JOURNAL

OF ENTREP RENEURSHIP

OF ENTREP RENEURSHIP

Inside the legacy and leadership of multigenerational businesses.

LABORA is a publication of the Benedictine Schools of Richmond, focusing on entrepreneurship, innovation and the evolving world of business.

BENEDICTINE SCHOOLS OF RICHMOND

PRESIDENT Jesse Grapes

VICE-PRESIDENT OF MISSION

Del Smith ’01

VICE-PRESIDENT OF STRATEGIC COMMUNICATIONS

Erin Parkhurst

VICE-PRESIDENT OF OPERATIONS

Ann Michele Sweeney

BENEDICTINE HEAD OF SCHOOL

Greg Lilly

SAINT GERTRUDE HEAD OF SCHOOL

Amy Roussy Pickral ’95

LABORA

CONTRIBUTING WRITERS

Mike Forster, Andy Garrigue, Rachel Slotterback, Joe Swedish ’69

CONTRIBUTING PHOTOGRAPHER

AJ Parson

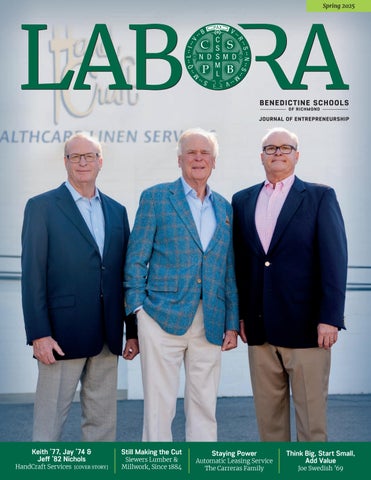

FEATURE | 4

Under the leadership of the Nichols brothers, HandCraft Services has evolved to become a powerhouse in the field of medical laundry.

FEATURE | 16

Family-owned since 1884, Siewers Lumber & Millwork has stood the test of time — serving Richmond with quality, consistency and craftsmanship.

FEATURE | 26

Four generations of the Carreras family have kept Automatic Leasing Service growing, evolving and thriving — no matter the challenge.

Benedictine and Saint Gertrude Family,

When I think about entrepreneurship, the first image that comes to mind is the courageous inventor — the man or woman who develops something that is totally new, something that’s never been seen before. But even inventors rely on science, technology and processes that were developed by somebody else. They build upon the shoulders of others, synergizing ideas to develop that new thing. There’s a lot of humility in being an entrepreneur.

In this edition of LABORA, you’ll read about generational family businesses that have grown, adapted and innovated. The alumni CEOs of these companies took something that existed and made it better. Sometimes, they accepted that they weren’t “best in class” and sought out other businesses to learn about new technologies that drove their innovation. The Nichols family and HandCraft Services are a prime example of this type of entrepreneurship. Their business bears little resemblance to the company that their father created in the 1950s because they had the humility to seek out the good ideas and technologies that allowed them to innovate.

The Benedictine Schools have also walked that path. As the concept of BSoR was being developed, teams of administrators, teachers and board members visited other schools to learn from their successes and mistakes. Culver Academies (Indiana), Regis Jesuit High School (Colorado), The Saint Paul’s Schools (Maryland), St. Cecelia Academy (Tennessee) and Oakcrest School (Washington, D.C.) are but a few from which BSoR extracted incredible ideas and best practices, leading to the campus environment that Benedictine and Saint Gertrude enjoy today.

We also believe in Jesus’ words: “To whom much is given, much is expected” (Luke 12:48). It’s in our educational philosophy. So, we are likewise generous in sharing our own lessons.

Recently, we were visited by Dr. Juan Antonio Casas (pictured left), board chair of the Gimnasio Campestre, an all-boys Catholic school in Bogotá, Colombia. His school is beginning the process of unification with their longtime sister school, Marymount. Dr. Casas spent a day on our campus, capturing lessons learned on BSoR’s formation and development to take back for their own innovation. We were humbled by the request for his visit, prayerful for the success of Gimnasio Campestre, and thankful that we are able to help in the growth of Catholic education around the world.

Yours in prayer and work,

JESSE GRAPES PRESIDENT, BENEDICTINE

Under the leadership of the Nichols brothers, HandCraft Services has evolved to become a powerhouse in the field of medical laundry.

IT COULD HAVE BEEN A BUMPY START TO THE NEW YEAR.

When Richmond experienced its now-infamous water crisis that began January 6, HandCraft Services could have been in a world of hurt. As could the 150 hospitals and 2,300 non-acute medical facilities that it serves. That is because water is the indispensable element of HandCraft’s business, and cleanliness is a non-negotiable condition in healthcare. So, the water needs to be clean. Because of systemic and other failures, clean water was not to be found by conventional means and became very much a precious commodity.

HandCraft is a full-service healthcare linen and uniform provider. The Richmond facility collects soiled textiles and cleans and re-distributes bed linens, scrubs (medical apparel), patient gowns, physician and lab

The lobby sign at the 2810 Cofer Road plant welcomes visitors.

“I’m proud of the fact that we have the most efficient healthcare laundry in the country.”

JEFF NICHOLS ’82

coats, mats and a host of other items to hospitals and medical facilities throughout Virginia. The company also serves medical facilities in other states, including North Carolina, South Carolina, West Virginia, Delaware, Maryland, eastern Tennessee and the District of Columbia. When those facilities lose access to those items, their patients lose access to those facilities. Water is the lifeblood of medical laundry.

And the lifeblood of HandCraft has come in the form of the Nichols brothers — Jay ’74, Keith ’77 and Jeff ’82 — who have steered the company to its current lofty heights of industry leadership.

Fast action and high efficiency, in the case of the Richmond crisis, kept the machines churning and the hospitals supplied. A fleet of tanker trucks pumped around the clock, providing muchneeded hydration at the facility, which is located in the Broad Rock Industrial Park, sited in South Richmond.

The plant gobbled up the contents of a 6,000-gallon tanker every 45 minutes. Even at that heady rate, the laundry line was slowed to 60 percent of its normal operating speed. “We usually do 70 loads an hour,” recalled Keith, who, along with his brothers, are the owners of HandCraft Services and have run the company for more than two decades. “During that time, we did 50 percent and limped along, but the hospitals were also below capacity.”

Something that was critical to alleviating any such threat to operations is the fact that HandCraft uses a mere half gallon of water per pound of laundry, an innovation that initially came about as a cost-saving measure but has minimized its impact on the environment (in addition to helping to make it economical and streamlined). According to Danamark (an expert in the area of water management), a typical commercial/industrial laundry uses around two-and-a-half to three gallons of water per pound of laundry. That means that, even when running the process at

“We work hard to stay ahead of the tech curve. We have lots of automation and put a lot of money back into our plants.”

full bore, HandCraft consumes a scant 20 percent of the water that other operations use. “I’m proud of the fact that we have the most efficient healthcare laundry in the country,” said Jeff. “Even the Richmond operation looks world class.”

The South Richmond plant, renovated at a cost of nearly $10 million, provides 60,000 square feet of processing space, enough to house a 17-step cleansing process that has over two tons of laundry spread across it at any given time. (Each load weighs 240 pounds.) The Richmond plant processes 155,000 pounds per day. Company-wide, HandCraft employees drive 110 to 128 million pounds through the process annually.

All those impressive numbers have their roots in a trip that Keith took to New York to investigate a non-competitor (due to geographic differences) that was focused on the same line

JAY NICHOLS ’74

of work. He had met the head of that company after joining a medical laundry management group in 1990. At the time of the visit (fall 2006) the company was processing 8 million pounds of laundry each year using a system that was characterized by small batches, small equipment and lots of manual steps.

What Keith saw was ground-shaking in terms of size and scope: massive pieces of equipment processing massive loads of product. “I knew we had to do something similar,” he recalled. Thus was born that $10 million renovation, which more accurately is described as the guts of a completely redesigned workflow, process and utilization of employees. The term “super plant” is no hyperbole when it comes to the end result. HandCraft’s first super plant opened in 2008. Remember,

Hunter Nichols ’14, Kattie Nichols Dibert ’09, Ward Hackett, Whit Anthes, Maggie Nichols Anthes ’09 and Curtis Nichols represent the next generation of leadership.

entrepreneurship is also found in the adoption of the great ideas of others. “That visit to New York changed everything,” noted Jeff. “We surpassed our expectations.”

Now, each of the company’s four plants — two in Richmond and two in North Carolina, in High Point and Wilson — is a massive operation that is impressive in its scope, speed and efficiency. “We work hard to stay ahead of the tech curve,” said Jay. “We have lots of automation and put a lot of money back into our plants.”

They also put a lot of blood and sweat into those plants. “I’ve been doing this since I was seven years old,” explained Jeff. He was prodded, or inspired, to do so from his father, John A. Nichols, who was steeped in the business. “Dad [’42] worked for T&E Laundry during the 1940s,” he added. “He knew what to expect.” (We surmise that, having served with the U.S. Army in five campaigns during World War II — including Normandy — there was not much that would have surprised Mr. Nichols.)

Shortly after Mr. Nichols returned from the war, his mother became ill, so he remained in Richmond and began working for T&E (a huge outfit that was formerly sited where the

Siegel Center now stands on Broad Street). After gaining hands-on knowledge, he and a partner struck out on their own, starting up Heritage Cleaners in Richmond’s Northside. That partnership endured until 1970, when the pair agreed to an amicable split. Mr. Nichols then struck up a partnership with the owner of HandCraft Fashion Cleaners. A falling out led to a (eventually) friendly offer from Mr. Nichols to buy out his partner. Shortly thereafter, the company name was shortened.

The brothers took ownership of the company when they bought out their father. An implied understanding was that the lads would take care of their mother. Along with their sister, Shelly Nichols Kuhn ’75, and brother, the Reverend Neal Nichols ’79, that is something they did until Margaret “Maggie” Nichols’ passing in 2024, after 98 years on this earth and 18 years since her husband had passed.

Meanwhile, the company’s original 90,000-square-foot behemoth on Roseneath Road proved a bit much to take on, and most of the floor space was rented out initially. It should be noted that at that time, Scott’s Addition was far from the trendy place it is today. While the brothers still own the

This year has proven momentous for the Nichols brothers. With Keith Nichols stepping down as CEO at the turn of the year, he joins Jeff and Jay, who are already in full retirement and semiretirement modes, respectively (though no longer involved in the day-to-day operations, Jeff and Jay are certainly still strategically engaged).

Collectively, the brothers share over 100 years of experience in the industry.

Curtis Nichols has taken the big boss reins as CEO from Keith. That role is one that he earned. “Curtis has done everything we’ve asked of him: depot, sales, floor,

maintenance,” said Jay. “He’s good. And I don’t just say that because he’s my son.”

The Nichols crew does not run their succession like a royal family. In fact, each and every member gets a taste of life outside the family circle before becoming integral to it. “The family has an unwritten rule that you have to work elsewhere for at least two years,” said Jeff, while pointing out that Julia Nichols ’19 is wrapping up her second year in the employ of an area information technology firm.

Jeff retired as president of sales and felt quite comfortable seeing Ward Hackett, Jay’s son-in-law (married to Cameron), fill the vacancy he created.

Other members of the next generation include Keith’s daughters Maggie Nichols Anthes ’09, who heads up human resources for the company, and her twin sister Kattie Nichols Dibert ’09, who is the head of safety. Whit Anthes (Maggie’s hubby), who manages retail non-acute delivery routes, is joined by Hunter Nichols ’14 (Jeff’s son), who recently came on board as a production manager.

A few of the offspring work outside of the HandCraft orbit, including Keith’s son, Jake ’15. But fret not, as he hasn’t wandered far: Jake is on the staff at Benedictine.

“In a way, we’re not in the laundry business. We’re in the logistics business.”

JAY NICHOLS ’74

facility, it is far removed from the laundry business, housing more than a dozen diverse entities such as a brewery, a fine-foods market and a management consulting group.

In 2008, the brothers moved the hospital operations to a state-ofthe-art facility that they developed in the city’s Southside. Such a processing center is an impressive mix of capital equipment and human capital. According to Keith, operations focus on three key criteria: employee ergonomics, energy efficiency and high productivity/quality control. Every workstation has been designed to maximize ergonomics — for instance, there is no heavy lifting or stooping by employees. The design seems to be working. During a visit to the plant in February of this year, it was noted

that the operation had gone 1,367 days (nearly four years) without a missed-work accident.

The brothers directed that the dryers be emplaced on a mezzanine, in order to reduce noise and to facilitate heat transfer to the production floor. The most is made of the air above, as that mezzanine also carries material-handling equipment such as the soil-sort deck and overhead sling system, which are utilized to achieve one of the highest productivity levels in the country. Furthermore, the Nichols brothers initiated a number of “green” practices into the operation, including the recycling of 230,000 pounds of plastic linen bags and 276,000 pounds of worn-out medical linen annually.

A HandCraft employee feeds machinery as the finished product is discharged in the foreground.

HANDCRAFT’S RICHMOND FACILITY RECENTLY RECEIVED A CALL FROM A NORTHERN VIRGINIA HOSPITAL THAT IT SERVICES. ONE OF THE HOSPITAL’S DOCTORS HAD MISPLACED A SMALL CRUCIFIX LAPEL PIN THAT WAS A MEMENTO OF HIS RECENTLY DECEASED WIFE. Was it possible that it wound up in that day’s laundry?

According to Carlos Iniguez, quality control manager at HandCraft, employees spent two and a half hours searching before finally locating it. “That sums up who we are as a company,” said Carlos Iniguez. “We care. A lot.”

Few such misplaced items warrant such a search. In fact, most are discovered at HandCraft before anyone thinks of contacting the company. Repatriating lost goods is actually quite an impactful activity for HandCraft. Many businesses have a “lost and found” function, usually consisting of a shelf holding such items as umbrellas, hats or books. HandCraft has an entire room dedicated to repatriation. “We have one lady who is responsible for finding them homes,” said Jay Nichols, who also noted that the company maintains a separate website for lost and found items.

That is because they face a flood of such items: rings, wedding bands, dentures, medical equipment, jewelry, stuffed animals, hearing aids, phones and laptops are just a few of the lost items that are listed on the massive spreadsheet that tracks such things. It even showed a glass eyeball that went missing (not for long, though).

The vast majority of the items are found during the initial processing of the laundry batch. Since the company’s tracking system can match the batch with the medical facility, repatriating is relatively simple. But there is a lot to return: During a calendar year, HandCraft typically recovers more than $1 million dollars’ worth of items, just from its Richmond operation. The company has similar processes in place at its other locations.

Typically, a representative of the hospital will provide the name of the person who has lost the item. He or she may pick up the item at the plant, or a HandCraft driver will bring it to the facility during his or her next delivery. Most items are held for 90 days before being purged.

The service, which is rare for an industrial laundry, is greatly appreciated. Imagine you are an ICU nurse on your way home from an exhausting 12-hour shift. You remember that the scrubs you wore that day had your engagement ring affixed to the drawstring — and those scrubs went down the laundry chute an hour ago.

“Ninety-nine percent of the stuff is found,” said Jay.

Equally important, that stuff is returned to its owners. And that must bring significant relief to so many of the folks who take care of us.

During a calendar year, HandCraft typically recovers more than $1 million worth of items, just from its Richmond operation. The company has similar processes in place at its other locations.

HandCraft leases a massive fleet of trucks, numbering in excess of three score, while it owns its own trailers (in the hundreds). Unlike a certain company that shares its name with a Brazilian river, HandCraft considers its drivers employees of the company. They are critical to satisfying a core logistic — pickup and delivery. According to Keith, the typical hospital receives a tractor-trailer visit seven days a week, so there is a steady drumbeat to that side of the business: Each driver will visit the same three or four clients on a daily basis. Same customer, every day. (By the way, most deliveries are at night, when hospitals are less busy.) On the non-acute medical side of things, the typical transaction is for 75 to 100 pounds per week. So, a driver might see 40 distinct customers one day and 40 the next, for a total of 200 customers a week.

With close to 150 hospitals and more than 2,300 non-acute medical practices (such as clinics, doctors’ offices and urgent care facilities), the drivers stay busy. What those numbers also mean, however, is that HandCraft can operate at scale levels that translate into efficiency and cost savings. “In a way, we’re not in the laundry business,” Jay said. “We’re in the logistics business.”

Backing up that assessment is the innovative radio frequency identification (RFID) system that the brothers introduced on the non-acute side of the house. Every piece of laundry carries an RFID tag, which HandCraft equipment scans along the way. While the system certainly assists with accurate billing, its main value lies in ensuring that the right items are delivered to the right places after processing. That is, Dr. Smith’s lab coat winds up with Dr. Smith — not Dr. Jones — and, more importantly, all the rest of Dr. Smith’s items are accurately placed. The system also allows the customers to control inventories and enables them to save by cutting back on items identified as excess to their operations.

Laundry is typically a significant expense for hospitals. For example, according to Definitive Healthcare, in 2023, NewYorkPresbyterian Weill Cornell Medical Center spent more than $15 million on laundry. But at its core, HandCraft is providing more than a laundry service. It owns the linens, scrubs and other items (procured from Medline and Sigmatex Lanier) that it cleans. The category of “hospital linens” includes sheets, pillowcases, blankets, towels, curtains, patient garments, uniforms, surgical items and microfiber/cleaning cloths. The company handles more than 1,800 SKUs (or individual item types).

THE

NICHOLS BROTHERS EXPANDED THEIR MEDICAL LAUNDRY LEGACY INTO A BOOMING REAL ESTATE FOOTPRINT — ANCHORED BY A RARE ARCHITECTURAL GEM IN RICHMOND’S HOTTEST DISTRICT.

While the Nichols name is synonymous with medical laundry, the brothers have also accumulated quite a real estate portfolio over the years.

The company’s original facilities are long gone (or transformed), but the family held on to what had been the major processing center (located at 1501 Roseneath Road in Richmond’s Scott’s Addition).

In 2016, sensing that the building was a hot commodity, “We gutted it all the way to the walls,” said Jay Nichols. “We put in new electrical, water and HVAC.”

Rather than take advantage of the city’s offer of historical tax credits

The Roseneath Road building, formerly used as a processing facility, now hosts a wide-range of non-laundry businesses.

(a healthy 42 percent offer), the brothers opted to finance the work themselves. That was because “you have to play by their rules,” noted Jay. “They are restrictive. And I don’t take directions well. They would never have let us gut the building.”

Today, the building (pictured above) sits at the heart of the booming district. Per Jay, it is one of only three buildings on the East Coast that bear the French Modine-style exterior. Of greater satisfaction is the building’s 100-percent occupancy, including such tenants as Stella’s Market, Väsen Brewery, Brandito Marketing consultants and a branch of Hazen and Sawyer (the largest privately owned environmental engineering

company in the country). Jay said that his team collaborated with potential clients in the design of their future space. “My only regret is that I didn’t have two of those buildings,” he rued.

The Nicholses real estate portfolio currently includes a number of properties that are home to diverse activities: office, retail, industrial and warehousing. The Nichols clan recently sold a full city block to a developer that is converting the property into a 400-apartment complex.

Take that, housing shortage.

That alleviates hospitals and non-acute facilities of the burden of purchasing and maintaining those items. (Examples of non-acute facilities include doctors’ offices, urgent care clinics and community clinics.) It also relieves those entities from having to inventory and feed a resupply pipeline. By making ownership part of its core duties, HandCraft allows medical facilities to focus on their core activities. Client satisfaction is key. “Anyone we’ve lost, we’ve been able to win back,” noted Jeff, citing the recapture of the University of Virginia’s hospital as an example.

The two North Carolina HandCraft facilities are located 130 miles from each other — one near Wilson and the other to the west, near Greensboro (High Point), with one tending to hospital support and the other to the non-acute side of the house. For example, the Wilson plant is 97,000 square feet and includes 3,500 square feet of office space and 1,250 square feet of mezzanine. Utility upgrades for its construction included water, sewer, natural gas and electrical services. The facility laundry equipment was made by Kannegiesser, a German-based manufacturer that is also on its third generation of company ownership. Kannegiesser is considered the “Mercedes-Benz” of commercial laundry equipment. The Jensen-Group has also provided the plant with equipment and is a company whose CEO is a third-generation Jensen. Based in Denmark, the company is highly regarded for its innovation.

Today, HandCraft is in the midst of yet another expansion with the construction of a 150,000-square-foot facility in Martinsburg, West Virginia. That plant will take on both hospital and non-acute customers and will service Northern Virginia and the greater District of Columbia area and its surroundings. According to Jeff, that site was chosen after the brothers realized that the completed project in total would be cheaper than just the cost of the land for a location sited in Northern Virginia. “We cannot compete with data centers,” explained Jeff.

HandCraft’s coverage map is extensive, as the company provides services to eastern states from Delaware to Georgia and as far west as Eastern Tennessee. While most contracts are set for a five-year period, “Our motto is, ‘We don’t want a customer for five years,’” said Jeff. “We want them for 25 years. It sounds simple, but treat your customers as you want to be treated. That is why we maintain a 98.7 percent customer retention rate.”

That desire has manifested itself in a client list that is as remarkable for its length as it is for its stability. And the Nichols brothers, while drivers of innovation, are also big fans of such stability.

HANDCRAFT SERVICES RECEIVES, SORTS, CLEANS, PRESSES, FOLDS AND DELIVERS APPROXIMATELY 120 MILLION POUNDS, OR 60,000 TONS, OF MEDICAL LAUNDRY EACH YEAR.

36,000 cars

Here are a few entities that come close to matching such heft:

109,000 grand pianos The entire population of the city of Denver Every phonein the U.S.

5.5 Eiffel Towers

2.5 million bushels of apples

92,000 adult male moose

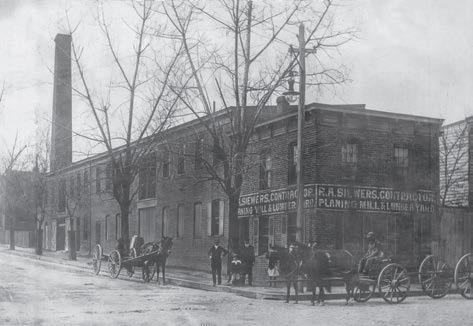

Family-owned since 1884, Siewers Lumber & Millwork has stood the test of time — serving Richmond with quality, consistency and craftsmanship.

When the Roman Catholic Diocese of Richmond decided to construct a bishop’s residence in 1906, it turned to R.A. Siewers

Contracting and Lumber for the job. The house was constructed for Augustine Van de Vyver, who was the sixth bishop of Richmond, and during whose episcopacy the school initially known as Benedictine College was founded, by the way.

“It was so satisfying to see that the craftsmanship and dedication to quality millwork that my great-grandfather had was still instilled in all that we were doing in the present.”

MICHAEL SIEWERS ’89

More than a century later, Bishop Barry Knestout became Richmond’s 13th bishop, and he decided to revert the building from its then-current use as office space and refit it to function, once again, as the bishop’s living quarters. When the building (which sits immediately behind the Cathedral of the Sacred Heart) was undergoing that transformation, the descendants of R.A. Siewers had their interest piqued.

“The crew doing the renovations would come by the lumberyard to source items such as moldings and other millwork, and we would hear about the progress through their visits to the lumberyard,” said Michael Siewers ’89. “As the project neared its end, Adria Hogan (a member of the team) invited us to come and tour the building. It was almost surreal to visit the house my great-grandfather built that was once again a job site.

“It was like a trip back in time interrupted by quick flashes of the present. It was so satisfying to see that the craftsmanship and dedication to quality millwork that my great-grandfather had was still instilled in all that we were doing in the present. To actually see his work firsthand and to know that we are carrying on his legacy brought a sense of fulfillment that I had never experienced before.”

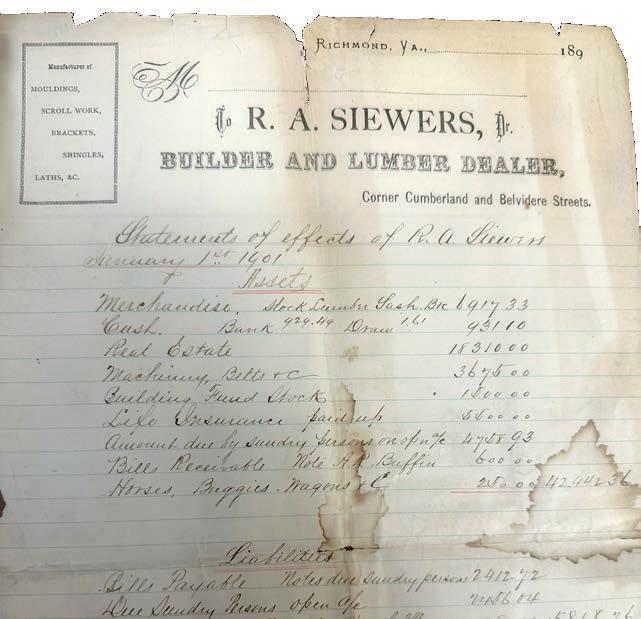

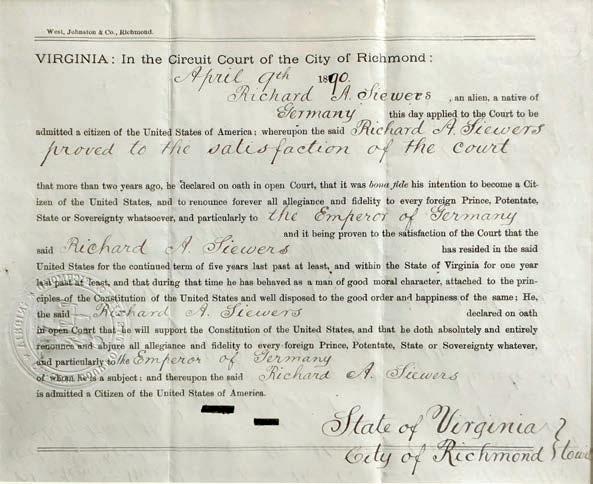

The company got its start well before R.A. Siewers took on the role of primary builder for that initial construction of the Bishop’s Residence.

Chester Arthur was president. The Dakotas, Wyoming and Idaho were not yet states (and the United States flag had but 38 stars on its bed of blue). What came to be known as the automobile was yet to take hold, and the airplane was just a dream held in the hearts of a pair of young brothers in Ohio. Meanwhile, the city of Richmond was still in recovery from having been scorched to the ground at the end of America’s Civil War. The year was 1884.

It was at this point and in that city that a German immigrant who had arrived from Westphalia set in motion a business venture, founded on the Golden Rule, that would grow and endure for more than 140 years. R.A. Siewers, along with his wife Sabine, not only launched their lumber business, they also established a family that would run that business to this very day.

Indeed, Siewers played a significant role in helping the former capital of the Confederacy in its phoenix-like ascension. And the

homes for which he provided the lumber and manpower to build throughout the city of Richmond are today being upgraded and rehabilitated with materials provided by his descendants.

And on this day, and for the past few years, R.A. Siewers Lumber and Millwork has been run by a fourth generation of Siewers. Research shows that family-owned businesses rarely have such longevity. In fact, only three percent of family businesses survive to have a fourth generation of unbroken family management, according to the Family Business Institute.

Also, after R.A. and Sabine Siewers passed away, the subsequent ownership/management was retained jointly between two and four Siewers men. Today, the company is run by three men who each bear the last name of Siewers.

Serving the central Virginia market, the company has a customer base that leans heavily toward renovation and remodeling. “The ideal customer is putting on a wing and wants everything to match what’s already there,” said Michael.

The pre-cut molding storage facility holds hundreds of stock items.

“He wants a seamless look,” added Richie Siewers ’81, the current CEO. “Our ideal customer is building an addition to their home and wants everything to match. The majority of what we get are specialty orders.”

Richmond has seen a tremendous upswing in gentrification in areas such as Church Hill and across the Fan District. In those areas, renovation specialists and homeowners of houses that are a century and a

This company balance sheet from the early days lists horses and buggies, along with other assets.

half old find themselves in a quandary: How does one match the craftsmanship that was applied those many years ago? That is where Siewers steps up with the answers. Company-served customer projects range from the do-it-yourselfer who wants to match a door that needs replacing to the contractor who is working to double the size of an existing home.

Indeed, a walk through the 6-acre site (which sits within a stone’s throw of The Diamond — home to Richmond’s Flying Squirrels) reveals just how special the millwork can be. For instance, one building houses over 2,000 different cutting blades that are used to craft molding and other trim work, giving the company the ability to match long-discontinued pieces. Some of their efforts match those crafted over a century ago. The company maintains a vast catalog of historic designs that can be replicated in the millwork.

A big-box home improvement store typically offers basic lumber cuts (2-by-4 studs, 2-by-10 boards, etc.), plywood, molding (30 or so options) and other basic styles of wood. A typical lumber yard offers bulk cuts, with an eye toward new construction. Siewers provides the best of both worlds: comparatively priced basic lumber along with the ability to create virtually any customized molding or any other wood product (although as a pricier proposition).

Michael, who today serves as the chief marketing officer, has been working for the company for three decades. Add another decade to that number, and you have chief executive officer Richie’s time on board. The two brothers, along with their cousin, John Siewers III, represent the fourth generation to run the company. (A fourth member of that generation, Freddy Siewers ’75, retired recently.)

“Our distinct competency is our integrity. People trust us — vendors, customers, employees and the community.”

The Shenandoah Building, built by R.A. Siewers, was recently converted into a boutique hotel.

The former Siewers home on W. Cary St., designed and built by R.A. Siewers.

R.A. Siewers’ work can be found in many parts of Richmond, including this building in the Fan District.

John has been a long-time mainstay, as he is nearing the 30-year mark in the business. He is the obvious rebel of the family, having graduated from Saint Christopher’s. But blood ties are stronger than school bonds, and he fits right in with his cousins — so much so that he has become the company’s chief operations officer, responsible for lumber purchasing and the production of the lumber yard.

Times have not always been the best for the company. Along with the rest of the country, the Siewers and their crews have ridden the crests and troughs of business cycles as well as the flow of history: the bank panics of 1893 and 1907 and the Great Depression, as well as the Spanish-American War, World Wars I and II and other world-shaking conflicts.

More recently, the Great Recession and the COVID-19 pandemic loomed large over the business. The “housing [industry] feels recessions the hardest,” noted Richie. “And lots of companies don’t make it.”

He added that, during the Great Recession (2008-09), “We had no layoffs. We are always conservative, and we know cycles will come. We are ready for them.”

They also showed flexibility. It was in the aftermath of that worldwide financial fiasco that the company started up a kitchen design component, which has grown and morphed into one of its most popular offerings. Included is a line of private-label Siewers

Another Siewers building.

cabinetry that the company can customize in size, with endless color options.

One benefit of its longevity is that the company has been able to build a layer of financial protection against macroeconomic-driven hardships. And, while it is certainly not bullet-proof, the company has weathered some significant hits. Michael notes the company’s “lean and financially stable” profile has paid off.

It is not just employees who receive that level of care. “Our distinct competency is our integrity,” said Freddy. “People trust us — vendors, customers, employees and the community.”

The current Scott’s Addition location is the second for the company. R.A. Siewers got things started at a site in Oregon Hill. Construction of the Downtown Expressway, however, forced the company (along with many others) to move in the early 1970s to its current location, a move that nearly drove it out of business. Ah, such are the travails of eminent domain.

The Siewers brothers stress service, quality and flexibility as the constants of their company. “If you buy 100 two-by-fours from us, you’ll get 100 good two-by-fours,” said Richie. “You don’t need to

John C. Siewers I 1877-1968

Richard Alvin Siewers 1859-1909

1887-1975

Freddie W. Siewers Jr. ’48 1936 -

buy 120 to get those one hundred.” Take a look around the yard and you will see plenty of different cuts of lumber, but you are unlikely to come across many knots (and certainly no warped pieces) in that wood.

“We follow the Golden Rule,” explained Freddy, who recently stepped down as CEO. “That goes back to my aunts, who grew up in the company. “Catholicism teaches us to treat our neighbors right. The two greatest commandments [given by Jesus] are all about love, care and trust. We try to do things right and to do the right things.”

As with any business, there are challenges to face. Michael points to workforce hiring as one with which the company must deal. “We are always looking for people with good attitudes and work ethics that will fit into our culture,” he said, adding that such traits are more important than possessing the needed skills. “We will train them on the skills needed to do their job.”

Retention of valued employees is also critical. “We want to keep the good team members with us until they decide to retire,” he said. “We hire to retire.”

A

Siewers II ’55 1937-2024

“We’ve brought on a lot of new talent, mostly through word-ofmouth,” added Richie, citing recent hires whose previous stints included working as a chef and serving in the military. “All we want is a good attitude in someone who can get along and show up to work.”

While sales and distribution are almost entirely focused on the greater Richmond area, the raw materials that go into the Siewers’ products have a much broader flavor to them. “We are dealing with vendors or suppliers who are mostly in the U.S. — along the East Coast, the Midwest and West Coast,” noted Michael. “The suppliers or vendors are sourcing the raw materials from states as far as California and sometimes international sources, like Canada and Africa.”

Sourcing lumber from Canada has its recent challenges, considering that the product has become a premier target for proposed tariffs. Should it arise as an issue, Siewers will rise to the occasion, just as it has for a century and a half.

And should the bishop seek to do another renovation, we have a good idea of the folks to whom he will turn.

The Siewers name has been synonymous with the region’s lumber business for a century and a half — supplying the Richmond area’s needs from rebuilding the city after the ravages of the Civil War to fueling today’s reimagination of neighborhoods like Scott’s Addition. The Siewers clan has been a part of that transformation every step of the way.

The Siewers brothers point to two key drivers that are necessary for generational continuity: focus and involvement. If a company founder has five children, and each of those has five of their own who are awarded ownership shares, the company could reach 25 third-generation co-owners. That dilution of ownership creates a high probability of splintering in opinion and direction. However, the brothers shared, a hands-on ownership approach gives those proprietors a keen insight into the issues the business faces,

something those who are remote from it may fail to appreciate.

And now, here’s the scoop on the Siewers family tree. (Surely, you didn’t think we’d tell you about a lumber family business without referencing a tree.)

Adolph (A.R.) and Elizabeth Siewers got the ball rolling. The couple, of Westphalia, Germany, raised a son, Richard Alvin, who immigrated to Richmond, married Sabine, and founded R.A. Siewers, Inc. in 1884.

One of their sons, John C., ran the company’s day-to-day operations from 1909 (the year Richard passed away) and was joined in that role 10 years later by his younger brother, Frederick W. Siewers Sr.

Frederick’s sons, Frederick “Freddie” W. Siewers Jr. ’48 and John “Johnny” C.

THE SIEWERS FAMILY COUNTS FIVE GENERATIONS WORKING IN THE BUSINESS — INCLUDING CURRENT EMPLOYEES JOHN MEACHAM ’24 AND RACHEL SIEWERS, WHO TAUGHT FINE ARTS AT BENEDICTINE FOR 14 YEARS. THAT CREW, HOWEVER, IS NOT ALONE IN ITS LONGEVITY WITH, AND IN ITS LOYALTY TO, THE BUSINESS.

Meet Mr. Walter Wood, who was hired as a carpenter in the old mill (located on Belvidere Street) in the late 1940s. Many years later, in the 1960s, his son-in-law, Johnny Herring Sr., came to work for the Siewers family. In the early 1970s, after the move to the Diamond District location, Mr. Wood’s son, Linwood, joined the team as well.

Over the years, Mr. Wood’s nephew, Joe Grove, worked for nearly half a century for the company. His grandson, Johnny Jr., became a truck driver, and his two great-grandsons, Gary Wayne Herring and Steve Mitchell, are both currently employees of the company.

Siewers II ’55, represented the third generation to run the business. Freddie, the battalion commander during his senior year at Benedictine, still has his hand in the mix, dropping by the shop to spread his good cheer. “Dad is our ambassador,” noted Richie. (Johnny passed away in 2024.)

Freddie’s three sons, Frederick “Freddy” ’75, Richie ’81 and Michael ’89 were joined by Johnny’s son, John Siewers III, in composing the fourth generation of ownership. While Freddy has retired after serving for 25 years as CEO, the other three men are still running the company full-time, with John filling the role of chief operating officer. Current family employees include Rachel Siewers, daughter of Freddy, and John Meacham, son of Ann Siewers Meacham ’78 — Freddy, Richie and Michael’s sister.

Siewers Lumber & Millwork still offers site delivery — though things have modernized quite a bit since this photo was taken.

Johnny Herring Sr. worked for more than 50 years before retiring, and Linwood has just entered semi-retirement this year. Mr. Wood’s great-great-grandson, Robert Mitchell — who is still in high school — has worked for the company during summer breaks, representing the fifth generation.

This is what is truly means to be a “family business.”

While most family-owned businesses (FOBs) struggle to survive beyond their founders, the Siewers legacy has thrived across five generations — far exceeding national averages. Family businesses face steep odds when it comes to long-term success, with few advancing past the second generation and even fewer enduring for more than a century. The Siewers family’s remarkable longevity stands as a rare exception to these national trends for family-owned businesses:

40% transition to a second generation 13% make it to a third generation 3% survive into a fourth generation

Nearly 48% of FOB failures are caused by the founder’s death

16.4% of failures happen after an orderly transition between generations

24 years average FOB lifespan

6.1% fail following an owner’s forced retirement

ALS trucks are loaded with washers and dryers at their headquarters in Richmond’s Scott’s Addition.

Four generations of the Carreras family have kept Automatic Leasing Service growing, evolving and thriving — no matter the challenge.

When a competitor undercut Automatic Leasing Service (ALS) and wiped out nearly a third of its revenue, it could have been the end of the story. Instead, it was just the beginning.

The loss of a major account in the early 2000s became a defining moment for ALS — a fourthgeneration, family-owned company specializing in multi-family laundry leasing. Rather than crumble under the setback, ALS used the crisis to reset: selling assets, paying off debt and rebuilding a leaner, more disciplined and more strategic business.

“We just never looked back,” said President and CEO Scott Carreras ’88, who leads the company alongside his wife, Chief Marketing Officer Maria Loehr Carreras ’83, and in partnership with his father, Jim Carreras ’58. Years later, ALS not only recovered that lost client — it emerged stronger than ever.

Founded in Richmond, Virginia, ALS has grown into a regional leader with seven offices, over 120 employees, and more than 120,000 washers and dryers on lease throughout apartment communities and more across the Mid-Atlantic and Southeast. Its success rests on the same principles forged during its hardest moments: resilience, transparency and service.

For ALS, the inevitable challenges that come with building a business don’t derail progress — they become the blueprint for it.

“We treat the company as a second family...”

MARIA LOEHR CARRERAS ’83

“Running a business is a series of challenges,” said Jim. “It’s challenge after challenge. The ability to respond to those challenges in a positive way is what makes you successful.”

ALS applied the lessons learned from its loss in the 2000s to a similar setback with another major real estate client.

“We lost them for pricing reasons, too,” Scott said. “But they phased us out slowly, so we had time to think. We knew we couldn’t compete dollar-for-dollar with national players, but we also knew they couldn’t match our responsiveness, our service, or our relationships.”

ALS kept the door open, stayed in contact, and waited for the right moment. That moment came years later when the client reached out, dissatisfied with the national provider’s service.

“It took 13 months to win that business back,” Scott said. “But on April 1, 2024, we closed a deal that added nearly 16,000 leased washers and dryers to our inventory.”

Maria reflected on the challenge, “It was a bumpy ride, but Jim said, ‘It’s going to be fine.’ And it was.”

That kind of reassurance speaks to ALS’s culture — a blend of old-school grit and modern adaptability. The company strives to solve customer issues quickly, with a goal of responding to all service requests within 24 hours. That service standard, along with the strength of its field team, remains the company’s competitive advantage.

Adversity hasn’t always come in the form of competition. In 2020, ALS faced a challenge that every business encountered: the COVID-19 pandemic.

Maria remembers how it unfolded. “Our son Phillip was the first employee to test positive. We were quarantining, and our employees were scared. We could hear the uncertainty building. I told Scott, ‘You need to explain to the team exactly what is going on, now.’”

Scott called an all-hands meeting, bringing in every truck and every employee: “We let everyone know exactly what was

Jim Carreras ’58, Margaret Carreras, Maria Loehr Carreras ’83, and Scott Carreras ’88 at ALS headquarters in Scott’s Addition.

happening. That we had it. That we were quarantining. And that the business would continue. It reassured people. It helped calm the fear.”

Safety protocols were implemented, PPE was distributed, and communication became constant.

“We were deemed essential, and we kept going,” Scott said. “We even grew during COVID, winning large bids against national competitors who couldn’t service their accounts. The hardest part was getting their teams to remove their old equipment.”

ALS continues to expand its footprint across Virginia, North Carolina, South Carolina, Maryland, and parts of eastern Georgia, Tennessee, and West Virginia. Yet the company remains family-run at its core, with the fourth generation now stepping into leadership roles.

Phillip Carreras ’19, who is completing his MBA from the College of Charleston, will support ALS at its Scott’s Addition headquarters across HR, accounting, sales and operational functions. His younger brother, John ’21, will be based in Wilmington, where he will handle service calls and help drive growth in new territories. Both began working at ALS in middle school.

“We treat the company as a second family,” Maria said. “We want people to feel ownership in their work, and we invest in them.”

That investment shows up in a robust profit-sharing program that started under Jim Carreras, and continues under Scott. “It’s a key part of ALS’s ability to attract and retain top talent and reward employees for their contributions to the company,” said Maria.

“We want to give back,” Scott explained. “That goes for our employees and our community. We support local schools, nonprofits, and causes important to our customers.”

Nearly 70 years after its founding, ALS continues to grow by sticking to what works: strong relationships, fast service, and a culture built on doing the right thing — especially when it’s hard. “You can’t grow if you don’t learn,” Scott said. “And you can’t lead if you’re not willing to work alongside your team.”

And when mistakes happen? Own them, said Scott. “We’ve flooded apartments, broken pipes and damaged floors. And we pay for it.”

ENTREPRENEURIAL SAVVY AND RESILIENCE HAVE HELPED THE CARRERAS FAMILY TURN A MODEST BEGINNING INTO A THRIVING BUSINESS THAT CONTINUES TO GROW, SERVING THOUSANDS ACROSS THE MID-ATLANTIC AND SOUTHEAST.

Clockwise, from above left: Phillip ’19, John ’21, Maria ’83, Scott ’88.

In 1934, Thomas J. Carreras went to a bankruptcy auction in Richmond hoping to buy a fan for his confectionery store. Instead, he bought an entire dry-cleaning business for $700. His wife, Mary, ran it, and one son, James Phillip Carreras ’34, worked after school and continued through the years, assuming ownership in 1952. They named the business LaFrance Cleaners and Laundry, which later became LaFrance Linen Service.

When wash-and-wear came on the market in the early ’50s, Phillip opened several laundromats, later placing coin-operated washers and dryers in apartment buildings — an effort that subsequently became Automatic Leasing Service (ALS).

Today, ALS is a thriving, fourth-generation company headquartered in Richmond’s Scott’s Addition, serving multi-family housing communities with in-unit leasing and shared laundry solutions, including hotels, college dormitories, campgrounds and marinas.

For the Carreras family, success comes down to a few simple but powerful principles:

• Do what you say you’re going to do.

• Be honest and upfront.

• Treat your employees like family.

• Give back to your community.

Giving back to the community has included generous support for the Benedictine Schools of Richmond, starting with the establishment of the J. Phillip Carreras Sr. Scholarship in the 1960s.

When Phillip’s two sons — Jim ’58 (above left) and William ’61 (above right) — attended Benedictine, he provided laundry services for the monks in lieu of paying tuition ($200 per year at the time), helping the family afford a high-quality Catholic education. After his sons graduated, Phillip (above center, middle row), began depositing the income he received from continuing to work for the monks into the fund. Today, Jim and his wife, Margaret, serve as trustees of that fund, which provides deserving students who lack the financial means with the opportunity to attend the schools.

In 2020, the new 65,000-square-foot McMurtrie-Reynolds Pavilion was unveiled, which includes the Carreras Family Auxiliary Gym. And in 2023, the Margaret Carreras Visual & Performing Arts Center, which occupies an entire wing on the third floor of the Saint Gertrude building, was dedicated. The space includes individual studios for each of the disciplines offered in the arts curriculum as well as an art gallery for rotating exhibits.

Jim Carreras ’58, Phillip’s son and a Wharton MBA graduate, bought the company from his father, Phillip. A former investment banker, Jim saw the potential in leasing laundry equipment to growing apartment communities. His instincts were right:

“For 20 years I had it all to myself,” Jim said.

As large apartment communities expanded, the leasing model became a core growth engine. Jim’s wife, Margaret, handled billing — transitioning from hand billing to computerized billing on an Apple IIe — and helped run operations.

Scott Carreras ’88 joined full-time, bringing energy, ambition and vision.

“Right off the bat, he was a natural — well suited for the business,” Jim said.

Maria Loehr Carreras ’83, a former client and now Scott’s wife, joined the company. She took over accounts payable, HR, payroll and marketing — becoming a critical part of daily operations.

2000–2010

Scott assumed total ownership of the business from Jim. But the two still talk daily.

“He’s a mentor to Scott,” explained Margaret.

Ownership expanded to include the fourth generation: Phillip ’19 and John ’21 Carreras.

Phillip, currently earning his MBA from the College of Charleston, will support HR, accounting, sales and operations at headquarters in Richmond. John, with a B.S. from the same college, will be involved in all aspects of operations as well, with plans to be based in Wilmington.

Three generations of the Carreras family at John’s BCP graduation in 2021.

SCOTT CARRERAS ’88 ON HIS GRANDFATHER, PHILLIP CARRERAS ’34:

“My grandfather was an opportunist. He’d never turn an opportunity down.”

SCOTT CARRERAS ’88 ON JIM CARRERAS ’58 AND PHILLIP CARRERAS ’34:

“My father’s motto was always ‘Work smarter, not harder.’ My grandfather judged how hard you worked by the calluses on your hands.”

MARIA CARRERAS ’83 ON HER ROLES AT THE COMPANY:

“Scott and I have a true partnership. In the beginning I supported Scott with proposals and all the behind-the-scenes administrative work. These days, my role is all about helping him keep the wheels on the track!”

JOHN CARRERAS ’21 ON LEARNING ABOUT WORK ETHIC WHEN HE FIRST WORKED AT ALS AT AGE 13:

“I will never forget working all day in the counting room without looking at my phone or taking breaks. That day, I met my mom for lunch and told her how much I had done and how exhausted I was. She simply said, ‘John, that’s work — welcome to the real world.’ Another memory that stands out is seeing my grandfather walk into the office while I was sitting down, putting stickers on bags. He looked at me and said, ‘John, you can’t work sitting down.’ That moment stuck with me.”

It’s many hands on deck in the mornings, as machines are loaded into trucks headed for various destinations across Virginia, the Mid-Atlantic and the Southeast.

PHILLIP CARRERAS ’19 ON HOW TO EARN RESPECT FROM YOUR EMPLOYEES:

“A large order was coming in, but the place was a mess. My Dad came out of his office and told us we needed to clear space. The acting manager at the time said he would call someone back to help, but my Dad, standing there in a full suit, said, ‘Hell with that, he’s helping a customer. I’ll move it with y’all.’ He jumped in, moving stacked washers across the warehouse in the heat, sweating through his suit. As I helped, too, one of his employees turned to me and said, ‘This is why we love working here. Not every business owner will break a sweat moving boxes alongside his team.’”

JOHN CARRERAS ’21 ON THE IMPORTANCE OF EDUCATION:

“My Dad’s favorite quote is, ‘Be a leader, not a follower,’ and I believe the foundation Benedictine provides helped instill that mindset.”

Scott and Jim communicate daily.

MARGARET CARRERAS ON HER ROLE IN THE BUSINESS, ESPECIALLY WHEN THEY TRANSITIONED FROM HANDWRITTEN BILLS DUE TO GROWING VOLUME:

“I set up the computer system for the billing. I used an Apple IIe. We had 300 accounts. It took two days to run all the bills!”

JIM CARRERAS ’58 ON THE KEYS TO SUCCESS:

“First, you must have the innate desire to succeed in life, at any cost. Second, is work ethic. (Margaret adds, ‘Jim always had a set of coveralls on the back seat, to assist his men in large installations.’) Third, education — and the confidence it brings. Benedictine does a great job. When I graduated, I could walk on water. And that degree of selfconfidence is so powerful.”

John Carreras ’21 and Phillip Carreras ’19.

Ever wonder what it takes to keep our 75-acre campus running smoothly for more than 550 Cadets and Gators? From wastewater and electricity to IT systems, athletic fields and beyond, the logistics behind the scenes are no small feat. Here’s a closer look at the systems, stats, and staff that keep everything humming.

1 About 600–650 games are played across all teams annually at BSoR, with 380 student-athletes transported throughout the year.

2 Our buses travel over 50,000 miles each year taking students to and from games. Annual bus fuel costs add up to $17,000.

3 Football games draw up to 3,000 Benedictine fans. Afterward, clean up takes 2 hours and involves coaches, staff and the Corps of Cadets.

4 Campus tech runs on 100 wireless access points, 20 switches, 13 data rooms and a 1-gigabit dedicated fiber line. 5 The IT team manages 407 devices — including 300 BCP Chromebooks and staff computers — and resolved 1,200 help tickets last year, most within 24–48 hours.

BSoR’s 75-acre campus includes 243,135 square feet of building space.

7 A retention pond on campus provides 500,000 gallons of irrigation and fire suppression through our private hydrants, supplementing county hydrants. It’s filled from the James River via a 30-horsepower pump and 4-inch industrial pipe.

8 Electricity costs an average of $28,750 per month — totaling around $345,000 per year. 9 We operate a Class III wastewater plant on-site because public sewer access is miles away.

“Most people think of classrooms, school supplies, uniforms or sports when they think of our schools — but BSoR is also a fullscale business, delivering what matters most to our families: a quality Catholic education for their children. The greatest challenge — and the greatest joy — of running BSoR is managing and leading a 200+ employee workforce who make it all happen for our Cadets and Gators.”

SCHOOLS OF RICHMOND — BY THE NUMBERS —

75

TOTAL CAMPUS ACREAGE

$13+ million COMBINED ANNUAL BUDGET (OPERATIONS & FOUNDATION)

200+ EMPLOYEES

550+ STUDENTS

10,000+ ALUMNI

Since 2016 ONGOING ACTIVE CONSTRUCTION PROJECTS

Thank you to Vice-President of Operations Ann Michele Sweeney; Director of Facilities Patrick Barksdale; Director of IT Thomas Glass; and Director of Athletics Fran Pochily for contributing to this article.

In today’s fast-moving business world, success isn’t just about strategy — it’s about mindset, continuous learning and embracing complexity. The leaders who thrive — like the Benedictine and Saint Gertrude alumni we feature in this issue of LABORA — are the ones who stay curious, passionate and above all, determined.

That’s the spirit behind this round-up. From bestselling books to top-rated podcasts, each of these selections offers a fresh perspective on what it means to build, grow and lead — especially when the path forward isn’t always clear.

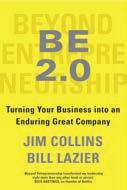

Jim Collins and Bill Lazier

The 2020 edition of Beyond Entrepreneurship, retitled BE 2.0, blends Jim Collins’ and Bill Lazier’s timeless leadership insights with new, practical guidance for building companies that endure. Collins honors his late mentor by expanding the original work with fresh insights drawn from his extensive research. The result is a thoughtful, actionable blueprint for turning a good business into a truly great one. — $30.00 (Hardcover)

Brené Brown

In Dare to Lead, Brené Brown asserts that effective leadership is rooted in vulnerability, values, trust and resilience. She challenges the traditional notion that leadership is about exerting power or control, advocating instead for creating environments where courage, risk-taking and honesty are encouraged. Brown emphasizes the importance of fostering a workplace culture that prioritizes bravery over fear, enabling teams to engage in meaningful conversations and grow together. — $28.00 (Hardcover)

Ben Horowitz

“That’s the hard thing about hard things — there is no formula for dealing with them,” writes Ben Horowitz. Sharing insights from his experiences as a CEO, Horowitz examines the significant challenges startups inevitably face. He emphasizes that success is determined by how leaders confront these obstacles, focusing on building resilient organizations and fostering environments where teams are motivated to overcome adversity. — $32.50 (Hardcover)

Simon Sinek

Great leaders prioritize their team’s well-being, building trust and loyalty that fuel long-term success. In his still-relevant and insightful 2014 book Leaders Eat Last, Simon Sinek explores the traits of effective leadership, emphasizing that the best leaders believe deeply in their organization’s “why.” By aligning their teams around purpose — not just profit — they create cultures where people feel valued and motivated to perform at their best. — $20 (Paperback)

Guy Raz

In the How I Built This podcast, host Guy Raz interviews a variety of business leaders, including Monica Nassif of Mrs. Meyer’s Clean Day, Michael Rubin of Fanatics and Todd Graves of Raising Cane’s. Raz explores their journeys from humble beginnings to building multi-million- or billion-dollar companies. Through insightful conversations, the podcast delves into the challenges they faced, the successes they achieved, and the continuous evolution required to stay relevant in the ever-changing business landscape.

Reid Hoffman

Hosted by LinkedIn co-founder Reid Hoffman, Masters of Scale examines how some of the most iconic companies evolve from startup to global powerhouses. Hoffman engages with a variety of business leaders, including former Starbucks CEO Howard Schultz and Madison Reed CEO Amy Errett, delving into their challenges and successes, and how they innovate to remain competitive.

Andrew Warner

Mixergy offers deep-dive interviews with startup founders and entrepreneurs who share how they built their businesses — from earning their first customers to developing strategies for scaling. Host Andrew Warner asks tough questions, drawing out insights on resilience, leadership and what it takes to grow a business from the ground up.

Andreessen Horowitz

Technology continually reshapes the business landscape. The a16z Podcast, produced by venture capital firm Andreessen Horowitz, features various hosts and interviews that explore how technological advancements influence business operations. The podcast offers guidance to business leaders on staying ahead of emerging trends, emphasizing that embracing innovation is key to paving the way for success.

Preston Pysh, Stig Brodersen and the Investor’s Podcast Network team

One of the most popular investing podcasts, We Study Billionaires, explores the strategies and philosophies of investors like Warren Buffett, Ray Dalio and Howard Marks. The hosts break down complex financial topics into digestible insights — ideal for leaders and professionals looking to think long-term, grow wealth and better understand global markets.

Rachel Slotterback contributed to this article. Rachel is the Chair of the English Department at Benedictine College Prep.

My years at Benedictine were the most formative of my life. That’s why I’ve established a scholarship in my estate plan — to give another student the same opportunity. A life insurance vehicle makes it possible to create a substantial fund without straining current finances. Please join me in leaving a legacy that supports future students.”

PAUL S. “CHIP” BLILEY, JR. | BENEDICTINE CLASS OF 1967

& PLANNED GIVING

— BEQUEST —

Include a specific amount or percentage in your will — one of the simplest ways to give while reducing your taxable estate.

— LIFE INSURANCE —

Incorporating planned giving into your financial strategy is a powerful way to shape the future of the Benedictine Schools of Richmond. Your gift — whether through a will, IRA or other asset — supports scholarships, programs, faculty and facilities. Every gift, regardless of size, strengthens our mission and inspires future generations of Cadets and Gators.

Have you included Benedictine or Saint Gertrude in your estate plans? By contacting our Advancement office, we can recognize your generosity through our legacy societies.

Name Benedictine Schools of Richmond as a beneficiary. An easy option for donors of any age, especially younger alums.

— IRAS OR RETIREMENT PLAN ASSETS — Designating these assets can reduce income and estate taxes. Required minimum distributions begin at age 73.

— REAL OR PERSONAL PROPERTY — Donate fully owned property and deduct its fair market value while avoiding capital gains tax.

— CHARITABLE GIFT ANNUITY —

In exchange for your gift, receive lifetime income through a simple contract with Benedictine Schools of Richmond.

— CHARITABLE TRUSTS - LEAD, REMAINDER OR UNITRUSTS —

Lead, remainder, or unitrusts may offer significant tax benefits — consult with us and your advisor to explore options.

For additional information about planned giving options that can also provide financial benefits to you and your heirs, please contact Kristina Pudner, Director of Scholarship Giving, at 804-708-9581 or kpudner@benedictineschools.org

Due to the unique corporate structure of Benedictine Schools Educational Foundation, qualified charitable distributions should be unrestricted gifts to Benedictine Schools of Richmond. Consult your financial advisor or attorney before making a planned gift.

BSoR entrepreneurial studies program takes the next step.

— JOE SWEDISH ’69, CHAIR OF THE BSOR ENTREPRENEURSHIP COMMITTEE —

Last year, we introduced the early framework for a new entrepreneurship program — one designed to spark curiosity, inspire innovation and equip students with the skills to navigate an everchanging world. At the time, we shared that the curriculum under development would include topics such as business and product development, market evaluation, sources of funds, cost-benefit evaluation and management skills. We also shared our intent to gauge student response, with the possibility of developing a stand-alone course in the future.

Today, I’m thrilled to report that momentum is building.

Behind the scenes, a dedicated Entrepreneurship Committee made up of educators, advisors and professionals has been meeting quarterly to guide the vision and ensure we’re aligning our efforts with best practices in the field. We’ve also engaged with established entrepreneurship programs, including the Batten Institute for Entrepreneurship at UVA’s Darden School of Business and Culver Academies, a top independent boarding school in Indiana, to learn how to bring a similarly high-caliber experience to our students.

With this foundation in place, we are now preparing to officially launch our program in November 2025.

More than just business education, this program will cultivate an entrepreneurial mindset and intelligence as a way of thinking marked by creativity, resourcefulness, risk-taking and resilience. It’s about planting a seed in every student — not just those who dream of starting a business, but all young people taking on roles and responsibilities throughout their careers that will require the foundational elements of entrepreneurship.

This initiative aligns directly with our schools’ strategic plan, which places a strong emphasis on having a variety of leadership development opportunities. We believe the entrepreneurial mindset is a natural extension of the formation our students receive at Benedictine and Saint Gertrude: character-driven, mission-oriented and focused on contributing meaningfully to the world by being leaders of consequence.

Importantly, we want all students — not just those taking specific classes — to have access to entrepreneurial experiences. While some students may choose to go deeper through co-curricular practical applications and enrichment opportunities, the program will be available to everyone, outside the traditional classroom setting.

Of course, we’re still in the early stages, and this is very much a “start small, grow intentionally” journey. But we are energized by the possibilities — and by the enthusiastic response we have experienced during the early phase of design.

Consistent with the nature of entrepreneurship, the program design is driven by innovative thinking to create a unique experience for students hoping to add a new dimension to their academic portfolio. As we move closer to the launch, we remain deeply committed to the idea that entrepreneurship is not just about building businesses — it’s about building lives of purpose that create value for the enterprise and the people it serves.

Last year, Joe ’69 and his wife, Gene, established the Joseph and Gene Swedish Family Foundation Entrepreneurial Scholarship. Its purpose is to challenge and reward aspiring entrepreneurs from both Benedictine and Saint Gertrude who engage meaningfully with the program and its associated work components. A successful entrepreneur and former leader of some of the nation’s largest healthcare corporations, Joe has long been a trailblazer and champion of innovation.