The Basics of Malting and Brewing

For thousands of years, fermentation was a mysterious process. How did grains, other plant materials, and water change into a liquid that made people feel good? Around 200 years ago, the mystery started to unravel.

Yeast (Saccharomyces spp.) can feed on sugar anaerobically by fermenting the sugar to ethanol:

C6H12O6 → 2C2H5OH + 2CO2

If the sugars are derived from grapes, then the products (spent growth medium) are wine and (after distillation) brandy. If the sugars are from apples, the product is hard cider. If the sugars are from grain, the products are beer and (if unhopped and after distillation) whisk(e)y.

Barley is the predominant grain used in most beers (Fig. 2.1). Barley retains its husk (or hull) on threshing, and this husk traditionally forms the filter bed through which the liquid extract of sugars is separated in the brewery.

FIG. 2.1. Two-row and six-row barley growing in the field. (Cour tesy G. P. Fox— © ASBC.)

The starch in barley is enclosed within cell walls and encased by storage proteins, but these wrappings are stripped away in the malting process (controlled germination of the barley grains). This softens the grain and makes it more readily milled. Unpleasant grainy and astringent characters are removed during malting.

Some beers are made chiefly from wheat but contain some barley as a source of husk. Gluten-free beers are produced using grains, such as sorghum, corn (maize), and rice, that do not contain the proteins that susceptible consumers are sensitive to. In addition, maltsters and brewers have shown considerable innovation in making malt and brewing with noncereal grains such as buckwheat and quinoa.

Malting

The malting process involves modification of the grain through the processes of steeping, germination, and kilning. Maltsters are tricking the grain into thinking it has been planted in soil and will grow into a plant. This creates a cascade of biochemical reactions to break down the food reserves of the endosperm. The products of these biochemical reactions would normally go to the developing embryo, which would then grow into a plant. But the maltster stops these processes at a timely point, so as not to waste too much energy for acrospire and rootlet growth, thereby saving these modified reserves for the brewer.

Malting starts with steeping of barley in successive batches of water at 14–18°C for up to 48 hours, until it reaches a moisture content of usually between 42 and 46%. The steep times and temperatures depend on variety, age of the grain, protein content, and targeted level of endosperm modification. Also, different types of grains require different steeping and germination times.

Steeping is usually achieved in a multistage process (typically three stages), with the steeps being interspersed with “air rests” that allow the barley to get some oxygen and to let carbon dioxide escape. This process requires large amounts of water.

Raising the moisture content allows the grain to germinate, a process that usually takes 3–5 days at 16–20°C. During germination, the enzymes start to break down the cell walls and some of the storage protein in the starchy endosperm, which is the grain’s energy reserve, rendering the grain friable (more readily milled) when dried. Starch- degrading enzymes are produced during germination and are important for breaking down the starch in the subsequent mashing process in the brewery. The visible signs of malting are a softening of the grain, the emergence of rootlets, and the growth of the acrospire (shoot) underneath the husk (Fig. 2.2).

After the prescribed germination time, the green malt is moved into a drying oven (kiln). Progressively increasing the temperature during kilning arrests germination, and regimes with increasing temperatures in the range of 50°C to perhaps 110°C are used to allow drying to <5% moisture, while preserving heatsensitive enzymes. The more intense the kilning process, the darker the malt and

the more roasted and burnt the flavor characteristics. A special roaster is used for darkercolored malts.

Maltsters do not usually mill the malt prior to delivery, as the milled malt can quickly absorb moisture and potentially degrade in quality. The finished malt is delivered intact to the brewery. Milling is carried out at the brewery just prior to mashing.

Brewing

In the brewery, the malted grain is first milled to reduce the malt kernels to smaller particles that are readily hydrated. The particles are then mixed with hot water for the mashing step. The water must possess the right mix of salts. For example, fine ales are historically produced from water with high levels of calcium. Famous pilsners are made from water with low levels of calcium.

2.2. Germinating barley. (Cour tesy L. Watson—Adapted, by permission, from Watson, L., and Henry, R. J. (2005) Microarray analysis of gene expression in germinating barley embryos (Hordeum vulgare L.). Funct. Integ. Genomics 5:155–162. https://doi.org/10.1007/s10142- 005- 0133- 6.)

Typically, mashes have a thickness of three parts water to one part malt and incorporate a stand (or incubation) at around 65°C, at which temperature the granules of starch are converted by gelatinization from an indigestible crystalline state into a “melted” form that is much more susceptible to enzymatic digestion by starch- degrading enzymes. This produces the fermentable sugars needed for fermentation. Some brewers add starch from other sources, such as corn and rice, to supplement that from malt. These other sources are called “adjuncts.”

Depending on several factors, including the malt quality and intended beer style, mashing can run from 1 to 2 hours. The next stage is lautering, where a higher-temperature water is used to wash out residual dissolved materials bound up in the solid grainy mass. In lautering, the liquid portion of the mash, known as “wort,” is recovered, either by straining through the residual spent grains or by filtering through plates.

The clarified wort is pumped into the kettle (often referred to as the “copper” because historically it was constructed from that metal), where it is boiled, usually for around 1–2 hours. Boiling serves various functions, including sanitization of wort, precipitation of proteins (that would otherwise come out of solution in the finished beer and cause cloudiness), and the removal of unpleasant grainy characters originating in the barley. Many brewers also add some adjunct sugars at this stage, at which most brewers introduce at least a proportion of their hops (Fig. 2.3).

The hops have two principal components of importance to the brewer: resins and essential oils. The resins (α-acids) are changed (isomerized) during boiling to yield iso- α-acids, which provide the bitterness to beer. Isomerization is a chemical process wherein chemical bonds are rearranged.

FIG.

Nowadays, hop products are often extracted at very low temperatures with liquefied carbon dioxide, and the extract is either added to the kettle during boiling or extensively isomerized outside the brewery for addition to the finished beer (thereby avoiding losses due to the tendency of the bitter substances to stick on to yeast and other solid surfaces). The use of these extracted products gives brewers more flexibility in terms of product diversification.

The oils are responsible for the “hoppy nose” on beer. They are very volatile, and if the hops are all added at the start of the boil, then all the aroma will be lost. In traditional lager brewing, a proportion of the hops are held back and only added toward the end of boiling, which allows a proportion of the aroma to remain in the wort. (This is called “late hopping.”) In traditional ale production, hops are added to the finished beer, enabling a complex mixture of oils to give a distinctive character to such products. (This is called “dry hopping.”) Liquid carbon dioxide can be used to extract oils as well as resins, and these extracts can also be added to modify the beer’s flavor.

After the precipitate produced during boiling (called the “hot break” or “trub”) has been removed, the hopped wort is cooled, aerated, and pitched with a specific yeast strain. The “cold break” that precipitates when the wort is cooled may be removed prior to adding yeast but not always.

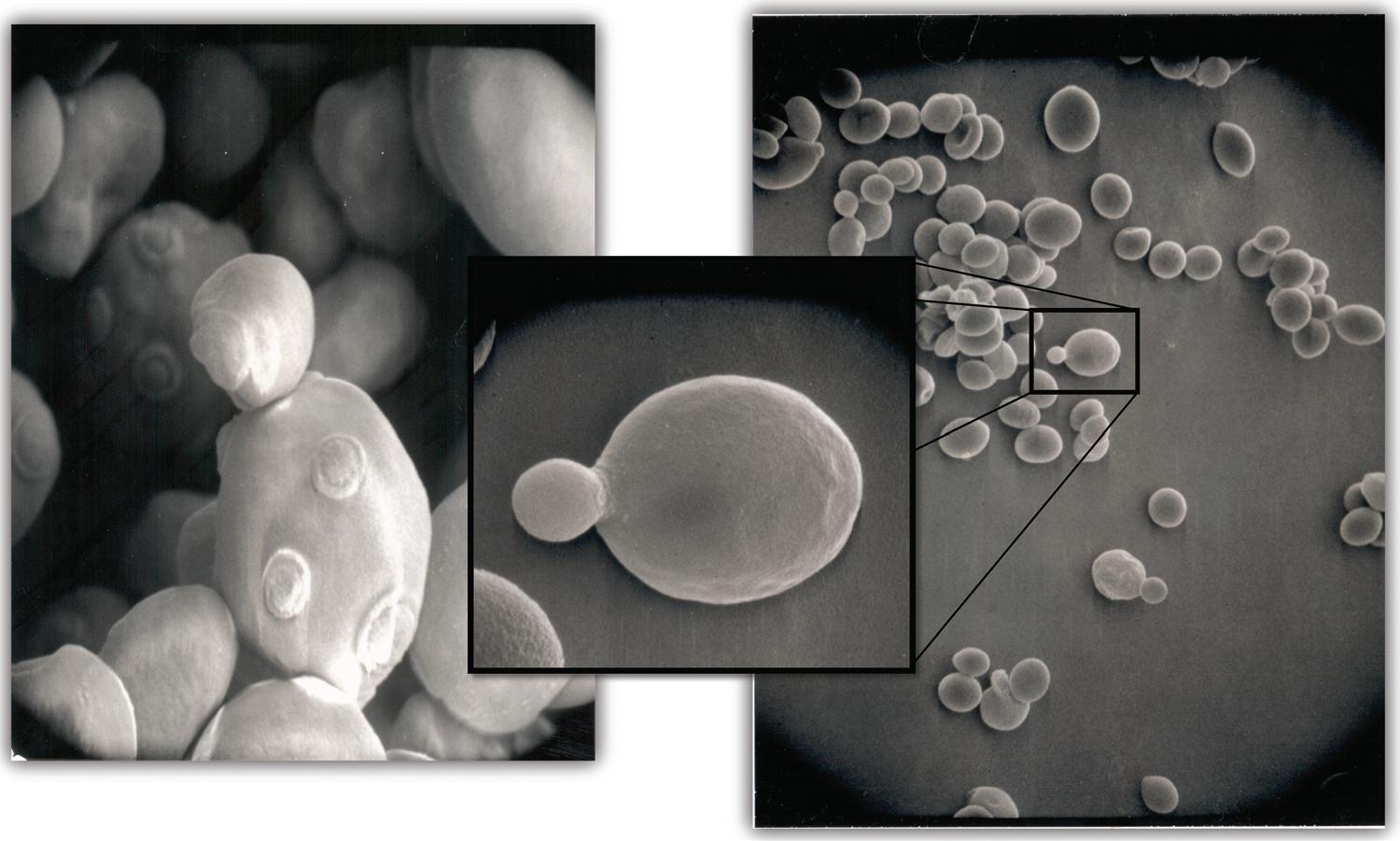

Brewing yeast (Fig. 2.4) can be divided into ale (Saccharomyces cerevisiae) and lager (Saccharomyces pastorianus) strains, the former type collecting at the surface of the fermenting wort and the latter settling to the bottom of a fermentation (although the nature of the fermentation vessel impacts this). Both types of yeast need oxygen to trigger their metabolism, but otherwise the alcoholic fermentation is anaerobic.

FIG. 2.3. Hop cones. (Cour tesy G. P. Fox— © ASBC.)

Ale fermentations are usually complete within a few days at temperatures as high as 20°C, whereas lager fermentations at as low as 6°C can take several weeks. Fermentation is complete when the desired alcohol content has been reached. The yeast produces unpleasant butterscotch/buttered popcorn and honey flavors (due to diacetyl and pentanedione, respectively) during all fermentations, and the fermentation/maturation should continue until these compounds have been metabolized by the yeast. At the end of fermentation, the yeast is harvested and cleaned for reuse; beer is the only alcoholic beverage for which yeast can be recycled in this way.

In traditional ale brewing, the beer is now mixed with hops, some priming sugars, and isinglass finings from the swim bladders of certain fish, which settle out the solids in the cask. The hops add extra aroma but also aid in stabilizing the beer. The extra sugar allows additional fermentation if yeast is present, increasing the carbon dioxide content in a process called “natural conditioning.”

In traditional lager brewing, the “green beer” is matured by several weeks of cold storage (called “lagering”) prior to filtering. Nowadays, most beers, both ales and lagers, receive a relatively short conditioning period after fermentation and before filtration. This conditioning is ideally performed at –1 to –2°C for a minimum of 3 days, under which conditions more proteins drop out of solution, making the beer less likely to get cloudy in the package or glass. Various stabilization treatments may be used.

The filtered beer is adjusted to the required carbonation level before packaging into cans, kegs, or glass/plastic bottles. The essentials of malting and brewing are summarized in Figure 2.5 and Table 2.1.

FIG. 2.4. Yeast as seen under an electron microscope. (Cour tesy Kyria Boundy- Mills, UC Davis— © ASBC.)

FIG. 2.5. Overview of malting and brewing. (Cour tesy C. W. Bamforth— © ASBC.)

Further Reading

Basarova, G., Savel, J., Basar, P., Basarov, P., and Lejsek, T. (2017) The Comprehensive Guide to Brewing from Raw Materials to Packaging. Fachverlag Hans Carl, Nuremberg, Germany.

Briggs, D. E., Boulton, C. A., Brookes, P. A., and Stevens, R. (2004). Brewing Science and Practice. CRC Press, Boca Raton, FL and Woodhead, Cambridge, UK.

Farber, M., and Barth, R. (2019) Mastering Brewing Science, Quality, and Production. Wiley, Hoboken, NJ.

Gales, P. W., ed. (2007) Brewing Chemistry and Technology in the Americas. American Society of Brewing Chemists, St. Paul, MN.

Hornsey, I. (2013) Brewing, 2nd ed. Royal Society of Chemistry, Cambridge, UK.

Kunze, W. (2019) Technology: Brewing and Malting, 6th ed. Versuchs- und Lehranstalt für Brauerei, Berlin, Germany.

Mosher, M., and Trantham, K. (2017) Brewing Science: A Multidisciplinary Approach. Springer, Cham, Switzerland.

Priest, F. G., and Stewart, G. G., eds. (2006) Handbook of Brewing, 2nd ed. Taylor and Francis, Boca Raton, FL.

Smart, C., ed. (2020) The Craft Brewing Handbook: A Practical Guide to Running a Successful Craft Brewery. Woodhead, Oxford, UK.

Watson, L., and Henry, R. J. (2005) Microarray analysis of gene expression in germinating barley embryos (Hordeum vulgare L.). Funct. Integ. Genomics 5:155–162.

TABLE 2.1. The essentials of malting and brewinga

Process stage

Selection of barley

Malting: steeping

Malting: germination

Malting: kilning

Malt: storage

Milling and mashing

Boiling

Fermentation

Maturation, stabilization, and packaging

a Courtesy C. W. Bamforth and G. P. Fox—© ASBC.

Description

Malting barleys (moisture content <12%) with relatively low total protein content (e.g., <11.5%), with high viability, released from dormancy, and with endosperm with mealy texture that hydrates readily and possesses cell walls that are readily degraded.

Staged addition of water at 14–18°C separated by air rests to raise moisture content to 43–46%.

Controlled germination for 3–6 days at 16–20°C to develop enzymes that degrade the endosperm cell walls and much of the protein, and which will be required in mashing.

Heating of malt at successively increasing temperatures (for mainstream malts, maximum temperature of 105°C) to dry the grain (target <6% water), while retaining high enzymic activity and developing color and flavor.

2–4 weeks storage to avoid processing problems in the brewery.

Generation of small particles that are easily hydrated. Mashing often starting at around 50°C (for 20 minutes) to allow remaining action of thermolabile β-glucanase and proteases, then increasing to 65°C (e.g., for 1 hour) for starch gelatinization and action of amylases. Wort is then separated from grains.

Wort is boiled with hops or hop preparations, typically for 1 hour. Clarification stage follows to remove trub (“hot break”) and residual hop material. Wort is cooled and air or oxygen are added.

Ales are typically fermented warmer (15–25°C) and therefore faster than lagers (6–15°C). Time range 3–14 days. Fermentation is at a targeted rate of specific gravity drop and to a target “attenuation.” Also, diacetyl and pentanedione, which give butterscotch/honey aromas, must be removed by prolonged contact of yeast with “green beer.”

Minimum regime is –1°C, usually for 2–3 days; some hold longer. Filtration (diatomaceous earth or perlite-based); removal of haze precursors by polyvinylpolypyrrolidone (polyphenols) and/or silica hydrogels or tannic acid or proteinases (proteins); removal of any contamination by pasteurization or filtration; adjustment of CO2 content, then filling of vessels.