Brewery Equipment Selection and Design 6

OVERVIEW

In planning for a brewpub, the brewery will probably be constrained for space because square footage costs money, and brewery space, unlike retail space, doesn’t make money. This means floor space is precious and must be carefully allocated. Based on the assumption that your operation is like most others, certain space-saving considerations for equipment selection should be kept in mind.

Most brewpub and craft brewery startups will try to save space, and initial startup costs, by combining equipment and system functions where they can because square footage is at a premium, and maximizing production volume, at that point, is not critical. The most common brewhouse configuration will incorporate a grist case, a combination mash-lauter tun (MLT), a combined brew kettle-whirlpool (KWT), a wort-cooling heat exchanger, and a hot liquor (heated water) tank (HLT). Figure 6.1 shows a classic two-vessel craft brewhouse. It may also include a cold liquor (chilled water) tank (CLT) as well if the operation wants to make lager beers, has high seasonal water temperatures, or needs cooling-water holding capacity. This type of brewhouse can produce 3–4 brews every 24 hours but will normally make just 1 or 2 brews per day, at least at first.

Higher-volume packaging and distributing breweries will be pressured to produce more wort per day, which can be accommodated by adding a relatively inexpensive, single-function whirlpool tank. This expands the brewhouse equipment to 3 vessels, including a combined mash-lauter tun, a brew kettle, and a whirlpool tank. This arrangement can produce about 5–6 brews per 24-hour day. A fully fitted out 4-vessel brewhouse would include a stirred mash tun, a lauter tun or mash filter, a brew kettle, and a whirlpool tank. An arrangement like this can produce 8–10 brews every 24 hours, depending on what is being brewed.

Cellar operations will include single- or multiple-brew-sized fermentation vessels (FV tanks) and single- or multiple-brew bright beer (BB) tanks. For brewpubs and breweries with a pub operation, serving tanks are typically sized to accommodate a partial or full brew (depending on the brew size). A brewpub might also incorporate a small keg washer so that serving tanks can be cleared out to make room for the next batch.

■

Packaging fillers, such as bottle and/or can fillers along with their associated equipment, may need working in as well. Many startup breweries will purchase small in-line bottle and can fillers initially and then upgrade to larger, faster rotary lines later. It’s a good idea to look ahead in your layout and plan for how those upgrades will work within the building’s floor space areas and process flow.

For the purposes of this book, we will assume the following standard equipment list as the typical arrangement for design guidelines, examples, and standard operating procedures (SOPs):

● Two-vessel brewhouse consisting of a mash-lauter tun and a kettle-whirlpool tank; hot and cold liquor tanks; plate and frame wort-cooling heat exchanger; and a sintered stone aeration system

● Fermenters and BB tanks consisting of one or more brew volume capacities

● Serving tanks and kegs with a keg washer with a manual filling set-up

● In-line can and bottle fillers

What are the advantages and disadvantages of new and used equipment?

The difference between new and used brewing equipment is the same as for anything else you buy. New is expensive but predictable; used is less expensive but unpredictable. You have a better idea of what you’re getting with new equipment and can have

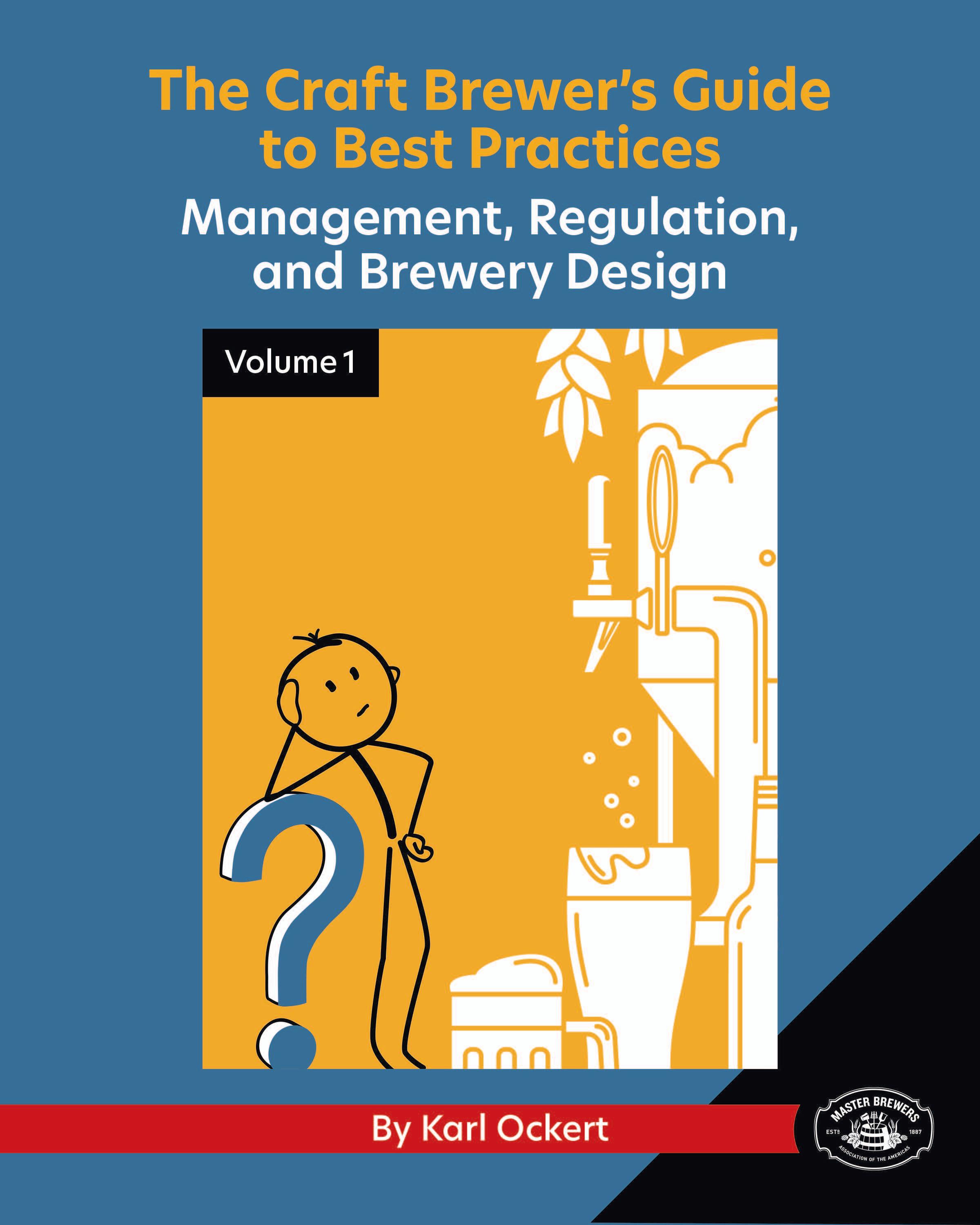

FIG. 6.1. A two-vessel brewhouse with a kettle-whirlpool (left), a mash-lauter tun (middle), a hot liquor tank (right), and a brew deck control panel (center). (Courtesy Montavilla Brew Works. Photo by K. Ockert—© MBAA.)

■

the system custom fitted to your space, but you pay a premium. On the other hand, you don’t know quite what you’re getting with used equipment, but it’s usually less expensive, at least initially. New equipment will provide the best fit for your operation and space and is less likely to cause startup issues. Used equipment may fit the needs and spaces as well; however, used equipment may require rigging out and transport to your brewery and maintenance and/or retrofitting and modification to meet the needs of your operation. It may also hold some performance surprises at startup. These additional costs should be factored in when deciding whether a used piece of equipment is actually a good deal. Due diligence is very important when buying used equipment and may be difficult to achieve, as the pieces may be located far away, packed up in storage, or otherwise inaccessible. If the budget is tight, used equipment options may be the way to go. If not, new equipment will usually cause fewer headaches.

What is a request for proposal ?

A request for proposal (RFP) is sent out to suppliers when you are considering equipment to purchase. This should be as detailed as possible so the supplier knows the correct equipment to bid on. All suppliers should receive the same RFP so they bid on the same specifications. When putting forth RFPs for a piece of equipment, it’s advantageous to be exacting in all the parameters needed, including type of construction materials, dimensions, safety features, performance requirements, utilities requirements, commissioning and training options, documentation and recommended spare parts lists as well as lead times, delivery costs, and installation expenses. Keep in mind that the more customized your specifications, the more costly the piece may be. The supplier will submit a proposal, which can then be discussed and refined. It is good practice to send out at least two or more RFPs for each piece of equipment or system to be purchased. Be sure to ask about payment terms in the RFP.

■ How is an equipment supplier selected?

If you decide to purchase new equipment, do your homework and shop around for a reputable supplier. There are many to choose from, but be aware that quite a few merely buy their tanks from an offshore manufacturer and then assemble them in the United States at their plant or simply purchase and resell the entire system. Using offshore fabricators may save 20% or more on equipment cost but is something you should be aware of when discussing products with a prospective supplier. Like any other supplier, you should ask for references and vet the company for equipment performance, parts, and service. Ask to see installations and chat with the brewers. Give each supplier the same production plan scenario and RFPs so you’ll collect “applesto-apples” bids.

■ What types of stainless steel are used to construct brewing equipment?

Stainless steel is a formulated alloy that is primarily iron mixed with other metals to give it strength, malleability, and resistance to corrosion. The other metals in the formulation are chromium, nickel, and molybdenum. Key types of stainless steel alloys

are used in brewing, and each includes a different combination of these metals, along with a very low carbon content. Clean, oil-free stainless steel will naturally form a chromium oxide coating on its surface, and that oxide coating is what resists rust and keeps the steel stainless. The primary cost drivers for stainless steel are the nickel and molybdenum contents and, to a lesser degree, chromium.

The principal grades of stainless steel for breweries are as follows:

● Type 304L. This alloy is the most common material for brewhouse and cellar tanks. It’s also called 18-8 because it’s composed of 18% chromium and 8% nickel. The L means that Type 304L has a lower carbon content than 304, giving it better weldability. Type 304L is the workhorse alloy in food and beverage tank designs. A 2B finish is the smooth cold-rolled mill finish and is acceptable, without any further polishing, for the tank interior.

● Type 316. With the addition of more nickel and 2% molybdenum, Type 316 resists corrosion and chloride pitting better than Type 304 and 304L. Type 316 is used for piping, fittings, pumps, valves, and heat exchanger plates.

● Type 316L. This alloy has a lower carbon content than Type 316, 0.03% versus 0.08%. The upcharge for Type 316L is 25–30% over Type 304L. For tanks, the 2B milled finish is acceptable.

● Duplex 2205. This is a different type of alloy, a hybrid stainless-ferric steel that is magnetic but also extremely resistant to stress-crack corrosion (SCC). Duplex 2205 is recommended for tanks with heat applications that are subject to SCC, such as hot liquor tanks (HLTs). Expect to pay about twice as much for Duplex 2205 than for Type 304L (Lewis, 2021; Palmer, 2021).

Table 6.1 shows the compositions of the different alloys above.

commonly used SS alloy, various applications

standard for beer tanks

and SCC corrosion, recommended for hot liquor tank interior

a Adapted from the ASTM A789 and A249 Standards. Courtesy K. Ockert—© MBAA.

b C = carbon; Cr = chromium; Mn = manganese; Mo = molybdenum; N= nitrogen; Ni = nickel.

TABLE 6.1. Composition of stainless steel alloysa,b

■ Can the stainless steel alloy type be verified?

When you purchase a tank to be built, you, as the customer, should specify the materials you want the fabricator to use. If you want the tank constructed of Type 304L, Type 316L, or Duplex 2205, make that part of the RFP and the purchase order. As the customer you can require proof of certification to ensure the stainless steel used meets the standard alloy composition and ranges. This certification can come from the manufacturer of the stainless steel and can also be checked with an x-ray fluorescence (XRF) gun (Olympus, n.d.). The XRF gun is a nondestructive method used directly on stainless materials prior to or during tank fabrication or at the time of acceptance. Through the x-ray process, the instrument reads the fluorescence of the metal in the sample and reports the percentages of each component, as well as the name of the alloy it most closely resembles. The test takes only minutes to generate a reading. XRF guns are very expensive but can be rented or contracted if the supplier or fabricator does not already have one.

■ What types of corrosion affects stainless steel?

Stainless steel alloys are very strong, very durable, and very corrosion-resistant compared to mild steel, brass, copper, and aluminum, which were the primary brewery tank and equipment construction materials of the past. However, stainless steel alloys are not completely indestructible. Corrosion can still cause pitting and cracking. These conditions can sometimes be ground out, patched, or repaired, allowing the tank or equipment to continue its duty. However, repair is not always possible, and tank replacement due to corrosion damage is, unfortunately, not uncommon.

● Galvanic. All corrosion stems from forms of galvanic corrosion because when two dissimilar metals come in contact with each other, or even when two areas on the same piece of metal differ, an electrochemical potential develops, and one will start corroding as electrons migrate to the other. This situation can occur with stainless steel and copper or brass piping without the use of a dielectric union, and it is also seen when a galvanized nut is threaded onto a stainless steel bolt. Galvanic corrosion is sometimes repairable if discovered and addressed promptly.

● Chloride pitting. Chloride pitting can have many causes, such as chloride in the tank insulation, hydrochloric acid formation from bleach solutions reacting with acid cleaners, salt solutions, or high-chloride sugar solutions. Each condition can pit the surface of stainless steel. Pitting may allow the growth of microbes into biofilms and render the tank unhygienic. It can also lead to broader corrosion issues and even tank failure if not addressed. Pitting may be ground out and repaired if discovered in time.

● Stress corrosion cracking (SCC). The worst corrosion is seen in high-heat liquid environments, especially those with high chloride concentrations. The presence of chlorides allows cracks to propagate more easily through the stainless steel at lower stresses. This contamination makes the steel less ductile, and it’s not possible to weld the cracks back together. This is a particular problem, and all too commonly seen, in HLTs made of Type 304L stainless steel.

Once this condition develops, the tanks are unrepairable and must be replaced. SCC corrosion-resistant alloys such as Duplex 2205 or AL6XN are recommended for the internal tank surface of these vessels.

■ How are new tanks cleaned and passivated?

All new tanks require a certain amount of care and attention prior to being put into service, and that usually includes a thorough cleaning and decontamination process involving several steps. This process, collectively called passivation, will assist in forming the protective chromium oxide layer. Tanks that are kept clean will continue to naturally form the chromium oxide layer and should not require further passivation unless contaminated with oils, iron metal, or very strong chemical cleaning solutions. Tank preparation and passivation include the following steps:

1. Road grime. A new tank is expensive, and it’s a good decision to protect that investment by shipping it covered with tarps to avoid its picking up dirt, oils, salts, and more during its trip to your brewery. This may not be as important if the fabricator is across town, but if this is a long trip, the tarp upcharge is well worth the cost and should be part of the RFP. Road grime will need to be removed from the outside of the tank with high-surfactant sudsy detergents, degreasers like tri-sodium phosphate (TSP), a plastic bristle brush (never use an abrasive like Scotch-Brite!®), and some elbow grease or a pressure washer. Rinse the inside of the tank thoroughly to dislodge loose dirt and soil.

2. Machine oils. During fabrication, machine oils are likely to be deposited on surfaces as the material is cut and shaped. Oil will keep the chromium oxide layer from forming, so it must be removed. Recirculated solutions of hot (2–3%) caustic detergent, TSP, or citrus peel-oil solvents are used to remove the residual road grime and oils from the stainless steel surfaces.

3. Adhesive residues. Fabricators will sometimes protect the tank with polyvinyl chloride (PVC) tape or coverings that use a self-adhesive. The adhesive can harden onto the stainless steel and be very difficult to remove. Degreasers, solvents, detergents, and elbow grease may be necessary to completely eliminate adhesive films. Once again, don’t use abrasive pads on stainless steel. They will permanently scratch the metal surface, which defeats hygienic design goals.

4. Free iron. Stainless steel is primarily made of iron, but alloying with chromium and nickel makes it corrosion-resistant. Free iron is metal that has been introduced to the surface of the stainless steel or scuffed into it. This nonstainless iron or steel is a contaminant and can rust. Sources of free iron are grinding abrasives and wire wheels, mild steel tools, and brake dust from transport on the road. The removal of free iron is the final passivation step after the previous cleaning and degreasing steps and uses an acid solution. The goal of the acid step is to remove any free-iron contaminants from the degreased metal surface and allow the protective chromium oxide layer to fully form. The primary chemicals used for the acid solution have traditionally entailed strong (often as high as 30%) hot nitric acid, which can cause collateral issues for soft metals and elastomers while also generating a hazardous end product

that must be dealt with. A NASA report on passivation recommends the use of a 4–10% (food grade) citric acid solution at 50–65° C (120–150° F) (NASA, n.d.).

The hotter temperature requires the lower concentration and vice versa. The solution is recirculated for 60 minutes and then rinsed thoroughly, followed by air drying to form the chromium oxide layer (Lewis, 2021; Palmer, 2021).

■ What is a 3-A standard stamp?

3-A SSI (Sanitary Standards Inc.) is a nonprofit organization formed in the 1920s to help standardize the equipment used to produce milk (www.3-a.org). Unlike beer, milk will support the growth of pathogens such as Salmonella and Listeria bacteria, and as the dairy industry grew, it needed to develop and implement sanitary standards for the equipment used in milk processing. The SSI organization has diversified and now evaluates and designates hygienic design for equipment used in the wider food, beverage, and drug industries. The group is supported by representatives of federal agencies like the U.S. Department of Agriculture and the U.S. Food and Drug Administration (FDA), the manufacturing companies, and the manufacturers of the equipment involved. Together they have established standards of hygienic design and a certification process, involving designated third-party testing, to evaluate equipment used in the manufacture and production of food, beverages, and pharmaceuticals. Equipment such as pumps, fittings, fillers, and processing systems that have been certified can use the 3-A stamp.

3-A has standards that apply to the surface finishes on stainless steel sheet and welds. The 3-A standard once used the grit polish number from polishing belts as the roughness measurement but has changed to a more precise method called the surface roughness average (Ra). The Ra is an average measurement of how much each point on a surface deviates in height from the mean height of the surface. It is measured in microinches or micrometers (microns). The measurement uses a surface roughness tester, or profilometer, incorporating a stylus that runs across the grain of the steel. The smaller the Ra number, the more smooth the finish. Formerly, the standard was a 150-grit finish, also called a #4 finish. This translates to an Ra of 1.06 microns (42 microinches) (Wikipedia, n.d.). The new 3-A sanitary standard is 0.83 microns (32 microinches), which would formerly be known as a 180-grit finish (3-A, n.d.). This standard applies to the 2B mill finish of the stainless steel sheet used to build the tanks and to the welds used to form them.

Tanks and pipes are welded together using either a heat fusion process that is autogenous or a metal filling method. The tungsten inert gas (TIG) method of welding is autogenous and used for welding together thin-walled materials such as stainless steel piping. The metal inert gas (MIG) method incorporates a mechanical wire feed to add metal to the weld, is a faster process, and is commonly used in tank construction.

3-A standards for sanitary welding include the following:

● Full oxygen (O2) purging of the weld using inert gas—typically, pure argon, with no or only very light discoloring of an interior pipe weld to be seen

● Full weld penetration so there are no jagged edges

● No misalignments between welded surfaces

● No spaces, pitting, or embedded or protruding materials in the weld

Pipe welds can be made using an automatic orbital welding machine or manually. Welders performing manual sanitary welding should be qualified through their company via training, testing, and certification conforming to the American Welding Society (AWS) B2.1 standard. Customers can check a welder’s certification with the fabricator, and his or her performance on welded tubing, by cutting a welded pipe in half to inspect the inside surface. Tank welds are easier to inspect and should conform to the standards described above.

■ What is a 2B mill finish?

A beer tank’s final finished surface must be very smooth to be cleanable and hygienic. The stainless steel finish should be specified in your tank designs. The most common is the 2B milled finish, which is very smooth and normally requires no further polishing or grinding. Because the surface finish can be manufacturer dependent, the surface specification to the fabricator should be a 2B surface with the 3-A standard of Ra 32 microinches (0.83 microns). This can be verified with a profilometer. The 2B mill finish is the product of cold rolling, heat treating, and pickling, along with a light rolling at the end to achieve a smooth, reflective sheen. For beer tanks the unscratched 2B finish works as a smooth surface that will clean easily.

The smoothest finish is electropolishing, which is more typically used on pharmaceutical tanks and sometimes in yeast propagators but is not necessary for brewing vessels. Electropolishing can improve the Ra of the surface by about 50%—for example, an Ra of 0.83 microns (32 microinches) can be electropolished to an Ra of 0.42 microns (16 microinches).

■ What are “sanitary” fittings?

While beer does not support the growth of pathogenic disease-causing microbes, contamination by the spoilers that do grow can make beer taste unintentionally sour or otherwise off-putting. The use of stainless steel and hygienic designs, such as 3-A certified equipment, in breweries has helped the craft brewer avoid contamination issues by making the equipment a lot easier to keep clean. In tanks this means smooth stainless steel surfaces, properly ground and polished welds, smooth-radius corners, and connections between fittings, pumps, equipment, piping, and hoses with sanitary fittings. The two principal sanitary fittings for breweries are tri-clamp in the United States and DIN 11851 specification in Europe. These fittings are allowed for both food and beverage uses and provide easy cleanability for hoses, valves, and other components used in the process.

● Tri-clamp. These fittings are very commonly seen in American craft breweries and are easy to source and purchase in the United States. Tri-clamp fittings are 3-A approved. The tri-clamp system consists of a clamp with two half-circle flanges, each with center grooves, connected by a single or double hinge. One of the flanges has a loose threaded attachment, usually with a wing nut. In practical use, the fittings to be joined each have a flared end with a groove to accommodate a tri-clamp gasket. To join the two fittings, the tri-clamp flanges encircle the flared junction of the two fittings, the threaded attachment and

wing nut swings into position to lock them into place, and the wing nut is hand tightened to form a seal (Fig. 6.2). Overtightening the wing nut with pliers can deform and damage the gasket, but a good method to tighten the tri-clamp fitting is to tap the hinge with another clamp while turning the wing nut by hand. Always point the wing nut down to avoid accidental release of the clamp. Variations of tri-clamps include spring loaded types for easier placement or tri-clamps with two brass nuts instead of the wing nut to make removal more difficult. Tri-clamps are useful for sanitary piping connections up to fittings of about 2.5 inches in diameter but cumbersome for use with larger piping.

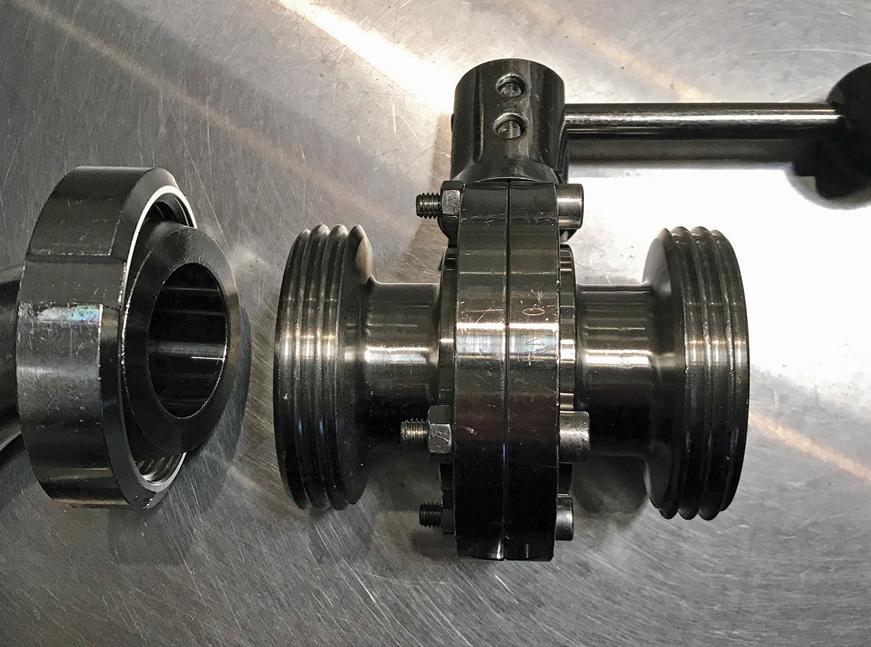

● DIN fittings. Deutsches Institut für Normung, or German Institute for Standardization, fittings are abbreviated as DIN or DN and must meet the 11851 standard. These are the most commonly used sanitary fittings in Europe, and many craft breweries use them as well, especially for larger-diameter sanitary connections. There are DIN standards for other fittings, including flanges used to mount tank-top systems on large beer tanks. DIN fittings are less readily available in the United States than tri-clamp and are metric based, leading to some adaptability issues with U.S. piping and hose diameters. DIN fittings will come in sizes loosely indicating their inner diameter in millimeters; for instance, a DIN 50 has a 54 mm inner diameter (2.126 inches) and a 64 mm outer diameter (2.52 inches). Table 6.2 gives the DIN inner diameter and outer diameter measurements in both millimeters and inches. DIN fittings use a thick, hygienic threaded male side with an inserted elastomer gasket that fits to a female side with a nut (Fig. 6.3). The two sides are threaded together and tightened with a spanner wrench.

● Other sanitary fittings. Around the globe and in the United States, other sanitary fittings used include John Perry, Bevel Seat, Perlick, I-Line, Acme, SMS, Swagelok TS, and American National Standards Institute (ANSI) flanges. These fittings can sometimes work better for certain applications than tri-clamp or DIN fittings.

FIG. 6.3. DIN fittings. (Courtesy Breakside Brewing Co. Photo by K. Ockert—© MBAA.)

FIG. 6.2. Tri-clamp fittings: a gasket and a clamp. (Courtesy Breakside Brewing Co. Photo by K. Ockert—© MBAA.)

TABLE 6.2. DIN pipe dimensionsa,b

a Adapted from the DIN 11851 Standards. Courtesy K. Ockert—© MBAA.

b ID = inner diameter; OD = outer diameter.

■ Is pipe thread considered sanitary?

Pipe thread is used on water and steam piping. It is a tapered, dense thread that is not considered hygienic for food or beverage use. Pipe thread is uncleanable and should be avoided in all wort or beer contact applications. A pipe thread to tri-clamp adapter does not make the connection cleanable or sanitary.

■ What is an American Society of Mechanical Engineers (ASME) pressure rating?

The American Society of Mechanical Engineers (ASME) is a nonprofit, professional organization that was founded in 1880 (asme.org). The ASME mission “is to advance engineering for the benefit of humanity.” The society sets many of the standards and codes for pressure-holding vessels, fittings, and equipment. In the brewery setting, the ASME stamp is used for beer tanks and equipment holding more than 100 kilopascals (kPa), 15 lbs. per square inch (15 psig or 1 bar) of pressure. Steam boiler certification, jacketing used for heating or cooling, and pressure-relief valve and rupture disc certification, among other applications, must carry the appropriate ASME stamp.

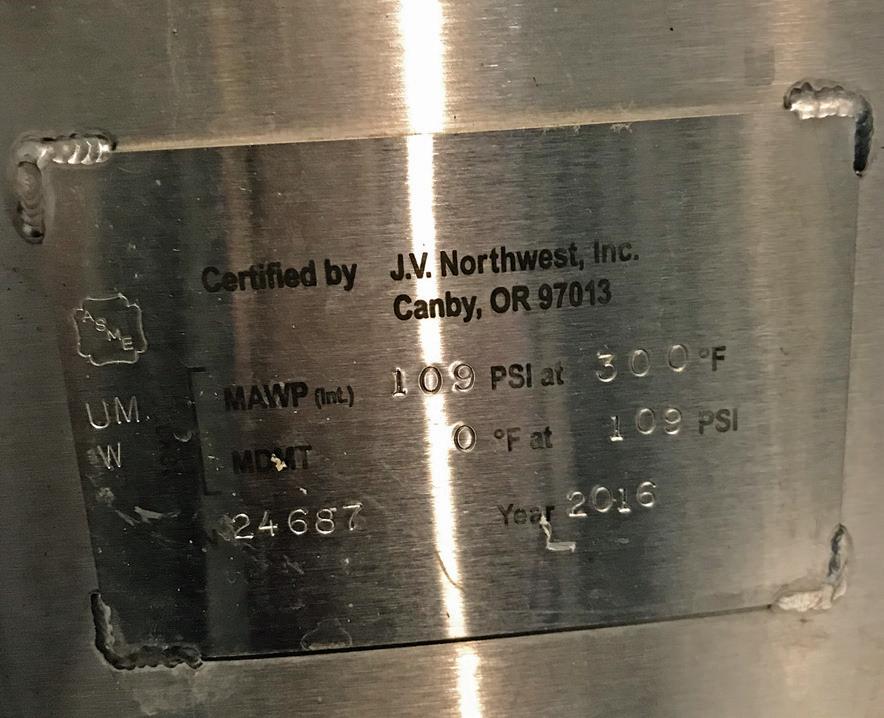

All tanks built in the United States are approved for up to 100 kPa (15 psig or 1 bar) of gauge pressure without an ASME pressure-rating certificate. If you want to finish off a fermentation and build carbonation pressure or go over the 100 kPa (15 psig) limit for any other reason, then the tank must be rated to contain the higher pressure and carry an ASME-stamped certification (Fig. 6.4). The ASME has guidelines for materials, and the construction of pressure-rated tanks must meet those guidelines.

The tank fabrication shop and the welder must also carry an ASME license to build the tank or perform any work on an ASME pressure-rated tank. In the United States, a foreign-built pressure-rated tank must conform to ASME guidelines and carry its stamp to legally hold more than 15 psig of pressure. So be careful with offshore FV, BB, or serving tanks that are supposed to be pressure rated. If in doubt, check with your state boiler or mechanical inspector. The tank itself will need to carry an actual stamped plate indicating the certified pressure rating.

Glycol or steam jackets using pressures higher than 15 psig will also require their own ASME-stamped plates, apart from the tank. A jacket’s ASME plates apply only to the jacket and not to the tank itself and should not be confused. In addition, any tank holding pressure must have an ASMEstamped pressure-relief valve or rupture disc that is set for less than the tank pressure rating. Expect an ASME-certified tank to cost at least 20% more than a noncertified tank.

FIG. 6.4. An ASME plate for a kettle steam jacket. (Courtesy Breakside Brewing Co. Photo by K. Ockert—© MBAA.)

■ What two main types of dimple jackets are used for heating and cooling?

Jacketing a tank transfers heat into the tank using steam in the brewhouse or transfers heat out of the tank using chilled glycol in the cellars. The surface area of the jacketing will be calculated to incorporate the heat loads and efficiency data for the type of jacket used. Steam jackets have an inlet at the top of the jacket, and condensed liquid is removed from a bottom outlet. Glycol jackets have an inlet at the bottom, which floods the jacket and purges air as it fills. Warmed glycol comes out of the outlet at the jacket top. Any jacket handling pressures in excess of 100 kPa (15 psig or 1 bar) must be ASME pressure rated and stamped. Two main types of dimpled jackets are used (ICC-NW, n.d.):

1. Mechanical. These use a sheet of stainless steel with mechanically formed dimples that are spot welded to a stainless steel base sheet. The edges are welded and sealed. This can then be formed around the tank as needed and welded into place, the base sheet acting as the contact surface for the wort or beer. Mechanical jackets have a high “pillow,” or air space, and don’t produce as much fluid turbulence as the resistance spot welded (RSW) jackets, described next, so they require more surface area in cooling applications. However, they can hold greater pressure and are a good fit for steam applications on brewhouse tanks.