Published in January 2024, Grand View Research’s Automotive Wrap Films Market Size, Share & Trends Analysis Report found that the global automotive wrap films market size was estimated at USD 7.11 billion in 2023 and is anticipated to grow at a compound annual growth rate of 22.1 percent from 2024 to 2030.

...growing consumer

According to Grand View Research, “the growing consumer demand for customizing vehicles fuels the market for wrap films in a variety of colors, coatings, and textures.”

Our cover story, Take It for a Spin, goes into this in more detail. Consumers are catching on to something commercial buyers and brand owners have known for awhile—vehicle graphics are efficient, stylish, and effective. This is true for full or partial wraps, decals, and even vinyl striping.

It’s all fun and games when designing and crafting various digitally printed graphics, but sometimes we have to get dirty. Clean Up discusses the importance of proper floor graphic preparation. Without removing residue like dirt and other debris, you are simply setting your graphic up for failure.

Elsewhere in this issue we spotlight a graphics shop with a flair for vinyl striping, share comprehensive charts on both fine art media and pressure-sensitive media options, and include a preview of the PRINTING United trade show occurring in September.

Cheers,

Melissa Donovan, editor mdonovan@rockportpubs.com

EDITOR IN CHIEF

Thomas Tetreault ttetreault@rockportpubs.com

EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ASSOCIATE EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

WEB EDITOR

Melissa Mueller

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

CONTRIBUTORS

Olivia Cahoon, Tim Greene, Mark Hanley, Melinda Tetreault, Amber Watson

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

NATIONAL ACCOUNT EXECUTIVES

Amanda Doyon adoyon@rockportpubs.com 978-921-7850, Ext. 170

Subscribe online at digitaloutput.net

CORPORATE & PUBLISHING OFFICE 64 Thissel Street #272 Prides Crossing, Massachusetts 01965

ROCKPORT CUSTOM PUBLISHING, LLC CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

Digital Output is published monthly by Rockport Custom Publishing LLC. ©Rockport Custom Publishing, LLC 2024. Reproduction by any means of the whole or part of Digital Output without written permission from the publisher is prohibited. Views expressed in the editorial pages do not imply our endorsement.

Vendors: We welcome your product news. Include prices, slides, photos, and digital files with your press release. Please forward product samples and media kits to Reviews Editor, Digital Output, 64 Thissel Street #272, Prides Crossing, MA 01965. We cannot be responsible for unsolicited product samples.

SUBSCRIPTION RATES

U.S.: $82.95 per year; $165 for 2 years; single copies: $6.95; Canada and Mexico: $99.50 per year (U.S.D.); Other international subscriptions: $275 per year (U.S.D.)

POSTMASTER

Please send address changes and form No. 3579 to: Digital Output 64 Thissel Street #272, Prides Crossing, MA 01965. Periodical Class postage rates paid at Beverly, Massachusetts and additional mailing offices.

CHANGE OF ADDRESS NOTICE

Six to eight weeks prior to moving, please clip the mailing label from the most recent issue and send it along with your new address (including zip code) to: Digital Output magazine, change of address notice, 64 Thissel Street #272, Prides Crossing, MA 0196. Attention: Circulation Department.

1)

by Digital Output Sta

he PRINTING United Expo takes place September 10 to 12, 2024 in Las Vegas, NV at the Las Vegas Convention Center. The event brings the entire print industry under one roof. We reached out to vendors in graphics/wide format to learn about their plans.

Agfa, booth C1761, showcases the Onset Grizzly X3 HS flatbed with new Autoloader; Jeti Tauro H3300 UHS 7c, a fast hybrid with robotic automation; Jeti Condor RTR5200 HS, a five-meter roll printer; Jeti Bronco H3300 S hybrid; and Anapurna Ciervo H3200, also a hybrid. INFO# 255

Aleyant, booth C100, unveils PDF2Press, a new solution for prepress automation. It allows for custom-built workflows to include preflight, file fix, imposition, and proof/approvals within Pressero. INFO# 256

ASLAN, booth SL10214, focuses on high-quality niche products for sign making. Highlights include the glittering film SparkleColour ASLAN SC 123, the flocked decorative film CaressColour ASLAN CC 124, and the protective laminate MagicProtect Matt ASLAN SL 99 with its spray paint-repellent and anti-sticker surface. INFO# 257

Beaver Paper, a member of Koehler Group, booth SL10202, produces TexPrint sublimation paper, ProTex protection tissue, and TexStyles graphic fabrics. It showcases a range of sustainable products. INFO# 258

Canon USA, Inc., booth C348A/C348B, welcomes attendees to get a close look at Canon’s wide range of production and large format products and solutions, from the newly announced varioPRINT iX1700 sheetfed inkjet press to innovations in display graphics. INFO# 259

Colex Finishing, booth C936, demonstrates the Colex Sharpcut SXC1732 with quick response code automation, Colex SXC3232 with textile/fabric 126 inches wide, Fotoba X/Y cutters with Jumbo Roll Feeders, and the new Fotoba XLA170 offering automatic vertical blade positioning. INFO# 260

DG DIMENSE, booth SL11041, exhibits the Dimensor S printer. It works in combination with DG DIMENSE waterbased color and structural inks as well as specialized media, enabling printing of vivid images and embossing patterns in a single, seamless process. INFO# 261

DGS, booth C1814, presents the fast track to structural design concept consisting of a range of eco-friendly paper-based rigid substrates (Roots), rigid board finishing system (BOARDers), and its online library of structural designs (BEEngo!). INFO# 262

Drytac, booth SL6089, hosts a series of live demonstrations. Knowledgeable staff are available to guide attendees through Drytac’s solutions. Visitors at the booth can learn about latest introductions— Polar Smooth 150 Air P solution and Interlam Eco Anti-Graffiti. Also, a new solution for textile and apparel is unveiled. INFO# 263

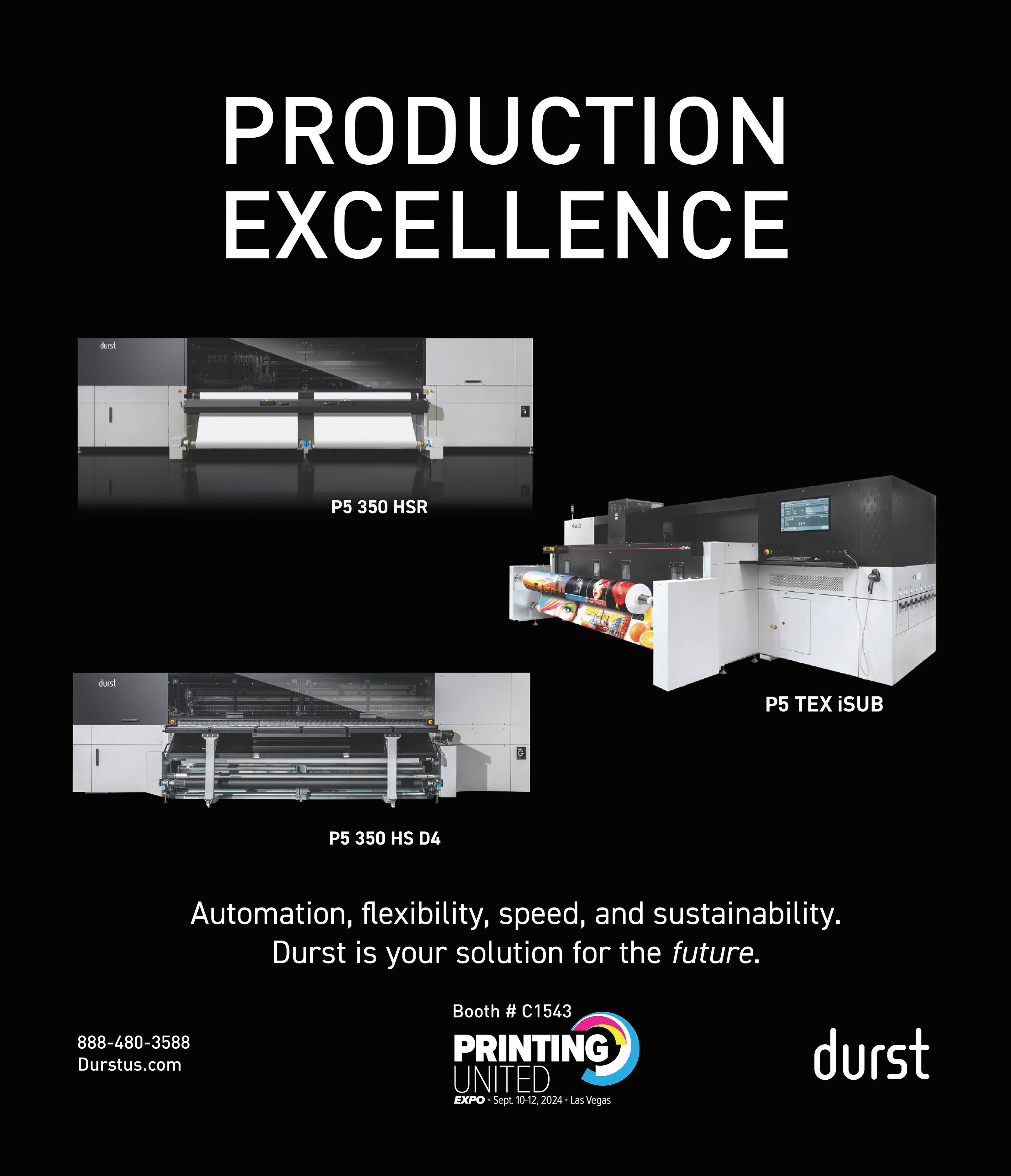

Durst Group, booth C1543, shows the hybrid P5 350 HS with D4 configuration, high-speed P5 350 HSR, P5 TEX iSUB, and Tau RSC

E. They are supported by UV and water-based inks as well as comprehensive software. INFO# 264

Epson, booth SL8101, brings the SureColor F9570 and SureColor F9570H 64-inch dye-sublimation printers. Featuring a space-saving design, they tout a PrecisionCore Micro TFP printhead and UltraChrome DS Ink. INFO# 265

FDC Graphic Films, Inc., booth SL6137, is a master converter and distributor of digital print media,

banner, sign vinyl films, overlaminates, and heat transfer films. It markets, converts, and distributes products from 3M, 3M DI-NOC Architectural Finishes, Lumina by FDC, ASLAN, Siser, Nekoosa, and Avery Dennison. INFO# 266

Flexcon, booth SL10040, colocates with SEI Laser by Matik. Featured is Flexcon Shimmercal specialty materials and FlexMark promotional products. See both run on Matik machines. INFO# 267

GBC and SEAL, booth C741, demonstrates the GBC CL-401 laminator, SEAL 62 Base laminator, and Flatbed Applicator. INFO# 268

Global Garage, booth C934, teaches attendees how to buy or sell pre-owned grand format print equipment. The booth is staffed with experts in the entire process and a logistics expert who knows how to move equipment to and from domestic and international locations. INFO# 269

Global Imaging, booth C1375, offers RGB illuminated flooring and T3 framing systems. Don’t miss the opportunity to get a first-hand understanding of this customizable, tool-free, modular system. It also showcases REXframe, Berger Fabrics, and takes meetings for demonstrations. INFO# 270

Graphco, booth C2455, displays the Augusta F150R Hybrid CNC Routing & Cutting System. It offers processing speeds approaching five feet per second, on-board stud welding, and an automated workflow. INFO# 271

Graphic Finishing Partners, booth SL5067, features the 663-TH Production Top Heat Laminator with Smart Finishing Technology. It includes a digital microcontroller system, swing-out supply film shafts, inline rotary slitters, and rear take up. INFO# 272

Graphic Whizard, booth C1727, showcases a new inline slit/cut/ crease machine. See advanced automated perfect binders and the PT 33LSC Micro duplex laminator with cut-to-bleed and encapsulation technology. INFO# 273

GTI Graphic Technology, Inc., booth C140, exhibits new D50 LED products, which offer a high CRI solution. These combine the benefits of LED technology with a close match to D50 spectral specifications ensuring tight conformance to ISO 3664:2009. INFO# 274

HP, booth C1415, highlights its HP Latex 2700 Printer series with four versions, optional dual roll attachment, and up to two years warranty. It uses HP’s white ink technology, has a 3.2-meter media width, and can withstand media up to 660lbs. INFO# 275

INX International, booth C920, promotes new ways to boost productivity, efficiency, and sustainability with advanced inks, coatings, and digital printing solutions. INFO# 276

Kornit Digital, booth SL5029/ SL12221, displays direct to garment system the Kornit Apollo. Backed by advanced, proprietary automation, the platform integrates versatile smart drying, concurrently managing various garment types with the proficiency of up to 400 garments per hour. INFO# 277

Mactac, booth SL13008, acts as an interactive hub featuring Spinnaker, a leading provider of pressure-sensitive sheets for paper merchants. It discusses the new cast film Gruv 7, Gruv 4, and Gruv 5 Air Egress vinyl media; as well as Print Vinyl Score. INFO# 278

Marabu, booth SL11023, showcases the StarLam 1600R Roll-toRoll Liquid Laminator, which applies a smooth, consistent coating of its water-based ClearShield Liquid Coatings. Marabu is the North American distributor of LSINC’s Peri One single-spindle, cylindrical printer based on the technology of the PeriQ360. INFO# 279

Mimaki USA, booth C1737, debuts four products covering three of Mimaki’s main vertical markets. Each debut is an expansion of an existing product line, reflecting customer feedback for higher production throughput without sacrificing image quality. INFO# 280

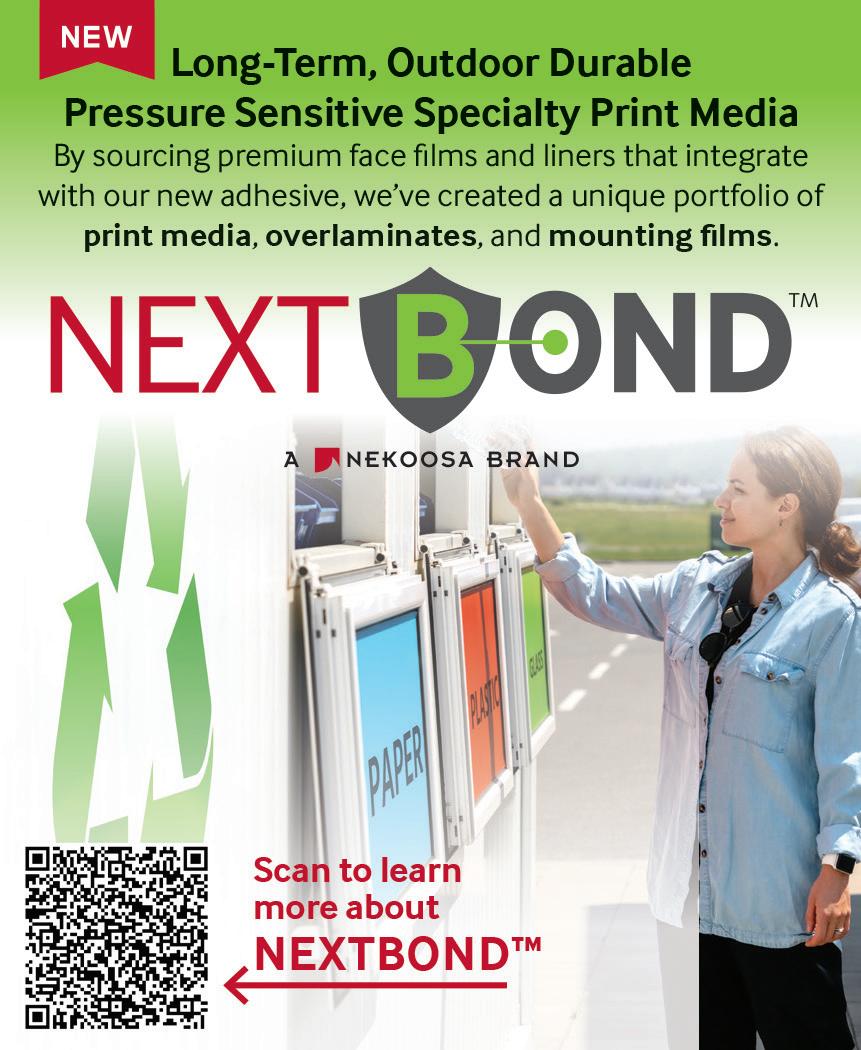

Nekoosa, booth SL7017, features NextBond, a durable adhesive that is robust, cost-effective, and eco-friendly for long-term print applications. Attendees can explore other product lines, such as Nekoosa Dye Sublimation Transfer Paper, Nekoosa Glass Finishes, and Nekoosa Promise. INFO# 281

Photo Tex Group, booth SL8121, demonstrates its new third-generation opaque block-out selfadhesive fabric. This advanced, patented adhesive can handle today’s new paints and additives. Yes, it is still removable anytime. It is non-toxic, LEED certified, and safe. INFO# 282

Ricoh DTG, booth C2161, exhibits the RICOH Ri 4000, which allows users to seamlessly switch between direct to garment and direct to film printing. The advanced technology ensures vibrant, high-quality prints on 100 percent cotton, 100 percent polyester, and blend fabrics. INFO# 283

Roland DGA, booth SL10088, displays the new EU-1000MF high-volume UV printer, the VersaOBJECT CO-i Series flatbed printers, and the VersaOBJECT MO-240 benchtop UV flatbed. Roland also showcases its expanded TrueVIS wide format family of printers. INFO# 284

Featuring a table size of 55x27 inches, the XpertJet 1462UF stands out in the industry. This large dimension allows for increased production capacity and profitability, enabling users to print on objects up to 5.91 inches thick. Whether you’re looking to enhance your existing UV printer or venture into new areas such as ADA compliant braille, awards, packaging, signage, or home décor, this printer is the ideal solution. Powered by MUTOH’s VerteLith Genuine RIP software and bundled with FlexiDESIGNER MUTOH Edition 21, a $2,199 value, the XpertJet 1462UF offers businesses a powerful solution to enhance productivity, expand creative possibilities, and deliver exceptional print quality. For more information or to request a free print sample, visit mutoh.com. INFO# 23

Engineered and manufactured by Saga, the ExpressCutPRO reduces labor and increases profits by eliminating the time-consuming task of manually cutting direct to film (DTF) or UV DTF transfers. Featuring an integrated conveyor belt and quick response workflow allows for a fully unattended workflow experience. Increase your output while reducing operation costs with ExpressCutPRO DTF Cutters. For more information visit supply55.com, call 734-668-0755, or email sales@supply55.com. Simplify your cutting operation today with ExpressCutPRO. INFO# 25

Newlife Magnetics is one of the world’s largest manufacturers of flexible magnetic materials. The company’s focus on science and engineering has led to its success in leading the magnet industry through research and development of exciting new products that solve customer problems, increase efficiency, and improve customers’ lives without harming the environment. Need a fresh way to display your graphics? Give new DCK micro-suction film a shot! The DCK micro-suction film adheres to various surfaces repeatedly. The versatility of DCK makes it ideal for almost any location. DCK micro-suction film opens up a range of possibilities for those looking for convenient and effective solutions for display purposes. Learn more at newlifemagnetics.com. INFO# 24

Unique to Trim USA, the BigStripe Custom Stripe Program gives you custom rotary slitting up to 30 inches wide, with capabilities to custom configure single- or multi-color, voided, overlaid, butted, or overlapped stripes. Use your choice of today’s most popular pressure-sensitive films by 3M and other leading manufacturers. Reflectives, opaques, and metallics are all eligible materials. These stripes are ideal for identifying fleets, railroad cars, boats, police and emergency vehicles, gas station awnings and canopies, decorative interior/exterior walls, and any other applications where big stripes are used. If you have a big job, Trim USA can cut it down to size! Visit trimusa.com. INFO# 26

swissQprint, booth C2375, demonstrates Kudu, a UV LED flatbed printer with ten color channels and 30 printheads; as well as rollto-roll printer Karibu. At the booth, impressive print results in neon colors and various applications highlight the versatility of swissQprint technology. INFO# 285

Tekra, booth C749, encourages attendees to check out its latest and greatest offerings, including JetView Latex Clear Polyester, Dry Erase Media, JetView UV Marnot Economy, and POLYVANTIS LEXAN DP Films. INFO# 286

Vanguard Digital Printing Systems, a Durst Group Company, booth C1537, offers live demonstrations of the VK3220THS flatbed, VKH900-HS hybrid, VKR3200-HS roll-to-roll printer, and VR6D-HS flatbed. INFO# 287

Vision, booth C2369, exhibits the 2550 CNC Router/Engraver with Oscillating Knife doing print to cut. The 25 Series Routers have multiple options like an Auto Braille Inserter, Oscillating Knife, and DACS. INFO# 288

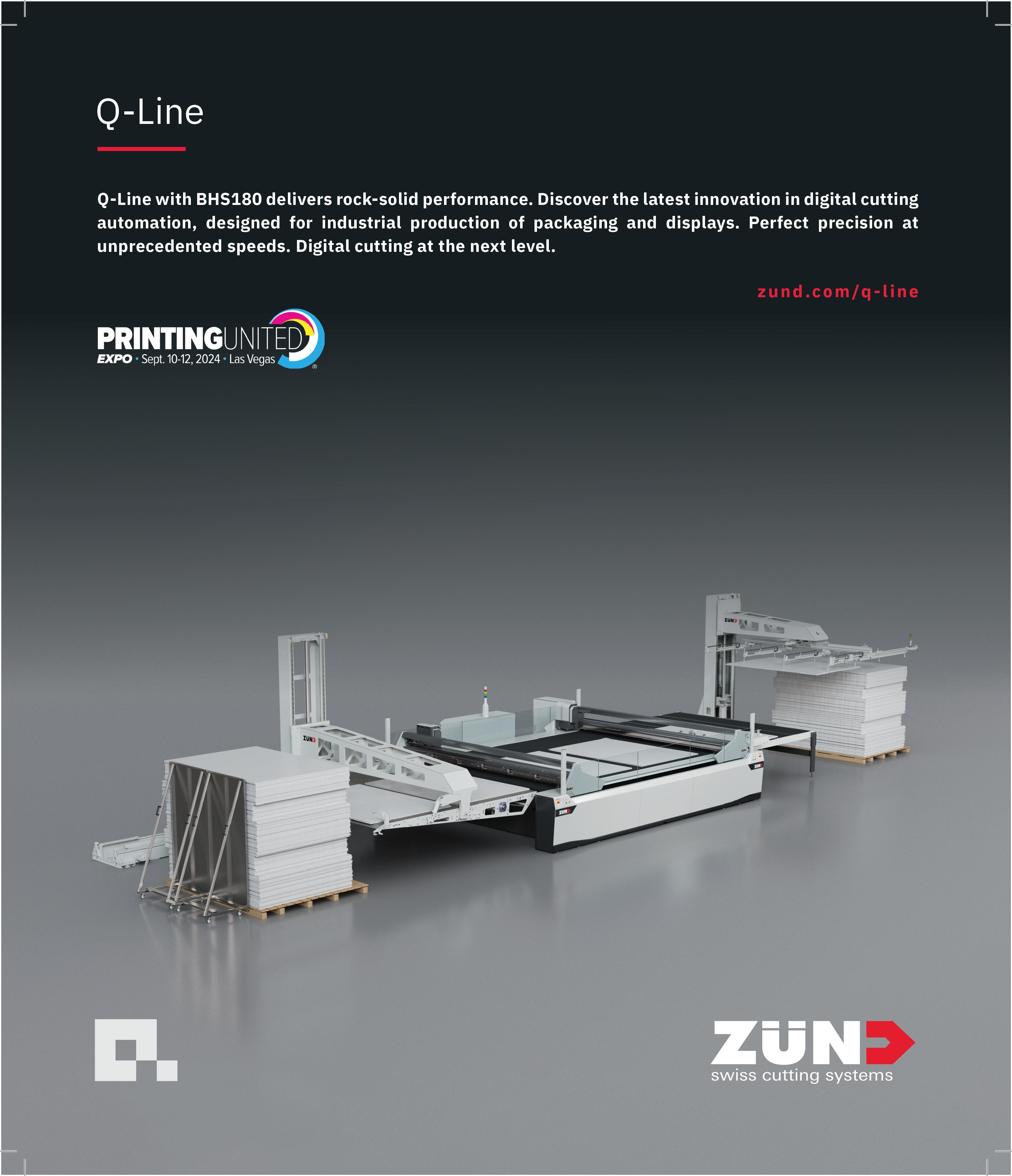

Zünd, C1161, features the industrial Q-Line system and the ultraversatile Zünd G3 “workhorse” now available with UNDERCAM registration. Also on display is a Robot PortaTable. Don’t miss the fully automated inline digital print-and-cut setup at Digitech booth C324 featuring the dualbeam Zünd D3. INFO# 289

Plan your days accordingly to take advantage of all there is to offer at PRINTING United Expo. D

by Significans Automation

Most experts agree that arti�icial intelligence (AI) is one of the most important technologies that humanity has created to date. Like it or not, AI is here to stay, and it will grow exponentially. It’s only a matter of time until this technology becomes an industrywide standard. So as a printer, your best bet is to deploy and continue to re�ine your use of AI systems to make yourself and your company more ef�icient and pro�itable.

AI is making an enormous impact on the print industry, revolutionizing traditional practices and introducing new, more ef�icient solutions. It offers huge opportunities to optimize production processes, personalize customer experiences, boost competitiveness, and help employees and management better perform their daily tasks. As AI continues to evolve, it promises a future of greater ef�iciency, easier customization, and more competitiveness.

AI is already changing the commercial printing landscape.

It can improve work�low automation by further speeding up production processes and reducing manual touchpoints. This facilitates leaner production, processes orders faster, assists with shipping and other logistics, tracks inventory and automatically places resupply orders, and takes on much of the “busy work” that eats away at your time—and pro�its.

Pre�lighting and ERP integration is a speci�ic application of AI deployed by Signi�icans Automation. Utilizing AI

here ensures �iles are production-ready with logical and con�iguring query responses to existing ERP systems, ensuring production-readiness and optimized work�lows.

Look at TKM Print Solutions, based in Akron, OH, it bene�its from AI by instituting advanced pre�lighting with logic and con�iguring query responses to its ERP. The result—the business doubled its production output.

Smart Marks and Finishing Tasks is another AI application deployed by Signi�icans Automation. AI-assisted “smart” print layouts help minimize waste by automatically maximizing the capacity of each sheet. AI-enabled systems are able to quickly calculate the best use of space, delivering clever solutions for even the most complex and irregular patterns.

Seattle, WA-based SuperGraphics applies Smart Marks to layouts for �inishing tasks. The result—anywhere from �ive to seven times faster processing times compared to processing times without using AI.

AI is complicated and often scary. But remember at the end of the day, it’s basically software—just like work�low software, it can be con�igured to create a speci�ic solution or solve a speci�ic problem. For an assessment of your work�low software systems and how AI can complement them, call Signi�icans Automation at 877-463-4465. Read more about Signi�icans Automation and how it uses AI in the October issue of Digital Output D

by Melissa Donovan

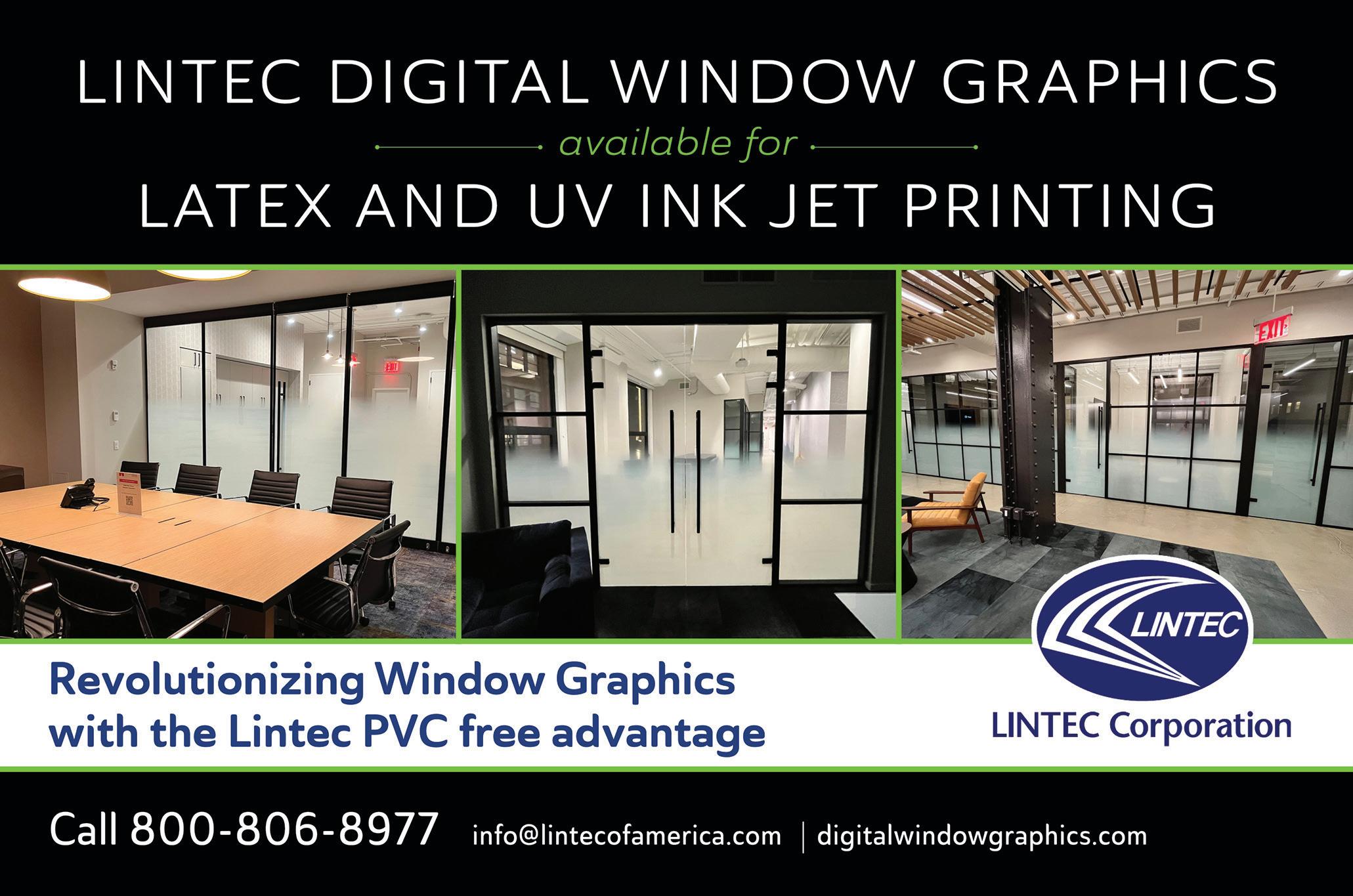

Vehicle graphics standout amid new introductions. The application maintains notoriety for the same reasons it first caused a stir when it came on the scene decades ago. Vehicle graphics, whether to promote a brand or customize a personal vehicle, are cost efficient. Pressure-sensitive materials used to decorate vehicles support this.

As the automotive market continues to change with new car models and revisions to current ones, printers and installers still remain engaged.

In business for the last 30 years, Wichita, KS-based Eagle Enterprises began as a simple operation in a residential

basement. Fast forward to 2024, and the multi-faceted organization is spread across three facilities totaling 50,000 square feet.

More guys are reaching out and asking us for something new. Lots of this is from people who originally only did vehicle striping, then moved to paint protection, and are looking for something di erent.

— TJ Clayton, operations manager, Eagle Enterprises

Core to its success is the business of designing and manufacturing graphics for marine, RV, automotive, fleet, rail, manufacturing, and retail customers. Applications from decals and stripes to full wraps, as well apparel and other products are produced on site. This is achieved through screen printing, digital printing, thermal die cutting, and doming. A staff of over 40 employees helps to complete the many tasks undertaken on a daily basis. Some of Eagle Enterprises’ main clients include automotive installers. It sells to them directly, and they in turn work

with automotive dealerships nationwide and internationally.

Wearing many hats, Eagle Enterprises is more than your typical print and vinyl shop. TJ Clayton, operations manager, Eagle Enterprises, notes that it also has experienced great success with its automotive template program, Eagle Cut. The idea for such a service was born around 2020 thanks to the suggestion from professional wrap installer, Justin Pate.

“Eagle Cut is a pay-per-cut system. Users have access to all of our graphic templates, which we designed in house, starting from custom stripes and going beyond that to full vehicles. The program allows users to download their own logos and work them into their designs for a full custom look,” says Clayton.

While we’ve been talking about the benefits of digital printing in the vehicle graphics space for years, amazingly enough, some have yet to witness and appreciate its benefits.

When it comes to trends in the vehicle graphics space, Clayton notices a strong uptick in interest in digitally printed graphics. “More guys are reaching out and asking us for something new. Lots of this is from people who originally only did vehicle striping, then moved to paint protection, and are looking for something different.”

In response, Clayton and his team direct them to vehicle graphics and digital printing. They even

encourage them to consider fleet graphics as an option and he admits this is something a lot of people still haven’t seen before.

Beyond printing, vehicle striping is another service offered at Eagle Enterprises. Vehicle striping is in a unique position right now, admits Clayton. While muscle cars aren’t being seen in a heightened capacity—and a segment where striping was heavily used—Clayton says many customers are scrambling to find that next big thing.

At Eagle Enterprises, one solution is two-tone striping, where two different colors of film are utilized. Two-tone striping can also occur when one color of film and another piece of film is digitally printed.

In Eagle Enterprises’ facilities, digital printing is achieved via latex and solvent ink sets.

Media from Avery Dennison Graphics Solutions is the product of choice, from the MPI 1105 high-gloss cast wrapping film series to the Supreme Wrapping Film vinyl wrap color change portfolio. “We look for high performance products,” says Clayton. This includes only using cast and 2-mil thickness, both of which Avery Dennison supplies.

Eagle Enterprises is proof that vehicle graphics are high in demand. The company leverages its expertise to reach new markets and maintain connections with trusted clients thanks to Avery Dennison’s partnership. D

See page 16 for more info.

190 3 Sigma 3sigma.cc

191 3M Commercial Solutions 3m.com/graphics

Arlon Graphics arlon.com

ASLAN Selbstklebefolien GmbH aslanvinyls.com

194 ATP Adhesive Systems atp-ag.com

195 Avery Dennison Graphics Solutions graphics.averydennison.com

196 Continental Grafix USA, Inc. cgxusa.com

Contra Vision North America, Inc. contravision.com

D&K Group, Inc. dkgroup.com

DAF Products dafgraphicmedia.com

200 Dotworks dotworks.com

DreamScape dreamscapewalls.com

Drytac drytac.com

203 FDC Graphic Films, Inc. fdcfilms.com

Flexcon Company, Inc. flexcon.com

FloorSignage, LLC floorsignage.com

gbc.com

kodak.globalbmg.com

kpmfusa.com

metamark.co.uk

by Melissa Donovan

he vehicle graphics market—including full wraps, partial, color change, decals, and vinyl striping—continues to grow. Published in January 2024, Grand View Research’s Automotive Wrap Films Market Size, Share & Trends Analysis Report found that the global automotive wrap films market size was estimated at USD 7.11 billion in 2023 and is anticipated

to reach a compound annual growth rate of 22.1 percent from 2024 to 2030. According to Grand View Research, “the growing consumer demand for customizing vehicles fuels the market for wrap films in a variety of colors, coatings, and textures.”

“Sales trends for vehicle graphic materials have continued to climb these last few

years, advancing the need for increased brand awareness and identification,” agrees Jay Kroll, product manager for cut, transit, and wall solutions, General Formulations.

Vehicle graphics have evolved over the years thanks to material introductions,

whether they are standout vinyls and films like metallic or fluorescent or matte solids that feature a sleek, upscale design. This is made possible thanks to advancements in the production of wrap films as well as the availability of raw materials, according to Grand View Research’s Automotive Wrap Films Market Size, Share & Trends Analysis Report

Where and how vehicle graphics are used has changed as well. What was once a very commercial market—advertising on wheels— is also making inroads in the consumer vehicle segment. Grand View Research refers to this as “passenger car applications,” which it reports dominated the market and accounted for a share in the wrap films market of 55.67 percent in 2023.

“Wrap films are in high demand due to rising requests from customers in personalizing their vehicles. Automotive wrap films are used to change a vehicle’s appearance or to protect the original paintwork, and passenger cars are widely customized for personal or commercial purposes. All of these factors for automotive wrap films in passenger cars are likely to impact market growth,” states the Automotive Wrap Films Market Size, Share & Trends Analysis Report

To express individuality, “commercial graphics are trending toward cleaner designs, interactive elements, and thinner laminates, where the individual car owner continues to favor varied finishes and colors to represent and express their individual brand,” shares Kroll.

New use cases from consumers is one reason why Molly Waters, senior technical specialist, Avery Dennison Graphics Solutions, believes new wrap product categories are introduced to the market, specifically color paint protection film (PPF) and high gloss vinyl films. “We believe this is due to the end user market requesting

more color options and improved paint-like finishes for vehicle wraps and graphics.”

Agreeing with Waters, Melissa Harton, marketing manager North America, Fedrigoni Self-Adhesives, says color PPF is attractive as it combines the best of traditional PPF and colored vinyl.

“Traditionally, PPF has been clear, primarily serving to protect vehicle paint from scratches, chips, and other damage. However, the introduction of colored PPF combines the protective qualities of traditional PPF with the aesthetic versatility of colored vinyl wraps,” shares Harton.

Vinyl striping is a great niche that falls under the realm of vehicle graphics, and it also a trending topic.

Demand is growing due to consumer interest. “They want to replicate factory striping kits for personalizing their vehicles,” explains Waters.

“Vinyl striping is an excellent way to add accents to a painted car. It can also be a cost-effective way to add special effects, such as reflective or ultra-metallic/glitter effects,” admits Eric Norby, product manager, FDC Graphic Films, Inc.

The recent interest in vinyl striping follows past patterns. “Vinyl striping has experienced fluctuating popularity over the decades. In the 1980s and 1990s, it was a prevalent trend, but interest waned in subsequent years. Recently, there has been a resurgence in the popularity of vinyl striping, particularly

in the European market. Although precise market share percentages are difficult to pinpoint, this renewed interest indicates a growing segment within the vehicle graphics market,” explains Harton.

“Vinyl striping is a low-cost, impactful way to accentuate a design or extend a partial wrap graphic to incorporate the whole vehicle. The lower point of entry may make this a more popular avenue for vehicle graphics but doesn’t register nearly as loudly due to the smaller amount of material used. This is still a valuable tool for any wrap shop to keep in its portfolio,” adds Kroll.

For print providers or wrap shops already offering vehicle graphics—partial, full, or decals—vinyl striping is a great add on.

“Striping provides an excellent means to embellish a design aesthetically. It can be implemented in conjunction with a printed graphic, either as an initial part of the design or as a revision. Having that flexibility in your toolbox as an installer can greatly benefit your offerings to your customers,” advises Brandon Eubanks, GM, Trim USA.

Norby encourages adding the service for two reasons—ease of install and high margins. When installing a literal stripe, “you don’t have to worry about draping or til-

ing a whole 60-inch piece of material over the vehicle properly—you can apply similar to laying down a strip of masking tape. And because the surface area is relatively low, the material price is low but can command a high margin.”

The low cost of material also means the application is an attractive, cost-effective option for those looking to enhance their vehicle’s appearance without committing to a full wrap. “Stripes allow for vehicle personalization similar to full or partial wraps but at a significantly lower cost and with less labor involved. Offering vinyl striping can thus cater to a broader customer base, including those looking for budget-friendly customization options,” says Harton.

“Vinyl striping can be a great complement for shops offering digitally printed graphics because it allows the shops to do the twotone stripe graphics as well as get into the market of recreating OEM decals. The boating market is another area a shop could get into easily using the same printing methods and films,” recommends Waters.

As with any application, striping relies on the correct material to do the job right. While nearly any material can be used in striping, there are certain caveats.

Users should be aware of the repercussions of a narrower roll. For example, “materials with a pattern, such as a gold leaf or a holographic effect, might lose their visual effects in a narrow roll,” suggests Norby.

While “you probably don’t need the most advanced slideable adhesive technology for a narrow stripe, it is still important to choose the right material for the application. In many instances, you’ll find that cast stripes are the appropriate material and at a reasonable price point,” adds Norby.

According to Harton, any cast or polymeric vinyl can be used for striping. “These materials offer better durability, conformability, and adhesive properties suited for the contours and surfaces of vehicles. Using the right media ensures that the stripes not only adhere properly and last longer but also maintain their appearance under various environmental conditions. This helps in delivering a highquality, professional finish that meets customer expectations and industry standards.”

For outdoor fleet graphic striping, Eubanks suggests a cast pigmented film. “It offers a vibrancy and richness of color that printed graphics can’t replicate. It also offers better UV stability over time.”

Installation can also create challenges, so understanding the nuances of a material and whether it is effective as a vinyl striping application is also important. Without the proper knowledge it becomes a challenge “for installers because of the intricate work striping involves and when it’s in conjunction with a partial wrap or other cut vinyl graphics for branding and design purposes,” adds Waters.

Ultimately, vinyl or pin striping “requires a flexible film with adhesive, applied to a clean surface,

and maintained appropriately to extend its usable lifespan. Pin striping can be done with a calendered cut vinyl as easily as it can a high-end cast color change film or PPF. Testing and experimentation with the particular application and method will be the ultimate judge when determining its fitness for use,” recommends Kroll.

In the end, he admits “sign shops and wrappers continue to be a group filled with creative problem solvers who can make many materials work regardless of their intended design.”

With consumers driving a large part of the demand for vehicle graphics, it isn’t surprising that vinyl striping is having a resurgence in popularity.

If you want to learn more about the latest trends in vehicle graphics visit digitaloutput.net and register to view our most recent webinar on the same topic. D

he importance of proper surface preparation cannot be overlooked for any application, but when it comes to floor graphics, installation failure can result in pedestrian slips and even worse injury. That is why cleaning and drying a floor—no matter if it’s

wood, brick, or carpet—is essential for maximum floor graphic adhesion.

Proper floor graphic installation leads to a safe, visually appealing graphic. Surface preparation is es-

by

Surface preparation is critical towards any successful vinyl graphic installation, but Amanda Smith, injury. sential to achieving this.

Below) HP Removable Adhesive Fabric and the new HP Removable Adhesive Fabric (Latex/solvent), made from recycled water bottles and coating materials, are ideal for floor graphic applications. They are one-step solutions with no need for lamination.

categories of floors and how preparation is similar or different. This includes stippled/textured hard surfaces—concrete, asphalt, brick; smooth hard surfaces—tile, laminate, wood; and carpet.

According to Matt Edwards, digital print media product manager, General Formulations, “whether the surface is carpet, slightly textured, or smooth, preparation involves removing any dirt, grease, and debris that may compromise the adhesive bond with the substrate.”

While all surfaces must be thoroughly cleaned, drying after cleaning is also important, points out Aarona Tesch, product marketing manager, ACCO Brands. “As any moisture can lead to bubbles or the graphic peeling off prematurely. The surface temperature and the environment should also be considered.”

“The greater the foot traffic and longevity expectation, the more crucial it becomes to create the cleanest surface possible to ensure a strong, even bond between the flooring surface and the adhesive across the full graphic,” shares Kempf.

marketing and communications manager, Mactac, admits it is a step easily overlooked and often misunderstood. “The best graphics installer understands proper procedures for cleaning and preparing various surfaces for optimized pressure-sensitive graphic applications.”

“Proper surface cleaning is essential for a perfect bond to the substrate and for the durability and longevity of application. Any kind of dirt and dust can have a negative impact on the adhesive,” shares René Bourgeois, VP sales North America, ASLAN Selbstklebefolien GmbH.

1 1) Avery Dennison MPI 2600 Wall & Floor Film Series is a tough, scuff-resistant, flexible, calendered vinyl designed specifically for indoor graphic applications. 2) WrapTheCarpet ASLAN DFP 49 is specially designed for short-term floor graphic applications on low-pile carpets indoors.

According to Michelle Kempf, VP, sales and marketing, Continental Grafix USA, Inc., “most importantly, a poorly prepared surface can be a safety concern as it can affect adhesion, leading to edge curling and lifting, which quickly becomes a safety hazard. Beyond safety, poor surface preparation may also affect appearance, durability, and the life span of the graphic.”

“By cleaning the installation area you maximize the durability and visual impact of a floor graphic providing a professional finish that withstands heavy foot traffic,” attests Mike Richardson, business development Manager –graphics media, Jessup Manufacturing Company.

For the purposes of this article, we’re looking at three different

“All three categories have one thing in common—they are a magnet for dust and dirt. This will without question adversely affect the performance of the adhesive,” says Kieran Blacknall, academy manager, Drytac.

Prior to cleaning or perhaps simultaneously, Brian Ebenger, VP of business development, XCEL, suggests graphics installers “identify if there are any coatings on the floor surface that may strengthen or weaken the adhesive performance including sealants, stains, de-icer, antigrime, or waterproofing.”

Then, the installer or print provider should identify the graphic size and clean the area at least six inches larger than the size of the graphic, recommends Michelle Oczkowski, product manager, Brand Management Group. She also suggests avoiding any citrusbased cleaners or detergents that contain enzymes or soap.

Concrete, asphalt, and brick are all examples of stippled or textured surfaces.

Due to the nature of the surface, textured floors might require more intense cleaning, like power washing, notes Richardson.

“For textured concrete surfaces installers pressure wash the area where they will be applying the film. This is the most effective way to get these types of surfaces fully clean and prepared,” recommends Joey Heiob, technical service representative, Avery Dennison Graphics Solutions.

Bourgeois suggests cleaning with a broom prior to application as well.

Since these types of surfaces are porous, it is important to “ensure ample time for any residual moisture to evaporate before applying a graphic, as trapped moisture

could cause the graphic to fail,” recommends Edwards.

Tile, laminate, and wood are smooth, hard surface options.

Smooth, hard surfaces are usually cleaned using a mop, sponge, or rag, lists Heiob.

Richardson also suggests giving these types of floors a good clean with a degreaser, then they are ready to go.

It seems obvious, but Bourgeois says cleaning carpets with a vacuum cleaner prior to application must be completed.

Many vendors encourage floor graphics on carpets with low-pile fibers. Richardson says that if the carpet in question features high-pile fibers, then they need to be flattened prior to applying the floor graphic—and a special adhesive is probably needed.

While surface preparation is essential, choosing the correct media for the job cannot be overlooked. The media’s adhesive influences surface preparation.

Blacknall agrees that surface preparation is critical to a successful installation. However, selecting the right material for the surface in question with the correct face film and adhesive is even more important.

“There are three types of energy related to surfaces—high-, medium-, and low-surface energy. By

understanding the science behind adhesives and surfaces, you will gain the power to make informed decisions about each project,” continues Blacknall.

High-surface energy substrates are usually attractive for adhesives and don’t need much convincing to stick. Examples are glass and smooth metals, says Blacknall.

Medium-surface energy substrates—wood, stone, or concrete—welcome adhesives “when they’re in the right mood,” so you might have to consider your approach more than you would with a high-energy surface, adds Blacknall.

“Low-energy surfaces, such as rubber and polypropylene, aren’t interested in any old adhesive. They have high standards and require you to pull out all the stops. Low-energy surfaces are very much the introverts of the bonding world,” states Blacknall.

Regarding adhesive, Tesch outlines the four main categories and how each influence surface preparation. The first, permanent adhesive, requires a very clean surface for maximum adhesion since it forms a strong bond. Any debris or dust comprises that bond, which leads to peeling or bubbles.

While removable adhesive is more forgiving and easier to adjust during installation, the surface still needs to be cleaned to ensure it applies well, admits Tesch.

High-tack adhesive is designed for rough or textured surfaces, which require a thorough cleaning prior

to application. Heat guns help ensure proper adhesion, according to Tesch.

Finally, low-tack adhesive is commonly used for temporary graphics. Tesch says while the surface must be clean, minor imperfections are more tolerable.

Surface preparation is important, but who is responsible? The print provider who created the graphic? The client who ordered it? The person in charge at the location where the graphic will ultimately be placed?

Smith believes it is a shared responsibility. “The print provider is typically responsible for ensuring that the printing surface is clean, smooth, and suitable for the printing process. However, the customer also plays a role in preparing the surface by providing the print provider with a clean and properly primed substrate.

This collaboration helps to ensure the best possible printing results and customer satisfaction.”

“It is the responsibility of the entire supply chain. The end user must specify that it’s for a floor, the print provider must ascertain the surface type, and the media supplier must ensure the correct material is provided. Communication is key to a successful installation,” agrees Blacknall.

A discussion between client, print provider, and installer at the beginning of the job is important. “The print provider may not be local to the installation site but is best positioned to provide specific instructions regarding surface preparation to the client or installer prior to installation. Ideally, this is addressed at the beginning of the job, so surface preparation can be appropriately worked into the schedule and managed by the appropriate party—either the client or installer, if not the printer,” says Kempf.

Edwards points out that floor graphics are used everywhere from large school emblems to small advertisements in grocery stores that could be professionally installed or delegated to a store employee. In these scenarios, while surface preparation is not the direct responsibility of the print provider, it is important to provide guidance on best practices to ensure a successful install.

If the print provider isn’t the installer in the job, then it’s the installer’s responsibility, says Ebenger. “The print provider is

responsible for the proper media selection for the application along with the proper print, dry, and finishing components. The installer/installation company is responsible for the proper surface preparation and complete installation process. Even experienced, certified installers should refer to the media’s manufacturer instructions to ensure proper installation for optimal performance.”

As the professional in the situation, Bourgeois says the print provider is responsible for proper surface preparation. “A

perfectly cleaned surface directly affects the result of their work.”

Clean release of a graphic is the goal, with minimal to no adhesive left behind—or a damaged surface. Proper surface preparation helps to achieve this.

“Proper surface preparation makes a big difference when it’s time to remove floor graphics. When the surface is clean and smooth, the graphics stick well but are easier to take off later, leaving less residue behind. If the surface isn’t prepped right, dirt and moisture can get trapped, making removal messy and possibly damaging the floor. Good preparation not only helps with sticking the graphics but also makes taking them off a lot simpler,” suggests Richardson.

Tesch believes that “clean, dry surfaces allow for easier removal

of the floor graphic with less chance of adhesive residue being left behind.”

“A properly cleaned surface enables the removal of the film cleanly in one piece,” notes Bourgeois. Although, he points out that even more important is that the right adhesive is chosen for the project at hand. “You need a special adhesive formulation when applying to stones such as granite and marble to make sure the adhesive doesn’t ingress into the stone,” for example.

The right adhesive creates uniform adhesion, which is critical in a clean removal. “Surfaces that have been cleaned properly allow for more uniform graphic adhesion and can make removal easier. Graphics with poor adhesion in some areas and stronger adhesion in other are more prone to tearing or leaving residue behind,” notes Kempf.

At the end of the day, “if the proper installation procedures are followed and the correct media is used, removing the graphic should be quick and easy,” concludes Blacknall.

Surface preparation is essential for floor graphics. As Ebenger says, “it is the difference between a great project and a failed project.”

Identifying the floor type as well as determining the correct material and adhesive for the job helps ensure a successful installation. Taking it a step further, cleaning that floor of any debris ensures the graphic remains in place for the desired amount of time. D