combines with carbon monoxide to produce sustainable aviation fuel (SAF) through Fischer-Tropsch synthesis.

"Other processes to produce SAF require an external source of green hydrogen," Fernández-Méndez explains. "We don't need that. We create our hydrogen ourselves."

By generating hydrogen internally through methane pyrolysis, MacroCarbon avoids competing for scarce green hydrogen or relying on external infrastructure, giving them a significant cost advantage.

Fourth revenue stream: Sustainable Aviation Fuel (SAF)

Source: IntechOpen

The carbon math

• Captured: Sargassum absorbs CO₂ while growing

• Permanently stored: Significant portions as biochar and carbon black

• Returned: Only the SAF, when burned, returns CO₂ to the atmosphere

Even accounting for CO₂ released when aircraft burn the SAF, the overall process removes more carbon than it emits.

MacroCarbon is not alone

The sargassum opportunity has sparked innovation across multiple sectors. Companies and governments throughout the Caribbean, Mexico, and beyond are exploring different pathways to turn crisis into value.

Grenada's government received over 30 proposals aimed at processing 10,000 tonnes of sargassum by 2026. Prime Minister Dickon Mitchell framed it clearly: "We believe we have a unique opportunity to turn the tide on what is viewed as a problem into a solution."

Local energy solutions

SarGas, founded in 2023, operates in Grenada using anaerobic digestion to convert sargassum into biogas. Their current small-scale digester powers a local bakery oven, and CEO Benjamin Nestorovic aims to scale to a larger facility handling 5,000-8,000 tonnes annually, and producing 160 kilowatts for the national grid.

Grenada relies almost entirely on imported diesel for electricity, which is both expensive and polluting. Biogas from sargassum offers a cheaper, cleaner alternative that complements solar by generating power overnight.

As Professor Saeid Baroutian from the University of Auckland notes: "If countries can replace 10% of their imported fossil fuel with locally produced sargassum-based bioenergy, it would be a huge improvement."

Source: Sprind

The race to turn sargassum into value

Fertilisers and agriculture

Multiple companies are working on biostimulants and fertilisers. The challenge is significant: sargassum absorbs toxic metals, such as arsenic, and requires salt removal before it can be used in agriculture.

But according to Jane Nurse, a consultant working with Grenada's government, fertiliser represents "the most realistic short-term goal" for sargassum valorisation.

MacroCarbon licenses bio-stimulant technology from established agricultural partners rather than developing it independently.

High-value products

Source: Atlántico Hoy

Several companies are targeting premium markets:

• CarbonWave (Mexico) produces skin-care products and soil additives from sargassum.

• Origin by Ocean has pitched Caribbean governments on building biorefineries for cosmetics and materials extraction.

• Sway (USA) transforms sargassum into bioplastics—sustainable alternatives to petroleum-based plastics.

• PANGAIA (UK) is developing sargassum-based yarn for fashion applications.

• ThalassoBiotech and SOSCarbon (Puerto Rico) focus on high-value ingredients for health and agriculture, while employing local fishing communities to harvest efficiently.

Source: Dominican Today

The economics & market

Source: Sprind

At commercial scale, MacroCarbon projects SAF production costs of nearly $1,500 per tonne. This is roughly 40% lower than many competing SAF pathways, which are typically priced at $2,500 per tonne or more. By comparison, conventional jet fuel costs much less, around $600–700 per tonne, making SAF appear uncompetitive at first glance.

Carbon prices changes the equation

However, the situation changes when factoring in carbon costs under the EU’s Emissions Trading System (ETS).

In 2025, carbon allowances are priced around €75–€85 per tonne of CO₂ (roughly $80–$90). Since burning one tonne of jet fuel releases about 3.15 tonnes of CO₂, this adds $250–$280 per tonne to the cost of fossil jet fuel for airlines.

As EU carbon prices continue to rise over the decade, driven by reductions in free allowances and stricter targets, carbon costs could eventually approach €200 ($200+) per tonne of CO₂, effectively adding $600 or more per tonne of jet fuel.

A study by Dr. Dana Shoukroun concludes that, after 2030, the most expensive path for the European aviation sector will be inaction, as carbon pricing and regulatory mandates will significantly ramp up.

The regulatory tailwind

Beyond carbon pricing, direct mandates create guaranteed demand. The EU's ReFuelEU Aviation Regulation mandates a gradual increase in the minimum share of SAF blended into jet fuel, starting at 2% from 2025 and rising to 6% by 2030, 20% by 2035, and reaching 70% by 2050.

Meeting these targets will require nearly 7 million tonnes or more of new biomass feedstock annually beyond current waste streams.

MacroCarbon seeks to fill part of this need by tapping ocean-sourced sargassum, an unconventional but abundant resource. Like any first-of-a-kind project, the company faces challenges like high capital expenditure, supply variability, and technical uncertainties.

Yet, compared with ventures that spent billions developing fundamentally uneconomic processes, these risks appear substantially more manageable, especially with strong regulatory support and increased market demand for SAF.

The BlueSAF plus vision

What sets MacroCarbon's approach apart isn't just the integrated biorefinery or the ocean-sourced feedstock, it's a fundamentally different vision for what climate solutions should achieve.

Dr. Fernández-Méndez calls it "BlueSAF Plus", and the name tells the story:

"It's blue, it comes from the ocean," she explains. "The plus is for 'plus it's carbon negative.'"

Source: MacroCarbon

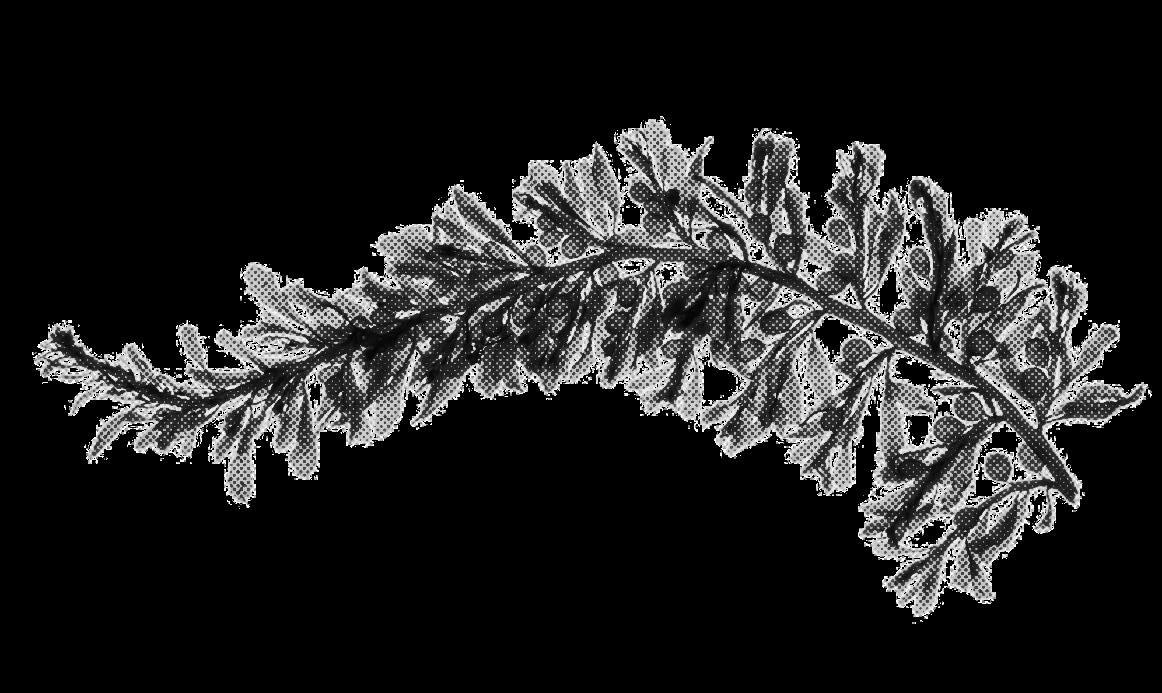

Enhancing marine biodiversity

The "Plus" encompasses a whole new aspect: marine biodiversity enhancement.

When cultivating sargassum in distributed aqua farms, MacroCarbon maintains floating ecosystems that support marine life. The seaweed provides habitat for fish, crustaceans, and other organisms. Unlike land-based biofuels that often damage habitats, this cultivation restores them.

Fernández-Méndez sees this as proof we can solve problems without creating new ones: "We can have a healthy ocean and we can still fly aeroplanes around the world."

The “We can have both” philosophy

Source: CarbonWave

There's pragmatic realism in MacroCarbon's vision: "It is important that we have a world in 10 years from now where it's not choosing between this or that. We can have both," Fernández-Méndez argues. "Because to be honest, the idea of 'reduce everything, let's not fly, let's not do this', that's not going to work. Even all the COP people and the UN people, they're all flying around the world all the time."

Solving multiple crises

BlueSAF Plus addresses several problems simultaneously:

• Environmental: Removes sargassum before it reaches beaches, preventing methane release and ecosystem damage.

• Economic: Turns a cost into revenuegenerating activity.

• Climate: Produces carbon-negative fuel while permanently sequestering carbon.

• Energy: Reduces aviation's fossil fuel dependence without requiring massive green hydrogen infrastructure.

The story matters

Source: MacroCarbon

Perhaps the most interesting evolution in Fernández-Méndez's journey has been recognising that good technology isn't enough.

"The most surprising thing for me, and it’s quite ironic coming from academia, where data is everything, is that in the startup world, you really need a good story. You can have all the data in the world, but if you don't tell it the right way at the right time, you won't succeed.”

BlueSAF Plus is that story. Carbon-negative fuel that enhances marine biodiversity while solving an environmental crisis and creating economic value.

Source: MacroCarbon

The road ahead

MacroCarbon isn't starting from zero. A 150-square-meter pilot barrier is already operational, testing ocean harvesting and proving the concept at sea.

In October 2025, the company achieved a major milestone: the Canary Islands government granted permits for a 40,000-square-meter (4 hectare) seaweed farm near the Plataforma Oceánica de Canarias (PLOCAN). This marks a significant scale-up from the pilot stage and positions MacroCarbon to demonstrate commercial viability.

Source: MacroCarbon

The commercial scale-up

The first commercial-scale facility is likewise planned for the Canary Islands. It will comprise 6-square-kilometres of distributed aqua farms, a 6-lane processing plant, and a Fischer-Tropsch unit capable of producing 8,000 tonnes SAF annually. The project requires about €80 million in capital, with operations targeted to begin within the next few years, pending funding.

From there, expansion follows the sargassum: Morocco, the Azores, Cape Verde, eventually the Caribbean, where the crisis is most acute, then Asia where coastal nations face similar challenges and aviation markets are growing fastest.

The technology is species-agnostic, so regional seaweed varieties work equally well. If feedstock availability fluctuates, facilities can supplement with agricultural waste, wastewater sludge, or other organic materials.

Source: MacroCarbon

Balancing academia & entrepreneurship

Fernández-Méndez maintains her professorship at the University of Bremen while building MacroCarbon, a deliberate choice. Academic research tackles fundamental questions. Entrepreneurship commercialises proven technology. The combination accelerates both.

By 2035, Fernández-Méndez expects MacroCarbon to have two or three working facilities with proven results. She also hopes seaweed will be widely accepted as a thirdgeneration feedstock, encouraging other companies to follow their lead.

The larger question

If MacroCarbon succeeds at scale, it will demonstrate that integrated biorefineries with multiple revenue streams can overcome the high capital costs that kills most deep tech ventures. The fundamental logic is sound. The feedstock is abundant. The technology is proven. In Europe, the market is guaranteed by regulation.

Whether Fernández-Méndez becomes the world's first sargassum billionaire, as climate writer Quico Toro predicted, misses the larger point.

The primary question is whether MacroCarbon can turn a rising tide into opportunity. That the seaweed choking Caribbean beaches could power the aircraft flying overhead. That the crisis is also the solution.

Source: IntechOpen