- Udit Dimothe & Sindhu Kamath

Supply chains are the backbone of every industry, quietly ensuring that products move seamlessly from manufacturers to consumers. Yet, in today’s hyperconnected, fast-moving world, managing supply chains has become more challenging than ever. Global disruptions whether it’s a pandemic, geopoliticaltension,traderestrictions,orclimate change can send shockwaves through supply networks, leading to production delays, soaring costs, and empty shelves. Traditional supply chain management relied heavily on historical data, manual decision-making, and human expertise, but these methods are proving inadequateinanerawhereunpredictabilityisthe norm.

This is where Artificial Intelligence (AI) and Machine Learning (ML) step in as game changers. Unlike conventional systems, AIpoweredsupplychainslearn,adapt,andrespond in real-time, helping businesses stay ahead of disruptions. These technologies can predict demand with greater accuracy, optimize inventory levels, automate logistics, and enhance supplier management, allowing companies to operate more efficiently, costeffectively, and resiliently.

Take Amazon, for example. The retail giant’s supply chain is one of the most advanced in the world, driven by AI-powered inventory forecasting, robotic fulfillment centers, and autonomous delivery solutions. Every time you place an order on Amazon, AI algorithms determine the nearest warehouse, the fastest shipping route, and the optimal packaging method within seconds. The result? Faster deliveries, reduced costs, and higher customer satisfaction.

But AI’s impact isn’t limited to just e-commerce. Automotive manufacturers use AI to predict supply chain risks, pharmaceutical companies leverage it for precision drug distribution, and logistics firms integrate it into fleet management to cut fuel costs. Across industries, AI is shifting supply chain management from a reactive process to a proactive strategy.

According to a McKinsey report, AI-driven supply chains can:

• Reduce forecasting errors by up to 50%, ensuringcompaniesdon’toverstockorrunout of essential goods.

• Lower overall supply chain costs by 15%, helping businesses stay profitable in competitive markets.

• Increase supply chain resilience, enabling companies to respond 10 times faster to unexpected disruptions.

Whether you’re an industry professional, a student of operations, or simply curious about the future of logistics, this deep dive will give you a clear understanding of how AI is reshaping the way businesses move goods around the world.

The days of manual supply chain management and intuition-based decision-making are fading fast. In a world where customer expectations are higher than ever, businesses need supply chains that are faster, smarter, and more resilient. Enter Artificial Intelligence (AI) and Machine Learning (ML)technologies that are transforming how companies forecast demand, manage inventory, optimizelogistics,andenhancesupplierrelationships.

This chart was created using excel.

Gone are the days when businesses relied solely onhistoricalsalesdataandgutfeelingstopredict demand. Today, AI-driven supply chains process massive amounts of real-time data, identifying patterns and making precise forecasts that were previously impossible. Machine Learning algorithms are constantly learning, adapting, and refining their models, helping businesses make more data-driven, efficient, and cost-effective decisions.

So, how exactly are AI and ML revolutionizing supplychainmanagement?Let’sbreakitdown:

One of the biggest challenges for businesses is matching supply with demand. Stock too much, and you’re stuck with unsold goods and high storage costs. Stocking too little, and you risk disappointing customers and losing sales. Traditional demand forecasting often struggles to strike the right balance because it doesn’t account for dynamic, real-time factors like weather conditions, sudden market shifts, social media trends, or geopolitical events.

AIchanges thegameby analyzingvastdatasets, frompastsalespatternstoexternalvariableslike economic indicators, competitor pricing, and even online sentiment. For instance, if an unexpected cold wave hits a region, an AIpowered supply chain system can instantly adjust demand predictions for winter clothing, ensuring retailers have enough stock to meet demand without overordering.

Big brands like Nike and Zara use AI-driven demand forecasting to maintain lean inventory models allowing them to minimize waste, reduce carrying costs, and restock efficiently based on real-time sales data. AI also helps companies move beyond static forecasting to dynamic, continuously updated predictions,ensuringbetteragilityinvolatilemarkets.

2.AI-DrivenLogisticsandRouteOptimization:

Efficient logistics is the lifeblood of a smooth supply chain, but fuel costs, traffic congestion, weather conditions, and shipping delays make it a complex puzzle to solve. AI and ML help optimize transportation routes, fleet management, and last-mile delivery, reducing both costs and carbon footprints.

For example, UPS’s AI-powered ORION system analyzes traffic patterns, weather forecasts, and package destinations to determine the most efficient routes for delivery trucks. By reducing unnecessary miles traveled, UPS has saved millions of gallons of fuel and cut delivery times significantly. Similarly, Amazon’s AI-powered logistics network strategically determines which warehouses should ship which products, ensuring faster delivery with lower transportation costs.

Intheairlineindustry,companieslikeDHLandFedEx useAItooptimizecargo loadbalancing,ensuringthat planes carry the maximum amount of freight without exceeding weight limits, improving fuel efficiency and cutting operational costs.

Beyondtraditionallogistics,autonomousvehicles and drone deliveries are emerging as the next frontier of AI-powered supply chain management. Amazon Prime Air and Zipline are already experimenting with drone deliveries, while self-driving trucks from companies like Tesla and Waymo promise to revolutionize long-haul transportation.

3. Predictive Maintenance in Warehouses and Manufacturing:

Factories and warehouses rely on highly complex machineryandroboticautomationsystemstofunction smoothly. When equipment breaks down unexpectedly, it can halt entire supply chain operations, causing delays, revenue losses, and

customer dissatisfaction. Traditionally, businesses followed a reactive maintenance model fixing machines only after they failed. However, this approach often led to unplanned downtime and costly repairs.

AI-driven predictive maintenance changes this approach by analyzing machine performance in real-time and identifying potential failures before they happen. By using IoT sensors and AI-powered analytics, supply chain managers can detect early warning signs of mechanical failures and schedule maintenance before a breakdown occurs.

Take Siemens, for example its AI-powered predictive maintenance system helps manufacturers reduce downtime by 30%, preventing costly operational disruptions. Similarly, Coca-Cola’s bottling plants use AIdriven monitoring systems to ensure that production lines run smoothly, reducing waste and improving efficiency.

Procurement the process of sourcing raw materials and selecting suppliers has traditionally been time-consuming, complex, and prone to inefficiencies. Businesses need to balance cost, quality, reliability, and risk when choosing suppliers, but making these decisions manuallyoftenleadstodelays,budgetoverruns, and supply chain vulnerabilities.

AIstreamlines procurement by:

• Identifying the best suppliers based on performance metrics, pricing trends, and past transaction history

• Automating contract negotiations using AI-driven analytics and risk assessment

• Detecting fraudulent transactions and supplier inconsistencies

For instance, Unilever uses AI-powered procurementtoolstoensureethicalsourcingand

sustainability compliance while optimizing costs. AI also helps companies diversify their supplier base, reducing reliance on a single vendor and mitigating supply chain risks.

5.SmartWarehousingandRoboticAutomation:

The rise of AI-driven robotic automation is transforming warehouses into smart fulfillment centers that operate 24/7 with minimal human intervention. Modern warehouses use:

• AI-powered robots for picking, packing, and sorting orders

• Computervisiontechnologytotrackinventory levels in real-time

• Automated guided vehicles (AGVs) for transporting goods efficiently

Retail giants like Amazon, Walmart, and Alibaba operate robotic fulfillment centers where AI-driven robots sort, package, and dispatch goods faster than human workers. These AI-enhanced warehouses increase order accuracy, reduce labor costs, and improveoverall efficiency.

6. AI-Driven Risk Management and Supply Chain Resilience:

Supply chain risks are unpredictable and inevitable whether it’s a global pandemic, trade war, natural disaster, or cyberattack. Businesses must be prepared to detect disruptions early and respond proactively to maintain operations.

AI-driven risk management tools analyze:

• Supplier reliability and geopolitical risks

• Real-time social media trends for early warning signs

• Historical patterns of disruptions to anticipate future risks

For example, during the COVID-19 pandemic, AIpowered risk assessment tools helped companies identify supply chain vulnerabilities and adjust sourcing strategies in real time. AI also plays a key

role in cybersecurity for supply chains, preventing data breaches and unauthorized access to sensitive logistics systems.

Despite the immense benefits, AI adoption in supply chains faces several challenges:

1.HighImplementationCosts

AI-powered supply chain systems require significant upfront investment in hardware, software, and infrastructure. Many small businesses find AIadoption cost prohibitive.

AI models rely on vast amounts of data, making supply chains vulnerable to cybersecurity threats. Companies must invest in secure AI models and encryption technologies to protect sensitive information.

3. Workforce Adaptation & Job Displacement

AI-driven automation reduces dependency on manual labor, leading to job displacement concerns. Companies must upskill employees to work alongside AI-driven systems.

4.Ethical&RegulatoryConcerns

AI in supply chains raises ethical concerns around:

• Data privacy (who owns AI-generated insights?)

• Fairness in supplier selection (bias in AI models)

• Sustainability and responsible AIuse

Governments and industry leaders are working on regulations and ethical AI frameworks to address these issues.

AIandML willcontinue toshapethefutureofsupply chains through:

• Hyper automation: AI + RPA will fully automate warehouse and logistics operations.

• AI-Powered Cognitive Supply Chains: AIwill enable real-time, self-learning supply chains that automatically adapt to market conditions.

• Sustainable AI: AI-driven green logistics will minimizesupply chain carbon footprints.

By 2030, over 50% of supply chain operations are expected to be fully AI-powered, creating more resilient,agile,andcost-efficientglobalsupplychains.

Amazon – Uses AI for demand forecasting, robotic fulfilment centres, and anticipatory shipping to speed up deliveries.

UPS – AI-poweredORIONsystemoptimizesdelivery routes to save fuel and reduce transit time.

Siemens – Uses AI-driven predictive maintenance to detect machine failures before they occur, reducing downtime.

Walmart – AI analyses real-time buying trends and weather data to optimize inventory and prevent stockouts.

Tesla – AI helps manage supplier risks and optimize procurement during component shortages like semiconductor chips.

DHL – UsesAI-drivenrobotsandpredictiveanalytics forefficient warehouse operations and logistics.

Unilever – AI streamlines procurement, supplier risk assessment, and sustainable sourcing compliance.

AI and Machine Learning are revolutionizing supply chain operations, making them smarter, faster, and more resilient. From predictive analyticstoautonomouslogistics,AIisreducing costs, improving efficiency, and enhancing decision-making across industries.

While challenges like high costs, data security, and workforce adaptation exist, businesses that invest in AI-driven supply chains today will gain a competitive advantagein the future.

ThefutureofsupplychainmanagementisAI-powered –andit’salreadyhere.

I’m currently pursuing an MBA in Marketing at TAPMI Manipal, with a background in hotel management and working as Operations manager in the past, I have a strong interest in operations and supply chain management, especially in how AIis transforming industry.

I am an MBA student at TAPMIwith a background in hotel management from WGSHA Manipal. Ihave a strong interest in operations and supply chain management, particularly in how AIis reshaping the industry. Ienjoy problemsolving, exploring business strategies, and finding innovative solutions to operational challenges.

- Lakshay Gogia & Bhakti Gupta

Operations and supply chain management has changed dramatically over the past few years with the influence of globalization, technology, and shifting consumers' buying habits. Firms today are confronted with issues such as sustainability, digitalization, risk management, and resilience in operations. Some of the operations and supply chain management challenges the industry is currently facing arepresented in this article

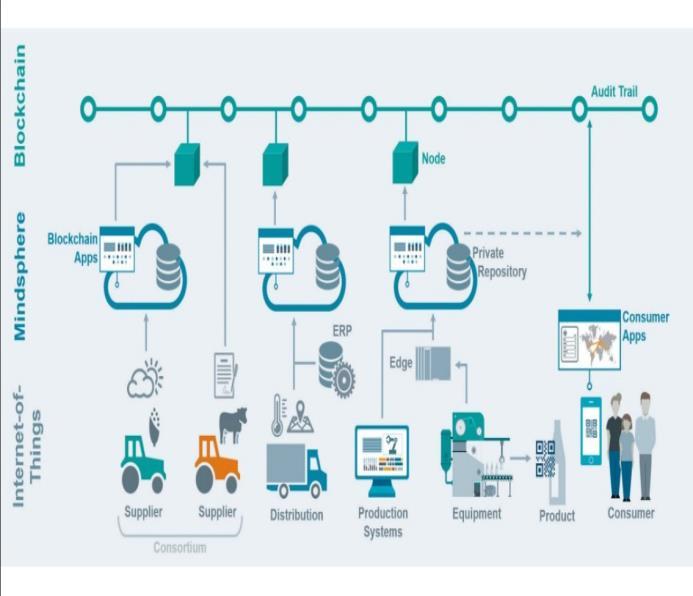

One of the most revolutionary supply chain operations and management changes is the digital revolution that has been brought about by technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and blockchain. Organisationsareadoptingthesetechnologiesinan attempttobemoreefficient,reducecosts,andmake better decisions.

• MachineLearningandAI:AIapplicationin predictive analytics assists companies in predicting demand, streamlining inventory planning, and automating logistics.

• IoT Integration: Smart sensors and RFID(radio frequency identification) tracking track shipments in real-time, minimizing inefficiencies.

• Blockchain for Transparency: Blockchain offers secure, and tamper-evident histories of transactions, building trust and reducing fraud in the supply chain.

We require sustainability; it is the future of the supply chain. Businesses are being called upon moreandmoretogogreenandreduce theircarbon footprint.

• Green Logistics: Companies are streamliningtransportationroutestoreduce fuel usage and emissions.

• Circular Supply Chains: The goods are recycled and reused to avoid wastage amenable circular economy.

• Ethical Sourcing: Companies are focusing on ethical working practices and ethically sourcing raw material.

Supply chain disruptions such as the COVID-19 pandemic, political unrest, and natural disasters have put in the limelight the need to have robust supply chains.

• Diversified Suppliers: Companies are reducing reliance on a single supplier to counterbalance risks.

• Nearshoring and Regionalization: Businesses are relocating production near their customers so they are less reliant on far-offsuppliers.

• Scenario Planning: Companies employ sophisticated simulations to predict potential disruptions and create contingency strategies.

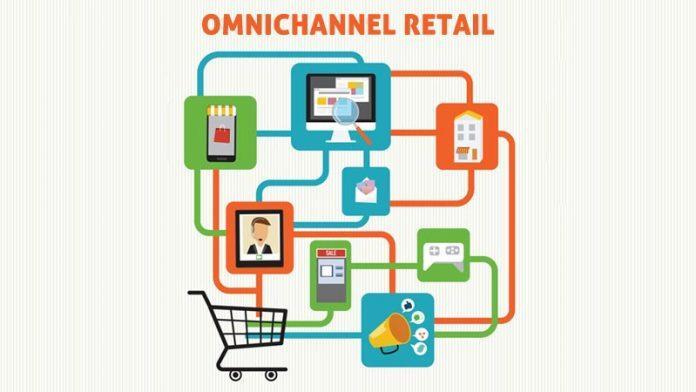

E-commerce transformed the operation of conventional supply chains. Businesses need to provide quality customer service across various channels, so they need to have seamless omnichannel strategy.

• Last-MileDeliverySolutions:Autonomous vehicles, drones, and small-fulfillment centres are being used by companies to accelerate delivery.

• Inventory Optimization: Inventory optimization through AI maintains the productsatoptimallevelsinthedistribution centres

• Customized Delivery: Businesses are applying data analysis for customized delivery in line with what is most significant to clients.

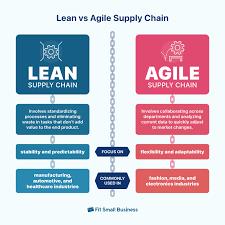

Firms increasingly apply lean and agile supply chain methodologies to respond promptly to shifting markets and customers' demands.

• Lean Supply Chains: Minimizes waste and maximizes how efficiently operations function.

• Agile Supply Chains: Emphasizes flexibility and responsiveness to changing market conditions.

• HybridMethods: Hybridmethodsareamix of lean and agile methods for achieving efficiency and flexibility.

OperationsAutomationandArtificial Intelligence

Automation and artificial intelligence are transforming operations management by doing it more effectively and with less human intervention.

• Robot Warehousing: Robots assist picking, packing, and sorting independently.

• Artificial Intelligence Production Planning: Artificial intelligence software schedules production and utilizes resources.

• AI-Based Chatbot Customer Support: AIbased chatbots improve response time and customer satisfaction.

Customers expect companies to be socially responsible and ethically motivated throughout the supply chain.

• Fair Trade Practices: Companies offer equitable remuneration and treatment of employees.

• Transparency Initiatives: Businesses are making their supply chain operations transparent so that they become evident to customers.

• Human Rights Issues: Firms are making efforts to eradicate child labour and forced labourin supply chains.

Reverse logistics comes into the limelight as companies are getting more and more concerned about their product returns, recycling, and wastage avoidance.

• Product Returns Management: Effective and timely management of returns is facilitated by efficient systems.

• Recycling and Reuse: Businesses are investing in recycling and reusing old products.

• End-of-Life Product Management: Firms arecreatingproductsthatarerecyclableand reusable.

Big data has transformed the manner in which firms make operational and supply chain decisions.

• Predictive Analytics: Assist business organizations to predict demand changes and shape their supply chain strategy in accordance with it.

• Real-Time Tracking Data: Provides detailed tracking of shipments and inventory levels.

• KPIs and Performance Metrics: Organizations are employing key performance indicators (KPIs) to track the performance of the supply chain.

Coordination among suppliers, manufacturers, and retailers is the key to making supply chains more efficient.

• Supplier Relationship Management: Dependabilityandlowercostsaretheresult of stronger relationships with suppliers.

• Cloud-Based Supply Chain Management: Comprisessharingdataandcoordinationin real-time.

• Shared Logistics Networks: Firms are bandingtogethertosharetransportationand distribution networks, lowering costs and making things work better.

The operations and supply chain management business world are reinventing at record pace with environmental pressures, consumer changes, and digitalization. Organizations have no option but to embrace new strategies like ethical sourcing,

supply chain resiliency, and AI-driven analytics in ordertostayahead.Astheworld'scrisescreatenew pathsacrossthebusiness landscape,beingonestep ahead with operations and supply chain management will be the name of the game when it comes to long-term success.

Lakshay, a second-year B.Com. (Hons) student at Delhi University, is passionate about finance, entrepreneurship, and social impact. As the Head of Partnerships and Events at Sri Venkateswara College’s E-Cell, he has led key initiatives, includingthebi-annualeventAarohan.Withexperienceinstrategiccollaborations and team leadership, he actively engages in competitions and mentorship programs. Beyond academics, he enjoys cooking and fitness, which keep him motivated.

Bhakti, a second-year B. Com (Hons) student from Sri Venkateswara College, is passionate about finance, world problems, and finding solutions to them. She enjoys reading books of genres such as crime, psychological thrillers, and philosophy.Shehopestoconnectwithlike-mindedindividualsandbuildvaluable connections.

Operationsandsupplychainmanagement(SCM) haveevolvedsignificantlyinrecentyears,driven by technological advancements, sustainability concerns, and global disruptions. For example, a McKinsey report found that companies implementing AI-driven supply chain management saw a 15% reduction in logistics costsanda35%improvementininventorylevels. This highlights the tangible benefits of modernizing supply chain operations. Modern businessesmustadapttothesechangestoremain competitive and resilient. This article explores key contemporary trends shaping operations and supply chain management today, with real-world examplesandactionableinsights.

1. AIandMachineLearning(ML)inSupply Chain Optimization - AI and machine learning are transforming supply chain operations by enabling predictive analytics, demand forecasting, and process automation. Companies are leveraging AI-powered tools to optimize inventory levels, reduce lead times, and enhance decision-making. Predictive analytics helps foresee disruptions and mitigate risks, ensuring seamless operations. For example, Amazon uses AIdriven demand forecasting to maintain optimal stock levels and prevent supply shortages.

- Kushagra Seth

Source - https://supplychainbeyond.com/unlockingthe-value-in-your-supply-chain-network/artificialintelligence-in-the-supply-chain-1/

2. Sustainability and Green Supply ChainsWithincreasingpressurefromconsumersand regulatory bodies, businesses are prioritizing sustainability in their supply chains. Green supply chain management (GSCM) focuses onminimizingenvironmentalimpactthrough eco-friendly sourcing, waste reduction, and energy-efficient logistics. Companies adoptingcirculareconomymodelsarefinding waystoreuseandrecyclematerials,reducing their carbon footprint. Tesla, for instance, integrates sustainable practices by using recyclablebatterycomponentsandrenewable energyinproduction.

Source - https://mgt-logistik.com/green-supplychain-management-adalah/

3. BlockchainforTransparencyandSecurityBlockchain technology is revolutionizing supply chain transparency by providing an immutable ledger for transactions. This enhances traceability, reduces fraud, and improves accountability in logistics and procurement. Industries like pharmaceuticals, food,andluxurygoodsareadoptingblockchain to ensure product authenticity and compliance with regulations. Walmart, for example, uses

blockchain to track food safety by monitoring themovementofproducefromfarmstoshelves inreal-time.Thisenhancestraceability,reduces fraud, and improves accountability in logistics and procurement. Industries like pharmaceuticals, food, and luxury goods are adopting blockchain to ensure product authenticity and compliance with regulations. Walmart,forexample,usesblockchaintotrack food safety by monitoring the movement of producefromfarmstoshelvesinreal-time.

Source - https://blockchain.oodles.io/blog/supplychain-traceability-sustainability-blockchaindevelopment/

- The COVID-19 pandemic and geopolitical tensions have underscoredtheimportanceofbuildingresilient supplychains.Companiesarediversifyingtheir supplier base, increasing regional production, and leveraging digital twins to simulate disruptions. The focus is shifting from cost efficiencytoagilityandadaptability.Toyota,for instance, has implemented multi-tier supplier visibility and risk assessment strategies to minimize production halts. Companies are diversifying their supplier base, increasing regional production, and leveraging digital twins to simulate disruptions. The focus is shifting from cost efficiency to agility and adaptability. Toyota, for instance, has implemented multi-tier supplier visibility and risk assessment strategies to minimize productionhalts.

Source- https://designer.microsoft.com/image-creator

- The rise of e-commerce has intensified the demand for efficient last-mile delivery solutions. Companies are investing in drone deliveries, autonomous vehicles, and micro-fulfillmentcenterstoexpeditedeliveries. Same-dayandon-demanddeliveryservices are becomingstandard,requiringreal-timetracking and route optimization. Logistics firms like FedEx and UPS are leveraging AI-powered route optimization to enhance delivery speed and reduce fuel consumption.

Source - https://designer.microsoft.com/image-creator

6. Internet of Things (IoT) in Logistics - IoTenabled devices are enhancing supply chain visibility by providing real-time data on shipment status, temperature conditions, and asset tracking. Smart sensors and RFID technology are improving inventory accuracy andreducinglossesduetotheftorspoilage.The integration of IoT with AI further enhances predictive maintenance and operational efficiency. DHL employs IoT-driven smart sensorstotrackshipmentconditionsandreduce transitdamage.

Source - https://designer.microsoft.com/image-creator

7. Digital Transformation and Smart Warehousing - Automation and robotics are revolutionizing warehouse operations, improving efficiency and reducing labor costs. Smart warehouses utilize robotic process automation (RPA), AI-driven picking systems, and cloud-based warehouse management systems(WMS)tostreamlineorderfulfillment. Companies are also adopting 3D printing for on-demand production, reducing dependency on large inventories. Amazon’s automated warehousesuseAI-poweredrobotstoaccelerate packagingandsortingprocesses.

– https://designer.microsoft.com/image-creator

Operations and supply chain management are undergoing rapid transformations due to technological advancements, sustainability initiatives, and the need for resilience. Companies that fail to adapt risk falling behind in an increasingly competitive and digitally connected world. Leveraging automation, AI, and advanced analytics will be crucial for optimizing processes and mitigating risks. Looking ahead, emerging trends such as hyper-automation, AI-driven decision-making, and the integration of quantum computing in logistics are expected to further redefinetheindustry,making itmoreefficientand responsive to global challenges. Additionally, the growingemphasisonethicalsourcingandcircular supply chains will push companies toward more responsible and sustainable operations, benefiting both the environment and long-term profitability. Businesses that embrace these trends will gain a competitive edge, ensuring efficiency, transparency,andsustainabilityintheiroperations. As these innovations continue to evolve, companies must remain agile and proactive in adopting best practices in supply chain management.

I am a student at Shyam Lal college, specializing in finance with a keen interest in investment banking and financial modeling. Passionate about the intersection of finance and operations, I am exploring how financial strategies can enhance supplychainefficiency. Withastronganalyticalmindset, Myaimistocontribute data-driven insights to modern business challenges.

Contactusat:

https://www.instagram.com/opscentrix_iimrohtak?igsh=cm8xM2NuODR4cDUy https://www.linkedin.com/in/opscentrix-iimrohtak/ operationsclub@iimrohtak.ac.in