Thermal Modelling & Junction Detailing

Samuel Hearne 20117371 ARC6114 Systems in Architecture

Table of Contents Introduction: Louis Khan.......................................................................................................................16 Kimbell Art Museum................................................................................................................................17 Climate Emergency...................................................................................................................................18 Transitional Space for Social Change....................................................................................................19 Insulation Types.........................................................................................................................................20 Render or Rainscreen Cladding Sytem?...............................................................................................21 Architectural Wire Mesh Facade..........................................................................................................22 Floor & Roof System................................................................................................................................23 1:20 Section...............................................................................................................................................24 Conclusion.................................................................................................................................................25 Appendices................................................................................................................................................26 Bibliography...............................................................................................................................................29

Introduction: Louis Khan

When designing architecture and with today’s access to technology and data, a question arises of how analysis can become architecture. Although using environmental data and introducing advanced modelling early into designs may benefit building performances, we must acknowledge, as designers, that not all pieces of architecture require this level of interference. We learn and adapt from historic architecture and memories. I believe this shift of attention upon architectural performance and often within this contemporary architectural period, we can forget about architectural moments.

When designing architecture, one must remember the source which displays and projects light onto our constructed forms to the naked eye, the Sun. The Sun defines the orientation of our buildings. Traditionally it’s what heats and cools living spaces and draws textures, colours, and forms, helping architecture achieve its true purpose. Louis Khan’s philosophy and charcoal illustration in 1971 entitled ‘Architecture Comes from the Making of a Room’ draws upon the importance of the Sun. Khan inscribes on the trace, ‘A room is not a room without natural light’. ‘A great American poet once asked the architect ‘What slice of the sun does your building have, what light enters your room’ as if to say the Sun never knew how great it is until it struck the side of a building’.

16

Kahn, L. (1971) Architecture Comes from the Making of a room. [charcoal on tracing paper] Philadelphia Museum of Art.

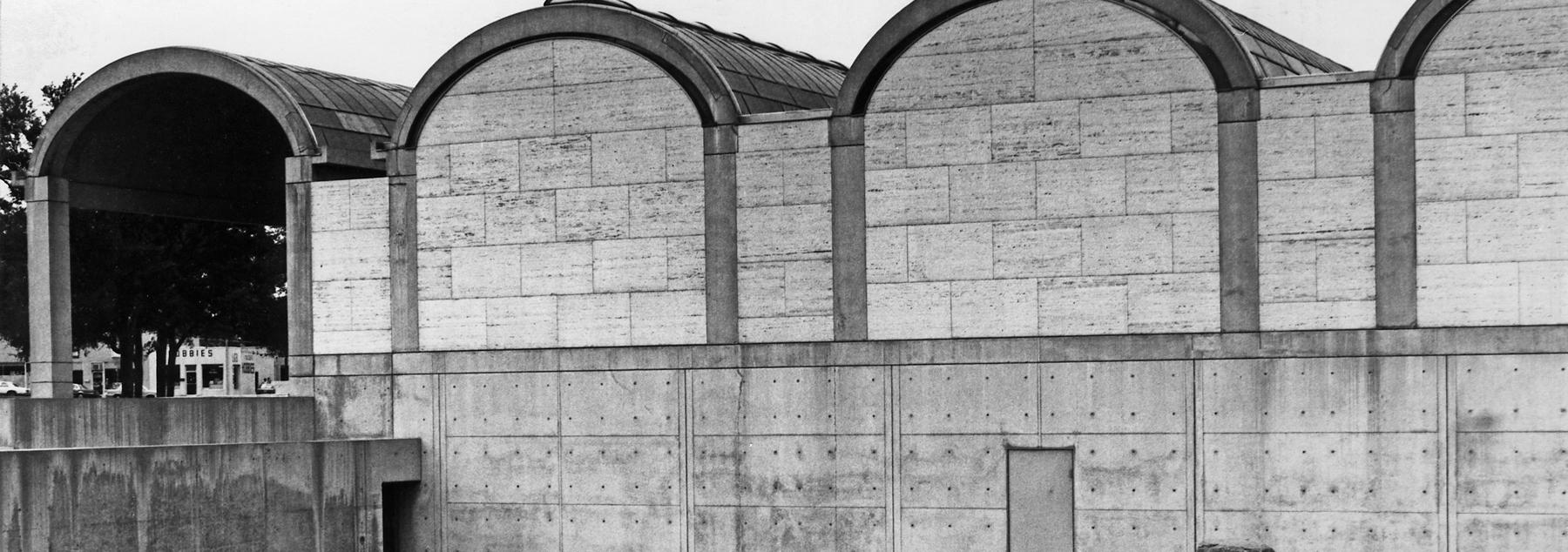

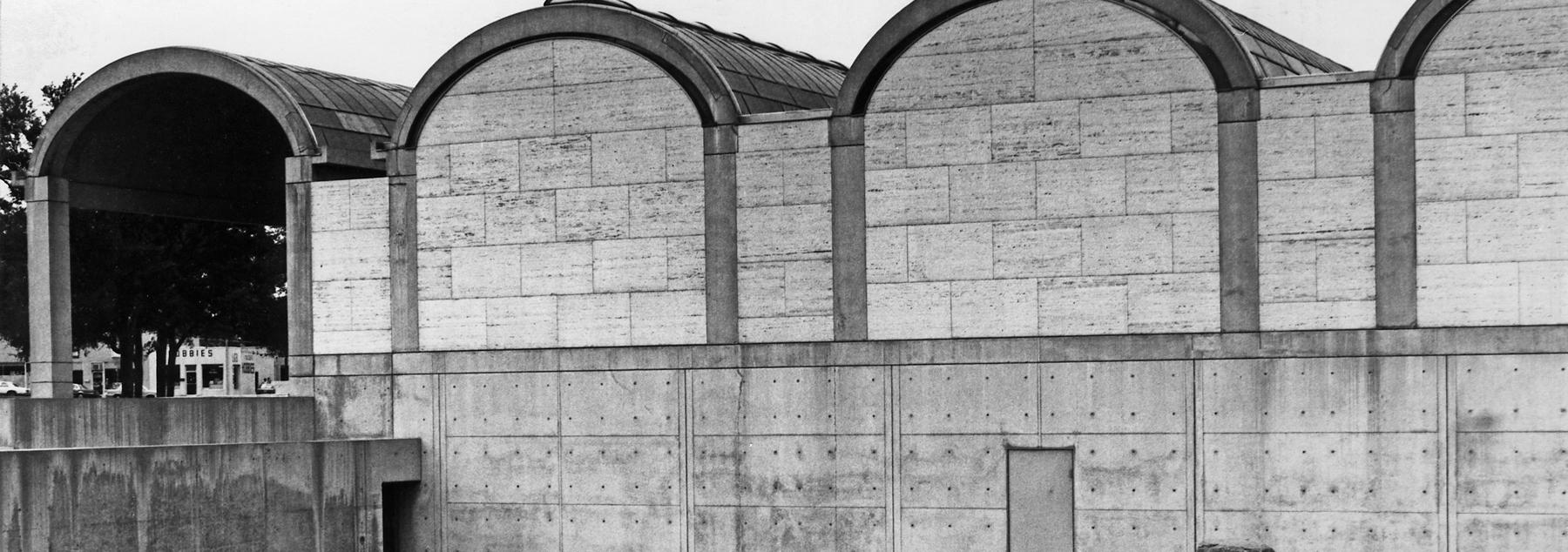

Kimbell Art Museum

The Kimbell Art Museum in Fort Worth, Texas, is widely regarded as one of the most significant architectural achievements of the modern era. Designed by Louis Kahn and completed in 1972, the building is a prime example of Kahn’s philosophy, which emphasises natural light and materials to create aweinspiring, timeless structures. The museum’s exterior is composed of sleek, white travertine and reinforced concrete, while the interior boasts vaulted ceilings that allow natural light to filter in, creating a serene and contemplative environment. Kahn’s skilful interplay between light and space is evident throughout the museum, with skylights, light wells, and clerestory windows showcasing delicate artwork and providing a dynamic visual experience that changes throughout the day.

To further sustain Khan’s philosophy, I acknowledge another one of his notable earlier statements. This extract, taken from Khan’s lecture Silence and Light at ETHB Zurich 1969, encompasses how at some point, the science and analysis of space, the measurable, must end and make way for the unmeasurable, the aesthetics and moments captured in environments.

‘I only wish that the first really worthwhile discovery of science would be that it recognised that the unmeasurable is what they’re really trying to understand, and that the measurable is only the servant of the unmeasurable; that everything that man makes must be fundamentally unmeasurable.’

17

Kahn, L. (1972) Kimbell Art Museum, Fort Worth, Texas

Climate Emergency

Today, there is an uneasy fluctuating balance between the measurable and the unmeasurable. Now more than ever, we must recognise that we are in a climate emergency whilst coincidingly capturing the beauty of places and spaces. With under six and a half years left on the climate clock to limit rising global warming temperatures to below 1.5°C, it is vital, now more than ever, to reflect upon the built environment’s wrongs and fight against climate change. The built environment industry is responsible for over 40% of the annual global CO2 emissions, a frightening statistic but one that can alter. Although the likes of Kahn were unaware of the later 21st-century scientific expression of embodied carbon, their buildings are monuments designed to last hundreds of years. As a future architect and an advocate of sustainable design, I am responsible for changing the course of environmental and sustainable neglect by implementing environmental measurables throughout my designs. I intend to design for longevity to achieve a commemorative feel or design for disassembly. We can not achieve both simultaneously.

Passivhaus has emerged as a leading, low-energy design philosophy that results in structures with little carbon emissions. Problem solvers today use advanced modelling techniques to increase energy efficiency in buildings and pursue the goal of zero carbon. This report concentrates on two aspects of advanced modelling: thermal modelling and junction detailing.

Thermal modelling and junction detailing are crucial components of Passivhaus design. Using these techniques creates buildings that require minimal heating and cooling systems. This results in a significant reduction in energy consumption and carbon emissions. Thermal modelling involves simulating the temperature changes within a building to optimise the insulation and airtightness of the structure. Junction detailing involves the precise connections between different building materials to prevent thermal bridging, which can cause the heat loss and increase energy consumption. By implementing these techniques, architects can create energy-efficient, comfortable, and healthy buildings for occupants.

18

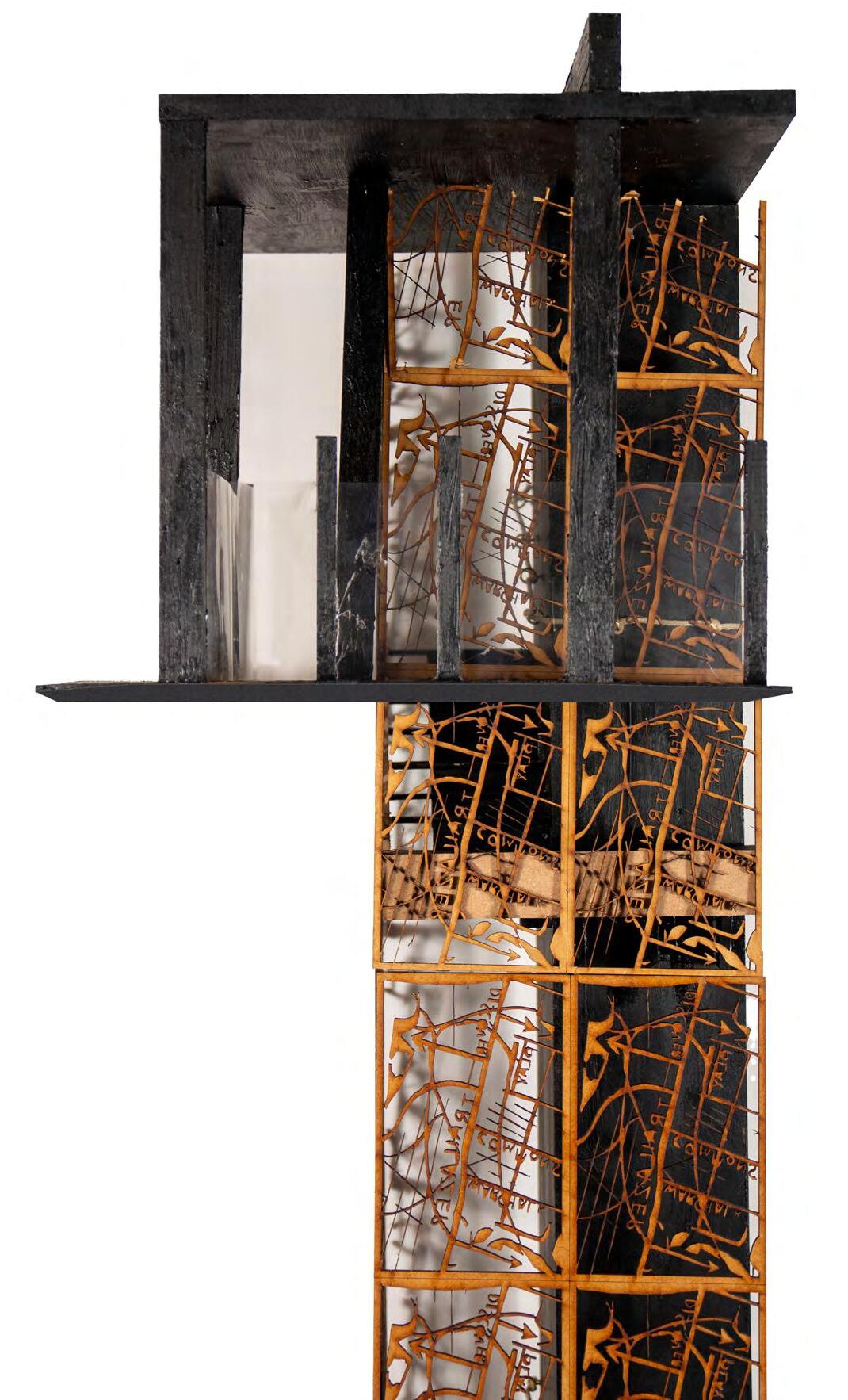

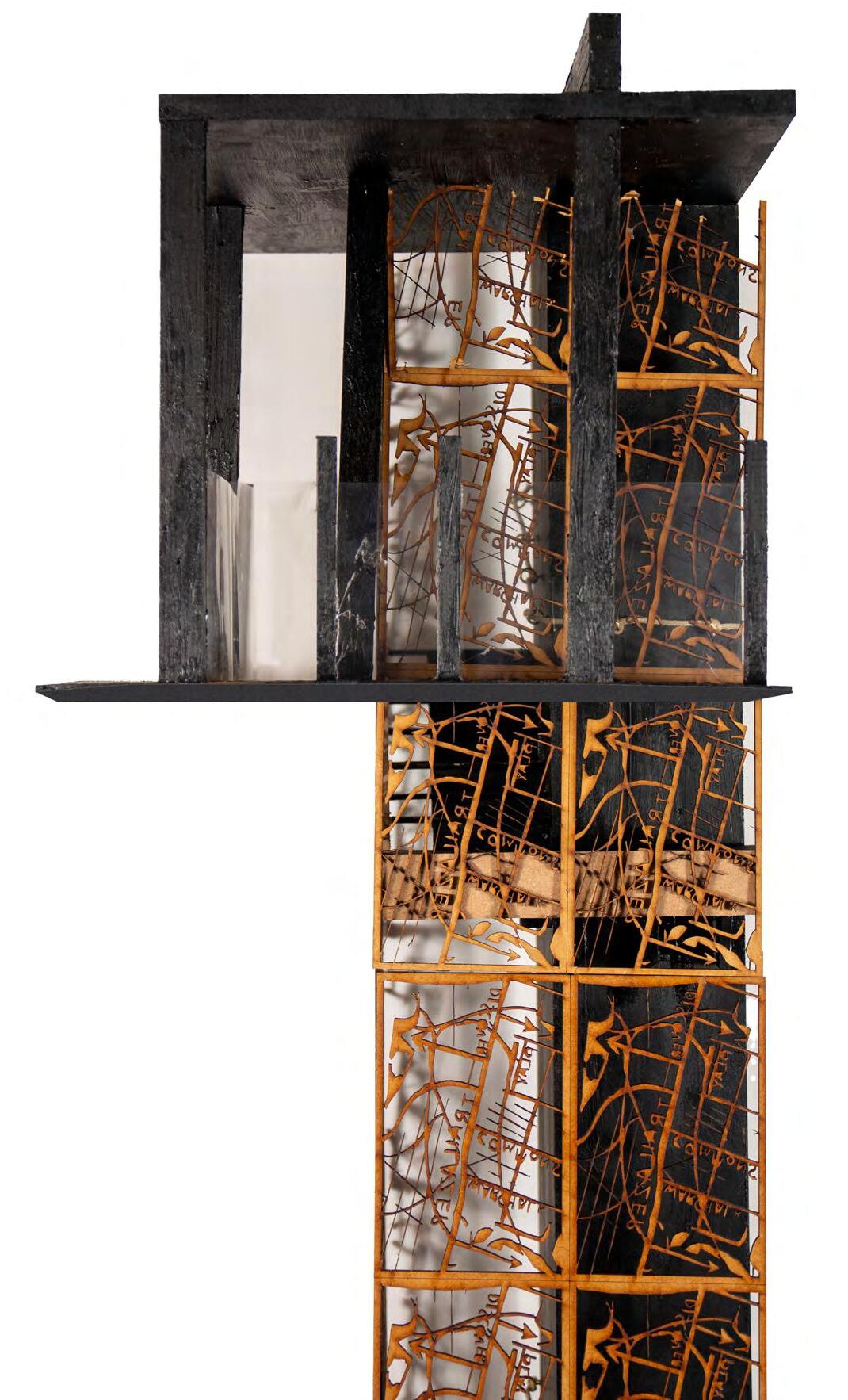

Hearne, S. (2022) 1:10 Bordesley Green Observation Tower

Transitional Space for Social Change

My transitional space for social change, Bordesley Green, Birmingham, underwent a thorough analysis and design alteration using advanced modelling. Initially, the tower piece of my 1:10 model proposal featured a thick steel frame that reflected the area’s industrial past. However, upon further investigation through thermal modelling, I concluded that steel’s high thermal conductivity and an unnecessarily high embodied carbon footprint disrupted its potential as a sustainable material for its application.

I modelled different iterations to find suitable replacement materials. I ultimately chose Mediumdensity concrete system for its low thermal conductivity value and compression properties to withstand high altitudes. The new structural proposal also includes an enclosed space to take a U-value. I redesigned the top viewing platform to provide a thermal bridge challenge when addressing the cantilever junction of the outdoor balcony.

Through these iterations, I will produce a final 1:20 construction detail that enhances the original transitional space design. The alterations will allow for a more sustainable and energy-efficient space that responds to the community’s needs.

19

Hearne, S. (2022) 1:10 Bordesley Green Observation Tower Viewing Platform

Steel Frame Structure & Mineral Wool Insulation

EPS & Medium-Denisty Concrete & Render

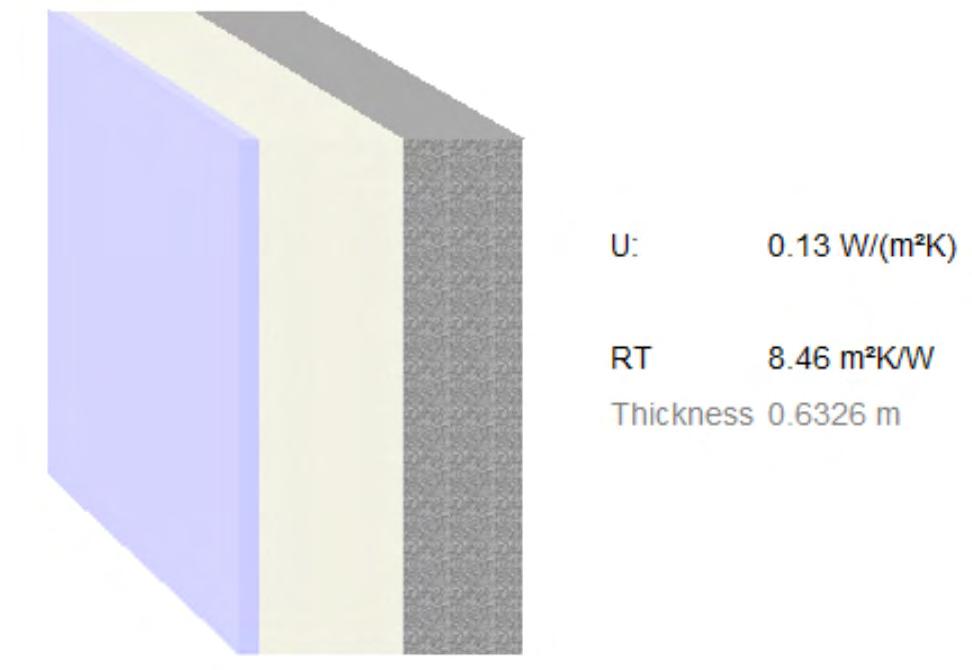

Advanced modelling techniques enabled me to generate virtual transcripts of material buildup and construction techniques. The free modelling software produced comprehensive 3D models of the building’s design, encompassing its construction elements, materials, and components. The software also offered valuable insights into the building’s thermal performance, enabling me to assess whether the buildups comply with the Passivhaus standard.

A significant advantage of using advanced modelling is that it enables me, the designer, to identify potential issues before construction begins. 3D visual building design enabled easy identification of thermal bridges or other problems that affect the building’s energy efficiency. Modelling allowed necessary modifications to the building design to ensure it met the required thermal performance standards.

Another significant benefit of using advanced modelling is that it enabled me to experiment with different construction techniques and materials quickly. By creating buildups using various insulation materials, it is possible to compare and evaluate the thermal performance of each approach. Through advanced modelling, I made informed decisions about the materials and techniques used in the final building design.

Insulation Types

Thermafleece - NatraHemp

Extruded Polystyrene (XPS)

Extruded Polystyrene - ICF

Wood Fibre - STEICO

Expanded Polystyrene (EPS)

20

After examining various types of insulation, I have concluded that Expanded Polystyrene (EPS) insulation is the best choice for my project. While there is controversy surrounding EPS due to its potential fire hazards, the transitional spaces occupational use has little fire risk. Another concern regarding EPS is the issue of improper disposal, as it is not currently locally recyclable. The environmental impact can reduce through proper disposal or repurposing.

Compared to other petrochemical-based insulations, EPS has a lower embodied carbon and thermal conductivity. It is an energy-efficient material that can effectively reduce heat transfer, helping to keep my transitional space cool in the summer and warm in the winter. Furthermore, in my BuildDesk calculations, I also considered some plant-based insulation options. However, I found that EPS provided better U-values even when used at a thinner thickness than the plant-based alternatives. Using less material not only reduces waste but also lowers the overall cost of the project.

After careful consideration and analysis, I have determined that EPS is the most suitable insulation for my project. While it is crucial to consider the potential risks and environmental impact of any material used in a construction project, EPS is a highly effective insulation that can be used safely and responsibly with the correct measures in place.

Render or Rainscreen Cladding System?

After selecting EPS as my insulation material, I explored the available options for cladding and rendering. I initially considered using render, but upon further investigation, I found that it had poor weathering characteristics, required regular maintenance, and was prone to cracking due to moisture trapped between the render and the external wall. Additionally, render tends to stain over time, which can be aesthetically unappealing.

I then looked into rainscreen cladding systems as an alternative. When comparing U-values, there was little difference between the U-values of render and rainscreen cladding systems. Instead of using render, the rainscreen system would consist of a black membrane that would be adhered to the insulation, with metal panels then tied back to the structure.

After using BuildDesk to verify U-values, I discovered a potential issue with thermal bridging. The mild steel wall ties used to tie back the metal panels have a high thermal conductivity. It causes a significant thermal bridge between the insulation and the metal panels, reducing the overall U-value. The lower the thermal conductivity, the higher the U-value.

In conclusion, while rainscreen cladding systems offer several benefits over traditional renderings, such as improved weathering resistance and reduced maintenance, it is imperative to tackle the problem of thermal bridging caused by mild steel wall ties. I either need to use polymer alternatives for the wall ties to achieve the desired U-value and energy efficiency due to the lower thermal conductivity of polymers or find an alternative cladding solution.

21

EPS

Medium-Denisty

&

Concrete Rainscreen

EPS & Medium-Denisty Concrete & Render

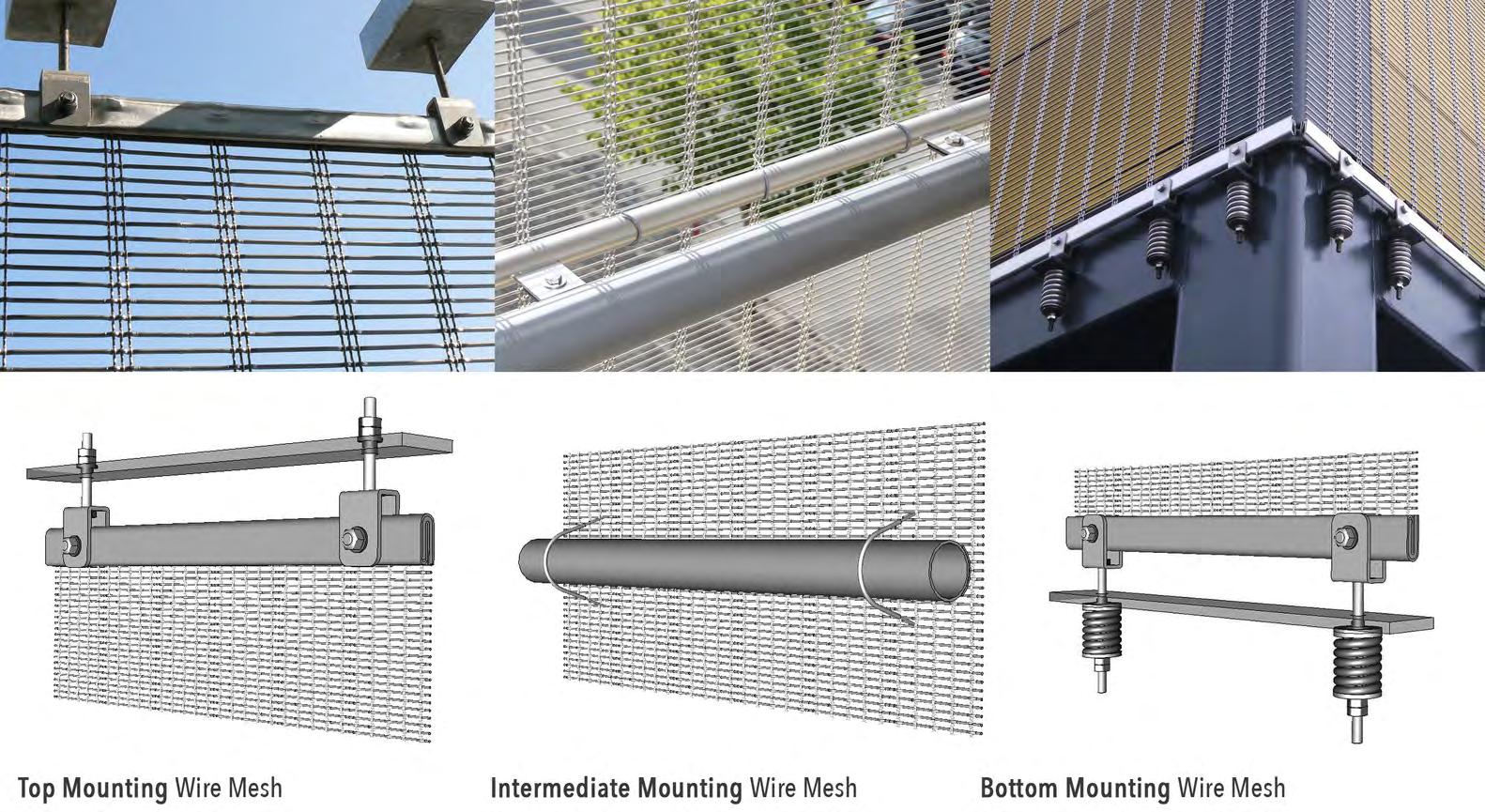

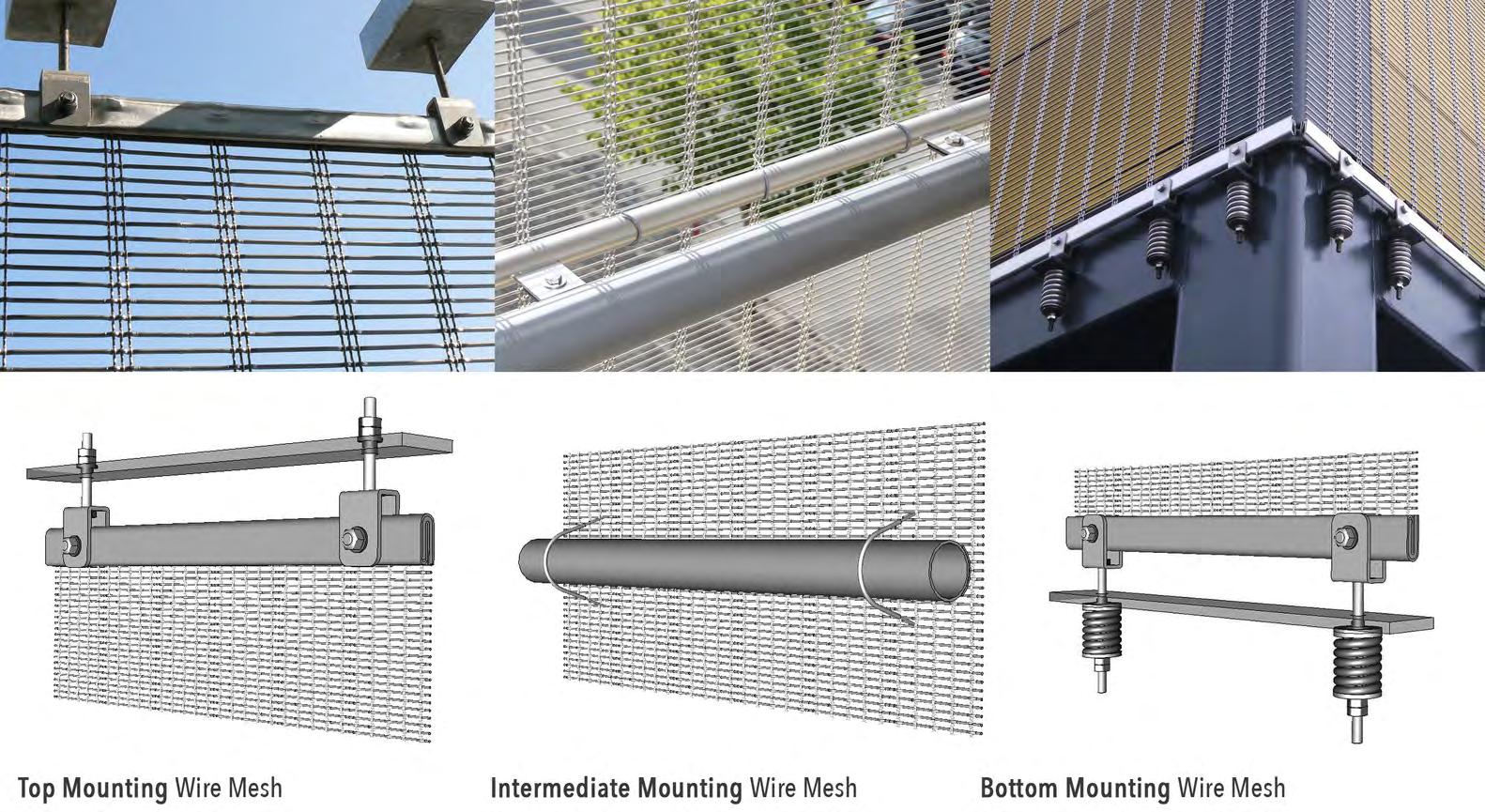

Architectural Wire Mesh Facade

Whilst exploring cladding options, metal mesh caught my attention as it imbues the architecture with a unique character. Made of stainless steel, a semi-transparent cladding blends design with practicality and possesses excellent technical properties. The resulting wire mesh facades create a luminous building envelope with a distinct design vocabulary and elegant solar protection. The mesh can reveal the metal forms previously illustrated in the 1:10 model. However, connecting a metal mesh facade cladding system to the building structure without causing a thermal bridge is a significant challenge.

Structural thermal breaks solve this issue by efficiently and responsibly thermally separating structural connections, minimising heat loss in the building envelope. These thermal breaks provide a low thermal conductivity barrier, reducing the impact of thermal bridging, which is a significant cause of heat loss in buildings. It leads to lower energy consumption, lower costs and decreased carbon emissions.

Apart from their thermal performance, structural thermal breaks are durable and easy to install. They come in various shapes and sizes to fit different connection types, making them versatile and adaptable to diverse building designs. Furthermore, structural thermal breaks get tested and certified to meet environmental standards, ensuring their reliability and enduring performance.

In summary, incorporating structural thermal breaks into the design enhances thermal efficiency. The metal mesh as facade cladding is an attractive option made more feasible and sustainable with the inclusion of structural thermal breaks in the design.

22

Structural Thermal Break

Architectural Wire Mesh Facade

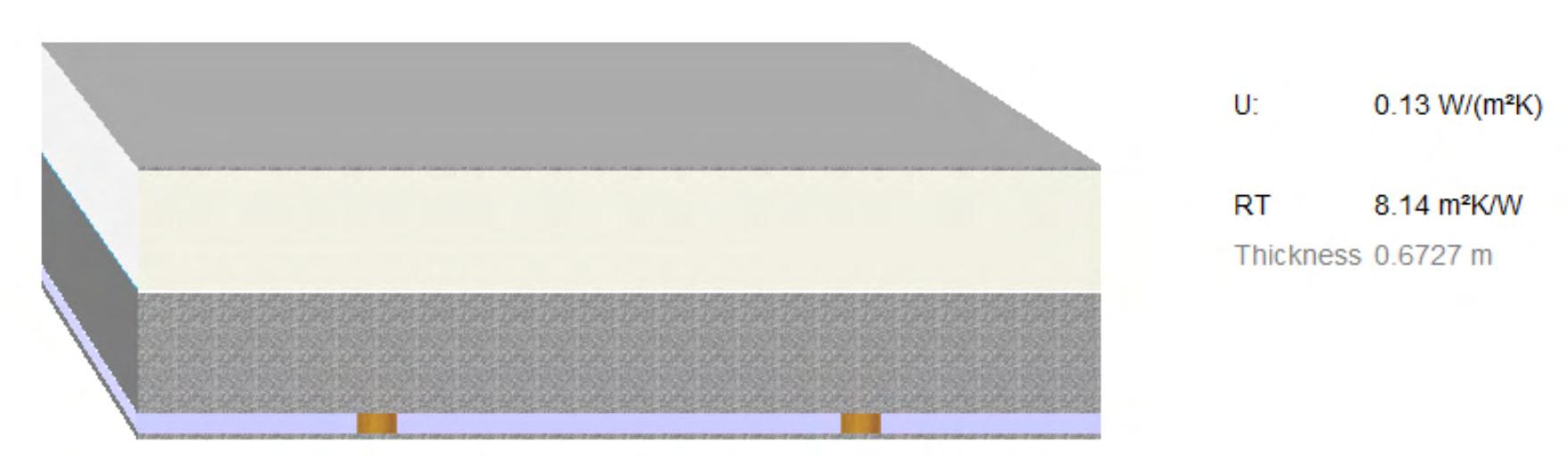

Roof & Flooring System

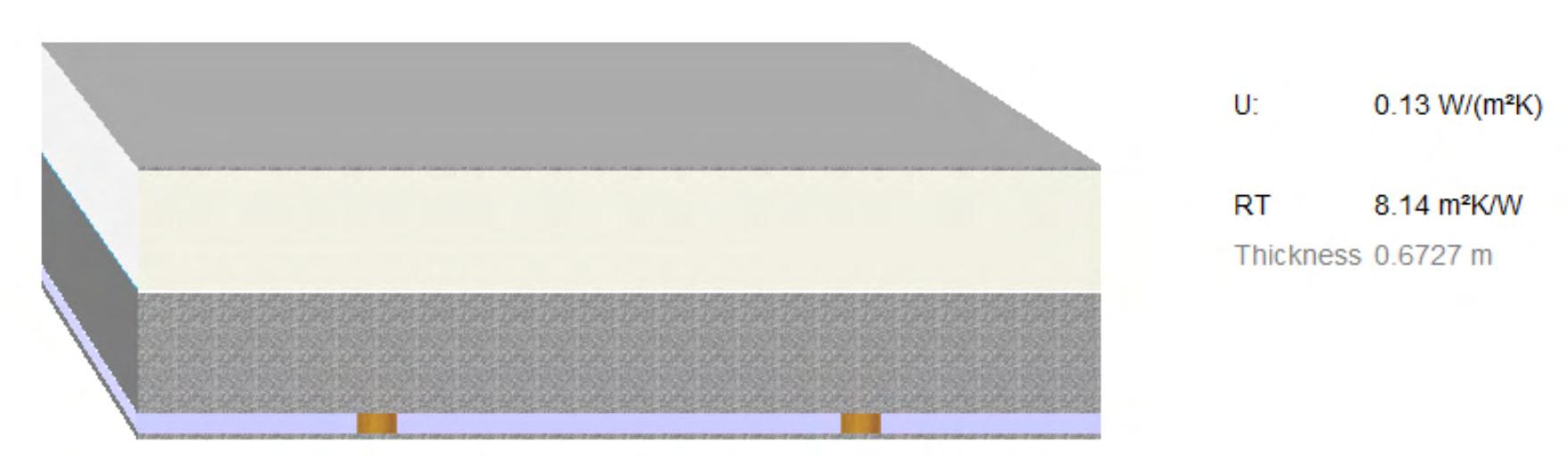

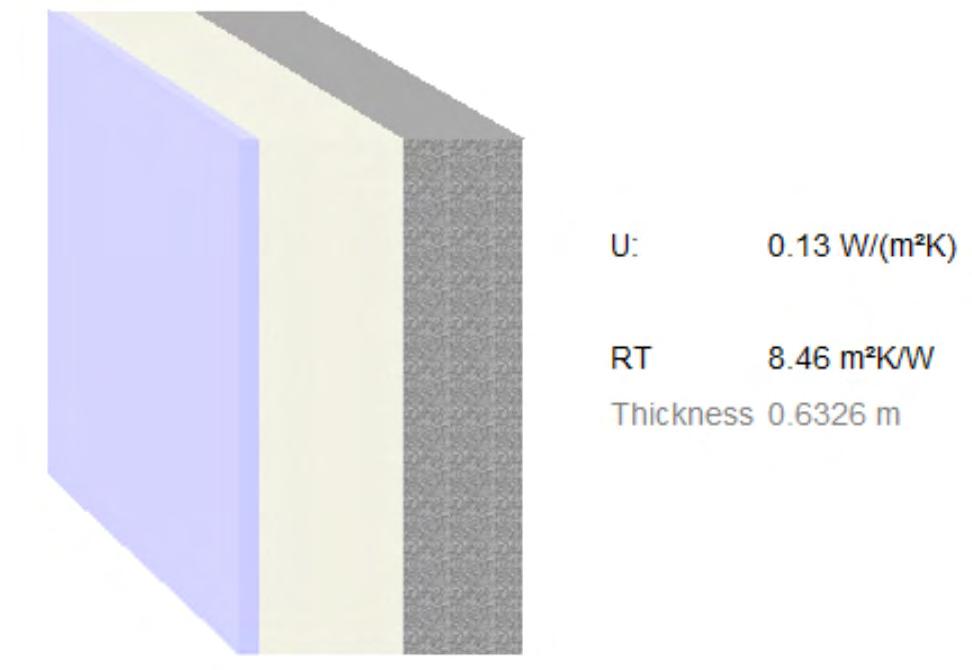

After deciding on the build-up for my external walls, I turned my attention to ensuring that the roof and floor were also continuously insulated to maintain the energy efficiency of the building. For this purpose, I have decided to use the same medium-density concrete and EPS build-up for the roof and flooring as I did for the walls.

By placing the insulation on the outside of the structure, I can guarantee that the building remains warm and energy-efficient. The external insulation prevents thermal bridging, which can cause heat loss through building elements that are not thermally insulated. By minimising thermal bridging, I can ensure that the building retains heat and minimises energy bills while maximising comfort. By using the same materials as the walls, I can ensure consistency and efficiency throughout the entire building.

23

Flatroof Buildup

Floor Buildup

24 1. 12.5mm Plasterboard 2. Vapour Control 3. 100mm EPS 4. 250mm Reinforced Concrete 5. 320mm EPS 6. Breather Membrane 7. Wire

Façade 8. Structural Thermal Break 9. Vapour Control Layer 10. 300mm insulation to roof

with roof membrane over 11. Insulation to

of parapet with flashing over 1 2 3 4 5 6 7 8 9 10 11 0 100cm 1:20 Scale @ A4

Mesh

deck

top

Conclusion

To conclude, I believe that advanced modelling at the beginning of the design process can positively impact the overall design outcomes. My understanding of low embodied carbon and low thermal conductivity alternative materials has improved, which has resulted in a change to my design material fabric. The software provided concise visual information, allowing me to create iterative systems that demonstrated how minimal differences in insulation thicknesses can affect thermal conductivity performance. Achieving Passivhaus standards can be achieved through various construction methods. Despite software illustrating this, some new builds still fail to consider minor alterations, such as the thermal bridges of junctions. As more software becomes widely available and accessible, introducing modelling early into the design process becomes an easy and effective approach for achieving the Passivhaus standard. However, we should always look to Kahn’s philosophy, ‘the measurable is only the servant of the unmeasurable.’ We must not rely on advanced modelling for how we design. They must remain tools for the master builder, the architect, to utilise as ultimately ‘everything that man makes must be fundamentally unmeasurable’.

25

Steel Frame

EPS & Medium-Denisty Concrete & Render

Hemp Insulation

XPS Insulation

26 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 12. March 2023 Thermal transmittance (U-value) according to Digest 465 Source: own catalogue Component: Steel cold frame. Brick facing. 150 mm MW This illustration of inhomogeneous layers is provided only to assist in visualising the arrangement. Assignment: External wall Manufacturer Name Thickness Lambda Q R 1 Cavity Airspaces (BRE) Normal cavity 50 mm, unventilated 0.0500 0.278 0.1799 2 Light steel-frame consisting of: 0.3500 ø 0.188 1.8628Air gaps Level 1: dU'' = 0.01 W/(m²K) 00.30 %3 BS EN 12524 Polyethylene 0.15 mm (600 Gauge) 0.0002 0.170 0.0009 4 BS EN 12524 Gypsum plasterboard 0.0125 0.250 0.0500 0.4252 R = p*R + (1-p)*R = 3.56 m²K/W Correction to U-value for according to delta U [W/(m²K)] Air gaps and fixings corrections need not be applied, as their total effect is less than 3% (Annex D BS 6946:1996). U = 1/R + U = 0.28 W/(m²K) The physical values of the building materials has been graded by their level of quality. These 5 levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot U = 0.28 W/(m²K) R 3.56 m²K/W Page 1/4 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue External walls Component: Ext. EPS insulation on concrete U=0.25 W/m²K Assignment: External wall [m], number [W/(mK)] [m²K/W] Render, cement and sand 2 Generic Building Materials Expanded polystyrene (EPS) Variable thickness 0.3200 0.040 8.0000 Fixings Plastic insulation anchors No./m²: 4/m² 0.500Fixings equivalent diameter: 0.01 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) 3 BS EN 12524 Concrete, Medium density 2200 0.2500 1.650 0.1515 R = R + R + R = 8.34 m²K/W Correction to U-value for according to delta U Air gaps BS EN ISO 6946 Annex F 0.0092 0.0092 U = 1/R + U = 0.13 W/(m²K) Q The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot U = RT Page 1/2 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Heat capacity Source: own catalogue - External walls Component: Ext. EPS insulation on concrete U=0.25 W/m²K The list of materials shown below may differ from those in the U-value calculation printout. Only material layers which are used in the heat capacity Single material layers shown in the U-value calculation printout may be separated to meet the exclusion criteria: A .. The total thickness of the layers exceed 0.1 m. B .. The mid point in the construction is reached. For insulation layers the following criteria applies: [m] [W/(mK)] capacity Density [kg/m³] Exclusion 1 Render, cement and sand 0.0200 1.000 1.00 1800.0 36.0 A, -, C Expanded polystyrene (EPS) Variable 0.3200 0.040 1.45 15.0 0.0 A, -, C Concrete, Medium density 2200 A, -, 3 Concrete, Medium density 2200 0.1000 1.650 1.00 2200.0 220.0Heat capacity = 220.0 kJ/(m²K) The following exclusion criteria apply: The total thickness of the layers exceed 0.1 m. An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot Page 2/2 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue External walls Component: XPS iteration OUTSIDE INSIDE Assignment: External wall [m], number [W/(mK)] [m²K/W] Rse 0.1300 BS EN ISO 6946Generic Building Materials Extruded polystyrene (XPS) General Purpose (XL) Fixings Vertical Twist galvanised steel No./m²:Fixings equivalent diameter: 0.0101 m alpha: 0.800 Generic Building Materials Extruded polystyrene (XPS) General Purpose (XL) Fixings Vertical Twist galvanised steel No./m²: 2.5/m² 50.000Air gaps Level 1: dU'' = 0.01 W/(m²K) 4 Generic Building Materials Extruded polystyrene (XPS) General Purpose (XL) 0.1000 0.027 3.7037 Fixings Vertical Twist galvanised steel No./m²: 2.5/m² 50.000Fixings equivalent diameter: 0.0101 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) 5 Generic Building Materials Extruded polystyrene (XPS) General Purpose (XL) 0.1000 0.027 3.7037 Fixings Vertical Twist galvanised steel No./m²:Fixings equivalent diameter: 0.0101 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) 0.7000 Page 1/3 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue - External walls Component: XPS iteration R = R + R + R = 15.23 m²K/W Correction to U-value for according to delta U [W/(m²K)] Air gaps 0.0803 U = 1/R + U = 0.15 W/(m²K) Q The physical values of the building materials has been graded by their level of quality. These levels are the following B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot U = 0.15 W/(m²K) R 15.23 m²K/W Page 2/3 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Heat capacity Source: own catalogue External walls Component: XPS iteration calculation printout. Only material layers which are used in the heat capacity calculation are listed. Single material layers shown in the U-value calculation printout may be separated to meet the exclusion criteria: .. The total thickness of the layers exceed 0.1 m. .. The mid point in the construction is reached. C .. An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). OUTSIDE INSIDE [m] [W/(mK)] capacity [kJ/(kgK)] [kg/m³] kJ/(m²K) End of calculation Cold Well ventilated air layer Extruded polystyrene (XPS) General Purpose (XL) A, -, C (XL) Extruded polystyrene (XPS) General Purpose 0.1000 0.027 1.45 35.0 0.0 A, -, C Extruded polystyrene (XPS) General Purpose (XL) A, -, C Concrete, Medium density 2200 0.1500 1.650 1.00 2200.0 330.0 A, Concrete, Medium density 2200Start of calculation Warm 0.7000 220.0 Heat capacity = 220.0 kJ/(m²K) The following exclusion criteria apply: A The total thickness of the layers exceed 0.1 m. C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). Q The physical values of the building materials has been graded by their level of quality. These 5 levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or others. Page 3/3 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue External walls Component: Hemp Iteration Correction according to BR 443 Rainscreen cladding User defined input - Pointloss: Name Pointloss Chi Ref. quantity Ref. area delta U Single Double 0.0310 0.57 1.00 0.0177 0.0500 Page 3/4 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue External walls Component: Hemp Iteration OUTSIDE INSIDE Assignment: External wall [m], number [W/(mK)] [m²K/W] Rse 0.1300Own catalogue Thermafleece Hemp batts Fixings Plastic insulation anchors No./m²: 2.5/m² 0.500Air gaps Level 1: dU'' = 0.01 W/(m²K) 3 Own catalogue Thermafleece Hemp batts 0.1000 0.040 2.5000 Fixings Plastic insulation anchors No./m²: 2.5/m² 0.500Fixings equivalent diameter: 0.01 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) 4 Own catalogue Thermafleece Hemp batts 0.1000 0.040 2.5000Fixings equivalent diameter: 0.01 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) Fixings Vertical Twist galvanised steel No./m²:Fixings equivalent diameter: 0.0101 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) Concrete, Medium density 2200 0.7000 Page 1/4 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue - External walls Component: Hemp Iteration R = R + R + R = 10.41 m²K/W Correction to U-value for according to delta U Air gaps BS EN ISO 6946 Annex F 0.0023 Rainscreen cladding BR 443 0.0500 U = 1/R U = 0.17 W/(m²K) The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or others. U = W/(m²K) R m²K/W Page 2/4 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Heat capacity Source: own catalogue External walls Component: Hemp Iteration The list of materials shown below may differ from those in the U-value calculation printout. Only material layers which are used in the heat capacity calculation are listed. Single material layers shown in the U-value calculation printout may be separated to meet the exclusion criteria: A The total thickness of the layers exceed 0.1 m. B The mid point in the construction is reached. For insulation layers the following criteria applies: C .. An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). OUTSIDE INSIDE [m] [W/(mK)] capacity [kJ/(kgK)] Density [kg/m³] kJ/(m²K) Well ventilated air layer A, -, C 2 Thermafleece Hemp batts 0.1000 0.040 1.80 28.0 0.0 A, -, C Thermafleece Hemp batts A, -, C 5 Thermafleece Hemp batts 0.1000 0.040 1.80 28.0 0.0 A, -, C 6 Concrete, Medium density 2200 0.1500 1.650 1.00 2200.0 330.0 A, -, Concrete, Medium density 22000.7000 220.0 Heat capacity = 220.0 kJ/(m²K) The following exclusion criteria apply: The total thickness of the layers exceed 0.1 m. C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). Q The physical values of the building materials has been graded by their level of quality. These 5 levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or others. Page 4/4

27 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue External walls Component: EPS insulation on concrete OUTSIDE INSIDE Assignment: External wall [m], number [W/(mK)] [m²K/W] Rse 0.1300Tyvek UV Facade 3 Generic Building Materials Expanded polystyrene (EPS) Variable thickness 0.3200 0.040 8.0000Fixings equivalent diameter: 0.01 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) 4 BS EN 12524 Concrete, Medium density 2200 0.2500 1.650 0.1515 Gypsum plasterboard 0.6331 R = R + R + R = 8.46 m²K/W according to [W/(m²K)] Air gaps 0.0089 U = 1/R + U = 0.13 W/(m²K) Q The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot U = W/(m²K) RT m²K/W Page 1/2 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Heat capacity Source: own catalogue - External walls Component: EPS insulation on concrete The list of materials shown below may differ from those in the U-value calculation printout. Only material layers which are used in the heat capacity calculation are listed. Single material layers shown in the U-value calculation printout may be separated to meet the exclusion criteria: A .. The total thickness of the layers exceed 0.1 m. B .. The mid point in the construction is reached. For insulation layers the following criteria applies: C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). OUTSIDE INSIDE [m] [W/(mK)] capacity [kJ/(kgK)] Density [kg/m³] kJ/(m²K) Well ventilated air layer A, -, C 2 Tyvek UV Facade 0.0006 0.500 1.70 325.0 0.3 A, -, C 4 Concrete, Medium density 2200 0.1625 1.650 1.00 2200.0 357.5 A, -, 4 Concrete, Medium density 2200 0.0875 1.650 1.00 2200.0 192.5Gypsum plasterboard0.6331 203.8 Heat capacity = 203.8 kJ/(m²K) The following exclusion criteria apply: The total thickness of the layers exceed 0.1 m. C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). Q The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or others. Page 2/2 DEMO VERSION

Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue External walls Component: ICF Assignment: External wall Manufacturer Name Thickness [m], number Lambda [W/(mK)] Q R [m²K/W] Render, gypsum and sand 2 Own catalogue Polystyrene 0.2500 0.035 7.1429Fixings equivalent diameter: 0.0101 m alpha: 0.800 Air gaps Level 1: dU'' = 0.01 W/(m²K) 3 BS EN 12524 Concrete, Medium density 2200 0.2500 1.650 0.1515 Own catalogue Polystyrene Fixings Vertical Twist galvanised steel No./m²: 2.5/m² 50.000Fixings equivalent diameter: 0.0101 m alpha: 0.800 0.6500 R = R R + R = 9.02 m²K/W [W/(m²K)] Mechanical fasteners BS EN ISO 6946 Annex F 0.0508 U = 1/R + U = 0.17 W/(m²K) The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or others. U = 0.17 W/(m²K) R 9.02 Page 1/2 DEMO VERSION

Documentation of the component 13. March 2023 Heat capacity Source: own catalogue - External walls Component: ICF The list of materials shown below may differ from those in the U-value calculation printout. Only material layers which are used in the heat capacity Single material layers shown in the U-value calculation printout may be A .. The total thickness of the layers exceed 0.1 m. For insulation layers the following criteria applies: C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). Name Thickness [m] lambda [W/(mK)] Q Thermal capacity [kJ/(kgK)] Q Density [kg/m³] Q Thermal kJ/(m²K) Criteria Exclusion 1 Render, gypsum and sand 0.1000 0.800 1.00 1600.0 160.0 A, -, C Concrete, Medium density 2200 A, -, C 3 Concrete, Medium density 2200 0.0500 1.650 1.00 2200.0 110.0 -, -, C 0.0500 0.035 1.30 1050.0 0.0 -, -, C 0.6500 0.0 Heat capacity = 0.0 kJ/(m²K) The total thickness of the layers exceed 0.1 m. C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or others. Page 2/2 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue External walls Component: Wood Fibre Assignment: External wall [m], number [W/(mK)] [m²K/W] Well ventilated air layer2 Own catalogue Bitumen felt/sheet 0.0350 0.050 0.7000 3 Own catalogue Steico Flex 036 0.2000 0.036 5.5556 Air gaps Level 0: dU'' = 0.00 W/(m²K) Generic Building Materials 5 BS EN 12524 Concrete, Medium density 2200 0.1500 1.650 0.0909 was not taken into consideration in the calculation R = R R + R = 6.74 m²K/W [W/(m²K)] Air gaps BS EN ISO 6946 Annex F 0.0000 0.0000 U = 1/R + U = 0.15 W/(m²K) Q The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot U = RT Page 1/2 DEMO VERSION

purposesonly. Documentation of the component 13. March 2023 Heat capacity Source: own catalogue - External walls Component: Wood Fibre The list of materials shown below may differ from those in the U-value calculation printout. Only material layers which are used in the heat capacity Single material layers shown in the U-value calculation printout may be separated to meet the exclusion criteria: A .. The total thickness of the layers exceed 0.1 m. B .. The mid point in the construction is reached. For insulation layers the following criteria applies: [m] [W/(mK)] capacity Density [kg/m³] Exclusion 1 Well ventilated air layer 0.0500 0.000 1.01 1.2 0.0 A, -, C 2 Bitumen felt/sheet 0.0350 0.050 1.00 260.0 0.0 A, -, C A, -, 5 Concrete, Medium density 2200 0.0500 1.650 1.00 2200.0 110.0 A, -,0.5550 220.0 Heat capacity = 220.0 kJ/(m²K) The following exclusion criteria apply: The total thickness of the layers exceed 0.1 m. C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or others. Page 2/2 ICF Insulation

Fibre Insulation EPS & Medium-Denisty Concrete Rainscreen

Fordemonstrationortesting purposesonly.

Fordemonstrationortesting purposesonly.

Fordemonstrationortesting

Wood

Flatroof Flooring

28 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Heat capacity Source: own catalogue - Flat roofs Component: EPS Roof The list of materials shown below may differ from those in the U-value calculation printout. Only material layers which are used in the heat capacity calculation are listed. Single material layers shown in the U-value calculation printout may be separated to meet the exclusion criteria: A The total thickness of the layers exceed 0.1 m. B The mid point in the construction is reached. For insulation layers the following criteria applies: OUTSIDE Name Thickness [m] lambda [W/(mK)] Q Thermal capacity [kJ/(kgK)] Q Density [kg/m³] Q Thermal kJ/(m²K) Criteria Exclusion Bitumen felt/sheet 0.0100 0.230 1.00 1100.0 11.0 A, -, C Polyethylene 0.15 mm (600 Gauge) 0.0002 0.170 2.20 920.0 0.3 A, Concrete, Medium density 2000 A, Concrete, Medium density 2000 0.0375 1.350 1.00 2000.0 75.0Inhomogeneous material layer consisting of: 0.0500 3.4Unventilated air layer: 50 mm, upwards heat flow6b Softwood Timber [500 kg/m³] 08.30% 0.130 1.60 500.0 3.3Gypsum plasterboardStart of calculation Warm 0.6727 89.6 Heat capacity = 89.6 kJ/(m²K) The following exclusion criteria apply: A The total thickness of the layers exceed 0.1 m. C An insulating layer is reached (defined as lambda <= 0.08 W/(mK)). Q The physical values of the building materials has been graded by their level of quality. These levels are the following A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot Page 3/3 DEMO VERSION Fordemonstrationortesting purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue Flat roofs Component: EPS Roof OUTSIDE This illustration of inhomogeneous layers is provided only to assist in visualising the arrangement. Assignment: Flat roof [m], number [W/(mK)] [m²K/W] Rse 0.0400 BS EN 12524 Bitumen felt/sheet Generic Building Materials Expanded polystyrene (EPS) Variable thickness Air gaps Level 1: dU'' = 0.01 W/(m²K) 3 BS EN 12524 Polyethylene 0.15 mm (600 Gauge) 0.0002 0.170 0.0009 Generic Building Materials Concrete screed (1800 kg/m³) Concrete, Medium density 2000 6 Inhomogeneous material consisting of: 0.0500 0.298 0.1679 Unventilated air layer: 50 mm, upwards heat flow6b BS EN 12524 Softwood Timber [500 kg/m³] 08.30 % 0.1307 BS EN 12524 Gypsum plasterboard 0.0125 0.250 0.0500 0.6727 R = (R + R '')/2 = 8.14 m²K/W Correction to U-value for according to delta U [W/(m²K)] Air gaps 0.0085 U = 1/R + U = 0.13 W/(m²K) Q The physical values of the building materials has been graded by their level of quality. These levels are the following B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot U = 0.13 W/(m²K) R 8.14 m²K/W Page 1/3 DEMO

Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue - Flat roofs Component: EPS Roof Draft of the component (portion in %): The inhomogeneous layer consists of two zones (A, B). The portion is given in %. consisting of material layers: 1, 2, 3, 4, 5, 6a, 7 consisting of material layers: 1, 2, 3, 4, 5, 6b, 7 Upper limit of the thermal transfer resistance R R = 0.12 [W/(m K)] = R 8.21 0.1 + 0.04 1 RT = 1 = 8.14 m K/W [m K/W] = d R [m K/W] = d 0.3000 0.040 = 7.50 [m K/W] = d R [m K/W] = d 0.0500 1.150 = 0.04 [m K/W] = d /( B) = 0.0500 /( 0.313 91.70% + 0.130 8.30%) R [m K/W] = d 0.0125 0.250 = 0.05 [m K/W] RT = R + Rsi + R = 8.13 m²K/W Page 2/3 DEMO VERSION

purposesonly. Documentation of the component 13. March 2023 Thermal transmittance (U-value) according to BS EN ISO 6946 Source: own catalogue Intermediate floors Component: EPS Floor DOWN This illustration of inhomogeneous layers is provided only to assist in visualising the Assignment: Floor - semi exposed, heatflow downwards [m], number [W/(mK)] [m²K/W] Generic Building Materials Concrete screed (1800 kg/m³) 2 BS EN 12524 Concrete, Medium density 2200 0.2500 1.650 0.1515 3 BS EN 12524 Polyethylene 0.15 mm (600 Gauge) 0.0002 0.170 0.0009 Generic Building Materials Expanded polystyrene (EPS) General Purpose Generic Building Materials Expanded polystyrene (EPS) General Purpose 6 Generic Building Materials Expanded polystyrene (EPS) General Purpose 0.1000 0.040 2.5000 layer 7a Unventilated Airspace BR 443 Normal cavity 25 mm, unventilated 95.80 % 0.139Softwood Timber [500 kg/m³]8 BS EN 12524 Gypsum plasterboard 0.0125 0.250 0.0500 Rse 0.1700 The unheated space is regarded with a reduction factor b according to EN ISO 13789. b = 1.00 R = (R + R '')/2 = 8.78 m²K/W U = b * 1/R = 0.11 W/(m²K) A: Data is entered and validated by the manufacturer or supplier. Data is continuously tested by 3rd party. B: Data is entered and validated by the manufacturer or supplier. Data is certified by 3rd party C: Data is entered and validated by the manufacturer or supplier. D: Information is entered by BuildDesk without special agreement with the manufacturer, supplier or others. E: Information is entered by the user of the BuildDesk software without special agreement with the manufacturer, supplier or ot U = RT Page 1/3

VERSION Fordemonstrationortesting purposesonly.

Fordemonstrationortesting

Bibliography

An artist’s impression of what the exterior of Mercato Ilford will look like. (n.d.). Standard. Available at: https://static.standard.co.uk/s3fs-public/thumbnails/image/2019/04/15/15/mercato-ilford-1504a.jpg?width=968 [Accessed 11 March 2023].

Climate Emergency. (n.d.). Declare a Climate Emergency | Go Zero Carbon by 2030. [online] Available at: https://www.climateemergency.uk/ [Accessed 12 March. 2023].

Econekt. (n.d.). Passivhaus Building Standards. [online] Available at: https://econekt.co.uk/passivhaus/ [Accessed 14 March. 2023].

Farrat. (n.d.). Prevent Thermal Bridging by using Farrat Structural Thermal Breaks. [online] Available at: https://farrat.com/structural-thermal-break-connections [Accessed 11 March. 2023].

Haver & Boecker. (n.d.). Architectural wire mesh. [online] Available at: https://www.haverboecker.com/en/ product-solutions/architectural-wire-mesh/ [Accessed 12 March. 2023].

Hawkes, D. (2008) The Environmental Imagination: Technics and Poetics of the Architectural Environment. [Online]. Independence: Taylor & Francis.

LANDON, A. (2019). East London Is Getting A Delicious, Sustainable Food Market. Available at: https:// secretldn.com/mercato-ilford-food-market/ [Accessed 12th March. 2023].

Mercato Metropolitano (n.d.). Mercato Metropolitano. [online] Available at: https://mercatometropolitano. com.[Accessed 10th March 2023]

Merrill, M. (2010) Louis Kahn : on the thoughtful making of spaces : the Dominican Motherhouse and a modern culture of space. Baden: Lars Müller.

Prewett Bizley architects | Passivhaus | Retrofit. (n.d.). Dundon Passivhaus Somerset. [online] Available at: http://www.prewettbizley.com/dundon-passivhaus-project [Accessed 13 March. 2023].

Redbridge (2021). London Borough of Redbridge - Citizen Space. [online] Available at: https://engagement. redbridge.gov.uk/civic-pride/ilford-town-market/ [Accessed 10 March 2023].

Redbridge (n.d.). Mercato Metropolitano. [online] www.redbridge.gov.uk. Available at: https://www.redbridge.gov.uk/regeneration-and-growth/regeneration-and-growth-areas/ilford/the-spark-ilford/mercato-metropolitano/ [Accessed 10th March 2023].

www.dupont.co.uk. (n.d.). Cladding Construction | DuPontTM Tyvek® UV Facade. [online] Available at: https://www.dupont.co.uk/products/tyvek-uv-facade.html [Accessed 11 March. 2023].

29