11 Sep 2025 | The Hilton Auckland

11 Sep 2025 | The Hilton Auckland

SCLAA’s official New Zealand launch signals a new era of collaboration, with global speakers unpacking technology, automation, and growth strategies shaping the supply chain of tomorrow.

SPEAKERS FROM Argon & Co, Sandfield, Vanderlande, Microlise, Infios, VISY Logisics, Prological, Bestrane, Mobiledock, b dynamic Logistics + MORE

CLOSE 5 SEPTEMBER

TAFE NSW Short Courses in Supply Chain & Logistics are perfect for when you’re short on time, think it’s time for a career change or time for a skills boost.

+ Chain of Responsibility (CoR) (TLIF0009)

+ Drive and Manoeuvre Trailers (900-81567)

+ First Attack Fire Equipment (900-83330) + Manual Handling (900-83139) + Safe Shipping Container Ventilation (800-000622) + Traffic Control & ITCP (900-83246)

Straight Talk

The Quiet Collapse of Mid-Tier Logistics

SCLAA National Mentoring Program

Epicor Helps Distributors in Australia and New Zealand

Vstrong Intelligent | Red Crab Tote-Picking System

Australian Manufacturing State of Play 2025

EFL 3PL Global partners with Infios

Picking success at every level for AFS Logistics

Wearables are powering the new age of customer fulfilment

8 Year-End Must-Dos for Warehouses

Harvestaire plants seeds for expansion with NetSuite

If You’re Not Building a Safety Culture, You’re Risking Lives

Digitally empowering the Supply Chain & Logistics Frontline

From Static to Smart

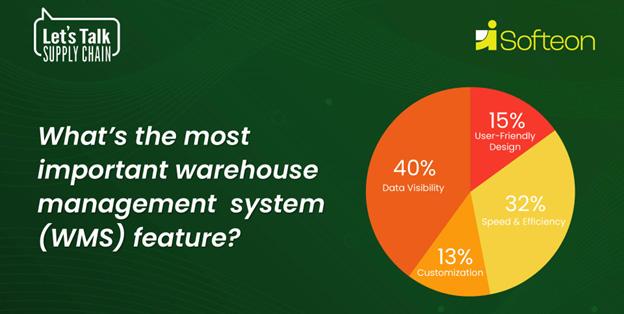

What’s the most important Warehouse Management System (WMS) feature?

A sweet solution

Expanding Bulk Warehousing and Haulage Operations

AI Maturity in Motion

Forkliftaction celebrates a quarter century of industry connection

Upcoming Events

Sue Tomic

SCLAA Board Chair

Managing Director for Chain Consulting Services.

Appointed to the Board in 2019.

Strengthening ties with our closest neighbour, New Zealand, is more than diplomacy - it’s critical for Australia’s strategic, economic, and social wellbeing.

Forging closer ties with New Zealand is in Australia’s best interests for several strategic, economic, and social reasons. The two nations share one of the closest bilateral relationships in the world — and deepening that connection offers tangible benefits.

On the back of Anthony Albanese’s visit to China last month, was a whistlestop trip and long overdue visit to our closest trading partner and defence ally, New Zealand.

Anthony Albanese wrapped a “successful visit” to New Zealand by joining Kiwi counterpart Christopher Luxon on a helicopter jaunt over the country’s Southern Alps. But even in the chilly tranquillity of New Zealand’s snowcapped peaks neither leader could escape the shadow of wars raging on multiple continents and conflict looming closer to home.

It was against this backdrop that Mr Albanese on Sunday stressed that Canberra and Wellington were in lock-step.

“When Australians think of New Zealand, we think of the Anzacs and we think of the sacrifice that we’ve made together in defence of our freedom,” he told reporters in Arrowtown, a historic mining town northwest of Queenstown.

“Australia and New Zealand are great friends – we think alike and we act alike on the international stage.

“And this visit here has been one of warmth, of engagement, of practical moves forward, including the meeting that we had yesterday afternoon with leaders in the business community of both Australia and New Zealand, talking about how we can expand that seamless economy, making sure that we can boost productivity to the benefit of both of our economies.

“So, it’s been a very successful visit.”

A day earlier, he and Mr Luxon released a statement outlining 41 shared commitments.

They ranged from deeper trans-Tasman economic ties amid “global economic uncertainty” to mutual defence aimed at “protecting and advancing our shared interests in our region”

Priority areas for Australia and New Zealand to work together were identified in the Trans-Tasman Roadmap

to 2035, agreed in 2023 and reconfirmed in 2024. These shared priorities span economics, security, mobility, and culture, each reinforcing the other, but unless acted on decisively, both countries risk falling behind.

Here are some key reasons why closer ties is a win-win for both nations:

Economic Benefits:

Trade and Integration: The Closer Economic Relations (CER) free trade agreement is already one of the most comprehensive bilateral free trade agreements globally. Building on it can further streamline labour mobility, mutual recognition of standards, and digital economy integration.

New Zealand is already one of Australia’s top trading partners. In 2024, two-way trade was valued at over $32 billion, with significant movement of goods, services, and capital.

Cross Tasman bilateral investment has been steadily increasing, particularly within the freight and logistics infrastructure and services sector. Successful businesses within Australia are realising their expansion strategies by making the natural progression to New Zealand. Strengthening ties encourages smoother crossborder business operations, making businesses more competitive and creating a larger, more integrated regional economy.

But without faster alignment of digital and regulatory frameworks, those gains risk stalling.

Security and Defence:

Regional Stability: Australia and New Zealand are natural partners in maintaining stability in the Indo-Pacific region. Stronger bilateral ties amplify their collective voice on the world stage and enhance their ability to influence regional and global issues, making their partnership a powerful force for stability and cooperation.

ANZAC Defence Ties: The Australia-New Zealand alliance is rooted in shared history (e.g., ANZAC). Both nations have a history of fighting alongside each other in global conflicts. Enhanced defence collaboration—joint training, intelligence sharing, cybersecurity—bolsters both nations’ resilience to modern threats.

Five Eyes Partnership: Both are members of the Five Eyes intelligence alliance. A closer bilateral focus strengthens operational trust and regional security coverage.

Yet none of these can be taken for granted. Influence shrinks if Canberra and Wellington act separately, and complacency in coordination would leave both nations exposed.

Both leaders confirmed they had discussed China and security in the Indo-Pacific, while also noting they had both recently visited China - a significant trading partner to both nations.

They also made sure to emphasise their commitment to the Pacific family and its security. Australia and New Zealand are often seen as joint leaders in the Pacific. Working together more closely allows for better development aid coordination, disaster response, and climate change adaptation programs.

On the home front, both leaders signalled a desire to deepen defence ties, with Mr Luxon saying he wanted Australia and New Zealand’s militaries to operate as one ANZAC force.

Workforce Mobility and Skills Exchange

Trans-Tasman Travel Arrangement: Citizens can live and work freely in each other’s country. This helps both nations address labour shortages (e.g., in health, construction, education) and attract global talent through a unified, mobile workforce.

Shared Standards & Qualifications: Enhanced mutual recognition of professional qualifications can create a more agile, competitive regional economy.

Yet mismatches and delays in recognition still frustrate employers. Unless these gaps close, the promise of a truly mobile workforce risks being wasted.

Cultural and Social Ties

Shared Values: Both countries are part of the Anglosphere and share a colonial history, leading to similar values and governance structures, which fosters a strong foundation for cooperation.

People-to-People Links: Over 670,000 New Zealanders live in Australia and more than 70,000 Australians live in New Zealand. Deep cultural affinities, sporting ties, and shared values make cooperation natural and beneficial.

Indigenous Collaboration: Both nations have rich Indigenous cultures. Closer ties support shared learning on policy, cultural preservation, and reconciliation efforts. These ties are often assumed to be secure, but without

investment, they risk becoming symbolic rather than strategic.

Common Environmental Challenges: Australia and New Zealand face similar climate risks. Joint approaches to emissions reduction, renewable energy development, and environmental protection strengthen their voice in global climate forums.

But action is urgent. Fragmented approaches drive up costs and weaken regional influence in the global transition.

Forging closer ties with New Zealand strengthens Australia’s economy, enhances regional security, supports social cohesion, and boosts influence in the Indo-Pacific. As two like-minded, democratic nations with deeply entwined interests, closer collaboration isn’t just advantageous — it’s a strategic imperative.

For the supply chain and logistics sector, these same dynamics apply. SCLAA recognises that our own growth depends on building stronger trans-Tasman links. That’s why we are proud to announce a milestone achievement in our strategic goals with our launch event in New Zealand, in collaboration with our Partners with established cross-Tasman interests.

For more information and to register I very much look forward to seeing you there!

Sue Tomic, SCLAA Chair sue.tomic@sclaa.com.au

you to be

of

Date: Thursday, 11 September 2025

Venue: The Hilton Auckland Princes Wharf, 147 Quay Street, Auckland Times: Seminar 2.30pm to 5.30pm (registrations from 2.00pm) (NZST) Neteorking 5.30pm to 8.30pm

SCLAA welcomes our newest National Partner, NowGo by Shippit. As a not for profit Industry Association, run by members for members, our ability to support the SCLAA infrastructure and to expand is highly dependent on our National Partners. We ask all our members to support our valued National Partners where they can.

NowGo by Shippit is a powerful last-mile delivery orchestration solution built to meet the needs of businesses that run complex, time-sensitive delivery operations and services.

Developed in Australia and trusted by category leaders like Reece, Mitre 10, Healius Pathology and News Corp, NowGo by Shippit enables private and contracted fleet operators to overcome growing pressures - from rising fuel costs and driver shortages to escalating customer expectations and tighter regulations.

NowGo is purpose-built to help industries such as trade supply, furniture and bulky goods, healthcare and pathology, and food and beverage streamline their lastmile operations at scale. It improves route efficiency by up to 12% and fleet utilisation by 15%, while reducing driver downtime, redeliveries and the kilometres driven - all of which impact cost, sustainability and customer experience.

Unlike generic routing tools, NowGo by Shippit is powered by a proprietary algorithm and AI-first architecture developed following Shippit’s acquisition of Premonition in 2022. This foundation allows it to handle massive volumes of real-time routing data, business constraints and delivery rules - from vehicle type and load capacity to site access requirements, SLAs and delivery windows - making it ideal for the most dynamic and demanding environments.

Key features include:

– Smarter, faster planning: Scenario-plan and reoptimise in real-time as conditions change.

– Built for complexity: Configure rules, vehicles and delivery logic - all in a single intuitive interface.

– Driver-first experience: A flexible, fully branded driver app with live updates and job details.

– Real-time visibility: Uber-like tracking and customer notifications that reduce inbound queries and redeliveries.

–

Deep performance analytics: Custom dashboards help teams optimise delivery ops and report on success.

NowGo by Shippit currently powers over 30 million deliveries annually and supports thousands of drivers every day. Backed by Shippit’s team of 200+ logistics and technology experts, it gives operators the tools to run faster, smarter and more profitable last-mile delivery networks.

For more information on how you can operate smarter, faster and more profitably, visit their website below.

SCLAA welcomes our newest National Partner, Epicor As a not for profit Industry Association, run by members for members, our ability to support the SCLAA infrastructure and to expand is highly dependent on our National Partners. We ask all our members to support our valued National Partners where they can.

From complex supply chains to fluctuating prices and customer demand, distributors need to adapt fast. Work with a partner who understands your business processes and brings solutions to help you operate more efficiently today while preparing for whatever comes next.

Epicor Software Corporation is a global company, employing more than 4,600 people with offices in 34 countries - including the U.S., U.K., UAE, Australia, Canada, Mexico and China. As of 2024, Epicor has more than 23,000 customers in 150 countries with more than 2.3M users daily.

Learn more +

Epicor Software Corporation drives business growth. We provide flexible, industry-specific software designed to fit the precise needs of our manufacturing, distribution, retail, and service industry customers. 50 years of experience with our customers’ unique business processes and operational requirements are built into every solution - in the cloud or on premises.

With this deep understanding of your industry, Epicor solutions dramatically improve performance and profitability while easing complexity so you can focus on growth.

For more information, connect with Epicor or visit www. epicor.com.

SCLAA welcomes our newest National Partner, Prological Consulting. As a not for profit Industry Association, run by members for members, our ability to support the SCLAA infrastructure and to expand is highly dependent on our National Partners. We ask all our members to support our valued National Partners where they can.

Prological Consulting is a premier supply chain consultancy operating in Australia and New Zealand. Established in 2010, we focus on the areas of:

Network design

Warehouse optimisation, design and sourcing including MHE & Automation.

Freight optimisation and sourcing.

About the Team

Trusted by government and leading national and international brands, our team brings unmatched experience, with a team average industry tenure of over 20 years in supply chain and logistics roles. Emphasising impact, efficiency, and unique insight, our team has made positive changes to more than a hundred organisations throughout their careers. If outright experience and tangible impact are qualities you need: Prological is the logical first choice for your next supply chain project.

Prological’s approach prioritises insight and analysis to find what is best for your business, whether it is a new property, new equipment, or even humble but impactful process improvements. Our experienced, independent lens has been honed to separate your strong ROI opportunities from the current flashy toys, where hasty uptake often runs late and over-budget. Taking a step back can be hard, especially when the pressure to act is high. But in our experience, the most successful supply chain investments begin with insight, not impulse. We work with you to first optimise your current operations, then guide you through sourcing and deploying the right property or technology, helping you avoid unnecessary cost and deliver the strongest return.

Renowned for his razor-sharp wit and effortless delivery, Jimeoin’s role as MC promises a fast-paced evening packed with off-the-cuff brilliance and perfectly timed punchlines. From opening remarks to spontaneous one-liners, this won’t be your standard industry dinner. It’s the supply chain and logistics’ night of nights - with world-class comedy keeping things fresh, sharp, and unforgettable.

14 Nov 2025 | Melbourne Town Hall 3 Course Dinner + Drinks Package

FT. KEYNOTE SPEAKER STEVE THOMPSETT

REGISTER NOW

This is an opportunity to align your brand with excellence, innovation, and leadership. Showcase your organisation, strengthen brand awareness to industry leaders and be an Ambassador of Excellence by recognising the highest achievers in the supply chain and logistics Industry. Solidify your position as a champion of progress and innovation; a partner driving our industry forward. Sponsorship inclusions and inclusion quantities

NOMINATIONS ARE CLOSING FOR THE AUSTRALIAN SUPPLY CHAIN & LOGISTICS AWARDS

ASCL INDUSTRY EXCELLENCE AWARD

Dedicated to Mike Munns, FAIMM Award Inaugurated 1987.

ASCL SUPPLY CHAIN MANAGEMENT AWARD

Dedicated to Doug Beattie Award Inaugurated 1984.

ASCL FUTURE LEADERS AWARD

Dedicated to Vince Aisthorpe Award inaugurated 2009.

ASCL AUTOMATION, ROBOTICS OR EMERGING TECHNOLOGY AWARD

Award Inaugurated 2021.

ASCL TRAINING, EDUCATION & DEVELOPMENT AWARD

Dedicated to the late Professor Peter Gilmour Award Inaugurated 2002.

ASCL INTERNATIONAL SUPPLY CHAIN AWARD

Award inaugurated 2016.

ASCL ENVIRONMENTAL EXCELLENCE AWARD

Dedicated to Mr Ken Pike, Award Inaugurated 1966.

ASCL BIG DATA, IT & BUSINESS INTELLIGENCE (BI) AWARD

Award inaugurated 2021.

ASCL START-UP AWARD

Award inaugurated 2021.

ASCL WORKPLACE HEALTH AND SAFETY AWARD

Award inaugurated 2024.

ASCL TRANSPORT LOGISTICS EXCELLENCE AWARD

Award inaugurated 2024.

VIEW AWARD CRITERIA SUBMISSIONS

James McIntosh took us around Tuff Trailer’s manufacturing site in Crestmead, a proudly Queenslandbased manufacturer and innovator in heavy-duty transport solutions. This visit offered attendees a behindthe-scenes look at how Tuff Trailers designs and builds their world-class trailer systems to support Australia’s most demanding transport conditions.

From custom builds to cutting-edge materials, the Tuff Trailers team demonstrated the level of precision, engineering excellence, and local manufacturing that underpins their operation.

It was a fascinating supply chain to witness in action with all their production being made to order and highly customised for each customer’s requirements.

We learnt about the different types of bespoke trailers they build to enable supply chains across the country. We also got to see the use of real time productivity dashboards on the shop floor.

It was a great site tour and we thank James and Tuff Trailers for taking us around. Attendees walked away inspired by Tuff’s commitment to innovation, safety, and sustainability.

Mentor program

Chris Josey has been very busy finalising the Queensland Branch’s Mentor Program . This program is integrated with the National Program , which has been growing in popularity each year. This year Queensland has 8 mentees with a Mentor allocated for each. Great work Chris!!.

Committee News

– George Hodgson is participating in the 2025 Mystery Box Rally to be held in August to raise funds for Cancer Council. A wonderful cause – for more information please visit https://www.mysteryboxrally.com.au/ rallies

– Congratulations to Nat and Mark who both have started new employment.

– Farewell to Rajaei who is stepping down from the committee – Thanks for all your support and insight.

Stay tuned to our socials and website for our upcoming event in September- we are just putting the final changes to it before sharing.

Monica Vorhauser

QLD Division President, monica.vorhauser@sclaa.com.au

The WA enrolment for the SCLAA’s 2025 Mentoring Program has been phenomenal.

With particular thanks to Daniel Green. The WA Mentoring Lead, and Sahar Goudarzi (Highly Commended Future Leader from last year’s ASCLAs) for her energetic advocacy of the program, we broke local records with fifteen mentee/mentor pairings.

The ice was broken in many of these relationships with a kick off event at the Empire Bar on Friday 11th July.

Attendees were not restricted to Mentoring Program members. Many turned up purely for the networking opportunities. It was an awesome mix of people, from senior managers to students, all coming together with a great vibe: supportive, welcoming, and ready to connect.

Also, a big shout out to those who put their hands out on the night to be mentors; we really appreciate you!

Inspired by this get together, we all then got into the real nuts and bolts of the program.

Most, if not all of the mentor/mentee pairings have made their initial connections, sharing details on their backgrounds and what they would like to gain from the program.

This process will continue until December with more one-to-one and group interactions.

It was great to catch up with John Ward, AWH (an SCLAA Corporate Partner) General Manager – National Operations, and a previous SCLAA WA State President at the organisation’s End of Financial Year Supplier’s Event. Thanks to AWH for their continued support of the SCLAA.

There’s lots more for SCLAA’s WA members to look forward to in the coming months, with an upcoming site visit to Harvestaire, generously sponsored by National Partner Oracle Netsuite, and a planned university hosted panel event.

The year will be rounded off by the traditional Christmas networking get together.

Brian Lynn WA State Director brian.lynn@sclaa.com.au

With many ANZ organisations planning ERP changes in the next three years, now’s the time to explore what’s driving the shift.

Join guest speaker Sam Higgins, VP, Principal Analyst at Forrester Research, in a live webinar as he shares insights from a recent Epicor-commissioned survey of 190 senior ERP leaders in ANZ.

Learn how distributors are using AI and next-gen ERP to boost growth, resilience, and customer centricity.

REGISTER NOW: Modernising The Distribution Business With Intelligent ERP

Connected, informed, empowered: The future of the frontline in supply chain logistics.

On Monday, 21 July, the Supply Chain & Logistics Association of Australia (SCLAA), in partnership with Optus - SCLAA’s newest national partner - hosted an industry forum focused on the future of the frontline in supply chain and logistics.

SCLAA Chair Sue Tomic, NSW Vice President Alice Brimicombe, and Mentoring Lead Michael Farragher were on-site to support the event and connect.

The NSW Committee is committed to SCLAA’s strategic purpose: connecting today’s supply chain professionals and partners to tomorrow’s growth opportunities, while championing collaboration, innovation, and success across our industry.

It was an energising afternoon of practical solutions, live demonstrations, and meaningful networking. Together with Optus and Samsung, we explored how leading organisations are transforming warehouse, transport, and distribution centre operations, driving greater efficiency, safety, and employee experience.

From expert presentations to hands-on tech demonstrations and thoughtful panel discussions, the message was clear:

1. Outdated tools and disjointed systems are most likely dragging down performance where it matters most, on the frontline.

2. You can simplify operations with integrated, mobilefirst tech that empowers your teams.

3. Smarter mobile fleet management cuts costs, boosts accountability and gets more from every asset.

4. You can bake in resilience and future-proof your operations by putting the right tools in your teams’ hands.

Leaders from across the logistics, freight, and warehousing sector joined us to unpack the challenges frontline operations face today. Opening the event, SCLAA Chair Sue Tomic shared that disruption is now

business-as-usual for the supply chain and logistics industry.

“Global and local factors have created a new normal – one that demands resilience, agility, and smarter decision-making. Digitisation and emerging technologies are no longer optional. They’re essential to building connected operations and collective capability across the ecosystem.”

A huge thank you to the expert presenters and panellists

- Tim Dillon from Tech Research Asia, Anthony Stewart from Samsung Australia, Michael Dyson from SOTI, and Jonathan Patchell from Kynection for sharing insights on how a mobile-first approach is reshaping how supply chain leaders think about employee experience, resilience, compliance, and operational control. We’d also like to recognise the invaluable support of Philip Parker and his Invia team for showcasing the power of their platforms for mobile fleet managed services.

From 21st to 23rd July, the highly anticipated CeMAT event brought together logistics, automation, and supply chain innovation leaders from across the globe. As a premier national event, it provided a unique platform for customers, professionals, and enthusiasts to connect, collaborate, and exchange ideas. The SCLAA was proud to be part of this year’s showcase.

Across the three days, the Knowledge Theatre hosted a series of inspiring and thought-provoking sessions, where industry experts shared valuable insights on emerging trends, new technologies, and the future direction of supply chain management. It was an incredible opportunity to hear first-hand from leaders who are shaping the industry, and to gain a deeper understanding of the challenges and opportunities that lie ahead. It was also great to see students exploring the

event, eager to learn and discover career possibilities in this fast-evolving sector.

One of the most exciting aspects of the event was seeing so many students in attendance. Their enthusiasm for learning about cutting-edge technologies and exploring career possibilities in the logistics and supply chain sector was truly encouraging. It’s clear the next generation is ready to step up and help drive innovation forward.

We extend our heartfelt thanks to everyone who visited the SCLAA stand during the event – your engagement and conversations made our presence all the more meaningful.

A huge thank you to everyone who visited the SCLAA stand, and to our amazing NSW Committee, Julian B, Alice Brimicombe, Michael Farragher, Riaz Haque, Rae Su, Drew Mckinnel and Hans Tobbe for their time and support at CeMAT. Your contribution made a real difference to our presence at the event.

Finally, a big thank you to CeMAT for hosting such a wellorganised and impactful event. By bringing together innovators, decision-makers, and future talent, CeMAT continues to push for real change in the industry, fostering collaboration and accelerating progress.

We look forward to building on the connections and ideas from this year – and to seeing you all at the next CeMAT!

Let’s Taco About Supply Chain – August 5th at El Loco, Slip Inn

On 5th August, we gathered at the vibrant El Loco in Slip Inn for our Let’s Taco About Supply Chain networking event – and what a night it was! With over 40 industry professionals and students joining us, the atmosphere was full of energy, great conversations, and plenty of laughs.

The venue was perfect for the occasion, serving up delicious food, sweet churros, and a lively backdrop for our supply chain and logistics quiz. Congratulations to our quiz winners, who took home a bottle of fine wine to enjoy – well deserved!

A huge thank you to our SCLAA NSW Committee members – Julian B, Irene Martínez González, Cathyanne Jones, Alice Brimicombe, Michael Farragher, Rae Su, Drew Mckinnel – for their time and effort in making this event such a success. Your support and teamwork made all the difference.

It was wonderful to reconnect and build new relationships after some time apart. We look forward to seeing everyone again at our next event. Stay tuned for more details!

Rae Su NSW/ACT Division Committee nsw@sclaa.com.au

We closed of the first half of the year with our strongest state End Of Financial Year event yet with 77 People at one of the busiest times of the year! It proved to be a fantastic night to network, connect and reconnect.

Thank you again to Will Fan and Vstrong Intelligent for sponsoring. It’s getting bigger and better every year!

This year’s Mentoring Program formally launched in July 10. About 30 mentors and almost 50 mentees have signed up to this important program. Due to the number of mentees, some mentors have taken on 2 mentees! We are very thankful for these leaders as this is a really meaningful way to help up and coming leaders in their careers. Personally, I connected with several students that made me very comfortable that the future is in good hands. A lot of our mentees are supremely driven and very focused. We are honoured to be a part of their journey.

This month, we also had the From Talk to Transformation: A Communication Masterclass hosted by our own Stephen Lakey and Renee Giarrusso on the 28th of August at The Library at the Dock. Communication is a critical skill whether you’re managing, influencing and especially if you’re leading! How do you communicate effectively and with impact?

Watch out for a couple of events in September

The Leadership in Zero Emissions Last Mile Delivery event presented by ANC will showcase Who Gives a Crap – a leader in sustainable delivery and corporate governance. Learn why sustainability is fast becoming a core strategy for brand health and customer satisfaction. On the 3rd of September, the 12th edition of the Future Warehouse and Logistics event will tackle everything from lean facility design, automation and robotics to sustainable operations. Learn from key speakers from Amazon, Ego Pharmaceuticals and Mondelez.

As always, keep the ASCL Awards in mind. November is fast approaching and seats are filling up! Make sure you register and more importantly don’t miss out on an opportunity to sponsor what is sure to be an excellent night of recognition.

Archival Garcia VICT/TAS State President Archival.Garcia@sclaa.com.au

David Doherty OAM is a past President and Life Member of the SCLAA and a highly regarded logistican. Send your Straight Talk feedback and comments to secretary@sclaa.com.au

Henry Kissinger opined something like: Management aims to facilitate the achievement of objectives through attention to process and action. Leadership however is visionary and takes people to perform at levels they didn’t believe they could, or to go to places they never imagined existed.

Are you a Follower, a Manager, or a Leader? You have a choice! Future development of effective Supply Chains necessitates the emergence and nurturing of next generation genuine Leaders. Cross functional experience, training, and education are paramount pathways. Of course, Professional Associations like the SCLAA, provide quality opportunities to network, benchmark and learn.

Supply Chain leadership programs are mandatory if future success in the ever-changing global business, economic and political environment is to be achieved. Next Practice development is also critical. What innovative practices do we need to research and implement for ongoing competitive Supply Chain value generation?

SCLAA was founded with intention for membership to include the full range of professionals and practitioners in Logistics and Supply Chain. (Life Member Vince Aisthorpe was the major protagonist) As technologies have increasingly been adopted to eliminate mundane operations it easy to overlook the continuing importance of people in warehousing, transport, factory operations, planning and such. In times past pathways were often utilised to give entry level workers opportunities to progress through the ranks to management. The world is different now, but we should recognise, support, nurture and appropriately reward people in those practitioner roles. Career progression should still be an option for people with potential and desire.

BTW a colleague of mine was President of a major manufacturing company. He insisted on working “on the tools” on the process line one full day a month. A good idea also for senior Supply Chain Managers to understand the challenges and such in the practitioner roles.

I have often pondered what you really need to know to be acclaimed as a Supply Chain and/or Logistics Professional. Academic Institutions and other training and educational organisations all have a view of the essential Agenda. But what do recruiters and/or employers expect and specify in terms of experience, training and education? Despite some attempts to implement individual certification programs there is still no generally accepted framework of credentials to assess and certify competency and knowledge in supply chain and or logistics.

A universally accepted Body of Knowledge has been discussed for decades without adoption/ implementation. Career Maps have been produced yet no genuine quality Certification Program.

Collaboration of all relevant organisations and associations should be able to create, develop and implement Certification Qualifications for all Supply Chain and Logistics roles. A relevant value generating Project for 2026 would demonstrate our capacity to become real Leaders. It Is Time!

I have experienced Companies who believed they were effectively practicing Supply Chain because they had purchased a “system”. Their business processes were adapted to meet the requirements of the purchased systems. Very sad really. Systems and technologies must reflect the real requirements and intentions of the business. Technologies bring powerful tools to enable businesses to work efficiently and effectively having regard to the clearly stated objectives. Don’t submit to hype.

Quality investment in technology and systems that enables effective Supply Chains is a genuine value generator. Submitting to hype with such investment is a recipe for disaster.

This and more was recently discussed at Supply Chain Partners Virtual Summit

Virtual Summit presented under auspices of SCLAA.

David Doherty OAM secretary@sclaa.com.au

Sue Tomic Chair SCLAA, CSO Enfield Intermodal Logistics Centre,

There’s been a lot of noise about resilience lately. Politicians love the word. So do procurement teams. But here’s the question no one’s answering: resilience from what? And more importantly, resilience with what?

Because if you look closely at Australia’s freight ecosystem, one critical layer is quietly disappearing, and we’re all about to feel the cost.

Not the multinationals. Not the one-man owner-drivers.

The businesses in between - the ones too lean to absorb 90-day payment terms, too big to pivot overnight, too stretched to win with scale, and too expensive to compete with subcontractors undercutting on margins they’ll never sustain.

These operators have long been the backbone of domestic freight. Regionally embedded, often familyfounded, and usually overlooked, but always turning up. They’ve carried this sector for decades with discipline, consistency, and commitment to service.

These are the businesses that make up the middle of the market, the steady, regional, often family-founded providers who’ve carried this sector for decades. And one by one, they’re collapsing, merging, or quietly stepping away.

And we are not talking about poor performers here.

And let’s be clear: we are not talking about poor performers. We’re talking about good businesses with disciplined operations, experienced drivers, modern fleets. Businesses that have become unviable, not through failure, but through systemic imbalance.

The commercial model is breaking them.

You don’t need a spreadsheet to see the problem. Fuel, insurance, compliance, wages - all up.

Credit terms, contract margins, customer tolerance - all down.

These operators are being asked to run on yesterday’s pricing, take on tomorrow’s risk, and deliver under today’s volatility. It doesn’t stack up. It never did. Meanwhile, larger operators are sweeping up market share, not necessarily because they offer better service, but because they can weather bad terms longer. That’s not competition. That’s attrition.

And when the middle collapses? So does competition, choice, and ultimately, supply chain diversity.

We keep talking about sovereign capability, decentralised supply, and building freight resilience.

But when your supply chain is dominated by a handful of players, running high-volume lanes on narrow margins, you don’t have resilience, you have exposure.

You have a brittle system that looks efficient… right until it breaks.

Without the middle tier, we lose:

• Redundancy

• Regional access

• Price competition

• Nimble service in second-tier freight lanes

And once they’re gone, they don’t come back easily.

It’s a capability issue.

It’s a policy issue.

It’s a national interest issue.

We can’t diversify our exports if we can’t move goods costeffectively across our own country. We can’t strengthen manufacturing if domestic freight costs outpace production margins. We can’t talk about emergency preparedness when we’ve quietly allowed our domestic logistics base to hollow out.

And yet, that’s exactly what’s happening.

Mid-tier logistics is becoming unviable, not because it can’t perform, but because it’s being structurally priced out of participation.

It’s time to stop romanticising “resilience” and start funding it. That means:

• Rebalancing risk: Payment terms that reflect realworld pressures.

• Rewarding performance: Contracts that value reliability, not just price.

• Rebuilding competition: Policy that supports midtier participation, not just consolidation.

Because when the middle disappears, we all lose not just operators, but exporters, retailers, consumers, and the economy itself.

If we’re serious about strengthening freight, we can’t just protect the top or prop up the bottom. We need to restore the middle before it’s gone for good.

We need to restore the middle - the layer that gives us flexibility, coverage, and competitive tension. The layer that doesn’t make headlines, but makes the system work. Because if we don’t, we won’t be talking about resilience anymore.

We’ll be talking about recovery.

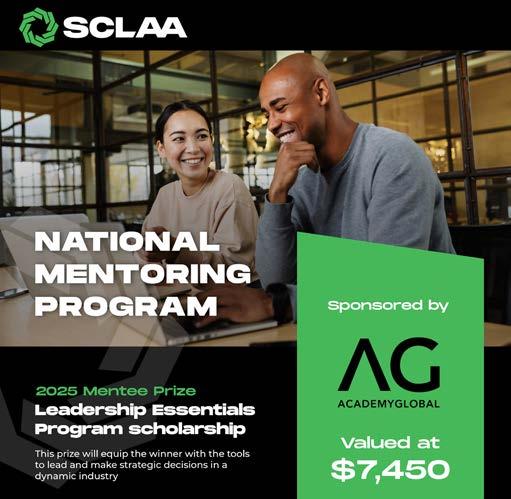

The Supply Chain & Logistics Association of Australia (SCLAA) has officially launched its 2025 National Mentoring Program, marking the largest intake in the program’s history, including a record number of students participating across all states and territories.

Running from July through December, this year’s program features an expanded structure designed to deliver impactful, career-shaping experiences. Each mentee will benefit from one-on-one mentoring sessions, focused on their individual goals and professional development objectives. Additionally, all participants will have access to a collection of online workshops, plus networking opportunities with peers, mentors, and industry leaders throughout the program.

SCLAA Mentoring Key Program Objectives:

– Supporting career progression and professional development for mentees

– Promoting knowledge sharing, leadership, and industry insights

– Fostering meaningful connections between professionals at different stages of their careers

– Strengthening the future talent pipeline within the Australian Supply Chain and Logistics sector

National Mentoring Lead Michael Farragher expressed his excitement for this year’s milestone:

“This is the biggest intake we’ve ever seen across Australia, and it’s particularly exciting to welcome a record number of students into the program. It reflects the growing interest in Supply Chain and Logistics as a dynamic career path, the increasing focus on upskilling and the value the mentoring program brings to emerging talent.”

Michael also extended his thanks to the dedicated state and territory coordinators for their hard work and leadership in launching and supporting the 2025 SCLAA Mentoring program:

– Devan Maniam (VIC/TAS)

– Chris Josey (QLD)

– Mathew Smith (SA)

– Daniel Green (WA)

– Drew McKinnel (NSW/ACT)

“These coordinators have gone above and beyond to get this program up and running and support it across the country — we couldn’t do it without their commitment,” Michael said.

The state coordinators also expressed their sincere gratitude and admiration for the 2025 mentors,

whose time, insight, and commitment play a vital role in supporting, upskilling, and developing the next generation of supply chain professionals. It’s wonderful to see many returning mentors this year, continuing to give back and share their expertise with new mentees. Their ongoing involvement is a testament to the value and impact of the program.

SCLAA would also like to extend a sincere thank you to all of our current sponsors for supporting the 2025 intake. In particular, a special thank you goes to AcademyGlobal for their generous prize awarded to one exceptional mentee - a Leadership Essentials Program scholarship valued at $7,450.

The Leadership Essentials Program is designed to provide professionals in the Supply Chain and Logistics sectors with a comprehensive understanding of core business principles. The program covers key areas including people management, finance, commercial and legal

acumen, and strategy and risk management, equipping participants with the skills needed to thrive in leadership roles.

While registrations for the 2025 intake are now closed, those interested in becoming a mentor or mentee in future years are encouraged to reach out to their state or territory coordinator to learn more about the program and how to be part of the 2026 intake.

If you or your organisation would like to sponsor any part of the SCLAA Mentoring program, please contact the SCLAA or your local coordinator to explore partnership opportunities that help support the growth and development of Australia’s future supply chain leaders. With strong momentum and a growing community, the SCLAA Mentoring Program continues to empower Australia’s future leaders in Supply Chain and Logistics.

“Supply Chain Excellence is built on the foundation of strong mentorship and continuous learning.”

Michael Farragher

National Mentoring Lead

Epicor, a global leader of industry-specific enterprise software to promote business growth, today continued its global portfolio expansion for the make, move, and sell industries with the upcoming release of Epicor Prophet 21 for distributors in Australia and New Zealand (ANZ).

Epicor Prophet 21 is an industry-leading SaaS ERP solution tailored for distributors, and part of the Epicor Industry ERP Cloud. Distributors can leverage advanced business intelligence and industry-specific integrations to strengthen operations, supplier relationships, protect against cyber threats, and strengthen time-to-value.

According to a new Forrester study in collaboration with Epicor, 78 percent of distributors across ANZ are planning to adopt or expand their use of AI in ERP, yet only 35 percent have implemented it meaningfully. This highlights a major gap between ambition and execution, with legacy ERP systems and siloed data cited as the top barriers to supply chain agility and modernisation. In addition, by 2028 68 percent of distributors in ANZ plan to change their ERP solution, with many already evaluating alternatives. This signals a major shift towards modern, SaaS-based ERP platforms.

“We’ve listened closely to the needs of distributors in Australia and New Zealand and are responding with increased resources and tailored solutions to meet their needs,” said Andy Coussins, Executive Vice President of International at Epicor. “Our expansion in this key market reflects our long-term global commitment and focus on providing distributors the SaaS-based, datadriven capabilities they need to make smarter, faster decisions.”

The upcoming release of Epicor Prophet 21 in ANZ, slated for December 2025, emphasises enhanced CountrySpecific Functionality (CSF), addressing the unique

needs and regulatory requirements of businesses within the region. These new regional capabilities are not only designed to strengthen compliance with local regulations but also enhance operational effectiveness and customer engagement through customisable forms and languages.

Expected features include:

– Robust compliance with local accounting standards such as IFRS and GAAP, as well as streamlined management of Goods and Services Tax (GST).

– Extensive Business Activity Statement (BAS) reporting capabilities to assist in fulfilling tax obligations, as well as adherence to the Payment Times Reporting Scheme (PTRS) which promotes fair payment practices to small business suppliers.

– Integration of BPAY which allows for convenient electronic payments through financial institutions, significantly improving transaction efficiency.

For more information or to schedule a demo of Epicor Prophet 21, please visit our website

About Epicor

Epicor Software Corporation equips hard-working businesses with enterprise solutions that keep the world turning. For more than 50 years, Epicor customers in the automotive, building supply, distribution, manufacturing, and retail industries have trusted Epicor to help them do business better. Innovative Epicor solution sets are carefully curated to fit customer needs and built to flexibly respond to their fast-changing reality. With deep industry knowledge and experience, Epicor accelerates its customers’ ambitions, whether to grow and transform, or simply become more productive and effective. Visit www. epicor.com for more information.

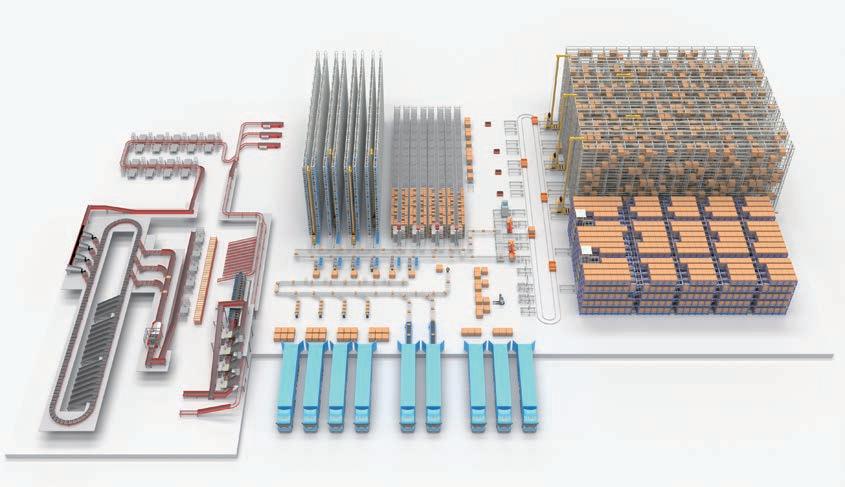

Vstrong Intelligent’s Red Crab Tote-Picking System offers a high-efficiency, intelligent automated warehousing solution, combining Miniload AS/RS, Multi-Shuttle Systems, and A-Frame Sorters. The system features high-density storage, fast and accurate picking, flexible scalability, and intelligent scheduling, significantly improving operational efficiency and accuracy.

Our solutions fully integrate automation and intelligent management, covering inbound, storage, picking, sorting, and outbound processes. Widely adaptable to e-commerce, pharmaceutical, and manufacturing industries, Red Crab reduces labor dependence, optimizes processes through data analytics, and drives digital transformation for supply chains.

Shuttle technology is a core R&D focus for Vstrong. This year, we introduced two new models: the 930 Adaptive Fork Four-Way Shuttle, supporting mixed tote and carton storage in high-throughput environments, and the 930-400 Curved Bidirectional Shuttle, designed for irregular facilities with flexible transport paths, even replacing conveyors in specific scenarios.

With end-to-end project services from design to implementation, Vstrong Intelligent empowers enterprises to achieve smarter, more efficient, and cost-effective logistics operations.

Find out how Petbarn uses Mobiledock to manage dock scheduling, reduce congestion and keep everything running smoothly. Petbarn: A Mobiledock success story.

With Australian B2B manufacturers facing unprecedented challenges from rising energy costs, complex industrial relations environments, and stringent ESG requirements, leading supply chain consultancy Prological has released a comprehensive report examining how strategic network design has become essential for competitive advantage.

The white paper reveals how manufacturers thriving in today’s challenging environment treat supply chain network design as a strategic imperative, not an operational afterthought.

Wholesale gas prices have tripled over the past decade, with some manufacturers seeing monthly electricity costs more than double within twelve months, forcing a fundamental rethink of operational strategies. Additionally, environmental requirements are making manufacturing more cost prohibitive in Australia, forcing companies to close local operations and import from overseas producers with larger carbon footprints. These combined pressures are pushing manufacturers toward high-value products with intellectual property, where Australia can maintain a strong competitive position.

The report explores key areas including:

Strategic network design methodology for B2B manufacturers

Building data-led supply chains with five core information pillars

– Implementation roadmaps and risk management strategies

– Leveraging Australia’s untapped export advantages

The paper includes a detailed case study of MMKembla, Australia’s only copper tube manufacturer, which has worked with Prological for 17 years to continuously optimise their national network, demonstrating how regular network design reviews create measurable ROI through cost savings and service improvements.

Peter Jones, Managing Director at Prological:

“Australian manufacturers are caught between rising costs and shrinking margins, but those who treat their supply chains as competitive weapons rather than cost centres are not just surviving – they’re thriving. This report shows that manufacturers approaching lease renewals or expansion decisions have a strategic opportunity to fundamentally transform their operations. The question isn’t whether to evolve – it’s whether to lead the

transformation or be left behind by competitors who act first.”

“Despite the challenges, Australia offers surprising advantages for manufacturers thinking globally – it costs less to export from Australia to many EU destinations than it does for many EU origin-to-destination pairings. These export advantages remain largely untapped, but can be unlocked with data-led, strategic network design. Without accurate, complete datasets, manufacturers are making expensive guesses rather than evidence-based decisions.”

To download the white paper, click here

Established in 2010, Prological Consulting has a strong focus on international and domestic freight strategy and design. Prological designs and implements supply chain innovation with the intent of supporting and enhancing already existing business strategy. With expertise across all key industry sectors, Prological Consulting delivers individualised, innovative, commercially viable and operationally sustainable outcomes for its clients. Prological and its extended team have a broad range of backgrounds, training and experiences and have completed assignments in Europe, Asia and North America as well as here at home in Australia and New Zealand. Visit: https://www.prologicalconsulting.com

– EFL 3PL Global advances digital transformation strategy with move to Infios’s cloud-based WMS platform

– Migration will deliver enhanced performance, 2540% cost savings, and improved latency for Asia-Pacific operations

– Partnership leverages Infios’s comprehensive technology suite including CLASS simulation tool for new market expansion

Leading third-party logistics provider EFL 3PL Global announced the transformation of its warehouse operations by transitioning to Infios’s cloud-based Warehouse Management (WMS) platform across its Asia-Pacific operations.

EFL 3PL Global, a subsidiary of Expolanka Holdings and part of SG Holdings (SGH), operates as a prominent logistics service provider in the Asia Pacific Region. With over 120,000+ CBM in distribution capacity across Sri Lanka, India and Malaysia, EFL 3PL Global delivers comprehensive 3PL solutions for the fashion, pharmaceutical, high-tech, telecommunications and FMCG sectors.

The company's transition to Infios’s cloud-based WMS platform marks a significant evolution in its digital transformation journey, which began with an on-premise solution in 2016, progressed to EFL 3PL-managed clouds and now advances to Infios’s Software-as-a-Service (SaaS) platform.

This strategic move addresses key operational challenges while positioning EFL 3PL Global for continued growth across the Asia-Pacific region. The cloud migration will enhance performance through improved server latency, with new infrastructure based in Singapore optimised for regional operations.

"The transition to Infios’s cloud-based WMS is expected to deliver significant cost savings of 25-40% while providing uninterrupted service and enhanced security. The platform's scalability and flexibility are crucial for our expansion plans, particularly in India where we're establishing operations in Chennai and Mumbai," said Supun Kanchana, Senior Manager at EFL 3PL Global.

“We have been extremely impressed by Infios’s commitment to continuous innovation. It's not just their WMS - they're capable of supporting all robotic technologies in the warehousing sector.”

EFL 3PL Global has also leveraged Infios’s CLASS simulation tool for the past four years to support its market

expansion. The tool enables detailed warehouse layout design, racking solutions analysi, and operational simulations, providing clients with clear visibility intoproposed solutions before implementation.

"EFL 3PL Global exemplifies how the right technology partner can enable business growth,” says Tim Moylan, Infios Chief Growth Officer. "Our comprehensive suite of solutions, from cloud-based WMS to simulation tools, supports EFL 3PL's expansion while ensuring optimal efficiency and customer satisfaction. The migration to our SaaS platform represents the next phase in our partnership, delivering enhanced performance, security and cost benefits."

Looking ahead, EFL 3PL Global plans to leverage Infios’s cloud platform to support its continued expansion across Asia-Pacific, with implementation already underway in India and Malaysia.

Infios, formerly Körber Supply Chain Software, is a global leader in supply chain execution, relentlessly making supply chains better - every single day. With a portfolio of adaptable solutions, Infios empowers businesses of all sizes to simplify operations, optimize efficiency, and drive measurable impact. Infios serves more than 5,000 customers across 70 countries, delivering adaptable and innovative technologies that evolve with changing business needs. The company's deep expertise and commitment to purposeful innovation help businesses turn supply chains into a competitive advantage, building resilience and shaping a more sustainable future.

Learn more at www.infios.com

For over 30 years, AFS Logistics, an Australian and New Zealand-based logistics provider, has offered end-to-end services across warehousing, freight forwarding, and 4PL distribution.

AFS Logistics has its own international shipping division, a proprietary cloud-based freight management system, MOVEiT, and a national delivery network integrated with over 120 carriers, giving them a strong 4PL capability.

With seven sites across ANZ, the AFS business continues to expand with a primary focus on customer service - and has relied on Linde Material Handling Australia to keep up with demand.

With over 35 Linde units in operation and more on the way, AFS Logistics’ material handling needs have grown significantly.

For the past four years, Linde Account Manager Mia Whiteoak has worked closely with the AFS Logistics team to ensure their needs are met.

“AFS Logistics needed a partner who could move quickly and support them as they grow,” says Mia. “From our very first conversation, it was about understanding their priorities and responding fast - whether it was sourcing new machines or finding a short-term rental at a moment’s notice.”

Shayne McDonnell, 3PL Director at AFS Logistics, leads the company’s third-party logistics arm, managing almost 40,000 square metres of warehousing space.

“We started our 3PL operation in 2018 with around 2,000 pallets,” says Shayne. “Today, we manage anywhere between 46,000 to 60,000 pallets across our sites so we’ve grown considerably over the past three years.”

As business demands increase, AFS Logistics’ 3PL business continues to adapt its fleet with Linde. The company’s operation primarily relies on high-reach trucks to manage heavy pallet volumes, complemented by electric counterbalance forklifts, order pickers, and pallet trucks to ensure smooth and efficient 3PL site operations.

“We have high shelving. Our business is mostly pallet picking, so Linde’s reach trucks are essential to our model,” Shayne explained. “But we’re also evolving - and as we move into more e-commerce, we’ve started using Linde’s V08 order pickers. These little run-around pallet trucks are an amazing unit. They help us with picking, and straightaway we can double our pick face because those little units go up 1 metre in the air. They let us pick from ground level and the first shelf, which has helped improve efficiency.”

With the business continuing to grow, the team is exploring ways to expand.

Shayne explains, “We’ve grown quickly, and with our rapid growth, Linde’s been able to support us at short notice. We might pick up a contract that needs two or three machines in a hurry, and Mia’s always found a way to source the right machines for us and turn it around very quickly.”

“Due to land prices increasing, it’s getting more and more expensive. So, we’re now looking at buildings that go up to 14 metres, compared to most others that only reach around 9 metres.”

To support AFS Logistics’ 3PL shift to higher racking systems, Linde has supplied reach trucks capable of lifting up to 12 metres - helping the business optimise space as warehouse costs continue to rise.

AFS Logistics uses a mix of long and short-term rental equipment from Linde, giving them the flexibility to adjust their fleet as needed.

“If we need a certain number of forklifts for a short period, 99 per cent of the time, whatever we need, Linde’s been able to provide.

“Another one of the benefits with Linde’s rental model is the service. If a machine goes down, it’s replaced quickly—within 24–48 hours,” Shayne said. “That’s critical for us, especially in peak periods when downtime isn’t an option.”

AFS Logistics’ Linde units are fitted with digital weight indicators, CCTV cameras and the Linde BlueSpot warning lights, all contributing to safer, more efficient operations.

“All three are valuable,” Shayne said. “The Linde BlueSpot, in particular, is a standout feature - it’s a visual cue for people unfamiliar with warehouse traffic. I always tell visitors, ‘If you see a blue light, a forklift is within three metres.’ It’s that simple. The CCTV cameras and weight indicators also help from an operational and efficiency point of view - they make it more efficient for the guys picking.”

For Shayne, Linde’s service and support are critical to keeping AFS Logistics running efficiently every day.

“Alongside our facilities and our focus on people and safety, having reliable equipment and support from Linde is essential for running efficiently and effectively,” he says.

AFS Logistics receives monthly KPI reports on all equipment, allowing the team to effectively monitor maintenance schedules and utilisation, which has improved operational oversight.

“Mia’s been great to work with,” Shayne says. “If I need anything, she’s very responsive - I know she’ll get onto it straight away. If there are any issues, she jumps onto it and fixes it promptly. Whether we need equipment urgently or we’re planning a new facility, she makes sure we’re covered.

“As soon as I heard we’re going higher, the first call I made was to Mia to make sure we could get the reach trucks we’d need,” Shayne added.

“And without hesitation, she said, ‘No problem.’ That level of service and reliability is what keeps us coming back.”

For Shayne and the AFS team, it’s all about servicing their customers - so the decision to stick with Linde is as much about performance as it is about people.

“I’ve been a Linde man most of my life. The machines are reliable, comfortable, and they look good too. But more importantly, I know I can count on the team.”

The e-commerce boom isn’t slowing down any time soon, and heightened customer expectations are putting immense pressure on retailers and the supply chain to deliver more parcels faster than ever before.

20.1% of all retail purchases in 2024 are expected to take place online, with the global e-commerce market expected to total over $7.9 trillion by 2027 (1)

Today’s customers expect to receive or pick up their orders in record time, including same-day and two-hour windows. This expectation is blurring the line between warehouses and retail stores, with orders no longer being fulfilled from warehouses alone, but increasingly from the back of stores and micro-fulfilment centres located closer to customers.

So, how are businesses coping with these ever-increasing demands? The answer is technology.

Warehouse and logistics leaders are always looking for ways to give their workers an instant productivity boost, process more orders, increase order accuracy, and meet the fastest delivery times, and one area seeing a huge investment is wearable technology.

Wearables are designed to keep workers’ hands free, as opposed to traditional handheld devices. Worn on either the wrist, hand or finger, these tiny powerhouses enable workers to pick and pack orders, load trailers and move boxes faster than their handheld counterparts, and move packages through the supply chain faster and in safer conditions.

This has critical flow-on effects for businesses further down the chain. For example, retailers can move incom-

ing shipments from the dock to shelves faster, so more products are available for in-store and online customers to purchase.

An impressive 93% of warehouse employees agree that new technologies are essential for attracting and retaining talent, according to Zebra’s 2025 Warehousing Vision Study, signalling a major shift in workforce priorities. Modern devices like wearables have become essential for simplifying tasks, reducing physical strain and ensuring smooth integration with automated systems. As a result, the demand for technology has become a defining factor in the labour market, with today’s workforce viewing it as a valuable ally in creating a safer, more productive and satisfying work environment.

Zebra offers the widest range of wearables in the market, including the newly-launched WS501, the world’s smallest all-in-one Android enterprise-class wearable mobile computer. Offering a range of mounting options (hand, wrist and finger), Zebra wearables meet the needs of practically any warehouse and logistics application, whether it’s order picking, inventory put-away, loading and unloading shipments or task management.

Learn more about Zebra’s range of wearables for warehousing and logistics here

(1) * Forbes Insider Intelligence, 38 E-Commerce Statistics Of 2024

As 2025 races toward the finish line, warehouses, distribution centres, and manufacturing facilities have a critical opportunity: use the final weeks of the year to prepare equipment and operations for a stronger, more reliable 2026.

Ignoring small issues now can lead to costly breakdowns, missed deadlines, and safety risks in the busy months ahead. A proactive year-end checklist isn’t just good practice - it’s a competitive advantage.

Here are eight essential actions to take before the calendar turns:

1. Create a Detailed Inspection Checklist

Whether you have one technician or a full maintenance team, establish a step-by-step inspection process for every type of machinery. This ensures each component is reviewed against the same standards and nothing slips through the cracks.

2. Inspect High-Wear Components

Different parts wear at different rates. Pay close attention to:

Belts, rollers, and bearings.

Motor temperature or vibration changes.

Conveyor frame alignment and safety guard integrity. Fixing these now avoids costly downtime and can prevent injuries.

3. Review Preventive Maintenance Logs

Maintenance records are more than paperwork - they’re a blueprint for reliability. Make sure all scheduled service is up to date, including lubrication, belt tension adjustments, and drum motor checks. If peak season delayed maintenance needs, catch up now.

4. Compare Throughput to Current Demand

Has your order volume, SKU mix, or product flow changed? Review throughput data to confirm your conveyor and sorter configurations are still optimised. Consider adding accumulation zones, upgrading controls, or reprogramming sortation logic for efficiency gains.

5. Verify Safety Compliance

Standards like Work Health and Safety (WHS) require continuous attention. Test emergency stops, pull cords, and warning signs. Ensure all safety devices are visible and operational, and retrain staff on lockout/tagout procedures.

6. Secure Spare Parts and Confirm Lead Times

Global supply chain delays can still impact critical parts. Stock up on high-risk wear items - belts, motors, sensors - and confirm lead time commitments for larger components in 2026.

Tim Abela

Service Manager, Interroll

Tim specializes in equipment maintenance, site auditing, and construction safety.

7. Update All System Documentation

Over time, changes to systems can go undocumented. Make sure electrical schematics, PLC backups, and mechanical drawings are accurate and securely stored. Accurate records speed troubleshooting and reduce downtime when issues arise.

8. Allocate Budget for Upgrades and Expansion

Year-end is budget season. If you expect growth or new product lines, now’s the time to earmark funds for additional conveyors, advanced sorters, or high-efficiency drum motors. Early planning makes integration smoother next year.

Final Word

The close of the year is more than a time to wrap upit’s the ideal moment to get ahead. By inspecting, documenting, and planning now, warehouse operators can enter 2026 with reliable equipment, higher efficiency, and fewer surprises.

If you’d like expert support with inspections, spare parts planning, or system upgrades, Interroll offers year-end system reviews to help you start the new year at peak performance.

Harvestaire is Australia’s leading provider of aftermarket combine harvester parts, focusing on both header and front parts. The company manufactures a broad range of harvester and tractor components at its West Australian factory and sources additional components from reliable manufacturers locally and internationally. Harvestaire has become a trusted name in the agricultural industry, pioneering innovations that increase productivity, harvest efficiency and reduce losses since 1980.

Homegrown quality yields growth

Harvestaire has three subsidiaries and serves 5,500 customers, supplying parts wholesale to dealers and directly to farmers. With a focus on exceptional service to meet the needs of its customers, Harvestaire expanded its reach in recent years by leveraging local manufacturing, maintaining a reliable distribution network across Australia. Furthermore, it has built a thriving ecommerce business, giving Australian farmers access to harvester parts knowledge previously reserved for large companies and dealers.

Manual processes wilt under pressure

Harvestaire’s rapid growth and an increasingly tight labour market made it challenging to manage more customers. The entire business was paper based with institutional knowledge limited to a handful of people, creating risk. Paper reliance also caused delays and inefficiencies that prevented the business from providing the high level of service leaders demanded. The company’s financial and operational data was siloed across systems and spreadsheets, and manually managing 7,500 SKUs became overwhelming for the team.

Cultivating efficiency with a unified system

Harvestaire deployed NetSuite ERP, CRM and SuiteCommerce Advanced to unify its back-end business functions and ecommerce. The switch centralised order management, providing a single view of customers, orders, inventory, and financials. Staff quickly adopted and personalised NetSuite, which allowed them to move their business processes into the system and fully automate them. This helped the business reach new markets, transition half of its phone orders to self-service online orders, and attract 1,000 new customers. Furthermore,

automated SMS marketing through SuiteCommerce Advanced helped generate additional revenue.

“NetSuite helps us capture all the information we need in a single ERP solution. The personalised system captures unique data, so we can now support Australian farmers in ways previously not possible in our industry. Being based in Perth, SuiteCommerce Advanced has made it possible for us to reach new markets like New Zealand and the US.”

Dirk Vorster, General Manager, Harvestaire

Ploughing ahead with market expansion

Harvestaire has achieved a customer satisfaction score of 89% by delivering a consistent, high-quality experience for both farmers and dealers. The business plans to continue expanding its market presence and driving additional revenue by leveraging NetSuite data to better target and engage customers. NetSuite has also reduced employee time spent on order processing and fulfilment by 75% so leadership can redeploy those resources to other initiatives.

Interested in learning more? Come and meet Dirk and the Harvestaire team for an exclusive site tour at their facility in Perth.

Date: Friday, 5 September 2025

Time: 12.00pm to 2.00pm

Registration Link: Click here

By Luke Olsen, Managing Director – APAC, Microlise

Between March 2024 and March 2025, a total of 157 fatalities occurred in accidents involving heavy trucks. Of these, 93 were linked to articulated trucks, while 73 involved heavy rigid trucks [1]. These aren’t just statistics. These are people - colleagues, family members, mates - gone. And every one of those numbers represents a system that failed. That’s the uncomfortable truth. If you run or manage a fleet and your idea of safety starts and ends with ticking a few compliance boxes, it’s time for a rethink. Safety can’t be reactionary. It can’t be a poster on the wall. It needs to be baked into every part of the operation from planning, leadership, communication and technology. It needs to live in the way people think, behave, and talk about risk. And if it doesn’t, you’re one phone call away from a worst-case scenario.

Let’s be honest, if your team doesn’t trust you, nothing you roll out will work. Fancy systems, new rules, training modules… they all fall flat if people feel like they’ll be blamed, ignored, or left out to dry. Trust is the backbone of a working safety culture. It’s what allows people to speak up before something goes wrong, not after. You build it by listening to drivers and acting on what they say. By following through on your promises. By giving people the confidence that they won’t get punished for flagging a problem. It’s not just about being a nice boss. It’s about creating a space where the truth gets heard before the damage is done.

The Australian Automobile Association still lists fatigue as one of the top contributors to road trauma [2]. But too many still reduce it to hours-driven or time-on-task. That’s surface-level thinking. We all know someone who can do 12 hours and still be sharp. We also know someone who’s a wreck after six. Fatigue is complex, it’s tied to sleep, yes, but also to what’s going on in someone’s life: stress, mental health, diet, relationships, even financial strain. Your job as a leader isn’t to wave the rulebook. It’s to understand the person behind the wheel. Are they coming in tired all week? Have they had a proper break? Are their shifts being stacked to cover a shortfall in planning? If you want to reduce fatigue risk, start by asking better questions and actually caring about the answers.

Safety doesn’t just come from the top. It’s lived and reinforced by the people closest to the drivers - your frontline team leads, depot managers, dispatchers. If they

push drivers to cut corners, ignore red flags, or ‘just get it done,’ then that’s your real culture, not the one written in your handbook. But if they’re leading toolbox talks, calling out great driving, encouraging feedback, and being available when someone’s unsure, that’s when culture sticks. What can you do? Start by training these leaders properly. Not just in compliance, but in communication and influence. They need to know they’re not just traffic coordinators - they’re the front line of your risk strategy.

The Chain of Responsibility laws make it crystal clear - everyone in the transport chain is responsible for safety [3] That means planners, schedulers, warehouse loaders, managers - not just the person in the cab. But how many organisations really live that? Too many still operate on ‘driver blame first’ when things go wrong. If your warehouse is overloading vehicles, if your schedules are unrealistic, or if your systems make it hard to report issues - you’re complicit.

Real culture means shared accountability. It means every link in the chain asks, ‘What’s my role in making this safer?’ If that’s not happening, your risk isn’t being managed - it’s just being pushed downstream.

Let’s talk about AI dashcams, telematics, distraction detection, and driver scoring tools [4]. Used right, they’re game-changing. They help spot patterns, flag fatigue, and show who needs coaching. Used wrong, they create resentment and fear. If drivers think technology is just there to catch them out, they’ll disengage - fast. And once trust is gone, it’s hard to get back. If you’re using these tools, be transparent. Explain what’s monitored, when footage is reviewed, how data is used, and what support is available. Show the wins - like the time a camera proved a driver wasn’t at fault. Let people see technology as backup, not a bat. Culture isn’t about surveillance. It’s about support. Get that balance right and your tools start working for you, not against you.

Drivers don’t wake up looking to break rules. They’re responding to pressure, gaps in systems, mixed messages, or lack of awareness. Speeding? Maybe they’re running late because of an unrealistic delivery

window. Fatigue? Maybe they couldn’t say no to an extra shift. Seatbelt use? Maybe they’re ‘just moving the truck around the corner’ - which, by the way, is still one of the most common contributors to preventable fatalities [5]. Changing behaviour means understanding context. Fix the workflows. Space the rosters. Set better expectations. And most importantly, reward the behaviour you want more of. That’s what drives change.

A true safety-first culture isn’t built in the heat of a crisis. It’s built during the quiet days when nothing goes wrong. That’s when you do your best work - shaping habits, reinforcing expectations, and creating normality around speaking up. Every meeting, every interaction, every job plan should have safety baked in. It’s not about running a safety campaign for a week. It’s about making it part of every day. What are you doing to keep safety conversations going when the spotlight’s off? That’s where it either fades or becomes real.

If your systems, schedules, and structures are making it hard to follow the rules, then people won’t follow them. That’s on you. Design your operations so that doing the

References

safe thing is the easy thing. Pre-start checks that don’t require paper. Rosters that allow for real rest. Delivery slots that factor in traffic, fatigue breaks, and real-life delays. When drivers don’t have to choose between compliance and getting the job done, they’ll pick safety every time. But you need to make that choice visible and practical.

So, here’s the reality: 157 fatalities occurred between March 2024 and March 2025. Of these, 93 were linked to articulated trucks, while 73 involved heavy rigid trucks. It’s not good enough [1]. Every meeting you skip, every dodged conversation, every red flag that’s ‘not urgent’that’s a potential incident in the making. If you’ve got the power to influence safety - and if you work in this industry, you do - then it’s time to step up and seek out support. It’s not about being perfect. It’s about being consistent, honest, and committed. Every policy, every technology rollout, every leadership hire should scream ‘safety comes first’. Because when something goes wrong, it’s not the policy that gets the call. It’s the people.

Let’s

do better. Let’s lead with safety, not just say we do.

[1] Road Safety Data Hub. ‘Quarterly Heavy Vehicle Road Deaths’. https://datahub.roadsafety.gov.au/safe-systems/safevehicles/quarterly-heavy-vehicle-road-deaths

[2] Australian Automobile Association. ‘Fatigue and Road Safety’. https://www.aaa.asn.au/research-data/road-safetyresearch-program/fatigued-driving/

[3] NHVR. ‘Chain of Responsibility Explained’. https://www.nhvr.gov.au/safety-accreditation-compliance/chain-ofresponsibility

[4] Transport Certification Australia. ‘Telematics and Safety Improvements’. https://tca.gov.au

[5] BITRE. ‘Seatbelt Use and Road Deaths’. https://www.bitre.gov.au

In July, Optus Enterprise partnered with the SCLAA to host a first-of-its-kind forum in Sydney—bringing together industry leaders, analysts, and technology partners to tackle some of the sector’s biggest challenges.

The message was clear: disruption is now the norm. From global volatility to evolving customer expectations, supply chains must be more resilient, agile, and digitally connected than ever before. As SCLAA Chair Sue Tomic put it, “Digitisation and emerging technologies are no longer optional—they’re essential.”

Tim Dillon from Tech Research Asia likened technology to the nervous system of modern supply chains—vital to performance and responsiveness. His research revealed:

• 98% of Australia’s 1.2 million supply chain workers rely on mobile devices; downtime can halt orders and deliveries.

• Outdated, siloed systems hinder scalability, integration, and security.

• AI, digital twins, and private wireless networks are already delivering 15–25% productivity gains in areas like asset tracking and delivery optimisation.

Optus Enterprise’s Martin Brown introduced the Optus Frontline Worker solution—bundling rugged Samsung devices, secure endpoint management, real-time workflow apps, and 4G/5G connectivity. Around half of