2 minute read

CONNECTION

from AEOLIAN - AADRL

by Salim Hilles

Building A Larger Network

Advertisement

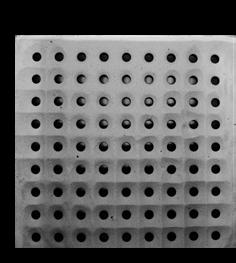

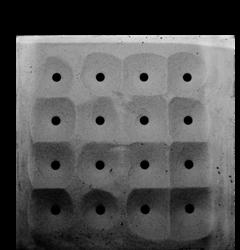

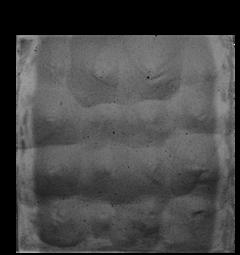

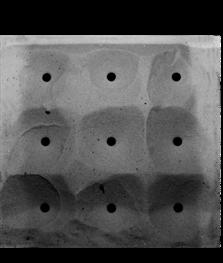

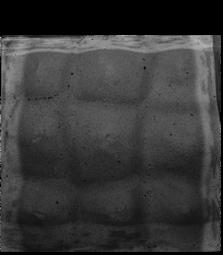

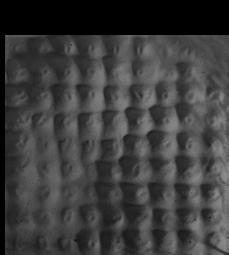

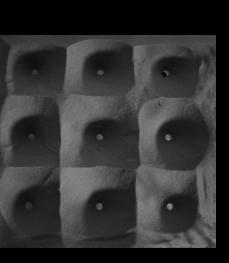

To further understand how sand particles aggregate, a small experiment was constructed inspired by Frei Otto’s granular aggregation experiment. This research examined the formulative behaviour of sand grains, how they aggregate, and what parameters affect the generate topology. The results in the catalogue below illustrates that no matter how many voids are placed or how thick each of these voids are, sand grains will retain an angle of inclination of 30-35 degrees. However, an influential change was how the number of voids affected the field topology. In specific, the more the voids, the more hill-like aggregations on an additive container , and more downward slopes on the subtractive container.

Glass

The research addresses the process of desertification by utilising the desert’s onsite materiality and investigating its material contingency. The elemental aspect of sand is explored as form of technology, whereas the research is looking into the possibilities of material transformation of sand into glass under high temperature.

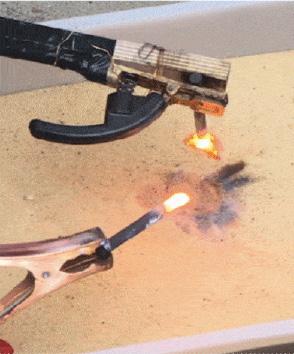

The welder with a maximum of 120 Ampere was used for the experiments with sand welding. The initial idea was to raise a glass structure on top of a piece of steel plate. For the welding process, there is a need for the skills of such craftsmanship, therefore some training process was necessary for the execution of the experiment. The first iteration was to touch the metal plate with the electrode under the surface of the sand to have a bigger surface area of glass, however, the welding under the sand was very hard to execute and worked without continuous welding. Therefore the welding process was done on top of the surface.

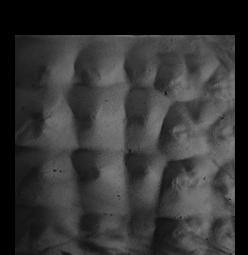

SAND WELDING 1.0

The experiment shows that the sand was indeed melting, however, it was mixing together with metal and is not clear. The glazing might be seen as a shiny cover on top of the metal. The sand which has not melted but was close to high temperatures changed its colour from warm terracotta to white.

The next experiment was executed without an electrode but with a copper rod 8mm in diameter soldering to another copper rod in the sand. The resulting pieces are almost pure glass with a little content of copper, which is the reason for the colour. Sand under high temperature begins to conduct electricity and therefore there is a feasibility to produce pure glass pieces. Glass was formed in bubbles, hollow inside. The maximum length achieve is no more than 2 cm, because of the lack of voltage of the tool.

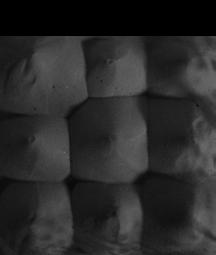

WELDING 3.0

The next attempt with welding was executed with the use of carbon electrodes. Two carbon electrodes touching each other create the electrical arch which reaches necessary temperatures. Electrodes are not melting so fast as regular ones and therefore not mixing with the fused glass. Moreover, the welding happened in a much smooth controlled way. Eventually the fusion might continue without breaks. The first examples are small, approximately 2-3cm in length pure glass pieces.