HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

EDITOR-IN-CHIEF

CHRIS BIRO editor@rpmmag.com

V.P. MARKETING/CUSTOMER RELATIONS TRISH BIRO trish@rpmmag.com

EVENT MEDIA events@rpmmag.com

EVENT SUBSCRIPTIONS COORDINATOR SHERRIE WEBER sherrie@rpmmag.com

ART DIRECTOR .......................................................... JIM McHARG

Photographic Contributions: Mark - Godragracing.org, George Pich, Louis Fronkier, Blake Farnan, Jerry Garrison, Eddie Maloney, Wes Taylor, Steven Taylor and Amber Hynes

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

Editorial Contributions:

Chuck Scott, Mark-Godragracing.org, Tim Biro, Stan Smith, George Pich, Jay Misener, Eddie Maloney, Wes Taylor, Steve Baur

Technical Writing Contribution: Chuck Scott, Shane Tecklenburg, Tim Biro and Jay Misener

For advertising information contact

TRISH BIRO ............... 519.752.3705 ................ trish@rpmmag.com

Special Events Manager: Chris Biro events@rpmmag.com

Special Events Sales: Trish Biro: 519-752-3705 trish@rpmmag.com

Subscriptions/Address Changes: Circulation circulation@rpmmag.com

General Inquiries: 519.752.3705 info@rpmmag.com

RPM Magazine has been a world leader in motorsports publishing for 26 Years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published.

Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

WE RESERVE THE RIGHT TO REFUSE ANY ADVERTISING WHICH WE CONSIDER TO CONTAIN MISLEADING, OFFENSIVE OR FALSE INFORMATION. REPRODUCTION OF ANY INFORMATION HEREIN IS STRICTLY PROHIBITED WITHOUT PRIOR WRITTEN CONSENT.

Internal combustion engines have been around for over 100 years and as technologically advanced as they have become, they all still draw air and fuel into their combustion chambers where the mixture is lit off by an electrical ignition system.

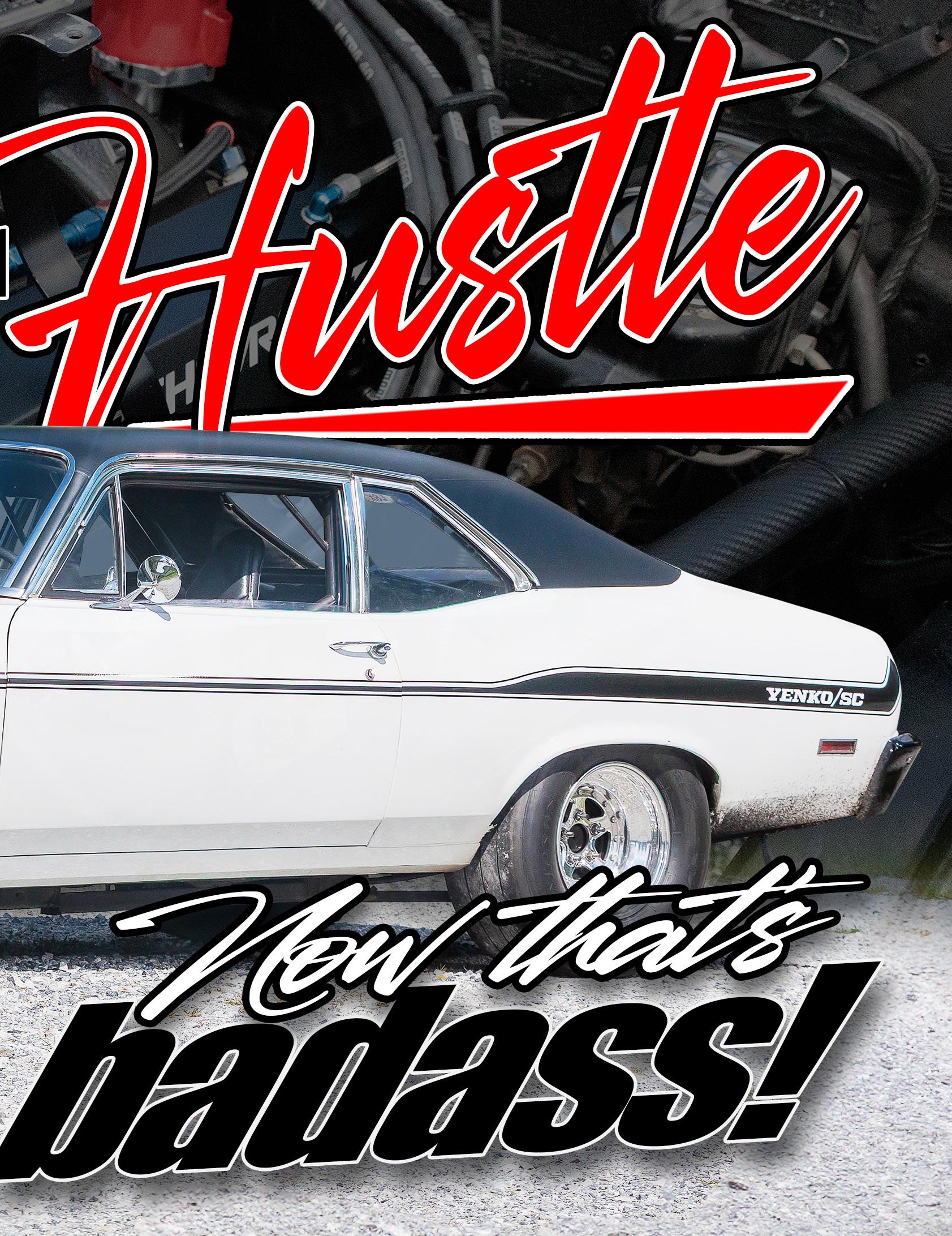

In their simplest form, they do this using only the available atmosphere and using a trick, yet simple mechanical box to mix the air and fuel just right. Justin Rowe’s Chevy Nova features one of these “simple” internal combustion engines, but it’s capable enough to push the Nova to 8-second elapsed times in the quarter-mile.

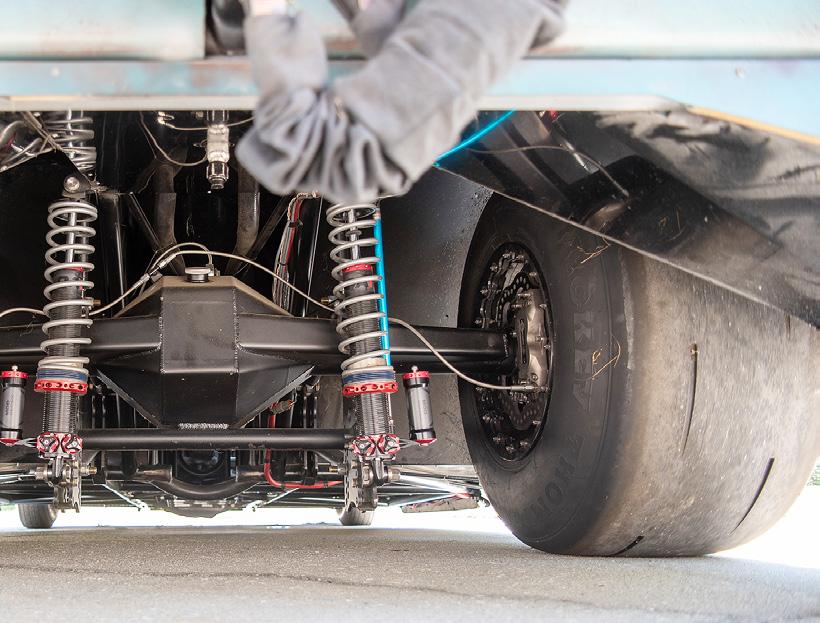

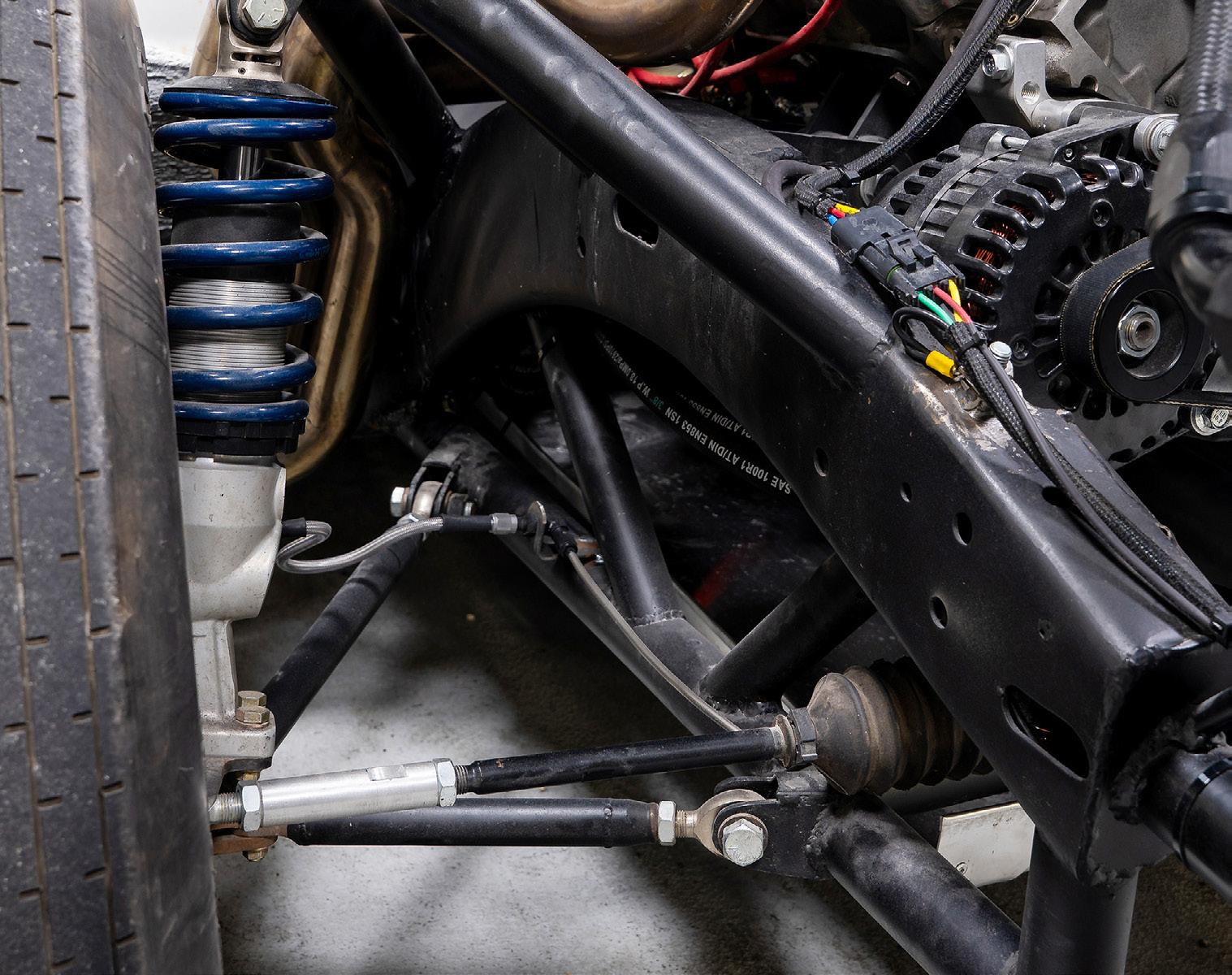

One thing it’s not is a Ford 9-inch! Rowe chose to keep his Chevrolet as much Chevy as possible and built a tough-as-nails 8.5 GM diff which includes Moser Engineering 33-spline axles, a Moser spool, C-clip eliminators, and Motive Gears 4.33:1 ring and pinion. Calvert Racing split mono-leaf springs with Caltracs and Menscer Motorsports double-adjustable rear shocks are used to plant the rear tires following Rowe’s skyhigh adventure in 2023. The front suspension was also upgraded with TRZ upper and lower control arms, travel limiters and AFCO double-adjustable shocks.

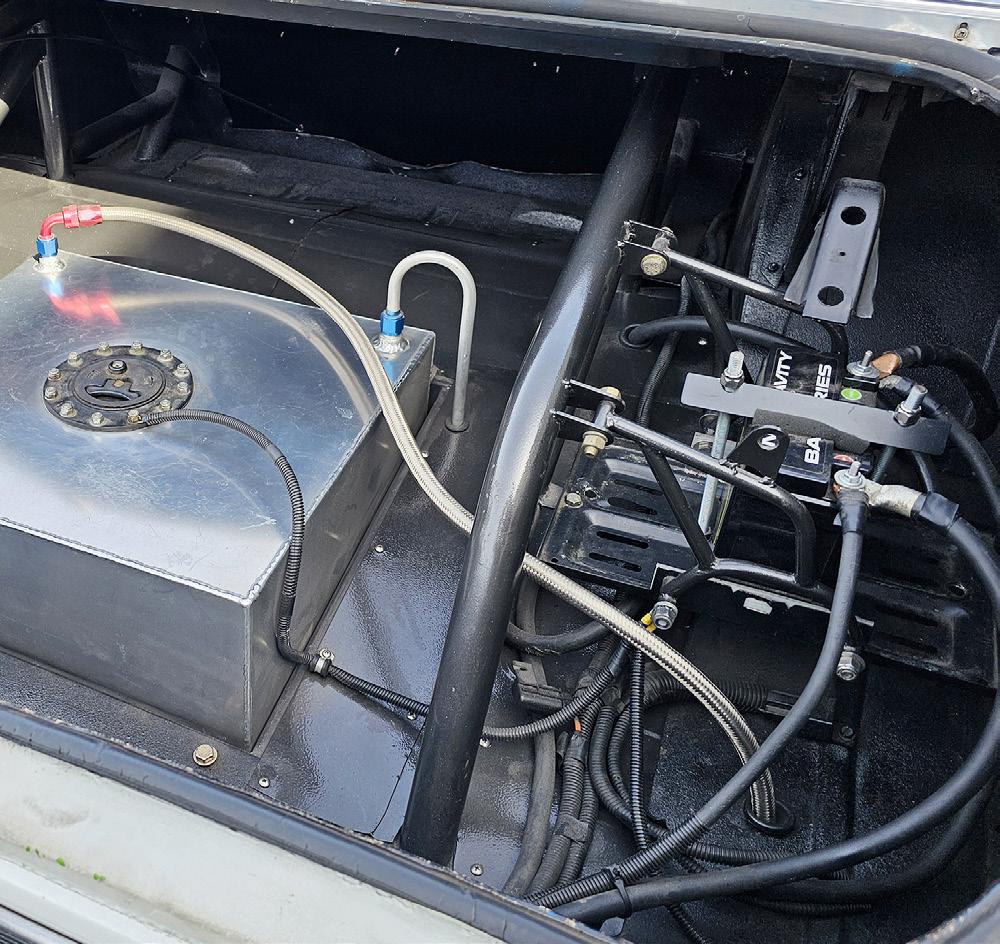

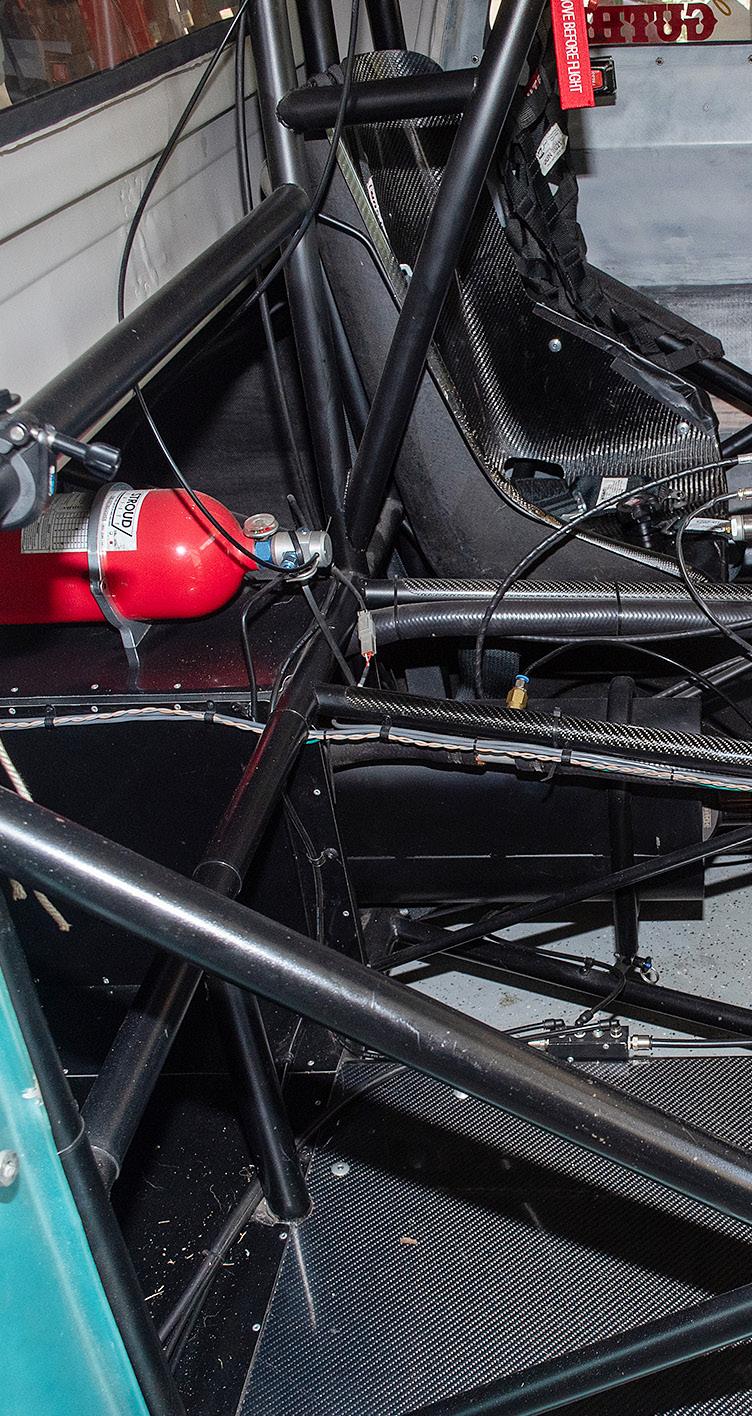

Some of Meshey’s trick cage work makes its way into the trunk area of the Nova along with an aluminum fuel cell sized for both track hits and street drives, and the battery.

Growing up with a father who raced a 1977 Chevy Camaro, Justin was bitten by the racing bug early on as memory after memory was imprinted on his young brain. By the time he was 15, he was ready for

his first car, and found it behind someone’s house. The owner parted ways with the 1969 Chevy Nova two-door and Justin and his father got it back on the road with a 350 smallblock.

Turn your LS into a legend in its own time with Trick Flow GenX® 280 HIP cylinder heads. These ultra-performance HIP’d (Hot Isostatic Pressed) castings are significantly stronger than regular heads and include many other outstanding features such as:

• Industry-leading airflow

• 280cc CNC Competition Ported intake runners

• 87cc CNC Competition Ported exhaust runners

• Manley 2.165" Severe Duty intake/1.600" Inconel Extreme Duty exhaust valves

• Trick-Alloy™ powdered metal valve guides

• Trick Flow by PAC Racing dual valve springs

• Clearance for 3/8" pushrods

• .750" decks

• 6-bolt-per cylinder mounting

• LS3 rocker stands included with assembled heads

Engineered for Performance!

New heads are just one part of the Serious Horsepower formula. To complete it, you’ll need some more components.

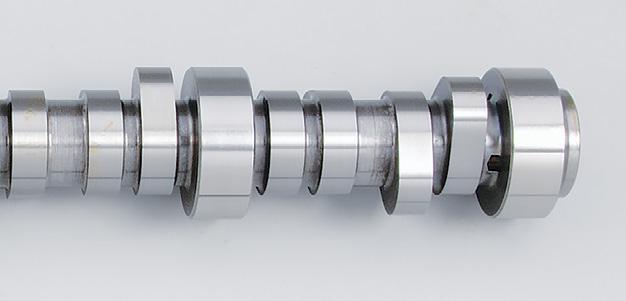

Track Max® Camshafts

• Dyno proven to significantly increase power

• Made from premium billet steel blanks

• Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift

R-Series Intake Manifolds for GM LS3

• Bring carbureted-style aspiration to LS3-style engines

• 3,500-7,500-plus RPM range

• Available in carbureted and carb-style EFI versions

Variable Valve Timing Delete Kits

• Removes VVT so your engine makes big power with aftermarket parts

• Available with 1- and 3-bolt cam gears

• Includes cam/crank timing gears; timing chain and damper; LS2/LS3 timing cover with bolts, seal, and gasket; cam sensor, harness, and bracket; water pump gaskets; and cam, cam sensor, and balancer bolts

it yet!

Each month we host some of our past issues of RPM Magazine in this section. If you haven’t read them yet, they are new to you! If you have, maybe there’s a favourite car/story you want to read again….here they are!

CLICK A COVER OR SCAN A QR CODE TO GO BACK IN TIME!

“I was 16 years old when I started racing my Nova,” Rowe said. “My first passes were at Maple Grove Raceway during the former Super Chevy Event. It ran 14.01 at 99 mph on my very first pass and did run 13.70’s after a few more runs. I was nervous being it was my first time ever racing.” The Ephrada, Pennsylvania, resident drove the Chevy through his senior year of high school and then daily for another year afterwards.

As the racing became more serious, the Nova saw less daily street duty, with the engine changing to a 377 cubic-inch small-block that ran low 11s, followed by a 415ci powerplant that put it into the mid 10s in the quarter-mile. Additional changes to that engine, as well as better tuning and better air dropped it into the 9.80s at 134 mph.

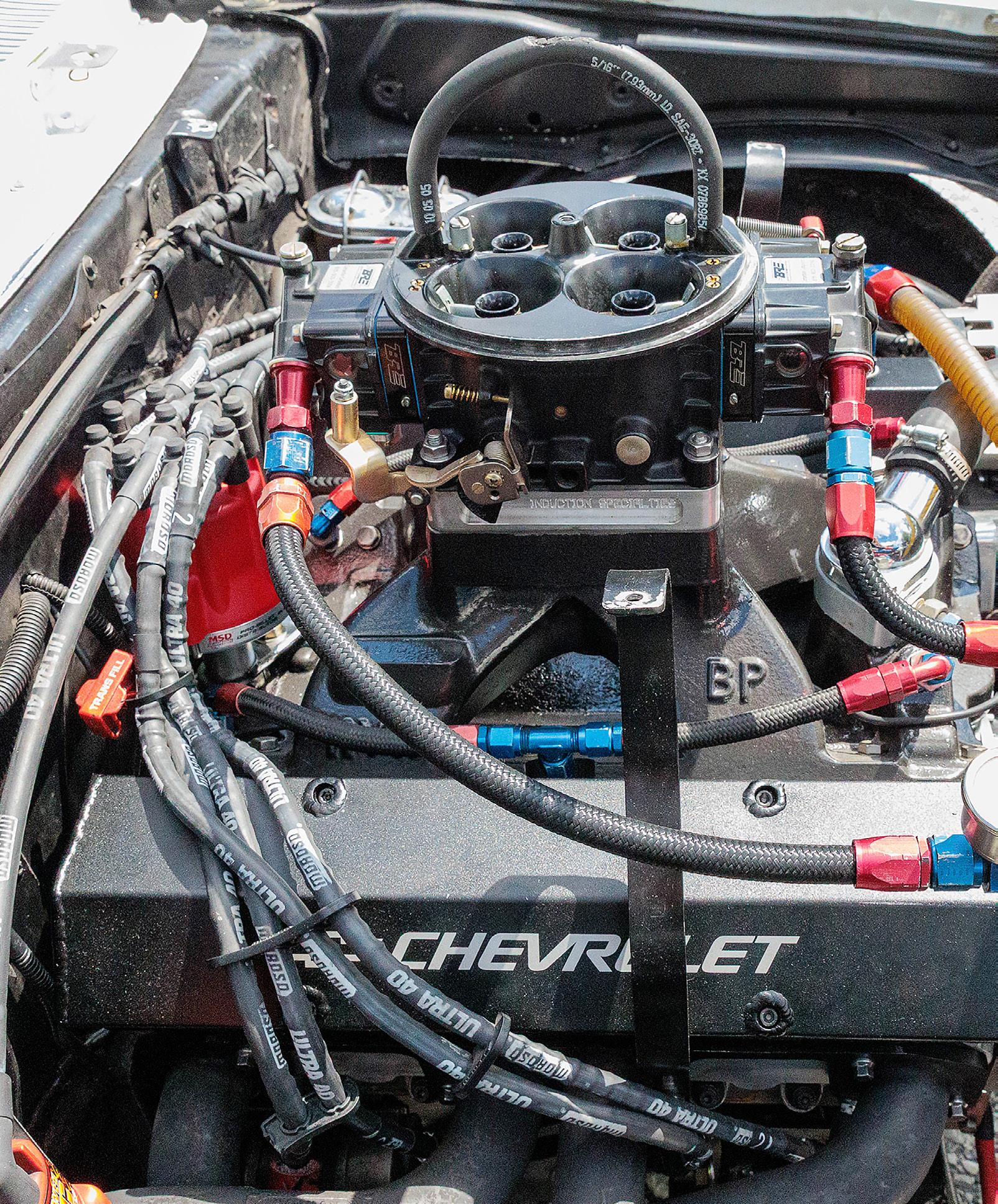

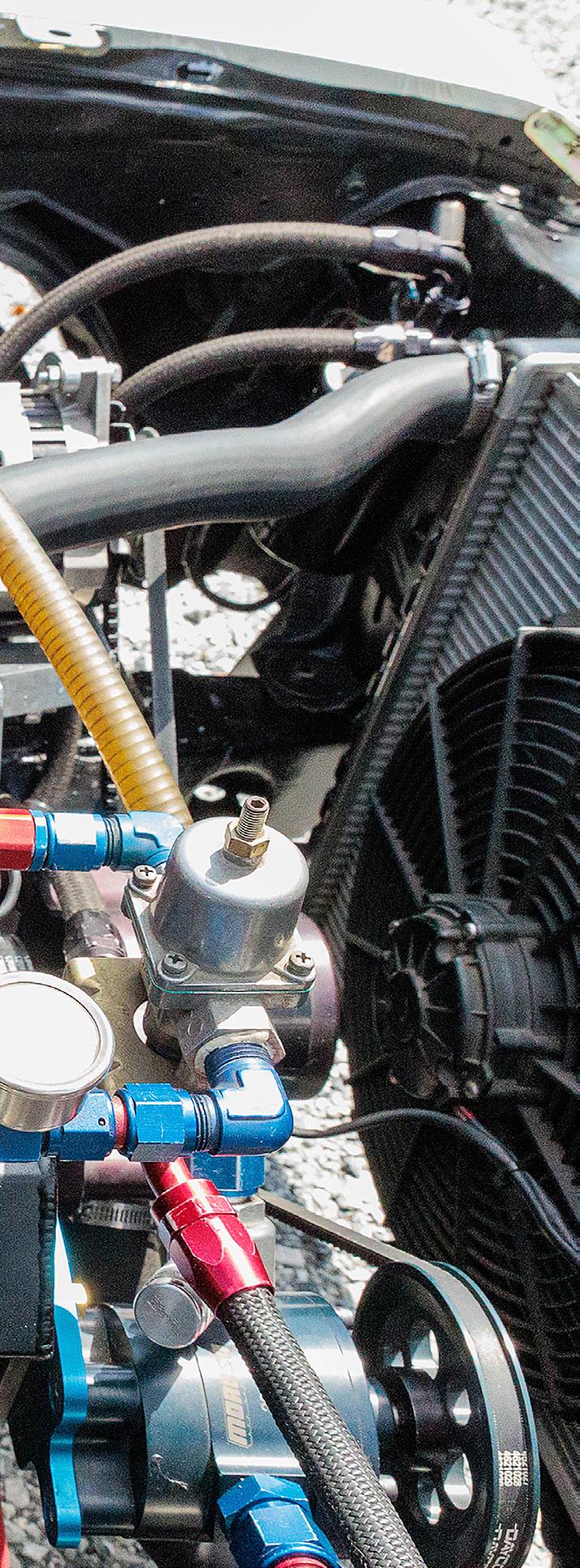

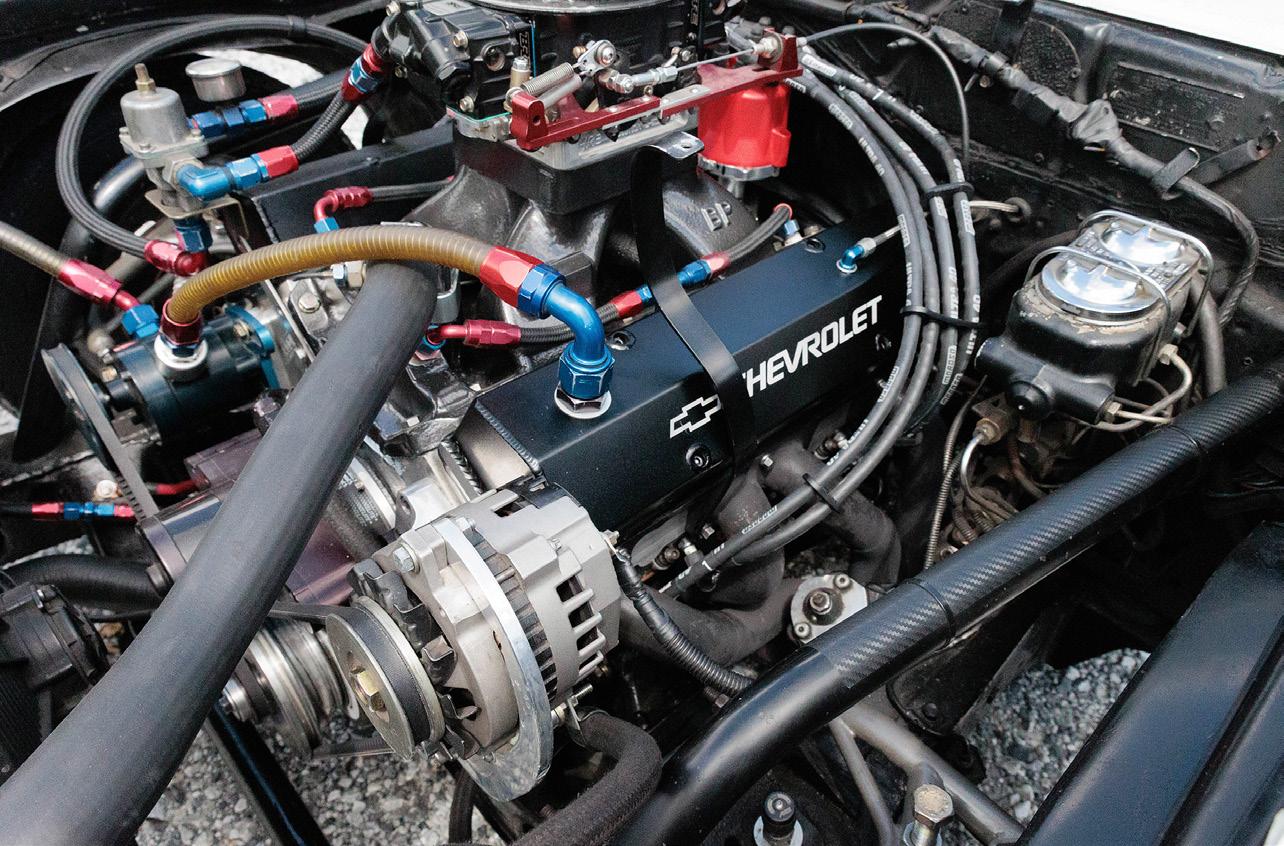

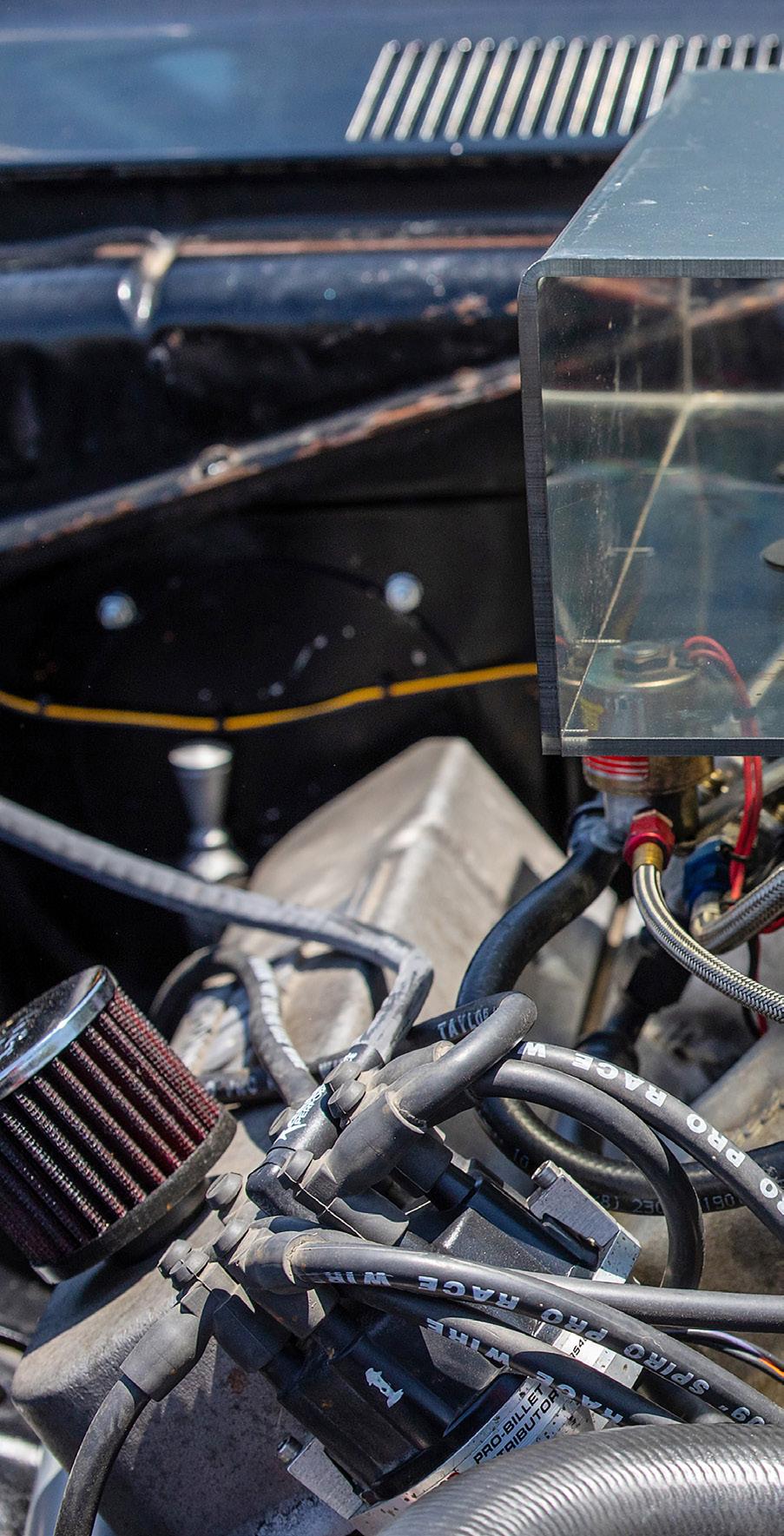

Over the last 27 years, Rowe has continued to modify and refine his Nova. Its current iteration is powered by a wicked 467 cubic-inch “small” block engine built by Pete and Corey Teasdale that is based on a Dart Machinery tall-deck, raised-cam block. Spinning inside is a Callies Performance Products Dragonslayer crankshaft slinging Oliver billet connecting rods, with an Erson solid roller camshaft spec’d out with 284/298 degrees of duration at .050, .8070-inch/.765-inch of valve lift, and a 112-degree lobe separation angle.

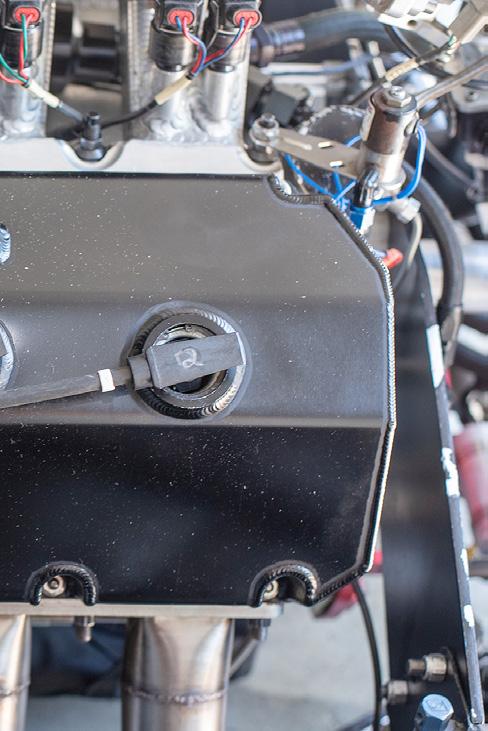

The big inch “small” block Chevy measures out to 467 cubes. It started life as a Dart tall-deck, raisedcam block and was filled with a Callies Dragonslayer crank, Oliver billet rods and forged pistons along with an Erson solid roller camshaft. Jesel 1.7:1 shaft-mount rocker arms were installed on the Brodix 15-degree cylinder heads and a Brodix high rise intake was ported for additional airflow. A Bob Book 1250cfm carburetor tops the package.

Jesel 1.7:1 shaft-mount rocker arms actuate the valves in the Brodix -12 15-degree cylinder heads and Bob Hartsock ported the Brodix HV1209 intake manifold for additional airflow.

Mixing the VP Racing Fuels Q16 petroleum is a Bob Book 1250cfm carburetor, and a Moroso 4-vane vacuum pump removes unwanted pressure from inside the block. Lighting the

air and fuel into an inferno is an MSD 7AL2 ignition box, MSD billet distributor, and an MSD HVC-2 ignition coil.

Behind the potent engine combination is a fully rollerized Turbo 350 automatic transmission and a PTC 8-inch torque converter with a 5,500rpm stall speed to get the small-block into the appropriate rev range at the hit.

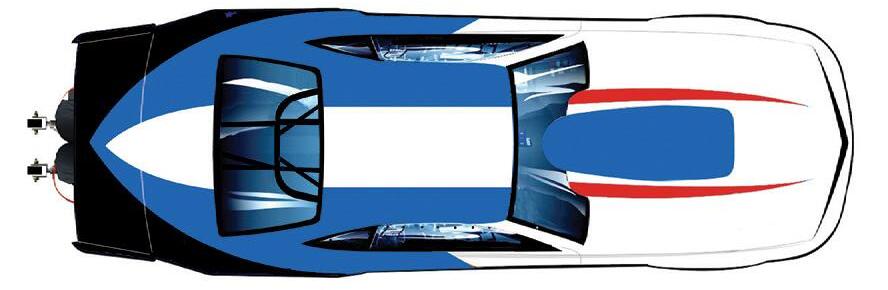

Body & Paint:

Steel car with composite hood. White vinyl wrap and black vinyl roof installed by owner.

Chassis & Suspension:

Front suspension has TRZ upper/lower control arms and AFCO double adjustable shocks.

Rear suspension has Calvert split mono leafsprings and Calvert traction bars with Menscer double adjustable shocks.

Engine:

4467 ci small block Chevy. Dart tall deck raised cam block. Erson solid roller 807 in/765 ex lift, 284 in/298 @ .050 112 lobe separation. Brodix -12 15 degree cylinder heads Jesel

1.7 shaft mount rocker arms. Moroso 4 vane vacuum pump. Fuel used is VP Q16.

Rotating Assembly:

Callies Dragonslayer crank, 4.250 stroke Oliver billet rods 6.200”, ATI balancer.

Induction:

Brodix HV1209 intake manifold, ported by Bob Hartsock, Bob Book carburetor 1250 cfm.

Power Adder:

Naturally aspirated.

Electronics:

MSD 7AL2 ignition box, MSD billet distributor, MSD HVCII coil.

Transmission & Converter:

TH350 fully rollerized, PTC 8” 5500 stall converter.

Rear Differential:

GM 8.5 bolt rear, Moser 33 spline axles, Moser spool, C-clip eliminators, Motive 4.33 gears.

Brakes:

Aftermarket front disc brakes, stock drum brakes on the rear.

Tires & Wheels:

Mickey Thompson Sportsman tires up front, Mickey Thompson 295-65-15 Drag Radials on the rear.

Interior:

Autometer carbon fiber gauges. Tach, oil pressure, water temp and vacuum. Hurst Quarter Stick shifter. RJS safety belts and full face helmet, Simpson double driving jacket and pants, RJS driving gloves.

Best ET & MPH:

8.86 at 151 mph, 1.24 – 60 ft, foot braking

Most Unique Feature(s):

I think it is unique running 8’s with a naturally aspirated big inch small block when everyone will build a big block.

Reason For Build:

I always wanted a Nova and found mine when I was a kid. It was a good father/son project.

Build Timeline:

I’ve owned this car for 27 years. It’s been one big never ending project There’s always things I am working on or changing.

Most Memorable Experience(s):

The first time the car ran 8’s. Also when I put the car up on the rear bumper in 2023. It took a year to fix the car to be ready to race again.

Thanks to:

Bob Meshey from Waycool Rodshop for doing the chassis and cage work. Pete Teasdale and his son Corey for doing the engine work. My Dad and my girlfriend Sarah for the help.

You will usually see a big block or small block with nitrous or some type of pressurized assistance powering a Chevy muscle car, but not under the hood of Justin Rowe’s Nova. He gets it done with a sizeable small block working all on its own. 8-second quarter-mile hits are a regular occurrence.

Surprisingly, rather than a 9-inch Ford rearend, there is an 8.5-inch General Motors unit that has been fitted with Moser Engineering 33-spline axles, a Moser spool, C-clip eliminators, and Motive Gears 4.33:1 ring and pinion pairing.

An autobody painter and body man with 16 years of experience under his belt, Rowe saved time, money, and work by opting for a vinyl wrap on his Nova when it came to finishing the exterior of the classic muscle machine.

Rowe stretched the white vinyl over the Nova’s body and also installed the black vinyl top. The Nova’s interior only has the essentials, that include a pair of lightweight racing bucket seats with RJS harnesses, a few Auto Meter gauges, and a

Hurst quarter stick shifter. Bob Meshey of Waycool Rod Shop handled the roll cage installation and chassis setup on the Calvert Racing split mono-leaf springs with Caltracs and Menscer Motorsports double-adjustable rear shocks.

To keep the factory muscle car feel alive in the Nova, a number of factory parts remain inside the cockpit, including the dash, door panels and interior trim. Justin opted for a pair of racing seats and traditional gauges to keep tabs on things and the cage work was completed by Bob Meshey of Waycool Rod Shop. He shifts a fully rollerized TH350 transmission through a tried, tested and true Hurst Quarter Stick shifter.

The front suspension was upgraded with TRZ upper and lower control arms and AFCO double-adjustable shocks. Weld Aluma Star wheels are wrapped in Mickey Thompson rubber, with Sportsman front runners and 295/65-15 drag radials in the rear, and Rowe upgraded the front brakes to an aftermarket disc setup, while the factory rear drum brake setup remains aft.

While Rowe does occasionally put street miles on his Nova, the track is where its most at home and there it has charged to a best quarter-mile elapsed time of 8.86 at 151 mph with a 1.24-seconf 60-ft time. And, as we said, the Nova does this without the assistance of any outside help to the small block.

The Original Patented CalTracs Traction System

Complete bolt on system: no mods,

Keeps axle from rotating, maintains pinion angle

Eliminates spring wrap up

Pre-load adjustability

Durable powder coated finish

Detailed Illustrated Installation Guide

Custom sets available,

“I always wanted a Nova and found mine when I was a kid,” Rowe said. “It was a good father/son project and I think it is unique running 8s with a naturally aspirated, big-inch smallblock when everyone will build a big-block.” Rowe noted his most memorable moments in the Chevy thus far having been when he first ran 8s with it, and when he stood it on its rear bumper in 2023.

“It bent all four tubular control arms and other steering parts,” Rowe explained. “It smashed the oil pan and four connecting rod bolts got into the windage tray. It smashed the transmission pan, it bent both front wheels and they would not hold air anymore, and the headers were also smashed flat on the bottom. It also bent the front shocks too. The engine was then freshened up and new rods

were put back in. I bought AFCO double-adjustable front shocks and added front-end limiters so it didn’t have so much front-end travel. I also added some weight up front.”

The damage was so catastrophic that it took Rowe a year to get the Nova’s all muscle hustle back in racing form, and it’s running better than ever.

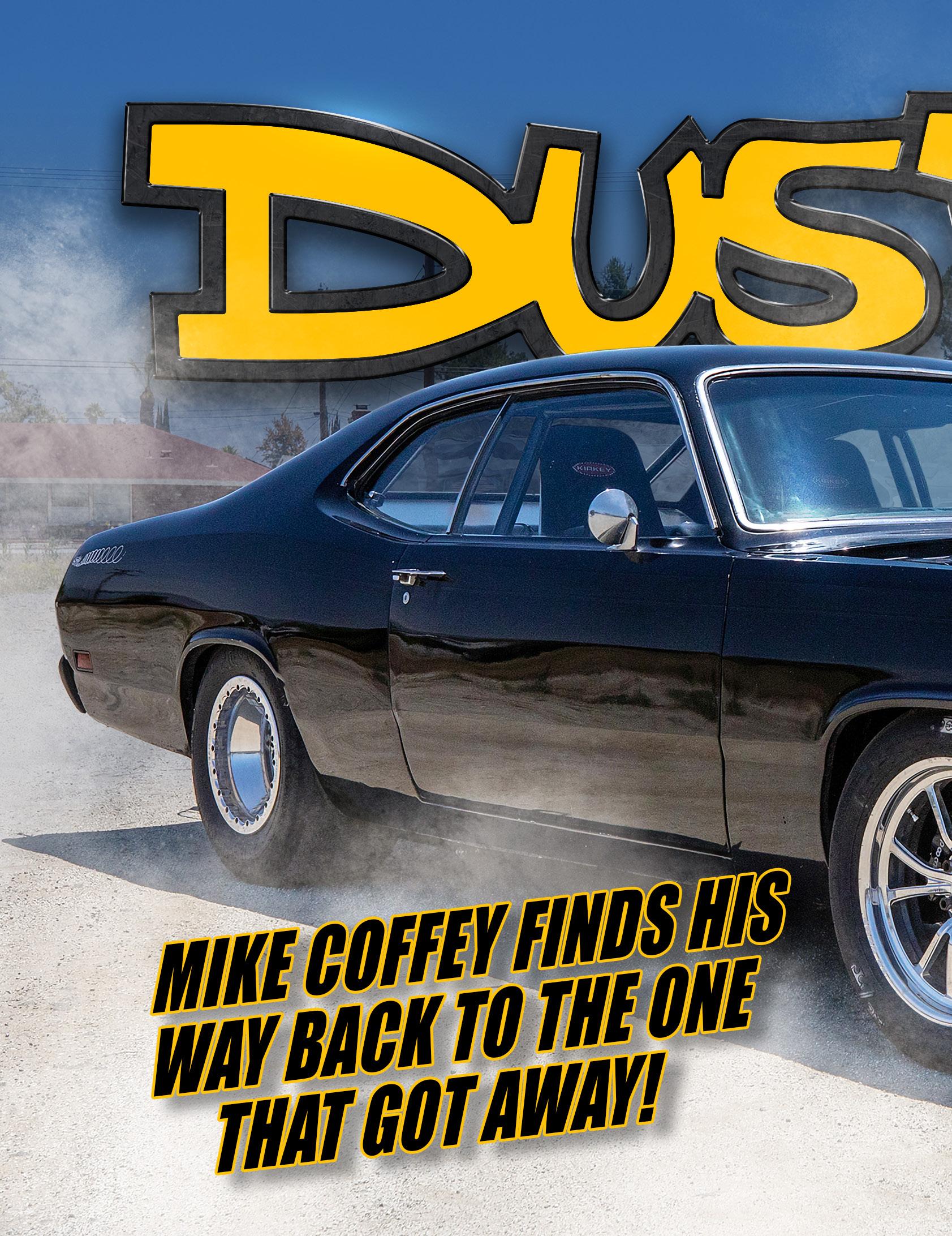

By the time we hit middle age, we often begin thinking about yesteryear and reliving the days of our youth...

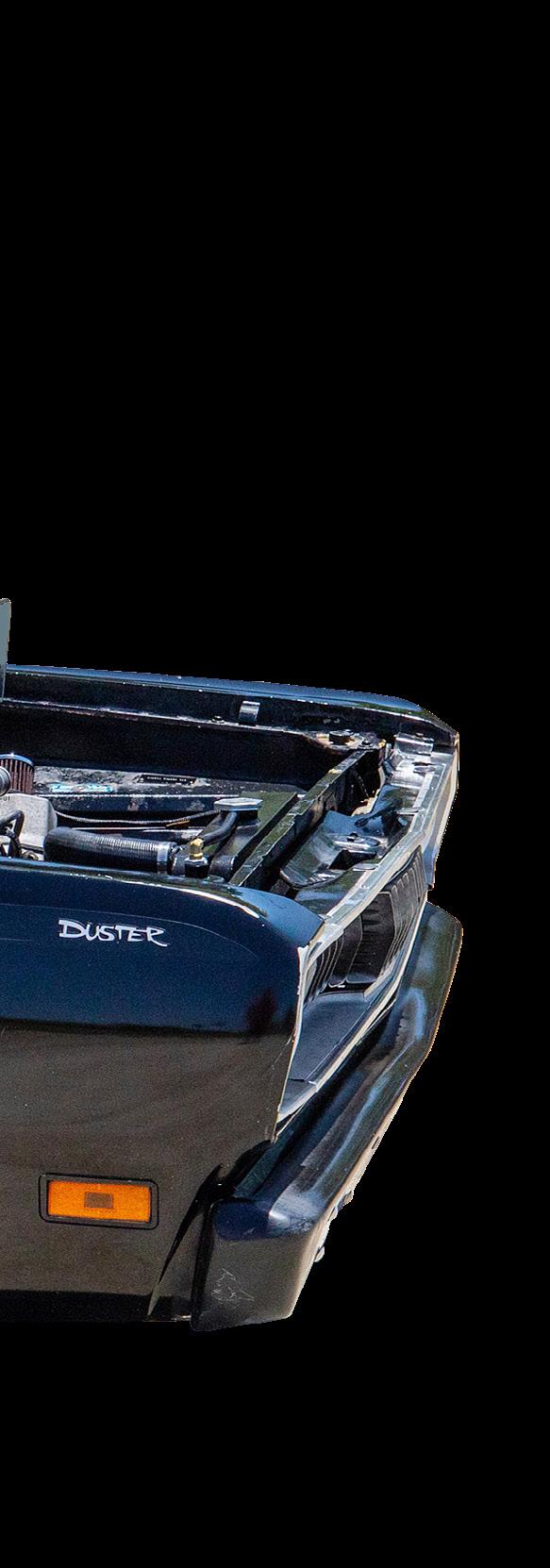

This survivor 1971 Plymouth Duster boasts an all steel body with composite bumpers. It was painted way back in the late 1970s (before a lot of RPM readers were even born) and looks the part that Coffey wants it to – a stockish street sleeper. The perfect persona for no-time strip action.

Sometimes those thoughts involve a car we once owned, and for Hemet, California’s Mike Coffey, that was a 1970 Plymouth Duster that he sold to help finance the purchase of a home. “I always felt like I had unfinished business with it,” Coffey said of his Plymouth, “and there was a lot I had done that I wanted to do differently.”

Now 48, Coffey grew up around cars and racing and began attending street races at the age of 15.

“We had a pretty hot street scene here in Hemet. We would get cars weekly from San Diego, Los Angeles, Ontario, Bakersfield, and even Arizona.”

A bunch of suspension work is responsible for the Duster’s level stance and performance and includes an RMS AlterKation front suspension with K-member and a Funkhouser Race Carsbuilt rear setup that included Calvert Racing springs, CalTrac bars and sliders, and a pair of Viking adjustable shocks.

...I could never make up my mind if I wanted a drag car, street car, or something in between...

Mike Coffey

His first car was a 1974 Plymouth Duster with a 340ci engine, and over the next 15 years, Coffey acquired more Mopars. During that time, he also took a few detours that led him to performance boats and sand drag racing, but about 3 years ago, he decided he wanted to get back into drag racing and find something to run smalltire, no prep races with on pump gas. While his 1971 Hemi Barracuda, 1971 Dodge Challenger, and 1966 A100 Dodge van didn’t fit the bill, the 1971 Plymouth Duster

he had picked up as a side project five years prior turned out to be the perfect platform.

“The last car I had raced was a black ‘70 Duster, so I had a soft spot for it immediately when I saw the ad on Craigslist,” Coffey recalled. Originally black in color and equipped with a 225ci slant-six engine, 904 TorqueFlite transmission and 7 ¼ rearend, the Duster received numerous other drivetrain combinations before ever hitting the pavement.

Plated and fully street legal is one of Coffey’s favourite parts of the build. “The Duster is as ‘all in one’ as possible; a No Prep car that can go rounds, or drive it on the street on pump gas. I did all I could to keep it not only a sleeper, but functional as a street car. All lights work, it’s truly street legal, registered and insured.” - Mike Coffey -

“I

could never make up my mind if I wanted a drag car, street car, or something in between,” Coffey explained.

forged pistons. The cylinder heads are off-the-shelf Indy SR pieces with Manley Performance valves and springs, Harland Sharp roller rockers,

NOT going for coffee!

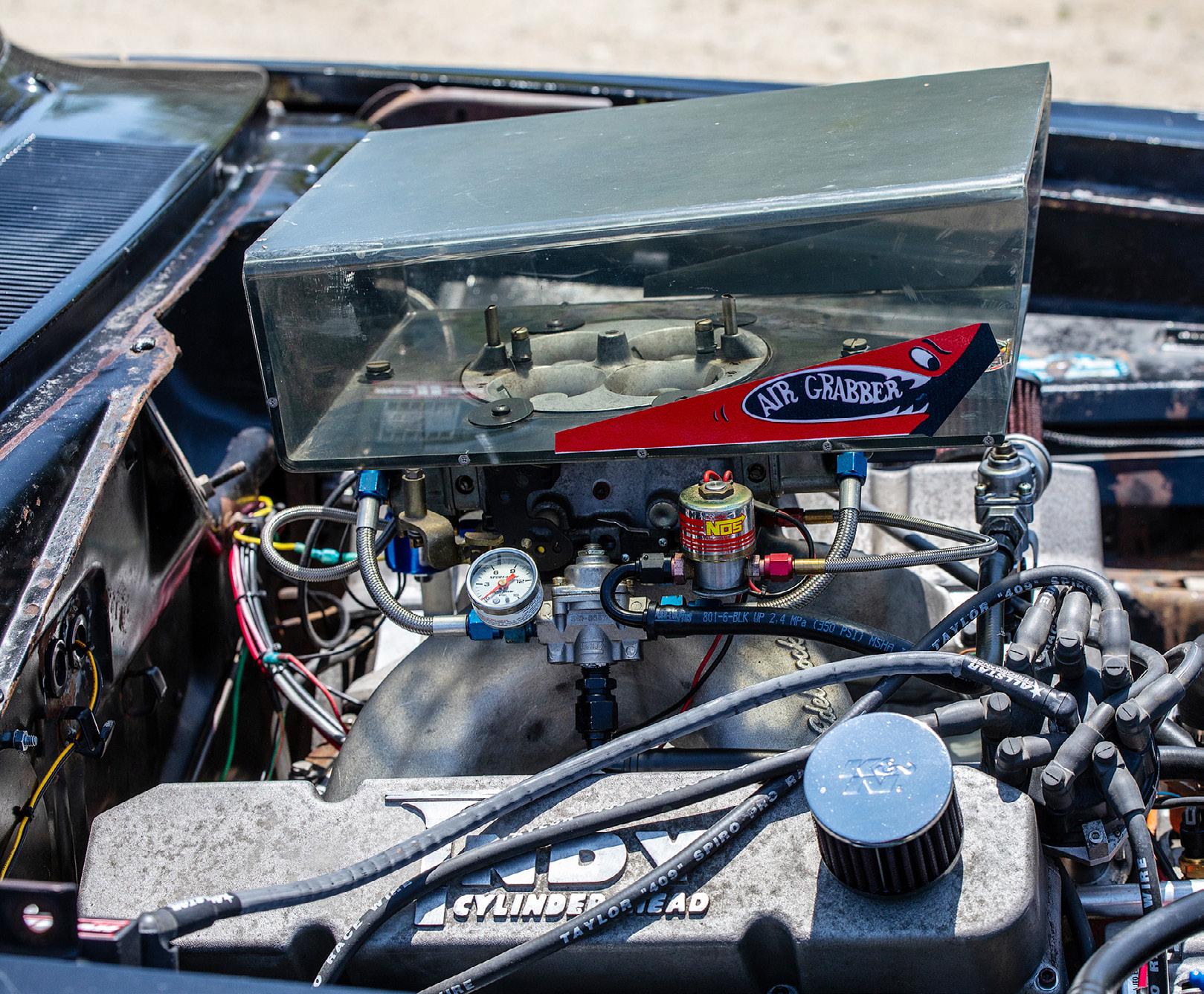

A 496 cubic-inch Mopar mill was built around a stock 440 block. An Eagle 4.150-inch-stroke crankshaft swings Eagle H-beam connecting rods pinned to Ross forged nitrous-spec pistons. Indy SR heads were equipped with Manley Performance valves and springs, Harland Sharp roller rockers, and Schneider push rods. An Isky hydraulic roller camshaft was spec’d for the project and the compression ratio is a pump-gas-friendly 10:1.

On top of the big beast of an engine is an Edelbrock Super Victor intake manifold with a Holley 1050 HP Dominator carburetor with a Nitrous Oxide Systems Big Shot plate sandwiched in between. A MagnaFuel 500 fuel pump and regulator draw from a 12-gallon fuel cell to provide fuel and Coffey went with an MSD billet distributor, MSD coil, and MSD Grid to provide the ignition source.

Sandwiched between the high rise Edelbrock Super Victor intake and Holley 1050 HP Dominator carb is an NOS Big Shot nitrous plate. Plans are to go with a direct port system in the near future and use the plate as a “scramble” system when needed.

Body & Paint:

All steel aside from bumpers, Re-painted in the late 70s in its original black. Added reproduction “340” Duster side stripes.

Chassis Modifications:

Stock rear wheel wells and sliders and leaf springs relocated by Slims Fab. The Chromoly roll cage, rear suspension, shock mounts, shifter stand, removable chute bracket all done by Funkhouser Race cars.

Suspension:

Front suspension is an “Alterkation” by RMS, consists of a custom K-member, Flaming River Mustang II rack and pinion steering, Mustang II style spindles, custom upper and lower arms, and Viking Coilovers.

Rear suspension is Calvert Racing leaf springs (1” drop) Calvert Cal-Trac bars, Calvert sliders. Adjustable spring plates, Antiroll bar with billet ends and shock mounts all from Funkhouser Race cars. Triple adjustable Viking shocks.

Engine:

496-inch Mopar based on a stock 1978 440 engine block with billet main caps. The Camshaft is an Isky hydraulic roller.

Rotating Assembly:

Eagle 4.150” crank and H beam rods, Ross forged pistons (10-1 compression).

Cylinder Heads:

Out of the box Indy SR cylinder heads, stainless Manley valves, Manley springs, Harland Sharp Roller rockers, Schneider push rods.

Induction & Fuel Delivery:

Edelbrock Super Victor intake, Holley 1050 HP

Dominator carburetor. Magnafuel 500 fuel pump and regulator, 12 gallon fuel cell.

Electronics:

MSD billet distributor, MSD coil, MSD Grid.

Power Adder:

NOS Big Shot system, currently with a 200 shot. Future upgrades will be a Fogger system with the plate as a “scramble”.

Transmission:

Powerglide by Mike’s Transmissions. JW Ultrabell and Flexplate, Trans brake, TCI pan, PTC 10” billet torque converter.

Rear End:

Aftermarket Dana 60, gun-drilled 40 spline axles with lightened flanges, spool, 3.55 Richmond Gears, 5/8 studs.

Brakes:

Mopar Performance master cylinder, aftermarket front rotors are slotted and cross drilled, rears are Pro Series with slotted rotors.

Tires & Wheels:

Front 17” RC comp Torx wheels, with Mickey Thompson 26x4.5 ET Drag tires, Rears are RC Comp Torx, double beadlock, 15x12. Tires are Hoosier 28x10.5 C07 compound.

Interior:

Holley EFI 12.3 Pro dash, MPI steering wheel on a Twisted Metal column, PPP shifter with air, Motion CO2 bottle and gauges, Kirkey race seats, Simpson harnesses, Moroso switch panel, Stroud chute w/ Motion release handle and cable. Stock back seat, dash, carpet, headliner, door panels, etc.

ET & MPH:

It’s an N/T car, but I will say it runs 5’s on a no prepped surface.

Most Unique Feature(s):

I think what makes it unique is that it’s as “all in one” as possible; a No prep car that can go rounds, or drive it on the street on pump gas. I did all I could to keep it not only a sleeper, but functional as a street car. All lights work, truly street legal, registered and insured.

Build Timeline:

Although it was over the course of 8 years, actual current build was about 3 years.

Most Memorable Experience(s):

Probably my first actual No Prep race at Barona, put on by Jerry Garrison. I Beat some full blown race cars, went a few rounds, had my sons helping and it was just a good time.

Thanks To:

Slims Fab. Matt Funkhouser (Funkhouser RaceCars) My Sons, (Michael Coffey, Brent Flatt, Korey Flatt.) My wife for being so understanding. Also Thanks to my Dad, Butch Lightfeldt and Ted Evans for getting me racing and into Mopars in the first place!

Front and rear suspensions were heavily modified to give the Duster proper track manners under the influence of the nitrous’d big block. Mustang II style front spindles and rack were used up front with the Alterkation parts and out back Slims Fab relocated the leaf spring perches and sliders to allow for a wider wheel/tire package, and a Funkhouser Race Cars anti-roll bar with billet ends was also installed.

Obviously, a stock TorqueFlite automatic transmission isn’t going to last long with an engine combination like that, so Coffey upgraded the original transmission to a

stock case Powerglide by Mike’s Transmissions. It has been fitted with a JW Ultrabell and flex plate, a transbrake, a TCI pan, and a PTC 10-inch billet torque converter.

Still a stick car, Evans relies on a G-Force g101a trans for transferring the nitroused ponies rearward to the fortified factory 8.8 rearend.

A simple interior is filled with a stock dash, carpet, door panels and trim, headliner and rear seat. Lightweight race seats replace the original bench up front and an interactive 12.3 Pro Dash keeps track of vital signs. An aftermarket column and steering wheel were used and a PPP shifter is air actuated.

The last stop on the drivetrain is a stout aftermarket Dana 60 stuffed with gundrilled, 40-spline axles with lightened flanges, a spool, 3.55 Richmond Gears, and 5/8-inch wheel studs.

Coffey noted that the Duster received a re-paint in the late ‘70s and it was still in

good enough condition to meet the “patina” style of build he had in mind. It didn’t have to be perfect, as he didn’t want the stress of having something in mint condition. It just needed to look nice, and Coffey added reproduction 340 decals for a bit of factory flavor.

Beneath the all-steel-bodied and fiberglass bumper-equipped skin you’ll find an RMS AlterKation front suspension that includes a custom K-member, a Flaming River rack and pinion steering system, Mustang II-style spindles, upper and lower control arms, and a pair of Viking shocks.

Coffey had Funkhouser Race Cars install the chromoly roll cage, rear suspension, shock mounts, shifter stand, and removable parachute bracket.

It’s pretty rare to see a seventies muscle car with original steel and even more rare to see one on the track that still has factory wheel wells and a rear seat. Funkhouser Race Cars installed the chromoly roll cage that was routed to allow use of the back seat.

The rear leaf spring suspension system was upgraded with Calvert Racing springs, CalTrac bars and sliders, and another pair of Viking adjustable shocks. To keep the Duster dancing down track properly, Coffey utilizes a Funkhouser Race Cars antiroll bar with billet ends. While the rear wheel wells are still stock, Slims Fab relocated the leaf spring perches and sliders to allow for a wider wheel/tire package.

Said rolling stock consists of RC Components Torx wheels measuring 17-inches in diameter up front and 15x12 inches out back. Mickey Thompson 26x4.5 ET Drag tires keep the Duster steering straight and Coffey relies on double bead locks and Hoosier 28x10.5 tires to stick the power to the pavement.

The Duster’s roomy trunk provides more than enough room for the nitrous bottle, battery and MagnaFuel 500 fuel pump and regulator that draw from a 12-gallon fuel cell.

RC Components Torx wheels were used front and back with 17s on the front skinned by Mickey T and Hossier28x10.5s beadlocked to 15x12s out back.

Behind the billet hoops you’ll find Dyna Light front disc brakes and Pro Series disc brakes in the rear.

The cockpit is fully upholstered, but spartan in appearance. A Holley EFI 12.3 Pro Dash concentrates engine information in one location, which is right behind the MPI steering wheel that is mounted on a Twisted Metal column. Transmission shifting is accomplished through the use of a Precision Performance Products airpowered shifter and a Motion CO2 bottle and gauges. The factory front seating is long gone, having been replaced by a pair of lightweight race seats wrapped with Simpson Harnesses. There is also a Moroso switch panel for basic operations and a Motion release handle and cable to launch the Stroud parachute.

With Coffey’s Duster being a noprep competitor, it’s no surprise that he is tight-lipped on exact elapsed times and speeds the Plymouth is capable of.

Mike Coffey

That said, he admitted it will run 5s on a no-prepped surface.

“I think what makes it unique is that it’s as ‘all in one’ as possible,” Coffey noted. “It’s a no-prep car that can go rounds, or drive it on the street on pump gas. I did all I could to keep it not only a sleeper, but functional as a street car. All lights work, it’s streetlegal, registered, and insured.”

Coffey spent about three years putting the Duster together in this configuration, and it seems he finally got his closure on what he could have done with his first car so long ago.

“Everything on this car was done my way, and how I wanted it,” Coffey said. His favorite memory with the car thus far happened at the first no-prep race at Barona where, along with help from his sons, he was able to “beat some full-blown race cars” and go a few rounds. When he gets to add the direct-port nitrous system he’s been wanting, we imagine things will get even more interesting.

Just when he thought he was out, Grant Guthrie was pulled back into racing after spotting a 1965 Chevy C10 that was collecting dust in a barn...

Guthrie’s first automobile was a 1968 Chevy step-side pickup that he shoehorned a 454 big-block and Turbo 400 three-speed transmission into. At just 16 years of age, he started bracket racing at his local track and messing around on the street here and there.

“At 18 or 19, I started running divisional points races and national events, and driving for a number of people in NHRA Super Stock, Stock, Super Gas, and Super Comp,” Guthrie explained. By 2010, he moved on from class racing and joined the heads-up grudge racing world.

This slick looking 1965 Chevy C10 was found literally on a back road in Georgia in the barn of the original owner. Once in his care, Grant Guthrie returned the truck to street duty for a few years and then decided he wanted to build the world’s fastest full size truck. The cab is still all steel and remaining body parts are carbon fiber panels by Gordon Nelson at Harry Glass. The paint was completed by owner.

In that category he competed behind the wheel of a Chevy Nova he named Dillinger, and later in a 1970 ½ Camaro he named Geronimo.

Four years later, Guthrie got out of racing altogether. Two years passed by before he happened to come across the Chevy truck that would spur his interest once again.

“I was driving down a dirt road in Georgia and saw a 1965 C10 sitting under a barn,” Guthrie recalled. “I stopped and was able to talk the 87-year-old tobacco farmer, who bought it new, into letting me buy it.”

A custom carbon hood with cowl scoop and twin air inlets for the turbochargers was constructed to cover the Hemi hiding between the frame rails underneath it. A massive wing hangs off the rear of the C10 with twin parachutes to help the custom disc brakes slow things down after a 3-second hit.

It sounded like the old timer didn’t really want to part with the old farm truck, but after a good bit of convincing, Guthrie was able to take the truck home.

He cruised it on the street for about a year before he figured out what he really wanted to do with it.

“One day I said, ‘I’m going to make this the fastest fullsize truck in the world,’” Guthrie explained. “It was a three-year build and on April 25, 2020, it became the fastest full-size truck in the world by far.”

...With a name like Warpath, Guthrie’s truck had to have serious hardware to go to battle with...

As you might have surmised from his previous two hot rods, Guthrie is of Native America decent and suitably named his new ride, “Warpath.” Likewise, the 1909 number on Warpath was chosen as it is the year that Geronimo died.

With a name like Warpath, Guthrie’s truck had to have serious hardware to go to battle with. The plan of attack began with a 25.1 SFI-certified chassis built by Jeff Miller of Bumblebee Racing in Gilbert, South Carolina.

Custom struts support the front end of the rails while a four-link suspension with an anti-roll bar and QA1 Pro Mod shocks do their best to support the Fab9 rearend that has been fitted with an NRC Motorsports-built third member with 3.90 gears and gun-drilled axles.

Guthrie credits “NRC Bob for the custom 9-inch rear end with gun-drilled axles and 3.90 gear and Jeff Miller of Bumblebee Racing for the trick chassis work. Suspension wise, a custom 4-link coilover setup with anti-roll bar was used out back and a strut setup with rack and pinion steering controls things up front.

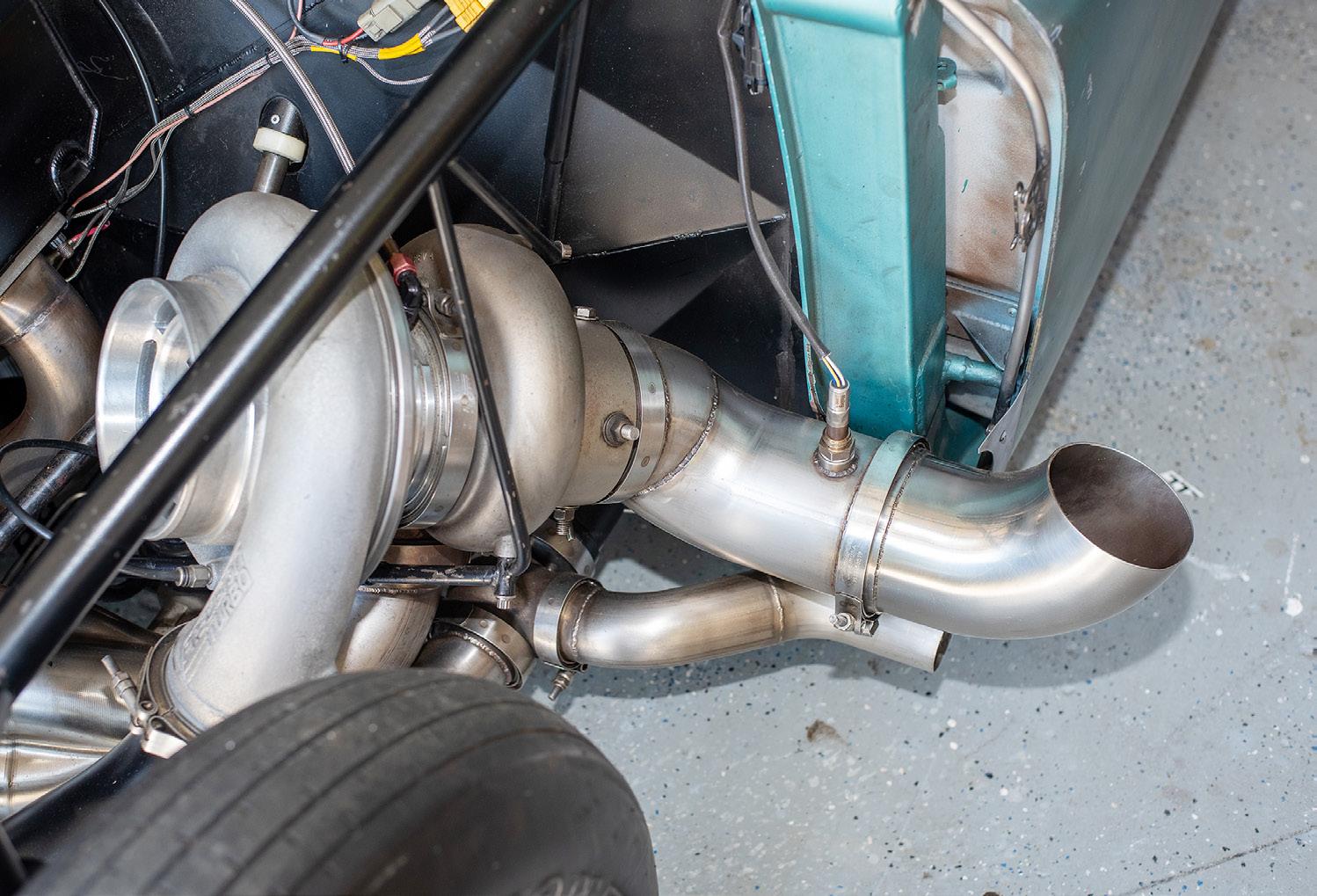

A pair of identical twins, being two 106mm turbocharges, were plumbed into the mix to assure Guthrie he could reach his lofty goals.

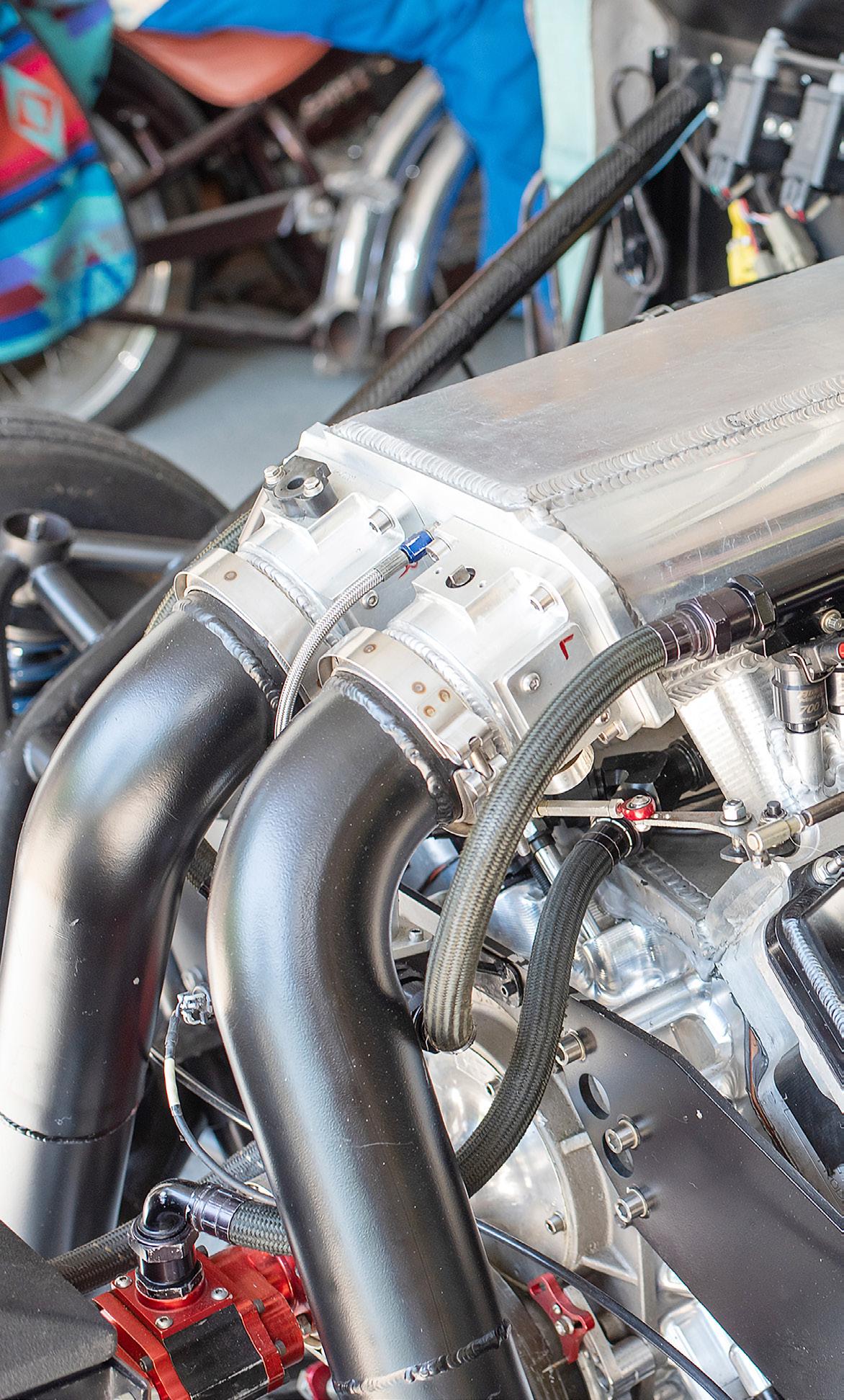

Between the frame rails you’ll find a big, bad, Brad Anderson Enterprises (BAE) 521 cubic-inch Hemi V-8 that’s been stuffed with a Bryant crankshaft, GRP connecting rods, and JE pistons wrapped with BAE piston rings. The cylinder heads are BA-5 pieces that have been fortified with BAE springs, push rods, Titanium valves, and BAE Stage V rocker arms.

To build “the fastest truck” you need some serious power and Guthrie relies on a BAE Hemi block filled with their spec Bryant crank, GRP rods and JE pistons. Heads are Stage 5 pieces and a Hogan’s intake with Wilson throttle body top things off.

Body & Paint:

The cab is all steel, with remaining carbon fiber panels by Gordon Nelson at Harry Glass. Paint completed by owner.

Chassis:

25.1 certified chromoly chassis by Jeff Miller Bumblebee Racing, Gilbert, South Carolina.

Suspension:

Aftermarket front struts, custom 4-link coilover rear with anti-roll bar and “Pro Mod” shocks.

Engine:

The engine block is a new style block from Jeremy at BAE, 521 +100 tall

Rotating Assembly:

Bryant crank, GRP rods, JE pistons, BAE rings.

Heads:

BAE Stage 5, BAE Springs, pushrods, Titanium valves, Stage five rockers.

Induction & Fuel Delivery: Hogan’s intake, Wilson throttle body, Waterman pump.

Power adder:

Precision twin 106mm turbos.

Transmission:

M&M 2 speed 400 transmission, ProTorque converter.

Rear Differential:

“NRC Bob” custom 9 inch, gun drilled axles, 3.90 gear.

Interior:

Holley EFI dash

Precision shifter

Simpson safety equipment

Carbon fiber race seat

ET:

“Let’s just say somewhere in the 3’s lol”

Sponsors: BAE

Jack French Optimizer Fuel Injectors

Gordon Nelson -Hairy Glass

Mickey Thompson

Precision Turbo

Melvin Horne-Xtreme Fabrication

Hemi Parts King

Jason Archer

NRC Bob

Holly EFI

Andy Pinkerton, Skippy‘s Performance

Special Thanks:

Jason Archer

Willie Keith Howze

Melvin Horne

Jeff Miller

Patrick Miller

Andy Pinkerton

Mark Mickey

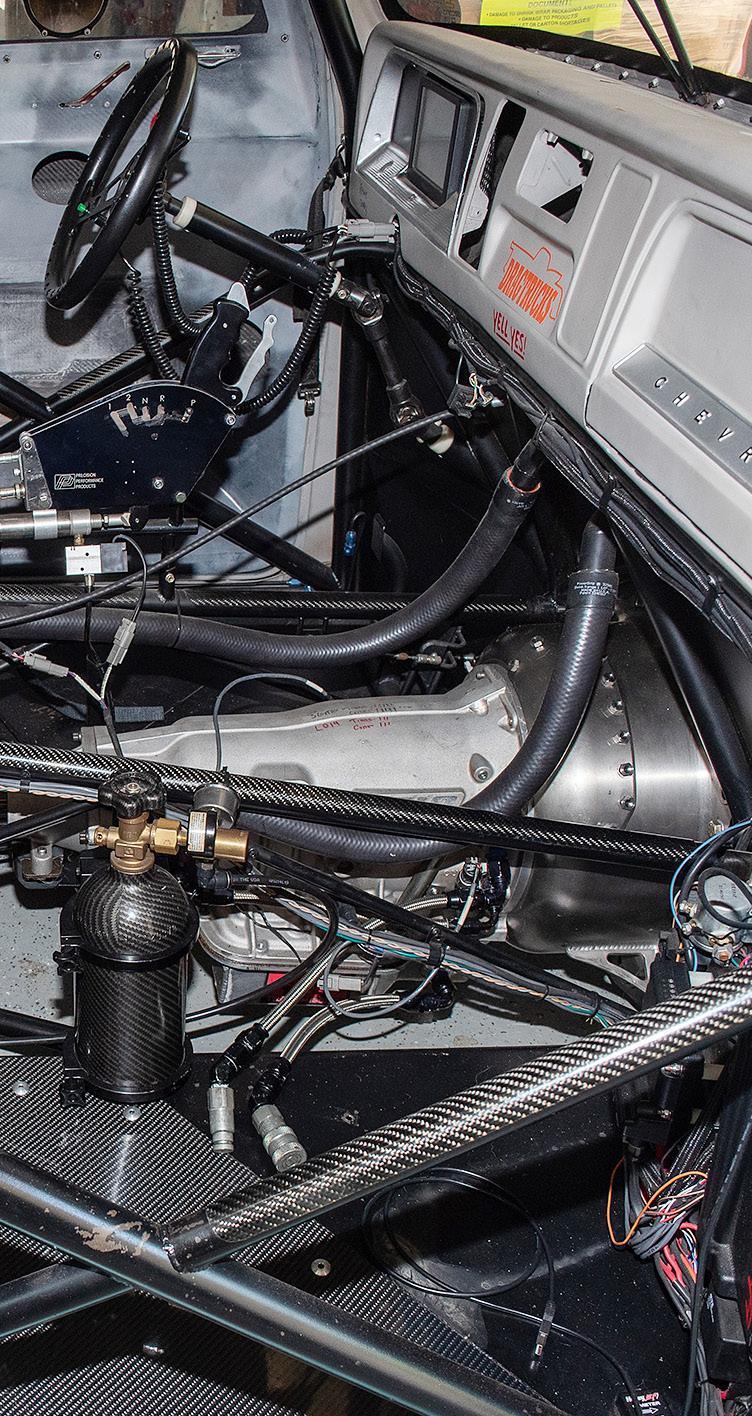

Inside the cockpit of the C10, the extensive bars of the chromoly cage were built around the confines of the factory cab and dash with a single digital display mounted behind the billet steering wheel to keep track of things before, during and after each run.

With hardware like that, you know there has to be something good filling those big combustion chambers and Warpath packs a pair of 106mm turbochargers that pressurize the Hogan’s Racing Manifolds fabricated aluminum intake that wears a Wilson Manifolds throttle body. Guthrie has a Holley EFI system managing

engine functions, ensuring the fuel from the Waterman pump and Billet Atomizer 3 700pph fuel injectors mixes perfectly with the compressed atmosphere for optimal performance.

Backing the beast of an engine is a near bullet proof, two-speed Turbo 400 with a ProTorque converter.

A highly modified 2-speed TH400-based transmission is the center of attention between the twin chassis rails and is shifted via a Precision shifter.

Guthrie straps in the Quarter-max Racing carbon fiber racing seat to shift the Precision Performance Products shifter, and uses just a single digital dash to view the powerplant’s vitals.

Though a patina paint finish on a classic C10 pickup became extremely popular at least a decade

ago, the style is still a popular choice today, not to mention a truck named “Warpath” is sure to be showing some battle scars. Guthrie put down the custom paint on the steel cab that is bookended by numerous carbon fiber components from Gordon Nelson at Harry Glass.

...Warpath has proven to be a formidable warrior...

Rolling on Weld Racing V-Series wheels and Mickey Thompson rubber, Warpath uses custom disc brakes to slow the big box of a truck down from some rather high speeds. How high you might ask? Well, we don’t have speeds to talk about, but Guthrie said Warpath runs in the 3s.

“April 25, 2020, it was the first full-size to ever run in the 3s,” Guthrie proclaimed. “I went to the first race in February 2022 and won untested.” Guthrie followed that stellar performance with a win just a month later at

his second race with Warpath. And in November of 2022, he went home with runner up due to a sensor malfunction in the final round.

“I’ve been drag racing for 45 years,” Guthrie shared. “I always loved fast trucks.” While this author hasn’t personally verified Warpath’s 3-second timeslips, he doesn’t doubt the capability of the arsenal that Warpath charges into battle with. And with victories already in hand, Warpath has proven to be a formidable warrior.

Fast cars and drag racing are alive and well in the Middle East, including in Doha, the capital city of Qatar which is about 7,000 miles away. Middle East drag race builds tend to be unique in design, as is the case with Abdulla Al-Mansoori and his LS powered 2007 Nissan Patrol VTC.

As a Mechanical Engineer, Abdulla knows a thing or two about a thing or two and merged his passion for engineering and fabrication with his love of cars and horsepower. “I’ve been passionate about cars and racing for as long as I can remember,” he explained. “Growing up, I was always drawn to the roar of powerful engines and the thrill of highspeed competition.

What started as a fascination with street cars quickly evolved into a deep interest in performance tuning and racing. Over the years, I’ve gained hands-on experience working with different builds, learning about engine performance, suspension setups, and tuning to extract the most out of a vehicle. Now, being part of Comman-

The Nissan Patrol is a wildly popular SUV in the Middle East with amazing off-road capabilities. Abdulla Al-Mansoori set out to build his 2017 model into an LS powered drag strip warrior, which meant a complete overhaul. He did however keep the original body and added a lightweight liftoff front end.

dos Racing has taken my passion to the next level, surrounding me with like-minded individuals who push the limits of performance.”

As he gained experience in many facets of motorsports, Al-Mansoori was drawn to starting a new project for himself and went on the search for something special.

Abdulla Al-Mansoori

The Patrol now sits low to the ground, and although Al-Mansoori chose to keep the original frame over going the full chassis route in his build, his Mechanical Engineering savvy saw him incorporate some pretty cool stuff in the design.

He had no specific brand or body style in mind, but just had a feeling that once the right candidate presented itself he would instantly know it was meant to be.

“I found this Nissan Patrol completely by accident in one of the area showrooms and immediately knew it had potential to be something unique. The

Patrol is an iconic vehicle here, known for its rugged off-road capability, but I saw an opportunity to turn it into a drag racing powerhouse,” he explained. And for North Americans, the Nissan Patrol is indeed quite unique as it was never offered here, making Al-Mansoori’s build even more of an attention getter when it’s raced Stateside.

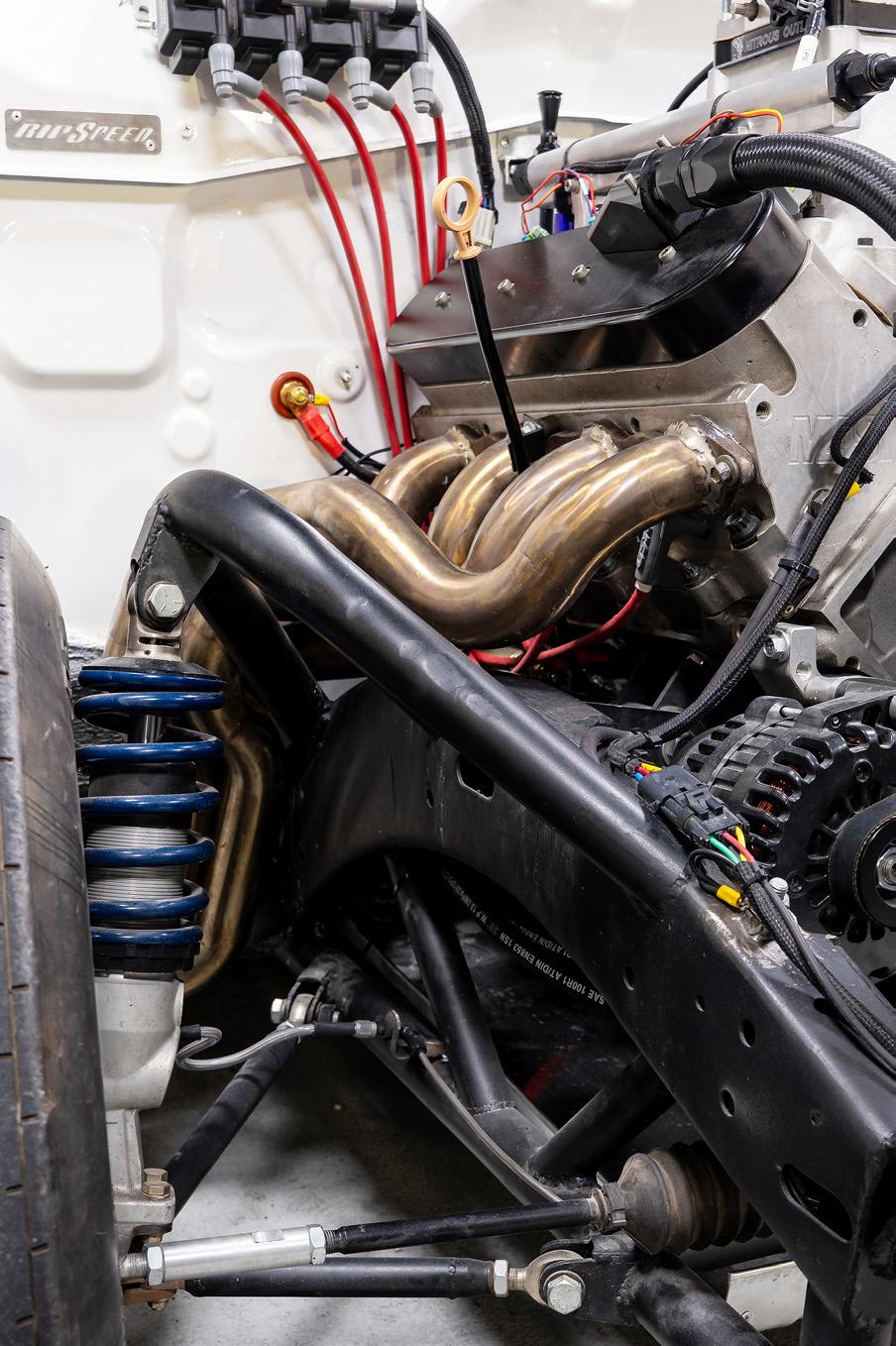

This RipSpeed-built fabricated rear end is about to be installed in the Patrol to replace the existing unit that won’t hold up once the nitrous is added.

The factory frame of the Patrol was used, so setting it up for sitting low and making hits on a drag strip meant that new ideas needed to be tested. While the upper tubes shown here are commonplace, check out the fabricated lower frame rail. Custom brakes were also used on all four corners.

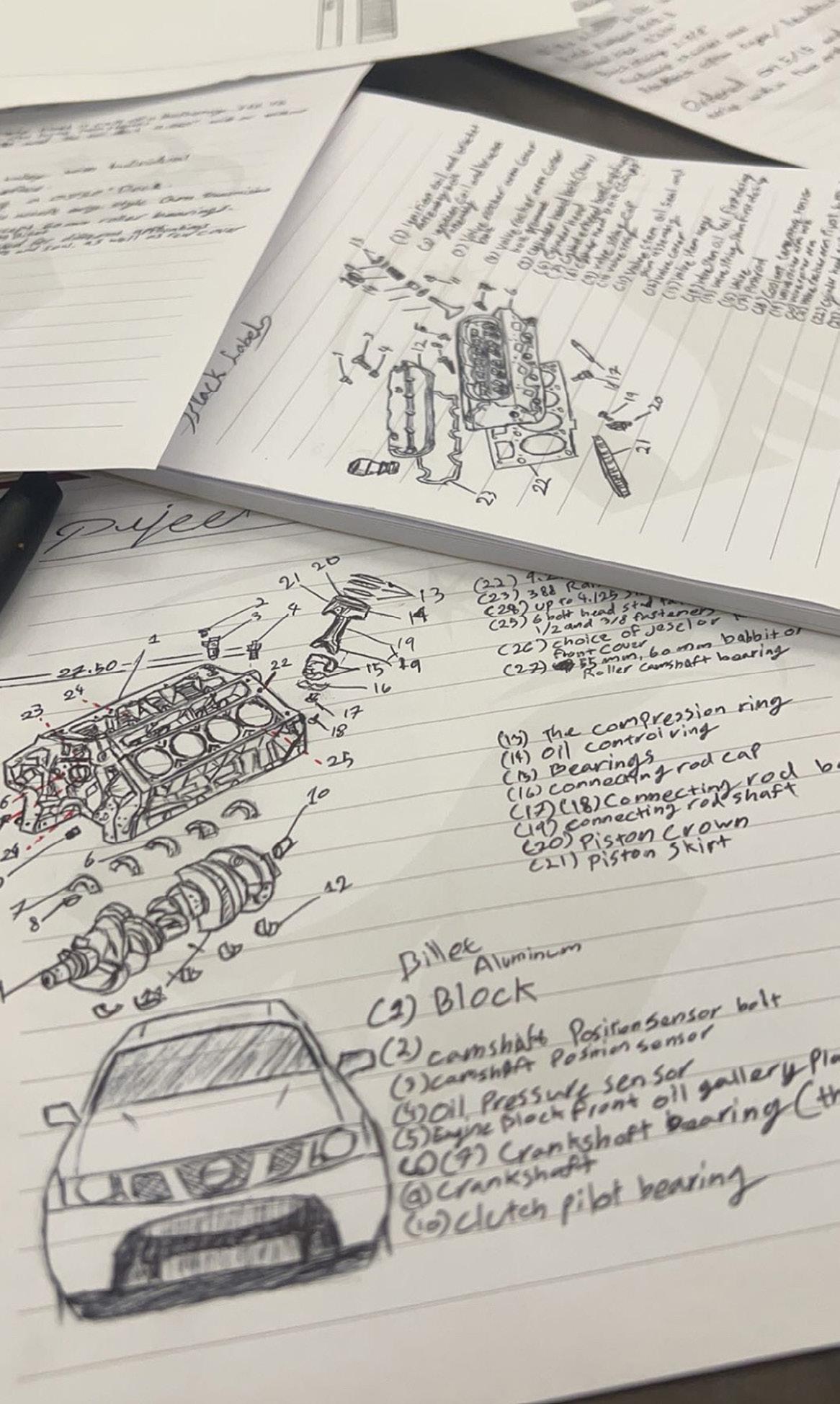

We weren’t kidding when we said that Al-Mansoori started by completely drawing the build out on paper in extensive detail. As a Mechanical Engineer it just seemed like the right thing to do.

When he first got the SUV it was completely stock, a standard daily-driver, but the plan right from the onset was never to keep it that way. Instead, Abdulla envisioned a naturally aspirated monster. “I wanted to build something that would stand out in a world dominated by turbocharged and supercharged builds.”

The Patrol was destined for the drag strip with the teardown starting as soon as it reached its new home and, as an Engineer accustomed to the details of design, Al-Mansoori started by completely drawing the build out on paper in extensive detail. He went over every single aspect of the project and began sourcing parts.

Body & Paint:

Fiberglass Nissan Patrol body with lightweight lift-off front end

Factory paint.

Chassis Modifications:

Reinforced factory chassis.

Custom engine and transmission mounts for optimal weight distribution.

Suspension:

Front - Strut bodies are forged from high strength & lightweight 2000 series aluminum alloy

Stainless steel Camaro spindle shafts.

Custom tubular control arms.

Double adjustable struts.

Rear – Was ladder bar/coilover, currently being upgraded to 4-link.

Engine:

LSR tall deck block. 455 Cubic inches with 12:1 compression ratio.

Custom high-lift cam, Callies Magnum crank, Wiseco custom forged pistons, Callies Ultra H-Beam rods. Cylinder heads are MAST Black Label CNC ported with Titanium valves. CID Air Strike intake with Wilson throttle body and 1600cc injectors.

Ignition:

MSD

Power Adder:

Naturally aspirated making over 800 HP. Currently installing a nitrous plate system.

Transmission:

Custom TH400 3-speed automatic.

Brakes & Hubs:

4 piston calipers, one piece forged slotted steel rotors, soft metallic brake pads, billet aluminum caliper mounts, billet hubs. 1/2” -20 screw-in wheel studs.

Timken bearings and races.

Tires & Wheels:

Holeshot wheels all around. 29 x 10.5 tires. Type and size will vary depending on racing.

Interior:

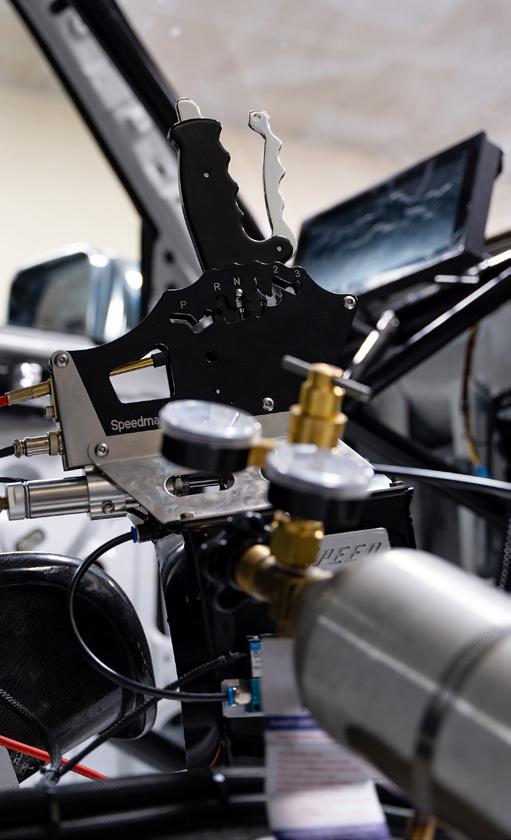

Full roll cage, fire suppression system, Holley dash, Speedmaster shifter, V2 carbon fiber racing bucket seat with multi-point harness.

Unique Features:

This Nissan Patrol is unlike anything most people have seen at the drag strip. The combination of an SUV body with a high horsepower LS engine.

Reason For Building:

I wanted to push the boundaries of what’s possible with a naturally aspirated engine that relied purely on mechanical efficiency, precision tuning, and raw horsepower. The Nissan Patrol was the perfect platform for this challenge. We will be adding nitrous to push the build even further.

Most Memorable Experience:

After the first full power launch in the Patrol the crowd went wild, and the reactions were priceless. It was a defining moment for the build and one that I’ll never forget.

Thanks To: RipSpeed Team – Engine build and tuning.

Top Performance – Sponsorship support. Lucas Oil – Providing high-performance lubrication for the build.

Plans for the Nissan are to continue to race regularly in the Arab Drag Racing League as well as at special events in the United States.

You might notice a nitrous plate sitting on top of the Air Strike intake, hiding under the throttle body. Nitrous oxide will be introduced to the engine this year with hopes of 7-second ¼-mile passes.

Taking just one year to complete, the build process was intense to say the least. “The most complicated part was transforming the frame and suspension from an off-road setup into a fully modified drag racing system. The Nissan Patrol was never designed for this type of performance, so every aspect of the suspension had to be reworked, from weight transfer and traction to stability at high speeds.” Since he would be using the factory frame over

building a complete tube chassis, reinforcing the original platform was first on the list. Al-Mansoori also realized that once completed the Patrol suspension needed adjustability. “Dialing in the geometry, and ensuring the suspension could handle the power while launching hard off the line was a major challenge. Every modification had to be carefully planned to turn an SUV into a competitive race machine,” he added.

The interface between the EFI system and a laptop makes setup and tuning very efficient.

The factory fiberglass Nissan Patrol body tub was used with various lightweight modifications for improved aerodynamics on the boxy shape, including a lift-off front end. The factory paint color was also kept with some subtle accents for appearance.

The factory front frame section was retained and a complete tubular lower section was fabricated along with upper bars to accept the new design. Front strut bodies are forged from high strength lightweight 2000 series aluminum alloy and double adjustable struts were used along with custom rack and pinion steering and tubular control arms. Likewise, the rear frame was modified to accept the custom adjustable ladder bar/coilover suspension, soon to changed out to a 4-link setup.

Qatar’s Al-Monsoori Nissan Patrol - 455 Cubic Inches of Engineered Power!

Once completed, the Patrol hit the strip and with a bit of tuning hit the 8-second quarter-mile ETs Al-Mansoori set out to achieve…now bring on 7-second hits!

The interior was gutted and only the necessities of drag racing were installed after the cage was fabricated. Two pedals, a steering column with quick release wheel, a single carbon fiber seat, Speedmaster shifter, fire suppression system and large interactive display make up the bulk of the equipment inside the Patrol.

Under the hood, a Chevy LS motor was chosen to slide between the framerails and provide motivation for the Nissan.

An LS-R tall deck block was machined and filled with a Callies Magnum forged crank, Wiseco pistons and Callies Ultra H-Beam rods. The final compression ratio is 12:1 and engine displacement comes in at a healthy 455 cubes. The camshaft was spec’d for naturally aspirated action and CNC-ported MAST Black Label heads were studded in place. A CID Air Strike intake manifold is equipped with 1600cc injectors and a Wilson throttle body tops things off. You might also notice a nitrous plate sitting under the throttle body. After reaching their naturally aspirated goals of 8-second ETs this season, nitrous will be introduced to the program shortly with goals of 7-second passes.

A heavily built TH400 transmission backs up the LS and sends power rearward to a custom built differential, which is also being swapped to a RipSpeed-built fabricated 9-inch rear end. The Patrol sits on Holeshot wheels all around with various rear tires used for different applications.

“I will never forget the first full power launch in the Patrol,” Al-Mansoori continued. “As I staged, the anticipation was intense. The moment I hit the throttle, the naturally aspirated LSR roared to life, and the Patrol hooked so hard that it lifted the front wheels well off the ground. Feeling an SUV do a wheelie was absolutely surreal and it was a true testament to the power, setup, and countless hours spent perfecting every detail.”

Article first appeared in the September 2021 digital issue.

RPM MAGAZINE Reprint IN Print!

RPM MAG’s commitment to features that appeared digital-only since June 2020.

Back in 2000, (the year when the clocks would stop and world was going to end), Steve Shrader put his mind into things other than wor rying about what would happen when the calendar swapped up in the new year, he went out and bought a brand new 1999 GT Mustang.

Steve had some fun in his newly acquired ride, and like all of us became addicted to modifying it, and had some innovative ideas on how to earn the funds to pay for the mods. It is amazing how one decision or a sequence of events can take us in a direction that will change our lives, and for Steve, his life would soon become all about cars, specifically Mustangs. Shrader realized a while after the “New Edge” 1999-04 Mustang hit the streets that many true enthusiasts never had a use for the tiny back seat, so he started building rear seat deletes out of his garage, and to his surprise, that funded his new found hobby.

His next endeavor was the forming of the Yellow Mustang Registry, and it grew to over 5,000 people and he traveled all over the eastern side of the country hosting events.

Soon after, Steve quit his day job to start Shrader Performance, with “Brightmare”, his now solid performing Mustang, being the shop car. Business was going well and in 2013 a Dynojet chassis dyno was added, allowing Steve to specialize in tuning all ’99-up Mustangs.

At first, the GT sported the usual bolt-ons, but Steve soon decided to spice things up with a Vortech S-Trim supercharger. He ran this setup on the TV show Pass Time and fooled all three judges by besting their 12.0 E.T with a 10.57, and took home the cash.

Body mods to the GT are subtle and include a modified Steeda R hood cut for a ram air system to the blower. A 99-01 SVT Cobra front bumper was also installed, the rear spoiler was nixed and a Stroud chute was hung from the rear.

Almost everyone ran on pure gasoline; but Shrader had a leg up by running E-85 (despite the naysayers back then). Nowadays, virtually all street-friendly four-digit horsepower cars run it.

Brightmare is bright indeed, sporting Ford’s Yellow GT paint, and Steve has made only some minor exterior changes, the most prominent of them being the custom ram-air inlet that’s cut through the hood for the centrifugal blower to breathe better. Not just any hood would do, though, and a stock replacement Steeda R hood was sourced for the project. The facelift is finished off by a 99-01 SVT Cobra bumper. You might also notice something missing from the back of the Stang. That’s because the factory rear spoiler got the axe and a Motion Raceworks parachute mount and Stroud chute were added. Weld Racing RTS wheels reside on all four corners but aren’t the typical “big and little” style, instead Steve went a little wider in the front for drivability; after all, it does see plenty of street miles.

The owner-built 5.0 boasts forged pistons and H-beam rods swung by the factory crank. Factory heads were massaged and a GT350 intake was added along with a dual pump based fuel system delivering copious amounts of E85. The centerpiece of the build is the Vortech YSi-B centrifugal supercharger.

There’s a Coyote

275 Mickey T Radials just fit the factory setup.

17x7s were used up front and 15x10s with 275/60 Mickey Thompson radials stick the car to the track out back, but we’ll talk more about sticking a a radial tire a little later on.

The exciting part sits under the hood. The space where the ole two-valve 4.6 liter once sat is now occupied by a much

was just not an economically viable option to make power, so Shrader opted for the Coyote five liter which offered greater potential for considerably less

Steve started with a secondgeneration stock block and built from there. The rotating assembly consists of DSS forged pistons pinned to Manley H-beam rods swung by the factory crank. Coyote heads do pretty well unless it’s an all-out application; for that reason, he choose to

have some port work done by Modular Head Shop and leave the rest alone. A GT350 intake was added into the mix for higher revving power and fueling comes from a return-style system attached to an ’03 Cobra tank, sporting two fuel pumps, all of which came

Inside the GT is mostly stock with the exception of the roll bar, shifter, belt,

from Fore Innovations. 95lb DeatschWerks injectors supply ample amounts of E-85 to the Coyote and Ford Racing’s control pack for the ever-so-popular swap made the install much more straightforward.

For adding power Shrader went boosted, but unlike

many others he opted for a centrifugal supercharger over turbo and stuck with his good friends at Vortech. For the most recent iteration of Brightmare’s power he went with their YSi-B, which is a massive straight cut gear-driven setup.

A Moroso battery box is the only thing to occupy the trunk space and the beefed up 8.8 rear diff sports a CHE axle brace to reinforce the setup for those 1000whp stick shifted launches.

He “pullied down” to a 2.85 pulley and picked up an Innovators West 10% overdrive crank pulley to reach the desired boost level. A Treadstone three-core intercooler and that sicklooking ram air inlet help keep the big blower cool. A pair of 1 7/8” Kooks swap headers flow through a custom 3-inch exhaust and dumped Magnaflow mufflers.

The remainder of the driveline certainly isn’t factory, but it isn’t as crazy as one might think. Brightnmare uses a Tremec T-56 Magnum trans with no internal modifications.

Body & Paint:

All original paint, rear spoiler delete, Motion Raceworks parachute mount, Stroud chute. 99-01 Cobra front bumper, Steeda R Hood modified for blower ram air inlet.

Chassis & Suspension/Modifications:

Front: Tokico 5-way adjustable coilover struts, UPR

K-member and A-arms and springs. Maximum Motorsports caster/camber plates, Steeda bump steer kit.

Rear: Viking Crusader double adjustable shocks, Steeda lowering springs, UPR upper/lower control arms, Racecraft anti-roll bar.

Engine:

Gen2 Coyote swap, 302ci, built by owner. Forged Manley H-beam rods, DSS forged pistons, stock GT crank. Stock heads ported by Modular Head Shop, stock cams.

Induction & Fuel Delivery:

GT350 intake manifold with stock Gen2 Coyote throttle body, 95 lb DW injectors, Fore fuel rails, return fuel system, 03 Cobra fuel tank with dual TI fuel pumps.

Exhaust:

Kooks long tube headers, custom 3” exhaust, Magnaflow mufflers.

Electronics:

Ford Racing Control pack, Line Lock. N2MB 2-step.

Power Adder:

Vortech YSi-B with a 2.85” pulley, 3 core Treadstone intercooler, ram air inlet to the YSI through hole in hood. 10% overdrive Innovators West crank pulley.

Transmission:

T56 Magnum out of the box, no internal modifications. McLeod RXT with billet steel flywheel. UPR firewall adjuster and quadrant, stock Ford clutch cable.

Rear End:

8.8 rear with 4.10 gear, CHE Extreme axle brace, Moser 31 spline axles, Eaton Detroit TrueTrac diff. PST steel driveshaft.

Brakes:

Mach 1 calipers/rotors front, stock GT rear brakes

Tires & Wheels:

Weld RTS, 15x10 rear, 17x7 front. M&H Racemaster tires front, M/T Radial Pro, 275/60/15 rear.

Interior:

6 pt roll bar with removable door bars, Shrader rear seat delete kit, RJS racing harnesses, parachute handle, T56 Magnum shifter,

ET & MPH – Race Only:

9.05 at 159 mph ¼ mile 5.90 at 122 mph 1/8 mile. Best 60ft 1.30 at Bristol Dragway during SCT 2021. Traps 160+ in roll racing events.

Thanks To:

“My girlfriend Amy for her amazing support. She’s by my side at every race. And thanks to Darren Hart for listening to me complain and for giving positive advice when I’m ready to push the car off a cliff sometimes. Thanks also to Brian at Vortech Superchargers for always supporting this little yellow car for whatever we decide to do with it.”

Power connects through a McLeod RXT with a billet steel flywheel and a firewall adjuster and quadrant were also used. The Ford 8.8 rearend sports a set of Moser 31 spline axles, an Eaton Tru-Trac and a 4.10 gear set. A CHE axle brace and PST steel driveshaft provide extra strength

on those 1000whp stick shifted launches.

The suspension is a well thought out stock style setup. Steve choose an aftermarket K-member and a-arms to cradle the Coyote up front and a pair of Tokico coilovers were used with Maximum Motorsports caster/camber plates

and a Steeda bump steer kit. Stock rear upper and lower control arms were tossed in favor of aftermarket units, while Steeda lowering springs slip over Viking Crusader shocks and an anti-roll bar from Racecraft keeps the GT from threewheeling off the launch.

Clean and simple was a matter of choice inside the Mustang. Steve uses a 6-point roll bar with removable door bars, and straps in with RJS harnesses.

A Motion Raceworks parachute handle, standard T-56 shifter, and Steve’s very own rear seat delete finish off the interior modifications. The rest is completely factory.

Now let’s revisit how this stick car hooks on the radial tire. Shrader has spent a considerable amount of time getting Brightmare running the way it does now. “It took many years of failures and mental anguish with various parts to finally get this setup to work properly,” he said. The Stang clicks off 1.30 sixty-foot times and goes 5.90 in the eighth, then pours on the steam to 9.05 at 159mph in the quarter. 90% of stick-shifted cars run slicks for a good reason – they tend to give a little more when coming off the 2-step at high RPM. Many times parts still break though, and generally stick cars hate radials unless they’re running a “slipper” style clutch that softens the blow at the hit. Steve went a different route and instead runs a standard “puck” style clutch and makes it work without breaking. A few factors are responsible for allowing this to work, but first and foremost is the linear power curve of the centrifugal blower that allows power to come in gradually.

This fully street legal Mustang was built to look like a “regular street car” from the outside but be able to kick ass and take names at the track. Be sure to read how Shrader controls the launches of his 1000hp stick car on radials to make consistent 1.30 60-foot times and low 9.0 runs without scattering parts.

Steve explains; “I use the natural linear boost curve of the Vortech to select what RPM to start with to get the boost I need at launch. One of the secrets to the launch is having the 2-step rpm set low, around 3500, where the Vortech makes only a few pounds of boost. I also set the 2-step switch on the clutch release pedal to engage high on the pedal, so that as you lift off the pedal the clutch engages and moves the car forward before the 2-step disengages and allows the boost to ramp in with RPM. With 1000 hp on tap, you still have to slip the clutch pedal pretty much all the way through first gear to avoid the tire spin, but it’s

much less shock to the car than dumping the clutch at 6000 on slicks and hoping stuff doesn’t break.” Basically, Steve can get the car to sixtyfoot with the best of them, without breaking, and then drive it home on a DOTapproved tire.

“The goal of this car is to have an understated exterior that says “street car”, but to be able to visit a track and compete with full blown race cars,” added Sharder. So not only is the Brightmare Mustang a big part of Steve Shrader’s life, but having a cool stick-shifted fully street legal car that car runs bottom 9s as a rolling business card is pretty cool, too!