STRAIGHT-WEIGHT PERFORMANCE

HIGH PERFORMANCE MINERAL DRAG RACING OIL

Mineral based engine oil designed to enable maximum power while providing ultimate protection under the most severe race conditions.

• Unique friction modifier system enables maximum power output

• “Stay-in-place” chemistry and 2X Zinc anti-wear system provide lasting protection

• High quality base stocks enable effective ring seal

• Advanced, proprietary additive system keeps your engine clean

• Designed to prevent separation caused by fuel dilution

• Available in 50WT, 60WT & 70WT

EDITOR-IN-CHIEF.............................................................. CHRIS BIRO

EDITOR@RPMMAG.COM

V.P. MARKETING/CUSTOMER RELATIONS TRISH BIRO TRISH@RPMMAG.COM

E VENT MEDIA ..................................................EVENTS@RPMMAG.COM

E VENT SUBSCRIPTIONS

BLAKE FARNAN, JERRY GARRISONI, EDDIE MALONEY, WES TAYLOR, STEVEN TAYLOR AND AMBER HYNES

RPM Magazine is a REGISTERED TRADEMARK of Revolution Publishing & Media Inc. RPM Magazine is a worldwide motorsports publication distributed online.

To subscribe to RPM go to www.rpmmag.com or email Trish Biro at trish@rpmmag.com, or call 519752-3705.

The focus of RPM is to bring a diverse mix of high performance street and race automobiles to life within its pages including race cars, muscle cars, hot rods and street legal machines with an emphasis on the “EXTREME,” including fast doorslammer and outlaw forms of drag racing. Not familiar with these types of cars? They are considered to be the top-shelf of the industry and are on the edge with regard to design, performance, and power!

RPM Magazine does not sell its mailing list or share any of the confidential information regarding its subscribers.

EDITORIAL CONTRIBUTIONS: CHUCK SCOTT, MARK GODRAGRACING.ORG, TIM BIRO, STAN SMITH, GEORGE PICH, JAY MISENER, EDDIE MALONEY, WES TAYLOR, AND SCOTT FORBES

TECHNICAL WRITING CONTRIBUTION: CHUCK SCOTT, SHANE TECKLENBURG, TIM BIRO AND JAY MISENER FOR

S PECIAL EVENTS SALES: TRISH BIRO: 519-752-3705 TRISH@RPMMAG.COM SUBSCRIPTIONS/ADDRESS CHANGES: CIRCULATION CIRCULATION@RPMMAG.COM

G ENERAL INQUIRIES: 519.752.3705 INFO@RPMMAG.COM

RPM Magazine has been a world leader in motorsports publishing for 24 years and has support locations in Ontario, Canada, Alabama, Texas, and Virginia, along with contributing writers and photojournalists worldwide.

If you have a story that may fit within the focus and scope of RPM Magazine’s coverage, please email our Editor In Chief at editor@rpmmag.com. Submission of an article does not guarantee that it will be published. Revolution Publishing & Media Inc. (RPM) / RPM Magazine IS NOT responsible for errors or omissions in ANY advertisement or article. Advertisements may be rearranged or altered at the sole discretion of RPM to allow the ad to fit in the space purchased by the advertiser.

WE RESERVE THE RIGHT TO REFUSE ANY ADVERTISING WHICH WE CONSIDER TO CONTAIN MISLEADING, OFFENSIVE OR FALSE INFORMATION. REPRODUCTION OF ANY INFORMATION HEREIN IS STRICTLY PROHIBITED WITHOUT PRIOR WRITTEN CONSENT.

Story by George Pich

Photos By Robert Richard

Story by George Pich

Photos By Robert Richard

Afterasteeplearning curveatayoungage, hoppinguphis1990 FordThunderbird SuperCoupecame naturallytoCorey Binkiewicz,soheran withit.

“My parents always said my first word was ‘car’,” Corey said with a smile, “My dad was always working on cars or the house and I was familiar with tools, etc. So, once I was old enough to get in trouble, I was constantly taking things apart to see how they worked or if there was a way to ‘soup’ them up.”

Growing up, he was heavily influenced by TV shows like Tool Time and generally anyone who was into making cars fast. He saw all the photos of his father’s Mustangs and Corvettes from before Corey was born and his dad’s buddies would always slip in a story of how they raced on the street during high school.

His dad sold the 2-seater toys, but just before Corey was born in fall of 1989 he found a “family” car he had to have, a brand new 1990 Ford Thunderbird Super Coupe.

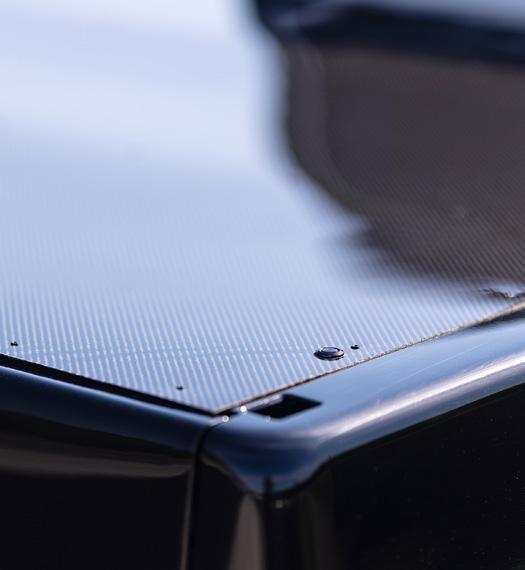

The slick and rare Super Coupe body is OEM steel and retains all of its lighting and trim. While weight was shaved off where possible, Corey wasn’t looking to produce a super lightweight racecar but rather a deceivingly fast unique street car.

The slick and rare Super Coupe body is OEM steel and retains all of its lighting and trim. While weight was shaved off where possible, Corey wasn’t looking to produce a super lightweight racecar but rather a deceivingly fast unique street car.

GenX® 260 square port GM LS7 cylinder heads from Trick Flow are your best choice for several reasons.

The A356-T6 aluminum castings feature more material for increased rigidity and strength. Valve angles and port locations work with existing LS7 intakes and pistons. Modular billet aluminum rocker arm mounts enhance valvetrain stability and are removable for shaft rocker setups. CNC Competition Ported runners deliver maximum airflow. Plus there’s clearance for 3/8" pushrods and through-deck coolant holes that fit all GM LS gasket and block combinations.

So take advantage of the huge power GenX 260 heads make and get ready to show your opponents your taillights.

Your Formula for GM LS Performance!

New heads are just one part of the horsepower formula. To make it complete, you’re going to need some other components.

Track Max® Camshafts

Give your GM LS an even bigger power boost with a Track Max camshaft. Available in several hydraulic roller designs up to 230°/238° duration and .625"/.625" of lift, they are dyno proven to produce significant power increases over the entire RPM range.

Active Fuel Management and Variable Valve Timing Delete Kits

The problem: most performance camshafts don’t work on engines equipped with AFM or VVT. The solution? Ditch them with these delete kits! They include everything to completely remove AFM and VVT the right way so your engine will make the power you expect with no hiccups.

Cylinder Head Bolt Kits

Keep combustion where it belongs! These high-quality cylinder head bolt kits provide consistent clamping force. The bolts are made from premium quality alloy steel with cold-formed heads and rolled threads. The kit contains all the bolts you need to install a pair of heads.

The factory front K-member was replaced with a custom piece and Menscer strut mounts and coilovers were also used up front.

When Corey finally decided to cut the car in order to reach the next level, he started back here. The factory independent rear suspension was replaced with an owner-built M9 chromoly 9-inch with Moser center section and 35 spline axles and spool hung from a custom ladder bar coilover setup.

As Corey and his older sister grew up, she was handed the keys to the Super Coupe first. Since Corey always liked going fast and was into go karts, dirt bikes, gas r/c cars and anything else with an engine, as he approached 16 he went Mustang shopping. Even though the T-bird had the supercharged V6, and was fast for the time, Corey wasn’t interested in getting the hand me down family coupe. “I wanted a manual trans, V8, and just more of a ‘hot rod’.

T-BirdSuperCoupe Ripsastripoff the track!

A few years before the supercharged V6 Thunderbird Super Coupe there was the Turbocharged 4 cylinder Turbo Coupe which some say was ahead of its time. Corey ditched the supercharger in his 1990 Super Coupe for a turbo, illustrating just how far the technology has come.

Long story short, I got the Thunderbird,” he said. Corey couldn’t find anything else and even if he could, he didn’t have the money to buy it at the time. So the T-bird it was, and he was happy to have it.

The car was in decent shape, having survived 16 Ohio winters, but had aging car bugs. Mechanical and electrical issues needed to be taken care of and

Corey hit the internet to find out how to fix them. It wasn’t long before he stumbled across the Super Coupe Club of America (SCCoA), and wouldn’t you know it, there were people on the group modifying their Super Coupes.

So even though the car wasn’t officially his yet, with each repair Corey would slip in a go-fast part or two.

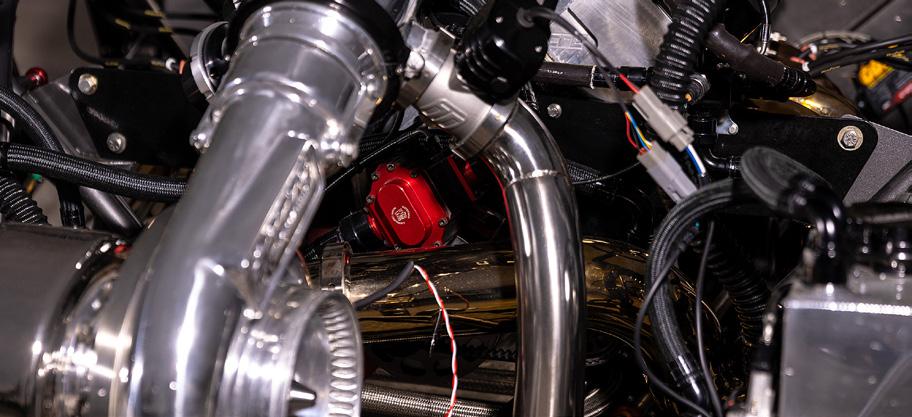

When he decided that he couldn’t keep up with the Joneses with his V6 program, Corey went with a small block Ford turbocharged combination with the help of Super Coupes Unlimited Inc. An Iron Eagle block was used as the base and cylinder heads are ported Yates C3s. The combination came in at 351ci. Corey converted a Roush intake to EFI and hand-built equal length runner symmetrical headers and a complete turbo system around a single 94mm turbocharger.

The SCCoA held Super Coupe shootouts, and the first shootout he could race in was on his birthday in 2007, making him just old enough to be allowed down the track. “I had an exhaust, pullies, and some cosmetic mods and the car went 14.92 @ 92mph and dyno’d

around 220rwhp and I won the Stock class!”

It was game-on from there and Corey threw every performance part he could on the Super Coupe, but soon realized that the platform was nowhere near as privileged as the Fox Body Mustang or Camaros of the day.

Aside from the pieces cut from the inner aprons under the hood, if Ford were to install a V8 turbo combination in the Super Coupe, it would look like this. The install looks factory and attention to detail is top-shelf.

Corey Binkiewicz’ 1990 Ford Thunderbird Super Coupe

■ Body And Paint:

Fiberglass cowl hood and the rest of the car is all stock, all steel, all glass.

Dupont Single stage urethane enamel black paint.

■ Chassis Modifications:

Hand-built chassis mods. Custom K member with factory style UCA/LCA front suspension.

3,455 pounds with driver.

■ Suspension:

TRZ chromoly ladder bars out back with Menscer Motorsports rear shocks. Fabricated K member up front with custom Menscer front coil overs with strut mounts.

■ Engine:

Dart 8.2 deck Iron Eagle, 4.150 bore. Wet sump, custom Stefs Pan.

■ Rotating Assembly:

Callies Magnum XL 3.250” Stroke Crank

Callies Ultra H beam 5.400” rods

Wiseco Custom Pistons with 0.250” wall H13 Pins

ATI damper

■ Cylinder Heads:

Yates C3 Heads and Intake- MBE prepped

5/16 Victory Titanium intake and Inconel exhaust valves

MBE/JHE PSI spring package 1.310” springs and micro locks

Manton Series 5 pushrods

T&D shaft mount rockers

Jesel Belt Drive

Cometic MLS

■ Induction & Fuel Delivery:

Roush intake converted to EFI with custom rails.

Motion Raceworks throttle body.

Twin 4303 Magnafuel pumps, Bosch 210 Injectors, One Ethanol R.

■ Power Adder:

Single Forced Induction Solutions 94/102 turbo

Custom owner-fabricated front mount intercooler with Garrett cores

TiAL Co2 Gate and BOV

■ Transmission:

T56 Magnum XL with G-Force dog ring gear set

Tick Performance billet front plate

Tick Performance billet shift forks

Billet Black Magic 11” single long style adjustable clutch

■ Rear End:

Moser chromoly M9, Moser aluminum 3rd member, Moser 35 spline axles and 3.81 gears.

■ Tires & Wheels:

15x11 Weld S77B beadlock rears with Pro 275 M/T radials

18x8 Weld S77B with 28” bias front runners

■ Interior:

Holley EFI digital dash

MPI wheel and custom column

8.50 chromoly cage

Stroud/Joes window net

Motion Raceworks billet chute handle and Co2 Bottle bracket

MGW shifter

■ ET & MPH:

5.11 @ 143 mph 1/8

8.18 partial 1/4 mile pass at 170+MPH

■ Most Unique Feature(S):

It’s a T Bird. A lot of people are so confused at the track, they have no idea what it is. And the 8.2 at nearly 9k through a single turbo is just a totally unique sound. It’s a mix of NASCAR and pro mod.

It is a one family owner car, basically the same age as me, we drove this from OH to FL every year for years on family vacation, sister and I arguing in the back.

It’s a stick shift on radials, people still think it can’t be done.

■ Reason For Build:

Never planned to, but once it was mine, I fell in love, I had so much time invested and heart that I won’t part with it.

■ Build Timeline:

It’s been a never-ending work in progress over 18 years now.

■ Most Memorable Experience:

I never, ever, expected the car to get this quick. I remember fabbing the chute mount thinking “I’m going to look like an idiot when this thing traps 140 in the ¼. Now It’s running 143 to the 1/8 and it’s not even wicked up yet! It will go 4’s and 7s all said and done, that’s for sure. Even though looking back it was sooooo slow, I sometimes miss the good old days playing on the street. Though I still do street drive this car every now and then!

Many of the stick guys sit around or cruise their cars due to the lack of prepped stick shift events. Theres a ton of no prep, but its just not my thing, I want to go as quick as possible and don’t want to wad up the car. So recently I’ve been buying into the small tire events and so far have been the only stick car there. It’s really rewarding to jump into a pool of really fast small tire cars in this big T Bird with a manual trans and actually put some pressure on them and go rounds. It’s shocked some people and I can usually hide it until the car gets up on the chip at the line – 4 foot flames are coming out of the side of the car and it’s incredibly violent, at that point people realize this isn’t the normal small tire car.

■ Thanks To:

Parents are huge, I hacked up their car!! They helped me out every time I blew it up and was stranded, gave me garage space, borrowed tools, and an extra set of hands when needed. My 90+ year old Grandmother is still my go to for bleeding the brakes or clutch, as long as I don’t yell.

Dave Dalke at Super Coupes Unlimited INC. The Thunderbird SC purists really weren’t fans of the switch to turbo and definitely aren’t interested in V8s. Even though Dave is king of the Super Coupes, he let me push him outside of the norm and we really took the platform to new levels. He has a full machine shop and his business partner Kevin Cragon at TI DYNO/Cragon Automotive supplied the chassis dyno. They both spent a lot of late nights and weekends supporting this car.

Garys Body Shop has since closed, but the painter who painted my car specifically Leroy Cunningham has reopened the shop as “Twice as Nice Auto Body” in Triadelphia WV. TRZ and Menscer went out on a limb. They didn’t immediately ask me what year Mustang I had and worked with me to tweak their normal items to work on this odd platform.

Mechman Alternators has always hooked this car up with a charging system supporting the high rpm.

FIS turbos makes a hell of an S400 frame turbo. I highly doubt any other S400 frame could do what I’m doing at this weight and setup.

Fabrication photos are available on Corey’s Instagram Binks_Built and his Facebook page

“I taught myself to weld, starting with MIG, then purchased a TIG about halfway through modding the car. Nearly everything on this car I had to make,” he said. As the Super Coupe’s life as a daily driver and weekend warrior at the dragstrip progressed, weak points like the factory transmission and eventually stock motor were found and rectified. In 2009 Corey had a new motor built, went turbo over the supercharger and made 450rwhp and ran high 11s in the 1/4 on 93 octane fuel.

By 2011 the body was at the point where it needed attention. Over the course of 8 months, fellow Super Coupe en-

thusiast Gary Bitzer took care of a complete overhaul with instructions from Corey to paint it so black that other cars would look gray beside it.

After the work, the car was removed from winter duty and more serious mods began, still using the 3.8L V6 motor as a base. The refreshed motor with a new sheet metal intake, bigger turbo and intercooler, a swap to E85 and a beefier 5-speed transmission, set new records, making 737rwhp, and still holds the 1/4-mile V6 manual trans Super Coupe record running 10.40s at 134mph at full weight (that was 4,000lbs with driver).

Corey completed what he refers to as a “significant, tasteful weight reduction” inside the car which mixes much of the factory Super Coupe trim with necessary race parts. After removing weight wherever possible inside and out, he was able to shave the car’s weight down to 3,455 pounds with driver from the over 4,000lbs it was prior to the V8 combination.

Binkiewicz rows the boat in the Super Coupe via a T56 Magnum transmission with a G-force dog ring gear set, a billet front plate and billet shift forks. A single disk 11-inch billet

With innovations in power and power adders coming faster than ever, Corey knew he couldn’t hang with the Coyote, Gen3 Hemi and LS combos, so for the first time ever, he cut into the Thunderbird.

First to go was the independent rear suspension in favor of an owner-built chromoly 9-inch with Moser center section and 35 spline axles and spool. TRZ made a custom set of ladder bars for the application, and Corey built a chromo-

ly backhalf for the car along with an 8.50 cert chromoly cage. He also fabricated the lightweight steering column, seat mounts and hung a custom pedal assembly for the clutch and manual brakes. Along with the cage work inside the T-bird, Corey completed what he refers to as a “significant, tasteful weight reduction” which mixes much of the factory Super Coupe trim with necessary race parts. In other words, he kept the car’s identity during the build.

The factory front K-member was replaced with a custom piece and motor plates were made for the 8.2 deck small block Ford that would be slid into the engine bay.

With the chassis complete, Binkiewicz reached back out to Dave Dalke at Super Coupes Unlimited Inc. (the builder of his V6s) to work with him on a V8 good for some serious RPMs. An Iron Eagle

block was filled with a Callies 3.25 stroke crank and 5.400 rods with Wiseco custom forged pistons. For heads, Corey sourced a mint set of Yates C3 heads. The combination came in at 351ci. A Roush intake from the same era was chosen and Corey converted the manifold to EFI and built the rails and flanges for the intake to properly fit the 8.2 deck height.

Corey

-- Corey Binkiewicz

-- Corey Binkiewicz

also built the 8.50 cert cage for the T-bird as well as the backhalf chassis. “I taught myself to weld, starting with MIG, then purchased a TIG about halfway through the car. Nearly everything on this car I had to make.”

also built the 8.50 cert cage for the T-bird as well as the backhalf chassis. “I taught myself to weld, starting with MIG, then purchased a TIG about halfway through the car. Nearly everything on this car I had to make.”

With over 1300rwhp at a modest 25 psi and shifting at 8,850 RPM, Corey has posted a 5.11 @ 143 in the 1/8 and 8.18 at over 170MPH on a partial 1/4-mile hit. With the wick turned up he expects 4s and 7s!

A Jesel belt drive spins a custom Comp cam with Morel lifters. Corey hand-built equal length runner symmetrical headers and a complete turbo system around a single 94mm turbo with 60mm co2 gate and single blow off valve. Eight individual smart coils feed Firecore 50 wires and Bosch 2100cc injectors are fed by twin Magnafuel 4303 pumps. Numerous pressure transducers and sensors cover the engine completely, including individual EGTs.

Corey fabricated the fuel cell and the car runs on One Ethanol R blend fuel. Tuning is handled by Binkiewicz, as well.

The T56 Magnum transmission was upgraded with

“The entire car was built in my single car garage, minus machine work, body work, paint and powder coating. Every weld on the car is mine and everything was done with incredibly minimal tools. A TIG, a 4.5” grinder, a porta band, and a Craftsman 200pc tool set.”

Corey Binkiewicz

a G-force dog ring gear set, a billet front plate and billet shift forks and a single disk 11-inch Black Magic billet Long Style adjustable clutch was used.

Today, as a Mechanical Engineer, Binkiewicz has a solid handle on how things work, but in those early days with the T-Bird he had to learn along the way. “The entire car was built in my single car garage, minus machine work, body work, paint and powder coating,” he explained.

“The cage was bent/built in the garage, the rear end too, literally everything. Every weld on the car is mine and everything was done with incredibly minimal tools. A TIG, a 4.5” grinder, a porta

band, and a craftsman 200pc tool set. I had the car on wheel dollies and had to roll it forward and back and side to side to get enough room to work. I painted the garage floor, dropped plumb bobs, and laid the chassis angles out in Sharpie on the floor.”

The car has chassis dyno’d over 1300rwhp at 25 psi and Corey spins the motor just about 9k, shifting at 8,850 RPM. With best numbers to date of 5.11 @ 143 in the 1/8 and 8.18 at over 170MPH on a partial 1/4-mile hit, Corey knows he’ll see 4s and 7s with the wick turned up, which truly makes this Thunderbird Coupe, Super!

Barry Cunningham’s 1940 Willys Coupe

From the pages of RPM Magazine, December 2013

Barry Cunningham’s 1940 Willys is one sweet ride! Barry chose the cool hot rod rake with the rear sitting just a bit higher than the front. The Willys is just one of those cars that you can get away with darn near anything when it comes to stance.

One of the most iconic cars in the world of hot rods is the 1940 Willys. These cars were the stuff of automotive dreams spanning many decades in the eyes of car guys and the foundation for some very cool rides in the 50s and 60s. Many of them also showed up on quarter-mile strips as gassers in the 60s when this race category was a mainstay among those involved in the hardcore world of fast hot rods.

Barry Cunningham has al ways been an old school hot rod type of guy. He likes the kind of brute force power that can only come from big blocks with big torque and can melt a set of rear tires at will when the gas pedal meets floor metal. Barry has owned many different rides that fit the giant horsepower bill over the years, but his 1940 Wil lys is a barely-street legal mon ster that is essentially raw pow er under a pretty skin.

Photos: Jerry Sutherland

The ‘40 Willys front end is amazing and the split front grill is probably Barry’s favorite part of the car.

Photos: Jerry Sutherland

The ‘40 Willys front end is amazing and the split front grill is probably Barry’s favorite part of the car.

While along for a ride the Willys is loud but not overpowering inside the cockpit, and because the blown big block sits nice and low in chassis it doesn’t take away your view out of an already miniature windshield. We have to admit, it was very cool to slip into this hot rod and head out on the back roads for some fun.

The first thing you will notice on the car is the wheelie bars. They are definitely not there for simple decoration because, with a bit of hook, this Willys would get you airborne and in some serious trouble. The second thing to take note of is the license plate on the car as Barry’s 1940 Coupe is legally registered for the road. Wheelie bars and license plates together are not something you see every day on a street machine, but it is the combination of these two things that attracts the most attention to this particular car.

Powering the hot rod is a 502 Chevy big block punched out to 540 cubic inches of craziness just in case it needs some extra horsepower to get from Point A to Point B in an even bigger hurry. The big Chevy delivers 750 horsepower at the rear wheels with 698 ft lbs of torque, according to Barry. And what better way to top it off than by giving it a nice boost from a 671 supercharger with twin Holley carbs.

All those ponies get there through a B&M Turbo 400 transmission with a 3500 stall converter and Ford 9 inch locker rear diff with 3.73 gears. The Willys is all street, for now, and might just see the drag strip again in the near future as the car does have some history on the quarter-mile. Just in case, a line lock kit has been installed for whenever Barry decides to conjure up a serious smoke show with his itchy gas pedal foot or a serious tire heating burnout in preparation for a Friday night hit at the strip.

The front end is a Mustang II setup and Barry commented on how well his Willys handles on the road; however, he has learned through experience that it will break the tires loose at 60 mph if he wants to tempt fate and really put his foot into it. It is definitely a lean, mean street-fightin’ machine with the kind of horsepower that will get you in trouble in a hurry if you choose the down position on the gas pedal.

Story by Jack DuBois

Photos By Blake Farnan

Story by Jack DuBois

Photos By Blake Farnan

Most every story in the world of fast cars and motorsports starts with something like, “I have been into anything with wheels since I was a kid”.

For Brodie “Super Kid” Brown, it all started on his 1st birthday when he was given a Pocket bike. While he couldn’t ride it yet, his parents Jackie and Rob would push him around on the front lawn of their property.

The Eclipse Orange Metallic paint on the Chevy II pops in the sunlight and the black roof (simulating vinyl) adds a nice touch. The car was known to the Brown’s prior to their purchase of it as a rolling chassis. It was a well -built car that would get Brodie’s feet wet in a doorslammer and also take more power down the road.

When Brodie was 2 years old, his father Rob tied a rope to the back of the bike and let him ride it around on the lawn, but it didn't take the youngster long to figure out what he was doing and the rope was off. By 3 he was riding his pocket bike and his electric chopper around the property and learned how to do burnouts and

wheelies in no time at all. Years later, at 18, it’s no wonder he has a long list of accomplishments behind the wheel of drag cars.

Brodie’s dad has drag raced for the past 38 years and his mom enjoyed some oval track action along with weekend hits at the dragstrip, so it’s no mistake that Brodie is hooked on horsepower.

By 5 years old he got his first Junior Dragster, and started getting seat time practicing in parking lots in Waterloo, Ontario. Since he was old enough to go down the drag strip, he progressed through each class maxing out at each ET level, running in the 7.50 class during his final year in Juniors in 2022.

FrombirthBrodiewasago fastkindaguy....nowat18 heiswowingeveryonewith histalentandtechnique!

Throughout these years, Brown raced at nearly a dozen different venues in Canada and the United States, stacking up wins, championships and valuable life experiences along the way. Following the final John Force Event at St. Thomas Dragway in 2014, when Brodie was just 8 years old, Force put Brodie in his car and told him to jump out fast like it’s on fire, and Bro-

die accepted the challenge. When he was 11, Brodie won his track Championship and was to accept his award at the largest car show in Canada, held in Toronto. Shy at the time, Brodie only agreed to go up on stage to accept the award with the guarantee that he wouldn’t have to talk. NHRA Funny Car standout Ron Capps happen to be up on stage when Brodie came up

and engaged him in a chat anyway; "how old are you kid", Capps asked. Brodie replied,"11". Ron came back with, "well I should be ready to retire by the time you’re old enough to race my car, do you want to race my car?' Brodie said, "no". After a hardy laugh from the crowd, Ron asked Brodie, "why not?" Brodie replied, "I want to race a Pro Mod" Ron laughed and said, "me too kid!"

The family worked together over the course about 8 months to create a solid platform for Brodie to go door-car drag racing. The ’63 steel OEM body was used with a removable front end and hood. Factory trim and lighting was reinstalled, and the headlights upgraded to LED, which sets the Deuce apart from looking like an all-out race car.

By the time he turned 16, Brodie was chomping at the bit to get behind the wheel of a doorslammer and in September 2022 got licensed in his Nova for 9-seconds in the 1/4 mile. The very next month he raced the car in his first event with 70 cars in the Mod class, and he made it

down to the final seven cars.

The car itself was previously owned by a family friend and the Browns all agreed that it was the one for Brodie.

Rear suspension is a 4-link coilover setup with Afco shocks and anti-roll bar while tubular control arms and coilover shocks with factory spindles were used up front. A heavily fortified fabricated 9-inch Ford rearend sends the naturally aspirated big block power outward to a pair of RC Components rear wheels with Mickey Thompson 29.5x13.5x 15 ET Drag slicks.

Purchased as a rolling chassis, the family worked together over the course about 8 months to create a solid platform for Brodie to get his feet wet in door-car drag racing.

The ’63 steel OEM body tub was used with a removable front end and hood, and the

Eclipse Orange paint definitely stands out in the staging lanes.

A bunch of the factory trim and lighting was reinstalled, and the headlights upgraded to LED, all of which sets the Deuce apart from looking like an all-out race car.

The chassis is a full-tube chromoly piece with chromoly cage and holds a 25.4 certification.

Rear suspension is 4-link coilover with Afco shocks and anti-roll bar while a custom setup with tubular control arms and coilover shocks with factory spindles was used up front. A heavily fortified fabricated 9-inch Ford rear end sends the

naturally aspirated big block power outward to a pair of RC Components rear wheels with Mickey Thompson 29.5 x 13.5 x 15 ET Drag slicks.

Brodie Brown’s 1963 Naturally Aspirated Big Block Chevy Nova SS

■ Body:

Nova SS body with composite front end. Paint is Eclipse Orange.

■ Chassis Modifications:

Full tube chassis. 25.4 chromoly cage.

■ Suspension:

Rear is 4-link coilover with Afco shocks and anti-roll bar. Front is custom setup with tubular control arms and coilover shocks with factory spindles.

■ Engine:

Chevy tall deck 572 crate motor. 4 bolt main, Aluminum rectangle port cylinder heads.

■ Induction & Fuel Delivery:

Chevy Performance air gap high rise cast tall deck intake manifold with Holley Dominator carb.

■ Power Adder:

None

■ Transmission:

Hutch 2 speed Powerglide, bolt-together converter.

■ Rear:

Fab 9 9-inch Ford rear end with Strange axles and spool.

■ Tires & Wheels:

RC Components rears with Mickey Thompson 29.5 x 13.5 x 15 ET Drag slicks.

■ Interior:

MSD Grid, Racepack dash, Leaf Racewear products.

■ ET & MPH:

5.89 in the 1/8 mile at 118mph. Car currently runs in the 6.0 Index class.

■ Reason For Build:

We fell in love with it. We have been family racing for over 30 years and want to keep it going.

■ Build Timeline:

Built during one off-season.

■ Most Memorable Experience:

Just being able to build my first race car.

■ Accomplishments:

Grade 12 student currently, and going into an H-VAC Apprenticeship. By age 11 raced at the following venues:

Grand Bend Motorplex

St. Thomas Dragway

Toronto Motorsports Park

King of The North in North Bay ON.

Napierville Dragway

Castrol Raceway in Edmonton

Mission City Raceway

Martin Michigan

Orlando Speed World

Memphis International Raceway

Track Champion at St. Thomas Dragway in 2017 at 11 years old and that same year he was in a music video with his Jr. Dragster.

Also race and ride dirt bikes and street bikes.

■ Thanks to:

Brown's Racing

The Browns have worked extensively to create a car that is built and looks as good as it performs. Inside the car, tinwork was painted dark gray and is accented by carbon fiber wheeltubs and the factory dash is painted to match the exterior. An aluminum race seat and custom column with removable steering wheel were also installed.

SuperKid-BrodieBrownReactiontimesthat kickass!

Tinwork was painted dark gray inside the car and is accented by carbon fiber wheeltubs and the factory dash painted to match the exterior.

Brodie sits in an aluminum race seat and shifts the Hutch’s 2 speed ’Glide via a billet pistol grip shifter and is fed information by the

Racepack display.

The power combination is quite simple and effective for this stage in Brodie’s drag racing – a Chevrolet 572-inch tall deck big block crate motor. No power adder. The motor boasts a 4-bolt main block and aluminum rectangle port cylinder heads.

A cast Bowtie intake with Holley Dominator carb finish things off up top, while custom side exit headers were coated to keep heat under control, prevent rust and look damn good, too.

Brodie turned 17 March 1st and for the 2023 race season went straight into the completed Nova running in Ian Hill’s Canada Heads-Up 6.0 Index Class points series at Toronto Motorsports Park.

He did quite well in this class, and even earned himself a name, literally! His mom Jackie explains; “Brodie was in the staging lanes standing by his car and another racer walked over to him and said, ‘Hey kid you’re going to have a good weekend, your Dad's letting you take his car out’.

...It’s pretty obvious that Brodie Brown is going places in the sport he loves...

Coming from multiple wins and a track Championship in Junior Dragster, Brodie finished out his first season in door-car drag racing in 3rd place in his class. He also broke a record in the class and was awarded a certificate for running a 6.002 in the 6.0 Index class!

Brodie smiled and said, ‘yeah’. “Brodie ended up lined up beside the guy and won the round. The next day the guy came to our pits and said, ‘I just came here to meet the super kid’. He was really nice and came to wish him luck because he was in the finals against him. It was a good race, but Brodie won and the name stuck”. Brodie

finished out the season in 3rd place, broke a record in his class and was awarded a certificate for running a 6.002 in the 6.0 Index class.

Given his performance up to this point, it’s pretty obvious that Brodie Brown is going places in the sport he loves, so fellow racers take note; there’s a new kid in town, and his name is Super!

by Wes Taylor

by Wes Taylor

Ziff Hudson is one of those names that seems to always be the topic of conversation in the world of small tire drag racing. He’s fast and he wins.

He started racing at the tender age of 17 in his '71 small block nitrous-assisted Nova, dominating local street car classes at several tracks. While life took hold, he took some time off for his two girls and started his towing company at age 21; Ziff never lost the

addiction

to drag racing.

When the time came to get back into the game, Hudson started with the PTRA in a Chevy 2, soon outgrowing the class and then moving onto a Mercury Zephyr. Earning the name "Outkast" the Merc came into the spotlight, however, not only was it different, but it was fast.

Ziff, with team members Jeremy Pearson and Craig Owen, broke many records in a few different classes with the car, but he had the next level in his sights; he wanted to become the first man on a radial 275 to go 3s. Outkast wouldn't cut it, so he joined most of the field with a Racecraft-built Fox Body. After a brutal fight, Hudson accomplished the daunting task, going 3.99 at 190 in April of 2017 and went on to pilot his Fox into the 3.70s before decid-

ing things were getting hairy for a stock-style suspension car, so he looked to Teddy Houser to build him a purpose-built race car.

Hudson's Vette has a sinister look; obviously, this isn't your average modified C7, but despite being a custom body, it does incorporate the curves given to the Corvette from Chevrolet. Cynergy Composites did a fantastic job reproducing the body, right down to the Z06 vented front fenders.

Although the Corvette looks black in most lighting situations, it is in fact a deep blue. The custom Tamco skin was expertly laid down by Tim Johnson. “After 2 silver cars, we decided it was time to change up the color, maybe for some good luck,”

Hudson said about the color change.

The one-piece front end incorporates a huge turbo inlet and passenger side exit for the Bullhorn style exhaust. The paint color is something you've got to lay eyes on in person. Laid down by Tim Johnson, the custom Tamco paint appears black in most lighting situations, but it is in fact a deep blue. “After 2 silver cars, we decided it was time to change up the color maybe for some good luck. I didn’t realize it was going to confuse people,” Hudson said about the color change. Although there aren't any actual factory lights on the car, a combination of airbrushing on the front end with decals portray a factory look.

Teddy Houser

cars

caliber, it's a certi fied 25.3 build, and all front and rear components are easily accessible and adjustable. The front suspension is based on a strut-style setup with tubular arms, while a complete custom four-link system resides out back. Remote reservoir coilovers with full adjustability reside on all four corners.

Not only does it take a wellbuilt chassis to compete at this level, but the engine must also be top-notch.

“Sexy” isn’t a word that fits most drag cars, but the lines of this Cynergy Composites bodied beast are just that. Although there aren't any actual factory lights on the car, a combination of airbrushing on the front end with decals portray a factory look.

Ziff looked to none other than TKM Performance for a class-competitive mill. TKM stuffed an all Billet CFE 4.600-inch block with a billet Bryant crankshaft, billet GRP rods, and Custom Wiseco pistons. The short block totals 498ci of boost-ready billet goodness. More billet bling tops the short block starting off with a pair of CFE cylinder heads filled with massive Victory valves, Manley springs, Jessel rockers and Manton pushrods. A trick set of TKM PCNC machined valve covers complete the

One is all you need…if it’s big enough! A massive Harts Turbo 140mm unit was plumbed into place by Jeff Tucker. Installation and detailing in this package are top-shelf, with most of the engine and its supporting components polished by Jeff Deters.

long block.

Jeff Tucker's custom headers and turbo system mount around a massive Harts Turbo 140mm unit, feeding air into a billet CFE intake manifold. Fueltech controls the entire car, while Turbosmart helps on the boost side. There

THEWORLDOFEXTREMEHORSEPOWERISACLICKAWAY

are a number of racers who don’t care about detailing areas that aren’t readily seen and others that want their engines to look just as good as the outside of the car. Hudson fits into the latter group, with most of the engine and its supporting components pol-

TKM Performance stuffed an all Billet CFE 4.600-inch block with a billet Bryant crankshaft, billet GRP rods, and Custom Wiseco pistons. The short block totals 498ci of boost-ready billet small block goodness.

ished by Jeff Deters.

All that turbocharged power transfers through a bolt-together Cameron's Torque Converters unit and into a billet three-speed Rossler TH400-based transmission. Houser built a full-floater rear end using a 10-inch housing to move the Mickey Thompson class-legal 275 radials.

Ziff's Z06 sits on a set of 17-inch Weld V-series up front wrapped in the now common motorcycle tire and has two sets of Weld Racing Alphas for the rear, depending on the class he's

Ziff Hudson’s 2020 Drag Radial Chevrolet Corvette

■ Body & Paint:

Cynergy Composites body, custom Tamco paint, painted by Tim Johnson.

■ Chassis & Suspension:

Teddy Houser custom built chassis and suspension.

■ Engine:

TKM 498 ci small block 4.600 bore space, CFE billet block.

■ Rotating Assembly: Bryant crankshaft, Wiseco pistons, GRP rods.

■ Cylinder Heads: CFE billet heads, Jesel rockers, Manton pushrods, Victory valves, Manley springs.

■ Induction & Fuel Delivery: Waterman fuel pump.

■ Electronics: Fueltech, controlled by Turbosmart Straight Gate e-gates, Fueltech injectors.

■ Power Adder:

Harts 140 mm single turbo.

■ Transmission:

Rossler 3 speed w/ lockup, Cameron's converter.

■ Rear End:

Teddy Houser custom built floater with 10 inch Ultra center section and Strange axles.

■ Brakes:

TBM brakes.

■ Tires & Wheels:

Mickey Thompson tires, Weld Alpha wheels, Macfab beadlock rears.

■ Interior: Ft600 Fueltech dash, all Stroud safety equipment, Mark Micke shifter, Mag’s Fab fire system

■ ET/MPH: 3.67 at 206 in the 1/8 mile to date.

■ Most Unique Feature(s):

Wanted to be different and prove you can do more with less as a single turbo has never been this fast and can be a front runner against every other power adder.

■ Reason For Build:

I felt like the Mustang had maxed out its potential and needed to upgrade to a purpose-built car for these kind of mph and ETs.

■ Build Timeline:

The first car took right around a year and the rebuild took around 5 months.

■ Most Memorable Experience:

Going to one of the biggest races of the year untested and being able to compete with the front runners of Pro275

■ Thanks to:

My right hand man DC Small, Deters Custom Finishing for the bling, PST Driveshafts, Wade @ Race Part Solutions, Firecore, MJB Wiring, Racecraft Inc, WM Titanium, VP Fuels, Jared Tucker Fab Work, Brad Gray Blown Mafia, Nate Whitworth for always being there for whatever I need work or race related and my better half Rose for always holding down the fort and work so I can do what I love without worry.

What’s Old Is New if you haven’t read it yet!

Over the coming months we will be hosting some of our past issues of RPM Magazine in this section. If you haven’t read them yet, they are new to you! If you have, maybe there’s a favourite car/story you want to read again….here they are!

The cockpit may look confusing, but it’s a neat and tidy setup of everything needed to run a car at this level. Fueltech controls this top-level machine with their interactive display mated to the FT600 ECU. Every single electronic system is easily accessible for servicing as is the entire transmission, CO2 system, Fire Aid, and Stroud safety systems. A billet shifter with Ziff's name on the mount complements the interior nicely.

running.

TBM brakes paired with a Stroud parachute bring the Z06 from over 200 to 0 quickly and safely

The cockpit does precisely what it should and is neat and tidy, thanks to Michael Bunton of MJB Wiring. Ziff has all the Fueltech

controls at his fingertips and a dashboard plugged into the FT600 ECU monitoring the car. Every single electronic system is easily accessible for servicing as is the entire transmission, CO2 system, Fire Aid, and Stroud safety systems. A billet shifter with Ziff's name on the mount complements the interior nicely.

The cage snakes its way through the interior like a Jungle Gym and carbon wheel tubs are accented by carbon floor and filler panels, and Hudson sits in a carbon seat, as well.

Believe it or not, this is Version 2 of Ziff's Vette; soon after the first unveiling, the Silver C7 had an issue and caught fire down the track. Thanks to the Fireaid system the fire was contained but not before much of the car was damaged, except for the chassis. Cars are rebuildable while lost lives are not; and Hudson’s experience illustrates how vital the proper safety gear is. The original silver Z06 build was completed in a touch over a year, but this rebuild showed its face in just 5 months.

All that turbocharged power transfers through a bolt-together Cameron's Torque Converters unit and into a three-speed Rossler TH400-based transmission. Houser built a full-floater rear end using a 10-inch housing to move the Mickey Thompson class-legal 275 radials.

To date the Corvette has been 3.67 at 206 in the 1/8 and Hudson is looking forward to a summer of good things in the car as he gets setup for its first full season in class competition. On top of his own racing, Hudson

also drives and tunes the “ZZ Top” Mustang for Doug Ghant that has recently switched over from No-Time to Limited Drag Radial, and tunes on other cars, too. “Doug pretty much gives me the reins to do whatever I want,”

Ziff added “And it’s honestly just as fun and rewarding as if it was my own. I have met some really good people along the way and now I enjoy tuning and helping other racers just as much as I do driving my own car.”

Third Gen, Square Body, C-Series, no matter what you want to call them, Chevrolet’s 1973 to 1991 model full size pickups have become iconic and are now one of their most sought after generations of trucks.

They are getting snapped up for street machines and street/ strip builds alike and this low-slung 1985 C10 of Chad Gower is an example of the latter. It snowballed from his first vehicle that he drove daily through high school and college, into a nasty blown small block that he can take his kids out

for ice cream in and then go hurt some feelings at the track.

Gower’s story of enjoying and building performance and race cars comes from roots a bit different than the usual “it runs in the family” scenario. Once he was done school at Nashville Auto-Diesel College (now known as Lincoln Tech) in Nashville TN, he went into the industry, the diesel Mechanic industry.

Lincoln Tech is well known for producing top quality automotive industry professionals, in fact they boast that: “The city of Nashville – the heart of Tennessee – is home to two proud American traditions: unbeatable music, and incredible cars. What the Grand Ole Opry is to country music, Lincoln Tech is to the auto career training tradition.”

Once he was rooted in the industry, Chad had another opportunity come along, and he began a new path as a Snap-On Tool Dealer. As you can imagine, the networking involved in his new career alone would create a number of opportunities for someone with this level of industry education and love of horsepower.

Gower seized one of those opportunities and for the past 7 years he has been a Fabricator and Technician at Tytech Performance. And it is this position that led to building his high school ride into what it is today.

Chad bought the pristine C10 from an older gent back in 2003 and after driving the truck through his high school and college years, he got in an accident and parked it for a while. He would eventually find a donor truck for clean OEM parts and get a slick Jet Black single stage paint job done that still shines like new today.

The

Keeping the factory trim, lighting and mirrors on the C10 not only make it look amazing, but help confirm its street identity, too. The only aftermarket panel is the cowl hood which is a nice addition on the square body for both looks and air flow.

Various modifications were also on the list of things to do before it saw street duty again, including a ladder bar rear suspension and a Tytech-built 406 small block with a hit of nitrous. This work started about 2 years before he went to work

for Tytech. “After working at Tytech we started on a few more changes that snowballed into this complete build,” Chad said with a smile. Starting with a quick front end swap, the stock front suspension was replaced with a Heidts front assembly.

The

With the new front end installed, Chad and the Tytech crew turned their attention to the rear of the truck and revisited the ladder bar setup that was completed a few years earlier.

They also installed an aftermarket fabricated 9-inch rear end hous-

ing, center section, axles and S-Trac carrier.

Of course, the heavy duty truck frame needed little to no work, however, Tytech built a cage for the truck, but not just any cage – you might have to look two or three times to see this one.

A nice clean install with lots of room to move, thanks to the sizeable engine bay of the square body Chevy truck. Gower uses an air to water cooler to cool the charge and a custom intake elbow is mated to a Wilson throttle body.

Chad and Tytech took great care to get the cage in place without taking away from the exceptionally clean interior. Custom parts such as leather wrapped trim, dash, and door panels with carbon inserts, a full array of

aftermarket gauges, a billet steering column and steering wheel and race seats were installed, but Gower went with top quality parts and installation that integrated seamlessly into the package.

To really showcase their talents, Tytech built a Ticon titanium exhaust from headers to the rear bumper and a carbon bed cover.

Chad Gower’s Street/Strip Blown Small Block 1985 Chevy C10

■ Body & Paint: Single stage black that is 9 years old!

■ Chassis & Suspension: Heidts front suspension, ladder bars, Viking coil overs

■ Engine: Tytech Performance 406 small block. Dart block, ported intake, Bullet custom camshaft and Jesel lifters. Recent upgrade to AFR 245 heads with Jesel rockers. Makes 1,250 rwhp.

■ Induction & Fuel Delivery: Aeromotive Trifekta, 225 Precision injectors. Air to water cooler. Custom elbow with Wilson throttle body.

■ Electronics: Holley HP, Racepack Smartwire.

■ Power Adder: F2 ProCharger.

■ Transmission: PTC –built TH400 and converterPTC built 400 and converter.

■ Rear End: Strange 9-inch housing and center section with 35 Spine axles, S-track with 3.50 gears.

■ Brakes: Wilwood disc front and rear

■ Wheels: Billet Specialties.

■ Interior: Leather wrapped trim, dash, and door panels with carbon inserts. Corbeau race seats and seat belts. Lotse Pro Drag steering wheel, Precision Performance shifter, Vintage Air A/C and custom gauges.

■ ET & MPH – Race only: TBD

■ Build Timeline: About 7 years for this latest rendition and 10 years total.

■ Thanks To: Tytech Performance.

One specific extra that was installed to deal with humid Tennessee summers was the Vintage Air air conditioning system. After all, this is an authentic street machine. The truck still has power steering, power windows and door locks, too.

The motor was next. With a solid foundation already in place –Tytech built it using a Dart block – the rotating assembly was updated, the nitrous was removed and replaced with an F2 ProCharger centrifugal supercharger with front serpentine system.

The interior of the truck is spotless. The cage was fabricated to blend in with its surroundings and its tough to notice at first glance. Leather wrapped trim, dash, and door panels with carbon inserts were installed along with a full array of aftermarket gauges inserted into the original gauge cluster area. ianhillracing.com FASTEST RADIAL ,

More recently, as of just a few months back, cylinder heads were upgraded to AFR 245s with Jesel rockers and Jesel lifters mate with the custom Bullet blower cam.

A PTC-built TH400 transmission and PTC converter handle the power and weight of square body hay-hauler.

During the past 7 years of the process, Tytech and Chad also removed all factory wiring and built a custom harness for the entire truck that incorporates a Holley HP system with the Racepak Smartwire.

Chad Gower’s C10 can be driven anywhere in comfort and hit the strip for some action as well. Chad slows things down to run in 6.00 and is looking for new personal best numbers this year that reflect the recent cylinder head swap.

And to really showcase their abilities, Tytech built a Ticon titanium exhaust from headers to the rear bumper and a carbon bed cover.

“This truck will always be special because it's where I started from,” Gower added.

“The sound and looks. There’s something about the looks of a square body that most people love, and couple that with the whistle of a supercharger. It’s always a blast to drive but I love the smile on my kid's

face when they go for rides or I drop them off at school. I can't stop and get fuel without someone coming up and saying, ‘I used to have a truck just like that’. Those are things I enjoy most about the truck.”

The combination makes 1,250 rear wheel horsepower, and while the C10 hasn’t been track tested since the most recent upgrades, it won’t be long before Chad hits the strip… after grabbing a cone for the kids, of course!