Abstract. This article delves into the groundbreaking potential of human-AI collaboration in operations management (OM), showcasing how the fusion of artificial intelligence(AI)withhumandecision-makingis revolutionizing industries. By leveraging AI’s unparalleled ability to analyze vast datasets and generate insights, while complementing it with the nuanced judgment and ethical reasoning of humans, organizations can achieve remarkable advancements in forecasting, maintenance, supply chain optimization, and workforce planning.Backedbyreal-world casestudies and anchored in robust theoretical frameworks like the Technology Acceptance Model (TAM) and SociotechnicalSystemsTheory,wecontendthat the true power of AI lies not merely in its technical implementation but in its seamless integration with human expertise, ethical considerations, and organizational culture. Unlocking this potential requires a strategic approach that aligns AI capabilities with human roles, fostering a symbiotic relationship that drives innovation and operational excellence.

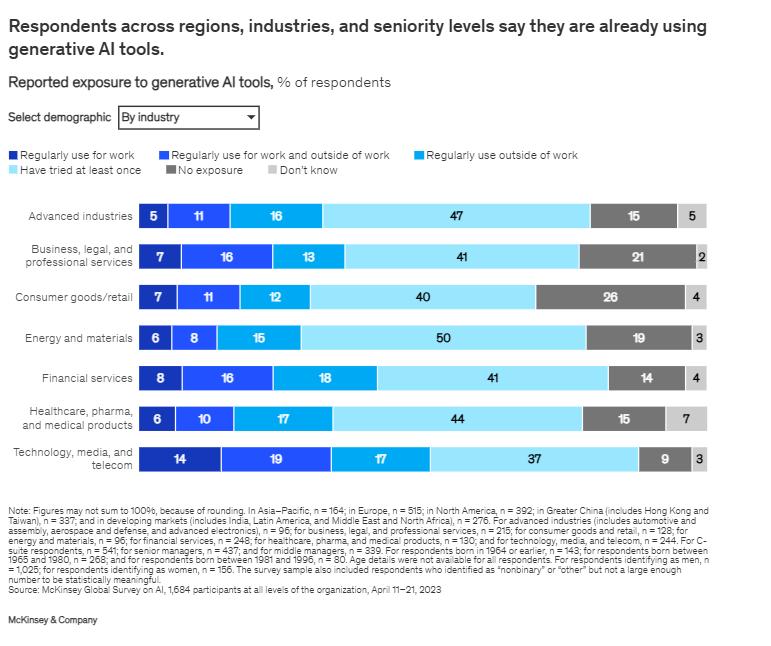

The integration of AI into operations management is reshaping industries by enabling unprecedented levels of efficiency, scalability, and strategic insight. While AI systems excel at processing vast amounts of data and generating predictions at remarkable speed, human oversight remains indispensable for contextsensitive decisions and ethical judgment. According to McKinsey & Company [1], organizations that embrace human-AI collaboration report up to a 35% increase in operational efficiency. However, technology alonecannot guaranteesuccess; harmonizingAI systems with human workflows is crucial for unlocking value.

- Srivathsan S

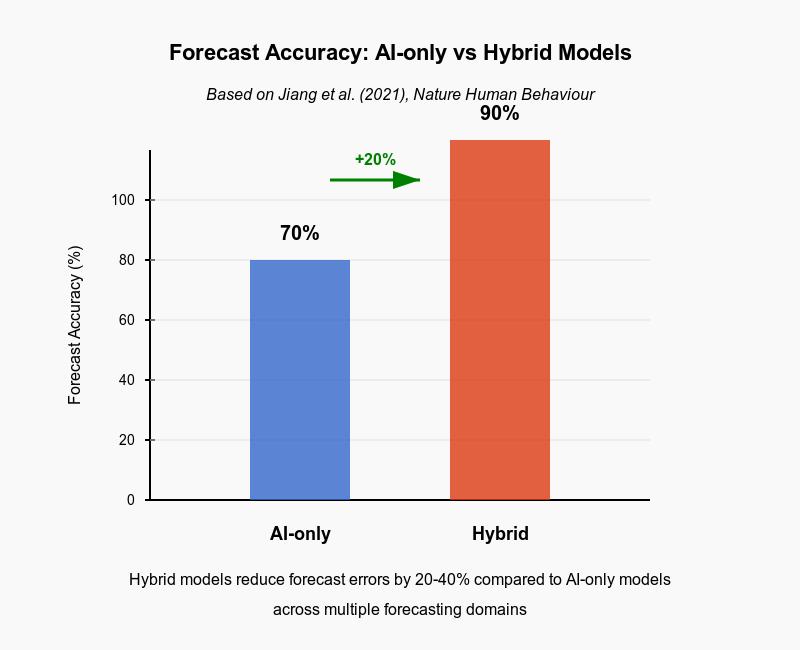

AI-driven forecasting leverages machine learning algorithms to analyze historical and real-time data, providing highly accurate predictions. Yet, these modelsoftenstruggleduringanomaliesorunexpected market shifts unless complemented by human judgment. Choi et al. [2] demonstrated that hybrid approaches combining AI with human expertise reduced forecast errors significantly compared to AIonly systems, particularly in dynamic environments.

Data Sources: [13]Image recreated for illustrative purposes

Predictive maintenance employs machine learning to analyze sensor data, identifying potential equipment failures before they occur. For example, GE Aviation achieved a 30% reduction in downtime by implementing predictive maintenance systems, with technicians retaining final decision-making authority [3]. This human-in-the-loop approach ensures reliability while leveraging AI’s analytical

capabilities.

Fig. 2. Predictive Maintenance ROI: Human-in-the-Loop vs. Fully Automated. Data Sources: McKinsey & Company, "Predictive Maintenance Insights," 2023; Deloitte Insights, "AI in Operations," 2022. Image recreated for illustrative purposes.

AImodelssimulatevariouslogisticsscenariosto recommend cost-efficient solutions. IBM’s Watson Supply Chain system, when paired with human oversight, reduced logistics costs by 15–25% [4]. Human experts refine AI-generated recommendations, ensuring feasibility and alignment with organizational goals.

AI tools assist in staff scheduling and resource allocation, but collaborative planning yields superior outcomes. Deloitte [5] reported a 30% decrease in absenteeism when employees cocreated schedules using AI tools, fostering greater engagement and satisfaction.

Computer vision technologies detect production defects with high accuracy. However, human review remains essential for edge cases, especially in industries like aerospace and automotive, where precision is paramount.

The TAM framework highlights why AI tools are often met with resistance from operations staff. Deloitte [6] found that 45% of workers distrust algorithmic suggestions, underscoring the need for transparency and explainability in AIsystems.

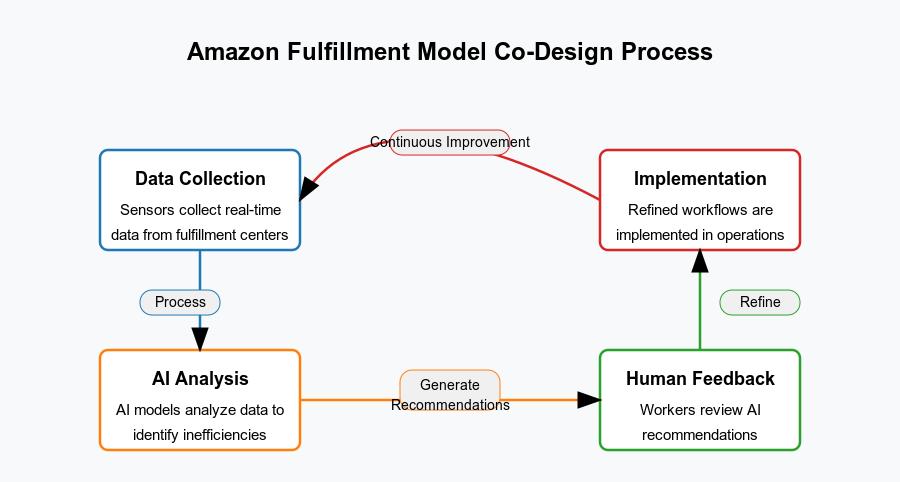

This theory advocates for the co-design of AI tools alongsidehumanusersto ensureseamless integration. Amazon’s fulfillment centers exemplify this approach through iterative feedback loops and continuous system refinement [7].

Fig. 3. Amazon Fulfillment Model Co-Design Process Data Source: Amazon Annual Report, 2021 [7]. Image recreated for illustrative purposes.

4.1

Amazon’suseofAItomanageforecastingandrobotic workflows, coupled with human exception handling, resulted in a 60% reduction in fulfillment time [8]. This hybrid model demonstrates how AI and humans can work synergistically to optimize operations.

Siemens Healthineers implemented AI systems to reduce MRI downtime by 30%. The success of this initiativewas bolsteredbyexplainable algorithms and clearly defined roles for human technicians, ensuring trust and accountability [9].

5.1 Workforce Resistance and Skills Gap

Despite the emergence of collaborative roles such as AI Operations Strategists, 52% of workers fear displacement by AI [10]. Addressing these concerns requires investment in reskilling and fostering a culture of inclusion.

5.2 Bias and Ethical Oversight

Unchecked AI systems may amplify biases, leading to unintended consequences. For instance, facial recognition tools used in HR processes exhibited racial and gender inaccuracies [11]. Ensuring fairness and accountability is critical for ethical AI deployment.

Fig. 4. Barriers to AI Adoption in OM.

Source: Deloitte AI Report, 2022 [6]

Explainable AI(XAI)

ExplainableAIenhancestrustandadoptionbymaking AI decision-making processes transparent and interpretable.

Digital twins virtual replicas of physical operations enabledynamicplanningandsimulation, empowering organizations to test strategies in a riskfree environment.

AI systems that learn from user feedback can continuously improve, creating a virtuous cycle of human-machine collaboration.

Frameworks like the EU AI Act (2023) [12] provide regulatory guidance, ensuring responsible AI development and deployment.

AIapplicationsinlogisticshavethepotentialtoreduce emissionsby15%by2030[13],contributingtoglobal sustainability efforts.

Human-AIcollaborationrepresentsaparadigmshiftin operations management, offering unparalleled opportunities for innovation and efficiency. To fully realize its benefits, organizations must prioritize transparent, co-designed systems where AI augments rather than replaces human expertise. Ethical design, workforce inclusion, and ongoing co-evolution of human and machine roles are essential for sustainable success.

1. McKinsey & Company, Generative AI in Operations , 2024.

2. T. Choi et al., “Big Data Analytics in Operations Management,” ResearchGate, 2018.

3. GE Aerospace, Predictive Maintenance Initiative , 2023.

4. IBM, Watson Supply Chain , 2023.

5. Deloitte, Human-Centric Workforce Planning , 2020.

6. Deloitte, State of AI 2022 Report , 2022.

7. Amazon, 2021 Annual Report , 2021.

8. Gartner, Supply Chain AI Insights , 2023.

9. World Economic Forum, Future of Jobs Report , 2023.

10. J. Buolamwini and T. Gebru, “Gender Shades,” Conference on Fairness, Accountability, and Transparency, 2018.

11. European Commission, EU AI Act , 2023.

12. E. Strubell et al., “Energy and Policy Considerations for Deep Learning,” ACL Anthology, 2019.

13. Jiang, L., Zhu, H., Tao, J., Yin, B., & Chen, K. (2021). "Improving AI-based forecasting with humanmachine hybrid intelligence," published in Nature Human Behaviour, Vol. 5, pp. 518-529.

Srivathsan S

Srivathsan S is currently pursuing a B.Tech in Computer and Communication EngineeringatAmritaVishwaVidyapeetham,Chennai.Asathird-yearstudent,he is deeply interested in the fields of business operations, data analytics, and AI applications in organizational decision-making. His work explores the synergy between technology and management.

- Raj Aryan & Dhaneshwar Sahu

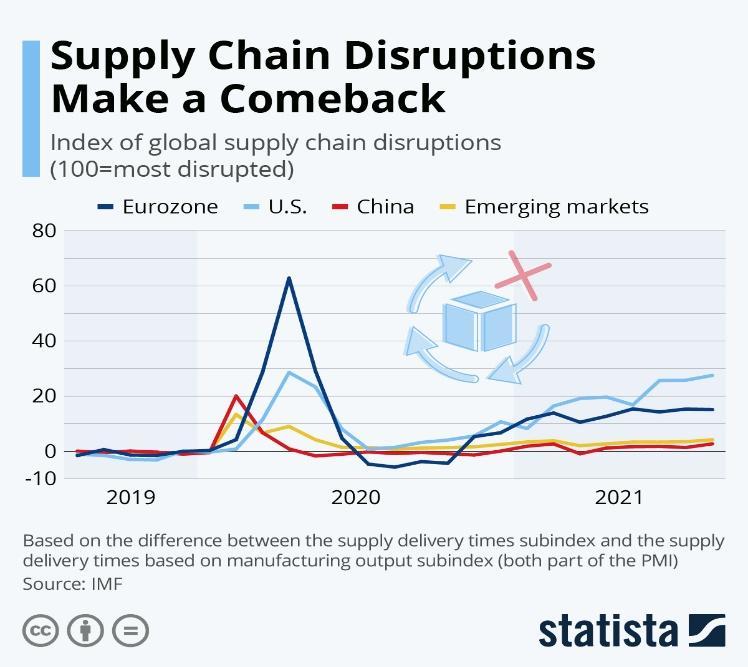

In today’s volatile and interconnected global economy, supply chain resilience has transitioned from a strategic advantage to an operational necessity. Unforeseen events such as the COVID19 pandemic, geopolitical conflicts, climateinduced disruptions, and changing consumer demands have exposed vulnerabilities in even the most robust supply chains. Companies are now investing in resilience to withstand, adapt to, and recover from these disruptions while maintaining continuity in operations. This article explores the strategies, challenges, and technological innovations driving the re-engineering of supply chains to foster resilience.

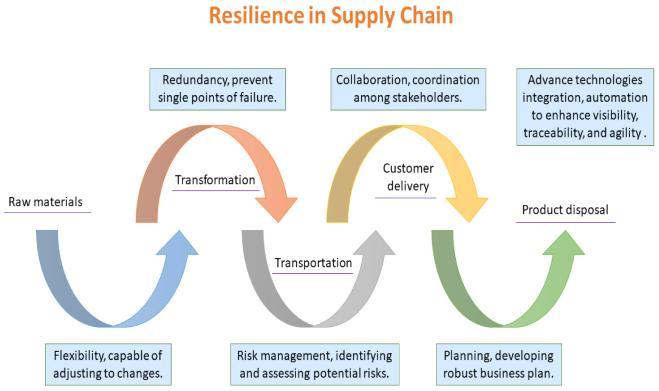

Supply chain resilience refers to the ability of a supplychaintopreparefor,respondto,andrecover from disruptions. It combines proactive risk management, adaptability, and operational efficiency to ensure minimal impact on business operations. The three critical dimensions of resilience are:

- Preparedness: Identifying vulnerabilities and formulating contingency plans.

- Adaptability: Quickly adjusting to changing conditions, such as dema fluctuations or supplier failures.

- Recovery: Restoring normal operations postdisruption with minimaldowntime.

The four pillars of resilient supply chain

• Contingency means having backup plans and

extra stock ready in case something goes wrong.

• Flexibility helps companies quickly adapt their operations when unexpected changes happen.

• Visibility is about having clear oversight of the entire supply chain to spot issues early.

• Collaboration involves strong teamwork within the company and with partners to handle disruptions smoothly.

Global disruptions have underscored the need for resilient supply chains. Some notable examples include:

- The COVID-19 Pandemic: Lockdowns disrupted manufacturing and logistics globally, leading to shortages of essential goods.

- Geopolitical Conflicts: Trade wars and sanctions have restricted access to critical raw materials, as seen in the semiconductor industry.

- Climate Events: Hurricanes, wildfires, and floods

Digital Twins: Supply Chain Simulation in a

In today's extremely dynamic and linked global economy, firms must foresee issues andimprovetheirsupplychainsinadvance.Digital Twins are virtual duplicates of physical supplybusinesses to test various operational scenarios before making world settings. Digital twins provide comprehensive visibility into supply chain elligence

Source - https://www.mckinsey.com/featuredinsights/2023-year-in-review/2023-the-year-in-charts

These events have pushed companies to reimagine their supply chains by localizing production, diversifying suppliers, and adopting digital tools for real-time visibility.

A resilient supply chain starts with robust risk management. Key strategies include:

-SupplierDiversification:Relyingonmultiplesuppliers from different geographies to mitigate risks of regional disruptions.

-InventoryManagement:Adoptingabalancedapproach to inventory, such as maintaining safety stock or leveraging just-in-case models.

-Scenario Planning: Using predictive analytics to anticipate potential disruptions and prepare response strategies.

Companies like Apple and Toyota have successfully navigated disruptions by integrating these practicesinto their operations.

Company Strategy Outcome

Amazon Regional warehousing and real-time tracking. Ensured continuity during disruptions.

Toyota Dual sourcing and just-in-time inventory. Reduced supply chain risks effectively.

Source: McKinsey &

According to DHL Logistics powered digital twins have lowered operational expenses by 25% while time supply chain visibility. This Source:https://www.mckinsey.com/capabilities/str ategy-and-corporate-finance/our-insights/strategicresilience-during-the-covid-19-crisis

Agility in logistics is pivotal for resilience. Flexible distribution networks enable companies to respond swiftly to disruptions. For instance:

-DecentralizedWarehousing: Amazon’suseofregional warehouses ensures that disruptions in one location do not affect nationwide deliveries.

-Last-Mile Innovations: Companies are leveraging drones and autonomous vehicles to enhance last-mile delivery during crises.

Technological Innovations in Resilient Supply Chains

Technology plays a transformative role in enhancing resilience. Some noteworthy advancements include:

-Digital Twins: Simulating supply chain processes to predict outcomes of potential disruptions.

-Blockchain: Ensuring transparency and traceability across the supply chain, thereby reducing fraud and inefficiencies.

-Artificial Intelligence (AI): AI-powered analytics optimize demand forecasting, inventory management, and route planning.

Greenportsandrenewableenergyaretransforming the logistics business as global supply chains drivenoptimizations, electrification of transportation networks and Source:https://www.mckinsey.com/capabilities/q uantumblack/our-insights/the-state-of-ai-in-2023generative-ais-breakout-year

Companies like Walmart and Maersk are leading the charge by integrating these technologies into their supply chains.

Consumer preferences have shifted dramatically in

recent years, emphasizing sustainability, personalization, and speed. Companies are responding by:

-SustainabilityInitiatives:Adoptinggreensupplychain practices, such as using renewable energy and reducing waste.

- Personalized Offerings: Leveraging data analytics to tailor products and services to individual customer needs.

- E-commerce Integration: Strengthening e-commerce capabilities to meet the demand for online shopping.

Zara, for instance, uses a demand-driven production model to adapt quickly to changing fashion trends.

A resilient workforce is as important as resilient systems. Companies are investing in training programs to equip employees with skills for crisis management. This includes:

- Cross-Functional Training: Ensuring employees can adapt to different roles during disruptions.

- Technology Upskilling: Familiarizing employees with digital tools and platforms used in supply chain operations.

Despite its importance, achieving supply chain resilience is fraught with challenges:

-Cost Pressures: Investments in resilience, such as diversifying suppliers or adopting technology, can be expensive.

-Regulatory Compliance: Navigating varying regulations across regions adds complexity.

-DataSecurity:Increasedrelianceondigitaltoolsraises concerns about cybersecurity.

To assess the effectiveness of resilience strategies, companies are adopting metrics such as:

- Time to Recovery (TTR): Measuring how quickly a supply chain can return to normal operations after a disruption.

- On-Time Delivery (OTD): Evaluating the consistency of delivery times under varying conditions.

- Inventory Turnover Ratio: Analyzing how efficiently inventory is managed during disruptions.

Metric Description Relevance

Time to Recovery (TTR)

On-Time Delivery (OTD)

Time taken to restore supply chain operations after disruption. Essential for operational continuity.

Percentage of orders delivered on time. Reflects reliability.

Inventory Turnover Ratio Frequency of inventory replacement. Indicates efficiency in disruption periods.

Source: Deloitte Insights.

References:

To assess the effectiveness of resilience strategies, companies are adopting metrics such as these to gauge recovery speed, reliability, and efficiency.

Inaneradefinedbyuncertainty,buildingaresilient supply chain is no longer just a strategic move it’s the foundation for long-term survival and growth. Rather than reacting to crises, companies must now anticipate them, using data, technology, and agile systems to stay one step ahead.

The integration of advanced tools like AI, blockchain, and digital twins isn’t just about staying modern it’s about creating smarter, more flexible supply chains that can pivot quickly under pressure. At the same time, today’s consumers expect fast, sustainable, and personalized experiences. Meeting these demands means supply chains must evolve to become more connected, transparent, and responsive.

While the road to resilience is filled with challenges be it high costs, shifting regulations, or digital risks organizations that take proactive steps today will lead tomorrow. Whether it’s through smarter inventory strategies, upskilled teams, or stronger partnerships, the future belongs tothosewhocanadaptfastandrecoverevenfaster.

Supply chain resilience isn’t just about bouncing back it’s about bouncing forward.

1. Chopra, S., & Sodhi, M. (2021). Managing Risk to Avoid Supply-Chain Breakdown. Harvard Business Review.

2. The Impact of COVID-19 on Supply Chains, McKinsey & Company, 2020. Supply Chain Resilience in the Age of Disruption, Deloitte Insights, 2023.

3. American Psychological Association. (2020). Publication manual of the American Psychological Association (7th ed.). American Psychological Association.

4. C.B. 'Bud' Johnston Library. (2015). Supply Chain & Logistics Management Research: APA Style Guide [Research guide]. Western Libraries. https://guides.lib.uwo.ca/logistics/apa

5. EasyBib. (2022, June 21). How to cite a report in APA https://www.easybib.com/guides/citationguides/apa-format/how-to-cite-a-report-apa/

6. Indiana University Libraries. (2015). Supply Chain Management: Citation. https://iu.libguides.com/c.php?g=407801&p=6044605

7. QuillBot. (2025, January 13). Chicago Journal Article Citations: Format & Examples. https://quillbot.com/blog/citation/chicago-journal-citation/

Raj Aryan

RajAryanisapre-finalyearB.TechstudentinComputerScienceandEngineering (Artificial Intelligence)at CSVTU,Bhilai. He is passionateabout AIapplications in operations and supply chain management. Raj is currently a project intern at IIM Bangalore under the Chairperson of Finance and Accounting and has also interned at IISc Bangalore.

Dhaneshwar Sahu

Dhaneshwar Sahu is a third-year B.Tech student in Computer Science and Engineering at CSVTU, Bhilai. He is currently a research intern at IIT BHU, focusing on technological innovations in supply chain systems. With a strong interest in logistics, automation, and digital transformation, he aims to build impactful solutions at scale.

Operations and Supply Chain Management (OSCM) is no longer an ivory tower activity but a path-breaker to prosperity. In order to thrive in the times of turbulence and velocity, organizations can no longer be guilty of indulgence in wastage, blind spots, or fixed systems. Organizations have to deal with new technologies, break down old models, and avoid disruptions in the future. In this article, a few of today's most essential problems that are redefining how business operations and supply chains arehandledare discussed.

Source:https://research.aimultiple.com/supply -chain-sustainability/

Technology and sustainability are no longer conflicting options in OSCM: they go hand in hand. Those new technologies of Artificial Intelligence (AI), Machine Learning (ML), and robots make everything from demand forecasting to inventory management and logisticstothesimplestthatitcanbe.AI-directed routingsavesthefuelburnedandtimebutrobots in the warehouse eliminate human errorandthe costof labor.

- Gungun Jain & Abhilasha Negi

Meanwhile, sustainability is a done deal. Shoppers, regulators, and investors are insisting on it. They are green logistics, employing reusable packaging and making investments in low-carbontransportation.Othersaregoingeven farther and developing circular supply chains— reuse, recycling, and remanufacturing-based systems instead of linearconsumption.

With the help of technology and sustainability, supply chains are not only efficient but also resilient, future-proof and sustainable. Together they achieve stakeholder trust and protect the bottom line from environmental as well as regulatory risks.

While information and systems are most important, actually, decisions are made by people and people do have biases. Behavioral OSCM corrects for this with its focus on human influence. Incontrasttorationaldecision-making assumptions in traditional models, behavioral models acknowledge the influence of emotion, habit, and perception governing operating decisions.

The most classic illustration is the bullwhip effect where minor demand variations at retail translate into enormous swings further up the pipeline. All too frequently, it is driven by panic, overreaction, or communication failure between partners.Moreandmorecompaniesareapplying behavioral science to create more effective training, refine forecasting, and re-engineer incentives. Educating managers not to become victims of mistakes such as anchoring or recency bias can have a direct impact on planning accuracy.

Building trust, transparency, and cooperation in supply chains also removes inefficiencies. The pairing of behavioral science and data analytics provides companies a tremendous advantage not only in running operations, but in leading humans.

Source:https://www.researchgate.net/figure/UE -SSCM-Service-Supply-Chain-Model3_fig3_26851117

Not every supply chain handles physical goods. Some handle services consider healthcare, IT, education, or hospitality. These types of service supplychainshandleresponsiveness,quality,and customerexperience.

There is one aspect, though, which is harder for SSCM: perishability of services services do not have warehouse or inventory capacity. That leaves great real-time capacity planning and demand forecasting on the table. For instance, hospitals need to dynamically allocate people, beds, and equipment depending on patients' requirements. In the same way, IT services companiesneedtodelivertechnicalcapabilityatdemand in termsof fixing clients' problems.

Technology is filling these gaps. ERP solutions, CRM, and AI bots have made the services reachable, trackable, and responsive. Effectiveness is not the goal but to deliver

consistently high-quality experiences that create long-clientrelationships.

Source:https://www.cbsnews.com/news/productshortages-inflation-supply-chain-2022

Pandemics, wars, and disasters have learned us tobeschoolmasters:globalsupplychainsarenot secure. During a shortage of strategic products such as semiconductors, food, or medicines, the knock-on effect touches other sectors. The socalled "shortage economy" has rendered onesource reliance and just-in-time inventory systems dubious.

Consequently, firms are creating stronger supply bases, reshoring, and constructing stronger networks. More and more, they're also using "just-in-case" inventing strategies paying a premium for greater holding costs in the guise of availability.

There is "just-in-time" stock planning, but with greater holding costs and greater availability, it's becoming the moreappealing option.

Capabilititessuchaspredictiveanalyticsandrealtime sense of demand have become strategic. They allow businesses to anticipate disruptions mounting up even before they take place and adjust accordingly. Speed, agility, and foresight nolongerarenice-to-haves theyarethecostof doingbusiness.

Innovation within OSCM isn't always a matter of implementing new technology it's about challengingthestatusquo.It'swhetherit'sdigital twins (computer models of supply chains) or collaboration software that exists in the cloud, innovation is combining systems more with each other, making them more responsive and customer-centric.

Digital twins enable business tomodel decisions, anticipate disruptions, and test strategies before they implement them. Cloud-based platforms enable suppliers, manufacturers, and retailers to share information in real-time and drive out delays, maximize visibility.

Apart from technology, innovation is also taking place in collaboration. Companies are coming togethertodevelopnewmaterials,testingsmart packaging, or building open innovation communities. The best supply chains today are no longer lowest cost or largest size They're mostcollaborative andinnovative.

Supply chains are no longer dumb networks. AI and ML are helping companies forecast demand, route optimization, and inventory planning with precision. Predictive maintenance minimizes downtime and optimizes equipment life, while automated warehouses drive productivity to the limits andreduce the involvementofhumans.

Cloud computing is virtually at the epicenter of geographically connecting systems. On-demand access to information allows companies to spot wastage and respond in one go. Data analysis, however, rendersrawfacts usable information

Speed, response, and accuracy form a priority agenda to maintain pace with mounting rising customerdemands.Technologyneverwassucha discretionary asset but a source of competitiveness.

Blockchain is beginning to emerge as a track and trace and visibility solution for the supply chain. Rather than standalone records of information, blockchain's common, tamper-evident and decentralisedledgerismore.It'ssimplertotrace, simpler to verify, and more to the point, compliance assured.

For superstore supermarket shopping, take just one example, blockchain can trace an item from farm to superstore shelf—lifeblood in an adulteration. Drugs have it in order to battle counterfeits by verifying authenticity at each handover.

Smart contracts computer programs that execute when a specific condition is met will further emancipate the world from middlemen and prevent fraud, accelerating payments and transactions even more. By eliminating middlemen and eliminating fraud, blockchain creates more trust and accomplishes more with less velocity.

The Internet of Things (IoT) connects the digital and physical worlds. To supply chains, this translatesintomonitoringshipments,monitoring equipment, and controlling inventories in real time. GPS track-and-trace units, RFID tags, temperature monitors, and intelligent shelves all reportbacktoheadquarters computers.

Illustration: Food consignments in transit can be traced to maintain refrigerated temperature levels.IoTsensorsinawarehousemonitorstocks andreplenish on order automatically.

With cloud and AI integration, IoT enables anticipatory decision-making—anticipatory and preventivedecision-making,ratherthanreactive. IoT manages wastage, enhances the quality of

services, and supply chains become customercentric andresponsive.

Sustainabilityisincreasinglybeingintegratedinto the strategy planning stage. Supply chains are redesigned to minimize environmental impact and solve social responsibilities. It is done through recycling material, optimal delivery routes, electric-delivery trucks, and fair-trade vendors.

Circular business models are in the future for companies as well—design for recycling, repair, and reuse. Lifecycle assessment tools monitor environmental performance, and emissions accounting software programs make reporting and compliancesimpler.

It is good business as well. Greening has customer and brand reputation and regulatory advantages as well. It's not just the right thing to do it's good business.

Source: https://www.mdpi.com/20711050/15/14/10838

Resilience is not response-after-the-fact it's proaction. The climate-disruption and cyber attackdisruptionthreatlandscapeis growing.The lean, cost-cut supply chains will be threatened. The backup and the agility are being laid bare by the new normal

The responses are multi-sourcing, buffer stock, and in-region production. Computer-based risk simulation looks forward to future disruption and simulates various response.

Relationships also matter. Well-coordinated relationships between suppliers and supply providers can make supply chains robust enough to ride the shock and emerge stronger. It is not about risk avoidance but riding the shock and emerging stronger.

Source:https://www.slideteam.net/manageme nt-powerpoint-presentation/ecommercelogistics-supply-chain-management-model.html

E-commerce redefined the playbook for customer expectations for operations. Velocity, convenience, and transparency are table stakes. Toprovidethem,companiesaremergingphysical and digital channels creating omnichannel networks of logistics that can take orders anywhere and deliver anywhere. Dark stores, micro-fulfillment centers, and last-mile modes of delivery are in vogue. Channel-based demand forecasting is augmented with artificial intelligence, and real-time visibility keeps customersuptospeed

Returns truly are a make-or-break test— particularly in clothing and electronics. Reverse logistics success is on thecompetitor'sto-do list.

It's actually a matter of making it seamless. It's not necessarily about superior technology, but superior strategy.

Source:https://3scsolution.com/insight/sustain able-supply-chain

Green supply chain management isn't just a question of reducing damage it's about creating more sustainable, more responsible, and more creative systems. Top companies have a basic set of best practices that merge business objectives with social and environmental responsibility.

1.LifeCycleThinking:Firmsembraceanend-toend perspective of product life cycles, from raw material sourcing to end-of-lifedisposal. Systems thinking in this case puts unforeseen environmental repercussions into the spotlight and enables more informed design, sourcing, and waste management choices.

2. Ethical Sourcing Practice: Well-defined, routine standards of workers' rights, occupational safety and health, and environment are the minimum. Others use third-party certifying bodiesthatoverseesuppliers' practice andrequire compliance.

3. Disclosure and Transparency: Disclosure of stakeholders' sustainability information confirms trustworthiness. Some companies publish supply chain sustainability reports nowadays with the support of tools such as GRI (Global Reporting Initiative) or CDP(Carbon Disclosure Project).

4. Regional and Local Supplying: Shorter supplier-mfg distances minimize transportation

emissions and reliance on high-risk worldwide logistics.

5. Circular Economy Integration: Planning of supply chain for end-of-life product recovery for reuse or recycling is being increasingly adopted. Take-back and reverse logistics provide the solutions.

6.Digitalempowerment:Blockchain,AI,andIoT technologies allow for end-to-end visibility and traceability, simpler monitoring of the environmental footprint and application of sustainability standards across the supply chain.

These practices do work innovative businesses in industries ranging from consumer goods to aerospace have put them into practice and have shown the ability to create sustained value for business and society.

Greening the supply chain means bringing environmental and social responsibility into each stage of operations, from sourcing to delivery. There are several effective levers that can help companies make the transition to a greener, more responsible supply chain.

Supply chain cooperation is perhaps the strongest strategy. By connecting suppliers to objectives such as lower emissions, improved conditions, or the utilisation of renewable resources, organisations have an amazing leverage throughout the value chain. Because through activity auditing and supplier scorecards, performance and accountability are monitored and enforced.

Product and packaging reengineering to consume less or cleaner materials is another possibility. Reduced packaging, composting options, and returnable product designs reduce waste and improve logistics.

Carbon monitoring and reporting technologies also enable companies to track and track their carbon footprint. Together with offset programs, these technologies can enable companies to

comply with legislation and stakeholder requirements.

Switching to cleaner methods of shipping goods from location to location, like train or electric vehicle fleets, and using AI to minimize delivery routes also minimizes gas.

Sustainably training employees and management in-housemakessurethatenvironmentalissuesare taken into consideration with everyday decisionmaking.

The idea is to consider sustainability as part of part of supply chain strategy instead of as a distinct project.

The supply chain and operations management businessischanging atlightspeed.Whateverwas once referred to as back-office a couple of years ago now is the central nervous system of strategy. Whether it is deployment of AI and blockchain, green supply chains, or geopolitical risk management, supply chains now need to be agile, transparent, and resilient. Crisis-proof, team-minded, and intelligent firms will be the champions of tomorrow. Markets worldwide still have room to grow, and customer demand is still hungry but growing, but OSCM champions will bethosethat are ableto change successfully, ethically, and in sufficient numbers.

1. New Technologies & Supply Chain Optimization (AI, Robotics, IoT)

https://www.mckinsey.com/capabilities/operations/our-insights/digital-supply-chain

2. Sustainability in Supply Chains

https://hbr.org/2021/05/your-supply-chain-needs-a-sustainability-strategy

3. Behavioral Supply Chain Management

https://www.informs.org/ORMS-Today/Public-Articles/June-Volume-47-Number-3/Behavioraloperations-research

4. Service Supply Chains

https://www.researchgate.net/publication/233475826_Service_supply_chain_management_A_review_of_ operational_models

5. The Shortage Economy & Disruption

https://www.weforum.org/agenda/2022/06/shortage-economy-supply-chain-crisis/

6. Innovation in Supply Chains

https://sloanreview.mit.edu/article/building-supply-chain-innovation-ecosystems/

7. Blockchain in Supply Chains

https://www2.deloitte.com/us/en/pages/consulting/articles/blockchain-supply-chain-innovation.html

8. IoT for Real-Time Monitoring

https://www.ibm.com/blogs/internet-of-things/iot-in-supply-chain/

9. Supply Chain Resilience and Risk Management

https://hbr.org/2020/09/global-supply-chains-in-a-post-pandemic-world

10. E-commerce and Omnichannel Logistics

https://www.pwc.com/us/en/industries/consumer-markets/library/omnichannel-retail.html

Gungun Jain is a first-year B.Tech student at Indira Gandhi Delhi Technical University for Women, specializing in Information Technology. With a strong interestinemergingtechnologiesandapassionforcreatingsustainable,impactful solutions for society, she brings a fresh and thoughtful perspective to operations and supply chain management.

Abhilasha Negi is a first-year B.Tech student at Bharati Vidyapeeth College of Engineering,specializinginElectronicsandCommunicationEngineering.Shehas akeeninterestinoperationsstrategy,sustainablesupplychains,andinnovationin logistics. Outside academics, she enjoys event management, exploring new technologies, and participating in social impact activities.

Contact us at:

https://www.instagram.com/opscentrix_iimrohtak?igsh=cm8xM2NuODR4cDUy https://www.linkedin.com/in/opscentrix-iimrohtak/ operationsclub@iimrohtak.ac.in