Gas Safety Week

Meet the Gas Safety Guardians

Technical Internal and external buried pipework

Boilers: Why focusing on efficiency makes sense

Issue 175 October 2023

Technical Working in higher risk buildings

THE BOILER WARRANTY HAS COME OF AGE... ATAG are now o ering a revolutionary 18 years warranty on our new Series 3 boiler with advanced flow control technology. Your customers can now benefit from up to 18 years peace of mind. Why not #addATAG to your quotes? Launching the new SERIES 3 BOILER To find out more scan the QR Code orcall 0800 254 5065 HYDROGEN BLEND READY atagheating.co.uk | @atagheating | @ATAGHeating | ATAGHeating ‘Excellent’ rating f ind out more

Gas Safety Week

Meet the Gas Safety Guardians

Technical Internal and external buried pipework

Boilers: Why focusing on efficiency makes sense

Issue 175 October 2023

Technical Working in higher risk buildings

MORE GET BOILER JOBS BOILER JOBS JOIN US NOW FREE BUSINESS WEBPAGE FOR INCREASED VISIBILITY GET THE BEST QUALIFIED LEADS IN THE UK ONLY PAY FOR THE JOBS YOU WANT NO CONTRACTS/SUBSCRIPTIONS OFFER YOUR CUSTOMERS FINANCE OPTIONS WITH OUR FREE TOOL BOILER INSTALLATION LEADS IN THE BUSINESS GET THE BEST SCAN THE CODE TO JOIN US visit www.boilerguide.co.uk/gassafe JOIN US IT’S FREE DID YOU KNOW? WE ALSO PROVIDE NEW HEAT PUMP LEADS JOIN US AND GIVE YOUR BUSINESS A BOOST 80% OF OUR ENQUIRIES GO ON TO BUY A NEW BOILER Boiler Guide is operated by Leads.io Ltd. IN YOUR AREA

In this issue

Issue 175 October 2023

11 Around the industry New building control regime for higher-risk buildings; New proposals could make heat pumps cheaper

14 The good, the bad and the ugly

16 Technical Working in higher-risk buildings: what does it mean for you?

19 Technical

The most recent frequently asked questions to Gas Safe Register’s Technical Team – from domestic pipework to cookers, and mobile catering to gas fires in bedrooms

20 Technical

The main points you should consider when installing pipework (downstream of a primary meter) in internal floors, and burying pipework externally in the ground

33 Your business

How business management software can boost your productivity and give you more free time; Choosing the right software for your business

06 Gas Safe news

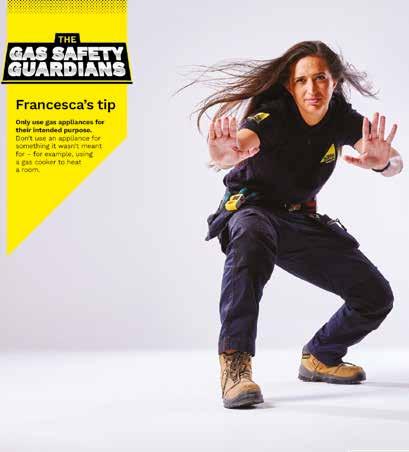

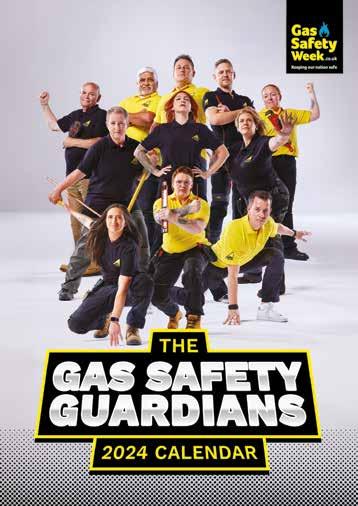

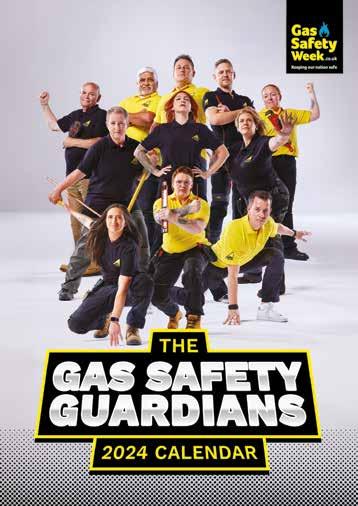

Meet the Gas Safety Superheroes who star in an exclusive calendar created for Gas Safety Week to showcase the diversity and real-life experience of gas engineers

08 Gas Safe news

The Gas Safe Register brand: what you need to know about using it, and the steps that Gas Safe Register and HSE take to ensure that it’s only used by those who are entitled to do so

24 Boilers

• How can gas engineers make their customers’ boilers more efficient? And when is the right time to invest in a new one?

• AI and the changing landscape of heating

• The lowdown on lower flow temperatures

22 Pipework

Thermography can help to discover hidden pipework and malfunctioning heating systems

30 Heat emit ters

Why focusing on efficient heat emitters is a sound way for your customers to plan for the future

36 The Legislative, Normative and Informative Documents List

42 Training

43 Products

The latest launches from ATAG, Baxi, Worcester Bosch and Viessmann

www.gassaferegister.co.uk 05 REGISTERED GAS ENGINEER

Comment

Gas Safety Week had just ended as we went to press with this edition. And what a week it was: the industry definitely got involved whole-heartedly, making sure that they supported the industry’s biggest national gas safety campaign to help their own audiences stay gas safe.

That’s what it’s all about: it’s up to each individual or company to choose what they want to say or do, and how they want to do it: whether it’s sharing messages on social media, updating a website, giving a special offer on boiler servicing or a gas safety check, or running a competition. And many take advantage of the special Gas Safety Week toolkit, created to help them do this.

In this edition, we’ve focused on this year’s theme of showcasing the diversity and breadth of experience of gas engineers, exemplified in the stunning Gas Safety Guardians calendar.

Next month, after the dust has settled, we’ll be looking in depth at the activities that people and organisations undertook to support. And look out for a fresh new design and approach for your official Gas Safe registration magazine and the Registered Gas Engineer website too!

Nicki Shearer, editor

Gas Safe Register, PO Box 631, DARLINGTON, DL1 9GD

Email: enquiries@gassaferegister.co.uk, register@gassaferegister.co.uk or technical@gassaferegister.co.uk

Managing editor: Sue Harker sue.harker@gassaferegister.co.uk

Editor: Nicki Shearer editorial@registeredgasengineer.co.uk

Publisher: Peter McCreary publisher@registeredgasengineer.co.uk

Technical consultants: Carl Banister, Stephen Gallagher, Jonathan Palmer, Rob Walkerdine

Production: Mark Turpin

Advertising enquiries only: Ian Carter ian@rgemagazine.co.uk

Additional print subscriptions £25 per year email: wgardiner@circdata.com, Tel 01635 869 868

The views expressed in this magazine are not necessarily those of Gas Safe Register. The publishers will accept an advertisement or other inserted material only on the condition that the advertiser warrants that such advertisement does not in any way infringe copyright or contravene the provisions of the Trade Descriptions Act. All copy is subject to the approval of the publisher, who reserves the right to refuse, amend, withdraw or otherwise deal with advertisements submitted to it at its absolute discretion and without explanation. All advertisements must comply with the British Code of Advertising Practice. ABC membership approved 19 March, 2009.

Registered Gas Engineer is written, designed and published by The Team on behalf of Gas Safe Register. 30 Park Street, London, SE1 9EQ

Meet the Gas Guardians

During Gas Safety Week last month (September), the nation’s gas engineers were recognised and celebrated in a special Gas Safety Guardians calendar. It’s the first of its kind and the limited-edition calendar exemplifies the diversity in our industry, featuring engineers from across the UK alongside gas safety tips every month.

The calendar’s release coincided with the latest gas safety inspection figures from Gas Safe Register, which found that one in every five UK homes contains potentially dangerous gas appliances, such as gas boilers, cookers or fires.

Inner superhero

The 10 engineers chosen for the calendar, whose job it is to keep the nation’s homes warm and safe from these dangerous gas appliances, channel their inner superhero in the photos. The Guardians stand with pride and intention, showing off their own tools and equipment, which, as all superheroes know, help them do their job to the best of their ability.

The new research also found that gas engineers are the most trusted tradespeople, trumping

plumbers, carpenters and hairdressers. For more than half of homeowners (55 per cent), their gas engineer was the best person to have on their contacts list.

The research with more than 2,000 UK homeowners reiterated the importance of having trust in the tradesperson hired: threequarters (74 per cent) would only ever have faith in a friend, family member or someone who was recommended to them.

Eight in 10 (82 per cent) said they have greater peace of mind if they know their engineer is Gas Safe registered, and 62 per cent say being properly qualified is the most important factor for them when recruiting a tradesperson. The research also

06 October 2023

CIRCULATION: Jan-Dec 2022 80,073 FROM THE EDITOR

L-R: Gordon Lishman, Gas Safe Charity; Jonathan Samuel, Gas Safe Register; Lily Clarke, Engineers of Eve; Barry Sheerman MP, Hilary Bath, Gas Safe Charity

Safety

found that 79 per cent of those who have hired a non-qualified or unregistered tradesperson said they regret not checking –highlighting the importance of ‘trusting the triangle’ and ensuring that a gas engineer is registered before having appliances safety checked or other gas work carried out.

Proud

Lily Clarke, who stars in the calendar, says: “Gas Safe registered engineers like me love what we do, and I’m so proud to make an important contribution to the community.

“As I always say to my customers, taking care of your gas appliances and being clued-up on the signs and symptoms that something could be faulty or potentially dangerous with any of them, means you are taking care of your home and your loved ones.”

Rob Denman, head of Professional and Field Services at Gas Safe Register, says: “Our first-of-its-kind calendar sets out to highlight the diversity of the 152,000-strong Gas Safe registered engineers’ community across the UK – from the breadth

of their personal and professional experience, to what they have worked on, the qualifications and training they have undertaken, and the size and type of properties they work on.

“Gas Safe registered engineers are incredibly knowledgeable and passionate about what they do,

and the role they play in our communities – and so the calendar gave us an opportunity to champion and hero Gas Safe registered engineers, who work tenaciously to ensure the nation is gas safe.”

Gas Safe Register also ran a Facebook competition

throughout the week, for a chance to win a £50 Amazon voucher, CO alarm and a copy of the Gas Safety Guardians calendar. There were 50 runnersup prizes of a calendar and CO alarm.

The exclusive calendar is not available to buy.

Celebrating a diverse industry

Gas Safety Week 2023 kicked off with an event at the Houses of Parliament to celebrate the diversity of the gas industry and reinforce the need to continue tackling gas safety and carbon monoxide issues.

Gas engineers, industry stakeholders, representatives from Gas Safe Register and the Gas Safe Charity came together to discuss the work that has been carried out over the past year, and to look ahead to Gas Safety Week.

Jonathan Samuel, CEO of Gas Safe Register, said: “Gas

Safety Week is the UK’s biggest national gas safety event, where the industry joins together to share messages and tips to help keep the UK safe from the dangers of gas.

“Each year, new organisations sign up and we seek new and creative ways to reach consumers. Gas Safe Register continues to provide the tools and materials to start conversations, and every campaign is stronger when those involved are using the same material and a consistent set of messages.”

Also attending was Lily Clarke, owner of gas business Engineers of Eve. Lily is determined to play her part in improving diversity in the industry and increasing the number of women working as gas engineers.

Lily left school not knowing what she wanted her career path to be, having never considered an apprenticeship or a role in the trade. She worked in an admin role for a local gas company, before asking them to sponsor her for an apprenticeship. She has now been Gas Safe registered for 13 years and also

works as a plumbing and gas assessor for JTL.

“I’m extremely proud that I was given the chance to become an assessor myself because now I’m able to give back to my students the best guidance that was given to me,” she told attendees.

“Not all engineers look like me, but my plan is to help change that. I want to show schoolleavers, especially females, that there are lots of opportunities out there in the trade. Who better to inspire them than someone who has experienced it themselves?”

REGISTERED GAS ENGINEER | GAS SAFE REGISTER NEWS www.gassaferegister.co.uk 07

The Gas Safe Register brand: what you need to know

Who can use the brand?

Businesses that are registered with Gas Safe have a non-exclusive licence to use the appropriate brand in accordance with the Register’s published brand guidelines.

Only registered gas businesses are permitted to display the appropriate Gas Safe Register brand and/or a Gas Safe registration number and these can only be used in association with the registered trading name. The trademarks ‘Gas Safe Register,’ ‘Gas Safe’ or ‘GSR’ can only be used by other parties under agreement, subject to prior written consent from HSE and Gas Safe Register.

Any business that is NOT Gas

Safe registered because it does not directly carry out gas work, but that wishes to use the brand, must obtain a written and signed non-exclusive brand licence agreement setting out how the brand may be used. An applicant will only be granted a brand licence agreement if it meets the criteria set by HSE and Gas Safe Register.

A brand licence will only be issued for the sole purpose of promoting the Register and gas safety and will not be issued to unregistered businesses subcontracting gas work or for endorsement or approval of accreditation by HSE and/or Gas Safe Register of the goods and/or services provided by the licensee.

Brand misuse and enforcement

Where trademarks are not being used in accordance with the brand guidelines, Gas Safe Register will contact the business concerned and take appropriate action. Failure to comply with the brand guidelines by a registered business is a breach of the Rules of Registration and appropriate action will be in accordance with the Sanctions Policy.

Enforcement of the brand guidelines is not limited to registered businesses and enforcement action will be taken by Gas Safe Register against any third parties using the trademarks in any marketing/advertising material without an appropriate licence or using the brand/trademarks inappropriately.

Legal action may be taken in the following instances:

• Where a business/organisation persists in using the incorrect trademark or using the trademark when unlicensed

• Where the business/organisation has not complied with Capita Business Services Ltd (CBSL) requests regarding the correct or proper use of the trademarks

• Where CBSL and or HSE believe that a business/organisation is confusing the public or ‘passing off’ their business through use of the trademarks or branding.

In some circumstances, the business/organisation details will be sent to the appropriate enforcement authority for possible action under the Consumer Protection from Unfair Trading Regulations 2008. This legislation is designed to protect consumers by prohibiting the use of unfair and prohibited commercial practices such as:

• Displaying a trust mark, quality mark or equivalent without having obtained the necessary authorisation

• Claiming that you have been approved, endorsed, or authorised by a public or private body when you have not.

Breaking these rules is a criminal offence and can result in an unlimited fine and/or two years’ imprisonment.

Regardless of the approach taken by enforcement authorities, Gas Safe Register will take legal action, where necessary, to stop any such infringement and/or incorrect brand usage.

Where an unregistered business is using ‘Gas Safe’ or a similar mark or logo to the Gas Safe trademarks and/or logos within its trading name, they will be contacted by Gas Safe Register or its legal representatives to instruct them to stop using it or to amend their trading name so that HSE and Gas Safe Register are satisfied that there is no confusion between their business and the brand.

Registered business trading titles

Existing businesses

Where an existing registered business (pre-April 2009) uses the trademark terms ‘Gas Safe Register’, ‘Gas Safe’ or ‘GSR’ within their trading name, they will have been contacted in writing requesting them to change their trading name so that HSE and Gas Safe Register are satisfied that there is no confusion between the registered business and the trademarks. Where this request has been declined by the business that was registered before April 2009, the Register will honour the continued use of the existing registered trading title.

New applicant businesses

Under the Rules of Registration, applications will be refused from businesses registering with trading names such as ‘Gas Safe’ or similar words or logos that may cause confusion to consumers and other businesses, or that are considered as ‘passing off’ the brand. Businesses will not be permitted to register with trading names that include the trademark terms.

Proper use of the brand

Two examples of appropriate brand use are shown on the right. You can find out more about using the brand by logging into your Gas Safe Register online account. In Help and Resources, choose the marketing toolkit, and logos and brand guidelines.

The Gas Safe Register name and brands are registered as trademarks on behalf of the Health & Safety Executive (HSE). The trademarks ‘Gas Safe Register,’ ‘Gas Safe’ or ‘GSR’ and the Gas Safe Register logo are all covered under the Register’s policies as well as relevant legislation.

The Register’s policies on Registration and Brand Enforcement are at: GasSafeRegister.co.uk/ who-we-are/our-policies/

REGISTERED GAS ENGINEER | GAS SAFE REGISTER NEWS 08 October 2023

Registered business version to be used by Gas Safe registered businesses only (identifiable by the black square background)

Corporate version to be used by Gas Safe Register and organisations that have a brand licence agreement with Gas Safe Register

THE INTELLIGENT HEAT PUMP

INTEGRATED DEFROST BUFFER

Save time as the buffer is already sized to defrost the outdoor unit every time.

HYDRO AUTOCONTROL

Save space and simplify installation with the unique 4/3 way valve design.

ONE BASE CONTROL

Extremely easy and intuitive commissioning process.

ViGuide installer app for commissioning, monitoring and remote support

ViCare app for homeowner control

+ Rated heating output 2.1 to 14.9 kW

+ CoP (coefficient of performance) to EN 14511: up to 5.0 (A7/W35)

+ MCS SCoP up to 3.14 at 65°C

+ Up to 70°C flow temperature for high hot water comfort

+ Environmentally responsible, natural refrigerant R290 (propane) with a particularly low GWP100 (global warming potential) of 0.02

Become a Heat Pump Partner and access the following benefits:

+ Qualified heat pump sales opportunities

+ VPlus loyalty scheme rewards

+ Access to extended guarantees

+ Pre-sales design service

Sign Up Now

www.fischerfutureheat.com/training VISIT www.fischerfutureheat.com/training REGISTER NOW Become a Fischer Accredited Installer SCAN ME TO REGISTER Transitioning UK Homes to Zero Emission Electric Heating FREE TRAINING COURSES Buy Direct From Us | 0116 296 3171 ELECTRIC SPACE & WATER HEATING FUTURE PROOF YOUR BUSINESS & INSTALL FISCHER PRODUCTS GET HANDS ON EXPERIENCE WITH RANGE OF RENEWABLE SYSTEMS JOIN A UK WIDE NETWORK OF INSTALLERS FULL TRAINING COURSE PROVIDED FOR FREE ✅ ✅ ✅ ✅ ✅

Get ready for 2F authentication

Gas Safe Register will be introducing two-factor authentication (2FA) towards the end of this year. It’s designed to protect you and the information that the Register holds about you – and many will already be familiar with it when you log into your banking, email or other apps.

When it’s implemented, you’ll need to use it every time you log into your Gas Safe Register online account. 2FA will be brought in incrementally but there are steps you should take now to get ready:

• Every person who logs into your online account on your behalf must set up their own

account with their own unique user ID and password. This includes anyone who handles your registration renewal, notifies, adds engineers or orders a licence card on your behalf. You will no longer be able to share your user ID and password with anyone else.

• You can add new users and set them up in your online account by choosing Account Settings > User Accounts

> Add Additional Users

> Set Permissions.

We’ll bring you more information in future editions of Registered Gas Engineer magazine and online at: www. registeredgasengineer.co.uk

New building control regime for higher-risk buildings

A new building control regime for higher-risk buildings (HRBs) has come into force.

From 1 October, the Building Safety Regulator becomes the building control authority for these types of project.

Higher-risk buildings are considered as any building in England that:

a) Is at least 18 metres in height or has at least seven storeys

b) Contains at least two residential units.

The Building Safety Act 2022 introduces new requirements on those who procure, design, plan,

manage and undertake building work on HRBs, with new enforcement powers being given to building control authorities.

While the Act has no specific impact on registered businesses carrying out gas work, some larger registered businesses may fall into the new definition of principal contractor or principal designer, and so may have additional duties to perform.

Additional information may also have to be provided when applying for building control approval applications.

Earn up to £900 cashback with Baxi

Applicants will need to demonstrate the competence of any person appointed to work on the project, how the building work will be managed during construction, and how change control will be managed throughout the process, for example.

You can learn more about the new requirements at: www.hse.gov.uk/buildingsafety/building-control/ regime-overview.htm

• Also see, Working in higher-risk buildings: what does this mean for you? Page 16.

Baxi has launched its latest and highest cashback scheme, under which members of the Baxi Works loyalty scheme could earn up to £900.

Until 8 January 2024, gas engineers who install and register any of the new 600 and 800 boiler ranges through Baxi Works are eligible for cashback. For every three boilers installed and registered, engineers will receive £300, capped at £900.

The promotion follows the launch of the Baxi 600 and 800 ranges.

The UK is falling behind other major economies on progress on how to use hydrogen to decarbonise its energy. In two years, it has dropped from second to eighth place in the International Hydrogen Progress Index.

The Energy Network Association’s (ENA) gas members and Hydrogen UK say more certainty is needed from the government on future hydrogen plans.

According to the index, in 2021, guided by the government's Hydrogen Strategy – which set out commitments, proposals for funding arrangements and timelines –the UK was second only to South Korea in making progress towards using hydrogen to achieve its net-zero goals.

A lack of legislation and political uncertainty around the policies and funding arrangements to support a

hydrogen roll-out have meant that no major projects have progressed to the ‘Final Investment Decision’ stage –used to determine if projects are to go ahead – in that time.

The US, Germany, Japan, Canada, the Netherlands and France have all leap-frogged the UK.

To regain the momentum, ENA’s gas members and Hydrogen UK have set out their recommendations for industry

and the government to deliver growth:

• Move faster and be more flexible with production support

• Identify and support strategic infrastructure investment now

• Give clarity on the minimum roles for hydrogen in industry, power, transport and heat, with support measures to make high-carbon expensive and low-carbon low cost

• Stimulate domestic supply chains.

REGISTERED GAS ENGINEER | AROUND THE INDUSTRY www.gassaferegister.co.uk 11

‘Hydrogen progress slipping behind other countries’

Check if you need to send HMRC a selfassessment tax return

You must register for selfassessment and file a tax return if, in the tax year 2022 to 2023, you were:

• Self-employed as a sole trader and earned more than £1,000

• A partner in a business partnership

• A director of a limited company.

If you haven’t registered yet, you need to do this by 5 October 2023.

When to file your return

The deadline to submit an online self-assessment return is 31 January 2024.

But you don’t need to wait until the deadline. If you file your tax return earlier, you’ll find out sooner whether you’re owed a refund. If you are owed a refund, you’ll get it quicker.

If you don’t register for self-assessment and file a tax return on time, HMRC may charge you penalties and interest.

More information

Go to GOV.UK and search:

• ‘Register for Self Assessment’ – to find out how to register

• ‘File your tax return early’ –for the benefits of filing early

• ‘Queries about Self Assessment’ – for other queries.

New proposals could make heat pumps cheaper

Some homeowners and small businesses could soon find it cheaper and easier to install heat pumps under new proposals from the government.

The Department for Energy Security & Net Zero (DESNZ) is consulting on proposals to amend the Boiler Upgrade Scheme by varying the levels of grant, depending on property type or existing fuel source.

DESNZ is also consulting on whether to remove the current need to install loft or cavity wall insulation first, and whether biomass boilers with a cooking function should become eligible.

Lord Callanan, minister for Energy Efficiency and Green Finance, says: “Heat pumps are a vital tool in cutting the carbon emissions from people heating their homes, while also helping to drive down costs and boosting our energy security.

“While a heat pump can be installed for a similar price to installing a gas boiler, the support we’ve put in place means it is an option for more and more households. Today’s changes will mean even more people could benefit from making the switch, offering them the option for a low-emission, low-cost form of heating their homes.”

The government’s £450 million Boiler Upgrade Scheme has been extended until 2028 and currently offers grants of £5,000 towards the installation of an air source heat pump, £6,000 off a ground source heat pump, and £5,000 off a biomass boiler. Consumers can also receive a zero-VAT rate on installations.

Henk van den Berg, strategic business manager, Heating & Renewables at Daikin UK, says: “We welcome the government’s consultation to improve the Boiler

Upgrade Scheme. The scheme is making an important contribution to increasing the take-up of low-carbon heating. We believe that there is much of merit in the consultation.

“We would, however, urge the new Energy Secretary to include hybrid heat pumps in the scheme. Hybrids are the quickest and most effective way to decarbonise existing properties. They also require lower levels of support to make them attractive, making the government's funding go even further.”

The consultation runs until 12 October and gas engineers, manufacturers and the wider industry are being asked to give their views on the proposed changes at: www.gov.uk/ government/consultations/ proposed-amendments-tothe-boiler-upgrade-schemeregulations

education and training needed’

Almost three-quarters of heating installers do not think the updates to Part L are a step in the right direction, according to research from Polypipe Building Products. A further one-quarter say they need to go further to have a real impact.

The updates cover the energy performance of new and existing buildings. The survey of 150 heating installers found that one-quarter think more innovation is needed to heat homes

THE NEW LEADER OF THE PACK

heating

effectively and comply with the new guidance.

When asked what would be most helpful to increase the usage of low-energy systems, installers said better education (35 per cent) and more heat pump training (32 per cent) should be the top priorities.

Head of Commercial Dan Love says: “We already have a number of tools, heat sources and systems that are able to operate efficiently using renewable or

low-energy heat sources.

“So while it is positive to see that three-quarters of installers feel that they have been well supported through the transition period, something that comes up in conversation regularly is a lack of training within the industry.

“For the industry to really shift in that direction, we must ensure that installers are aware of industry innovations and are able to access the training required to diversify their skills.”

12 October 2023

Introducing the ESRTP6 Programmable Room Thermostat,

fantastic innovative product from the ESi range of

controls for residential and commercial

For more information about our complete range of products call 01280 816 868 or visit www.esicontrols.co.uk 2021_Registered gas engineer advert 186x65 AW.indd 1 10/02/2021 10:21

another

use.

‘More

Next-day UFH spares from Continal

Heating engineers can get underfloor heating (UFH) spares delivered the next working day from Continal Underfloor Heating’s new online shop.

A wide range of spare components, tools, smart home accessories and thermostats are available, including common UFH parts such as pump manifold assemblies, power cables, mixing valves, isolation valves and blanking caps. There are also useful tools to make fitting Continal’s UFH systems easier, including pipe cutters, tacker guns and pipe decoilers.

Orders placed before 2pm will be delivered the next working day. Continal founder Chris Ingram says: “Our new online shop means installers can access the spare parts and tools they need quickly.” www.continal.co.uk/shop

Can you help keep people safe from abuse or neglect?

As a gas engineer, you enter customers’ homes every day. We know you are experts at helping people keep safe from gas escapes, but what about other forms of safety? Would you know what to do if you saw your customer or someone in a customer’s home being abused or neglected?

Someone is being abused when another person does something that damages their quality of life or puts them at risk of harm. This can be an isolated incident or happen repeatedly, and the abuse may be deliberate or unintentional, but it is usually carried out by someone known to the victim.

Some adults may be more at risk of abuse than others, including those who depend on others for their care, or who are older, frail and unable to protect

themselves. Others at a higher risk of abuse include carers, people with long-term health needs and those suffering from dementia or memory loss.

Abuse can happen anywhere: at home, in a care home, hospital, day centre or in a public place. As well as physical, sexual and emotional abuse, there can also be neglect (not providing adequate food, drink, medication or clothing) or financial and discriminatory abuse.

A wide range of behaviours are considered self-abusive,

where people neglect to care for their own health and hygiene or exhibit severe hoarding tendencies.

If, while in a customer’s home, you notice something that concerns you, or if someone approaches you for help, there are a number of things you can do:

• Contact your local Adult Social Care team. You can find details online at your local council’s website.

• Call the police on 101. If someone may be at immediate risk of harm, please call 999.

Ideal unveils heat pump line

Ideal Heating has launched its first UK heat pump production line. The line forms part of a £60 million investment programme at the Hull site, which includes an expanded distribution hub and a research and development centre.

REGISTERED GAS ENGINEER | AROUND THE INDUSTRY www.gassaferegister.co.uk 13

Thegoodthebad+theugly

Send us your pictures

Registered Gas Engineer wants to see your pictures – whether you’ve come across some horrors or instances of really good work. Please email your stories and pictures to editorial@registeredgasengineer.co.uk or via Twitter to @RGEMag

We may share some of your pictures on social media, so remember to include your contact details so we can tag you (or let us know if you’d rather we didn’t).

Danny Stuart was called out for a boiler service and discovered an issue with the chimney/flue. Apparently, a builder had made the alterations after installing the roof. The chimney/flue has now been installed correctly with a vertical flue terminal.

Terry Morgan was carrying out a landlord gas safety report and found lead gas pipework throughout the property, which was leaking in several places. The installation was isolated and a warning notice issued. The lead pipework has now been replaced.

Jack Grant found this corroded boiler casing during a safety inspection. He noticed it was badly rusted and managed to push his finger straight through the casing. The appliance was made safe.

Nathan Wood came across this poorly installed gas cooker installation, which has now been refitted correctly.

Duncan Neal removed a working fire to replace it with a new one once he swept the chimney and fixed the damp in the fireplace opening. The customer had never had the appliance serviced.

REGISTERED GAS ENGINEER | YOUR PHOTOS 14 October 2023

Jason Starr attended a boiler where the customer was experiencing ignition issues. The heat exchanger had corroded and debris had blocked the sump and condense trap due to lack of servicing. A warning notice was issued and it was made safe.

This month’s winner

Thomas Celisse found this folded over gas pipe while on a gas safety check in a property. Luckily it was not leaking as it was next to the pilot light on the boiler. It has been made safe.

Jamie Sutherland attended a gas boiler service to find a water tap connector on the gas supply with no service valve and no service valve fitted to the flow pipe. The boiler was made safe, and the correct parts have now been fitted, as seen in the second photo.

Win a Wera tool set Win

There’s a prize for the best photo sent in (in our opinion). Please remember to take your pictures at high resolution and email them to: editorial@registeredgasengineer.co.uk

This month iHeat is giving away a 25-piece Wera Kompact tool set with tools and bits from Wera’s top 20 for plumbing and heating systems.

iHeat is one of the fastest-growing and most trusted boiler installation companies in the UK, seeing major success due to its forward-thinking approaches, as well as the convenience it provides for its engineers.

iHeat operates with a network of more than 300 self-employed installers all over the country, each having the freedom to manage their own workload at the touch of a button via the straightforward iHeat app.

The simplicity of iHeat’s strategy means engineers never have to worry about working out of their local area or working into the evening. iHeat takes care of all the logistics, invoicing, materials and customer communication for any job, freeing up installers to work as much or as little as they’d like.

Some installation companies carry out disruptive and delaying location assessments, whereas iHeat provides time-saving online quotes in as little as 60 seconds.

iHeat covers all types of boiler installation, including upgrades, conversions, servicing and back-boiler removals. Installing highly efficient and eco-conscious boilers from the most well-known and celebrated manufacturers in Europe, iHeat fuses simplicity with innovation, representing the future of the domestic heating industry. www.iheat.co.uk

This month’s winner is Jason Starr from Essex. Congratulations!

www.gassaferegister.co.uk 15 REGISTERED GAS ENGINEER | YOUR PHOTOS

The Building Safety Act 2022, Section 65, and the Higher Risk Buildings (Key Building Information etc) (England) Regulations 2023 set out the new regime to manage building safety.

HSE is the new Building Safety Regulator in England, as set out in the Building Safety Act. The Building Safety Regulator will have three primary functions:

• To oversee the safety and standards of all buildings

• To help and encourage the built environment industry and building control professionals to improve their competence

• To lead the implementation of the new regulatory framework for high-rise buildings

www.hse.gov.uk/buildingsafety/regulator

Working in higher-risk buildings: what does this mean for you?

T he new building safety regime will affect some Gas Safe registered businesses from April 2024. The requirement for all work to be carried out safely and competently by a registered business/engineer still stands. But there are likely to be new competency and/or technical requirements applicable to work carried out in high-rise buildings.

The full details are yet to be confirmed but these are likely to focus on having sufficient knowledge and understanding of the new building safety regime to operate compliantly. They will cover the new roles and responsibilities of those responsible for designing, installing and maintaining the safety of buildings within the regime.

From an installation process, the regime will be designed to ensure that registered businesses work competently and safely. Specific technical areas will be concerned with fire separation and building compartment penetration aspects, including pipework, flues and ventilation.

All work undertaken by

tradespeople in high-rise buildings – including registered businesses – will need to be identifiable through the notification process. This is likely to mean that the notification process will require you to confirm whether or not the work was carried out in an high-rise building.

When the requirement comes into effect, the Gas Safe Register notification process will be updated to enable businesses to confirm where work has been carried out in a high-rise building.

Higher-risk buildings

Part 4 of the Building Safety Act defines what constitutes a higher-risk building under these regulations, which are scheduled to come into effect from 6 April 2024. The following definition applies to occupied higher-risk buildings: Higher-risk buildings must have at least two residential units and be at least 18 metres in height or have at least seven storeys.

A residential unit is a dwelling or any other unit of living accommodation and is defined in

the Act in Section 115.

Examples of a residential unit are a flat, a studio flat, a home of multiple occupation, shared accommodation within university halls (eg, a bedroom with shared kitchen and bathroom) or a unit within a supported accommodation building.

A residential unit can be found in any type of building and could have any tenure. Privately owned, private rented and social rented units are all considered residential units under the higher-risk regime.

Exclusions to the ‘occupation’ aspect of the above parameters include:

• Care homes

• Hospitals

• Secure residential institutions

• Hotels

• Military barracks

• Ministry of Defence (MOD) accommodation.

However, mixed-use buildings that meet the higher-risk buildings criteria are covered by the regulations, such as a shopping centre that includes residential properties. Boarding schools and university accommodation

meeting these parameters are also covered.

Buildings that contain supported and sheltered accommodation are considered higher-risk buildings if they meet the height or storeys threshold, as they contain residential units. Examples of supported and sheltered accommodation that could fall under the higher-risk regime include domestic abuse refuges, children’s homes and supported or sheltered homes for older people and those with additional care needs that does not fall within the definition of a care home. ■

Further reading

• www.hse.gov.uk/buildingsafety/building-control/overview

• Criteria for being a higher-risk building during the occupation phase of the new higher-risk regime, available on gov.uk

• IGEM document: Fire stopping and its impact on gas safety, IGEM

• IGEM/G/5 Edition 3: Gas in multi-occupancy buildings with amendments April 2023

16 October 2023

REGISTERED GAS ENGINEER | TECHNICAL

Consistent quality. Endless support . Maximised rewards.

We’re it.

Powered by ON technology, our reliable, space-saving Navien Combi Boiler (NCB) range puts hot water first. And, at Navien, we put you first. From expert training and technical support, to earning points towards exclusive rewards with the Navien Choice loyalty programme, to warranties of up to 12 years – when you’re looking for more as a Navien installer, we’re ON it.

navien.co.uk/professional

UFH Problem Solvers

We have the UK’s widest range of underfloor heating systems. Combine this with our expert sales advisers, and you can see why Continal always provides the best solutions.

We design all our systems to work with any heat source, floor construction and covering. Whatever your project we have the solution.

0333

1750 www.continal.co.uk 20 years without a system failure Free UFH trade training Dedicated UFH Experts UK’s widest range of UFH Rated ‘Excellent’ on “I’ve used many UFH companies and Continal are the best by far!” Need a quote? We make it easy. Simply scan the QR code to see all the ways you can get a quote for UFH project.

800

From the helplines

The calls that the Gas Safe Register Technical Team receive can vary significantly daily. Generally, most are related to domestic work but the calls vary from one end of the gas industry to the other.

The Technical Team aim to provide you with information supported by the vast range of documentation to which they have access, and their own expansive knowledge.

The following questions are some of those that have been asked most frequently over the past month.

Domestic pipework

Q: Are two pliable connections permitted on a domestic gas meter installation?

A: Yes, in certain circumstances. But generally there should not be two flexible connectors on a meter installation. The meter installation will end at the outlet of the meter, apart from on a semi-recessed meter.

Technical Bulletin 084 gives information on this and BS 6400-1 contains more detailed guidance on all aspects of low-pressure gas meter installations.

Q: What is the correct method for running gas pipework behind a dot-and-dab wall surface?

A: Gas pipework can be chased into the existing wall, with suitable protection applied. The pipe chase should be made good before applying the plaster board. It’s good practice to cover the pipe with a steel plate with a thickness of at least 1mm.

Another method is to protect the pipe against corrosion and fasten it to the surface of the wall to be over-boarded. Encase the protected pipe throughout its length in the plaster board adhesive before applying the plaster board. Again, it’s good practice to cover the pipe with a steel plate with a thickness of at least 1mm. More guidance is given in BS 6891.

Cookers

Q: Can a flexible connection be used to connect a gas hob?

A: In the first instance, you should refer to the appliance installation instructions. If these state the gas connection to the appliance must be done using rigid pipework, then a flexible connector is not acceptable. If there is no mention of the type of connection required, then you should revert to BS 6172, which states that a hob can be connected via a flexible connector. An isolation valve must also be fitted to the pipework in an accessible location. Please also see Technical Bulletin 036.

Mobile catering

Q: Is there a requirement for extraction canopies on mobile catering vehicles?

A: This depends on the requirements of the individual appliances installed in the vehicle. Where forced mechanical extraction is in place, it must be interlocked so as to render the appliances inoperable if the extraction fails. More guidance is given in UKLPG CoP 24 Part 3, Section 8.6.1.

Non-domestic ventilation

Q: What are the ventilation requirements for a boiler in a plant room with louvre doors?

A: The manufacturer’s instructions dictate the ventilation requirements for a gas

appliance/s. In the absence of MIs, you should refer to IGEM/ UP/10, which will show high-level ventilation as 2cm2 per kW at high level and 4cm2 per kW at low level. If the ventilation is via louvre doors, they must provide at least 6cm2 per kW.

Fires

Q: Can a gas fire be installed in a bedroom?

A: In the first instance, please check the manufacturer’s installation instructions, and reference Regulation 30(1)–(4) of the GSIUR. Room-sealed appliances can be installed in rooms used for sleeping. A flued appliance with a heat input less than 14kW gross that has an atmospheric sensing device (ASD) fitted can be fitted in a room used for sleeping.

Flueless space heaters should only be installed in a room designed for sleeping if they incorporate an ASD AND the manufacturer’s instructions state that this is acceptable. You should refer to the manufacturer’s instructions for confirmation. Make sure you pay attention to the appliance location in relation to sleeping furniture, bedding and curtains, etc.

Neighbour complaints (boundary)

Q: My chimney/flue is terminating at high level from a bedroom: does the boundary regulation still apply?

A: The property boundary has no height limits. The boundary line applies from the ground level infinitely.

Bibliography

Technical Bulletin 084: The prohibition of two pliable connectors on a domestic gas meter installation

Technical Bulletin 036: Fixed hobs and ovens flexible gas supplies

BS 6400-1:2016 – Specification for installation, exchange, relocation, maintenance and removal of gas meters with a maximum capacity not exceeding 6m3/h – Low pressure (2nd family gases)

BS 6891: 2015 – Specification for the installation and maintenance of low-pressure gas installation pipework up to 35mm (R1/4) on premises

BS 6172: 2010 – Specification for installation, servicing, and maintenance of domestic gas cooking appliances (2nd and 3rd family gases)

IGEM/UP/10: 2016 – Installation of flued gas appliances in industrial and commercial premises

UKLPG CoP 24 Part 3: Use of LPG Cylinders. Use of LPG for Commercial Catering Events, Street Food and Mobile Catering

REGISTERED GAS ENGINEER | TECHNICAL www.gassaferegister.co.uk 19

Internal and external

Over the coming months, Gas Safe Register’s Technical Team will be looking at the guidance on installing buried pipework in domestic properties, multi-occupancy flats and commercial properties. This month’s article reviews the requirements of BS 6891. While you should always read the relevant sections of the standard to understand the requirements for burying pipework, here the Technical Team highlight the main points that you should consider when installing pipework (downstream of a primary meter) in internal floors, and burying pipework externally in the ground.

Internal buried pipework

Ground floors in older properties are often wooden suspended floors or a solid concrete oversite floor with a further screed on top. Both these traditional types of flooring construction can be a source of heat loss, partly because of the underfloor ventilation needed for wooden floors and because they lack insulation (although insulation can be installed to wooden suspended floors retrospectively).

It is relatively straightforward to run supported gas pipework within, between or under the joists of an existing wooden suspended floor. But in a new housing development, you’ll face

different floor constructions that are designed for greater energy efficiency.

Many use a ‘beam and block’ construction on the ground floor, in which a membrane sits above the insulation and below the final screed or concrete floor surface. In these constructions, the gas pipework shall be run above the membrane and sometimes under the insulation. However, pipes will often be installed within the screed floor and there are some important considerations for either method.

Wherever pipework is installed within or is likely to come in contact with a corrosive environment, such as cement/ moisture with screed flooring, then suitable measures shall be taken to protect the pipework from degradation.

buried pipework

Do

✔ Wherever possible, use pipework that has a protective factory-finished coating, such as plastic-coated copper and steel. Corrugated stainless-steel tube (CSST) with a protective sheath is designed for this sort of application.

✔ Joints buried in floors shall be kept to a minimum and shall only be soldered or threaded.

✔ Pipework without a factory coating or any exposed joints shall be wrapped and protected using PVC wrapping tape or self-bonding silicone tape and can be painted using bituminous paints, following the manufacturer’s instructions. Older properties often have a steel ‘carcass’ pipework buried in screed floors that were painted this way.

✔ Pipework may be galvanised or painted but will often require additional on-site corrosion protection.

✔ Grease-impregnated tape can be used, but may require additional PVC wrap (see Technical Bulletin 106).

✔ Thin wall waterproof insulation may be used, provided that it is sealed from water ingress. Do not use hair felt insulation.

✔ Assembled pipework shall be gas tightness tested before applying added protection against corrosion and before the screed finish cover is applied.

✔ When installed within a screed, pipework shall have a minimum 25mm covering of screed above the installed pipework.

✔ The flooring insulation can be notched to allow for gas pipe to be run beneath wet underfloor heating circuits but shall not be run under electric underfloor heating.

✔ Pipework shall be run at 90° to the wall.

Don’t

✘ Install pipework in structural elements of the floor, such as concrete slabs, structural floorings or power-floated floors.

✘ Install rigid stainless-steel pipe in floor screeds.

✘ Install mechanical fittings and press end fittings in solid floors, floor screeds or concrete slab

✘ Damage the membrane by securing clips. Pipework laid within the screed or under the insulation above a membrane will be secure in place without the need for any securing clips

✘ Install any gas pipework in the void beneath the ground floor pre-stressed beams. This ventilated void area may appear similar to a traditional wooden suspended floor but there is no provision in BS 6891 that permits the installation of gas pipework within this area.

✘ Install polyethylene (PE) pipework inside a property.

External buried pipework

As with internal buried pipework, pipework that is to be buried externally needs to be protected against corrosion. Copper and steel pipework used internally may be protected by applying a protective wrap, PVC tape or self-bonding silicone tapes, and can be painted using bituminous paints – but this method of protecting non-factory covered pipework is not suitable for

BS 6891: Table 5 – Buried external pipework

Location of pipework

Private gardens including pathways (no vehicular traffic)

Minimum depth of cover (mm)

375

Private drives with light vehicular traffic 450(A)

Private drives where there is a likelyhood of heavy traffic (such as LPG road tankers) 600(A)

Fields and agricultural land 1,100

Other private ground 600(A)

(A) Where, due to ground conditions, it is not possible to excavate a trench to give the specified depth of cover, additional mechnaical protection shall be provided above the pipe, such as burying concrete slabs belowground level at approximately 100mm above the pipework.

external buried pipework.

Metallic pipework to be buried underground shall either be:

• Pre-insulated copper tube with solid covering conforming to BS EN 13349 (normally a roll of annealed factory coated copper tube), or

• Pliable corrugated stainlesssteel tube with a factory-applied cover of suitable 0.5mm thickness, which has been specified by the manufacturer’s instructions for direct burial. Always refer to the manufacturer’s instructions.

An alternative to metallic pipework is to use polyethylene (PE) pipework – the same material used for gas service pipework –provided that it is only used externally and transitions to metallic pipework before entering a property. Joints are usually above ground and it is important that the above-ground PE is protected from UV light and accidental damage by enclosing it in a suitable sleeve.

All types of buried pipework should be continuous in length, without joints underground wherever possible. Any joints used underground shall be specified for this application and will often require additional corrosion protection.

How deep?

Depending on its location, pipework shall be buried to

the minimum depth shown in BS 6891: Table 5 (above).

These dimensions are from the finished ground surface to the top of the buried pipe, which means the trench itself is normally dug out up to 75mm deeper.

The bottom of the trench will have a backfill layer of cohesive or granular material such as sand: when the pipework is laid on top, it will have the same material backfilled up to 75mm above it. This is done to protect the pipework from larger/sharp stones when backfilling with suitable previously excavated topsoil. Hard chalk is not suitable for backfill, and wet clay next to pipework should be avoided.

The trench can be backfilled, leaving any joints exposed prior to carrying out a gas tightness test. When gradually backfilling, a yellow plastic gas marker tape indicating the location of the pipework shall be laid 100mm300mm above the pipe. ■

Bibliography

BS 6891:2015 +A1:2019 – Specification for the installation and maintenance of low pressure gas installation pipework of up to 35mm (R1¼) on premises

Technical Bulletin 106: Corrosion protection of gas installation pipework using grease-impregnated tap BS EN 13349: 2002 – Copper and copper alloys. Pre-insulated copper tubes with solid covering

www.gassaferegister.co.uk 21 REGISTERED GAS ENGINEER | TECHNICAL

Picture perfect

Testo looks at how thermography can help discover hidden pipework and malfunctioning heating systems.

Thermography refers to the act of creating a visual image through the use of a thermal imaging camera. These cameras use infra-red energy emitted by the subject to show apparent surface temperatures, and can give a visual representation of both heat and cold.

Core to its uses is the ability to assess temperature and show it visually.

What can you use a thermal imaging camera for?

A thermal imaging camera is a useful addition to any heating engineer’s toolbox and is one of the most versatile test and measurement tools. It allows for a large area to be examined effectively with less wasted time and cost.

It’s particularly helpful for hidden pipework that runs below ground and is in direct contact with screed or other flooring materials. In a traditional wet heating system, where the hot water from the boiler is being run to radiators, a thermal imaging camera helps you to simply trace the pipework – which can be invaluable if you don’t know the pipework layout.

For underfloor heating systems, it’s the only nondestructive technology that provides a simple assessment of how well the system has been installed and its performance. Even a basic thermal imaging camera will have the ability to visualise temperature differences down to 100mK (0.1°C).

System leaks

When you have located any hot water pipework, the camera can also help to diagnose any potential sites of leaks within the system. Again, this is where high thermal sensitivity comes into play: typically, pipework runs show up as very ‘linear’ lines of higher temperature than the background. Potential leaks tend to show up as areas that are distinctly hotter than either the background or the pipework run, and usually it is possible to see this area grow in size as hot

water is pushed out into the screed material.

Sometimes it can be necessary to create a greater temperature difference to really highlight the possible leak site: these conditions can be generated by making the property as cold as possible: open all the windows and doors for a time and then switch the heating system on high from cold.

One topic we often get asked about is detecting cold water pipework and this has some unique issues. In most cases, the temperature of pipework carrying cold water will be at the same background temperature as the floor: this won’t allow for enough temperature difference to detect directly.

However, a thermal imaging camera can detect cold water when it has penetrated through to the screed or flooring material

because, when that occurs, the area that is damp can be detected through evaporative cooling effect, especially if you can introduce some airflow across the suspected area by opening a door or window.

Radiator performance

Thermal imaging can also quickly diagnose issues within radiators due to blockages or air. Radiators that are blocked will show as having large cold spots that the camera can show clearly. This supports you in providing a powerflushing service, as you’ll be able to show your customers a clear reason why they need this.

When the powerflushing has been carried out, the camera will be able to show the benefits clearly via before and after images. ■

www.testo.com/en-UK/ products/thermal-imager

REGISTERED GAS ENGINEER | PIPEWORK 22 October 2023

“Even a basic thermal imaging camera can visualise temperature differences down to 0.1°C.”

“It’s particularly helpful for hidden pipework below ground.”

© 2018 Omega Flex, Inc. All rights reserved. FGP-771UK 10/18 FREE ON-LINE GUIDES FREE ON-SITE VISITS FREE TRAINING MADE IN BRITAIN www.tracpipe.co.uk Find out more... FREE SUPPORT We’ve got something NEW up our sleeve... TracPipe® with an integrated containment sleeve! Save time and money by not having to apply a secondary sleeve! With TracPipeCC® we’ve got it covered! Call +44 (0)1295 67 66 70 Email eurosales@omegaflex.com

Boosting boiler efficiency

Homeowners struggling with the rising cost of living are looking for ways to reduce their fuel bills, with a particular focus on their heating. So how can gas engineers make their customers’ boilers more efficient?

And when is the right time to invest in a new one? Registered Gas Engineer investigates.

Despite the government’s attempts to encourage take up of low-carbon systems such as heat pumps, most UK households still rely on gas boilers for their heating and hot water.

With utility bills still high, many people are asking gas engineers for advice on how they can boost the efficiency of their boiler. So what simple tips can you recommend to help customers keep their bills down?

It almost goes without saying, but it’s extremely important that boilers are serviced every year by a registered engineer. This will make sure they are safe, as well as highlighting any issues that might cause a breakdown.

Ian Trott, training manager at Baxi, says: “An annual service will ensure the boiler is working efficiently but, more importantly, it can provide an opportunity to discuss broader efficiency measures. Improvements such as the installation of loft insulation, double-glazing or introducing thermostatic radiator valves (TRVs) will help to maximise the efficiency the boiler can deliver.”

But we know that people struggling to make ends meet may be tempted to delay servicing. Martyn Bridges, director of Technical Services at Worcester Bosch, says this may change going forward: “Presently there is no national requirement to have a boiler annually serviced, although there is a requirement in rented properties for a landlord’s gas safety record check, and quite often the boiler gets

serviced when this is happening.

“I believe the government wants to address this, particularly with increasing amounts of biogas and perhaps hydrogen being injected into the grid, so we will likely see an increasing focus on the importance of servicing.”

There is no legislated list of exactly what a boiler service should involve, although there is established best practice. Christian Engelke, technical director at Viessmann, says: “The boiler needs to be cleaned, the electrodes checked and cleaned and if necessary, replaced. Also, the heat exchanger needs to be cleaned from inside.

“Homeowners should also ask their gas engineer to check how efficient their boiler is. They can check how often it cycles per hour, and measure flue temperature and CO2 so that the efficiency can be calculated.”

Lower flow temperatures

Updates to Part L of the Building Regulations mandated the use of

lower flow temperatures in new system installations across England. While this does not yet apply to existing installations, lowering flow temperatures can help to improve the boiler’s efficiency.

Sean Keleher, technical director at Navien UK, says: “By lowering the domestic hot water (DHW) temperature by 5°C-10°C, the same level of comfort can be achieved without the added energy usage. Typically, boilers heat the home’s DHW to 60°C+, a common practice carried over from older boilers. Most modern combi boilers allow installers to reduce this temperature so less energy, water and money is wasted.”

Ian adds: “Part L’s role is to maximise the efficiency of heating systems: correct sizing, and having them work effectively at 55°C or lower is a key component. This has reinvigorated the need for best practice in terms of ensuring that heat-loss calculations are carried

out and the system is installed so that comfort is achieved at the lower flow temperature.

“Part L has also prescribed closer monitoring of water quality, so it is worth remembering to check water quality, top up inhibitors, and ensure that a filter has been installed and is serviced with the boiler. While many homeowners will underestimate the link between water quality and energy usage, a clean system is an efficient one.”

Martyn agrees that understanding the building’s heat loss is a fundamental step towards optimising efficiency.

“If the boiler is a condensing boiler in reasonable shape and age, and the gas engineer can visibly confirm conditions in the house such as loft insulation and sealed drafts, then they should undertake a heat-loss calculation and see if the radiators can be run at a lower temperature,” he says.

“See whether the boiler can be range rated and, if possible, adjust its range rating to the

24 October 2023

“We will likely see an increasing focus on the importance of servicing.”

heating load requirements. I would also suggest checking that the controls meet the minimum requirements under Boiler Plus. If not, see whether the customer would be happy to upgrade the controls, or go further with load or weather compensation if the boiler is compatible.”

Tackling oversized boilers

According to the Energy Saving Trust, the average UK home requires just 6kW of heat, even on a cold day, but most gas boilers are two or three times that size. Most modern appliances will automatically modulate down to reduce the amount of on/off cycling, but older models may not, and successful modulation is also down to the boiler having the correct controls.

Ian explains: “If a boiler is oversized, the higher energy will cause water to be heated so quickly that the boiler will cycle on and off more frequently, which uses more energy than a correctly sized boiler running for longer periods of time.”

But Sean believes gas engineers need to be more concerned about avoiding undersizing. He says: “Avoiding

undersizing a boiler is incredibly important. When a boiler is installed in a property where it can’t keep up with the demand, it is working at an excess of 100 per cent, meaning that more energy is being used and the longevity of the system can be seriously affected. This increases the homeowner’s energy bills in the short term and heightens the risk of needing a replacement boiler much sooner than is necessarily required.”

When is it time for an upgrade?

Homeowners understandably want to make their boilers last as long as possible, but there does come a point when its inefficiency begins to add significant costs to monthly energy bills. When is the right time to upgrade?

A complete boiler breakdown may well prompt an upgrade, but Sean believes that homes that do not have combi or condensing boiler should be encouraged to upgrade. He says: “Noncondensing boilers waste heat through the flue, putting warmth into the air instead of in the home. Not only is this inefficient, but it is costing the billpayer money.

“Another way homeowners may improve their heating system

is by upgrading the radiators to larger, more economical alternatives. New radiators have a larger surface area, which helps to heat rooms quicker, while using less energy to do so.”

Ian agrees, adding: “If the homeowner’s boiler was installed before 2005, there is a good chance it will be non-condensing, so upgrading will almost certainly make a difference to energy bills. It is worth giving your customers the option and helping them understand the benefits of upgrading.

“If a customer’s boiler is a modern condensing boiler, replacing it will not achieve the gains in efficiency or energy saving that you would see from a non-condensing boiler. In these instances, changes to the building fabric and occupant behaviour could make the biggest difference, as well as accessory enhancements such as controls and weather compensation.”

Changing behaviour

The way occupants use their heating can have one of the biggest impacts on energy usage. Leaving the heating or hot water on for hours when the home is empty will obviously consume energy, as will keeping the thermostat at a higher temperature than is needed.

Engineers can help them make simple changes such as reducing the thermostat temperature by 1°C, or improving heating controls, which have low upfront costs but can make a big difference to the bills.

Ian says: “Upgrades like smart controls can optimise the boiler and heating system. Whether as part of a smart control system or separately, weather compensation can ensure that, no matter what the temperature the system has been designed for, the boiler will provide heat at the correct load.

“It is worth helping customers understand that heating temperatures shouldn’t be assessed by feeling how hot the radiator is but by how warm the rooms are. Helping them zone their home either through basic measures like keeping doors closed or pairing sophisticated controls with TRVs will also help significantly. The aim is to ensure that radiators are heating one room to the required level, as opposed to heating the entire house unnecessarily.”

Christian agrees, adding: “For a combi boiler, we recommend upgrading the controller to load or weather compensation. Installers should optimise the set maximum flow temperature settings by reducing them until the point at which the system is not able to maintain room temperature.

“For system boilers, we recommend changing to a four-pipe system and then upgrade to weather or load compensation.” ■

REGISTERED GAS ENGINEER | BOILERS www.gassaferegister.co.uk 25

“Your customers should understand that heating temperatures shouldn’t be assessed by feeling how hot the radiator is but by how warm the rooms are.”

AI and the changing landscape of heating

AI technology is leading the way to a new way of working with domestic and commercial heating systems, writes

Navien UK training manager Gavin Edwards.

Developments in artificial intelligence (AI) are accelerating rapidly. The future and direction of heating is changing course towards an industry where AI can make engineers’ jobs easier while minimising the risk of downtime for their customers.

But despite AI creating headlines and demanding space on government agendas, it’s not yet a hot topic among heating engineers.

The ease and convenience that it can bring to operating a heating system will quickly become the norm for homeowners and so it’s worth taking some time to understand how it will transform the industry and positively impact customer satisfaction.

boiler faults remotely or preventing a fault before the problem can arise. However, although it can automate certain tasks, some situations will always require human judgement and problem-solving skills. Gas engineers can continue to rely on their critical thinking skills to analyse complex issues, adapt to changing conditions and make quick decisions.

Live monitoring

Fundamentally, AI is about the collection of data. This data can usually be accessed via a smartphone application, so that engineers can get live feedback on what the components are doing, so as to prevent faults. They can know what parts they will need without seeing the heating system, and also advise the homeowner on how to monitor usage; all of which makes their job easier and boosts customer satisfaction.

In other industries, such as the creative arts and automation, there are concerns that AI could replace the need for workers entirely. However, it cannot completely replace the expertise and experience of a gas engineer. Rather, it provides an opportunity to enhance your skills and knowledge to remain relevant in a competitive market.

AI technology is automating many of the repetitive tasks that gas engineers typically perform, such as live monitoring, detecting

It can also help take the pressure off engineers and reduce the number of callouts by giving homeowners more visibility of their systems. Using mobile apps and user-friendly interfaces, AI provides homeowners with a live, self-monitoring and reactive system that can recommend calling out a heating engineer even before a fault has occurred, meaning fewer problems for the engineer to fix down the line and less disturbance to the household.

Crucially, AI can grow with the householder. It can learn their routines, bringing ease and comfort to their everyday lives. AI can learn how to adapt boiler functions such as adjusting flow temperatures and understanding when to turn the heating on or off, based on the homeowner’s lifestyle.

Other possibilities could include using third-party data

Navien UK’s ON AI is designed to work with the ON technology that features in its NCB ON range of combi crossover boilers, as well as the Smart Plus and Smart Plus ON AI controllers. Featuring a variety of different tools designed to make users’ lives easier, including firmware-over-the-air (FOTA) updates, capable of updating the boiler’s built-in AI technology wirelessly, ON AI can give users an in-depth analysis of their heating and hot water usage, as well as identify any boiler issues before the problem worsens.

Navien’s Smart Plus ON AI controller has been designed to benefit the homeowner and the heating engineer, providing smart diagnostics for both in different depths. www.navien.co.uk/technology/on-ai

providers to create a comfortable temperature – for example, adapting to the climate outside of the property.

Preventative maintenance

Through continuous real-time data monitoring, AI can keep a watch on the health of the boiler and will notify the homeowner if

something isn’t quite right. The development of intelligent diagnostics means that homeowners will receive information about potential faults, which can be shared with their heating engineer, giving them more time to collect any parts required for the repair and helping to achieve a first-time fix. ■

REGISTERED GAS ENGINEER | BOILERS 26 October 2023

“AI provides a live, self-monitoring and reactive system that can recommend calling out a heating engineer even before a fault has occurred.”

STELRAD. YOUR FIRST CHOICE FOR A RENEWABLE FUTURE.

All Stelard radiators are fully compatible to meet with the requirements of the newly updated Part L Documentation, with the intention of reducing carbon emissions, increasing the energy efficiency of both domestic and commercial properties, and future proofing for low carbon technology.

Stelrad’s range of high output radiators are aesthetically designed to meet your needs, now and in the future.

Compact 900

NEW 900 HIGH STELRAD COMPACT THE UK’S NO.1 COMPACT RADIATOR

K3 AND VERTICAL RANGES

Not just any rad. Stelrad.

out more at Stelrad.com

Find

Compact with Style K3

Compact Vertical

Planar K3

Compact K3

The lowdown on lower flow temperatures

Nesta, the UK’s innovation agency with a mission to create a sustainable future, explains how lower boiler flow temperatures and a new online efficiency tool can help save your customers money.

With concerns around energy prices and the rising cost of living continuing into another winter, every little helps when it comes to saving money and energy. More than ever, UK households will be looking to trusted experts like gas engineers for practical advice on how they can save money. And there is one easy way to help anyone with a combi boiler save money on their bills.

Until recently, exactly how much energy could be saved by lowering boiler flow temperatures had not been fully established. But after testing and modelling, Nesta has confirmed that lowering boiler flow temperatures reduces gas use and saves on energy bills by ensuring the boiler is in condensing mode for longer and operating more efficiently.

Lowering the flow temperature is a bit like reducing your speed when you’re driving. If a high flow temperature is like driving at 70 miles per hour, you’ll get to your destination quickly but use a lot of fuel. Driving at 50 miles per hour takes a bit longer, but will get you to the same place on less fuel. By reducing the boiler flow temperature from 80°C to 60°C, households could save an average of £96 and 173kg of carbon dioxide (CO2) emissions each year.

Nesta recommends a flow temperature of 60°C because evidence suggests this temperature, even in the depths of winter, provides a good balance between an increase in boiler efficiency, a reasonable warm-up time and a strong chance that households are able to meet their heat demand whatever their situation or temperature preference.

However, most households could lower their flow temperature to 55°C in milder winter conditions, and to 50°C or lower in the spring.

Take the challenge

Last autumn, Nesta launched the Money Saving Boiler Challenge to raise awareness of these findings, creating an online tool at moneysavingboilerchallenge.com that includes a step-by-step guide to support people through the process of lowering flow temperatures.

New tool offers practical advice

Nesta has now developed another online tool to help gas engineers give tailored energy advice to their customers, based on a short questionnaire. This is currently a Beta service and the developers are very interested in gathering feedback from engineers who use it. You can

for the customer, based on a short questionnaire.

• An advice library – a resource to help engineers quickly answer common customer questions or incorporate the advice into their service.

While in the customer’s home, the engineer can simply open the tool and answer a few questions about the customer and their home, which will generate specific advice on energy saving. This advice can be sent directly to their customer by email.

More than 216,000 people have used the tool and reduced their boiler flow since last October, saving around £20 million on energy bills and 37,000 tonnes of CO2 each year. Results from a randomised controlled trial by Nesta found that 95 per cent of those who lowered their boiler flow temperature kept it at a lower setting.

The next time you’re asked for advice from customers on how to save energy, a helpful tip would be to show them how to lower their boiler flow temperature – something they can do themselves in a matter of minutes.

share your thoughts by using the feedback pop-up in the tool.

The home heating advice generator provides gas engineers with bespoke written prompts to help them share energy saving advice with customers, based on details about the customer’s home.

Built with the input of gas engineers, the tool makes it quick and easy for engineers to give bespoke energy efficiency advice to customers during routine visits such as servicing, maintenance or installation.

The tool has two functions:

• An advice generator –generates personalised advice

The tool gives two specific boiler flow temperature recommendations – one for winter and one for spring/autumn – based on the customer’s current flow temperature and the way they’ve responded to the questions about their current heating experience.

It also gives advice on TRVs, load/weather compensation and smart thermostats, based on the controls they have in their home.

As well as supporting households to make informed decisions on how to save energy, the advice could lead to potential follow-up work for engineers including installing TRVs, thermostats and compensation controls. ■

www.nesta.org.uk/energyefficient-advice

REGISTERED GAS ENGINEER | BOILERS 28 October 2023

“Nesta has developed an online tool to help gas engineers give tailored energy advice to their customers, based on a short questionnaire.”

8 out of 10 cats prefer JG LowFit.

It’s the low-profile underfloor heating system that offers maximum warmth and minimal floor height build-up. With our expert technical support, it’s also the preferred choice for installers, looking for a trusted system your customers will thank you for.

Discover our full range at johnguest.com/lowfit

16 MM

LOW-PROFILE SYSTEM

PERFECT FOR RETROFIT & NEW BUILD

BESPOKE HEATING DESIGN

QUICK, HASSLE FREE INSTALLATION

LIFETIME TECHNICAL SUPPORT

T RUSTED QUALITY GUAR A NTEED

Focus on efficiency for the future