Today, doing more with less is a reality across all industries, and print is no exception. This is true for both print buyers and manufacturers. Modern tools are essential to succeeding in this current landscape.

Print providers may chose to amplify their workflow in order to gain insight from the production floor. This helps determine what

Today, doing more with less is

is working, what isn’t, and where profit and savings potential can be tapped. Mission-Critical MIS discusses how print management information systems (MIS) continue to evolve to make it easier to access, operate, and implement through intuitive user interfaces and reporting tools. A Target Chart in this issue highlights today’s print MIS options. Find a webinar on the topic online at dpsmagazine.com/webinars.

Adding value is another way to improve profit potential. One popular way to do this is through embellishments. In the Gilded Age of Print we highlight the effects that promise to heighten any printed piece.

We are entering trade show season with a bang. This issue highlights expectations for the upcoming Labelexpo Americas, happening in Chicago, IL from September 10 to 12, 2024 and Printing United, taking place simultaneously in Las Vegas, NV. Visit dpsmagazine.com for up-to-theminute updates from both events.

Best regards,

Cassandra Balentine, editor cbalentine@rockportpubs.com

dpsmagazine.com

Volume 26, Number 5 • ISSN: 1529-2320

EDITOR IN CHIEF

Thomas Tetreault 978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Mark Hanley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault 64 Thissel Street #272 Prides Crossing, MA 01965

Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 64 Thissel Street #272 Prides Crossing, MA 01965

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy Tyler

By OPS Magazine Staff

Inkjet continues to advance its scope and relevance in the print industry. From direct mail to photobooks and transactional applications, the technology is versatile.

To find success in a rapidly growing and competitive market, it is essential for print providers to stay abreast of the latest trends, tools, and technologies. One of the ways Canon inkjet customers can do this is through thINK, an independent community of Canon Solutions America production inkjet customers designed to provide a forum for members to network, gain knowledge, discuss common challenges, and access tools, training, and resources.

The organization convenes annually for the thINK Ahead event, which took place this year from July 15 to 17 in Boca Raton, FL.

Attendees were given insight into Canon's market strength, with FrancisA. McMahon, EVP, Canon Solutions America, reporting a record-breaking first half for its Production Print Solutions group.

Throughout the conference, visitors were able to catch a shuttle over to the nearby Canon Americas Customer Innovation Center for tours and demonstrations of the latest production print equipment. This year, thINK Ahead 2024 guests were among the first to see four new Canon inkjet products making their U.S. debut after premiering at drupa-the ProStream 3160, ColorStream 8200, varioPRlNT iX 1700, and the LabelStream LS2000.

The main attraction of the thINK Ahead conference is its informative and topical sessions. Over three tracks, ses-

format; and mergers and acquisition activity in the printing industry.

It wasn't strictly business. thINK attendees were encouraged to participate in wellness activities like pickleball, a SK and fun run/walk, as well as yoga on conference mornings. Nighttime entertainment included the comedian Marcus Monroe as well as the event's popular Cabana Nights party.

Canon inkjet customers have an excellent resource in the thINK community. Aside from the annual thINK Ahead sion topics covered sales, marketing, conference, the thinkforum.com website and pricing strategies; human resources considerations for print providers; direct mail initiatives, outlook, and opportunities; navigating taxes post Wayfair; artificial intelligence response optimization and future uses; opportunities in wide and application is a non-stop resource with news and research; services; designer, marketing, and press operator tools; as well as training and events. dps 1. & 2. thlNK celebrated its tenth conference in Boca Raton, FLfrom July 15to 17,2024.

By OPS Magazine Staff

Printing United is a comprehensive printing event designed to bring together the entire printing industry in one place. This year, the show takes place at the Las Vegas Convention Center in Las Vegas, NV from September 10 to 12, 2024.

Exhibitor Highlights

Aleyant, booth ClO0, launches PDF2Press, a workflow software designed to automate the artwork file upload process for consumers. Integrated seamlessly with Aleyant's print ecommerce software; Pressero, PDF2Press promises to enhance efficiency and accuracy in print production workflows. INFO# 200

ASLAN, booth SL10214, spotlights its latest self-adhesive specialties and establishes strategic alliances with industry leaders. INFO# 201

Aurigma, booth C163, showcases a new version of its editor with improved preflight capabilities and introduces updated 3D preview functionality, enhanced workflows for products with embellishments, and a new solution for direct mail applications. INFO# 202

Baumer hhs, booth C1990, features its Field Smart camera-based verification

system, tesla 24VDC electrically-activated hot melt applicators, and cold glue dispensing solutions. INFO# 203

Bluecrest, booth Cll73, features the Epic inserter with OttoMate Cabot workcell automation, the BlueCrest Strata cloud-based software platform, and mailing preparation software from BCC Software, a BlueCrest company. INFO# 204

Canon U.S.A., Inc., booth C348, invites attendees to get a close look at its range of production and large format products and solutions, from the newly announced varioPRINT iXl700 sheetfed inkjet press to innovations in production printing solutions, display graphics, and wallcoverings. Live demonstrations take place throughout the show with experts ready to answer questions. INFO# 205

The Challenge Machinery Company, booth C2815, features the CHAMP 185Pro hydraulic paper cutter, which

brings large cutter strength and accuracy to the 18-inch cutting market. INFO# 206 Duplo USA, exhibits its portfolio ofautomated print embellishment, packaging, and finishing solutions with B2 format equipment front and center. The booth highlights the DuSense DDC-8000 B2 Raised Spot UV Coater, the DSM-1000 B2 Platen Die Cutter, the DC-746 B2 Slitter/Cutter/Creaser, and the 700i Pro Digital Booklet System. INFO# 207 Durst Group, booth Cl543, showcases its hybrid PS 350 HS with D4 configuration, the high-speed roll-to-roll PS 350 HSR, the PS TEX iSUB, and the Tau RSC E label printer. These printers are supported by UV- and water-based inks, a software ecosystem, and a knowledgeable team. INFO# 208

1. Sharp shows off its production press lineup in booth C2490. 2. Aurigmashowcasesanewversion ofitseditorinboothC163.

Elitron, booth SL6004, shows the Spark Series flexible cutting system and the Kombo TH. INFO# 209

EMT International, booth C2731, highlights its full line of direct mail offerings for finishing equipment. The company announces its latest development— a postcard solution offering flexibility, precision, and speed. INFO# 210

Epson, booth SL8101, features technology for a range of applications, from indoor and outdoor signage to photography and graphics to textile. INFO# 211

Fiery, booth C335, invites attendees to unlock their digital printing superpowers with the latest digital front end, color management, and automated workflow innovations. See the Fiery Impress for packaging workflows, Digital Factory for direct to film printing, new artificial intelligence-driven workflows, and color and imaging tools. INFO# 212

Four Pees, booth C222, provides automation solutions that streamline print and packaging production across the globe, inclduing Atomyx, a cloudbased print production management platform. INFO# 213

Gelato, booth C1215, showcases GelatoConnect, a print production software platform designed to support production hubs in optimizing efficiency and quality and expanding revenue by accessing additional product categories and geographical markets. INFO# 214

Global Garage, booth C934, allows attendees to buy or sell equipment with premier experts in pre-owned grand format print equipment. INFO# 215

Global Imaging, booth C1375, shows off its display made from T3 framing systems. Don’t miss the opportunity to get a first-hand understanding of this tool-free, modular system. INFO# 216

Graphic Whizard, booth C1727, showcases its latest innovations including a new inline Slit/Cut/Crease machine. See the latest advanced automated perfect binders, designed for impeccable binding quality and increased efficiency. Also debuted is a new PT 33LSC Micro duplex laminator with cutto-bleed and encapsulation technology. Don’t miss the new multi-piece inline folders for the GW SCC line, engineered to handle complex folding tasks with precision. INFO# 217

GTI Graphic Technology, Inc. (GTI), booth C140, highlights the new D50 LED lamp, which offers a high CRI solution for its Graphiclite portfolio of products. This lamp combines the benefits of LED technology with a close match to D50 spectral specifications ensuring tight conformance to the ISO 3664:2009 viewing standard. INFO# 218

Harris & Bruno and Taktiful, booth C928, team up to showcase the "Next Big Thing in Digital Embellishment." Combining Harris & Bruno's ZRX digital embellishment machine with Taktiful's innovative software for design, sales, and estimating, this partnership promises to revolutionize the world of digitalembellishment.Stop byandlearn how you can flood coat, spot coat, and foil stamp on uncoated media in a single pass, while your sales team consistently meets competitive pricing. INFO# 219

lnkcups, booth C2749, highlights its direct-to-object digital printing and pad printing solutions, which includes cylindrical UV inkjet printing technology for printing on cylindrical objects and vessels, flatbed UV printing technology for digital decoration of bags and industrial applications, as well as pad printing solutions for applications such as promotional products. This includes the XJET Switch UV flatbed printer. INFO# 220

1ST America, booth C3083, is the North American arm of IST Metz in Nurtingen Germany. IST, along with sister company IST INTECH, showcases several technologies including FREECure, SMARTcure, and UV Analyzer. INFO# 221

Kavalan, boothSL13078,featuresits banner materials, which offer an alternative to PVC that doesn't compromise

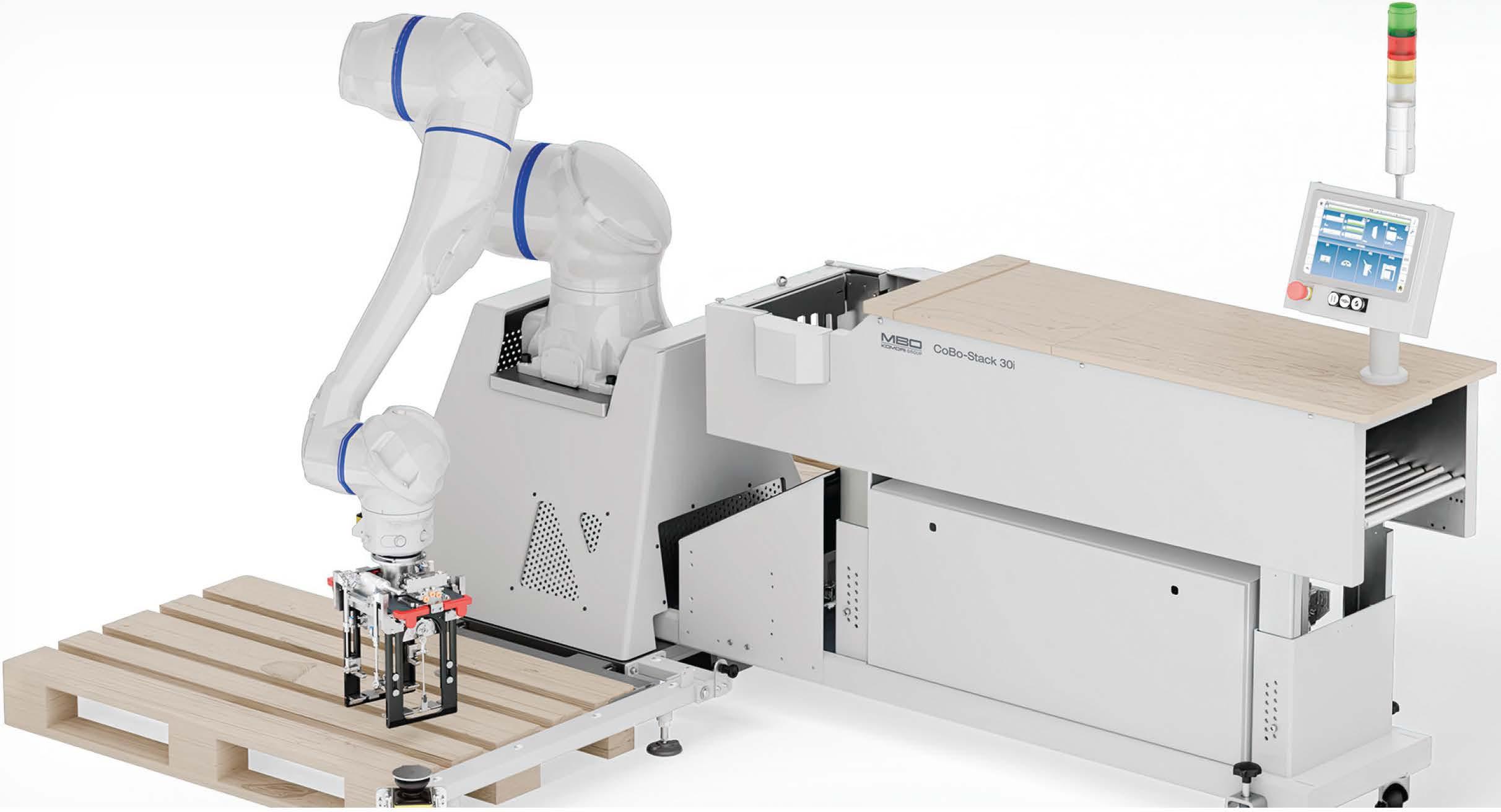

3.MBO demonstratesthenewCoboStack3DicollaborativerobottechnologyinboothC2149.

on quality, appearance, or performance. Available through Media One, the range includes materials for indoor, outdoor and backlit applications, as well as a double-sidedblock-outtextilematerial,a meshbannermaterial,anda coated wall covering material. All Kavalan materials holdLCA certifications, confirming their superior eco-performance over traditional PVC banners. INFO# 222

Konica Minolta, booth C3491, presents a number of devices to help printers see the potential to expand their business in new ways. The company features the AccurioPress C1410s, AccurioWide250,AccurioLabel230, PKG1300, and AccurioShine 3600 with iFoil One. INFO# 223

Kyocera Document Solutions America, booth C2175, shows off its innovations in the TASKalfa Pro 15000c and TASKalfa Pro 55000c, as well as gives booth visitors a look at its textile printer, FOREARTH. Kyocera is ready to once again show the international print community how its high-volume inkjet printers continue todriveindustry trends and create newpossibilities. INFO#224

Landa, booth C2995, invites attendees to learn about the Landa Sll & SllP digital Bl offset presses driven by Nanography. These presses offer versatility and productivity, handling various substrates with ease. With unmatched color gamut and printing 11,200 sheets per hour, the Sll & SllP maximize

profitability and efficiency. Gain insight on how these groundbreaking presses can streamline your operations and drive growth. INFO# 225

MBO America, booth C2149, highlights its new Collaborative Robot technology,theCoboStack30i. Thecompany also showcases its web embellishment modules, the SpotCoater (SC23) and ContourCutter (CC23), expanding its portfolio of commercial-quality, rollfed finishing solutions. Don't miss the chance to meet with its industry experts and discuss roll-fed finishing, commercial folding, pharmaceutical folding, or die-cutting needs. INFO# 226

MHP Technology, booth C306, the pioneers of canvas stretching and frame assembly machines, invite attendees to enjoy some original German Biergarten refreshments while experiencing an immersive 360 degree experience of the new MHP ULTRA fully automated canvas stretching machine. And attendees can test its unmatched canvas tension live on its canvas drum kit. INFO# 227

Muller Martini, booth C2561, introduces innovations from both Muller Martini and Hunkeler in digital saddle stitching, digital perfect binding, and paper finishing solutions, seamlessly integrated into Muller Martini's Connex Workflow System. This display will highlight how Muller Martini is "Driving the Digital Transformation" with these latest in cutting-edge print finishing technologies. INFO# 228

Nobelus, booth C2545, demonstrates its thermal laminating systems and provides samples of its tactile finishes. The company showcases double-sided lamination on its Amiga 52 Double and Podmaster IDH-54 Quatro lamination systems. It also highlights the silver halide replacement(SHR)digitalphotofinishing solutionsusinganAmiga52Embossand PlatinumSHR Laminate. INFO#229

printlQ, booth C3343, specializes in delivering an intelligent, cloud-based MIS solution directly to the core of your

business. Its focus is to maximize visibility and connectivity across the workflow while driving efficiencies and creating new revenue streams. Its team of specialists will be on hand to discuss your current print production workflow and how an MIS solution like printIQ can help scale your business through digital transformation. INFO# 230

Quadient, booth C2931, showcases the new Quadient MACH 9DS full-color dynamic envelope printer, along with the Quadient DS-700 iQ folder inserter system. Visitors will also get a sneak peek at the new Quadient DS-1200 G5 iQ inserter system and Quadient MACH 7 color inkjet printer. In addition to the mail systems, Quadient demonstrates its advanced software offerings. INFO# 231

Ricoh, booth C2161, features the Pro C7500, RICOH Pro C9500, Ricoh-powered EFI 30h, and the RICOH Auto Color Adjuster. Ricoh’s Direct-to-Garment Ri4000 is also highlighted. Learn more about the new RICOH Pro VC80000 through a interactive experience and hear from Ricoh’s experts about its suite of software and services solutions ranging from print MIS, workflow integration, and automation, and job on-boarding and batching. INFO# 232

RISO, booth C539, highlights its cutsheet inkjet solutions with a specific focus on its ability to address the changing climate of print. Print is keeping the same volumes, but breaking up long run jobs into multiple short run jobs—and the versatility, small footprint, and low price point of RISO allows for multiple units to be in the same space, printing multiple jobs simultaneously. In addition to the ComColor GL and VALEZUS printers, it showcases an envelope feeding accessory and the SDD three-sided booklet trimming accessor. INFO# 233

Rochester Software Associates, booth C1986, provides prepress, transform, output management, and web to print software solutions for in-plant print centers, commercial printers, and print

service providers. The company has all its products available to experience, including WebCRD, QDirect, and ReadyPrint. INFO# 234

Rollem International, booth C1461, demonstrates two Insignia Die Cutters, a B2 plus the IS6H PLUS model, offering die-cutting, kiss-cutting, creasing, perforating, embossing, hole punching, and automated waste removal. Their ease of operation and fast changeovers guarantee profits in folding cartons, packaging, and custom postcard markets. The Jetstream XY system features automated postcard converting—a B2 sheet with 9-up jumbo postcards. The Champion 990 economical slit, score, and perf model and the Semi-Slitter kiss-cutting system are also displayed. INFO# 235

Sharp Imaging and Information Company of America (Sharp), booth C2490, presents its newly expanded line of digital press technologies. Show attendees are invited to witness major advancements in its production print capabilities, including its flagship four- and six-color printing systems and high-speed, monochrome production printing systems launched this Spring. Additionally, Sharp highlights the recently launched Pro Series production models featuring exciting new enhancements. Building on Sharp’s theme of having the right products together with the right partners, the 111year strong technology powerhouse also includes representation from various companies in its booth to provide consultative support for the Sharp printing systems, such as organizations specializing in finishing, custom print embellishments, packaging, software solutions,

and helping digital embellishment users become more profitable designing, operating, selling, and marketing embellished products. INFO# 236

Standard Finishing Systems, booth C1561, features live demonstrations of the latest finishing and feeding technologies from Horizon and Hunkeler including the new Horizon BQ-300 Perfect Binder, the Hunkeler Gen8 Roll-to-Stack system, and the Hunkeler/Horizon Rollto-Saddlestitch system. INFO# 237

Tecnau, booth C513, exhibits two new lines for first U.S. showings. The labor-saving Revolution 50 AutoSetup line offers fully automated job changeovers with no manual intervention. The Automation-assisted StreamFolder 5152 produces glued book blocks for offline binding. Tecnau also exhibits CutReady including the cost-effective TC 7000 TS guillotine cutter for straight clean-bleedcut heavy paper applications, and Stack 1212 B2 sheet finishing inline with Kompac Phoenix 20 coater. INFO# 238

Ultimate Tech, booth C3277, showcases Automation in Overdrive where the key to automation is combining hardware automation with software workflow. Ultimate Tech leads in imposition, nesting, and finishing automation and visitors can see its latest Ultimate Impostrip with true shape nesting and Ultimate BestCut driving the Itotec Paper Cutter in action at the booth. INFO# 239

Wausau Coated Products, booth C1815, is a family-owned and operated manufacturer of adhesive-based label products that has been crafting label excellence for more than 40 years. It is a one-stop resource worldwide for premium quality stocked products and custom-engineered constructions to

meet customer-specific applications and end-user needs. Visit the booth to learn more about sheet label products and custom capabilities. INFO# 240

Xeikon North America, booth C1143, features the first North America showing of the TX500 (TITON) Press in collaboration with Kurz Digital Embellishment Solutions. The company also highlights collaboration with Kurz. The Xeikon Café features coffee and happy hours. INFO# 241

Xerox, booth C2614, showcases the company’s end-to-end Production Ecosystem. From feeding and finishing to predictive AI and fleet management solutions, innovative digital print solutions including the Xerox Iridesse Production Press and Xerox Versant 280 Production Press, Xerox helps print providers grow their business and deliver the high-quality output clients require. The Xerox exhibit also features automation workflows including Xerox FreeFlow Vision Connect and XMPie’s omni-channel marketing platform that helps clients deliver personalized, relevant communications across print and digital media. INFO# 242

Zünd, booth C1161, features the latest advances in high-performance digital cutting automation—from the latest, most advanced, industrial Q-Line system to the ultra-versatile Zünd G3 “workhorse” now available with UNDERCAM registration system, adapted from the Q-Line and specifically designed for processing materials that benefit from cutting/creasing from the back, unprinted side. Also displayed is a Robot PortaTable setup for automatic material-advancing from rolls and robotic picking for a fully automated, non-stop, unattended production process. INFO# 243

For those looking to scope out the broad trends happening in the print industry, Printing United provides access to a variety of technologies under one roof. dps

By Cassandra Balentine

Labelexpo Americas is where converters, brand owners, and packaging designers go to see the latest equipment, technologies, and solutions to make their business successful. It is also the premier platform to hear from notable industry thought leaders who are at the intersection of innovation and transformation.

The event takes place September 10 to 12, 2024 at the Donald E. Stephens Convention Center in Chicago, IL. In addition to exhibitor technology, show organizer, Informa PLC, features a oneday conference program featuring hot industry topics; expert-led master classes and premier workshops; Eco Stage; and networking opportunities.

Exhibitor Highlights

AB Graphic International (ABG), booth 3223, showcases the NSU Lite, a new addition to its Non-Stop Winding range. This system is demonstrated inline with ABG’s fourth generation converter platform and the recently launched Vectra AutoSet Turret Rewinder. Additionally, ABG presents its flagship Digicon Series 3, including the ABG Connect workflow system. INFO# 249

Avery Dennison, booth 119, invites attendees to explore interactive displays highlighting RFID technology that help increase transparency and build efficiencies. Discover products that advance sustainability, enable recycling, and lower your carbon impact. INFO# 250

Bobst, booth 5601, continues to build on its industry vision for packaging. Following the opening of its new Competence Center in Atlanta, GA—where customers could experience the labels and flexible packaging portfolio live—the North American team is available and visitors can experience live demonstrations on the BOBST DIGITAL MASTER 340 among others. INFO# 251

Canon U.S.A., Inc., booth 5803, displays the LabelStream LS2000 inkjet label press, Colorado M-series 64-inch roll-to-roll printer, and the LX-P5510,

LX-D5500, LX-P1300 dye- and pigment-based inkjet desktop label printers. INFO# 252

CERM, booth 437, develops smart MIS software for label and packaging printing. It offers an automated workflow connecting all elements of your business through key standard integrations. Visitors can explore CERM’s latest innovations, including artificial intelligence (AI)-based scheduling and new partner integrations. Visit the booth to discover how CERM can transform your operations and improve your productivity. INFO# 253

Channeled Resources Group (CRG), booth 1211, showcases its inventory of Blank Labels, including commodity

1. UPM Raflatac showcases its new portfolio of carbon action plastic labels in booth 515. 2. Konica Minolta’s AccurioLabel 230 is displayed in booth 6545.

sized blank labels for thermal transfer and direct thermal applications. CRG also promotes its pressure-sensitive roll label materials. INFO# 254

Dantex Group, booth 6129, presents its PicoJet 1200 digital inkjet technology. Pico offers highly productive, affordable label printing for short to long runs, no minimum run quantity, minimal waste, super-fast turnaround, and makes label production fast and easy. INFO# 255

Domino, booth 5821, demonstrates the N730i and N610i digital UV inkjet label presses, K600i dual bar digital UV inkjet, and introduces the new K300 digital coding solution. INFO# 256

Durst North America, booth 3123, showcases the new hybrid KJet alongside the Durst Tau RSCi, and Durst’s software and solutions. Making its American debut, the KJet combines OMET’s dual servo flexographic printing units with Durst’s RSCi inkjet technology. INFO# 257

EMT International, booth 136, presents its portfolio of Rotocontrol label finishing machines featuring inspection slitter/rewinders, pharmaceutical security, booklet & ECL production, and digital finishing. Available in basic inspection/rewinding configurations, Rotocontrol machines can be fitted with numerous modules either at order

or later in the field for enhanced capabilities such as integrated vision inspection, semi-automatic turrets as well as multiple slitting, counting, and product detection methods. Also featured is EMT International’s Chameleon web finishing technology and auxiliary processing solutions for the global inkjet market. INFO# 258

EyeC, booth 1535, highlights the improved EyeC Profiler 1200 DT presentation. In addition to technical improvements for optimized speed, handling, and ease of maintenance, the scanner-based inspection solution with its fresh design sets new standards in the quality control of large format print samples. INFO# 259

Excelitas, booth 381, showcases its Phoseon brand of UV LED curing solutions for labels and packaging. Learn more about the Phoseon Nexus ONE expanded platform for flexographic printing, along with UV LED curing systems for digital printing. INFO# 260

Fedrigoni Self-Adhesives, booth 3101, showcases a range of products in its booth for a variety of industries like wine and spirits, home and personal, and food and beverage. INFO# 261

GlobalVision, booth 1621, features products and services that fulfill proofreading and quality assurance needs and requirements for regulated industries. The technology featured at the booth includes capabilities such as Braille height inspection, print inspection, text

inspection, barcode inspection, Cloud PDF and Proof inspection, large format scanners for full press sheet inspection, and counting systems for inserts, cartons, and vials. INFO# 262

Gonderflex, booth 6421, showcases its GFXL 3000 Finisher in the show’s dedicated FlexPack Factory area. The finisher is a versatile, multi-process midweb finishing platform for flexible packaging, shrink sleeve, labels, and even folding carton. Also on display is a R330 digital finishing machine for labels with flexographic printing and semi-rotary die cutting along a GFSRE-1300 compact label slitting machine. INFO# 263

HEIDELBERG & Gallus, booth 3523, unveil the latest Gallus One 17-inch digital inkjet label press, featuring an extended color gamut at 230 feet per minute (fpm), and new “system to compose.” With compatibility across leading product lines, Gallus machines now boost unparalleled adaptability, modularity, and versatility. INFO# 264

HP, booth 3226, showcases some of its latest innovations in label and flexible packaging printing technology and demonstrates how converters can bring the value of HP Indigo digital print to any job, enabling them to grow faster and diversify into new businesses like flexible packaging and shrink sleeves. The company exhibits the HP Indigo 200K Digital Press with an addon slitter and the HP Indigo 6K Digital Press. INFO# 265

HYBRID Software, booth 3015, displays the new PACKZ 10, an all-in-one PDF editor and prepress application for both digital and conventional printing; CLOUDFLOW, the modern workflow engine; a full complement of ColorLogic color management; and iC3D 3D imaging and prototyping. Hybrid Software technology drives several digital presses on the across the show floor. INFO# 266

IIJ , booth 6107, is a global company specializing in integrating configurable digital inkjet print systems into

customer applications through collaborative design, implementation, production, and servicing across a range of markets including décor, security, coding and marking, labels, and packaging. Its equipment, powered by Konica Minolta printheads, offers customized solutions with dedicated customer service using appropriate technologies that fit a range of inks including UV or aqueous, security or specialty, generic or functional to fit the customers optimal solution. INFO# 267

INX International, booth 129, invites attendees to learn how sustainable Genesis washable inks support a circular economy and makes it easier to recycle plastic films. Combat counterfeit products with VerifyInk, a covert taggant technology offering a versatile security solution, which can be printed on paper, flexible packaging, and shrink labels. Eliminate post-shrink adhesion loss and ink flaking with INXFlex Contour, and discover how its full line of tag and label inks and coatings can enhance your printing capabilities. INFO# 268

Konica Minolta, booth 6545, showcases its newest label press, the AccurioLabel 400, which offers CMYK plus a new fifth station white dry toner for true white applications that help expand creative label design. The AccurioLabel

230 digital toner press is also on display. Finally, Konica Minolta’s new JETvarnish 3D Web 400, a 100 percent web-fed digital embellishment solution that seamlessly integrates spot UV varnish, hot foil stamping, and variable data printing in a single pass. INFO# 269

KTI, booth 1040, showcases its fourspindle MTR Series Turret Rewinder. Available in web widths up to 22 inches, roll diameters up to 16 inches, and speeds up to 750 fpm, the MTR Series Turret Rewinder includes an integrated dance for superior web control and PLC touch screen controls. INFO# 270

KURZ, booth 729, showcases innovative digital embellishment, hot stamping, and full-color equipment on the show floor. The company invites attendees to visit the booth for live demonstrations and to discover the cutting-edge technologies it offers. INFO# 271

Mark Andy, booths 319 and 424, exhibits five printing presses, offline finishing systems, and products designed to drive progress in the narrow web industry. Highlights include the DOMINO iQ-R digital engine integrated with the Mark Andy 2200 flexographic press, the Digital Pro MAX, the Digital Series HD, and the new P Series S9 for the label and flexible packaging markets. Further, Mark Andy Print Products, supplying the offset, flexographic, digital, and letterpress industries, introduces a new line of branded products. INFO# 272

Nobelus, booth 3622, illustrates how soft-touch Karess Film and rugged, durable FineGrit Film give prime labels an unforgettable tactile appeal. Using the 330 Mini finishing system from GM and wet adhesive from Applied Molecules, Nobelus hosts live demonstrations of the wet lamination process. INFO# 273

Polyart Group, booth 439, launches two sustainable substrates—r-Polyart and Fiberskin Tag. INFO# 274

PPG Teslin, booth 5619, showcases its TESLIN material and label stock, a synthetic material renowned for exceptional durability and performance in challenging environments. Designed to meet the rigorous demands of various industries, Teslin label stock is available in five standard types—GeneralPurpose Permanent, Ultimate Bond, General-Purpose Removable, BS 5609-certified for marine conditions, and two Pharmaceutical-Grades—tight mandrel and low-energy and sterilization applications. INFO# 275

Rosas Maschinenbau, booth 6515, demonstrates its Leopard 30 di-directional table-top rewinder featuring an advanced RFID HF & UHF tag serialization module with code verifier, backside serialization, and thermal inkjet printing for numbering and coding. INFO# 276

S-OneLP ventures “Beyond the Box” in booths 6385 and 1353. Booth 6385 showcases capital equipment with live demonstrations of the Cellcoat T14 Thermal Laminator, plus discover the CatPak eBeam System. Booth 1353 features Michelman primers, Kustom Koatings overprint varnishes, and visitors have a chance to learn about the latest flexible packaging films. INFO# 277

Sun Chemical, booth 831, displays its full portfolio of sustainable solutions for the flexible packaging and narrow web, tag, and label printing markets under the theme Labels Transform. Products highlighted include biorenewable, compostable, and recyclable inks, coatings, and adhesives. INFO# 278

ByCassandraBalentine

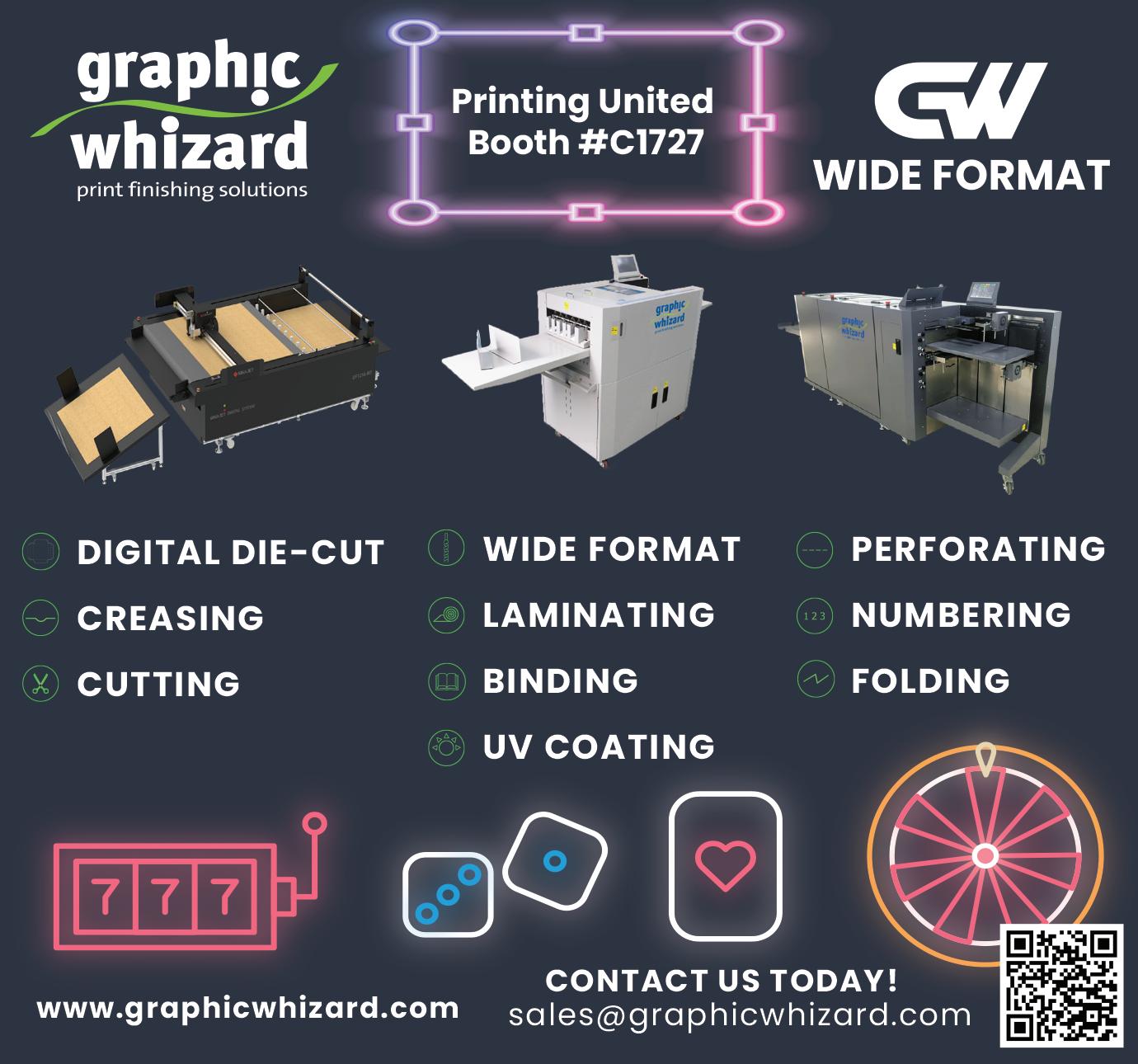

e are all familiar with the embellishments and enhancements available today-metallic and neon inks, embossing and debossing, spot coating, holographic, digital die cutting, the list goes on. These features add value to a printed piece, whether it's a label, a ticket, or a piece of direct mail. These effects catch the eyes ofbrand owners across several vertical markets. As digital print technologies permeate new industries, traditional means of adding embellishments to print evolve to complement digital processes.

All printed applications benefit from some type of embellishment. However, adoption is driven by certain industry demands.

In today's print market, Mark Nixon, EVP, sales and marketing, Scodix, sees an undeniable desire for businesses to connect with their customers. Embellishment is a powerful

Above: Scodix's newest presses are designed to unlock potential for businesses and brands. The Scodix Ultra 2500 SHD and the Scodix Ultra6500 SHD each offer the company's range of 16 applications, including UV, foil, Braille, andembossing.

tool for elevating the consumer experience. "From bejewelled wedding invites to holographic security labels on luxury consumergoods, or adding sheen to the personalization on direct mail, to intricate foil micro fonts on beauty packaging, embellishment captivates attention, addsvalue, andenrichesexperiences.In a market that highlyappreciatesindividuality, theadaptabilitytoproduceunique design solutions efficiently and cost effectivelyisgreatly valued."

"The primary driver for the adoption of digital print enhancement technology has been the value it brings to making the material output more noticeable, engaging, interactive, and sensory in nature," secondsJohn Dembia, product marketing manager, Industrial Print Products, Konica Minolta.

Adding texture and foil to graphic design helps create a more dramatic, eye-catchingimpact.

Sharon Beeman, VP global sales, S-OneLP, agrees, noting that today's print providers use embellishments to enhance visual appeal and tactile experience of printed materials in order to differentiate and capture attention in a crowded marketplace, helping brands standoutfromthecompetition.

Brands and marketers understand that attracting potential buyers requires packaging andprinted materials to have a visually alluring element. "Whether it be the stark contrast between a matte substrate and glimmering foil, an entire area shining with holographic imagery, or a spot polymer that draws attention toalogo, package, orprintedpiecemust have something that catches the eye of consumers from the first glance," comments Dragan Nikolic, manager, businessdevelopment, Nobelus.

The use of embellishment helps marketers stand out in crowded markets across many industry segments. Because of this, brand owners-and the

print providers that serve them-increasingly look to embellishment technologies to stand out.

Embellishmentslikefoil stamping, spot varnishes, andtexturedeffectsarenot justaboutaesthetics. Kevin Abergel, founder, Taktiful andTaktifulSoftwareSolutions, believes they create a tactile experience that enhancesbrandperception andcustomerengagement.

In the realm of direct mail, embellishments are used to catch the recipient'seyeandmakethemail piece stand out among a sea of plain envelopes and flyers. "It'sastrategicmove to increase open rates and engagement, as the unique feel and appearance can pique curiosity and encourage interaction," commentsAbergel.

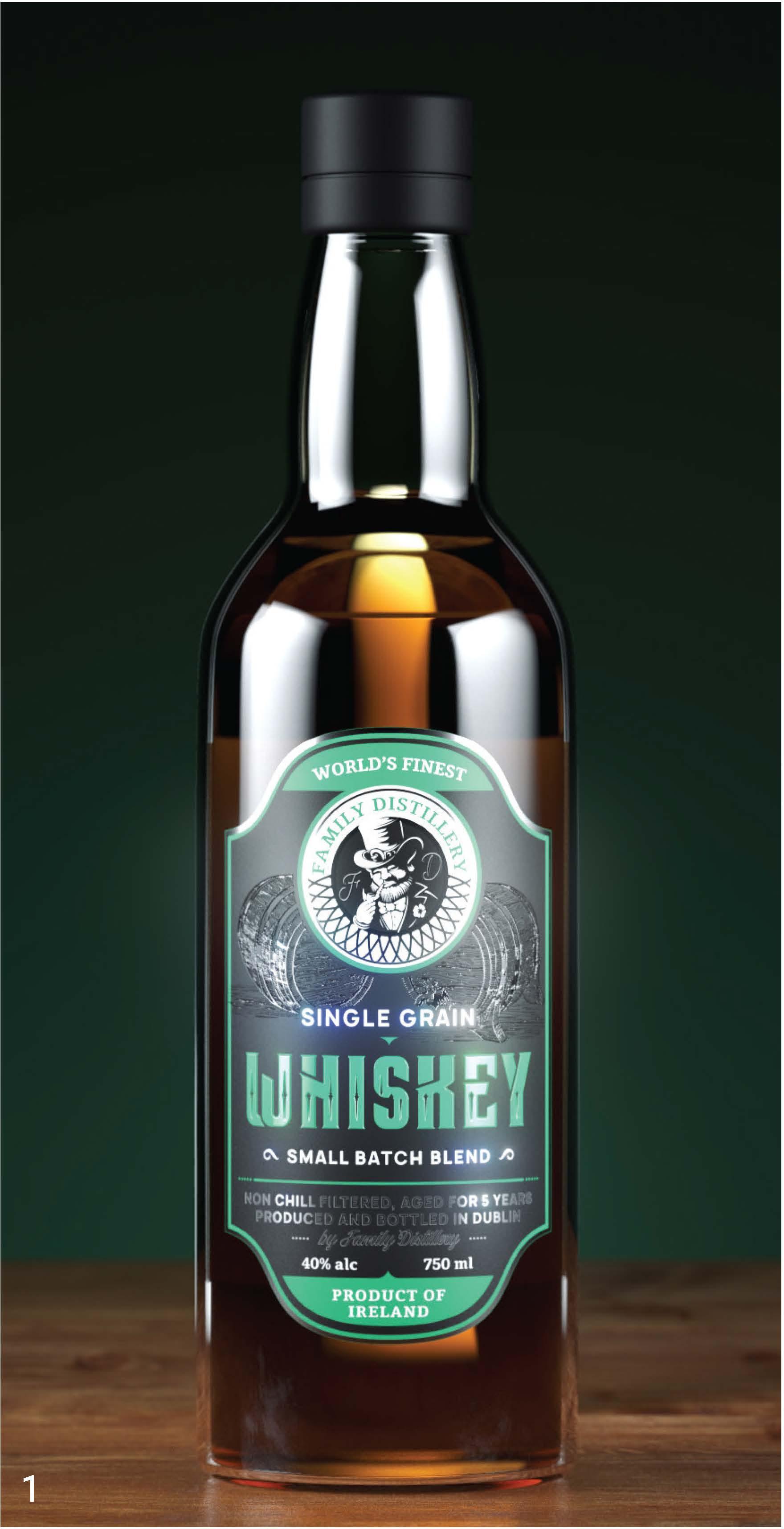

For packaging and labels, embellishments often serve a dual purpose. "They enhance shelf appeal and convey a sense of quality and luxury, which can justify a higher price point or encourage a purchase decision. In sectors like cosmetics, wines and spirits, and premium foodproducts, where packaging is a critical part of the productexperience, embellishmentssignificantly impact consumer perception andsales," hecontinues.

He also sees embellishment technologies making a significant impact in markets like trading card games (TCG), gaming, andthecannabisindustry.

Embellishments are also used in areassuchasbookcovers, businesscards, andinvitationstoconveyprestigeandattention to detail, reinforcing the brand's identity and values. "This approach is critical in an era where physical marketing needs to work harder to capture attentionanddelivermemorableexperiences," addsAbergel.

Specific to the TCG and gaming markets, embellishments are used to enhance the collectibility and aesthetic appealofcardsandgamingcomponents. Heexplainsthatspecialeditionsofcards often feature foil treatments, holographic effects, and textured finishes that not

1. ABG's DigiJet utilizes inkjet technology and is capable of producing a variety of effects including raised varnish, digital cold foil-with inkjet trigger image, cast and cure, variable data printing, and laserdiecuttingthrough Digilase.

only make them visually striking but also more desirable as collector items. "This tactic not only adds to the gameplay experience but also boosts the market value of these cards."

For the cannabis market, where differentiation is key due to the increasing number of products and brands, embellishments on packaging can convey premium quality and create a strong brand identity. ''As the market grows and evolves, companies tum to sophisticated packaging solutions that feature embossed details, metallic foils, and intricate designs to stand out on dispensary shelves. This not only helps in complying with packaging regulations by making labels clear and engaging but also elevates the consumer's unboxing experience, adding a touch of luxury to everyday products," says Abergel.

2. Taktiful's Reaktorisavirtual3Dprevisualizationenvironmentwhereuserscanuploadartfilesandexperimentwithdifferentdigitalembellishments.3. TheKonicaMinoltaAlphaJETisasingle-passB1+digitalinkjet press featuring a unique combination ofwater-based CMYK inks and inline digital embellishment, eco-spot UVcoating,andgreen-foiltechnologies.

He adds that these embellishments are not merely decorative; they play a crucial role in brand storytelling and consumer engagement across these dynamic industries.

To achieve valuable effects on digitally printed output, several technologies exist. From high-end machinery to more obtainable sleeking devices, and the workflow that drives it all, there is a solution for every print provider looking to add pizazzand profit-to digitally printed output.

"Many of our customers have a combination of traditional finishing machines like our Digicon Series 3 and digital embellishments from DigiJet," shares Floriana Montella, product manager, DigiJet and DigiLase, AB Graphic International (ABG). "Our digital embellishment solution is ideal for shorter runs that are much in demand. It allows for multiple SKUs with a tool-less process and quick turnaround times."

AB Graphics' DigiJet is a digital embellishment solution that utilizes inkjet technology and is capable of producing a

variety of effects including raised varnish, digital cold foil-with inkjettriggerimage, cast and cure, variable data printing, and laser die cutting through DigiLase.

The ABG Digicon Series 3 is its flagship traditional embellishment solution, offering a range of capabilities such as hot foil, cold foil, screen printing, die cutting, embossing, flexographic printing, and fast-track die cutting.

Montella says the Digicon Series 3 is constantly developed to keep up with the demand from today's digital printers, especially the HP Indigo Vl2 Digital press. "With innovations such as ABG's patented fast track die, capable of running at 180 meters per minute and new flexographic technology, it can keep pace with evolving printing needs and provide the best finishing solutions for digital prints. Additionally, the DigiJet is capable of handling shorter or long runs with multiple SKUs, and turns jobs around quickly to meet the fast-paced demands of today's industry:'

Konica Minolta offers a series of different models in its 3D Embellishment Solutions product lineup for sheet and roll-fed digital special effects. "The Konica Minolta AlphaJET is the world's first single-pass Bl-plus digital inkjet press from printing to finishing, with a unique combination of water-based CMYK inks with inline digital embellishment, ecospot UV coating, and "green"-foil technologies," offers Dembia.

Konica Minolta's portfolio also includes the JETvarnish 3D Evolution, a B 1-sized commercial printing and packaging enhancement platform, the JETvamish 3D Web 400 narrow web label and flexible packaging enrichment press, and the all-purpose AccurioShine 3600 system.

All Konica Minolta embellishment presses feature 2D/3D UV dimensional textures and variable embossed foil capabilities for digital, offset, gravure, and flexographic materials. ''All of our products deliver this and more, but on much different scales. Volumes and

Nixon says the strength of these digital enhancement presses lies in their ability to produce embellishments of the highest quality whilst reducing environmental impact, delivering new levels of automation, and reducing the cost per page for incorporating value-added enhancement into printed products.

The Scodix Ultra 2500 SHD is available in a 28-inch (B2) format and the Ultra 6500 is in a 41-inch (B1) format.

On the workflow end, Color-Logic offers two distinct embellishment solutions to printers.

The Color-Logic Metallic Color System equips print providers and designers with the tools and capabilities needed to create stunning metallic effects during the design stage. With five colors, this system enhances the visual appearance and impact of printed materials.

The Touch7 Neon Color System from Color-Logic is an accurate digital printing color system designed for neon or fluorescent inks. It offers print providers and designers a predictable system that enables them to create expanded gamut and pastel colors, according to Mark Geeves, co-founder and director of sales and marketing, Color-Logic Inc. “These vibrant hues can be seamlessly incorporated into printed marketing pieces to captivate audiences.”

Another vendor, Taktiful Software Solutions, is on a mission to “revolutionize the print embellishment industry by creating software-as-a-solution products that address the needs and challenges faced by embellishment professionals.

Our aim is to help mainstream the adoption of digital embellishments by making it easy and profitable for everyone involved,” says Abergel.

Taktiful’s three flagship products include Taktify, Reaktor, and Kreator.

Taktify is an artificial intelligence (AI)-based estimating and pricing software designed to help printers accurately determine production costs. “It functions like the Kelley Blue Book for print pricing, using a combination of Taktiful’s extensive pricing database and combining it with the specific user’s historical sales data to train their personalized AI pricing model,” explains Abergel. “This allows for optimal pricing strategies that consider various factors such as client location, client verticals, job complexity, perceived value, and market trends.”

Reaktor is a virtual 3D previsualization environment where users can upload art files and experiment with different digital embellishments. This platform is designed to facilitate creative design and proofing, making it easier to visualize end products and make adjustments before final production.

Marketers utilize embellishment tools in many creative ways across various industries and vertical markets.

“Marketers are only limited by their imagination. Our customers are using our 3D embellishment solutions to adapt to the expectations of their customers, whose needs are evolving towards delivering more impact with printing media.

The impact of touch on consumers’ purchasing habits is increasingly important and many research studies support the benefits of the power of touch in print,” shares Dembia.

Nikolic’s personal favorite example is a business card that was first laminated with Nobelus’ soft-touch Karess Laminate before being overprinted and enhanced with spot sleeking. “The velvety soft matte laminate contrasts beautifully with the shining metallic appeal of the digital foil.”

Scodix devices also sit on the production floor of top-tier packaging and commercial customers. Recently new to the Scodix group are Cardston and Brodnax 21C, two prominent players for trading and collectible cards. The variety of Scodix applications available from a single press provides these companies with productivity and efficiency for fast time to market and cost savings.

Beeman says S-OneLP’s technology can also provide a sustainable element. “Using the eBeam curing system with JetFx spot embellishment reduces the need for an additional layer of substrate.”

Although manufacturers today offer presses and printers with five, six, or more colors, Geeves feels that many of the print providers operating these presses fail to utilize enhanced capabilities. “To effectively market embellishments and enhancements, print providers must produce print samples demonstrating their capabilities. Only then will brands and corporate marketers become fully aware of the power of these enhancements.”

With the right tools at the helm, the results are limitless when it comes to the embellishment and enhancement capabilities for digitally printed output. As these tools continue to evolve, print providers must educate clients on the possibilities and take advantage of the profit potential. dps

By Cassandra Balentine

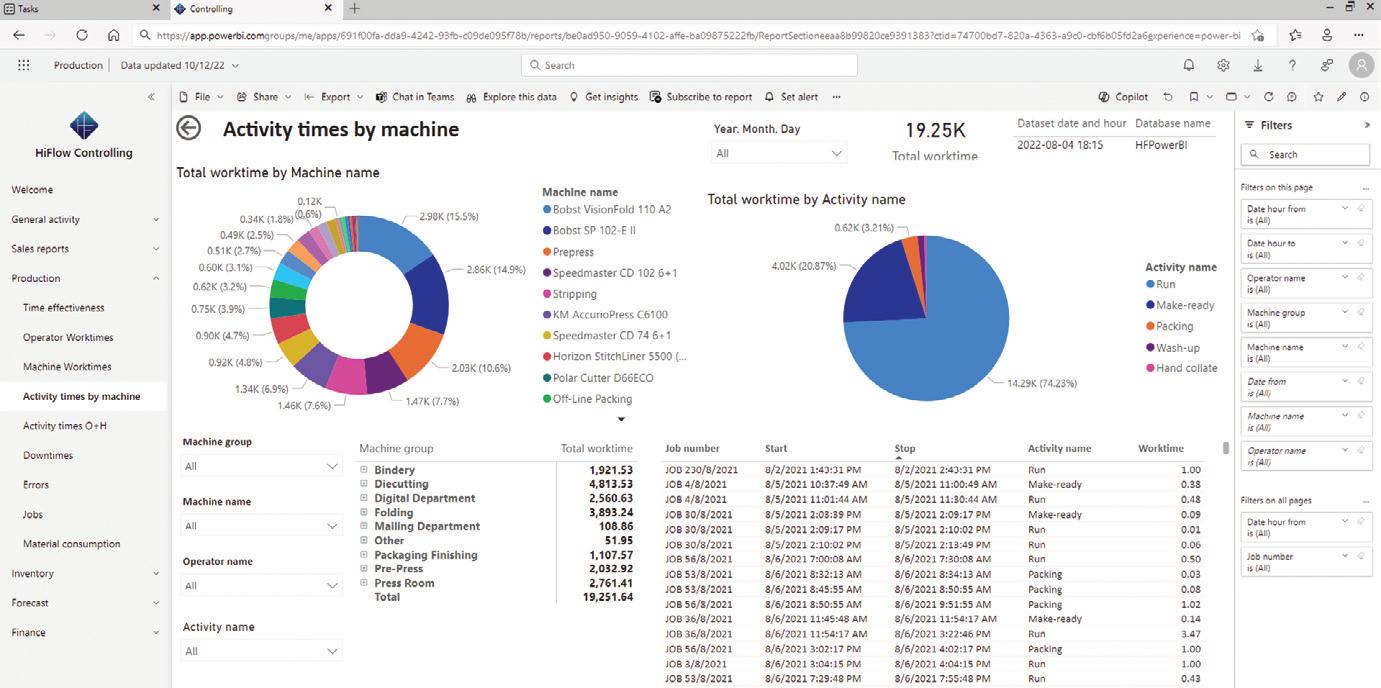

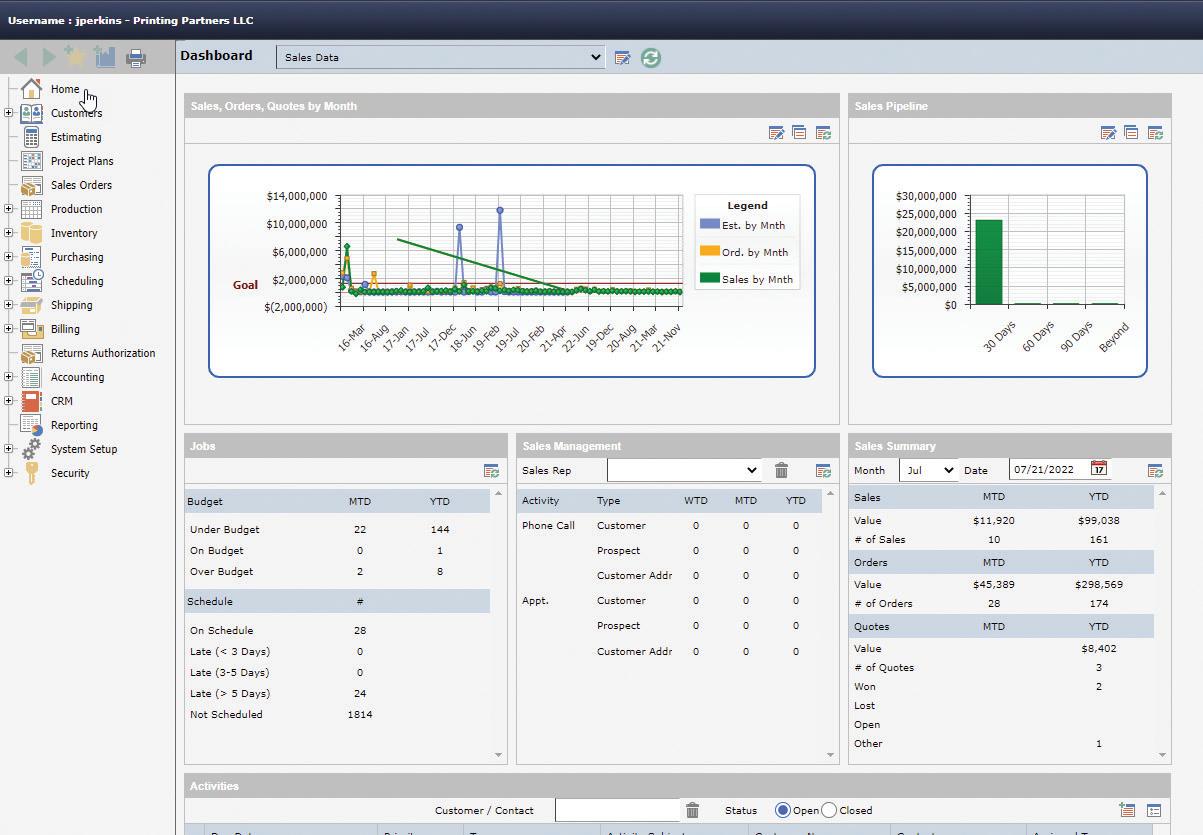

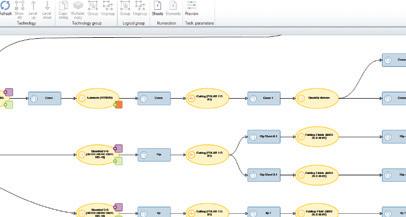

Print management information systems (MIS) continue to evolve beyond the traditional intuition, moving into enterprise resource planning (ERP) territory. Because digital print encourages more frequent, highly complex, shorter run work, it is imperative that print providers have the right tools on hand to remain effective and efficient. Modern print and service providers offer this.

Certain tools and functions enable more power to managers and operators alike, making for a productive shop floor no matter the application. From ease of use to accessibility and reporting, modern MIS solutions offer value to the production workflow.

Accessibility is a key consideration in an increasingly mobile world.

Mark Alioto, CEO, Revshop, points out that this is because users need to be able to get system access wherever they might be. “We live in a new hybrid on/offsite working environment,” he asserts.

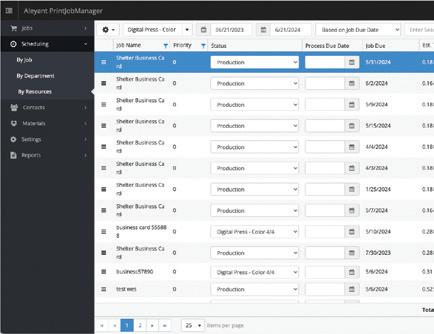

“Accessibility is vital, which is why most software is now cloud based. This allows for access anywhere in the world,” seconds David Graves, CEO, Aleyant.

“We have some organizations where the majority of users are remote. Having an easy way to manage teammates and federate authentication play a big role in making an MIS simple to administer,” says Adam Homsi, founder, InkCloud.

Matt Prusa, senior director, software sales, Avanti Slingshot, RICOH Graphic Communications, also feels that modern software should be browser-based, al-

lowing secure access from multiple and remote locations. “Owners and leaders need access to information 24/7, and CSRs and salespeople often receive inquiries outside of business hours.”

“In our experience, providing a cloudbased solution that does not require an

additional client installation but rather a browser accessible platform greatly increases the usability and efficiency of a platform,” suggests Craig Powell, GM, North America, printIQ.

Depending on the functionality, Jef Stoffels, head of marketing, Dataline, believes remote log-on functions are a useful addition to MIS software, including CRM, dashboards and reports, basic calculation, and estimation features that can be accessed by a salesman or management while out of the office/on the road. “Logistics and installation—signage—can be connected remotely to the MIS as a natural extension of the production project. When an installation is completed successfully, the customer signs off and installation pictures are added to the project so post calculation and invoicing can be triggered after that.”

The main drivers for investing in remote services include reducing machinery downtime, optimizing performance, and speeding up support. “As we continue to navigate the hybrid model of remote and in-person services, we believe that the print industry is undergoing significant transformation. Embracing technological advancements like remote services not only enhances efficiency and reduces costs but also prepares the industry for future challenges,” says Alfonso A. Hernandez, Jr., VP of sales, HiFlow Solutions.

We’re in a technology era. User interfaces are expected to be easy to navigate and understand. This is essential to an MIS, especially as a changing labor force is a top challenge for the foreseeable future.

Some production facilities struggle with high turnover rates. “A system that does not have a high entry barrier is critical in such cases. At the same time, management expects true and reliable data that will be visible in the system in real time. This is crucial for making data-driven decisions and closely monitoring the company’s margins,” offers Hernandez.

Alioto sees intuitive user interfaces (UI) as a mission-critical element of any print MIS platform.

“An intuitive and easy-to-use interface is a must-have today. High entry points with difficult interfaces are simply not acceptable. Considering the current challenges in acquiring a workforce, adding another hurdle with complicated software is a clear mistake,” asserts Hernandez.

Graves feels there are always detractors within any organization. An easy-to-

use interface allows users to overcome some of the detractors.

Helle Vogt Mikkelsen, head of marketing and strategic partnerships, PrintVis, feels that an intuitive UI reduces the learning time for new users, enabling them to become proficient quickly. “An intuitive UI can guide users through complex workflows, ensuring that all necessary steps are followed correctly—for example in estimating. Satisfied users are more likely to embrace the system and utilize its full range of features.”

“An implementation project to get the MIS built is already a lot of hard work and the last thing you want to see after all that effort is slow acceptance from shop floor staff because the system is hard to navigate,” comments Powell.

“While an intuitive UI is consequential, the MIS must address intricate job

requirements and handle varying complexity across multiple job functions— eg. customer service operators (CSR), estimating, production floor operators, and finance,” asserts Prusa. “When evaluating MIS vendors, it’s important that they demonstrate capabilities to properly address each user’s unique role requirements.”

At the end of the day, the UI of every software needs to enable the user to work fast and easy. “As there are different levels of users for print MIS software, the experience will be different,” suggests Stoffels.

With this in mind, Stoffels says MIS should include expert sections of the software needed to offer all the informa-

tion in one the place; manager levels can use a limited set of functions to get the information they need; and operators on the shop floor need limited functionality that allows them to use and feed the information they are required to.

Hernandez believes that layouts and views that are self explanatory and intuitive are essential to meet the modern challenges the industry is facing. “When an MIS has an interface that most users already know, like the Microsoft interface, it makes initial onboarding very easy.”

When evaluating print MIS options, Homsi recommends looking at your most common workflows. “Ask yourself

what actions are done most by your team and ensure the MIS makes this easy for your organization’s users. Not only are these actions done over and over again but having a good user experience also translates into less upfront training.”

In a data-driven world, what is measured is managed. It is important to consider analytic functions when looking into an MIS. Todays’ reporting and analytics functions use real-time data for everything going on in the print company, which provides the ability to feed all users with the information needed at any given moment.

A modern print company should be driven by clear data. “Only in this way they can be assured the business processes are running as they should,” says Stoffels.

Hernandez feels that analytics is what an MIS does best, and it does it across departments—production analytics provide insights into the efficiency and performance of the production process. Warehouse analytics provide information on inventory levels, turnover rates, and supply chain performance. Reports on sales trends, customer order patterns, and profitability by customer segment can inform marketing strategies and customer relationship management efforts. “Modern print MIS solutions provide analytics on quality control measures, including defect rates, rework rates, and inspection results.”

Reporting is a rapidly changing aspect of MIS. “As data becomes more easily accessible to decision makers, how it is consumed will evolve as the business grows,” says Prusa. “While standard

2. HiFlow Solutions features customizable dashboards that provide quick access to job queues and machine status.

reporting should meet a business’ base requirements, business intelligence (BI) has the power to customize how data is presented from multiple sources such as MIS, accounting, web to print, and printer device data. Centralized access to real time and historical information will drive accountability, functional visibility, and better business decision-making across the organization.”

BI is essential in the print and packaging industry, enabling companies to collect, analyze, and use data for informed decision making and process improvement, ultimately enhancing efficiency, quality, and profitability, agrees Vogt Mikkelsen.

Powell points out that modern print MIS solutions are increasingly asked to provide advanced reporting and analytics functions to enable data-driven decision making.

When investigating reporting capabilities for an MIS, Graves feels that custom reports are a must.

“We see a lot more complex scenarios where you’re processing jobs from various intake channels, which can include a storefront, the back-end dashboard, API, etc. You’ll want to look to MIS solutions that allow you to segment data by these additional dimensions so that management can understand the analytics,” suggests Homsi.

It is important for the system to provide users with the possibility to generate new reports/dashboards or change existing ones by themselves. “As both the specialized designer, developer, implementer, and the owner of the system, we can address many of our clients’ custom needs. We see that this flexibility is crucial in the current ERP/MIS market,” says Hernandez.

“Self-serve, non-technical user data access is critical,” adds Alioto. He suggests looking for a MIS that is intuitive and has robust dashboards and alerts, which can replace old industry practices of needing to run reports to get reporting and analytic data.

A data-driven approach to business operations is essential for future success. Print MIS is well adept at gathering, analyzing, and organizing mission-critical information. It is essential that

owners and operators are able to leverage this data with intuitive UIs, remote accessibility, as well as complex and custom reporting capacities.

Find more on print MIS, including a webinar, at dpsmagazine.com. dps

10Aleyant 26aleyant.com

1CERM 13cerm.net

3Graphic Whizard Inc. 15graphicwhizard.com

14HiFlow Solutions 22 hiflowsolutions.com

4Komori America 23komori-america.us

12Landa Digital Printing 7landanano.com

2PressWise by SmartSoft25presswise.com

5Rollem Interntional 9rollemusa.com

11Shark Finishing Machinery27sharkmachinery.com

6Sharp Electronics Corp. 9sharpusa.com

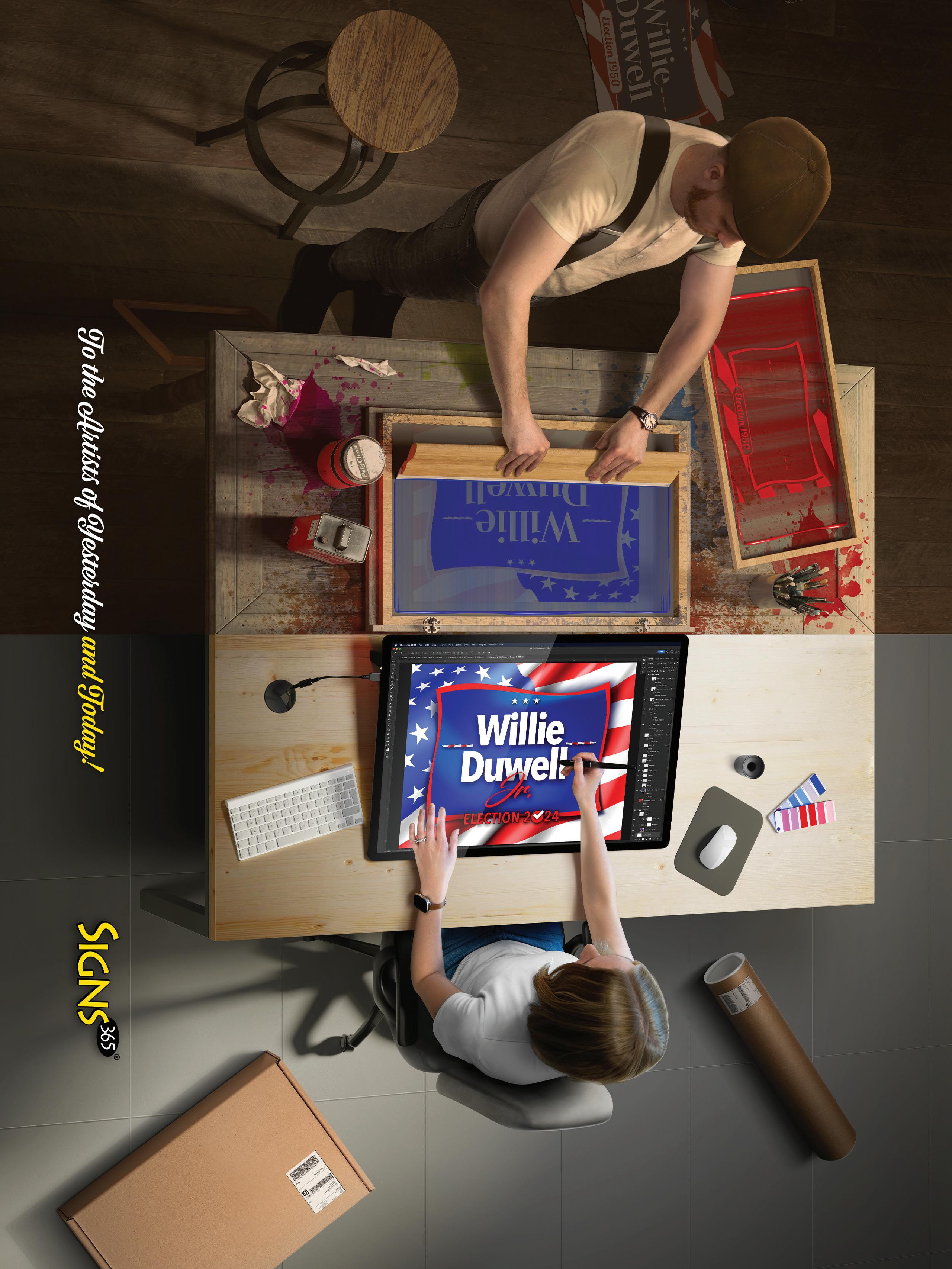

7Signs365 28signs365.com

8Standard Finishing Systems2 standardfinishing.com

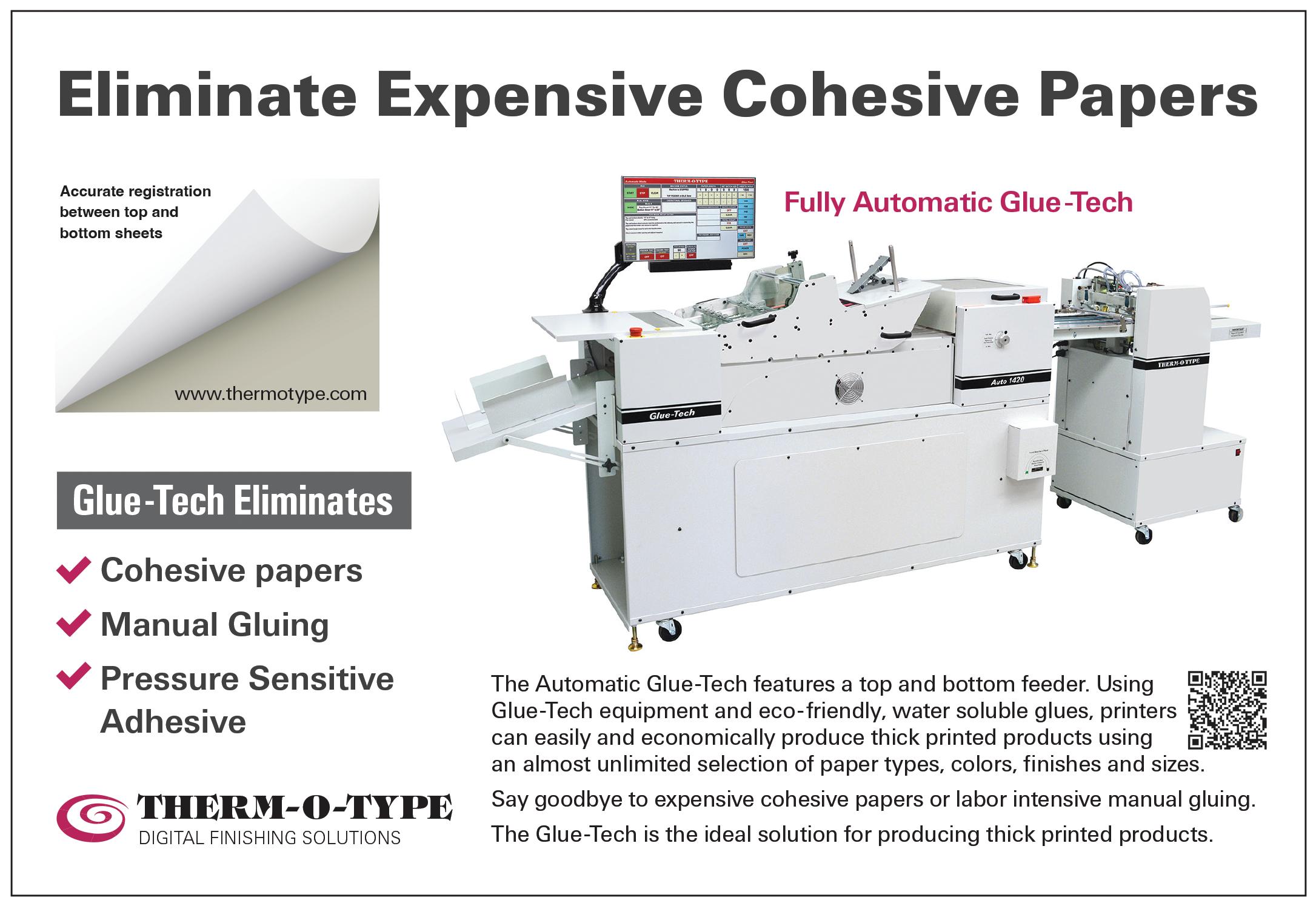

9Therm-O-Type 19thermotype.com

13Valloy Inc. 27valloy.com