Sammy Doublet

Portfolio

Selected Projects

Project 01. The Textile Factory

Year: 2

Tutors: Hannah Corlett, Niall Mclaughlin

Bartlett UG12 - Settlement

Instagram: @bartlett_ug12

A small-scale textile factory and workshop that produces and repairs shawls and clothing for local people and exports. The programme picks up on the weaving history of the area.

The industrial shed clamps to an arterial road that is raised on a flood levee, stepping down the sloping terrain to finally land at the banks of the vital trading conduit, the River Glaven - running through Cley-next-the-sea, in North Norfolk.

Using a ‘worsted’ fabric blend of harvested water reed fibre and imported cotton wool, the factory aims to elevate the artisanal approach to textile weaving.

Through a dialogue between the artisan and the customer, the textiles become a record of the personalities and lives of the settlement.

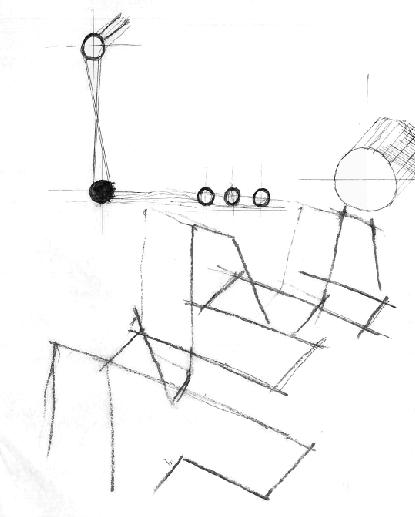

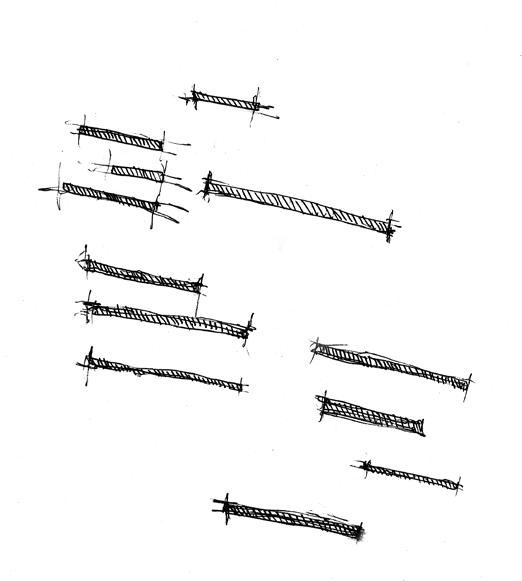

The three core processes of textile manufacture: scutching, spinning and weaving are each given a unit that together step down from road to river bank. Connecting them are the system of warps, threads and fibres that are lifted above the customers head from the machinery in a tapestry of heddles, harnesses and shafts, carrying a continuous thread through the structure from the scutching unit through to weaving.

Technical Detailing - Earlier Experiments with shingle roofing - 1:20 @ A3

Key

1 355×55mm Dark Oak Rafters, with prefabricated Steel Flitch Plate joints

2 Vapour Barrier Load-Bearing Layer

3 Polythene Vapour Barrier

4 Polystyrene Insulation

5 Plywood Sheathing

6 Counterbattens

7 Battens

8 325mm Oak Shingles

9 Patent Glazing Bar with custom - made flashing

10 - Double Glazed 10mm Toughened Glass

11 - Wood Fillets

12 - Transparent Insulating Material

13 - Load Bearing Layer for roof coveringinbetween insulation

14 - Ceiling Joists

15 - Steel Flitch Plate Anchor Inserted into Oak Column and connected to timber floor joists

16 - Reinforced Concrete (RC) Pile Cap with cast-in-situ RC Piles inserted into Steel casing

Project 02.

Year: 1

The Bird Reserve and Acoustic Gallery

Tutor: Alastair Browning

Materials For Change

My first year project was an acoustic gallery and nature reserve for Greattits and Wrens, celebrating birdsong in the tree canopy above the mound; redressing the balance between the noisy London Wall Road and the green pocket of land to the north.

The building lies to the north of London Wall Road, inserting into a mound of earth populated with trees. This mound is encased by a portion of the Roman Wall of the City of London, and a section of the old fort that housed Roman Soldiers.

The Wren House, Final Model 1:100

The use of light wells and ducts to avoid standard windows means the user never fully sees the nature reserve – they can hear the birds, but never see them. Through an indoor garden below mound level and a birdsong recording studio, the project acts as both a sensory experience and a rewilding centre. The experiential room becomes a register of the positive ecological impact the building makes.

nature in the City of London.