dpsmagazine.com

Volume 26, Number 3 • ISSN: 1529-2320

dpsmagazine.com

Volume 26, Number 3 • ISSN: 1529-2320

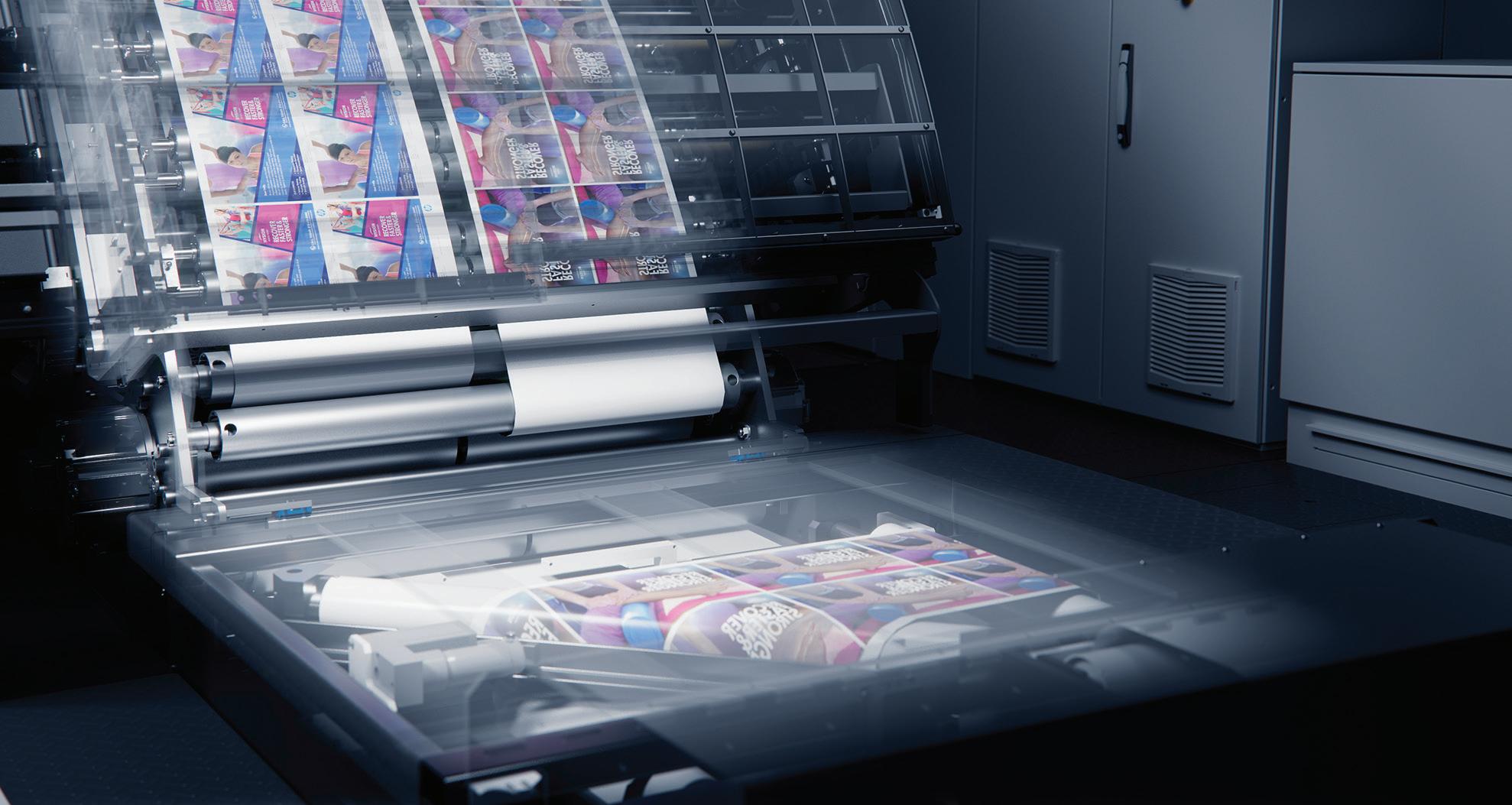

Sheet-fed, toner-based production presses continue to show promise in the commercial print space. With a low capital investment and diverse options in terms of speed, quality, and applications, these production presses feature mature technologies that enable print providers the opportunity to expand their business while maintaining current contracts. Read more in Diverse Toner

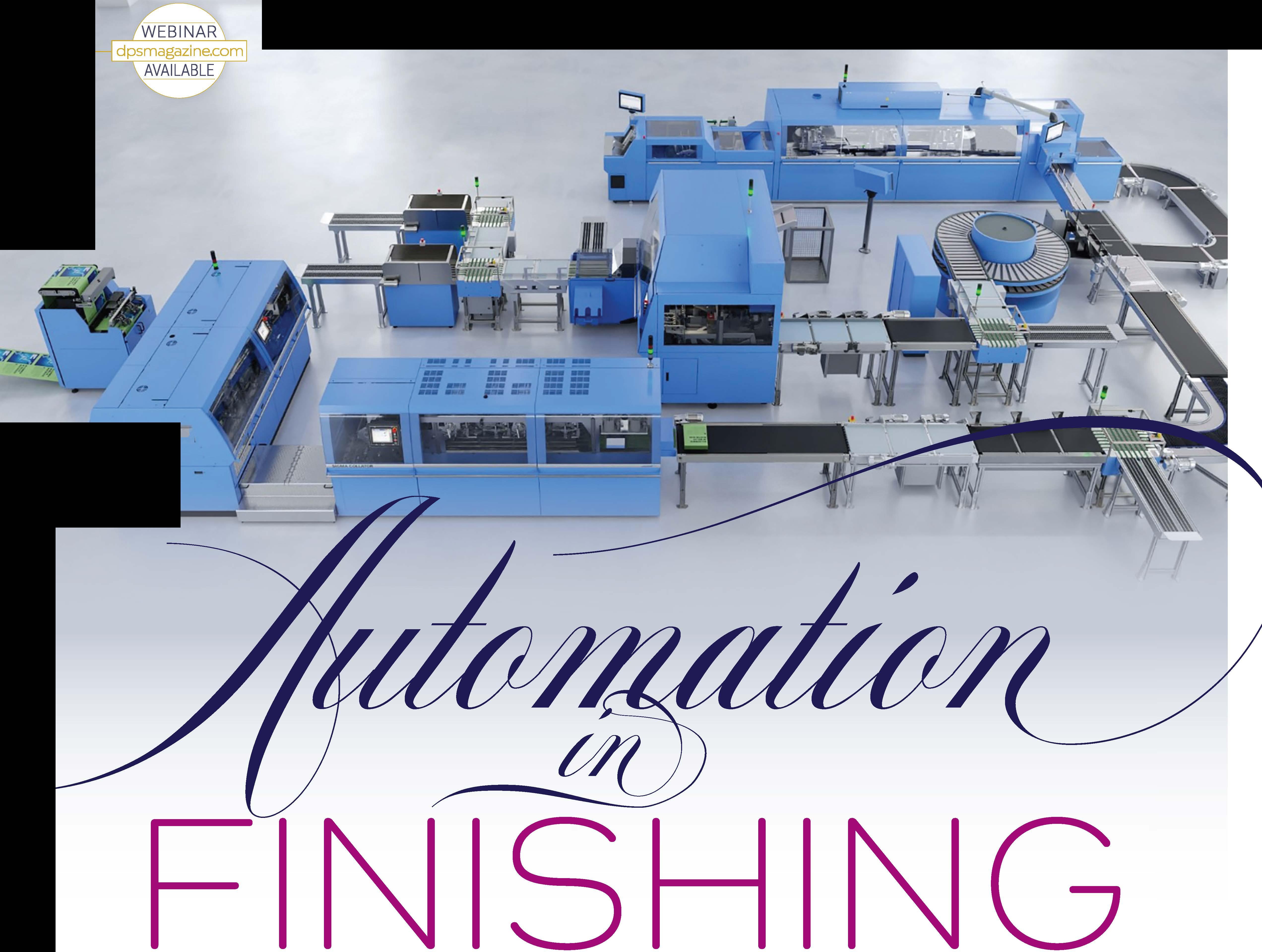

No matter what the output technology is, it is essential to prevent bottlenecks in finishing.

No matter what the output technology is, it is essential to prevent bottlenecks in finishing. Greater automation allows finishing operations increased productivity, improved quality control, and reduced errors. We discuss this and more in Automation in Finishing. Find a webinar on the topic at dpsmagazine.com/webinars.

Also in this issue you’ll find a Spotlight article focused on a successful direct mail provider that relies on state-of-the-art printing and finishing technologies to efficiently manage its workload.

This is our last issue before the print industry embarks on the muchanticipated Drupa 2024 trade fair. To prepare for this event, we present highlights of what is expected on the show floor. Stay tuned for updates online at dpsmagazine.com and check out our recap of Drupa in the upcoming July/August issue.

Best regards,

Cassandra Balentine, editor cbalentine@rockportpubs.com

Cassandra Balentine, editor cbalentine@rockportpubs.com

EDITOR IN CHIEF

Thomas Tetreault

978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Mark Hanley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault 100 Cummings Center, STE 321E Beverly, Massachusetts 01915 Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 100 Cummings Center, STE 321E Beverly, Massachusetts 01915

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy Tyler

In little over a month, after partnering with Significans Automation, Bozeman, MT-based Allegra Printing, a full-service printing and marketing franchisee, boosted sales by 30 percent, reduced labor costs by 35 percent, drastically minimized turnaround times, recovered its original investment, and predicts an overall return on investment (ROI) of over 300 percent.

Matt Cook, CEO, Allegra Bozeman Marketing, Print & Mail is the first to admit that he's an impatient person. "I've worked for 28 years running multiple companies. After my wife and I purchased the Bozeman Allegra print franchise in 2022, I noticed it was taking forever to get jobs out the door. I grew impatient because there were too many human touchpoints slowing down production-in some cases as many as 20 to 25 per order. Turnaround times were unacceptable, customers were unhappy, and employees were stressed out."

Cook researched and took into accountrecommendationsfromcolleagues. The answer-install Enfocus Switch workflow software. However, he was initially told that this solution was ideal only for multi-million dollar companies. As it turned out, this information was incorrect. He reached out to Marc Raad, president of Significans in September 2023.

"I was surprised that I could speak to a person right away. Significans showed genuine interest in understanding my specific production set up, immediate needs, and future goals. In November, we were engaged in an assessment that mapped out our current and future state. The aim was to boost revenue by driving out inefficiencies, eventually achieving 100 percent end-to-end in-shop automation and seamless integration with our existing systems," recalls Cook.

After the first meeting with Significans-and despite some initial skepticism-Cook and his wife Tresa, who deals with customers "on the front lines," began to realize the enormous potential.

On February 1, 2024, Significans installed a highly customized Turbo Switch Pack at Cook's facility. The suite

of software and support services help companies begin their journey into modern, workflow automation. They combine best-in-class workflow automation and layout software with software maintenance, uniquely configured workflows, powerful Enfocus Apps (produced by Significans), as well as installation, training, and support. Unlike many other solutions, Turbo Switch Packs can be fully deployed in hours, delivering immediate capacity gains and ROI.

Results were almost immediate. Cook has more time to service and upsell his customers-instead of wasting time dealing with production bottlenecks. Touchpoints diminished and morale improved. This also leveled the customer playing field because walk-in and regular clients are receiving much better service.

"Best of all, it took just over one month to begin recouping our original investment and we expect our efficiencies to balloon to over 300 percent in the months to come. Plus, our online proofing system, Enfocus Review is now fully automated," says Cook.

For an assessment of your workflow system, call Significans at 877-463-4465. You'll be directed not to a salesperson or a third party, but to one of our regional workflow automation and integration experts with years of production-floor experience. "We Are Integration." dps

The print industry convenes once again for Drupa, taking place May 28 to June 7, 2024 in Düsseldorf, Germany. The printing technologies trade fair is focused on inspiration, innovations, high-caliber knowledge transfer, and intensive networking.

Here’s a sampling of what to expect at the upcoming event. Find more coverage of Drupa 2024 at dpsmagazine.com.

AB Graphic International, hall 16, stand D10, shows the SRI3 label finishing system and seaming rewinder from its shrink sleeve range. INFO# 300

ACTEGA, hall 3, stand B31, presents product and technology solutions developed for printers and converters seeking more sustainable solutions and high-value embellishment options. INFO# 301 Alwan, hall 7A, stand E10, co-exhibits with ColorConsulting highlighting Alwan ColorHub. INFO# 302

Arrow Systems, Inc., hall 5, stand A36 – B35, showcases the latest digital printing and finishing equipment with its European partner, Katun. The ArrowJet Hybrid Pro M Series makes its debut along with the EZCut 350R digital knife finisher. INFO #303

Baumer hhs, hall 6, stand 6A30, highlights the Side Seam Gluing Solution, which is based on high-performance application heads used for bottom gluing straight-line box production. INFO# 304

BERHALTER, hall 1, stand D51, spotlights its Swiss Die-Cutter B4 and B6 models. INFO # 305

BOBST, hall 10, stand B30-1 – B30-3, announces its latest advancements across all industry segments—flexible packaging, labels, folding carton, corrugated board, and services—to help its customers to thrive in the current and future packaging environment. INFO# 306

BW Converting, hall 16, stands D20 & C21, showcases Baldwin Technology’s redesigned LED-UV curing platform, enhanced QuadCure UV line, and superior print inspection technologies that boost efficiency and productivity. PCMC introduces the ION Hybrid Digital Press

W+D unveils faster, more versatile mailing technologies, including the BB820+ and the i-Jet 3. INFO# 307

Canon, hall 8A, stand B41-1 - B41-8, demonstrates how its combination of technology innovations, expert teams, support services, and dynamic collaboration empowers print service providers to transform their businesses. The full portfolio of Canon production print technologies are showcased, including sheetfed inkjet and toner presses; high-speed, web-fed inkjet production lines; and flatbed and roll-toroll wide format printers. INFO# 308

The Cronite Company, hall 12, stand A02, offers intaglio equipment and supplies for establishing high security and printing for fine packaging. INFO# 309

1. Photo Source: Messe Düsseldorf/drupa 2024. Drupa 2024 starts on May 28. 2. Honle shows LED UV curing for sheetfed printing in hall 16. 3. HP highlights new products in hall 17.

Hönle AG, hall 16, stand D12, consisting of printing specialists Hönle, Eltosch Grafix, PrintConcept, and GEPA Coating Solutions, features its efficient customized curing and drying solutions. Its product portfolio includes LED-UV as well as conventional UV, inertUV, and IR systems. INFO#310

DALIM SOFTWARE, hall 16, stand A40 and hall 7A, stand D01, introduces new generation workflow automation software. DALIM ES FUSION delivers a complete solution with workflow enabling automation, viewer approvals facilitating collaboration, and centralized asset management. TWIST HORIZON is a new generation workflow automation engine. INFO# 311

Enfocus, hall 8B, stand A12, brings its suite of affordable, flexible automation software in a co-exhibition with sister companies Esko, Pantone, and

X-Rite. The stand includes Enfocus Review, an online, browser-based PDF proofing solution that is now fully in the cloud. INFO# 312

eProductivity Software (ePS), hall 7A, stand E03, launches its new cloud-based MIS. INFO# 313

Esko, hall 3, stand B31, unveils sCloud, a multi-tenant platform that delivers on cloud computing, data sharing, and artificial intelligence (AI). INFO# 314

Fiery, hall 8B, stand B10, shows digital front ends, color management, and workflow automation. INFO# 315

frontline.io, hall 9, stand D04, demonstrates augmented reality, virtual reality, and mixed reality, and collaborates with established partners across the show. INFO# 316

Harris & Bruno, hall 16, stand D03, unveils H&B’s ZRX, which offers flood coat, spot coat, and foil stamp—all in one pass. INFO# 317

Gelato, hall 9, stand A06, introduces GelatoConnect, a production platform that streamlines the production process from procurement to workflows to logistics. Historically, GelatoConnect has only been available to printers in the Gelato Network. Drupa marks the launch of GelatoConnect to everyone. INFO # 318

GEW, hall 16 stand E01, introduces a new UV LED system, including its latest LED systems for sheetfed offset and industrial printing applications. INFO# 319

GTI Graphic Technology, Inc., hall 5, stand E10, showcases a new D50 LED lamp, which offers a high CRI solution for its Graphiclite portfolio. INFO# 320

Highcon, Hall 9, stand B24, showcases its new portfolio, which includes the Highcon Beam 3, the innovative Beam Writer, and the upgraded Highcon Beam 2C. INFO# 321

HP, Inc., hall 17, stand A01-1 – A019, highlights the recently introduced HP PageWide Plus Package designed to deliver next-level productivity, efficiency, and automation, alongside expanded application versatility for the HP PageWide Advantage 2200 press. The company also introduces three new digital presses leveraging HP Indigo’s LEP technology, along with an expanded portfolio of intelligent solutions digitizing the production floor. INFO# 322

Hybrid Software’s operating companies, hall 7A, stand D03, unify as the heartbeat for industrial printing and packaging customers. Shown is HYBRID Software’s integrated ColorLogic’s color management software inside its PACKZ PDF editor and CLOUDFLOW enterprise workflow. Global Graphics Software’s Digital Front End, SmartDFE, is demonstrated in multiple OEM partner booths. iC3D’s new packaging distortion technology, Capture 3D, offers photorealistic visualization and powerful production automation. Xitron shares its full catalog of software solutions for all print processes. Meteor Inkjet showcases its complete portfolio of the largest range of electronics driving inkjet printheads. INFO# 323

INX International Ink Co., hall 3, stand E83, presents a range of inks, coatings,

and color management solutions and demonstrates its commitment to sustainability, product innovation, and customer partnerships. INX assists brand owners and customers in making products easier to recycle and promotes the development of circular economies. INFO# 324

ISRA VISION, hall 10, stand A28, highlights printed film inspection systems for flexible packaging, PrintSTAR EVO; and DecoSTAR EVO for printed metal sheets, including a defect classification. Additionally, it introduces new solutions for digitally printed corrugated boards along with EPROMI, a potent production management intelligence tool. INFO# 325.

KARLVILLE SWISS, hall 17, stand A012, is a guest at the HP booth showing the latest technology and innovation, demonstrating the possibility of making digitally printed pouches in a short time and with little waste. INFO# 326

Kodak, hall 5, stand A02-1 – A02-2, showcases a range of products, including continuous inkjet technology and solutions for traditional print. The company demonstrates that it is the one-stop partner for the digital and traditional production needs of printers who want to successfully realize a vision for the future of their business. INFO# 327

Komori, hall 15, stand E02, promotes automation that maximizes customer value and proposes solutions that are friendly to both people and the environment in order to make the future sustainable under the theme “Connected Automation.” Komori recently introduced the J-throne 29, a 29-inch sheetfed UV inkjet digital printing system, which is unveiled for the first time and sequentially released for general availability. The company also shows a range of technology with the theme of Connected Automation. Visitors see a seamlessly connected smart factory utilizing Autonomous Mobile Robots to link prepress and press as well as postpress that incorporates MBO folding machines and the MBO CoBo-Stack collaborative robot. INFO# 328

Kongsberg Precision Cutting Systems, hall 8A, stand B43, debuts the Kongsberg Ultimate and provides a sneak preview of the new addition to its automation line, a new seven-axis robot cell that allows customers to increase throughput utilizing multiple pallets and multiple cutting systems. INFO# 329

KURZ, Hall 3, stand E71-1, presents the DM-MAXLINER 3D digital embellishment machine, along with the premiere of the DM-MAXLINER 2D, a sheet-fed digital metallization system designed for high-quality metallization of a range of substrates, including uncoated paper. Additionally, KURZ showcases the compact and user-friendly DMSMARTLINER for sheet-fed digital metallization and the debut of MPRINT’s ultra-compact full-color 4C digital printing system. INFO# 330

Kyocera, hall 8A, stand C20, is poised to revolutionize the graphic arts sector with the European debut of the TASKalfa 55000c, which offers the ability to print vibrant colors on various media types, including offset coated substrates. Alongside this new device, it showcases the TASKalfa Pro 15000c high-speed, sheetfed commercial printer. INFO# 331

Landa Digital Printing, hall 3, stand B31, highlights the next-generation of its B1 digital print technology, the Landa S11 and S11P Nanographic Printing Presses. The new Landa models are designed to offer production versatility while reaching speeds of up to 11,200 sheets per hour. Further, the new Landa presses offer a new PrintAI module, which opens the door to additional profit-generating opportunities for many businesses. INFO# 332

MAQUINAS MIRUNA LTDA, hall 12, stand E63, exhibits its up-to-date, single head model #3 stitching machine for printing finishing industries as well its great collection of spool capacity for galvanized and coppered wire. INFO# 333

Müller Martini, hall 1, stand 1B50, highlights its Smart Factory as its answer to sustainability in the printing industry—not only significantly reducing the carbon footprint, but also driving the digital transformation. Müller Martini also demonstrates the economic and ecological benefits in the trade fair’s “Touchpoint Sustainability” exhibit in hall 14. INFO# 334

OneVision, hall 8A, stand A40, demonstrates—for first time—its innovative solutions for digital production tracking throughout the entire production process. INFO# 335

OnPrintShop, hall 7A, stand D21, highlights a new version of its web to print offering. INFO# 336

Polyart, hall 4, stand E05, highlights its three primary product lines and services. INFO# 337

Quadient, hall 6, stand F30, introduces the new MACH 9DS full-color dynamic envelope printing solution designed to run in line with Quadient production inserters. INFO# 338

Ricoh, hall 8A, stand A21-1 – A21-2, showcases its newly launched inkjet- and toner-based production printing devices including the RICOH Pro Z75 B2 sheetfed system and the worldwide debut of the RICOH Pro VC80000 continuous feed press. INFO# 339

S-OneLP, hall 17, invites attendees to view its HP eBeam Collaboration Book, highlighting the benefits of its CatPak eBeam Coating System with the option to add the JetFx Spot Embellishment print bar developed with wet-on-wet technology. INFO# 340

Scodix, hall 5, stand E11, launches two new presses, the Scodix Ultra 2500 SHD and the Scodix Ultra 6500 SHD. In addition to Scodix SHD (Smart High Definition) technology. The two new presses also serve as the debut of Scodix MLE (Multi-layer Enhancement) and Scodix AI, an automated embellishment creator tool. INFO# 341

Seiko Instruments’ printhead division, hall 5, stand C30, unveils the ACROBAT RCE2560 600 dpi printhead. The excitement surrounding the RCE2560 stems from its combination of 600 dpi resolution, true recirculation, isolated channel technology, and integrated next-generation waveform controllers. INFO# 342

Sistrade, hall 7A, stand A02, shows attendees how its solutions transform the printing and packaging industry. Visitors are encouraged to discover how its advanced solution empowers businesses to optimize efficiency by automating the production process and improving human resources management. INFO# 343

TechkonUSA, hall 9, stand A03, demonstrates the latest generation of its SpectroVision In-Line Color Measurement system. Get real-time color measurements at full production speeds, cut makeready, avoid costly remakes, reduce waste, and increase productivity. The system can be retrofitted to most digital, flexographic, and offset presses and provides a rapid return on investment, typically under six months. INFO# 344

Technomatic, hall 16, stand C03, partners with iJetColor/Printware to showcase the latest innovations in inkjet envelope solutions, including the iJetColor 1175 Pro. INFO# 345

Tecnau, hall 8A, stand B41, presents its new end-to-end solutions with enhanced automation, connectivity, and performance. Tecnau highlights the

availability of innovative finishing solutions that accompany print service providers in their continued digital journey, adding new applications, reducing cost with automation, and boosting productivity. INFO# 346

theurer, hall 9, stand D06, showcases its browser-based scheduling board and fully automated production automation with AI. INFO# 347

TRESU, hall 10, stand B21, presents an offline TRESU iCoat II sheetfed coater for digital printing as well as the company’s new TRESU InkFlex ink supply system. INFO# 348

Valloy Inc., hall 8B, stand C38, unveils its DuoBlade FX and DuoBlade SF. DuoBlade FX is a sheetfed digital finisher that changes creasing, full-cut, half-cut, pen drawing jobs automatically by detecting a quick response code. DuoBlade SF is a roll-to-piece digital finisher that can be used to make tickets, boxes, and back-scored stickers using a vacuum pad and conveyer. Valloy also showcases professional RIP software for white color in BIZPRESS13R digital roll label press. The company also shows invisible, fluorescent clear toner, which is available for security printing. INFO# 349

X-Rite, hall 8B, stand A12, unveils Autura Ink, a cloud-based ink formulation software that is simple and easy to use for seasoned and new ink technicians alike. X-Rite also announces expanded capabilities for PantoneLIVE. INFO# 350

Zünd, hall 9, stand B03, continues to expand its portfolio of cutting systems, software tools, and automation solutions. The goal is to offer productivity for all—for every customer, every requirement, and every budget. INFO# 351

These exhibits are only a fraction of what is displayed in the halls of Drupa 2024. For additional information, visit dpsmagazine.com and check out our post-show coverage in our upcoming July/August issue. dps

Print shops build their businesses around steady work, regular requests that are often scheduled on a monthly basis. These jobs generally leave room for the sporadic surprise, but not much-running a tight ship is the name of the game these days, without much downtime available press to press.

Some years,jobs pop up and disrupt regular requests and steady work. Take 2024, it's a presidential election year and direct mail will be in full force. How does a printer capture all this extra revenue, while placating its regular customers? Outsourcing is one option. Another is adding a powerful digital press to the lineup, one that not only addresses those higher volumes of work coming through the door, but also produces existing work more efficiently.

Wallace Graphics began in 1987 as a one-man shop and today is a full-service commercial printer.

The business is run out of two locationsin GA, Duluth andJohns Creek, the former holds print production and acts as warehouse, the latter is where its promotional

and apparel work occurs and also houses a warehouse. Between the two spaces the square footage equals 100,000 and 145 staff are employed. Both locations enable the print provider to reach customers all over the U.S. and offer offset and digital printing, in wide and narrow formats. Applications range from direct mail pieces like brochures, postcards, and catalogs to wide format work like custom wallcoverings, vinyl banners, and

After seeingseveral MBO finishinglines

in production, itgaveusthe comfort needed tomoveinto theroll-to-rollenvironment.

- Jake Wallace, VP, and Jonathan Wallace, president, Wallace Graphics

floor graphics. Direct mail is a large portion of the commercial printer's business, it's offered services for the application for over 20 years. This means it not only prints the materials, but also addresses/labels, offers barcode tracking, and mails across the entire U.S. Wallace Graphics has a strong background in digital print, with an introduction to the medium sometime in the early 2000s. "For nearly 20 years, we used digital printing primarily for small

runs that were too small to print on our 40-inch presses and variable data letters. Naturally sheet count thresholds increased as

1. & 2. Wallace Graphics is a full-service commercial printer with two spaces in GA. Complementing Wallace Graphics' presses,specificallyonthedirectmailside of things, is a range of finishing devices from MBO.

digital presses grew in both number and sheet size during that time,” admit Jake Wallace, VP, and Jonathan Wallace, president, Wallace Graphics.

In 2023 the company purchased the HP PageWide Advantage 2200 to expand its capabilities. Looking at addressing challenges like “outputting more volume with less square feet, reducing the number of stages in production, and producing existing work more efficiently,” according to the Wallaces, made the press the right candidate for the job.

The HP PageWide Advantage 2200 presents new revenue opportunities for the print provider. “It gives us the capability to compete in direct mail markets we weren’t cost competitive in the past,” note the Wallaces.

A presidential election year, they anticipate direct mail requests to be much higher than other non-election years. The HP PageWide Advantage 2200 will allow Wallace Graphics to maintain production numbers for its year round customers and add on additional work.

Complementing its presses, specifically on the direct mail side of things, is a range of finishing devices from MBO.

Part of the lineup is the MBO DPS 60 Dynamic Perf & Score Unit, a sheeter, and folding units, which are able to handle almost any folded piece that ultimately ends up in the mail stream. Another advantage to the configuration, it provides the flexibility needed to move jobs that could print offset to inkjet due to finishing efficiencies.

A recent upgrade to the MBO setup was a Palamides stacker, adding it to the backend of the system allows for handling of cut sheets.

“After seeing several MBO finishing lines in production, it gave us the comfort needed to move into the roll-to-roll environment. In addition to the comfort level, it opens all kinds of opportunities to our company that we have not had in the past,” say the Wallaces.

With state-of-the art printing and finishing technology, Wallace Graphics produces direct mail pieces faster and at a lower cost point. “The power of this equipment allows us to go after larger, program-style business that we couldn’t compete with in the past due to cost and front end capabilities,” conclude the Wallaces. dps

Toner-based devices with production-level capabilities present advantages for many businesses. For the purposes of this article, we define production as cutsheet or sheetfed toner-based printers delivering 60-plus pages per minute (ppm).

According to Bob Barbera, director, production solutions marketing, Canon U.S.A., Inc., commercial printers keep returning to toner given its diverse range and capabilities.

“Toner-based printers still have a secure foothold on specific volume bands and categories in the production market,” adds Kent Villarreal, senior product manager, production print, Sharp Imaging and Information Company of America.

Toner-based production printers offer “easy operation, lower cost to entry, as well as ease of paper switching for very short runs,” shares Gregory Pas, manager, marketing communications, Fujifilm North America Corporation, Graphic Communication Division.

Specifically in terms of sheetfed toner, “the lower capital investment costs, toner press

capabilities regarding media and inline finishing, print quality, and smaller press footprints are some of the reasons for continued high demand,” continues Barbera. However, Barbera feels that it’s important to note that inkjet and toner are “not an either-or proposition, and there’s substantial growth expected for inkjet presses within the realm of commercial printing. Future inkjet presses that deliver high-quality work on offset coated and uncoated papers with lower capital investments will help drive this growth.”

Toner-based printers still have a secure foothold on specific volume bands and categories in the production market.

— Kent Villarreal, senior product manager, Sharp Imaging and Information Company of America

Kelly Leahy, global product marketing manager, Xerox Corporation, agrees, explaining that Xerox developed an approach referred to as “better together”— signifying that inkjet is complementary to both toner and offset.

This approach provides diverse and cost-effective quality, speed, media, and finishing options—all supported with integrated workflow automation for seamless coexistence. “Pairing inkjet with toner-based innovation engines unlocks the ultimate in production agility. High image quality, non-standard media, and embellishment jobs can be run on toner-based engines, delivering more ‘wow’ per page. CMYK-only jobs can run quickly,

1. The Xerox Iridesse Production Press offers on-press automation and advanced media handling. 2. Sharp recently introduced the 1200S six-color press.

economically, and beautifully produced on inkjet using a wide range of media,” continues Leahy.

While toner-based production capabilities continue to offer the most flexibility in terms of the media type, quality, and capabilities, Villarreal admits that inkjet has come a long way recently and will continue to make advancements and expand into new markets.

The number of applications accessible from toner-based color production presses is impressive.

Pas lists brochures, books, point of purchase, posters, pocket folders, direct mail, photos, and envelopes as examples. He notes that any application limitations are dependent on the press and how it handles certain paper weights.

Depending on the press’ specifications, toner-based devices are also able to print “high-value” applications like magnets and even packaging applications, shares Barbera.

Another unique application set is what Leahy refers to as “functional goods” or “print being a product.” Items of note include bookmarks, luggage tags, gift tags, coasters, stickers, and magnets.

Over the last two years, Canon unveiled a new line of imagePRESS color presses, comprising of the imagePRESS V900 Series, imagePRESS V1000, and imagePRESS V1350. “The imagePRESS V family consistently enhances strengths like exceptional print quality, productivity, and versatile applications by introducing innovations

in automation, image precision, and color calibration,” notes Barbera.

The imagePRESS V900 Series provides a powerful solution in a small footprint that allows customers to run a range of applications and a diverse selection of media and media sizes. The imagePRESS V1000 supports a range of applications with faster print speeds. The imagePRESS V1350 is a workhorse for customers with high-volume production as well as a need to print on stocks up to 24pt, which opens the door for new applications including packaging.

In April of 2023, Fujifilm launched its Revoria series of digital toner presses. The Revoria PC1120 offers high-speed printing of 120 ppm even when printing six colors, high-definition resolution at 2,400x2,400 dpi, and the ability to support a broad range of stocks—both

52 gsm lightweight paper and 400 gsm heavyweight paper.

Sharp recently announced the BP1200S six-color and BP-1200C four-color digital press series. “Printing up to six colors in a single pass, including CMYK, gold, silver, bright pink, textured, and clear toners, these printing systems feature realtime color stabilization as well as precise paper handling and time-saving finishing options such as square fold, crease, twoedge trimming, and a range of folding options, all of which help set the stage for these workhorses,” says Villarreal.

The color models offer speeds of up to 120 ppm on a variety of media sizes and types with thicknesses up to 400 gsm. They are equipped with a powerful Fiery digital front end and print up to six colors in one pass. Villarreal says the realtime color stabilization and precise paper handling features are the foundation of these precision print engines, which are ready to evangelize marketing messages through beautifully printed works of art.

The Xerox Iridesse Production Press stands out with its stunning image quality, on-press automation, and media handling. Xerox’s Color FLX Technology enables the Iridesse to run six colors inline (CMYK + 2 Specialty Colors including Gold, Silver, White, Clear, and Fluorescent Pink) while maintaining Spot On registration at a rated speed of 120 ppm. This unique configuration allows gold or silver to be placed under CMYK to create unique iridescent mixed metallic palettes and spot effects while fluorescent pink can be blended with CMYK to match more accurately those hard to achieve

Pantones. On press automation enabled by EZ Press Check and PredictPrint media manager ensure the best image quality and media handling, all automatically.

Hardware, software, and even service announcements continue in the tonerbased production print space.

Canon focused on color calibration with its recent imagePRESS V family. This is in response to customer and market insights, according to Barbera. The latest advancement involves the integration of inline spectrophotometers—further streamlining the automation process.

“With the growing scarcity of skilled operators, automating and simplifying engine color calibration, G7 calibration, and profiling becomes crucial. This automation translates to significant time savings, as any operator can effortlessly execute these tasks,” explains Barbera.

Typically, the calibration and profiling process could take someone 30 minutes (or more) for each media type and requires manually measuring the various color patches. However, with the imagePRESS V family and PRISMAsync print server, operators initiate automated color tasks, which concludes within minutes with minimal manual intervention.

The imagePRESS V family also has an optional unit called the Sensing Unit that streamlines and automates the quality control during the press run with closed-loop control of front to back registration accuracy and color consistency

throughout a run. The unit also adds great efficiency to certain press color makeready functions such as sheet uniformity correction and color laydown adjustment for difficult substrate surfaces.

The Fujifilm Revoria Press PC1120 S, its flagship model, has recently undergone updates to offer CMYK+2 specialty color for six-color, one-pass printing, it also includes specialty toner pink to expand the color gamut. These enhancements are in response to customers asking for better image quality and consistency, as well as ease of operation, according to Pas.

The Sharp BP-1200S, in collaboration with Color-Logic and Touch7, stand out. “Unleashing the Sharp BP-1200S opens up a world of possibilities, enables the realization of breathtaking metallic embellishments and vivid colors, limited only by one’s creativity. Furthermore, this collaboration delivers a comprehensive turnkey solution with Sharp bundling both ColorLogic and Touch7 capacities, empowering customers to immediately tap into the press’ full potential and explore the realm of specialty inks,” shares Villarreal.

The finishing portion of toner-based presses also receive attention in the upgrade department. For the Xerox Iridesse Production Press, new Xerox High Capacity XLS Vacuum Feeders and a Plockmatic MPS XL Stacker is available. These enable high-capacity feeding and stacks of standard and extra-long sheets. Leahy notes that these “unlock new applications and revenue streams.”

Updates occur involving RIP solutions as well as workflow support tools.

Much is related to the cloud. “Notably, there’s a significant evolution in the engine and RIP technology, with an increasing integration of cloud-based applications and tools. These innovations leverage seamless communication with the engine and print server, empowering customers to optimize their workflow and reporting capabilities,” shares Barbera.

An example of the advancements in cloud-based applications and tools from Canon are its PRISMAlytics Dashboard and PRISMAcolor Manager. Users compare performance over any period of time and view the graphical results from all supported/connected engines. They can also download the information for their own reporting. And the new version of PRISMAlytics Dashboard now supports the full Canon production portfolio including imagePRESS with PRISMAsync or Fiery, varioPRINT, Canon inkjet production presses, and imagePROGRAF large format printers.

The PRISMAcolor Manager cloud tool verifies the day to day, device to device color performance of CMYK printing systems. “It helps provide customer service ambassadors greater knowledge of press color capabilities while also providing production managers detailed efficacy information about the success of a shop’s color makeready procedures,” shares Barbera.

The increased adoption of JDF/JMFsupported devices and software is important to note. According to Barbera, implementations are revolutionizing file preparation, job settings, and bi-directional communications. A good example is the PRISMAsync app bundle, accessible on the Enfocus App Store. This bundle enables Enfocus Switch customers to make dynamic decisions or adjust settings based on JMF responses from Canon PRISMAsync driven digital presses, enhancing automation and workflow efficiency.

“In today’s world we know that skilled labor is at a premium, so we are continuously focused on workflow automation both on and off the press. This enables our clients to do more with less while maintaining the highest quality,” shares Leahy.

This includes tools like PredictPrint Media Manager, Xerox FreeFlow Core, and Xerox FreeFlow Vision, which create efficiencies by eliminating human touches to save time and reduce the potential for errors or waste. These tools

ensure quality and consistency during a print run and allow print providers to monitor the entire production process with real-time visibility and control of production operations via a highly visual, versatile, and modern dashboard.

Canon imagePRESS is sold and serviced by its authorized dealer network and Canon Solution America. For a Canon authorized dealer to be certified to sell imagePRESS they must become service authorized. Canon U.S.A. Inc. provides second level support to its distribution channels.

Fujifilm offers direct service with a click charge maintenance agreement. Villarreal points out that there are several ways in which Sharp services and supports its production devices. First, it is dealer-centric, meaning that it has made it easy for dealers to sell and service its products. “It’s what we

do well with our other non-production print lines.”

Xerox offers full service maintenance contracts that are deployed by trained service and support specialists. The Xerox Productivity Plus program is also available to print service providers. This innovative, client-focused maintenance program makes it easy to simply diagnose and quickly replace many basic and some advanced items on the Iridesse Production Press.

It is clear that toner-based production presses show promise in the commercial print space, especially as new introductions to the market are on the horizon. With a low capital investment and diverse options in terms of speed, quality, and applications, toner-based production presses offer print providers opportunity to expand their business while maintaining current contracts. dps

utomation is increasingly essential to print providers. This is especially true for digital or hybrid print environments looking to reduce human errors and touchpoints in order to remain profitable on high volumes of complex, short-run jobs. Automation happens everywhere from order entry to machine-level automation, material handling, and everything in between.

While the benefits of automation are obvious from job to job when running longer offset prints, it is even more dramatic when processing digitally printed products in run lengths as low as book-of-one. ''Automated digital workflows in the bindery enable efficient planning and tracking of all jobs as they move through the shop with

access to real-time and historical data to monitor and improve efficiency as well as error alerts and maintenance notifications to maximize the up-time of equipment," shares Bob Flinn, director of business development, Standard Finishing Systems.

Binderies adopt automation for many reasons. For those that handle digital or a hybrid of digital and offset work, the push for automation addresses the need to streamline production processes, reduce manual labor, and increase

Above: Muller Martini has developed many hybrid offset/digital finishing solutions based upon its Smart Factory: Finishing 4.0 engineering ideology.

efficiency. "In digital/hybrid print environments where shorter print runs and variable data printing are common, automation helps manage the diverse range of print jobs more effectively. It allows for seamless integration of finishing processes with the printing workflow, ensuring faster turnaround times and consistent quality," shares Stefano Palamides, managing director, palamides GmbH.

The personalization of printed products for greater effectiveness and the need for equipment solutions that have a higher level of productivity to counter the labor shortages in the graphic arts also drive demand for automation, says Andy Fetherman, president/CEO, Muller Martini Corp.

Changing industry conditions are the primary impetus for automation. "Today's digital, web to print (W2P), variable data, and highly personalized applications require a higher level of tracking from prepress through shipping as well as a high number of machine setups per shift. Additionally, skilled operators are aging out of the industry and there is a shortage of new operators willing or able to train on non-automated, legacy equipment. With automated binding equipment, setup is completed in many cases with the press of a button. This lowers the barrier of entry for new operators while allowing for more machine setups per shift, resulting in more jobs processed per day," offers Flinn.

Automation in binding within digital/ hybrid print environments responds to the need to enhance operationalefficiency, reduce costs, and meet the increasing demand for personalized and short-run print jobs. "In these settings, where the volume and variety of printjobs can fluctuate significantly, automation allows for quicker setup times, minimal manual intervention, and more consistent quality," comments Dmitry Sevostyanov, CEO, Customer's Canvas.

Further, as customer expectations for shorter turnaround times and customization options continue to grow, automation

within binding processes ensures that print service providers (PSPs) can remain competitive and responsive to market needs. "This shift not only streamlines production but also enables a more agile production environment capable of adapting to the rapid changes in print demand and specifications," adds Sevostyanov.

Stefano Formentini, VP, sales and marketing, Meccanotecnica; and Manrico Caglioni, president, Book Automation, Inc. - part of the Meccanotecnica Group, feel that in today's fragmented world, entertainment platforms and tools continuously introduce fresh ways for content distribution. "Consequently, we observe a dual effect-a noticeable decline in book volume per title juxtaposed with a surge in the number of new titles published annually. This phenomenon, coupled with advancements in printing technology such as the development of digital presses, is fostering the emergence of innovative business models tailored to efficiently manage book production, particularly in short and ultra-short print runs."

They feel the evolution of new business models necessitates a paradigm shift in book manufacturing practices. "Enhanced workflow management and heightened automation are imperative to effectively handle the numerous, different jobs that printers and binders produce on a daily basis. With this in mind, streamlined processes and increased automation are essential for optimizing efficiency and meeting evolving market demands;' comment Formentini and Caglioni.

Aarona Tesch, product marketing manager, ACCO Brands/GBC, admits that bindery has typically been a bottleneck in production print, especially as digital and offset presses increase in throughput capacity. "By implementing these automation technologies, PSPs can improve efficiency, reduce labor

costs, minimize errors, and enhance the overall quality of printed materials in digital print or hybrid digital/ offset print environments."

While automation is the holy grail, its implementation is fraught with adoption barriers, such as the initial investment cost, compatibility with existing workflows, and implementation concerns. These should continue to decline with continued advancements by finishing vendors and integration partners.

Cost is one of the biggest barriers. "Most printers today stay in touch with the changes in technology and know that automation is a must. However, not many are able to convert all of their legacy, manual binding systems to automated ones at once without staring down a significant upfront cost. As a result, automation is adopted in stages. But, it is being adopted," stresses Flinn.

"The upfront costs associated with implementing automated systems, including purchasing new machinery and software, can be prohibitive for some businesses, particularly smaller ones," share Formentini and Caglioni.

Integration complexities are another challenge. "Integrating automation technologies into existing workflows can be complex and time consuming," add Formentini and Caglioni.

Automation solutions typically cannot be retrofit on existingequipment, so companies typically have to invest in these newly automated solutions. "While the return on investment is often very good, 1. For book-of-one production, the Standard Horizon BQ-500 Perfect Binder reaches production speeds of up to 800 books per hour. The system also features interchangeable EVA and PUR glue tanks with a new and improved tank removal process for cleaner and easier tank changeover.

one must also look at updating their prepress workflow todrivethese highly automated products," says Fetherman.

Workflow considerations also come into play. "Transitioning to automated processes requires thorough reevaluation and optimization of existing workflows. This can be challenging, as it may disrupt established practices and necessitate significant changes to maximize efficiency," say Formentini and Caglioni.

''Adopting automation tools for prepress tasks such as setting up product catalogs, providing automated online quoting, and facilitating digital previews and approvals presents significant challenges. Creating detailed, user-friendly product catalogs is technologically demanding, given the need to accurately represent a variety of print options. Similarly, developing automated quoting systems that can instantly calculate printing costs with accuracy involves sophisticated algorithms. Offering precise digital previews and efficient online approval processes requires advanced digital representation and customer feedback mechanisms. Overcoming these obstacles is crucial for the effective use

of W2P automation, whichaimstostreamline operations and improve customer experience," comments Sevostyanov.

Printersmayalsofaceresistancefrom employees who fear job displacement or lack the necessary skills to operate automated systems, offers Palamides.

It may be a challenge to find automation solutions that accommodate the variety of substrates and finishing requirements in digital print environments, suggests Palamides.

Al Scolari, president, APS Imaging Solutions, Inc., also sees the challenge in supporting the many different substrates printed on today, as well as the speeds. "These issues are being addressed with new equipment," he states.

Tesch summarizes that while automation offers numerous benefits in improving efficiency and streamlining processes in bindery operations, several challenges hinder its adoption-initial investment cost, integration complexity, training and skills gap, workflow disruption, customization, and flexibility.

The next major focus for bindery automation is in back-end automation solutions. "This will consist of using cobots, automated guided vehicles, and other robotic devices to provide more efficient paper and finished product processing with minimal labor requirements," says Fetherman.

Formentini and Caglioni feel that the significance of automation in the bindery sector is poised to grow exponentially. "It isbecomingan increasinglystrategicand critical factor for both printers and binders, with its proper adoption serving as a defining factor in their success. Embracing automation effectively will not only enhance operational efficiency but also play a pivotal role in shaping the competitiveness and longevity of businesses in the printing and binding industry."

In the next five years, Palamides sees the role of automation in finishing, particularly in digital print environments, continuing to evolve and expand. ''As printers increasingly perceive themselves as manufacturing companies and embrace Industry 4.0 principles, automation will becomemoreintegraltotheiroperations. We anticipate further advancements in robotics, AI-driven technologies, and Internet of Things-enabled devices that allow for even greater automation and connectivity in finishing processes. This will lead to increased efficiency, productivity, and quality in digital print production, driving the industry forward into a new era of smart manufacturing!'

Flinnsaysroboticsisanareawherewe expect the most innovation and growth, comparatively. ''Already, we've seen many manufacturers like Horizon showcase robot prototypes on show floors to demonstrate automation in material handling. While we may not see anything like a widespread adoption of these new technologies in five years, I think we'll see robotics operating on the production floors of more early adopters!'

In the next few years, Tesch expects automation in bindery, particularly in digital print environments, to continue to evolve and expand in several key areasincludingintegrationandconnectivity, artificial intelligence (AI), enhanced personalization and customization, and on demand and short-run production.

2. APS ImagingSolutionsspecializes in digital layflat binding.

“Flexible automation systems will facilitate quick job changeovers, minimize set up times, and enable cost-effective production of small batch sizes without sacrificing quality or efficiency. Further, Smart manufacturing and Industry 4.0 will—with cloud-based applications— optimize efficiency and agility in bindery operations,” says Tesch.

From a prepress perspective, Sevostyanov says finishing automation is becoming more critical in digital print environments. “We’ll see smarter, automated systems that prepare files for printing with less manual work, using AI to fix common issues before printing begins. Online customization tools will also get better, making it easier for customers to design and visualize complex products, including binding details.”

The connection between prepress and bindery will tighten, with automated setups for binding based on the digital

prepress data. “This means less guesswork and more precision in meeting customer specifications. Additionally, the approval process between clients and printers will streamline, thanks to automation handling revisions and feedback more efficiently,” says Sevostyanov.

Further, as the printing industry focuses more on sustainability, Sevostyanov feels that automation will help reduce waste and optimize the use of materials and energy. “In essence, automation will make prepress and bindery faster, more accurate, and less wasteful, truly changing how digital printing jobs are prepared and executed,” he predicts.

Automation brings many specific benefits to finishing operations in digital or hybrid production environments.

Greater automation allows finishing operations increased productivity,

improved quality control, and reduced errors. “Automation streamlines the production process by eliminating manual intervention, minimizing the risk of human error, and ensuring consistency in the finished products. In digital print environments, where jobs often have tight deadlines and high variability, automation helps meet customer demands more efficiently while maintaining profitability,” adds Palamides.

“Driven by shorter run lengths, skilled labor shortages, advances in machine-level automation, and more robust digital workflow systems, there is no doubt that bindery automation will continue to spread in digital, offset, and hybrid printing plants in the next five years and beyond,” concludes Flinn.

For more on the topic of finishing automation, visit dpsmagazine.com for additional web-exclusive content as well as a webinar. dps

1 Canon Solutions America 2 pps.csa.canon.com

2 Crawford Technologies, Inc. 21 crawfordtech.com

6 Esko/Enfocus 13 esko.com

3 Komori America 10-11 komori-america.us

4 MBO/Komori Group 17 shop.mboamerica.com

5 Muller Martini 5 mullermartini.com

15 National Postal Forum 27 npf.org

7 Printware 9 ijetcolor.com

13 Shark Finishing Machinery 26 sharkmachinery.com 8 Sharp Electronics Corp. 19 business.sharpusa.com 12 Significans Automation 7 significans.com

9 Signs 365 28 signs365.com

10 Standard Finishing 15 standardfinishing.com

11 Therm-O-Type 25 thermotype.com

14 Valloy, Inc. 26 valloy.com